Efficiency of Emission Reduction Technologies for Residential Biomass Combustion Appliances: Electrostatic Precipitator and Catalyst

Abstract

:1. Introduction

2. Materials and Methods

2.1. Combustion Appliances and Fuels

2.2. Test Procedure

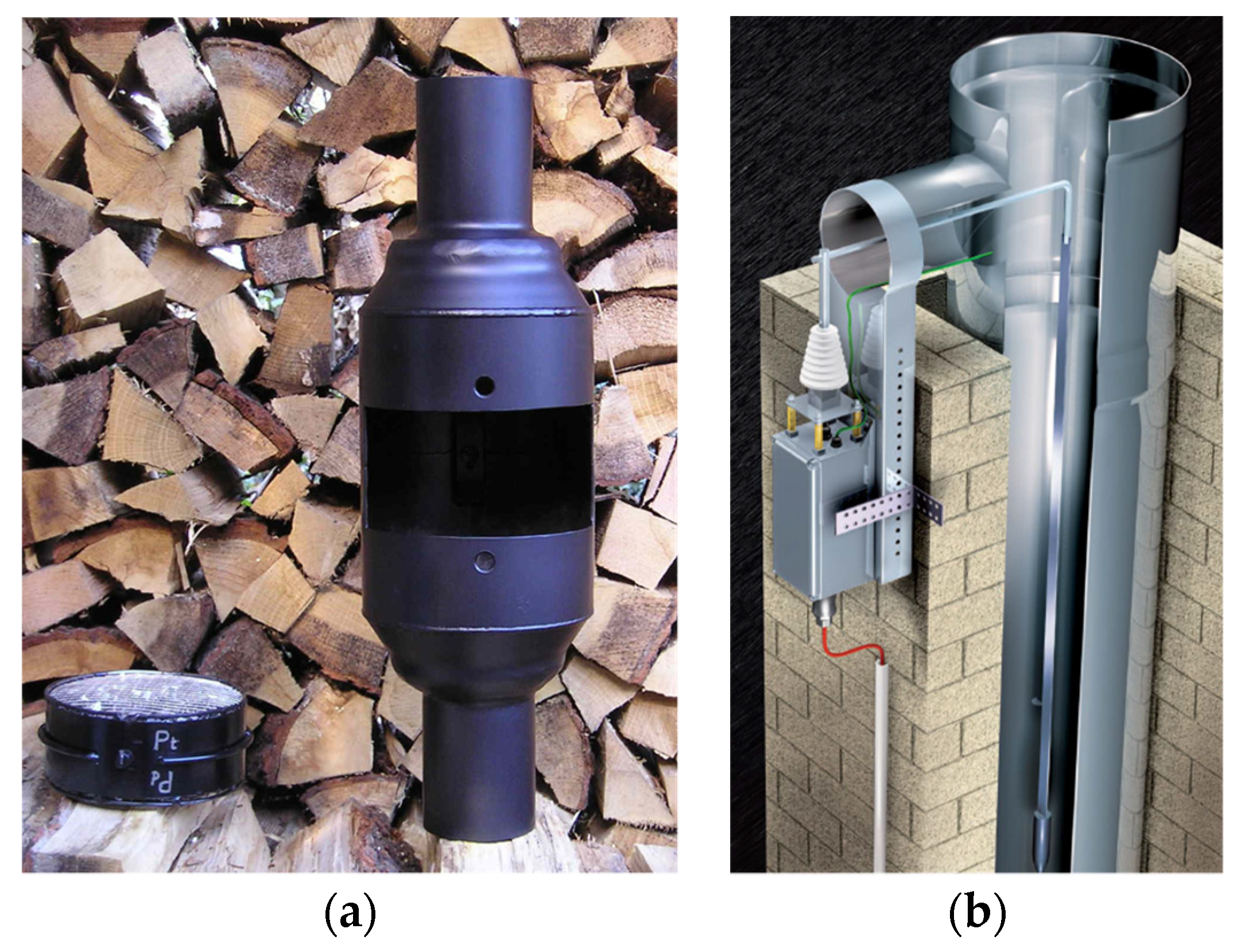

2.3. Depollution Devices

2.4. Gaseous and Particulate Matter Measurements

2.5. Statistical Analysis

3. Results and Discussion

3.1. Woodstove

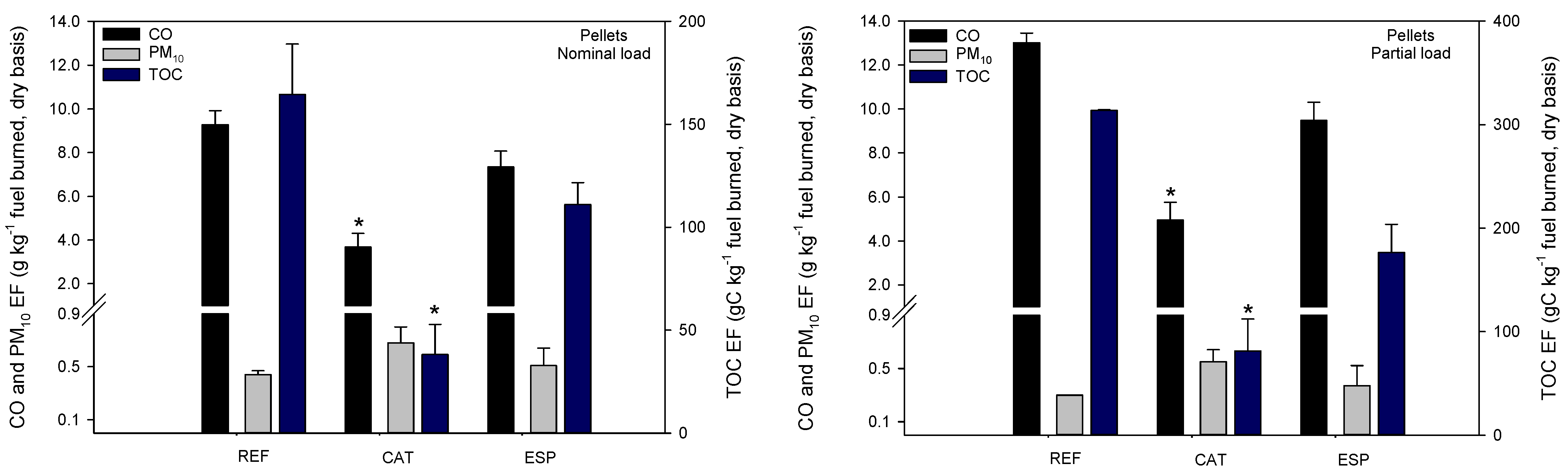

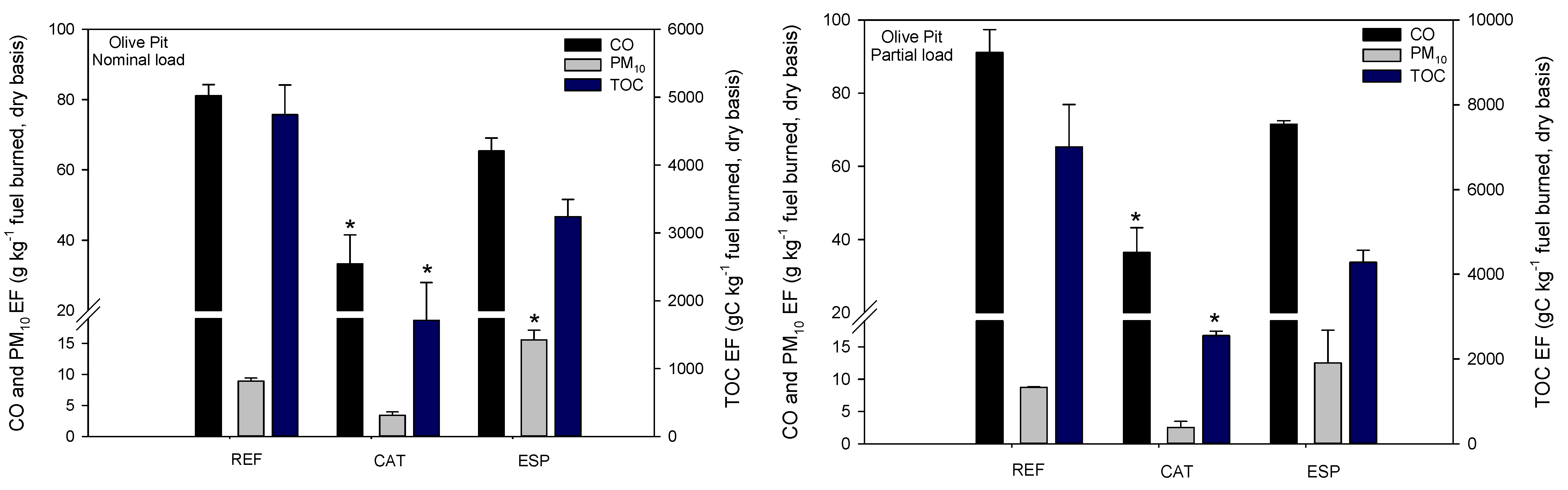

3.2. Pellet Stove

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Saffari, A.; Daher, N.; Samara, C.; Voutsa, D.; Kouras, A.; Manoli, E.; Karagkiozidou, O.; Vlachokostas, C.; Moussiopoulos, N.; Shafer, M.M.; et al. Increased Biomass Burning Due to the Economic Crisis in Greece and Its Adverse Impact on Wintertime Air Quality in Thessaloniki. Environ. Sci. Technol. 