Study on Distribution Law of Stress and Permeability around Hydraulic Fracturing Borehole in Coal and Rock

Abstract

:1. Introduction

2. Mechanical Model of Coal Rock Fracture

3. Distribution of Stress and Permeability of Coal Rock around Fracturing Boreholes

3.1. Stress State of Coal Rock around the Borehole

3.2. Range of Fracture Zone and Plastic Zone

3.3. The Evolution of Permeability of Coal Rock around the Borehole

4. Study on Geological and Engineering Parameters

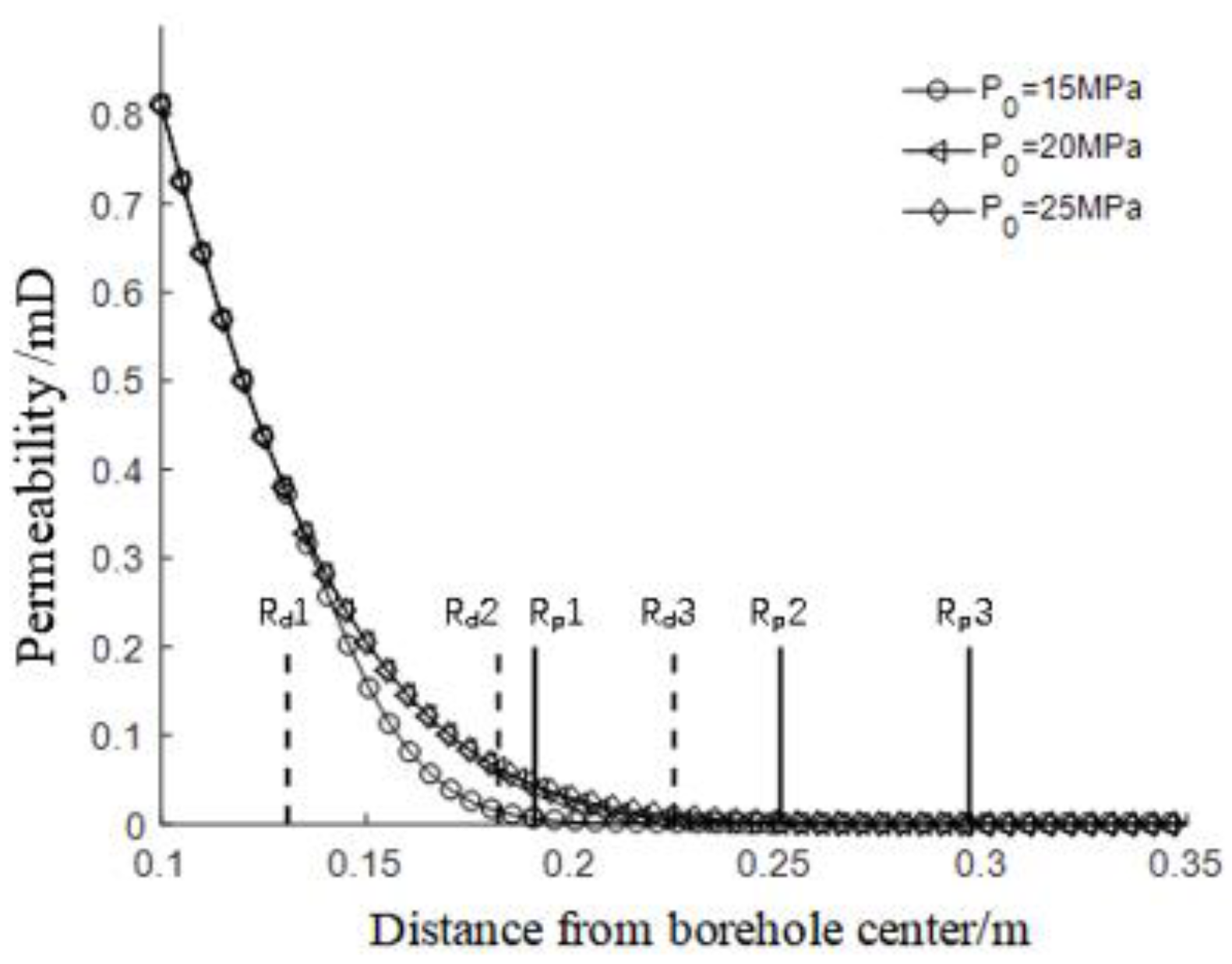

4.1. Influence of Ground Stress on the Permeability of Coal Rock

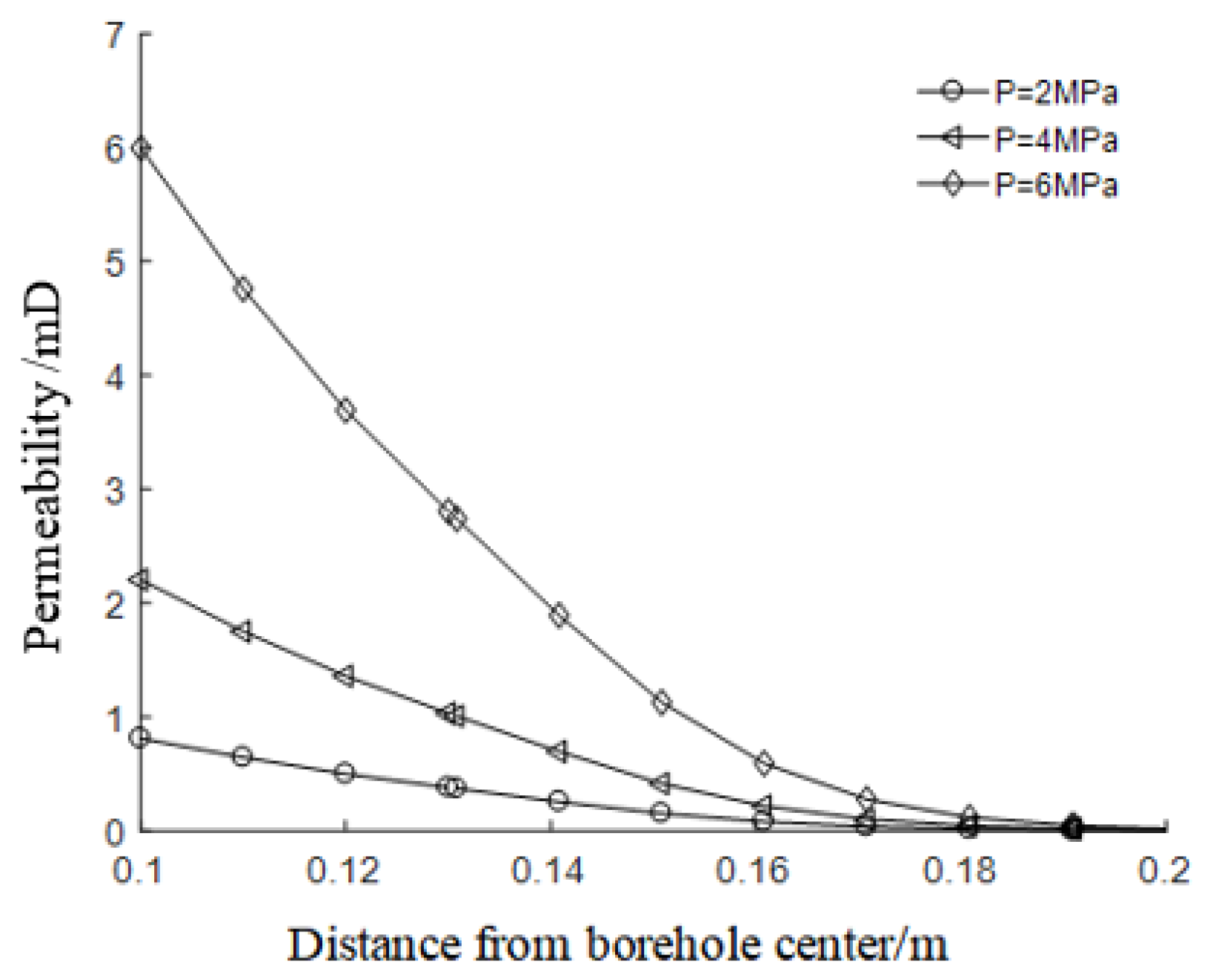

4.2. Influence of Gas Pressure on the Permeability of Coal Rock

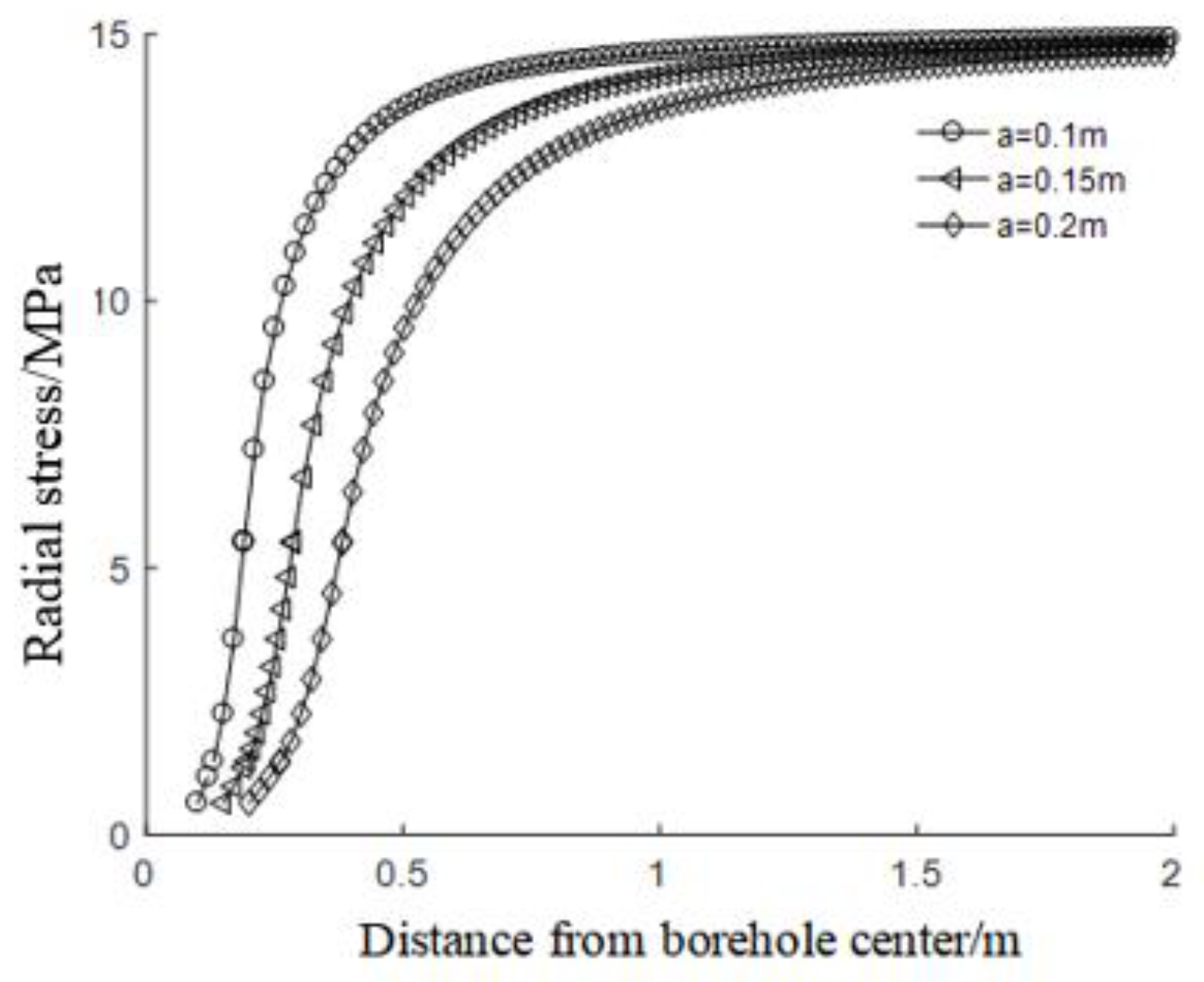

4.3. Influence of Drilling Radius on the Permeability of Coal Rock

4.4. Influence of Fracturing Pressure on the Permeability of Coal Rock

