The Effects of Soiling and Frequency of Optimal Cleaning of PV Panels in Palestine

Abstract

:1. Introduction

2. Literature Review

3. Methodology

3.1. Location of the Study

3.2. Description of a PV System

3.3. The Procedure of the Experimental Study

4. Results and Discussion

5. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Banos, R.; Manzano-Agugliaro, F.; Montoya, F.G.; Gil, C.; Alcayde, A.; Gómez, J. Optimization methods applied to renewable and sustainable energy: A review. Renew. Sustain. Energy Rev. 2011, 15, 1753–1766. [Google Scholar] [CrossRef]

- Juaidi, A.; Anayah, F.; Assaf, R.; Hasan, A.A.; Monna, S.; Herzallah, L.; Abdallah, R.; Dutournié, P.; Jeguirim, M. An overview of renewable energy strategies and policies in Palestine: Strengths and challenges. Energy Sustain. Dev. 2022, 68, 258–272. [Google Scholar] [CrossRef]

- Del Pero, C.; Aste, N.; Leonforte, F. The effect of rain on photovoltaic systems. Renew. Energy 2021, 179, 1803–1814. [Google Scholar] [CrossRef]

- Salamah, T.; Ramahi, A.; Alamara, K.; Juaidi, A.; Abdallah, R.; Abdelkareem, M.A.; Amer, E.C.; Olabi, A.G. Effect of dust and methods of cleaning on the performance of solar PV module for different climate regions: Comprehensive review. Sci. Total Environ. 2022, 827, 154050. [Google Scholar] [CrossRef] [PubMed]

- Caron, S.; Garrido, J.; Ballestrín, J.; Sutter, F.; Röger, M.; Manzano-Agugliaro, F. A comparative analysis of opto-thermal figures of merit for high temperature solar thermal absorber coatings. Renew. Sustain. Energy Rev. 2022, 154, 111818. [Google Scholar] [CrossRef]

- Dai, H.; Mamkhezri, J.; Arshed, N.; Javaid, A.; Salem, S.; Khan, Y.A. Role of Energy Mix in Determining Climate Change Vulnerability in G7 Countries. Sustainability 2022, 14, 2161. [Google Scholar] [CrossRef]

- Szyba, M.; Mikulik, J. Energy Production from Biodegradable Waste as an Example of the Circular Economy. Energies 2022, 15, 1269. [Google Scholar] [CrossRef]

- Juaidi, A.; Montoya, F.G.; Ibrik, I.H.; Manzano-Agugliaro, F. An overview of renewable energy potential in Palestine. Renew. Sustain. Energy Rev. 2016, 65, 943–960. [Google Scholar] [CrossRef]

- Fernández-García, A.; Juaidi, A.; Sutter, F.; Martínez-Arcos, L.; Manzano-Agugliaro, F. Solar reflector materials degradation due to the sand deposited on the backside protective paints. Energies 2018, 11, 808. [Google Scholar] [CrossRef] [Green Version]

- Hernandez-Escobedo, Q.; Rodríguez-García, E.; Saldaña-Flores, R.; Fernández-García, A.; Manzano-Agugliaro, F. Solar energy resource assessment in Mexican states along the Gulf of Mexico. Renew. Sustain. Energy Rev. 2015, 43, 216–238. [Google Scholar] [CrossRef]

- Perea-Moreno, A.J.; García-Cruz, A.; Novas, N.; Manzano-Agugliaro, F. Rooftop analysis for solar flat plate collector assessment to achieving sustainability energy. J. Clean. Prod. 2017, 148, 545–554. [Google Scholar] [CrossRef]