2013, 47, 13313–13320. [Google Scholar] [CrossRef] [PubMed]

- Altuwayjiri, A.; Soleimanian, E.; Moroni, S.; Palomba, P.; Borgini, A.; De Marco, C.; Ruprecht, A.A.; Sioutas, C. The Impact of Stay-Home Policies during Coronavirus-19 Pandemic on the Chemical and Toxicological Characteristics of Ambient PM2.5 in the Metropolitan Area of Milan, Italy. Sci. Total Environ. 2021, 758, 143582. [Google Scholar] [CrossRef]

- Evangeliou, N.; Platt, S.M.; Eckhardt, S.; Lund Myhre, C.; Laj, P.; Alados-Arboledas, L.; Backman, J.; Brem, B.T.; Fiebig, M.; Flentje, H.; et al. Changes in Black Carbon Emissions over Europe Due to COVID-19 Lockdowns. Atmos. Chem. Phys. 2021, 21, 2675–2692. [Google Scholar] [CrossRef]

- Mashayekhi, R.; Pavlovic, R.; Racine, J.; Moran, M.D.; Manseau, P.M.; Duhamel, A.; Katal, A.; Miville, J.; Niemi, D.; Peng, S.J.; et al. Isolating the Impact of COVID-19 Lockdown Measures on Urban Air Quality in Canada. Air Qual. Atmos. Health 2021, 14, 1549–1570. [Google Scholar] [CrossRef] [PubMed]

- Petit, J.E.; Dupont, J.C.; Favez, O.; Gros, V.; Zhang, Y.; Sciare, J.; Simon, L.; Truong, F.; Bonnaire, N.; Amodeo, T.; et al. Response of Atmospheric Composition to COVID-19 Lockdown Measures during Spring in the Paris Region (France). Atmos. Chem. Phys. 2021, 21, 17167–17183. [Google Scholar] [CrossRef]

- Huth, P. Residential Wood Burning. Environmental Impact and Sustainable Solutions. In Background Paper—Clean Heat; Clean Heat: Berlin, Germany, 2016. [Google Scholar]