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.F.; He, X.Q.; Wang, E.Y.; Li, Y.Z. Research progress and development tendency of the hydraulic technology for increasing the permeability of coal seams. J. China Coal Soc. 2014, 39, 1945–1955. [Google Scholar]

- Lin, B.Q.; Meng, J.; Ning, J.; Zhang, M.B.; Li, Q.G.; Liu, Y. Study on Dynamic Characteristics of Hydraulic Fracturing in Gas-bearing Coal. J. Min. Saf. Eng. 2012, 29, 106–110. [Google Scholar]

- Guohua, Z.; Guanpin, W.; Fengcai, H. Theory of start-split affusion stress and star-split location about through coal de lam in a ions’bore of hydraulic fracture. J. China Coal Soc. 2007, 1, 52–55. [Google Scholar]

- Li, B.; Song, Z.; Ren, J. Gas migration mechanism of hydraulic fracturing on soft coal roof. J. Liaoning Tech. Univ. (Nat. Sci.) 2014, 33, 317–320. [Google Scholar]

- Li, H.; Li, X.; Zhang, L. Research on Hydraulic Fracturing in Low Permeability Soft Coal Seam. Coal Technol. 2014, 33, 16–19. [Google Scholar]

- Li, J.G.; Dai, G.L.; Li, Q.M. Application of hydraulic fracturing and permeability improvement technology for low permeability coal seam. Coal Eng. 2016, 48, 66–69. [Google Scholar]

- Liu, H.; Shang, Z. Hydraulic Punching and Hydraulic Fracturing Coupling Permeability Improving Technique in “Three Soft” Coal Seam. Saf. Coal Mines 2017, 48, 71–75. [Google Scholar]

- Li, H.; Wu, Q. Study on coal seam stress test based on hydraulic fracturing technology. Coal Chem. Ind. 2018, 41, 103–108, 112. [Google Scholar]

- Gao, S. Study on Hydraulic Fracturing Permeability-enhancing Technology for Upward Crossing-seam Boreholes of Deep Coal Seam. J. Anhui Univ. Sci. Technol. (Nat. Sci.) 2019, 39, 72–76. [Google Scholar]

- Sun, P.; Xu, L.; Tang, J. Study on the Influence Law of Underground Hydraulic Fracturing on Gas Content of Deep and Low Permeability Coal Seam. Min. Saf. Environ. Prot. 2019, 46, 30–34. [Google Scholar]

- Jiang, Z.-G.; Cheng, Y.-Y. Application of High and Low Pressure Cyclic Hydraulic Fracturing in Gas Anomaly Area of Liziya Coal Mine. Coal Technol. 2020, 39, 78–81. [Google Scholar]

- Li, X.; Li, Q.; Hu, Y.; Teng, L.; Yang, S. Evolution Characteristics of Mining Fissures in Overlying Strata of Stope after Converting from Open-Pit to Underground. Arab. J. Geosci. 2021, 14, 1–18. [Google Scholar] [CrossRef]

- Li, X.; Li, Q.; Hu, Y.; Chen, Q.; Peng, J.; Xie, Y.; Wang, J. Study on Three-Dimensional Dynamic Stability of Open-Pit High Slope under Blasting Vibration. Lithosphere 2022, 2022, 6426550. [Google Scholar] [CrossRef]

