AI Energy Optimal Strategy on Variable Speed Drives for Multi-Parallel Aqua Pumping System

Abstract

:1. Introduction

2. Modeling of Intelligent Aqua Pump Drive System

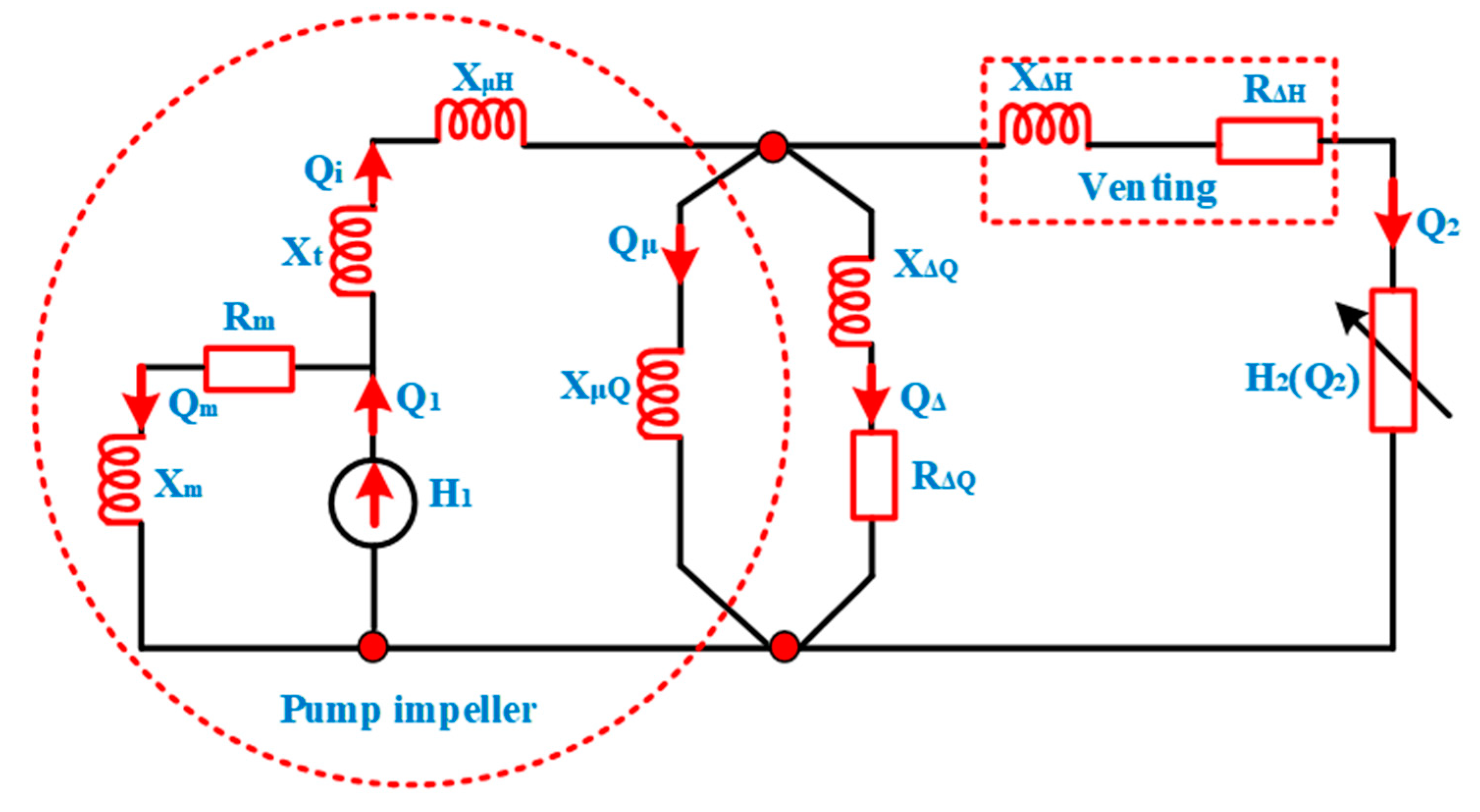

2.1. Mathematical Modeling of Aqua Pump

- —nominal head and volumetric loss of fluid in CP;

- —nominal power and module of the hydraulic impedance of CP;

- —per unit density of fluid and gravitational constant.