- Almeida, S.M.; Manousakas, M.; Diapouli, E.; Kertesz, Z.; Samek, L.; Hristova, E.; Šega, K.; Alvarez, R.P.; Belis, C.A.; Eleftheriadis, K.; et al. Ambient Particulate Matter Source Apportionment Using Receptor Modelling in European and Central Asia Urban Areas. Environ. Pollut. 2020, 266, 115199. [Google Scholar] [CrossRef]

- Amato, F.; Alastuey, A.; Karanasiou, A.; Lucarelli, F.; Nava, S.; Calzolai, G.; Severi, M.; Becagli, S.; Gianelle, V.L.; Colombi, C.; et al. AIRUSE-LIFE+: A Harmonized PM Speciation and Source Apportionment in Five Southern European Cities. Atmos. Chem. Phys. 2016, 16, 3289–3309. [Google Scholar] [CrossRef] [Green Version]

- Perrone, M.G.; Vratolis, S.; Georgieva, E.; Török, S.; Šega, K.; Veleva, B.; Osán, J.; Bešlić, I.; Kertész, Z.; Pernigotti, D.; et al. Sources and Geographic Origin of Particulate Matter in Urban Areas of the Danube Macro-Region: The Cases of Zagreb (Croatia), Budapest (Hungary) and Sofia (Bulgaria). Sci. Total Environ. 2018, 619–620, 1515–1529. [Google Scholar] [CrossRef]

- Vicente, E.D.; Alves, C.A. An Overview of Particulate Emissions from Residential Biomass Combustion. Atmos. Res. 2018, 199, 159–185. [Google Scholar] [CrossRef]

- Karanasiou, A.; Alastuey, A.; Amato, F.; Renzi, M.; Stafoggia, M.; Tobias, A.; Reche, C.; Forastiere, F.; Gumy, S.; Mudu, P.; et al. Short-Term Health Effects from Outdoor Exposure to Biomass Burning Emissions: A Review. Sci. Total Environ. 2021, 781, 146739. [Google Scholar] [CrossRef]

- Paredes, M.C.; Muñoz, M.P.; Salgado, M.V.; Maldonado, A.K. Association between Coal and Firewood Combustion and Hospital Admissions and Mortality in Chile 2015—An Ecological Approach. Ann. Agric. Environ. Med. 2020, 27, 418–426. [Google Scholar] [CrossRef] [PubMed]

- Riddervold, I.S.; Bønløkke, J.H.; Olin, A.C.; Grønborg, T.K.; Schlünssen, V.; Skogstrand, K.; Hougaard, D.; Massling, A.; Sigsgaard, T. Effects of Wood Smoke Particles from Wood-Burning Stoves on the Respiratory Health of Atopic Humans. Part. Fibre Toxicol. 2012, 9, 12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Savolahti, M.; Lehtomäki, H.; Karvosenoja, N.; Ville-Veikko, P.; Korhonen, A.; Kukkonen, J.; Kupiainen, K.; Kangas, L.; Karppinen, A.; Hänninen, O. Residential Wood Combustion in Finland: PM2.5 Emissions and Health Impacts with and without Abatement Measures. Int. J. Environ. Res. Public Health 2019, 16, 2920. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sigsgaard, T.; Forsberg, B.; Annesi-Maesano, I.; Blomberg, A.; Bølling, A.; Boman, C.; Bønløkke, J.; Brauer, M.; Bruce, N.; Héroux, M.E.; et al. Health Impacts of Anthropogenic Biomass Burning in the Developed World. Eur. Respir. J. 2015, 46, 1577–1588. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oudin, A.; Segersson, D.; Adolfsson, R.; Forsberg, B. Association between Air Pollution from Residential Wood Burning and Dementia Incidence in a Longitudinal Study in Northern Sweden. PLoS ONE 2018, 13, e0198283. [Google Scholar] [CrossRef] [Green Version]

