1. Introduction

Since 2003, long-term experience with the operation of wells using progressive cavity pumping units (PCPUs) driven by a rotating rod string has shown that screw pumps are one of the most effective means for artificial lifting of heavy oils under conditions of low reservoir productivity rates and high gas content at high saturation pressure [

1,

2,

3,

4,

5,

6,

7]. The author of [

1] provides a study in which a simplified flow model of a PCP is used to control the PCP system and to undertake quick calculations of flow rates. The study presented in [

2] focuses on evaluating the effects of the different variables (such as the fraction of gas voids, frequency of rotation, and pressure drop) on the performance of a PCP with two-phase flow. One of the first models used to simulate and analyze PCP performance was that proposed by Belcher in [

3]: it was named the “infinite parallel plate” and simulated the slip effect as that of a convergent–divergent bearing. Models are being developed that combine an analytical model to predict the theoretical performance of a pump with a slippage model [

4]. Other studies [

5,

6,

7,

8,

9,

10] have focused on studying the effect of the rotor movement on the sealings of stators for various speeds and pressures and on the improvement of pump design.

The simplicity of the PCP design is associated with the absence of valves and complex junctions, thereby significantly reducing hydraulic losses. With a higher viscosity value, fewer crossflows occur through the sealing lines of the elastomer–rotor couple; therefore, the viscosity does not have a significant impact on the screw pump’s delivery rate.

The opposite situation is observed with the other methods of operation (sucker-rod pump, electric submergible pump (ESP), diaphragm pump, etc.). The average delivery rate of the sucker-rod pumping unit is 0.35 at a viscosity of 300 mPa·s, whereas for the PCP unit this indicator equals 0.9 ÷ 0.95. The simplicity of operation makes it possible to reduce operating costs and, thus, the cost of oil production.

It is essential to consider downhole conditions for the efficient operation of downhole equipment. Optimization of PCP wear can be achieved through the geometry of the pump, proper selection of stator elastomers and wear-resistant rotor coatings, and correct selection of the pump size for a specific application [

11,

12,

13,

14,

15,

16,

17].

Despite the significant amount of research on the development and optimization of PCP design for well conditions, the operation of wells with PCP is associated with a shortage of effective technical means to prevent or significantly reduce complications in the operation of sucker-rod pumps, particularly in wells with high dogleg severity, which leads to reductions in equipment operating times and in the efficiency of well fluid extraction [

18,

19].

This is why the development of new technical means for PCP-operated wells is an urgent task and the focus of the present study.

The novelty of this research is the new method developed for modeling the motion of a sucker-rod string during the operation of curved and directional wells. The mathematical model of rod motion elaborated, involving a reduced disc in the curved section of the well, makes it possible to detect hazardous resonance phenomenon. When operating crooked wells, the sucker-rod string takes the shape of a helix or a sine wave of varying pitch. For wells with a number of severe dogleg sections, the frequencies of the forced and natural oscillations of the sucker-rod string may coincide, leading to the increased amplitude of the oscillations and vibration of the sucker-rod string. We developed a new centralizer with the friction of mating surfaces in order to increase the mean time between failures (MTBF) in PCPs.

2. Analysis of the Operation of Progressive Cavity Pumping Units

The major problems in wells operated by PCP units are the breakage of sucker rods and the abrasion of the pump’s helical pair [

20,

21]. For instance, 175 cases of sucker-rod breakage were observed during the operation of PCP units at five producing companies of Sheshmaoil Management Limited Liability Company (Republic of Tatarstan). The rotation of a sucker-rod string creates tensions, which must be calculated by approximation since a sucker-rod string is not a rod (shaft) with a constant section due to the presence of couplings and joints; friction forces and other factors have to be considered. The rotation of the sucker-rod string is influenced by:

- (a)

axial tension force due to the self-weight of the rods;

- (b)

fluid pressure;

- (c)

bending loads in a curved wellbore;

- (d)

tangential stresses.

Tangential and tensile stresses reach their maximum values in the upper part of the sucker-rod string. For example, in joint stock company (JSC) Kondurchaneft, rod partings occur in the upper fifth of the sucker-rod string, in JSC Sheshmaoil, at one third, and in JSC Ideloil, rods usually break in the second fifth of the string. It appears that the longer the string of the sucker rods, the closer to the wellhead the rod breakages occur. The greater the curvature build-up (referred to as the “elbow”), the greater the collision between the rods and the tubing; therefore, it is recommended that centralizers, preferably also functioning as bearings, be installed at these points. The arrangement of the centralizers is based on the placement of their bearings at the points on the rods with maximum radial loads [

22]. High dogleg severity means that the curvature gain or decline in a wellbore equals 2 deg/10 m and higher. Such a section of a wellbore is called an “elbow”.