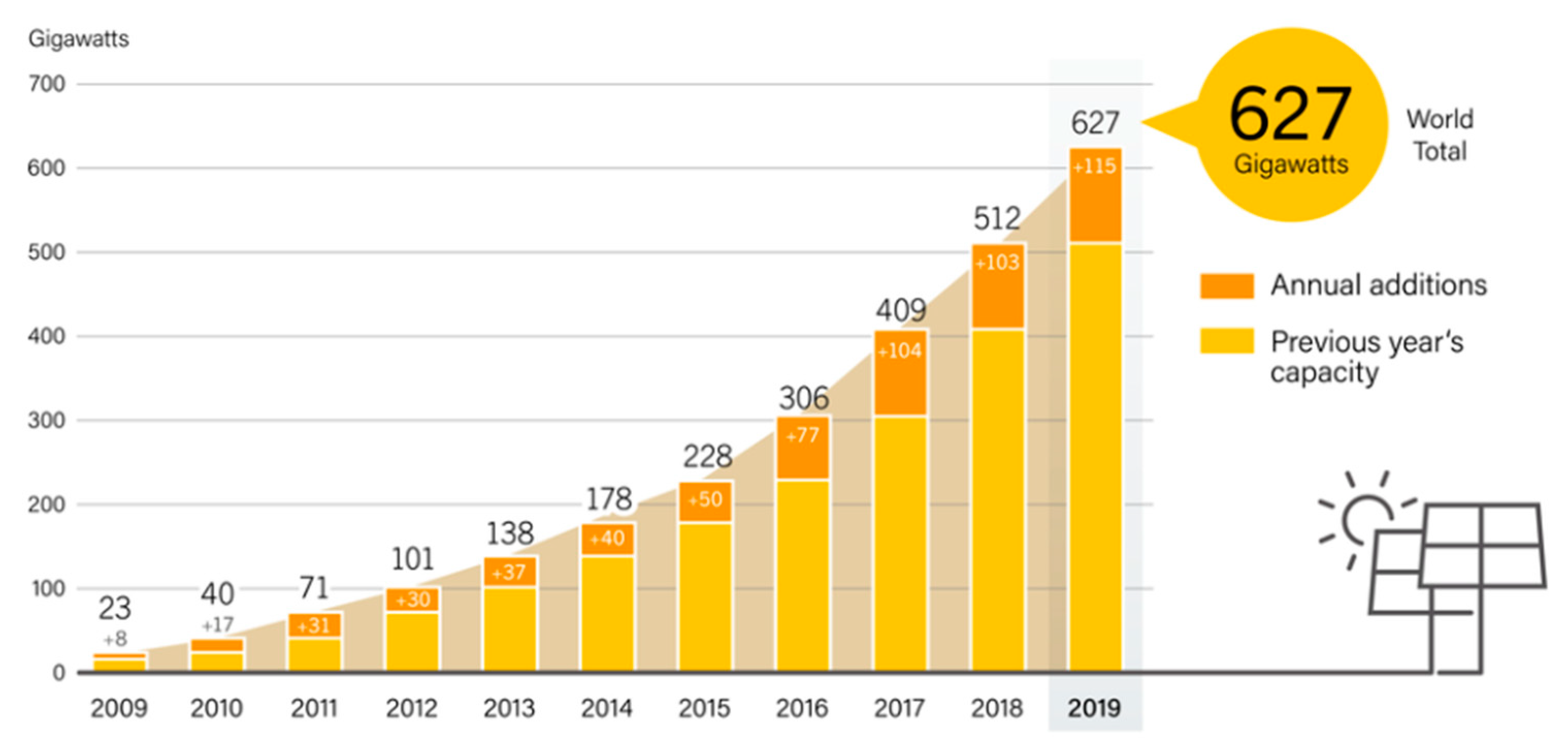

- REN21. Renewables 2020 Global Status Report. 2020. Available online: https://www.ren21.net/wpcontent/uploads/2019/05/gsr_2020_full_report_en.pdf (accessed on 11 February 2022).

- Castellano, N.N.; Parra, J.A.G.; Valls-Guirado, J.; Manzano-Agugliaro, F. Optimal displacement of photovoltaic array’s rows using a novel shading model. Appl. Energy 2015, 144, 1–9. [Google Scholar] [CrossRef]

- Abdallah, R.; Juaidi, A.; Assad, M.; Salameh, T.; Manzano-Agugliaro, F. Energy recovery from waste tires using pyrolysis: Palestine as case of study. Energies 2020, 13, 1817. [Google Scholar] [CrossRef] [Green Version]

- Abdallah, R.; Juaidi, A.; Abdel-Fattah, S.; Manzano-Agugliaro, F. Estimating the optimum tilt angles for south-facing surfaces in Palestine. Energies 2020, 13, 623. [Google Scholar] [CrossRef] [Green Version]

- Monna, S.; Juaidi, A.; Abdallah, R.; Salameh, T. Sustainable energy retrofitting for residential buildings in Palestine, a simulation based approach. In Proceedings of the 2021 12th International Renewable Engineering Conference (IREC), Amman, Jordan, 14–15 April 2021; pp. 1–5. [Google Scholar]

- Abdallah, R.; Natsheh, E.; Juaidi, A.; Samara, S.; Manzano-Agugliaro, F. A Multi-Level World Comprehensive Neural Network Model for Maximum Annual Solar Irradiation on a Flat Surface. Energies 2020, 13, 6422. [Google Scholar] [CrossRef]

- Monna, S.; Juaidi, A.; Abdallah, R.; Itma, M. A Comparative Assessment for the Potential Energy Production from PV Installation on Residential Buildings. Sustainability 2020, 12, 10344. [Google Scholar] [CrossRef]

- Monna, S.; Juaidi, A.; Abdallah, R.; Albatayneh, A.; Dutournie, P.; Jeguirim, M. Towards sustainable energy retrofitting, a simulation for potential energy use reduction in residential buildings in Palestine. Energies 2021, 14, 3876. [Google Scholar] [CrossRef]

- Energy Sector Management Assistance Program. Global Photovoltaic Power Potential by Country; World Bank: Washington, DC, USA, 2020. [Google Scholar]

- Hussin, N.S.M.; Amin, N.A.M.; Safar, M.J.A.; Zulkafli, R.S.; Majid, M.S.A.; Rojan, M.A.; Zaman, I. Performance factors of the photovoltaic system: A review. MATEC Web Conf. 2018, 225, 03020. [Google Scholar] [CrossRef]

- Usman, Z.; Tah, J.; Abanda, H.; Nche, C. A critical appraisal of pv-systems’ performance. Buildings 2020, 10, 192. [Google Scholar] [CrossRef]

- Hendriana, D.; Sinaga, E.F.; Djajadi, A.K.T. Experimental Testbed and Performance Evaluation for Rooftop Solar PV System and Generator Set. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 26 March–10 April 2019; pp. 1–8. [Google Scholar] [CrossRef]