- Tsiodra, I.; Grivas, G.; Tavernaraki, K.; Bougiatioti, A.; Apostolaki, M.; Paraskevopoulou, D.; Gogou, A.; Parinos, C.; Oikonomou, K.; Tsagkaraki, M.; et al. Annual Exposure to Polycyclic Aromatic Hydrocarbons in Urban Environments Linked to Wintertime Wood-Burning Episodes. Atmos. Chem. Phys. 2021, 21, 17865–17883. [Google Scholar] [CrossRef]

- EEB. Where There’s Fire, There’s Smoke—Emissions from Domestic Heating with Wood; Green Transition: Copenhagen, Denmark, 2021. [Google Scholar]

- Borchers-Arriagada, N.; Palmer, A.J.; Bowman, D.M.J.S.; Williamson, G.J.; Johnston, F.H. Health Impacts of Ambient Biomass Smoke in Tasmania, Australia. Int. J. Environ. Res. Public Health 2020, 17, 3264. [Google Scholar] [CrossRef]

- Robinson, D.L.; Horsley, J.A.; Johnston, F.H.; Morgan, G.G. The Effects on Mortality and the Associated Financial Costs of Wood Heater Pollution in a Regional Australian City. Med. J. Aust. 2021, 215, 269–272. [Google Scholar] [CrossRef]

- Nuutinen, K.; Jokiniemi, J.; Sippula, O.; Lamberg, H.; Sutinen, J.; Horttanainen, P.; Tissari, J. Effect of Air Staging on Fine Particle, Dust and Gaseous Emissions from Masonry Heaters. Biomass Bioenergy 2014, 67, 167–178. [Google Scholar] [CrossRef]

- Lamberg, H.; Sippula, O.; Tissari, J.; Jokiniemi, J. Effects of Air-Staging and Load on Fine Particle and Gaseous Emissions from a Small-Scale Pellet Boiler. Energy Fuels 2011, 25, 4952–4960. [Google Scholar] [CrossRef]

- Brandelet, B.; Rose, C.; Rogaume, C.; Rogaume, Y. Impact of Ignition Technique on Total Emissions of a Firewood Stove. Biomass Bioenergy 2018, 108, 15–24. [Google Scholar] [CrossRef]

- Fachinger, F.; Drewnick, F.; Gieré, R.; Borrmann, S. How the User Can Influence Particulate Emissions from Residential Wood and Pellet Stoves: Emission Factors for Different Fuels and Burning Conditions. Atmos. Environ. 2017, 158, 216–226. [Google Scholar] [CrossRef]

- Vicente, E.D.; Duarte, M.A.; Calvo, A.I.; Nunes, T.F.; Tarelho, L.; Alves, C.A. Emission of Carbon Monoxide, Total Hydrocarbons and Particulate Matter during Wood Combustion in a Stove Operating under Distinct Conditions. Fuel Process. Technol. 2015, 131, 182–192. [Google Scholar] [CrossRef] [Green Version]

- Jaworek, A.; Sobczyk, A.T.; Marchewicz, A.; Krupa, A.; Czech, T. Particulate Matter Emission Control from Small Residential Boilers after Biomass Combustion. A Review. Renew. Sustain. Energy Rev. 2021, 137, 110446. [Google Scholar] [CrossRef]

- Molchanov, O.; Krpec, K.; Horák, J. Electrostatic Precipitation as a Method to Control the Emissions of Particulate Matter from Small-Scale Combustion Units. J. Clean. Prod. 2020, 246, 119022. [Google Scholar] [CrossRef]

- Carroll, J.; Finnan, J. Use of Electrostatic Precipitators in Small-Scale Biomass Furnaces to Reduce Particulate Emissions from a Range of Feedstocks. Biosyst. Eng. 2020, 163, 94–102. [Google Scholar] [CrossRef]