Table 1 shows that high severity is observed in all companies and significantly contributes to the breakage of rods, and the breakage incidence increases as the rods approach the “elbow”. If we consider a distance of ±50 m between the depth of the rod breakage and the nearest location of 2 deg/10 m severity, then we can see that:

- (a)

42% of rods breakages within the “elbow” took place at JSC Kondurchaneft;

- (b)

45% took place at JSC Sheshmaoil;

- (c)

76% took place at JSC Ideloil.

The most complicated situation related to the frequency of rod breakages caused by high dogleg severity. There were accounts for JSC Ideloil in which both artificial and unintentional (natural) curvature developed while drilling wells, the latter occurring frequently. It is worth mentioning that, rather than horizontal wells, PCPs mostly operate in directional wells with deliberately artificial deviations. In wells with high dogleg severity, no rod breaks along the couplings have been recorded; mainly, the rods break along the body and, less often, along the wrench square and threads [

20,

22].

Figure 1 shows that the frequencies of repairs due to rod failures at the facilities of LLC Sheshmaoil Management Company have changed constantly; for example, the number of rod failures was minimal in 2008 and 2010. The average percentage of specific dependence (SD) of rod breakage on the number of PCP repairs is 20%.

Table 2 provides information on workovers of wells with PCPs, the number of wells with PCPs, as well as the specific dependencies of:

- (a)

PCP repairs on the number of wells with PCPs;

- (b)

PCP repairs excluding other types of repairs and well interventions (WIs) on the number of wells with PCPs;

- (c)

rod breakages on the number of wells with PCP.

Table 2 shows that the specific dependence of PCP unit repairs on the number of PCP-operated wells is decreasing: while the specific dependence was equal to 0.9 when PCPs were first implemented, it has been about 0.5 in recent years, indicating one repair per two PCP-operated wells per year. If we exclude other types of repairs, which have no effect on the MTBF, the specific dependence drops, particularly in the years 2004, 2009, 2014, 2017, and 2019. Other types of repairs include well interventions (hydraulic fracturing, bottom-hole zone treatment, re-perforations, etc.), replacing the surface drive and the electric motor, troubleshooting the well-head fittings, readjusting the rotor without needing to lift the downhole pumping equipment, and flushing the well.

The highest SD values were recorded in 2005, 2012, and 2013. SD displays a positive trend, in accordance with the growing application of PCPs.

Table 3 indicates that the majority of rod failures occur across the bodies.

Table 4 presents the distribution of rotating string failures at the facilities of LLC MC Sheshmaoil by pump type and size, and it indicates that the failure rate is higher for screw pumps of larger sizes, as well as for ShVN-7 pumps. The digit in the name of the ShVN pump refers to the pump’s capacity in m

3/day at a rotor speed of 100 rpm.

To represent the dangerous phenomenon of resonance that can occur during the rotation of rods, a mathematical model of rod motion using a reduced disc in the curved section of a well was here developed for the first time ever, and data from the implementation of this model in an actual wellsite are shown. The presence of the reduced disc as part of the sucker-rod string reduces the angular frequency of the sucker-rod rotation, as well as helping to determine the source of the resonant oscillations. Without a reduced disc, the sucker-rod string has a maximum rotational frequency that is lower than the forced oscillation frequency of the sucker-rod string. As the length of sucker rods is much greater than the length of machine shafts, the time required for dangerous resonance to fade away, for example, will be much greater. Hence, the sucker rods remain in this position for quite a long period and are subjected to impacts from the tubing.

3. Materials and Methods

The aspiration to increase PCPs’ operating times in deviated wells is understandable both from the economic and technical perspectives [

22,

23].