- Mani, M.; Pillai, R. Impact of dust on solar photovoltaic (PV) performance: Research status, challenges and recommendations. Renew. Sustain. Energy Rev. 2010, 14, 3124–3131. [Google Scholar] [CrossRef]

- Bana, S.; Saini, R.P. Experimental investigation on power output of different photovoltaic array configurations under uniform and partial shading scenarios. Energy 2017, 127, 438–453. [Google Scholar] [CrossRef]

- Dwivedi, L.K.; Yadav, P.; Saket, R.K. MATLAB based modelling and maximum power point tracking (MPPT) method for photovoltaic system under partial shading conditions. Int. Res. J. Eng. Technol. 2016, 3. [Google Scholar]

- John, J.J.; Warade, S.; Tamizhmani, G.; Kottantharayil, A. Study of soiling loss on photovoltaic modules with artificially deposited dust of different gravimetric densities and compositions collected from different locations in India. IEEE J. Photovolt. 2015, 6, 236–243. [Google Scholar] [CrossRef]

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.-H. Solar energy: Potential and future prospects. Renew. Sust. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- Kaldellis, J.; Fragos, P. Ash deposition impact on the energy performance of photovoltaic generators. J. Clean. Prod. 2011, 19, 311–317. [Google Scholar] [CrossRef]

- Khadka, N.; Bista, A.; Adhikari, B.; Shrestha, A.; Bista, D.; Adhikary, B. Current practices of solar photovoltaic panel cleaning system and future prospects of machine learning implementation. IEEE Access 2020, 8, 135948–135962. [Google Scholar] [CrossRef]

- Bosman, L.B.; Leon-Salas, W.D.; Hutzel, W.; Soto, E.A. PV system predictive maintenance: Challenges, current approaches, and opportunities. Energies 2020, 13, 1398. [Google Scholar] [CrossRef] [Green Version]

- Şevik, S.; Aktaş, A. Performance enhancing and improvement studies in a 600 kW solar photovoltaic (PV) power plant; manual and natural cleaning, rainwater harvesting and the snow load removal on the PV arrays. Renew. Energy 2022, 181, 490–503. [Google Scholar] [CrossRef]

- Alamri, H.R.; Rezk, H.; Abd-Elbary, H.; Ziedan, H.A.; Elnozahy, A. Experimental Investigation to Improve the Energy Efficiency of Solar PV Panels Using Hydrophobic SiO2 Nanomaterial. Coatings 2020, 10, 503. [Google Scholar] [CrossRef]

- Azouzoute, A.; Zitouni, H.; El Ydrissi, M.; Hajjaj, C.; Garoum, M.; Ghennioui, A. Developing a cleaning strategy for hybrid solar plants PV/CSP: Case study for semi-arid climate. Energy 2021, 228, 120565. [Google Scholar] [CrossRef]

- Hudedmani, M.G.; Joshi, G.; Umayal, R.M.; Revankar, A. A comparative study of dust cleaning methods for the solar PV panels. Adv. J. Grad. Res. 2017, 1, 24–29. [Google Scholar] [CrossRef] [Green Version]

- Hardt, M.; Martínez, D.; González, A.; Garrido, C.; Aladren, S.; Villa, J.R.; Saenz, J. HECTOR—Heliostat Cleaning Team-Oriented Robot. In Proceedings of the Solar-PACES 2011 Conference, Granada, Spain, 20–23 September 2011; pp. 20–23. [Google Scholar]

- Jaradat, M.A.; Tauseef, M.; Altaf, Y.; Saab, R.; Adel, H.; Yousuf, N.; Zurigat, Y. A fully portable robot system for cleaning solar panels. In Proceedings of the 2015 10th International Symposium on Mechatronics and its Applications (ISMA), Sharjah, United Arab Emirates, 8–10 December 2015; pp. 1–6. [Google Scholar]

- Gheitasi, A.; Almaliky, A.; Albaqawi, N. Development of an automatic cleaning system for photovoltaic plants. In Proceedings of the 2015 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Brisbane, QL, Australia, 15–18 November 2015; pp. 1–4. [Google Scholar]

- Hassan, M.U.; Nawaz, M.I.; Iqbal, J. Towards autonomous cleaning of photovoltaic modules: Design and realization of a robotic cleaner. In Proceedings of the 2017 First International Conference on Latest trends in Electrical Engineering and Computing Technologies (INTELLECT), Karachi, Pakistan, 15–16 November 2017; pp. 1–6. [Google Scholar]

- Anderson, M.; Grandy, A.; Hastie, J.; Sweezey, A.; Ranky, R.; Mavroidis, C.; Markopoulos, Y. Robotic device for cleaning photovoltaic panel arrays. In Mobile Robotics: Solutions and Challenges; World Scientific: Singapore, 2010; pp. 367–377. [Google Scholar]

- Al Baloushi, A.; Saeed, M.; Marwan, S.; AlGghafri, S.; Moumouni, Y. Portable robot for cleaning photovoltaic system: Ensuring consistent and optimal year-round photovoltaic panel performance. In Proceedings of the 2018 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, Sharjah, Abu Dhabi, United Arab Emirates, 6 February–5 April 2018; pp. 1–4. [Google Scholar]

- Son, J.; Kundu, S.; Verma, L.K.; Sakhuja, M.; Danner, A.J.; Bhatia, C.S.; Yang, H. A practical superhydrophilic self-cleaning and antireflective surface for outdoor photovoltaic applications. Sol. Energy Mater. Sol. Cells 2012, 98, 46–51. [Google Scholar] [CrossRef]