2.2. Mathematical Modeling of Induction Motor Drive-Based VFD

2.2.1. Steady-State Analysis of Induction Motor Drive

2.2.2. Dynamic Analysis of Induction Motor Drive

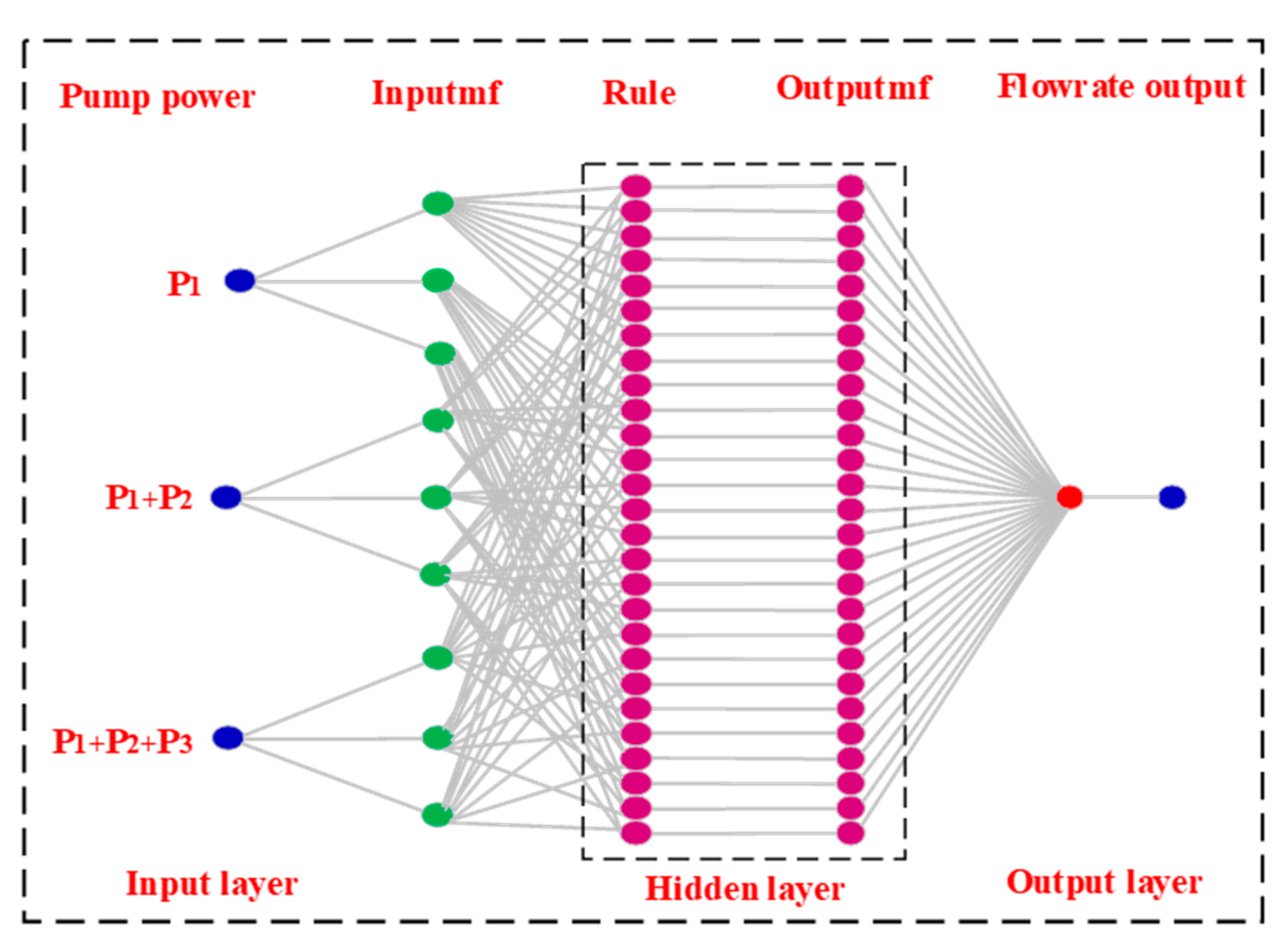

2.3. Intelligent Controller for Pump Drive System

3. Methodology