To do this, it is necessary to advance beyond the existing technical solutions and the experience of specialists by:

The solution to the first problem involves the application of a reduced disc with eccentricity to the sucker-rod string, thereby making it possible to create a model of sucker-rod rotation with deviation from the axis that corresponds to the motion of sucker rods in a borehole. When the rod string rotates with an angular velocity, the reduced disc’s center of gravity creates a circular motion that generates centrifugal force. The reduced disc on the rod is located in the crooked section. The reduced disc allows for the deviation of the sucker rods from the vertical axis of a wellbore. Determining the moment of inertia of the reduced disc’s mass makes it possible to determine the sucker-rod string’s stiffness, the circular rotation frequency, and the number of sucker-rod revolutions under resonance. The number of reduced discs on the sucker-rod string depends on the curvature pattern. The main method used in the current study was to determine the frequency of natural torsional oscillations of the rods, and in this paper, a model with two arms (elbows) is considered. Modeling the proposed sucker-rods with reduced discs the formulas, developed here for the first time, makes it possible to determine the resonant oscillations that occur when sucker-rod strings start and stop their rotations. Using curvature data from wells, this model makes it possible to determine the angular frequencies and numbers of revolutions of sucker rods during resonant oscillations by increasing the mass and overall dimensions of the reduced disc.

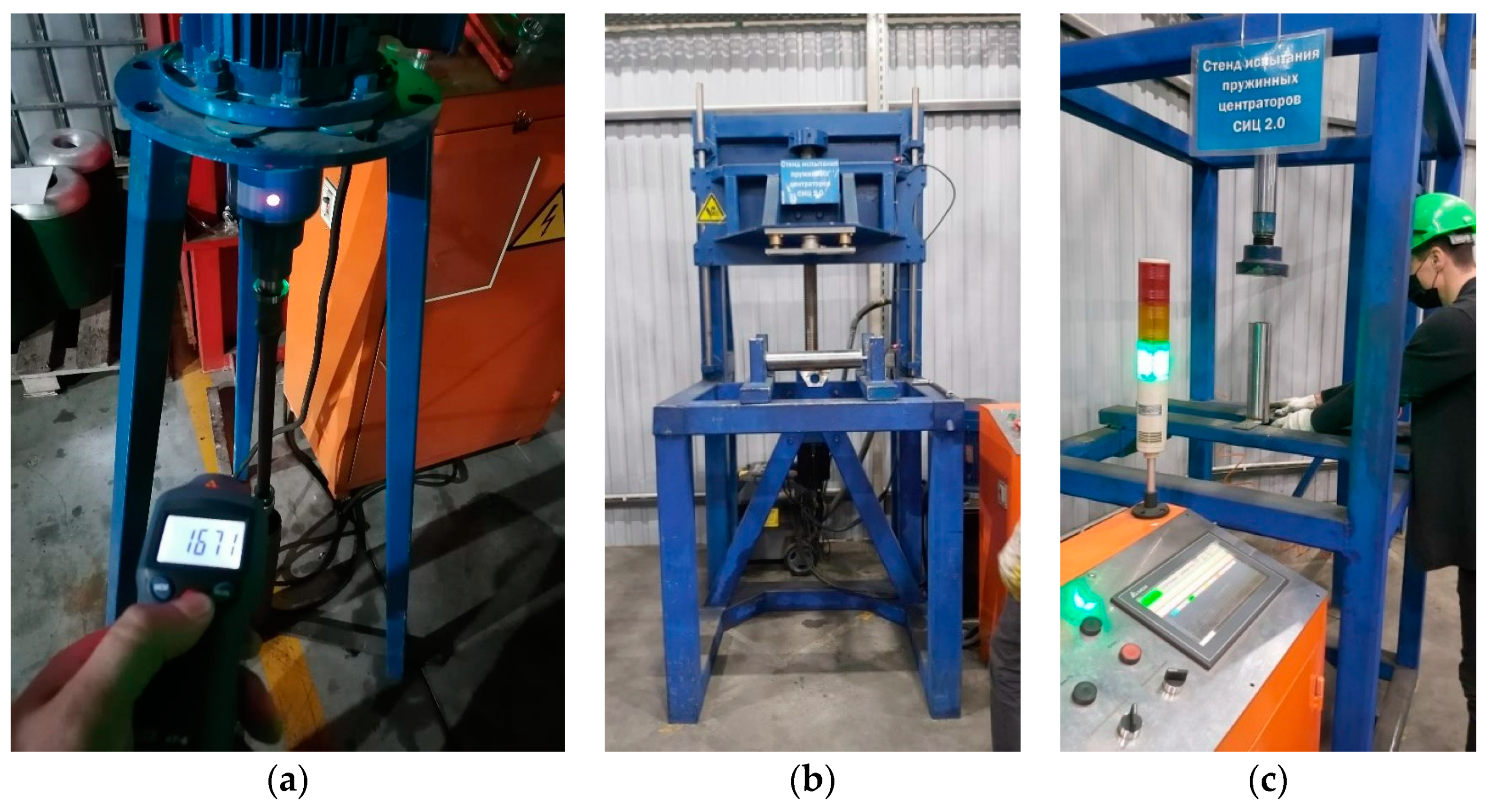

The solution to the second problem involves the development, manufacture, and testing of centralizers that additionally function as bearings. Due to the limited overall dimensions, plain bearings were considered, and the drilling centralizers’’ bowsprings were used as centralizing bars, reliably fixed to the detachable half-shells. The centralizers were tested at the following test benches:

- (a)

a vertical test bench with an electric motor and a frequency converter;

- (b)

a horizontal test bench for bow spring centralizers (SITs-2) with a pipe simulator;

- (c)

a vertical test bench for spring centralizers (SITs-2).

A detailed description of the calculation of the rods’ rotational motion is provided in [

24,

25]. The authors of the present study recently [

26] presented a design model for rod strings with one arm that makes it possible to determine the frequency of the natural torsional oscillations of rods. It was revealed that the presence of a reduced disc leads to a decrease in the circular rotation frequency of the sucker rods and the number of their revolutions. In practice, wells often have multiple “elbows” (shoulders) [

27], so it is necessary to consider the design scheme and the mathematical model of the torsional oscillations of sucker rods in two curved sections of a well (

Figure 2 and

Figure 3). The distance from the wellhead A to the reduced disc D

1 corresponds to a

1, the distance from D

1 to the point of the nodal joint M corresponds to a

2, the distance from M to the reduced disc D

2 is b

2, the distance from D

2 to the sucker-rod screw pump B equals b

1, and

l represents the distance between the reduced disc D

1 and the reduced disc D

2. All distances are measured in meters.

The circular frequency of the shaft within the sections AM and MB is determined by a formula similar to that for the single-arm layout:

- -

where is the mass reduction factor ( = 1/3), JD is the moment of inertia of the reduced disc, and is the moment of inertia of the rods.

The moments of inertia of the rods are determined by the following formulas:

- -

for the MB section:

where is the density of the sucker-rod steel (kg/m3).

The rod string stiffness is calculated as follows:

where is the shear modulus (MPa).

is the polar moment of inertia of a rod with a diameter

:

- -

for the MB section:

By equating

and

, we obtain:

Considering that

, Formula (8) can be given the following form:

where

The circular oscillation frequency is defined as follows:

where

is derived from (10).

4. Results

4.1. Calculation Results fo a Sucker-Rod-String Model for a Specific Well

We next consider the application of the above formulas in a proper case using the data obtained from well no. 3633 managed by JSC Ideloil, which operates the Bashkirian stage of the Dachnoye field. Twelve cases of rod body breakage occurred within two years of PCP operation in well no. 3633. The average rod breakage depth was 287 m, and 11 cases of rod breakage occurred within an average distance of 8 m from the area of maximum dogleg severity of 2 deg/10 m; i.e., this well illustrates the effect of dogleg severity on the rod breakage rate. The maximum dogleg severity at well no. 3633 was 2.39 deg/10 m at the depth of 250 m, and the average severity at the points of rod breakage was 1.85 deg/10 m (

Figure 4).

We proposed to compensate for the effect of curved sections on the torsional oscillations of sucker rods by replacing these sections with sufficiently long rectilinear rods with virtual (reduced) discs placed on them at the centers of the sections. For this model to lead to realistic results, the most difficult challenge was to determine the initial characteristics of the discs, such as their mass and moment of inertia. To solve this problem, the radius of the curvature in the curved sections was defined as the radius of a circular arc in the form of the conjunction with two branches of straight lines, allowing for a smooth transition from one branch to the other. The distance between the points of tangency correlated with the length of the rods in the first approximation; based on this length, the mass of the reduced disc was determined. Then, by varying the radius of the circular arc, the effect of the obtained characteristics on the results of the vibration process was analyzed. In contrast to the cases of torsional vibration in rather short machinery shafts, the mass of which can be neglected in comparison with the mass of the discs, we had to consider the distributed mass, which had a substantial value, when a sucker-rod string vibrates. To achieve this, the mass of the rod string was replaced with a concentrated mass, which was relocated to the suspension points of the discs. In this case, it was accepted that the value of such a mass is proportional to the value of the true mass.

The coefficient of proportionality used to determine the value of a true mass is called the mass reduction factor.