- He, G.; Zhou, C.; Li, Z. Review of self-cleaning method for solar cell array. Procedia Eng. 2011, 16, 640–645. [Google Scholar] [CrossRef] [Green Version]

- Sarkın, A.S.; Ekren, N.; Sağlam, Ş. A review of anti-reflection and self-cleaning coatings on photovoltaic panels. Sol. Energy 2020, 199, 63–73. [Google Scholar] [CrossRef]

- Arabatzis, I.; Todorova, N.; Fasaki, I.; Tsesmeli, C.; Peppas, A.; Li, W.X.; Zhao, Z. Photocatalytic, self-cleaning, antireflective coating for photovoltaic panels: Characterization and monitoring in real conditions. Sol. Energy 2018, 159, 251–259. [Google Scholar] [CrossRef]

- Syafiq, A.; Balakrishnan, V.; Ali, M.S.; Dhoble, S.J.; Abd Rahim, N.; Omar, A. Application of transparent self-cleaning coating for photovoltaic panel: A review. Curr. Opin. Chem. Eng. 2022, 36, 100801. [Google Scholar] [CrossRef]

- Zhong, H.; Hu, Y.; Wang, Y.; Yang, H. TiO2/silane coupling agent composed of two layers structure: A super-hydrophilic self-cleaning coating applied in PV panels. Appl. Energy 2017, 204, 932–938. [Google Scholar] [CrossRef]

- Soklič, A.; Tasbihi, M.; Kete, M.; Štangar, U.L. Deposition and possible influence of a self-cleaning thin TiO2/SiO2 film on a photovoltaic module efficiency. Catal. Today 2015, 252, 54–60. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H.; Sopian, K. A review of dust accumulation and cleaning methods for solar photovoltaic systems. J. Clean. Prod. 2020, 276, 123187. [Google Scholar] [CrossRef]

- Deb, D.; Brahmbhatt, N.L. Review of yield increase of solar panels through soiling prevention, and a proposed water-free automated cleaning solution. Renew. Sustain. Energy Rev. 2018, 82, 3306–3313. [Google Scholar] [CrossRef]

- Haydar, J.; NourAldeen, A.; Fayad, H.; Fahs, W.; Hassan, H.A.H. A low cost automated cleaning system for photovoltaic panels. In Proceedings of the 2018 International Arab Conference on Information Technology (ACIT), Werdanye, Lebanon, 28–30 November 2018; pp. 1–3. [Google Scholar]

- Thomas, S.K.; Joseph, S.; Sarrop, T.S.; Haris, S.B.; Roopak, R. Solar Panel Automated Cleaning (SPAC) System. In Proceedings of the 2018 International Conference on Emerging Trends and Innovations in Engineering and Technological Research (ICETIETR), Cochin, India, 11–13 July 2018; pp. 1–3. [Google Scholar]

- Chanchangi, Y.N.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Dust and PV Performance in Nigeria: A review. Renew. Sustain. Energy Rev. 2020, 121, 109704. [Google Scholar] [CrossRef]

- Mondal, A.K.; Bansal, K. A brief history and future aspects in automatic cleaning systems for solar photovoltaic panels. Adv. Robot. 2015, 29, 515–524. [Google Scholar] [CrossRef]

- Wilson, D.I. Challenges in cleaning: Recent developments and future prospects. Heat Transf. Eng. 2005, 26, 51–59. [Google Scholar] [CrossRef]

- Micheli, L.; Fernández, E.F.; Muller, M.; Almonacid, F. Extracting and generating PV soiling profiles for analysis, forecasting, and cleaning optimization. IEEE J. Photovolt. 2019, 10, 197–205. [Google Scholar] [CrossRef]

- Al-Badra, M.Z.; Abd-Elhady, M.S.; Kandil, H.A. A novel technique for cleaning PV panels using antistatic coating with a mechanical vibrator. Energy Rep. 2020, 6, 1633–1637. [Google Scholar] [CrossRef]

- Shah, A.H.; Hassan, A.; Laghari, M.S.; Alraeesi, A. The influence of cleaning frequency of photovoltaic modules on power losses in the desert climate. Sustainability 2020, 12, 9750. [Google Scholar] [CrossRef]

- Al-Housani, M.; Bicer, Y.; Koç, M. Experimental investigations on PV cleaning of large-scale solar power plants in desert climates: Comparison of cleaning techniques for drone retrofitting. Energy Convers. Manag. 2019, 185, 800–815. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T. The effect of dust accumulation and cleaning methods on PV panels’ outcomes based on an experimental study of six locations in Northern Oman. Sol. Energy 2019, 187, 30–38. [Google Scholar] [CrossRef]

- Al-Tarawneh, A.; Ahmed, M.Z.; Al-Tarawneh, A. The Effect of Soiling and Periodic Cleaning on the Performance of Solar Power Plants in Ma’an, Jordan. Innov. Syst. Des. Eng. 2018, 9, 14–18. [Google Scholar]

- Bunyan, H.; Ali, W.; Alnaser, M. Enhancing the Performance of Photovoltaic Panel by Proper Washing Periods in Kuwait. Smart Grid Renew. Energy 2016, 7, 190–196. [Google Scholar] [CrossRef] [Green Version]