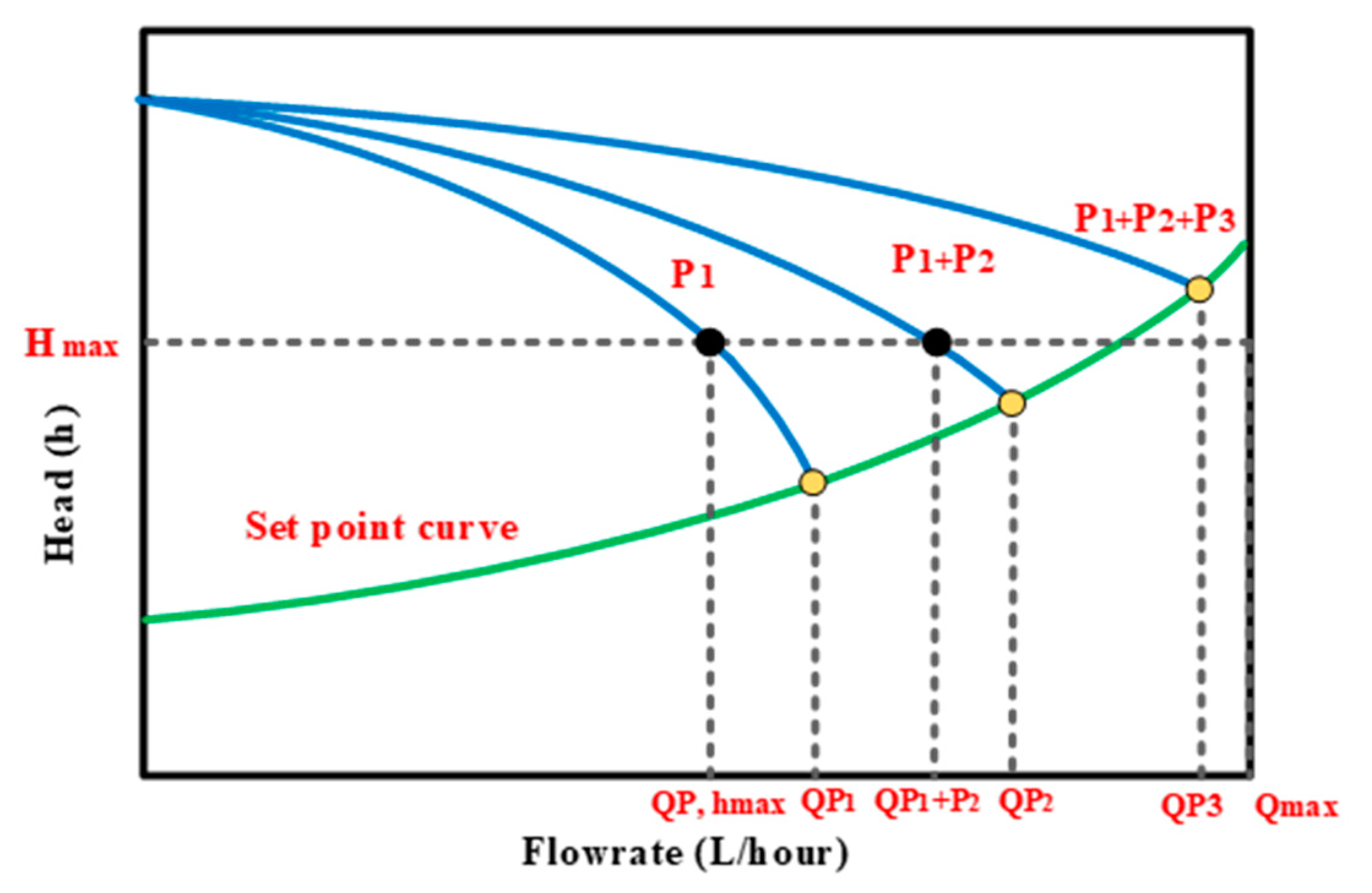

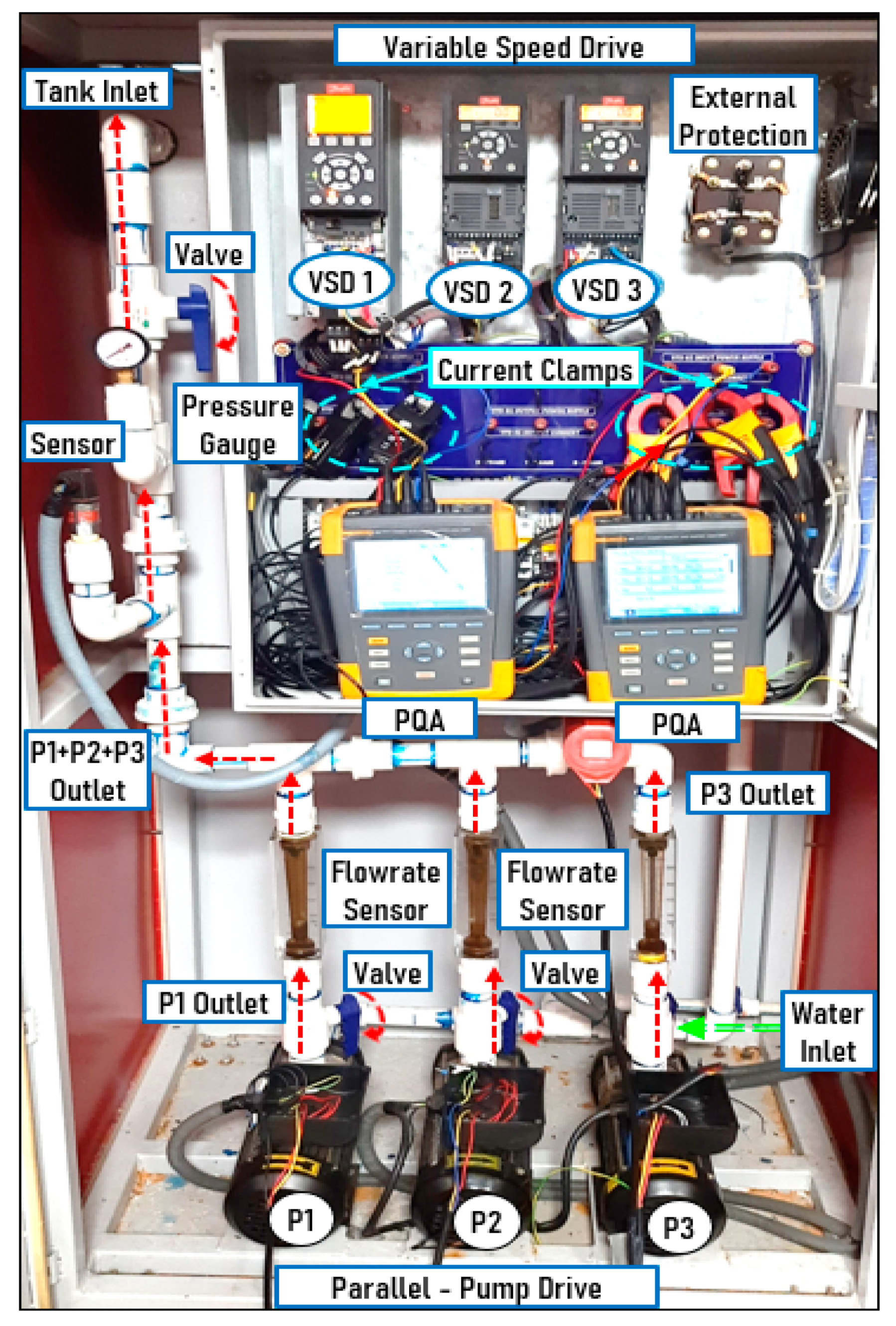

4. Realization of Multi-Parallel Pumping System