When discs D1 and D2 rotate in opposite directions to each other, there will be some segment with the center at point M whose angle of rotation from the condition of equilibrium is equal to zero. Then, the sections AM and MB of the rod will have the same frequencies of natural vibrations, and each of these sections can be regarded as a single-arm system. The cross-section of the rod with the point M in its center is called a nodal or dead point. Thus, the solution to the problem of determining the natural oscillation frequencies of a system with two curved sections comes down to determining the position of the point M.

When there is an “elbow” in the rod string, the frequencies of natural oscillations in comparison with a straight string are lower; i.e., the resonant frequency of the system is reduced significantly, depending on the geometric shape and size of the curved section. When comparing the frequency of free torsional vibrations with the resonant frequency, deceleration due to the contact between the rods and the tubing occurs at the points of curvature. The sucker rod is exposed to shock by the tubing, and this can happen both when the ground drive is started and when it is stopped because there can be no immediate rotation gain in or instantaneous stopping of the sucker-rod string.

When an “elbow” emerges, the rod string resonates; after passing the “elbow” zone, the resonance torque disappears. In these places (“elbows”), slowdown occurs. As the rods pass the resonance point, they are exposed to shock action by the tubing, and this can occur both when the surface drive is started and when it is stopped. Once in a complex stressed state, the rod can break after such shocks because the rod is not designed to twist (combined with its vibration) in such a way; i.e., the rod is designed without regard for these type of shocks. If the rod is positioned vertically and upright, the resonance will be higher than the actual RPM.

The number of revolutions of a rod with reduced discs is not the actual number of the rod’s revolutions, but the “resonance” number or the frequency of natural torsional oscillations. Should two reduced discs be placed in any section of an ordinary shaft, twisted in opposite directions, and released, the shaft will oscillate with the frequency referred to as the frequency of natural torsional oscillations of the shaft. To distinguish between the rotational frequency of the sucker-rod string and the rotational frequency of the string based on the proposed mathematical model with reduced discs, the latter frequency is referred to as the “resonant” rotational frequency.

Mathematical model calculations based on data obtained from well no. 3633 indicated the following:

- -

the main design parameters required for the functioning of the mathematical model increase as the sucker rod diameter increases (

Table 5);

- -

when the rods rotate under the proposed model, the rod enters the resonance zone when its natural oscillation frequency reaches 4.41 (or 5.91 or 7.63) rpm, depending on the rod’s diameter;

- -

if the point M approaches the point B—for example, by 200 m—the “resonant” frequency of the model’s rotation decreases by 30% and, vice versa, as the point M moves towards the point A, the “resonant” frequency of the model’s rotation increases;

- -

if the point M moves toward the point A by 100 m, the “resonant” frequency of rotation increases by 30%; moving the point M further by 80 m increases the “resonant” frequency of rotation by more than three times, and in this case, the rigidity of the mathematical model is multiplied by many times;

- -

increasing the mass of the reduced disc results in a decrease in the “resonant” frequency of rotation (

Figure 5).

Table 5.

Estimated data for well no. 3633 operated by Ideloil JSC.

Table 5.

Estimated data for well no. 3633 operated by Ideloil JSC.

| Sucker Rod Diameter [mm] | Circular Speed

2πω [s−1] | Rigidity of the

Mathematical Model with Reduced Discs | “Resonant” Rotation Frequency [rpm] |

|---|

| 19 | 0.46 | 0.51 | 4.41 |

| 22 | 0.62 | 0.92 | 5.91 |

| 25 | 0.8 | 1.53 | 7.63 |

4.2. Application of Centralizers as Part of a Sucker-Rod String

To reduce the adverse effects of dogleg severity and the existence of “elbows” in PCP-operated wells, centralizers should be used to keep a sucker-rod string in the center of the tubing while rotating [

28]. Application of centralizers helps reduce the number of well workovers caused by rod breakages and abrasion of tubing and rods. The Innovation and Examination Department of Sheshmaoil MC LLC has designed centralizers for sucker rods (TsNShP) that involve sliding bearings with centering ribs (bars) similar to those of a drilling centralizer (

Figure 6).

The lower (2) and upper (3) detachable restrainers of the centralizer movement are installed on the body of the sucker rod (1); these restrainers are comprised of detachable half-bushings and are bolted to each other by fasteners. It is recommended to install the centralizer and the restrainers on a short rod with a length of 0.5 … 1.5 m. A centralizer consisting of the lower (4) and upper (5) detachable half-shells pulled together through mounting holes by fasteners is placed between the restrainers on the sucker rod. A minimum of three centering ribs (6) (d = 73.2 mm) made in the shape of elastic arc-shaped slats of a specified cross-section are installed in the half-shells. The end sections of the centering ribs (6) are bent to fit into the slots of the lower detachable half-shells. The lower detachable half-shells are plain bearings. Application of centering ribs ensures the concentric placement of the sucker rods in the tubing and prevents the sucker rods from touching the tubing walls. The outer diameter of the centering ribs in a free state is greater than the inner diameter of the tubing.