- Nevalainen, P.; Kinnunen, N. Developmental Study of Soot-Oxidation Catalysts for Fireplaces: The Effect of Binder and Preparation Techniques on Catalyst Texture and Activity. Catalysts 2019, 9, 957. [Google Scholar] [CrossRef] [Green Version]

- Hukkanen, A.; Kaivosoja, T.; Sippula, O.; Nuutinen, K.; Jokiniemi, J.; Tissari, J. Reduction of Gaseous and Particulate Emissions from Small-Scale Wood Combustion with a Catalytic Combustor. Atmos. Environ. 2012, 50, 16–23. [Google Scholar] [CrossRef]

- Reichert, G.; Schmidl, C.; Haslinger, W.; Stressler, H.; Sturmlechner, R.; Schwabl, M.; Wöhler, M.; Hochenauer, C. Catalytic Efficiency of Oxidizing Honeycomb Catalysts Integrated in Firewood Stoves Evaluated by a Novel Measuring Methodology under Real-Life Operating Conditions. Renew. Energy 2018, 117, 300–313. [Google Scholar] [CrossRef]

- Wöhler, M.; Jaeger, D.; Pelz, S.K.; Thorwarth, H. Potential of Integrated Emissions Reduction Systems in a Firewood Stove under Real Life Operation Conditions. Energy Fuels 2017, 31, 7562–7571. [Google Scholar] [CrossRef] [Green Version]

- Messerer, A.; Schmatloch, V.; Po, U. Combined Particle Emission Reduction and Heat Recovery from Combustion Exhaust—A Novel Approach for Small Wood-Fired Appliances. Biomass Bioenergy 2007, 31, 512–521. [Google Scholar] [CrossRef]

- Suhonen, H.; Laitinen, A.; Kortelainen, M.; Koponen, H.; Kinnunen, N.; Suvanto, M.; Tissari, J.; Sippula, O. Novel Fine Particle Reduction Method for Wood Stoves Based on High-Temperature Electric Collection of Naturally Charged Soot Particles. J. Clean. Prod. 2021, 312, 127831. [Google Scholar] [CrossRef]

- Nussbaumer, T.; Lauber, A. Formation Mechanisms and Physical Properties of Particles from Wood Combustion for Design and Operation of Electrostatic Precipitators. In Proceedings of the 18th European Biomass Conference and Exhibition, Lyon, France, 3–7 May 2010. [Google Scholar] [CrossRef]

- Ozil, F.; Tschamber, V.; Haasb, F.; Trouvéa, G. Efficiency of Catalytic Processes for the Reduction of CO and VOC Emissions from Wood Combustion in Domestic Fireplaces. Fuel Process. Technol. 2009, 90, 1053–1061. [Google Scholar] [CrossRef]

- Vicente, E.D.; Vicente, A.M.; Evtyugina, M.; Carvalho, R.; Tarelho, L.A.C.; Paniagua, S.; Nunes, T.; Otero, M.; Calvo, L.F.; Alves, C. Emissions from Residential Pellet Combustion of an Invasive Acacia Species. Renew. Energy 2019, 140, 319–329. [Google Scholar] [CrossRef]

- Kuenen, J.; Trozzi, C.; Nielsen, O.-K.; Plejdrup, M.S.; Dore, C.; Nielsen, M.; Kubica, K.; Paradiz, B.; Dilara, P.; Klimont, Z.; et al. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019; European Environment Agency: Copenhagen, Denmark, 2019; Volume 3.