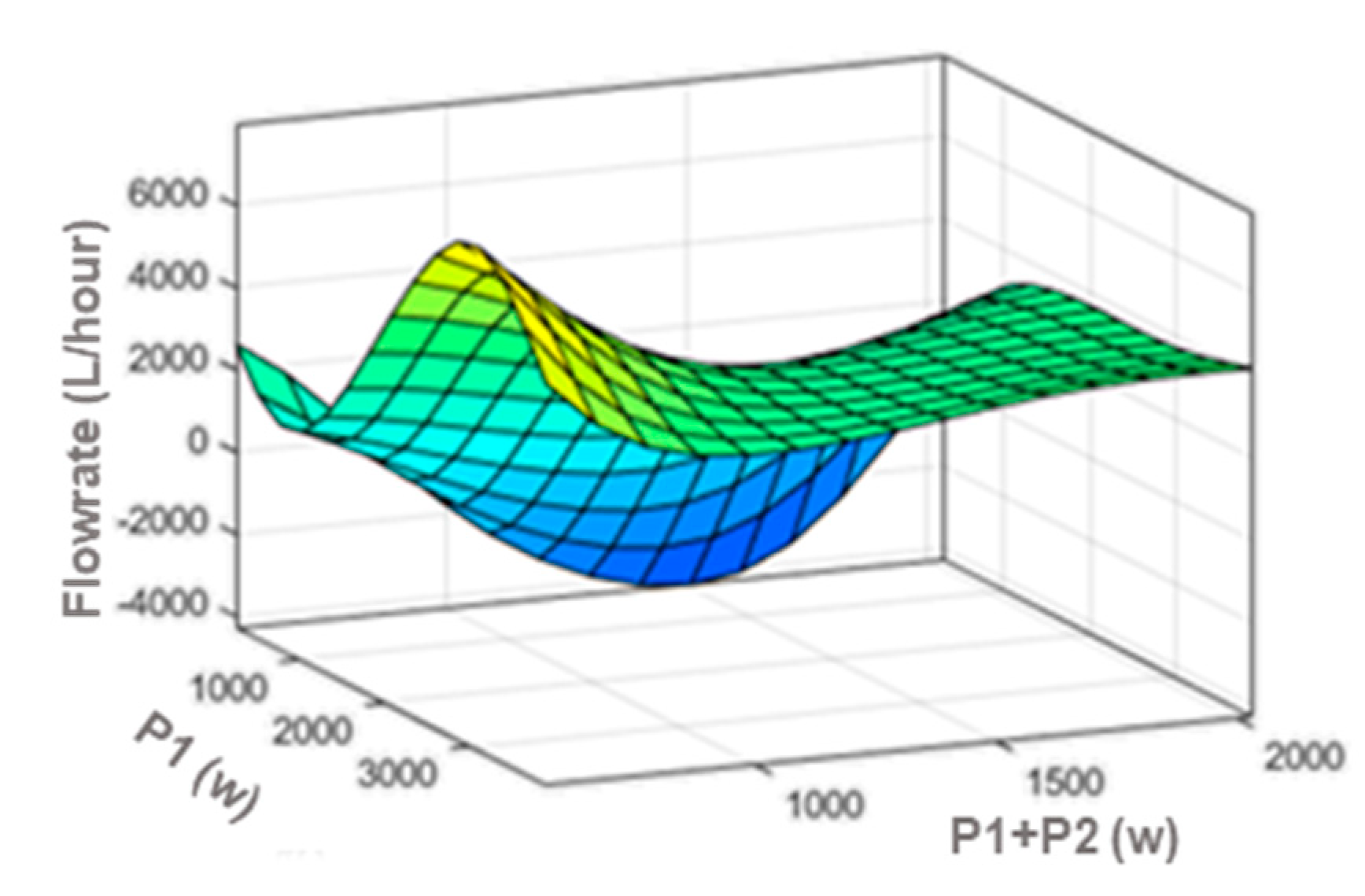

4.1. Simulation of AI-Based Multi-Parallel Pumping System

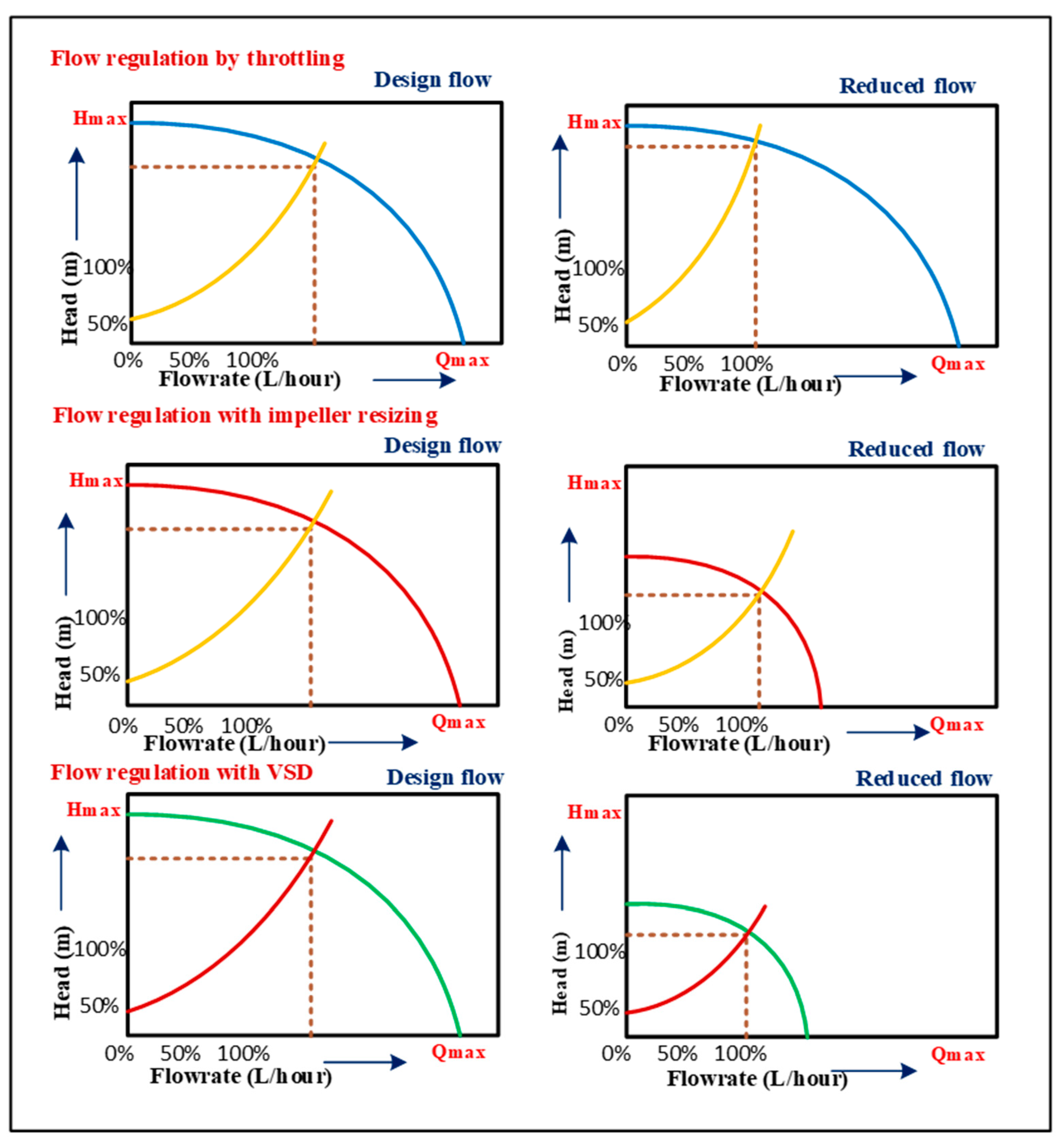