The centralizer’s operation principle is as follows. Prior to installation in the well, the lower (2) and upper (3) detachable restrainers are installed on the sucker rods (1), and then a centering device is positioned between them. The centralizer can also be installed on a short rod at the factory; in this case, the centralizer will be delivered as a set. The centering ribs become deformed as they move through different tubing diameters, depending on the tubing wall thickness; shrinking and expanding, they travel further together with the sucker rods. The elastic force of the centering ribs (6) keeps the sucker rods (1) in the center of the tubing. The centering ribs regain their initial form once the centering device is recovered to the surface.

According to the approved test program and procedure for verifying TsNSh-22-73 centralizers, they were successfully tested on test benches at Sheshmaoil MC LLC, Tatprom Holding LLC, and Naberezhnye Chelny Pipe Plant LLC (N.Chelny) (

Figure 7). It is planned to deploy 14 TsShNP centralizers in the first quarter of 2022 in two wells. The annual savings in costs for JSC Sheshmaoil as a result of the implementation of centralizers will amount to 494,691 rubles, excluding value-added tax (VAT).

The restoring force directed perpendicularly towards the longitudinal axis of the centralizer was determined on a horizontal test bench. The load was applied in the pipe simulator to determine the bending deflection until the minimum restoring force value was obtained. In this way, centralizer slats were tested in different positions (

Table 6).

Thanks to this type of centralizer, it is possible to operate horizontal and strongly deviated wells, thus increasing productivity and making it possible to gain access to hard-to-reach pay zones.

5. Discussion

This is the first time that calculations have been undertaken for a well with two curved sections using reduced discs as deflectors of sucker rods from the vertical axis; the axes of the discs do not align with the axis of the wellbore. With the design model of sucker-rod strings developed, the stiffness of the sucker-rod string increases as the diameter of the sucker rod increases, and the angular rotation speed of the sucker-rod strings also increases. The resonant RPM increases in proportion to the growth of the angular frequency. The curvature pattern of the sucker rods in the well is influenced by the weight and size of the reduced disc. Using centralizers as part of a sucker-rod string can help minimize dangerous resonant oscillations and increase PCPs’ service lives.

6. Conclusions

High dogleg severity significantly contributes to rod breakage; rods often break close to the “elbows” with a dogleg severity of 2 deg/10 m or higher.

The design layout and mathematical model for the torsional oscillations of sucker rods with two reduced discs at two curved sections of a well were here developed for the first time.

Increasing the number, size, and weight of the reduced discs and approximating the curved sections to the screw pump reduced the circular speed and rigidity of the sucker-rod string proposed by the mathematical model.

The TsShNP centralizer developed by the Innovation and Examination Department of Sheshmaoil LLC enhances the reliability of the sucker-rod string and ensures the required coaxiality of the sucker-rod string and the tubing is maintained.

Author Contributions

Conceptualization, A.A.I., M.M.O.A. and A.N.D.; Methodology, A.A.I. and M.M.O.A.; Software, A.A.I. and M.M.O.A.; Validation, A.A.I., A.N.D. and Y.A.G.; Format analysis, A.A.I.; Investigation, A.A.I., M.M.O.A. and A.N.D.; Resources, A.A.I. and K.S.N.; Data curation, A.A.I. and M.M.O.A.; Writing—original draft preparation, A.A.I. and M.M.O.A.; Writing—review and editing, A.A.I. and Y.A.G.; Visualization, A.A.I. and M.M.O.A.; Supervision, A.N.D.; Project administration, Y.A.G.; Funding acquisition, A.A.I., A.N.D. and Y.A.G. All authors have read and agreed to the published version of the manuscript.