- Ma, K.; Wang, L.; Xu, W.J.; Zhao, Y.X.; Yuan, Y.; Chen, X.Y.; Zhang, F.Y. Physical simulation of fracture propagation in lacustrine shale during hydraulic fracturing. China Sci. Pap. 2021, 1, 1–7. [Google Scholar]

- Guo, T.K.; Sun, Y.M.; Liu, X.W.; Chen, M.; Liu, X.Q. Physical simulation test of multi-stage stagedfracturing for shale horizontal wells. J. Shenzhen Univ. Sci. Eng. 2022, 03, 111–118. [Google Scholar]

- Jiao, Z.; Chen, C.; Xiao, H. Analysis on propagation law of hydraulic fracturing cracks in hard roof sandstone. Sci. Technol. Eng. 2021, 21, 14528–14534. [Google Scholar]

- Zhao, S.; Li, Y.; Chai, H. Pre-existing crack angle optimization of thick sandstone roof during directional hydraulie fracturing and its application to anti-rockburst. J. China Coal Soc. 2020, 49, 61–71. [Google Scholar]

- Du, X.; Pang, D.; Cheng, Y.; Zhao, Y.; Hou, Z.; Liu, Z.; Wu, T.; Shu, C. Adsorption of CH4, N2, CO2 and their mixture on montmorillonite with implications for enhanced hydrocarbon extraction by gas injection. Appl. Clay Sci. 2021, 210, 106160. [Google Scholar] [CrossRef]

- Zhao, Y.; Cao, S.; Shang, D.; Yang, H.; Yu, Y.; Li, Y.; Liu, J.; Wang, H.; Pan, R.; Yang, H.; et al. Crack propagation and crack direction changes during the hydraulic fracturing of coalbed. Comput. Geotech. 2019, 111, 229–242. [Google Scholar] [CrossRef]

- Yong, L.; Cao, S.; Fantuzzi, N.; Liu, Y. Elasto-plastic analysis of a circular borehole in elastic-strain softening coal seams. Int. J. Rock Mech. Min. Sci. 2015, 80, 316–324. [Google Scholar]

- Li, X.; Yin, G. Relationship between effective volumetric stress and permeability of gas-filled coal. J. Chongqing Univ. 2011, 34, 103–108. [Google Scholar]

- Meng, Z.; Zhang, J.; Wang, R. In-situ stress, pore pressure and stress-dependent permeability in the Southern Qinshui Basin. Int. J. Rock Mech. Min. Sci. 2011, 48, 122–131. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Elastic modulus of coal/MPa | 1500 |

| Ground stress/MPa | 15 |

| Poisson ratio of coal | 0.3 |

| Internal friction angle | π/6 |

| Force of cohesion/MPa | 2 |

| Uniaxial compressive strength of coal rock/MPa | 8 |

| Residual strength of coal rock/MPa | 1 |

| Brittleness coefficient of coal rock | 0.5 |

| Fracture pressure/MPa | 0.6 |

| Radius of drill hole/m | 0.1 |

| Stress sensitivity factor/MPa−1 | 0.37 |

| Biot coefficient | 0.66 |

| Gas pressure/MPa | 2 |

| Permeability of unpressurized coal rock/mD | 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Zhao, Y.; Yu, Y.; Zhang, B.; Jia, L.; Du, X. Study on Distribution Law of Stress and Permeability around Hydraulic Fracturing Borehole in Coal and Rock. Energies 2022, 15, 4210. https://doi.org/10.3390/en15124210

Wu X, Zhao Y, Yu Y, Zhang B, Jia L, Du X. Study on Distribution Law of Stress and Permeability around Hydraulic Fracturing Borehole in Coal and Rock. Energies. 2022; 15(12):4210. https://doi.org/10.3390/en15124210

Chicago/Turabian StyleWu, Xiaomin, Yuan Zhao, Yongjun Yu, Bo Zhang, Li Jia, and Xidong Du. 2022. "Study on Distribution Law of Stress and Permeability around Hydraulic Fracturing Borehole in Coal and Rock" Energies 15, no. 12: 4210. https://doi.org/10.3390/en15124210