- Hammoud, M.; Shokr, B.; Assi, A.; Hallal, J.; Khoury, P. Effect of dust cleaning on the enhancement of the power generation of a coastal PV-power plant at Zahrani Lebanon. Sol. Energy 2019, 184, 195–201. [Google Scholar] [CrossRef]

- Mohamed, A.O.; Hasan, A. Effect of Dust Accumulation on Performance of Photovoltaic Solar Modules in Sahara Environment. J. Basic Appl. Sci. Res. 2012, 2, 11030–11036. [Google Scholar]

- Hammad, B.; Al-Abed, M.; Al-Ghandoor, A.; Al-Sardeah, A.; Al-Bashir, A. Modeling and analysis of dust and temperature effects on photovoltaic systems’ performance and optimal cleaning frequency: Jordan case study. Renew. Sustain. Energy Rev. 2018, 82, 2218–2234. [Google Scholar] [CrossRef]

- Urrejola, E.; Antonanzas, J.; Ayala, P.; Salgado, M.; Ramírez-Sagner, G.; Cortés, C.; Pino, A.; Escobar, R. Effect of soiling and sunlight exposure on the performance ratio of photovoltaic technologies in Santiago. Chile. Energy Convers. Manag. 2016, 114, 338–347. [Google Scholar] [CrossRef]

- Naeem, M.; Mani, G.T. Cleaning frequency optimization for soiled photovoltaic modules. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC), New Orleans, LA, USA, 14–19 June 2015; pp. 1–5. [Google Scholar]

- Moharram, K.A.; Abd-Elhady, M.S.; Kandil, H.A.; El-Sherif, H. Influence of cleaning using water and surfactants on the performance of photovoltaic panels. Energy Convers. Manag. 2013, 68, 266–272. [Google Scholar] [CrossRef]

- Sakarapunthip, N.; Chenvidhya, D.; Chuangchote, S.; Kirtikara, K.; Chenvidhya, T.; Onreabroy, W. Effects of dust accumulation and module cleaning on performance ratio of solar rooftop system and solar power plants. Jpn. J. Appl. Phys. 2017, 56, 08ME02. [Google Scholar] [CrossRef]

- Aidara, M.C.; Ndiaye, M.L.; Mbaye, A.; Sylla, M.; Ndiaye, P.A.; Ndiaye, A. Study of the performance of a system for dry cleaning dust deposited on the surface of solar photovoltaic panels. Int. J. Phys. Sci. 2018, 13, 16–23. [Google Scholar]

- Elminir, H.K.; Ghitas, A.E.; Hamid, R.H.; El-Hussainy, F.; Beheary, M.M.; Abdel-Moneim, K.M. Effect of dust on the transparent cover of solar collectors. Energy Convers. Manag. 2006, 47, 3192–3203. [Google Scholar] [CrossRef]

- Jiang, H.; Lu, L.; Sun, K. Experimental investigation of the impact of airborne dust deposition on the performance of solar photovoltaic (PV) modules. Atmos. Environ. 2011, 45, 4299–4304. [Google Scholar] [CrossRef]

- Cabanillas, R.E.; Munguía, H. Dust accumulation effect on efficiency of Si photovoltaic modules. J. Renew. Sustain. Energy 2011, 3, 43114. [Google Scholar] [CrossRef]

- Wakim, F. Introduction of PV Power Generation to Kuwait. Kuwait: Kuwait Institute for Scientific Researchers; [Report No. 440]; Kuwait Institute for Scientific Researchers: Kuwait City, Kuwait, 1981. [Google Scholar]

- Said, S.A.M.; Walwil, H.M. Fundamental studies on dust fouling effects on PV module performance. Sol. Energy 2014, 107, 328–337. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Kapsali, M. Simulating the dust effect on the energy performance of photovoltaic generators based on experimental measurements. Energy 2011, 36, 5154–5161. [Google Scholar] [CrossRef]

- Weber, B.; Quiñones, A.; Almanza, R.; Duran, M.D. Performance reduction of PV systems by dust deposition. Energy Procedia 2014, 57, 99–108. [Google Scholar] [CrossRef] [Green Version]

- Majeed, R.; Waqas, A.; Sami, H.; Ali, M.; Shahzad, N. Experimental investigation of soiling losses and a novel cost-effective cleaning system for PV modules. Sol. Energy 2020, 201, 298–306. [Google Scholar] [CrossRef]

- Natsheh, E.M. Power generation of solar PV systems in Palestine. Appl. Sol. Energy 2016, 52, 193–196. [Google Scholar] [CrossRef]

- Abu-Naser, M. Solar panels cleaning frequency for maximum financial profit. Open J. Energy Effic. 2017, 6, 80–86. [Google Scholar] [CrossRef] [Green Version]

- Boykiw, E. The Effect of Settling Dust in the Arava Valley on the Performance of Solar Photovoltaic Panels. Master’s Thesis, Allegheny College, Meadville, PA, USA, 2011. [Google Scholar]

- Fathi, M.; Abderrezek, M.; Friedrich, M. Reducing dust effects on photovoltaic panels by hydrophobic coating. Clean Techn. Environ. Policy 2017, 19, 577–585. [Google Scholar] [CrossRef]

