Smart Predictive Maintenance Device for Critical In-Service Motors

Abstract

:1. Introduction

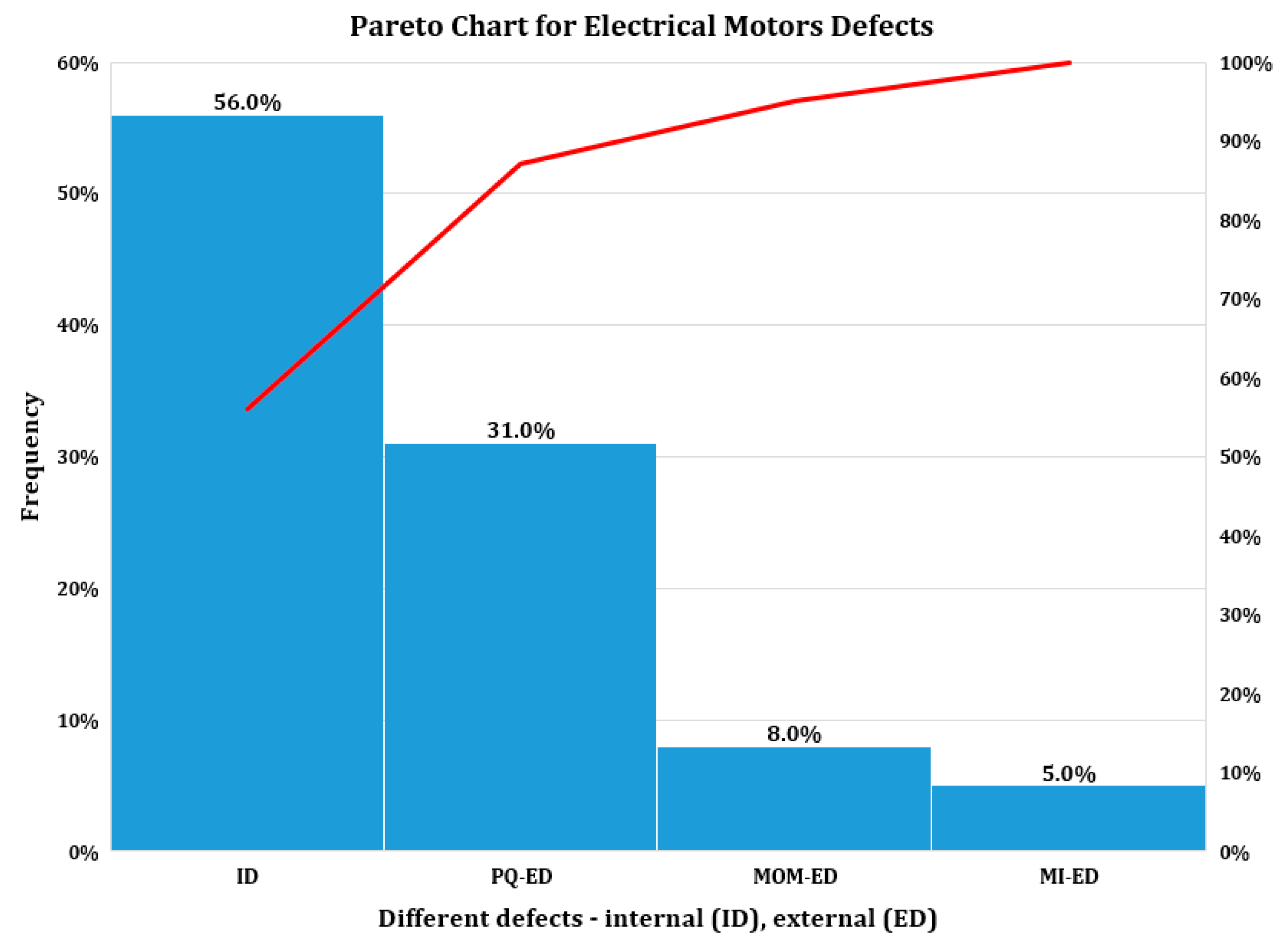

2. Motor Faults Causes and Consequences

- Internal defects (ID), which are mostly caused by short circuits between a phase and the metal casing, short circuits between phases or windings, overheating of the windings, breakage of a bar (for short-circuit rotor type motors), or problems related to tribology.

- External defects, which have as causes various factors exogenous to the motor, such as:

- ○

- Power quality issues of the motor supply energy source (PQ-ED): harmonics, imbalances, voltages swells, sags or interruptions, overvoltage, etc.

- ○

- Motor misoperation mode (MOM-ED): various overloads, dysfunctional transient states (improper starts and stops), and loads with large rotational inertia.

- ○

- Motor mechanical installations issue (MI-ED): improper installation in the electric drives system: misalignment between motor and load, mechanical imbalances, overload of the shaft, etc.

2.1. Motor Internal Faults

2.2. Motor External Faults

2.2.1. Supply Voltage Waveform Distortion

- Increased winding and magnetic core temperature, caused by additional losses in the conductive and magnetic materials (higher copper and iron losses).

- Variations of the motor torque values, which leads to a reduction in its efficiency.

- The appearance of oscillations of the motor torque at the shaft, which generates additional mechanical stresses on the electric drive system.

- Interactions between the magnetic flux determined by the fundamental harmonic and those generated by the higher-order harmonics.