- Reichert, G.; Schmidl, C.; Haslinger, W.; Stressler, H.; Sturmlechner, R.; Schwabl, M.; Kienzl, N.; Hochenauer, C. Long Term Durability and Safety Aspects of Oxidizing Honeycomb Catalysts Integrated in Firewood Stoves. Biomass Bioenergy 2017, 105, 428–442. [Google Scholar] [CrossRef]

- Ryšavý, J.; Horák, J.; Hopan, F.; Kuboňová, L.; Krpec, K.; Molchanov, O.; Garba, M.; Ochodek, T. Influence of Flue Gas Parameters on Conversion Rates of Honeycomb Catalysts. Sep. Purif. Technol. 2022, 278, 119491. [Google Scholar] [CrossRef]

- Brunner, T.; Wuercher, G.; Obernberger, I. 2-Year Field Operation Monitoring of Electrostatic Precipitators for Residential Wood Heating Systems. Biomass Bioenergy 2018, 111, 278–287. [Google Scholar] [CrossRef]

- Kaivosoja, T.; Jalava, P.I.; Lamberg, H.; Virén, A.; Tapanainen, M.; Torvela, T.; Tapper, U.; Sippula, O.; Tissari, J.; Hillamo, R.; et al. Comparison of Emissions and Toxicological Properties of Fine Particles from Wood and Oil Boilers in Small (20–25 kW) and Medium (5–10 MW) Scale. Atmos. Environ. 2013, 77, 193–201. [Google Scholar] [CrossRef]

- Klauser, F.; Schmidl, C.; Reichert, G.; Carlon, E.; Kistler, M.; Schwabl, M.; Haslinger, W.; Kasper-Giebl, A. Effect of Oxidizing Honeycomb Catalysts Integrated in a Firewood Room Heater on Gaseous and Particulate Emissions, Including Polycyclic Aromatic Hydrocarbons (PAHs). Energy Fuels 2018, 32, 11876–11886. [Google Scholar] [CrossRef]

- Vicente, E.D.; Vicente, A.M.; Evtyugina, M.; Tarelho, L.A.C.; Almeida, S.M.; Alves, C. Emissions from Residential Combustion of Certified and Uncertified Pellets. Renew. Energy 2020, 161, 1059–1071. [Google Scholar] [CrossRef]

- Kaivosoja, T.; Virén, A.; Tissari, J.; Ruuskanen, J.; Tarhanen, J.; Sippula, O.; Jokiniemi, J. Effects of a Catalytic Converter on PCDD/F, Chlorophenol and PAH Emissions in Residential Wood Combustion. Chemosphere 2012, 88, 278–285. [Google Scholar] [CrossRef] [PubMed]

| Pellet Stove | Woodstove | |||

|---|---|---|---|---|

| Wood Pellets | Olive Pit | Pine | ||

| Proximate analysis (wt.%, as received) | Moisture | 8.4 | 12.9 | 9.9 |

| Ultimate analysis (wt.%, dry basis) | Ash | 0.73 | 0.66 | 0.4 |

| C | 49.7 | 50.9 | 51.4 | |

| H | 6.9 | 6.59 | 6.2 | |

| N | 0.16 | 0.21 | 0.16 | |

| S | <0.01 | <0.01 | <0.01 | |

| O (by difference) | 42.5 | 41.6 | 41.84 | |

| Woodstove—Pine Firewood | |||

|---|---|---|---|

| REF | CAT | ESP | |

| O2 (%) | 13.5 ± 0.401 | 12.9 ± 1.80 | 13.6 ± 0.725 |

| Temperature: chimney (°C) | 162 ± 8.07 | 171 ± 19.5 | 157 ± 12.5 |

| Temperature: combustion chamber (°C) | 564 ± 22.4 | 586 ± 18.7 | 568 ± 32.6 |

| CO (mg Nm−3, dry basis, 13% O2) | 3299 ± 430 | 2814 ± 462 | 3075 ± 396 |

| TOC (mgC Nm−3, dry basis 13% O2) | 110 ± 34.1 | 133 ± 75.7 | 123 ± 24.9 |

| NOx as NO2 (mg Nm−3, dry basis, 13% O2) | 155 ± 23.7 | 98.1 ± 24.5 | 112 ± 18.8 |