- Fathi, M.; Abderrezek, M.; Grana, P. Technical and economic assessment of cleaning protocol for photovoltaic power plants: Case of Algerian Sahara sites. Sol. Energy 2017, 147, 358–367. [Google Scholar] [CrossRef]

- Figgis, B.; Ennaoui, A.; Ahzi, S.; Rémond, Y. Review of PV soiling particle mechanics in desert environments. Renew. Sust. Energ. Rev. 2017, 76, 872–881. [Google Scholar] [CrossRef]

- García, M.; Marroyo, L.; Lorenzo, E.; Pérez, M. Soiling and other optical losses in solar-tracking PV plants in navarra. Prog. Photovolt. Res. Appl. 2011, 19, 211–217. [Google Scholar] [CrossRef] [Green Version]

- Garg, H. Effect of dirt on transparent covers in flat-plate solar energy collectors. Sol. Energy 1974, 15, 299–302. [Google Scholar] [CrossRef]

- Ghazi, S.; Ip, K. The effect of weather conditions on the efficiency of PV panels in the southeast of UK. Renew. Energy 2014, 69, 50–59. [Google Scholar]

- Abushgair, K.; Al-Waked, R. Effects of Coating Materials as a Cleaning Agent on the Performance of Poly-Crystal PV Panels. Coatings 2021, 11, 544. [Google Scholar] [CrossRef]

- Younis, A.; Onsa, M. A brief summary of cleaning operations and their effect on the photovoltaic performance in Africa and the Middle East. Energy Rep. 2022, 8, 2334–2347. [Google Scholar] [CrossRef]

- Alghamdi, A.S.; Bahaj, A.S.; Blunden, L.S.; Wu, Y. Dust removal from solar PV modules by automated cleaning systems. Energies 2019, 12, 2923. [Google Scholar] [CrossRef] [Green Version]

- Syafiq, A.; Pandey, A.K.; Adzman, N.N.; Abd Rahim, N. Advances in approaches and methods for self-cleaning of solar photovoltaic panels. Sol. Energy 2018, 162, 597–619. [Google Scholar] [CrossRef]

- Jiang, Y.; Lu, L.; Lu, H. A novel model to estimate the cleaning frequency for dirty solar photovoltaic (PV) modules in desert environment. Sol. Energy 2016, 140, 236–240. [Google Scholar] [CrossRef]

- Alnaser, N.W.; Al Othman, M.J.; Dakhel, A.A.; Batarseh, I.; Lee, J.K.; Najmaii, S.; Alothman, A.; Al Shawaikh, H.; Alnaser, W.E. Comparison between performance of man-made and naturally cleaned PV panels in a middle of a desert. Renew. Sustain. Energy Rev. 2018, 82, 1048–1055. [Google Scholar] [CrossRef]

- Mithhu, M.M.H.; Rima, T.A.; Khan, M.R. Global analysis of optimal cleaning cycle and profit of soiling affected solar panels. Appl. Energy 2021, 285, 116436. [Google Scholar] [CrossRef]

- Sayyah, A.; Horenstein, M.N.; Mazumder, M.K. Energy yield loss caused by dust deposition on photovoltaic panels. Sol. Energy 2014, 107, 576–604. [Google Scholar] [CrossRef]

- Assali, A.; Khatib, T.; Najjar, A. Renewable energy awareness among future generation of Palestine. Renew. Energy 2019, 136, 254–263. [Google Scholar] [CrossRef]

- Salah, W.A.; Abuhelwa, M.; Bashir, M.J. The key role of sustainable renewable energy technologies in facing shortage of energy supplies in Palestine: Current practice and future potential. J. Clean. Prod. 2021, 293, 125348. [Google Scholar] [CrossRef]

- Hamed, T.A.; Peric, K. The role of renewable energy resources in alleviating energy poverty in Palestine. Renew. Energy Focus 2020, 35, 97–107. [Google Scholar] [CrossRef]

- Ibrik, I.H.; Mahmoud, M.M. Energy efficiency improvement procedures and audit results of electrical, thermal and solar applications in Palestine. Energy Policy 2005, 33, 651–658. [Google Scholar] [CrossRef]

| No. | Author | Country (Year) | Cleaning Method | Cleaning Frequency | Test Duration | Main Result |

|---|---|---|---|---|---|---|

| 1 | Al-Badra et al. | Egypt (2020) | Self-cleaning (Nano-coating) mechanical vibrator. | Every 2 weeks for the coating panel, monthly for the combination of coating and vibration. | 6 Weeks | The uncleaned panel efficiency decreased by 3.69%, the coating panel decreased by 2.74%, and the combination of coating and vibration panel’s efficiency decreased by 1.45% [57]. |

| 2 | Shah et al. | UAE (2020) | - | 10 days 20 days 1 month 3 months | 3.5 Months | The drop in electric power compared to a daily cleaned reference PV module was 3%, 5% 7%, and 13% for 10 days, 20 days, 1 month, and 3 months respectively [58]. |

| 3 | AL-Housani et al. | Qatar (2019) | Microfiber-based cloth wiper | Weekly | 6 Months | There was an average performance improvement in the power output of the cleaned panels compare to the case of unclean panels which was 7.7% in winter and 3.1% in summer [59]. |

| 4 | Kazem and Chaichan | Oman (2019) | Water | Monthly | One Year | In the city of Muscat, there was a 52% reduction in power in the uncleaned PV module where the reduction in the monthly cleaning in the afternoon PV module was 34%, and it was 31% and 32% in the evening and early morning, respectively [60]. |