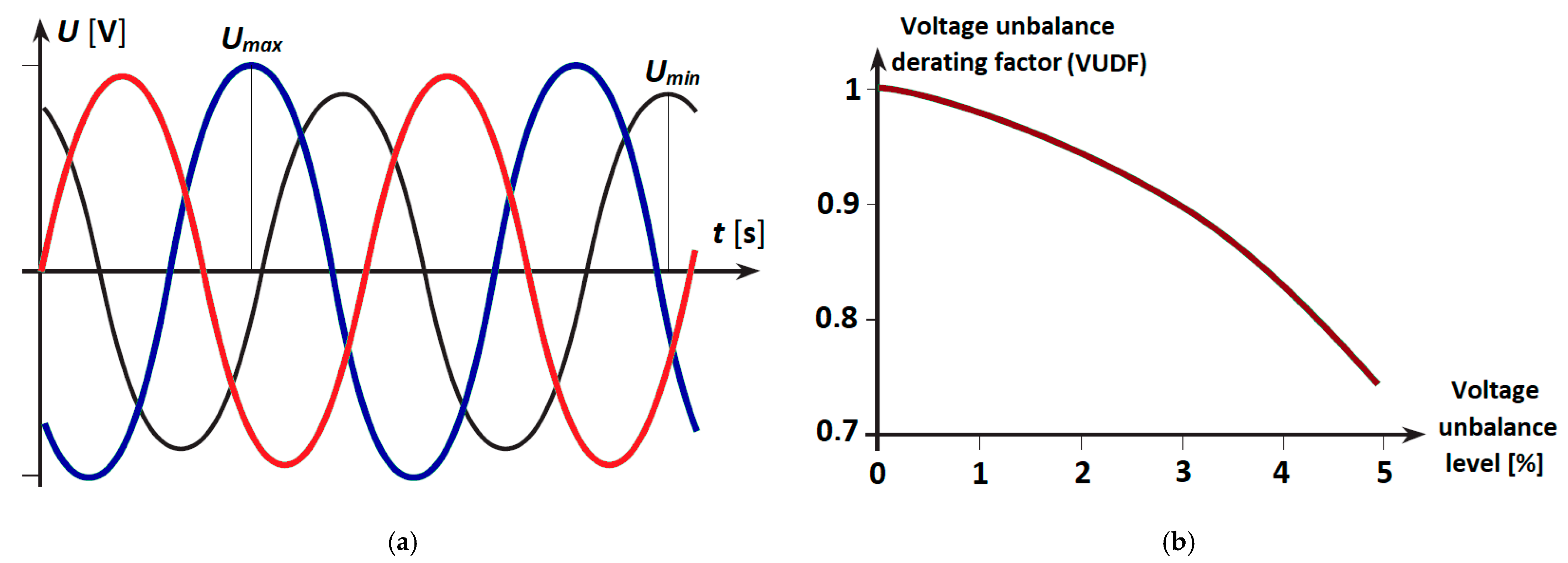

2.2.2. Supply Voltage Unbalance

2.2.3. Voltage Swells, Sags, and Interruptions

2.2.4. Motor Misoperation Modes and Motor Mechanical Installations Issues

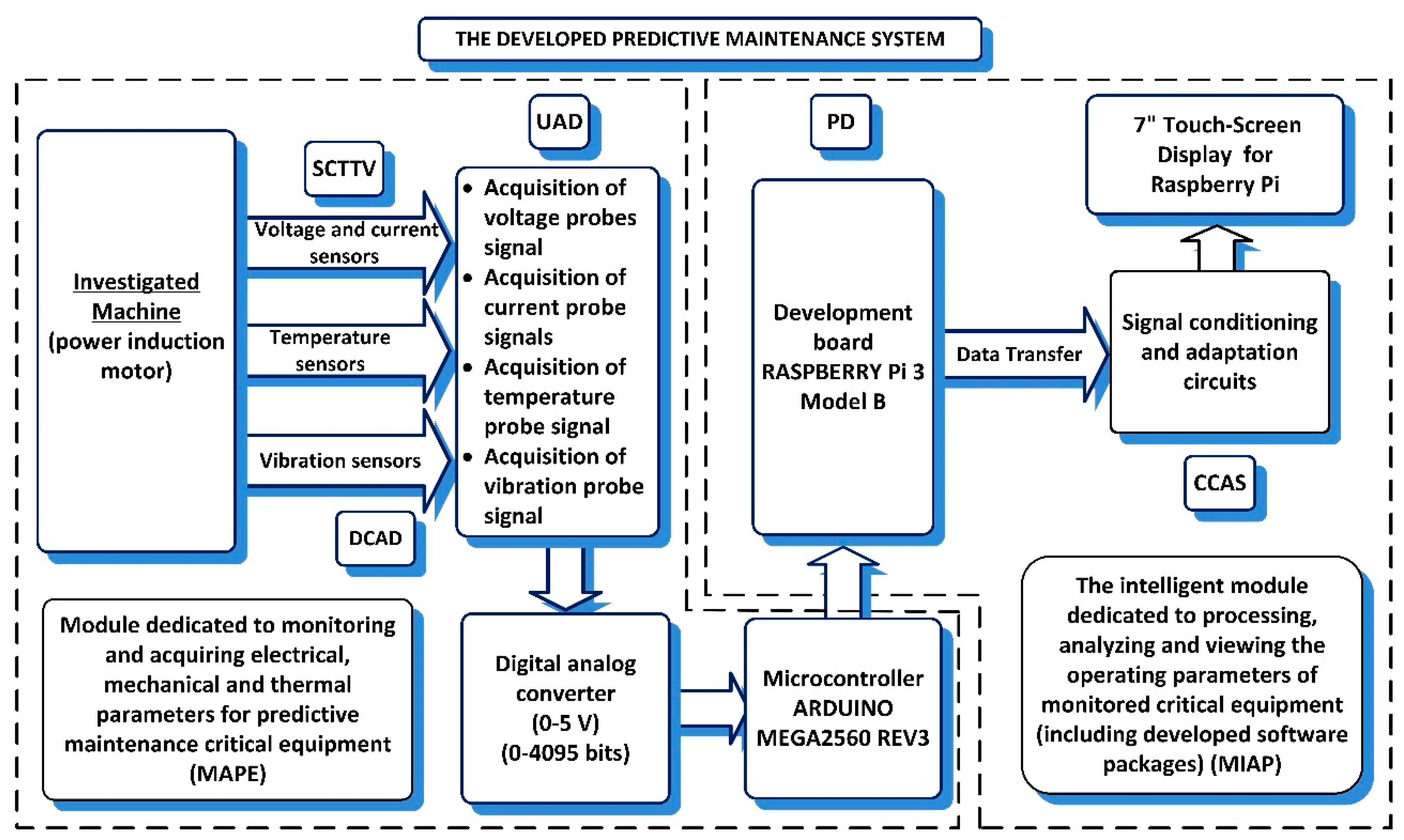

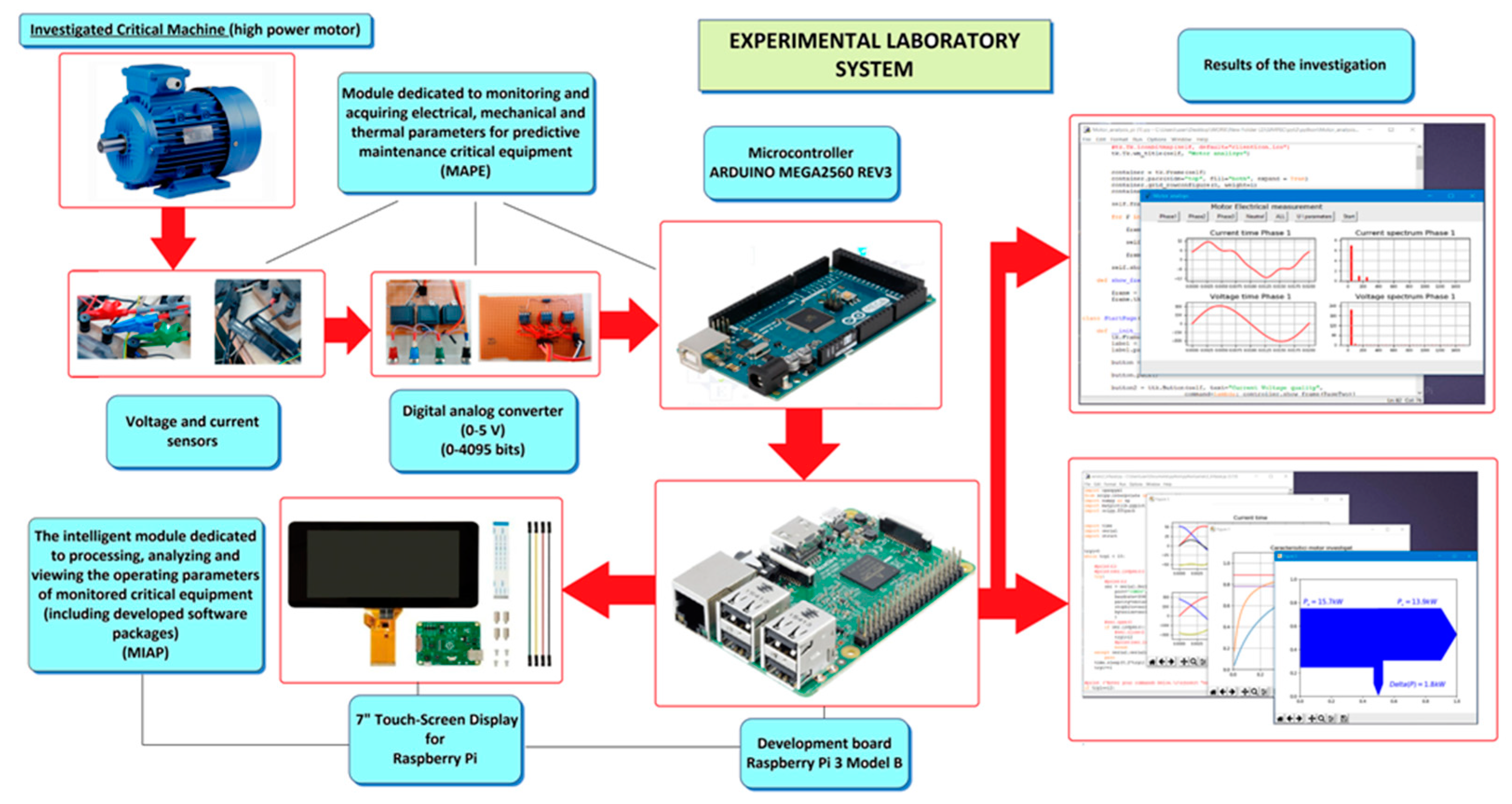