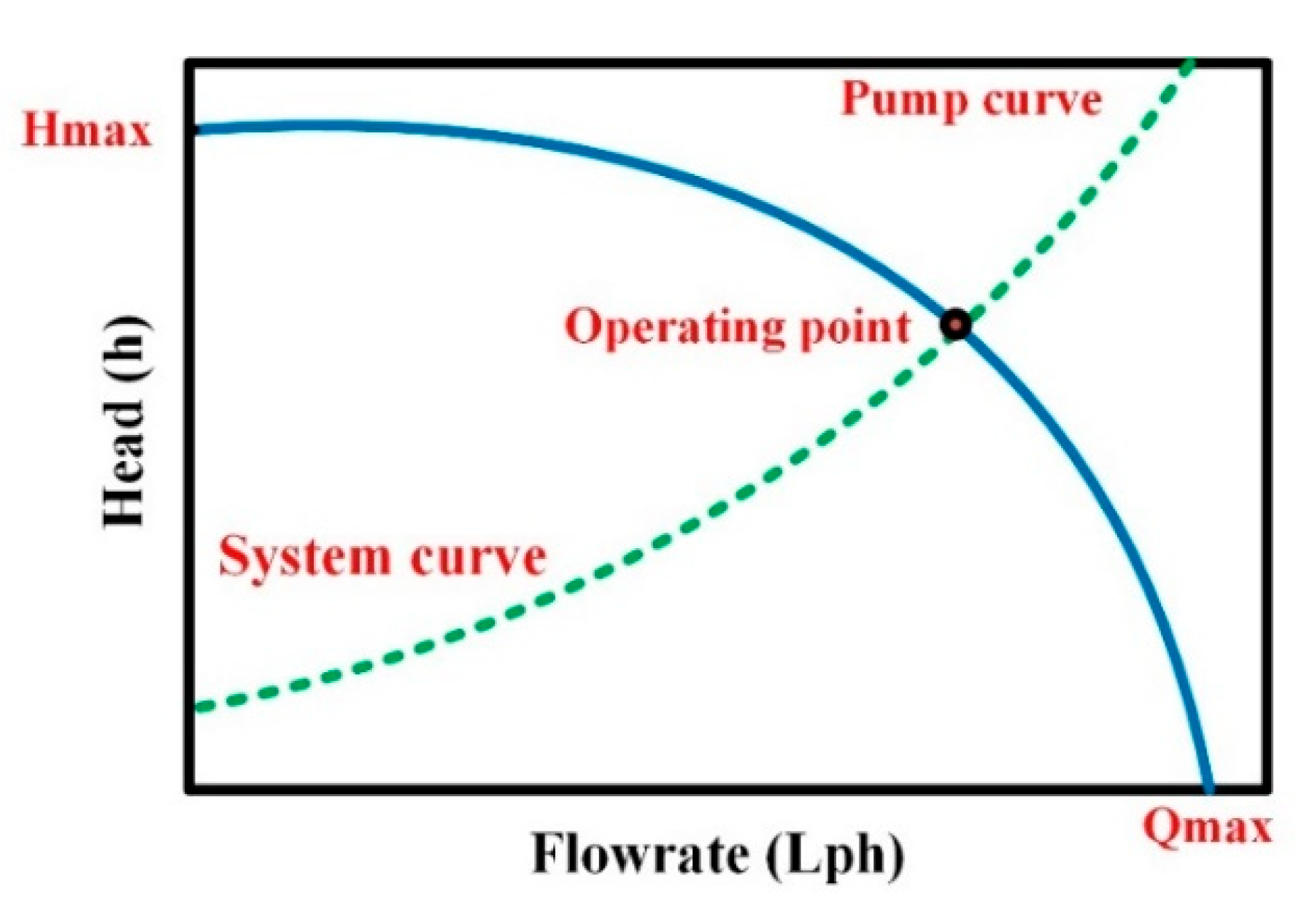

4.1.1. Effects of Different Flow Regulation Strategies on Energy Consumption

4.1.2. Optimizing Pumping Using Variable Speed Drives