| Wood Pellets—Nominal Load | Wood Pellets—Partial Load | |||||

|---|---|---|---|---|---|---|

| REF | CAT | ESP | REF | CAT | ESP | |

| O2 (%) | 17.7 ± 0.489 | 17.5 ± 0.482 | 17.2 ± 0.476 | 18.3 ± 0.477 | 18.0 ± 0.453 | 17.8 ± 0.428 |

| Temperature: chimney (°C) | 64.0 ± 1.35 | 65.0 ± 0.896 | 66.0 ± 0.990 | 53.6 ± 1.18 | 55.0 ± 0.980 | 56.8 ± 0.859 |

| Temperature: combustion chamber (°C) | 536 ± 56.5 | 556 ± 55.4 | 581 ± 55.4 | 498 ± 60.1 | 536 ± 59.8 | 549 ± 60.9 |

| CO (mg Nm−3, dry basis, 13% O2) | 905 ± 76.0 | 493 ± 89.0 | 648 ± 52.8 | 1277 ± 49.8 | 639 ± 91.8 | 836 ± 41.6 |

| TOC (mgC Nm−3, dry basis 13% O2) | 16.0 ± 2.93 | 5.08 ± 2.02 | 9.78 ± 0.732 | 30.7 ± 0.218 | 10.2 ± 3.45 | 15.5 ± 1.89 |

| NOx as NO2 (mg Nm−3, dry basis, 13% O2) | 179 ± 5.14 | 284 ± 16.0 | 181 ± 3.62 | 177 ± 13.3 | 291 ± 9.40 | 177 ± 6.08 |

| Olive Pit—Nominal Load | Olive Pit—Partial Load | |||||

|---|---|---|---|---|---|---|

| REF | CAT | ESP | REF | CAT | ESP | |

| O2 (%) | 18.3 ± 0.350 | 15.6 ± 1.25 | 17.9 ± 0.333 | 18.2 ± 0.197 | 15.5 ± 0.520 | 18.2 ± 0.176 |

| Temperature: chimney (°C) | 52.7 ± 1.80 | 117 ± 4.00 | 57.9 ± 1.56 | 48.3 ± 0.985 | 101 ± 8.77 | 50.3 ± 1.39 |

| Temperature: combustion chamber (°C) | 457 ± 76.1 | 665 ± 98.9 | 504 ± 57.9 | 458 ± 68.6 | 645 ± 69.6 | 411 ± 46.9 |

| CO (mg Nm−3, dry basis, 13% O2) | 6330 ± 304 | 2218 ± 552 | 4943 ± 280 | 7044 ± 594 | 2376 ± 212 | 6042 ± 291 |

| TOC (mgC Nm−3, dry basis 13% O2) | 370 ± 41.8 | 114 ± 37.2 | 245 ±19.2 | 542 ± 94.5 | 169 ± 24.1 | 353 ± 39.9 |

| NOx as NO2 (mg Nm−3, dry basis, 13% O2) | 268 ± 15.5 | 244 ± 39.6 | 245 ± 18.9 | 268 ± 47.7 | 235 ± 23.4 | 256 ± 14.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vicente, E.D.; Duarte, M.A.; Tarelho, L.A.C.; Alves, C.A. Efficiency of Emission Reduction Technologies for Residential Biomass Combustion Appliances: Electrostatic Precipitator and Catalyst. Energies 2022, 15, 4066. https://doi.org/10.3390/en15114066

Vicente ED, Duarte MA, Tarelho LAC, Alves CA. Efficiency of Emission Reduction Technologies for Residential Biomass Combustion Appliances: Electrostatic Precipitator and Catalyst. Energies. 2022; 15(11):4066. https://doi.org/10.3390/en15114066

Chicago/Turabian StyleVicente, Estela D., Márcio A. Duarte, Luís A. C. Tarelho, and Célia A. Alves. 2022. "Efficiency of Emission Reduction Technologies for Residential Biomass Combustion Appliances: Electrostatic Precipitator and Catalyst" Energies 15, no. 11: 4066. https://doi.org/10.3390/en15114066