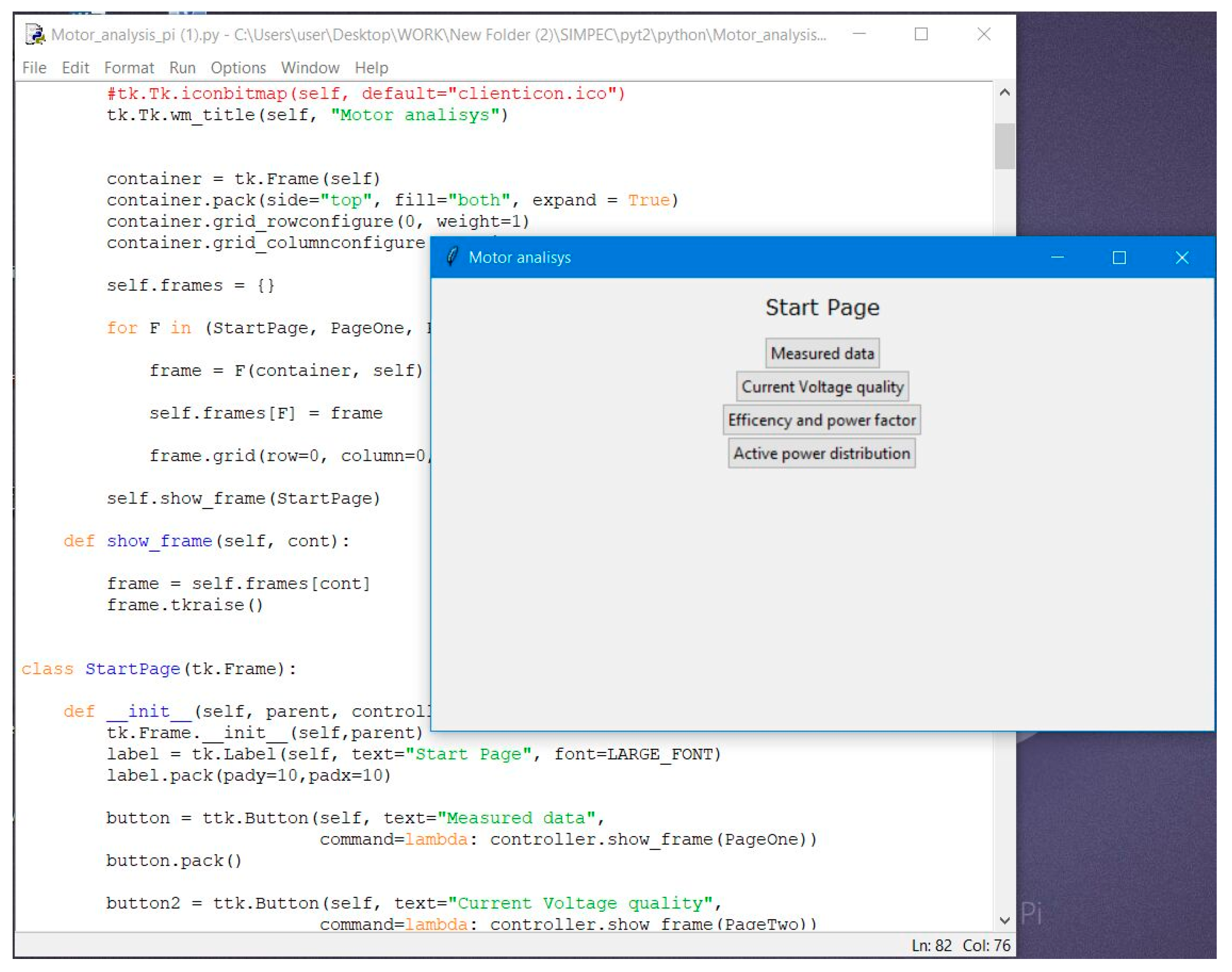

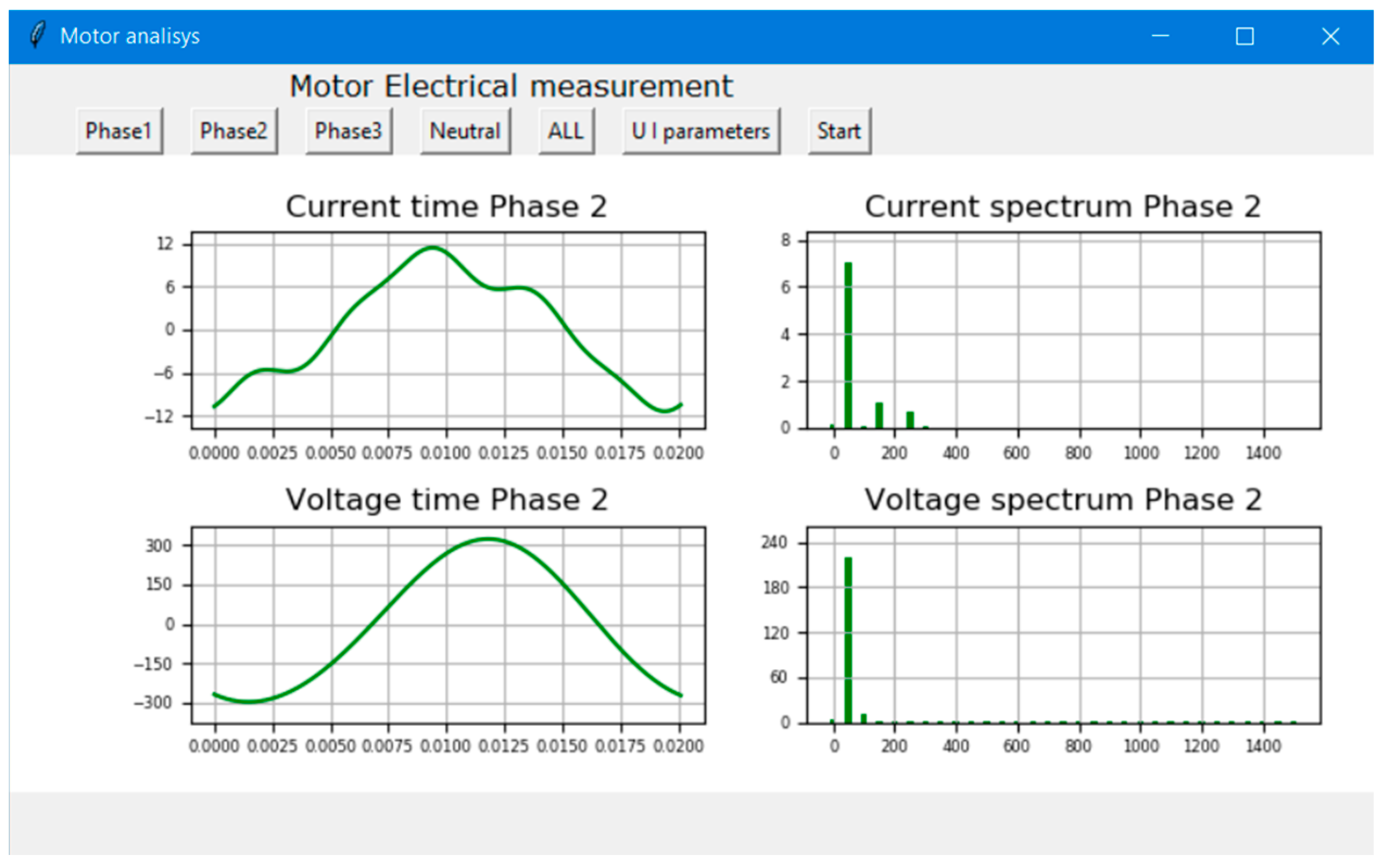

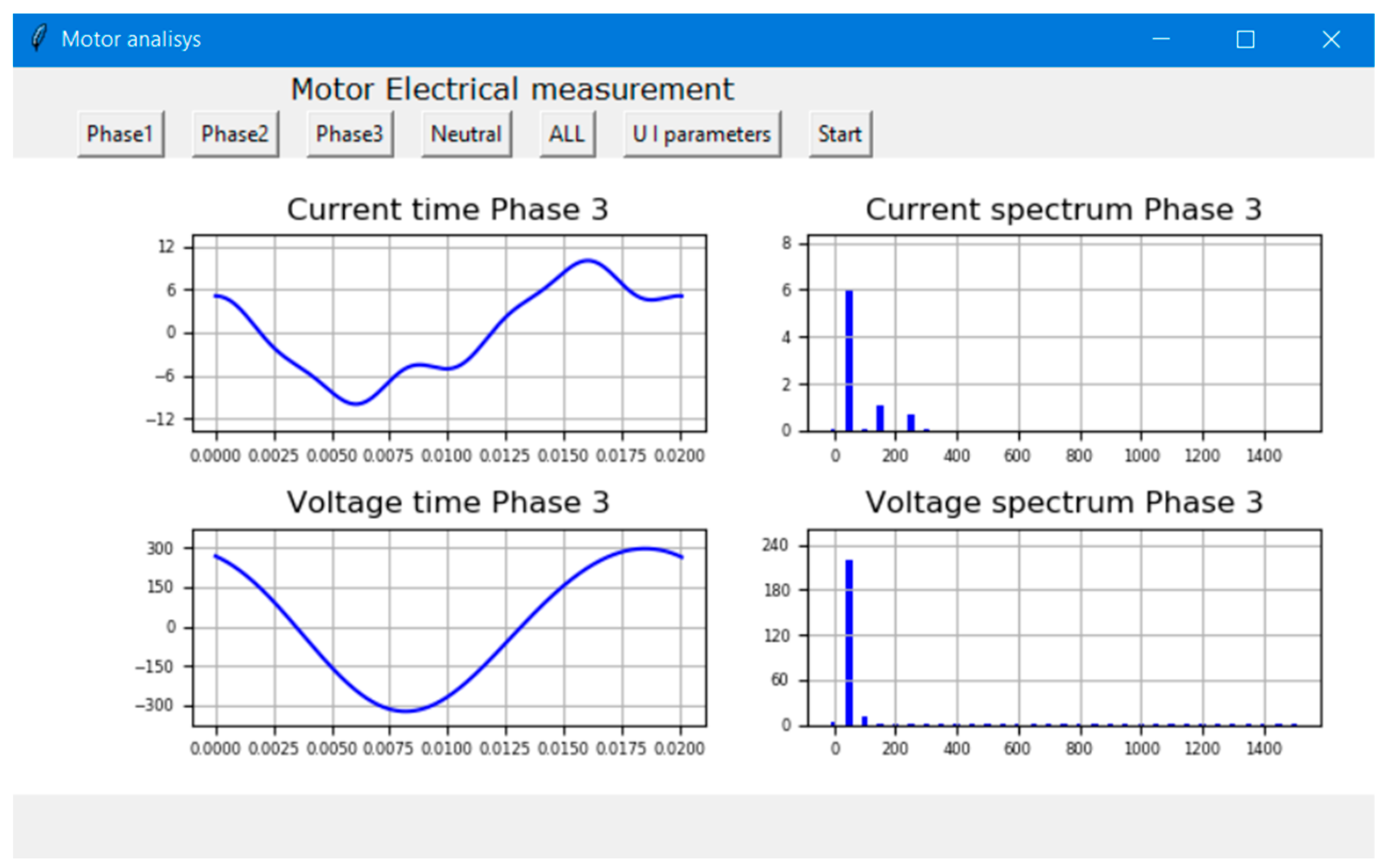

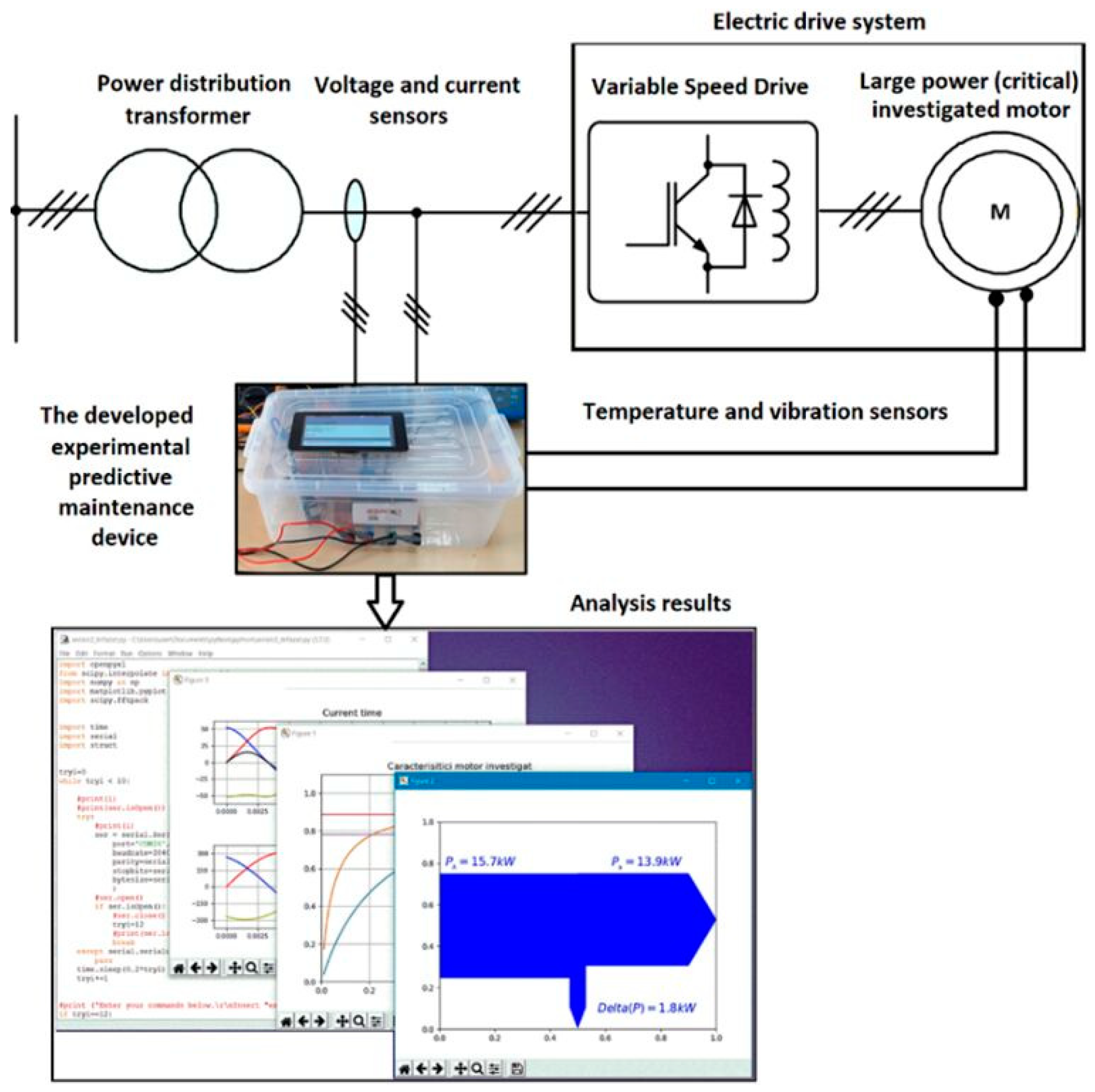

3. The Predictive Maintenance Device Design and Implementation

- Continuously monitor the essential operating parameters values (electrical, thermal, and mechanical) of the investigated critical electrical equipment (motor) and to signal their deviation from the rated ones. Additionally, these abnormal variations are to be stored in a journalized manner.