| 5 | Ahmed et al. | Jordan (2018) | Filtered deionized water only | Monthly | 10 Months | There was an average of 2.205% of the output power difference between the cleaned and the uncleaned panels [61]. |

| 6 | Bunyan et al. | Kuwait (2016) | Water washing | Daily and monthly | One Year | The most affected months were April, May, October, and December with a reduction in the power of 15.07%, 13.74%,10.685%, and 8.742%, respectively compared to the cleaned panels [62]. |

| 7 | Hammoud et al. | Lebanon (2018) | Robot cleaning | Every 2 Weeks | 3.5 Months | There was an improvement of 32.23% in the output production power [63]. |

| 8 | Mohamed and Hasan | Libya (2012) | Water washing | Weekly | 4 Months | Weekly cleaning was sufficient to limit power loss in the range of 2–2.5% which was targeted in that study [64]. |

| 9 | Hammad et al. | Jordan (2018) | Manual cleaning and natural rainfall | 4 cleaning times with 3 frequencies: 53, 65, 74 days | 192 Days | They found that the optimum cleaning frequency is between 12 and 15 days depending on ANN and MLR models. (Tilt angle was 26° in the experiment) [65]. |

| 10 | Urrejola et al. | Chile (2016) | Manually using a brush with water | Monthly | 2 Years | A monthly decay of 17.36% in the performance ratio, the suggested cleaning frequency was 45 days [66]. |

| 11 | Naeem et al. | USA (2015) | Brush using water | Three times every year | 10 Years including other studies | The annual soiling loss would be reduced from 1.9% to 1.2% when the cleaning is done 3 times per year [67]. |

| 12 | Moharram et al. | Egypt (2013) | Non-pressurized water and a combination of anionic and cationic surfactants | Daily and once after 45 days | 59 Days | The efficiency of the PV modules has decreased from 15% at the beginning to 8% at the end of the 45 days when cleaning with non-pressurized water, and the efficiency decreased from 15% to an average of 12% after 45 days of cleaning with a mixture of anionic and cationic surfactants [68]. |

| 13 | Sakarapunthip et al. | Thailand (2017) | Manual | Once/2 Months | - | There was an increase in the output energy by 10% after cleaning [69]. |

| 14 | Cherif Aidara et al. | Senegal (2018) | Waterless cleaning system | Daily | One Month | The uncleaned module efficiency decreased by 24.09% while the cleaned panels decreased just by 10.16% [70]. |

| 15 | Elminir et al. | Egypt (2006) | - | - | - | There was an average decrease of 17.4% monthly in the PV efficiency [71]. |

| 16 | Jiang et al. | China (2011) | - | - | - | PV efficiency drop was 26% [72]. |

| 17 | Cabanillas and Munguía | Mexico (2011) | - | - | - | The amorphous module’s maximum power was reduced due to dust in the range between 8–13% while the monocrystalline and polycrystalline modules had a reduction of maximum power between 4% and 7% [73]. |

| 18 | Wakim | Kuwait (2010) | - | Monthly | - | PV efficiency decrease was 17% [74]. |

| 19 | Said and Walwil | KSA (2014) | - | Monthly | - | PV efficiency decrease was 7% [75]. |

| 20 | Kaldellis and Kapsali | (Greece) (2011) | - | - | - | Artificial dust (limestone) amount of 0.7 gm/m2 decreased the efficiency by 0.6% While 1.2 gm/m2 decreased the efficiency by 0.8% The natural air pollution with the same masses above affected the efficiencies by 0.1% and 0.17%, respectively. (the values are compared with a cleaned panel) [76]. |

| 21 | Weber et al. | Mexico (2013) | - | - | - | For nearly 60 dry days, deposits and dust accumulation affected PV panels’ efficiency by 15% while in the whole year, the reduction of efficiency was 3.6% because of the natural cleaning that comes from rainfall, this huge difference in reduction after rainfall is normal and expected in Mexico since there are 125 rainy days per year [77]. |

| 22 | Majeed et al. | Pakistan (2020) | - | - | - | Power loss due to dust accumulation in the case of mono PV was 16.6% and 11.55% in the poly PV, both at an angle of 34.5°, and dust density of 4.6 g/m2 [78]. |

| Month | Jan. | Feb. | Mar. | Apr. | May | Jun. | Jul. | Aug. | Sept. | Oct. | Nov. | Dec. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GHI (kWh/m2) | 87.74 | 102.11 | 154.06 | 187.55 | 225.49 | 243.46 | 247.35 | 224.34 | 184.82 | 145.01 | 103.83 | 86.64 |

| Monthly Total Rainfall (mm) | 145.5 | 124 | 18.5 | 9 | 0 | 0 | 0 | 0 | 0 | 1.5 | 38.5 | 49.7 |

| Mean Monthly Maximum Temperatures (°C) | 23.5 | 24 | 23.5 | 27.8 | 31.8 | 31.9 | 35.3 | 36.3 | 34.9 | 28.2 | 24.6 | 18.4 |

| Number Of Rainy Days | 9 | 8 | 8 | 2 | 0 | 0 | 0 | 0 | 1 | 2 | 5 | 3 |

| Mean Monthly Wind Speed (Km/h) | 5.53 | 4.05 | 4.24 | 4.98 | 5.53 | 5.16 | 5.35 | 4.98 | 4.42 | 4.42 | 3.50 | 5.53 |