Funding

This paper has been supported by the RUDN University Strategic Academic Leadership Program.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Nomenclature

| PCPU | | progressive cavity pumping units |

| PCP | | progressive cavity pump |

| ESP | | electric submersible pump |

| MTBF | | mean time between failures |

| MC LLC | | management company limited liability company |

| SD | | specific dependence |

| WI | | well interventions |

| ShVN | | PCP, sucker-rod screw pump |

| SITs-2 | | test bench for bow spring centralizers |

| TsShNP | | centralizer for sucker rods |

| RPM | | rotations per minute |

| VAT | | value-added tax |

| A | | the point of the wellhead |

| B | | the point of the sucker-rod screw pump |

| D1 and D2 | | discs 1 and 2, respectively |

| m | the distance from the wellhead A to the reduced disc D1 |

| m | the distance from D1 to the point of the nodal joint M |

| M | | the point of the nodal joint |

| m | the distance from M to the reduced disc D2 |

| m | the distance from D2 to the sucker-rod screw pump B |

| l | m | the distance from disc D1 to disc D2 |

| 2πs−1 | the circular frequencies for the AM section and the MB section, respectively |

| kg/m2 | the moments of inertia of the rods for the AM section and the MB section, respectively |

| kg/m2 | the moments of inertia of the reduced discs D1 and D2, respectively |

| | the rod string stiffness for the AM section and the MB section, respectively |

| MPa | the shear modulus |

| kg/m2 | the polar moment of inertia of a rod |

| | the mass reduction factor |

| kg/m3 | the density of the sucker-rod steel |

| mm | the diameter of a rod |

References

- Moineau, R. A New Capsulism. Ph.D. Thesis, The University of Paris, Paris, France, 1930. [Google Scholar]

- Martin, A.; Kenyery, F.; Tremante, A. Experimental Study of Two-Phase Pumping in Progressive Cavity Pumps. SPE 53967. In Proceedings of the Latin American and Caribbean Petroleum Engineering Conference, Caracas, Venezuela, 1–6 April 1999. [Google Scholar] [CrossRef]

- Belcher, I. An Investigation into the Operating Characteristics of the Progressive Cavity Pump. Ph.D. Thesis, The British Library, London, UK, 1991. [Google Scholar]

- Nguyen, T.; Tu, H.; Al-Safran, E.; Saasen, A. Simulation of single-phase liquid flow in progressing cavity pump. J. Pet. Sci. Eng. 2016, 147, 617–623. [Google Scholar] [CrossRef]

- Zheng, L.; Wu, X.; Han, G.; Li, H.; Zuo, Y.; Zhou, D. Analytical model for the flow in progressing cavity pump with the metallic stator and rotor in clearance fit. Math. Probl. Eng. 2018, 2018, 3696930. [Google Scholar] [CrossRef]

- Saveth, K.J.; Klein, S.T. The Progressing Cavity Pump: Principle and Capabilities. In Proceedings of the SPE Production Operations Symposium, Oklahoma City, OK, USA, 13 March 1989; pp. 429–434. [Google Scholar] [CrossRef]

- Samuel, R.; Saveth, K.J. Optimal design of Progressing Cavity Pumps (PCP). J. Energy Resour. Technol. 2006, 128, 275–279. [Google Scholar] [CrossRef]

- Pan, L.; Tan, J. Numerical investigation of contact stress between rotor and stator in a two-lead progressing cavity pump. J. Pet. Sci. Eng. 2015, 134, 176–185. [Google Scholar] [CrossRef]

- Gamboa, J.; Olivet, A.; Sorelys, E. New approach for modeling progressive cavity pumps performance. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 5 October 2003; pp. 1–9. [Google Scholar] [CrossRef]

- Gamboa, J.; Olivet, A.; Iglesias, J.; Gonzalez, P. Understanding the performance of a progressive cavity pump with metallic stator. In Proceedings of the Twentieth International Pump Users Symposium, Texas A&M University, College Station, TX, USA, 17 March 2003; pp. 19–31. [Google Scholar] [CrossRef]

- Delpassand, M.S. Progressing Cavity (PC) Pump Design Optimization for Abrasive Applications. SPE-37455-MS. In Proceedings of the SPE Production Operations Symposium, Oklahoma City, Oklahoma, 1–5 March 1997. [Google Scholar] [CrossRef]

- Müller, J.; Kouhi, Y.; Leonow, S.; Mönnigmann, M. Wear detection for progressing cavity pumps with system identification methods. IFAC-PapersOnLine 2020, 53, 13650–13655. [Google Scholar] [CrossRef]

- Ocanto, L.; Rojas, A. Progressing cavity pump pattern recognition in heavy and extra-heavy oil cold production. SPE 69701. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium, Porlamar, Margarita Island, Venezuela, 12 March 2001; pp. 1–5. [Google Scholar] [CrossRef]