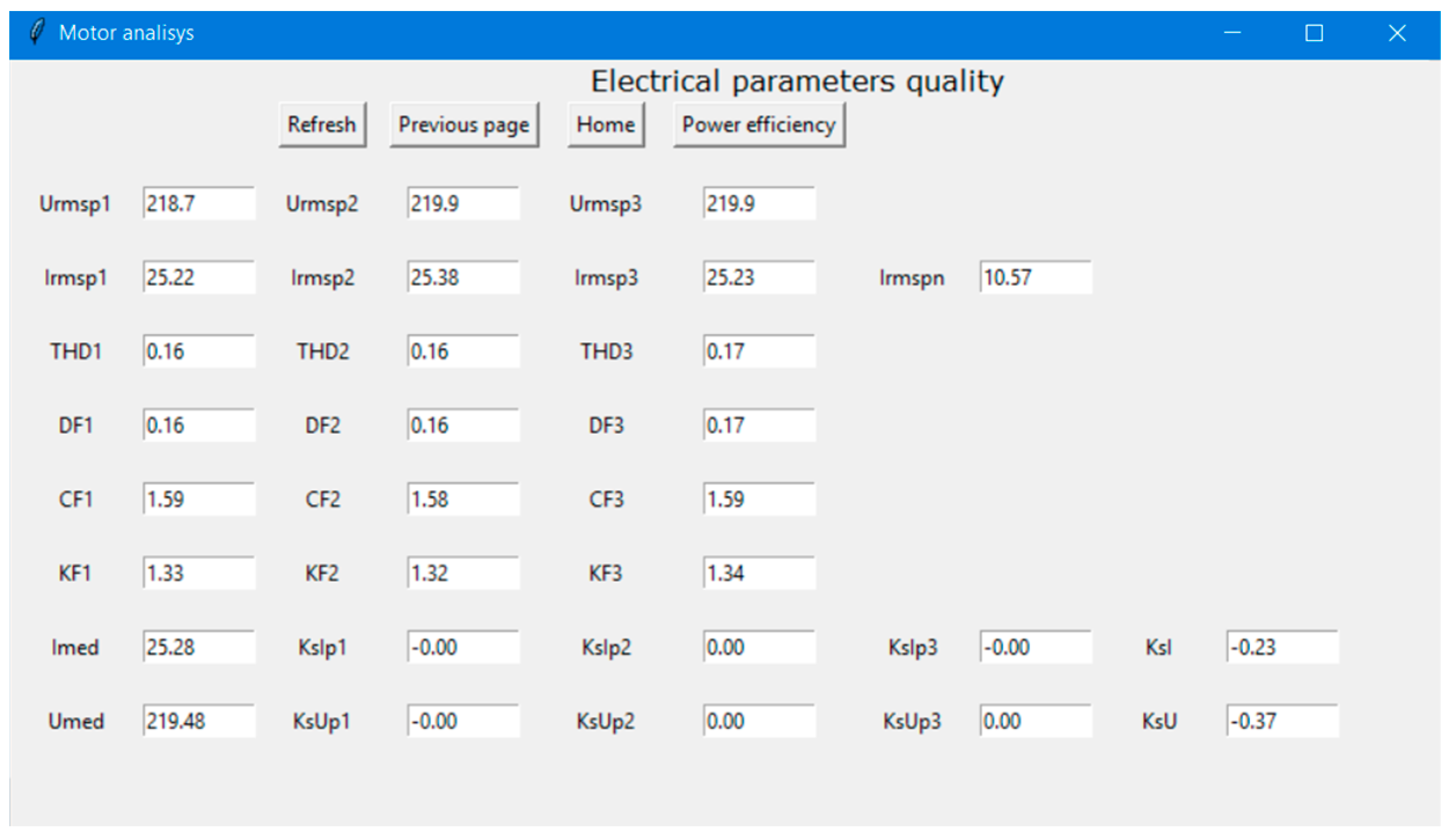

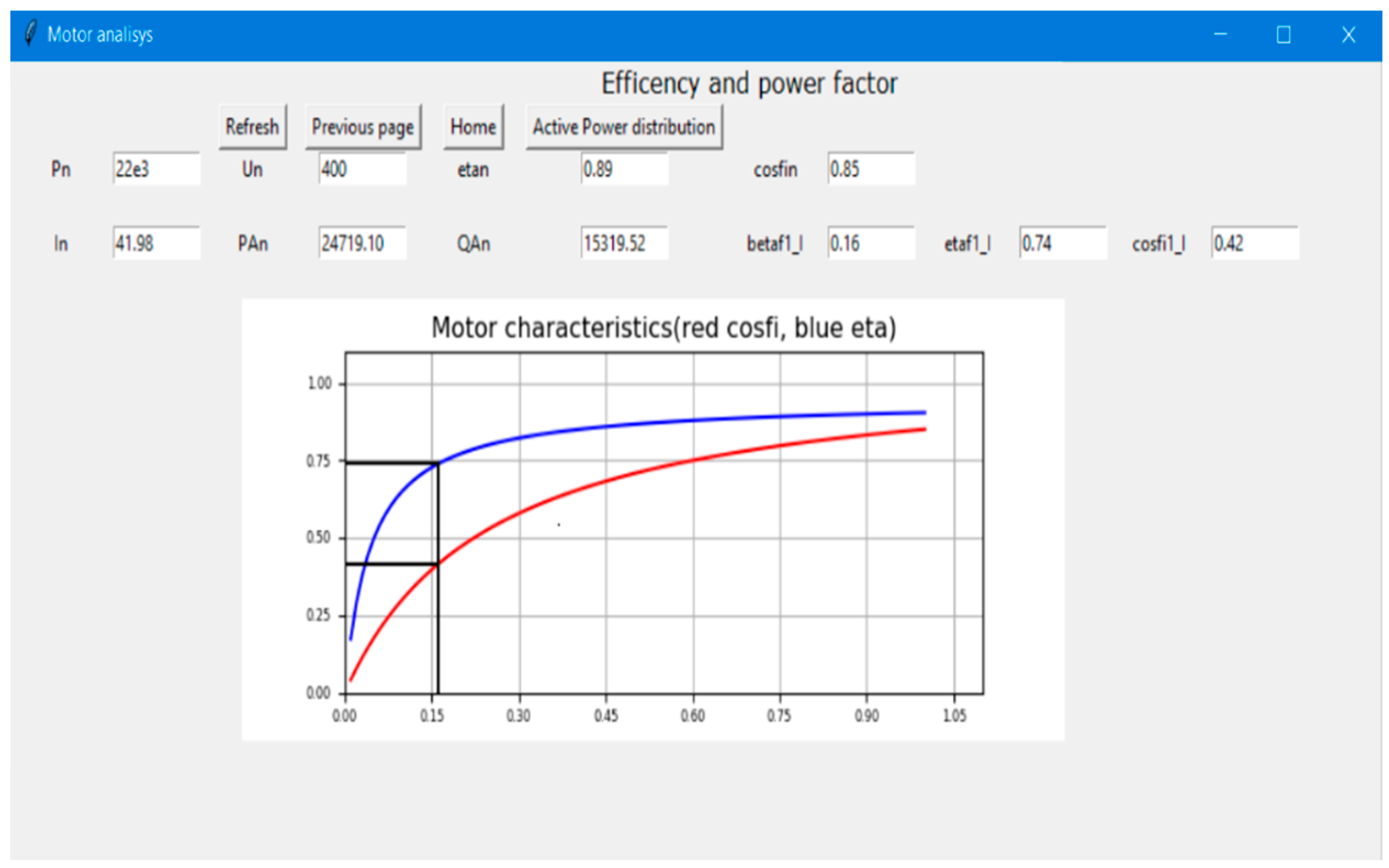

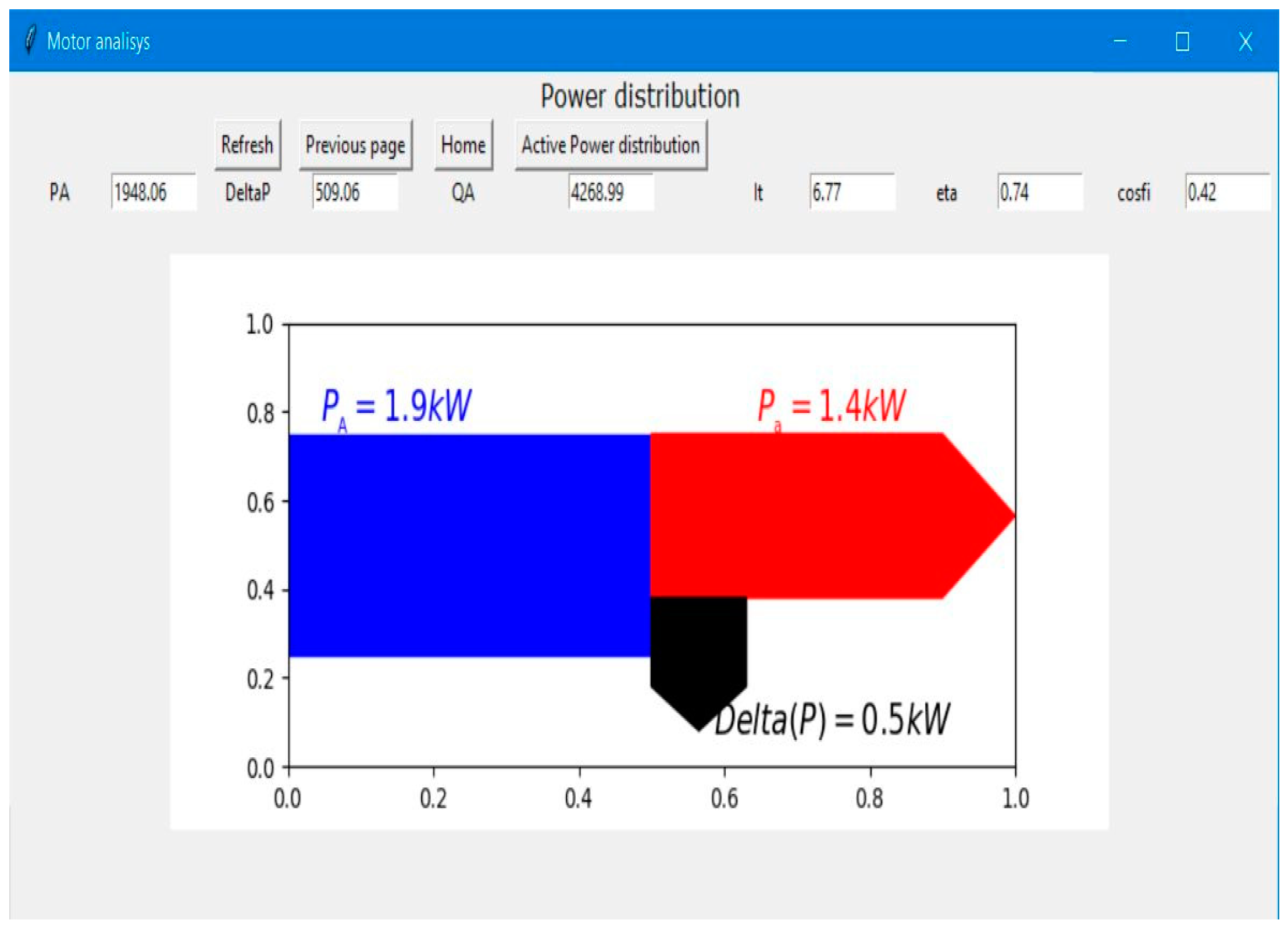

- Facilitate a continuous determination of power quality and energy indicators of the tested equipment (voltage and current waveforms characteristics, active and reactive power distribution within the machine, operating efficiency, power factors, etc.). Thus, a maintenance report of the equipment is to be continuously generated.

- The smart device must be also able to suggest the potential cause of the notified abnormal variations together with any remedies (if the defect is identified in a malfunction database of the developed system, constantly updated). Thus, the user of the installation could correctly address the indicated issue and consequentially maintain the continuity of the activity.