| Mean Monthly Relative Humidity (%) | 69 | 60 | 56 | 64 | 53 | 63 | 63 | 65 | 63 | 55 | 56 | 69 |

| Maximum Power = 330 W | Open Circuit Voltage = 45.9 V |

| Short Circuit Current = 9.26 A | Maximum Power Voltage = 37.3 V |

| Maximum Power Current = 8.85 A | Power Tolerance = 0~+3% |

| Maximum system voltage = DC 1000 V | Module Application: class A |

| Nominal operating cell temperature = 45 ± 2 °C | Operating temperature: −40 to +85 °C |

| Weight = 23 kg | Dimensions = 1956 × 992 × 50 mm |

| Cell technology = Poly-Si. | Module Efficiency (%) = 17.01 |

| Date | Weekly | 2 Weeks | Monthly | 2 Months | 6 Months | 1 Year |

|---|---|---|---|---|---|---|

| 7 January 2021 | 7.42 | |||||

| 14 January 2021 | 9.54 | 16.90 | ||||

| 21 January 2021 | 8.52 | |||||

| 28 January 2021 | 7.88 | 16.28 | 33.08 | |||

| 7 February 2021 | 10.16 | |||||

| 14 February 2021 | 7.97 | 17.94 | ||||

| 21 February 2021 | 8.88 | |||||

| 28 February 2021 | 7.24 | 16.02 | 33.89 | 66.46 | ||

| 7 March 2021 | 11.18 | |||||

| 14 March 2021 | 11.47 | 22.45 | ||||

| 21 March 2021 | 12.53 | |||||

| 28 March 2021 | 10.1 | 21.35 | 44.72 | |||

| 7 April 2021 | 11.81 | |||||

| 14 April 2021 | 13.52 | 24.93 | ||||

| 21 April 2021 | 10.71 | |||||

| 28 April 2021 | 12.50 | 22.98 | 47.51 | 89.12 | ||

| 7 May 2021 | 13.65 | |||||

| 14 May 2021 | 11.22 | 24.47 | ||||

| 21 May 2021 | 13.91 | |||||

| 28 May 2021 | 13.72 | 27.14 | 50.96 | |||

| 7 June 2021 | 17.78 | |||||

| 14 June 2021 | 11.34 | 28.3 | ||||

| 21 June 2021 | 11.95 | |||||

| 28 June 2021 | 12.26 | 23.51 | 51.56 | 99.26 | 243.27 | |

| 7 July 2021 | 17.89 | |||||

| 14 July 2021 | 12.34 | 29.30 | ||||

| 21 July 2021 | 12.63 | |||||

| 28 July 2021 | 12.32 | 24.17 | 53.23 | |||

| 7 August 2021 | 19.51 | |||||

| 14 August 2021 | 12.01 | 30.54 | ||||

| 21 August 2021 | 11.71 | |||||

| 28 August 2021 | 11.22 | 22.16 | 52.45 | 102.03 | ||

| 7 September 2021 | 18.12 | |||||

| 14 September 2021 | 11.10 | 28.38 | ||||

| 21 September 2021 | 10.92 | |||||

| 28 September 2021 | 10.28 | 20.51 | 48.70 | |||

| 7 October 2021 | 14.62 | |||||

| 14 October 2021 | 10.33 | 24.63 | ||||

| 21 October 2021 | 10.45 | |||||

| 28 October 2021 | 10.01 | 20.29 | 44.80 | 91.29 | ||

| 7 November 2021 | 12.60 | |||||

| 14 November 2021 | 8.56 | 20.97 | ||||

| 21 November 2021 | 8.62 | |||||

| 28 November 2021 | 8.37 | 16.83 | 37.73 | |||

| 7 December 2021 | 8.82 | |||||

| 14 December 2021 | 8.64 | 17.38 | ||||

| 21 December 2021 | 8.83 | |||||

| 28 December 2021 | 8.13 | 16.86 | 34.15 | 71.36 | 252.37 | 473.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdallah, R.; Juaidi, A.; Abdel-Fattah, S.; Qadi, M.; Shadid, M.; Albatayneh, A.; Çamur, H.; García-Cruz, A.; Manzano-Agugliaro, F. The Effects of Soiling and Frequency of Optimal Cleaning of PV Panels in Palestine. Energies 2022, 15, 4232. https://doi.org/10.3390/en15124232

Abdallah R, Juaidi A, Abdel-Fattah S, Qadi M, Shadid M, Albatayneh A, Çamur H, García-Cruz A, Manzano-Agugliaro F. The Effects of Soiling and Frequency of Optimal Cleaning of PV Panels in Palestine. Energies. 2022; 15(12):4232. https://doi.org/10.3390/en15124232

Chicago/Turabian StyleAbdallah, Ramez, Adel Juaidi, Salameh Abdel-Fattah, Mahmoud Qadi, Montaser Shadid, Aiman Albatayneh, Hüseyin Çamur, Amos García-Cruz, and Francisco Manzano-Agugliaro. 2022. "The Effects of Soiling and Frequency of Optimal Cleaning of PV Panels in Palestine" Energies 15, no. 12: 4232. https://doi.org/10.3390/en15124232