- Ramos, M.A.; Brown, J.C.; Rojas, M.D.C.; Flores, J.G.; Kuyuco, O. Producing Extra Heavy Oil using Bottom Drive Progressive Cavity Pump from Orinoco Belt Cerro Negro Area, Venezuela. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium, Calgary, AB, Canada, 1 November 2005; pp. 1–6. [Google Scholar] [CrossRef]

- Taheri, A.; Hooshmandkoochi, A. Optimum Selection of Artificial Lift System for Iranian Heavy Oil Fields. In Proceedings of the SPE Western Regional/AAPG Pacific Section/GSA Cordilleran Section Joint Meeting, Anchorage, AK, USA, 8 May 2006; pp. 1–12. [Google Scholar] [CrossRef]

- He, L.; Gang, C.; Dingmin, W.; Guochen, S.; Jiexin, L. The Successful Application of 2000 PCP Wells in Daqing Oilfield. In Proceedings of the International Petroleum Technology Conference, Doha, Qatar, 21 November 2005; pp. 1–11. [Google Scholar] [CrossRef]

- Colodette, G.; Pereira, C.A.G.; Siqueira, C.A.M.; Spinelli Ribeiro, G.A.; Rodrigues, R.; Matos, J.S.; Ribeiro, M.P. Flow Assurance and Artificial Lift Innovations for Jubarte Heavy Oil in Brazil. SPE Proj. Facil. Constr. 2008, 3, 1–8. [Google Scholar] [CrossRef]

- Sathyamoorthy, S.; Steyn, A.; McGilvray, J.; Fuchs, H.; Ainebyona, B.; Kyomugisha, P.; Vijapurapu, S.; Kagga, N.; Rindfuss, R.; Basiima, D. First Application of Progressing Cavity Pumps for Appraisal Well Testing in the Ugandan Albertine Graben Basin. SPE Prod. Oper. 2013, 28, 85–94. [Google Scholar] [CrossRef]

- Petrov, A.; Mikhaylov, A.; Litvinenko, K.; Ramazanov, R. Artificial Lift Practice for Heavy Oil Production with Sand Control. In Proceedings of the SPE Russian Oil & Gas Technical Conference and Exhibition, Moscow, Russia, 26–28 October 2010; pp. 1–8. [Google Scholar] [CrossRef]

- Isaev, A.A.; Arkhipov, K.I. Analysis of operation of wells equipped with screw rod pump units with surface drives: Problems, solutions. Sci. Notes Almetyevsk State Pet. Inst. 2010, VIII, 77–84. [Google Scholar]

- Isaev, A.A.; Takhautdinov, R.; Arkhipov, K. Increase of Oil Recovery Factor of Hard-to-Recover Oil Formations. In Proceedings of the SPE Russian Oil and Gas Conference and Exhibition, Moscow, Russia, 26 October 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Isaev, A.A. Development of sucker-rod blades for screw pumping units during operation of complicated wells. In Dissertation of the Candidate of Technical Sciences; UGNTU Publisher: Ufa, Russia, 2016; p. 126. [Google Scholar]

- Wittrisch, C.; Cholet, H. Progressing Cavity Pumps, 2nd ed.; Editions Technip: Paris, France, 2013; p. 224. [Google Scholar]

- Isaev, A.A.; Aliev, M.M.; Takhautdinov, R.S.; Malykhin, V.I.; Sharifullin, A.A. The results implementation of a set of measures to enhance the production efficiency of high-viscosity oil. In Proceedings of the SPE Annual Caspian Technical Conference, Baku, Azerbaijan, 16 October 2019; pp. 1–28. [Google Scholar] [CrossRef]

- Isaev, A.A. The forces caused by the rotation of sucker rods. Oil Gas Novations 2019, 10, 83–87. [Google Scholar]

- Isaev, A.A.; Aliev, M.M.; Sharifullin, A.A. Calculation of loads on a rotating rod string in deviated oil wells. Oilfield Eng. 2020, 2, 61–65. [Google Scholar] [CrossRef]

- Isaev, A.A.; Takhautdinov, R.S.; Arkhipov, K.I. Ways to reduce loads on the sucker-rod string of a ground-driven screw sucker-rod pump installation. Oil Gas Bus. 2010, 6, 83–87. [Google Scholar]

- Isaev, A.A.; Takhautdinov, R.S.; Valiev, R.F. Pump Rod with Centering Element. Applicant and Patent Holder OOO NPO “Innovatsija”—No. 2013117775. Russian Patent for Invention No. 2523267, 17 April 2013. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).