- The device must be robust, reliable, and allow for a minimally invasive installation in the electrical installation, as the critical receivers (large power motors or machineries) rarely admit the interruption of the power supply for upgraded or improvement processes.

- The developed intelligent system must also allow the remote transmission of the maintenance report so that it can be accessed from various locations with the help of mobile and portable communication devices (mobile phone, tablet, etc.).

4. Discussions

5. Conclusions

- Improving the computation procedure of the examined motor operational energetical parameters. This demands the considerations of other essential power quality parameters that define the motor functionality under other states, e.g., unbalanced or distorted states, which are often encountered in low-voltage installations. Additionally, the motor transients are also to be investigated by this maintenance device, since during the switching processes, the electric and mechanical stresses within the machine are considerable and could endanger the motor’s operation after the transient decay.

- Developing a better determination of the motor circuit parameter. This could be achieved by adopting an advanced motor model that also requires construction and material data of the machine and the usage of various numerical methods in developing the improved circuit model. Thus, the concept of the “generic” motor is to be updated also by periodically acquiring supplementary data from various motor manufacturers.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hashemian, H.M.; Bean, W.C. State-of-the-Art Predictive Maintenance Techniques. IEEE Trans. Instrum. Meas. 2010, 60, 226–236. [Google Scholar] [CrossRef]

- Gono, R. Reliability and maintenance of electrical power system: Invited lecture. In Proceedings of the 18th International Scientific Conference on Electric Power Engineering (EPE), Kouty nad Desnou, Czech Republic, 17–19 May 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Manjare, A.A.; Patil, B.G. A Review: Condition Based Techniques and Predictive Maintenance for Motor. In Proceedings of the 2021 International Conference on Artificial Intelligence and Smart Systems (ICAIS), Coimbatore, India, 25–27 March 2021; pp. 807–813. [Google Scholar] [CrossRef]

- Goundar, S.S.; Pillai, M.R.; Mamun, K.A.; Islam, F.R.; Deo, R. Real time condition monitoring system for industrial motors. In Proceedings of the 2nd Asia-Pacific World Congress on Computer Science and Engineering (APWC on CSE), Nadi, Fiji, 2–4 December 2015; pp. 1–9. [Google Scholar] [CrossRef]

- Cazacu, E.; Petrescu, L.; Petrescu, M.C. The major predictive maintenance actions of the electric equipments in the industrial facilities. Sci. Bull. Electr. Eng. Fac. 2018, 18, 26–33. [Google Scholar] [CrossRef] [Green Version]

- Janssens, O.; Loccufier, M.; van Hoecke, S. Thermal Imaging and Vibration-Based Multisensor Fault Detection for Rotating Machinery. IEEE Trans. Ind. Inform. 2018, 15, 434–444. [Google Scholar] [CrossRef] [Green Version]

- Alfredo Osornio-Rios, R.; Antonino-Daviu, J.A.; de Jesus Romero-Troncoso, R. Recent Industrial Applications of Infrared Thermography: A Review. IEEE Trans. Ind. Inform. 2018, 15, 615–625. [Google Scholar] [CrossRef]

- Novoa, C.G.; Berríos, G.A.G.; Söderberg, R.A. Predictive maintenance for motors based on vibration analysis with compact rio. In Proceedings of the 2017 IEEE Central America and Panama Student Conference (CONESCAPAN), Panama, Panama, 20–22 September 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Lu, B.; Durocher, D.B.; Stemper, P. Predictive maintenance techniques. IEEE Ind. Appl. Mag. 2009, 15, 52–60. [Google Scholar] [CrossRef]

- Rahm, L.; Lorenz, J.; Khaydarov, V.; Maywald, T.; Glas, T.; Urbas, L. Predictive maintenance with NOA: Application and insights for rotating equipment. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; pp. 761–767. [Google Scholar] [CrossRef]

- Al-Mansour, A.; Lee, K.-W.W.; Al-Qaili, A.H. Prediction of Pavement Maintenance Performance Using an Expert System. Appl. Sci. 2022, 12, 4802. [Google Scholar] [CrossRef]

- Jones, G.; Frost, N. Introduction to Predictive Models for Motor Dielectric Aging. In Proceedings of the 2020 IEEE Electrical Insulation Conference (EIC), Knoxville, TN, USA, 22 June 2020–3 July 2020; pp. 282–285. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, B.; Kanemaru, M.; Lin, C.; Liu, D.; Miyoshi, M.; Teo, K.N.; Habetler, T.G. Model-Based Analysis and Quantification of Bearing Faults in Induction Machines. IEEE Trans. Ind. Appl. 2020, 56, 2158–2170. [Google Scholar] [CrossRef]

- Antonino-Daviu, J.; Dunai, L.; Climente-Alarcon, V. Design of innovative laboratory sessions for electric motors predictive maintenance teaching. In Proceedings of the IECON 2017-43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–31 November 2017; pp. 3965–3970. [Google Scholar] [CrossRef]

- Baklouti, A.; Mifdal, L.; Dellagi, S.; Chelbi, A. An Optimal Preventive Maintenance Policy for a Solar Photovoltaic System. Sustainability 2020, 12, 4266. [Google Scholar] [CrossRef]

- Sung, G.-M.; Shen, Y.-S.; Keno, L.T.; Yu, C.-P. Internet-of-Things Based Controller of a Three-Phase Induction Motor Using a Variable-Frequency Driver. In Proceedings of the 2019 IEEE Eurasia Conference on IOT, Communication and Engineering (ECICE), Yunlin, Taiwan, 3–6 October 2019; pp. 156–159. [Google Scholar] [CrossRef]

- Penrose, H.W. Simple Time-to-Failure Estimation Techniques for Reliability and Maintenance of Equipment. IEEE Electr. Insul. Mag. 2009, 25, 14–18. [Google Scholar] [CrossRef]

- Jung, J.; Lee, J.; Kwon, B. Online Diagnosis of Induction Motors Using MCSA. IEEE Trans. Ind. Electron. 2006, 53, 1842–1852. [Google Scholar] [CrossRef]

- Mariut, L.; Filip, M.; Helerea, E.; Peter, I. Analysis and modeling on the induction machine faults. In Proceedings of the 3rd International Symposium on Electrical and Electronics Engineering (ISEEE), Galati, Romania, 16–18 September 2010; pp. 11–16. [Google Scholar] [CrossRef]

- Paun, A.; Vinga, C.M.; Frigura-Iliasa, F.M.; Vatau, D.; Cazacu, E.; Petrescu, L. Study about the active power and energy losses of a 400V 57 kW asynchronous motor. In Proceedings of the 19th International Scientific Conference on Electric Power Engineering (EPE), Brno, Czech Republic, 16–18 May 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Cazacu, E.; Năvrăpescu, V.; Nemoianu, I.V. On-site efficiency evaluation for in-service induction motors. Rev. Roum. Sci. Techn. Électrotechn. et Énerg. 2013, 58, 63–72. [Google Scholar]

- Baurand, G.; Moliton, V. The Protection of LV Motors, Schneider Electric. Cahier Technique, no. 211. 2002. Available online: https://www.se.com/lt/lt/download/document/ECT211/ (accessed on 2 May 2022).

- Glen, A.M.; Weindorf, W.J. Electric Motor Drive Installation and Troubleshooting, 3rd ed.; American Technical Pubblishers: Orland Park, IL, USA, 2015. [Google Scholar]

- Ferracci, P.H. Power quality, Schneider Electric. Cahier Technique. no. 199. 2001. Available online: https://www.se.com/au/en/download/document/ECT199/ (accessed on 2 May 2022).

- Melani, A.H.A.; Murad, C.A.; Caminada Netto, A.; Souza, G.F.M.; Nabeta, S.I. Maintenance Strategy Optimization of a Coal-Fired Power Plant Cooling Tower through Generalized Stochastic Petri Nets. Energies 2019, 12, 1951. [Google Scholar] [CrossRef] [Green Version]

- Orság, P.; Kocman, S.; Otýpka, J. Impact of mains power quality on operation characteristics of induction motor. In Proceedings of the 2014 14th International Conference on Environment and Electrical Engineering, Krakow, Poland, 10–12 May 2014; pp. 382–385. [Google Scholar] [CrossRef]

- Peter, A.A.; Okakwu, I.K.; Olowasogo, E.S.; Alayande, A.S.; Airoboman, A.E. Influence of Power Quality Problem on the Performance of an Induction Motor. Am. J. Electr. Power Energy Syst. 2015, 4, 39–44. [Google Scholar] [CrossRef]

- Neves, A.B.F.; Filho, A.d.L.F.; de Mendonça, M.V.B. Effects of voltage unbalance on torque and efficiency of a three-phase induction motor. In Proceedings of the 16th International Conference on Harmonics and Quality of Power (ICHQP), Bucharest, Romania, 25–28 May 2014; pp. 679–683. [Google Scholar] [CrossRef]

- De Castro e Silva, M.D.; Ferreira Filho, A.L.; Neves, A.B.F.; Mendonça, M.V.B. Effects of sequence voltage components on torque and efficiency of a three-phase induction motor. Electric Power Syst. Res. 2016, 140, 942–949. [Google Scholar] [CrossRef]

- Duque-Perez, O.; Morinigo-Sotelo, D.; Perez-Alonso, M. Diagnosis of induction motors fed by supplies with high harmonic content using motor current signature analysis. In Proceedings of the International Conference on Power Engineering, Energy and Electrical Drives, Malaga, Spain, 11–13 May 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Deraz, S.A.; Azazi, H.Z. Impact of distorted voltage on three-phase induction motor performance. In Proceedings of the Nineteenth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 19–21 December 2017; pp. 857–863. [Google Scholar] [CrossRef]

- Donolo, P.D.; Pezzani, C.M.; Bossio, G.R.; de Angelo, C.H.; Donolo, M.A. Derating of Induction Motors Due to Power Quality Issues Considering the Motor Efficiency Class. IEEE Trans. Ind. Appl. 2020, 56, 961–969. [Google Scholar] [CrossRef]

- Babaa, F.; Bennis, O. Steady State Analytical Study of Stator Current Harmonic Spectrum Components on Three-Phase Induction Motor under Unbalanced Supply Voltage. In Proceedings of the International Conference on Control, Automation and Diagnosis (ICCAD), Paris, France, 7–9 October 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Chauhan, S.; Singh, S.B. Effects of Voltage Unbalance and Harmonics on 3-Phase Induction Motor During the Condition of Undervoltage and Overvoltage. In Proceedings of the 6th International Conference on Signal Processing and Integrated Networks (SPIN), Noida, India, 7–8 March 2019; pp. 1141–1146. [Google Scholar] [CrossRef]

- Al-Badri, M.; Pillay, P.; Angers, P. A Novel in Situ Efficiency Estimation Algorithm for Three-Phase Induction Motors Operating with Distorted Unbalanced Voltages. IEEE Trans. Ind. Appl. 2017, 53, 5338–5347. [Google Scholar] [CrossRef]

- Silwal, B.; Mohamed, A.H.; Nonneman, J.; de Paepe, M.; Sergeant, P. Assessment of Different Cooling Techniques for Reduced Mechanical Stress in the Windings of Electrical Machines. Energies 2019, 12, 1967. [Google Scholar] [CrossRef] [Green Version]

- Ching-Yin, L. Effects of unbalanced voltage on the operation performance of a three-phase induction motor. IEEE Trans. Energy Convers. 1999, 14, 202–208. [Google Scholar] [CrossRef]

- Van Wyk, A.L.; Khan, M.A.; Barendse, P. Impact of over/under and voltage unbalanced supplies on energy-efficient motors. In Proceedings of the IEEE International Electric Machines & Drives Conference (IEMDC), Niagara Falls, ON, Canada, 15–18 May 2011; pp. 1380–1385. [Google Scholar] [CrossRef]

- Faiz, J.; Ebrahimpour, H.; Pillay, P. Influence of unbalanced voltage on the steady-state performance of a three-phase squirrel-cage induction motor. IEEE Trans. Energy Convers. 2004, 19, 657–662. [Google Scholar] [CrossRef]

- Donolo, P.; Bossio, G.; de Angelo, C.; García, G.; Donolo, M. Voltage unbalance and harmonic distortion effects on induction motor power, torque and vibrations. Electric Power Syst. Res. 2016, 140, 866–873. [Google Scholar] [CrossRef]

- IEC TS 60034-25:2014; Rotating Electrical Machines—Part 25: AC Electrical Machines Used in Power Drive Systems—Application Guide. 2014. Available online: https://webstore.iec.ch/publication/128 (accessed on 2 May 2022).

- IEC 61000-4-30:2015+AMD1:2021; CSV Consolidated Version. Electromagnetic Compatibility (EMC)—Part 4-30: Testing and Measurement Techniques—Power Quality Measurement Methods. 2021. Available online: https://webstore.iec.ch/publication/65716 (accessed on 2 May 2022).

- IEEE Std. 1459-2010; Standard Definitions for the Measurement of Electric Power Quantities Under Sinusoidal, Nonsinusoidal, Balanced, or Unbalanced Conditions. IEEE: New York, NY, USA, 2010.

- Cazacu, E. Research report nr. 1PN-III-P2-2.1-CI-2018-1220/204CI—25.07.2018. Intelligent System of Predictive Maintenance for Critical Industrial Electrical Equipments. 2018. Available online: http://www.simpec.elth.pub.ro/index.html (accessed on 2 May 2022).

- Available online: https://store.arduino.cc/arduino-mega-2560-rev3 (accessed on 2 May 2022).

- Available online: https://www.raspberrypi.org/products/raspberry-pi-3-model-b/ (accessed on 2 May 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cazacu, E.; Petrescu, L.-G.; Ioniță, V. Smart Predictive Maintenance Device for Critical In-Service Motors. Energies 2022, 15, 4283. https://doi.org/10.3390/en15124283

Cazacu E, Petrescu L-G, Ioniță V. Smart Predictive Maintenance Device for Critical In-Service Motors. Energies. 2022; 15(12):4283. https://doi.org/10.3390/en15124283

Chicago/Turabian StyleCazacu, Emil, Lucian-Gabriel Petrescu, and Valentin Ioniță. 2022. "Smart Predictive Maintenance Device for Critical In-Service Motors" Energies 15, no. 12: 4283. https://doi.org/10.3390/en15124283

APA StyleCazacu, E., Petrescu, L.-G., & Ioniță, V. (2022). Smart Predictive Maintenance Device for Critical In-Service Motors. Energies, 15(12), 4283. https://doi.org/10.3390/en15124283