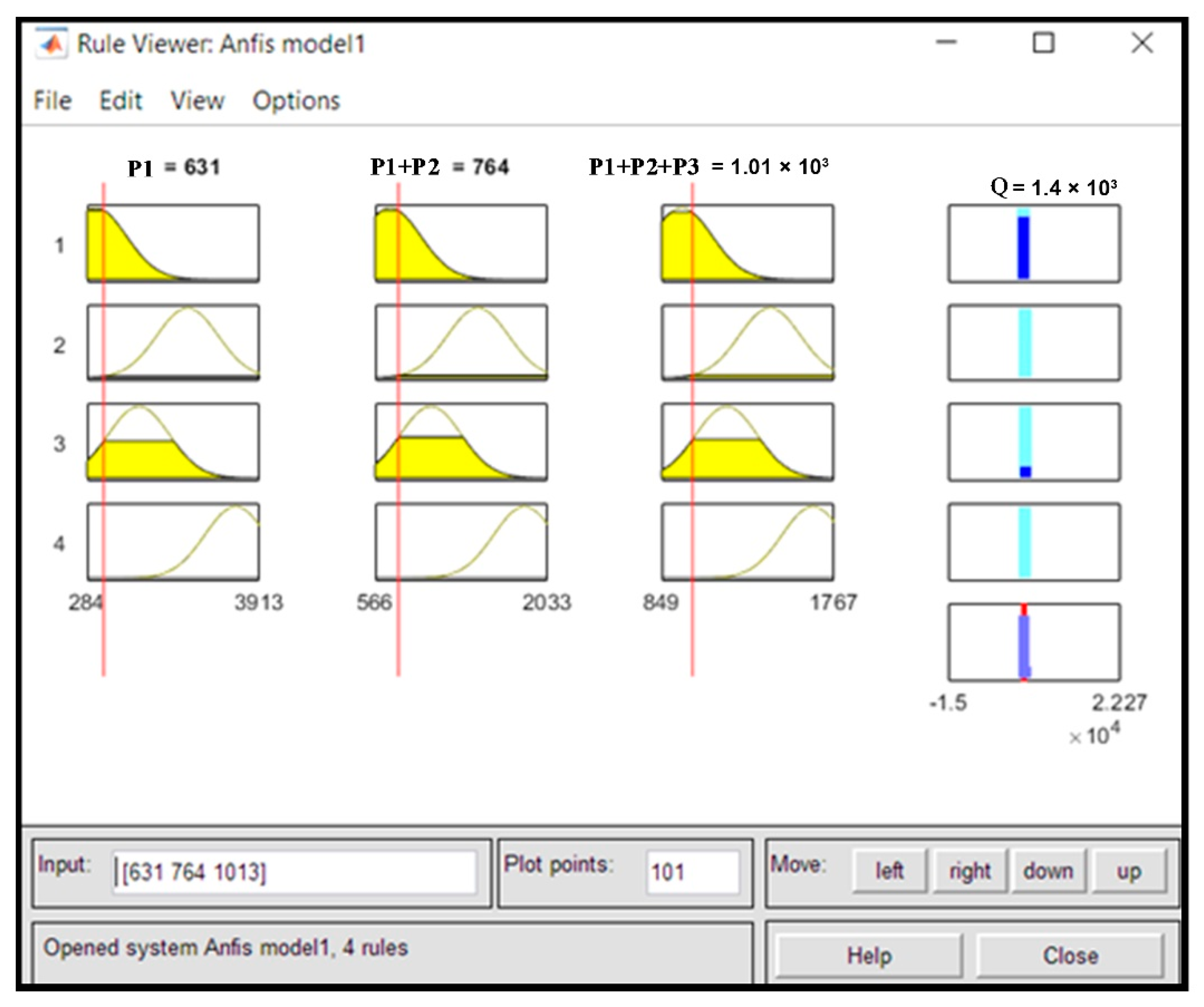

4.1.3. Adaptive Neuro-Fuzzy Inference System

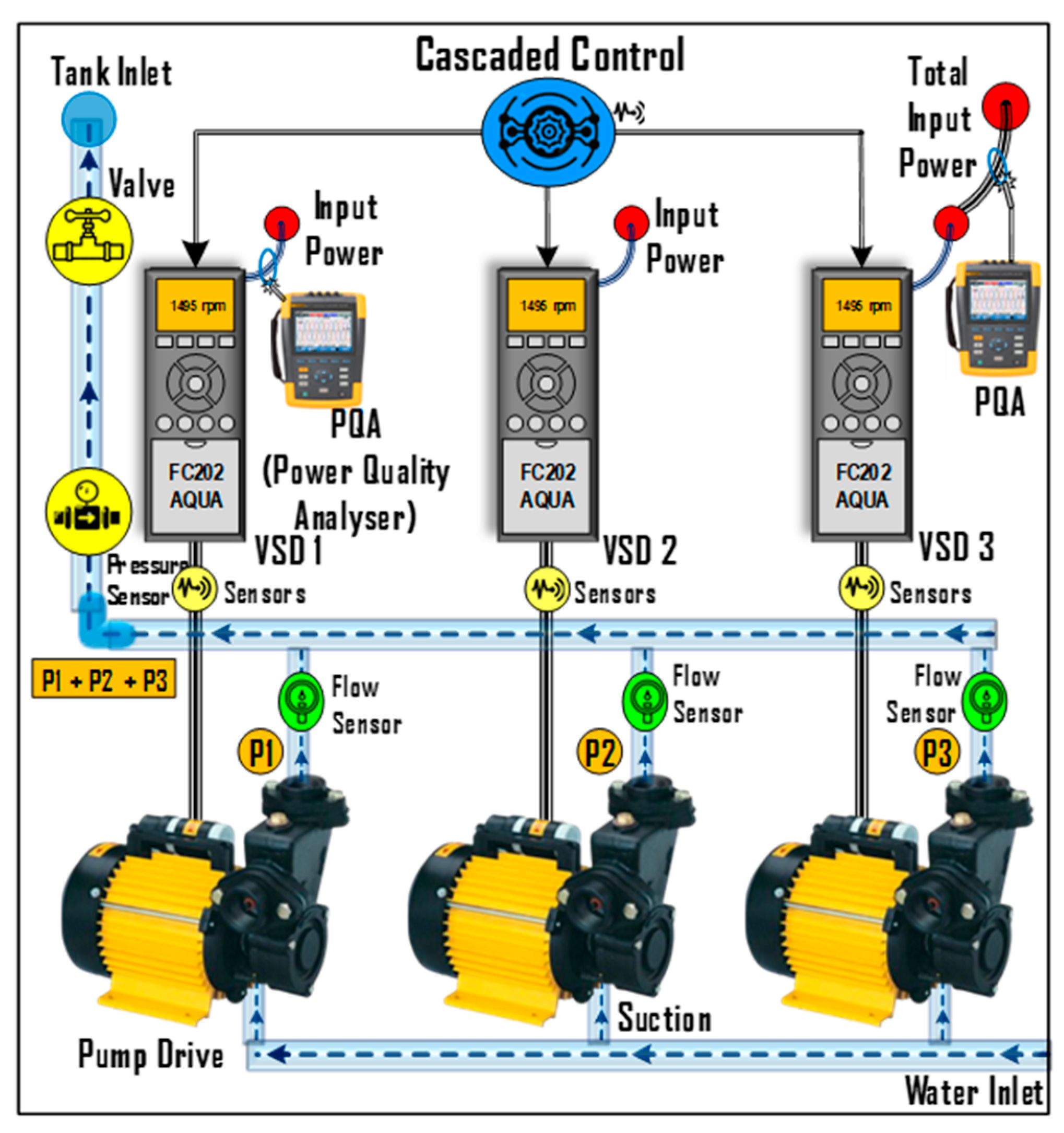

4.2. Experimental Test for Multi-Parallel Pumping System

Hardware System Description

5. Result and Discussion

5.1. Simulation Result

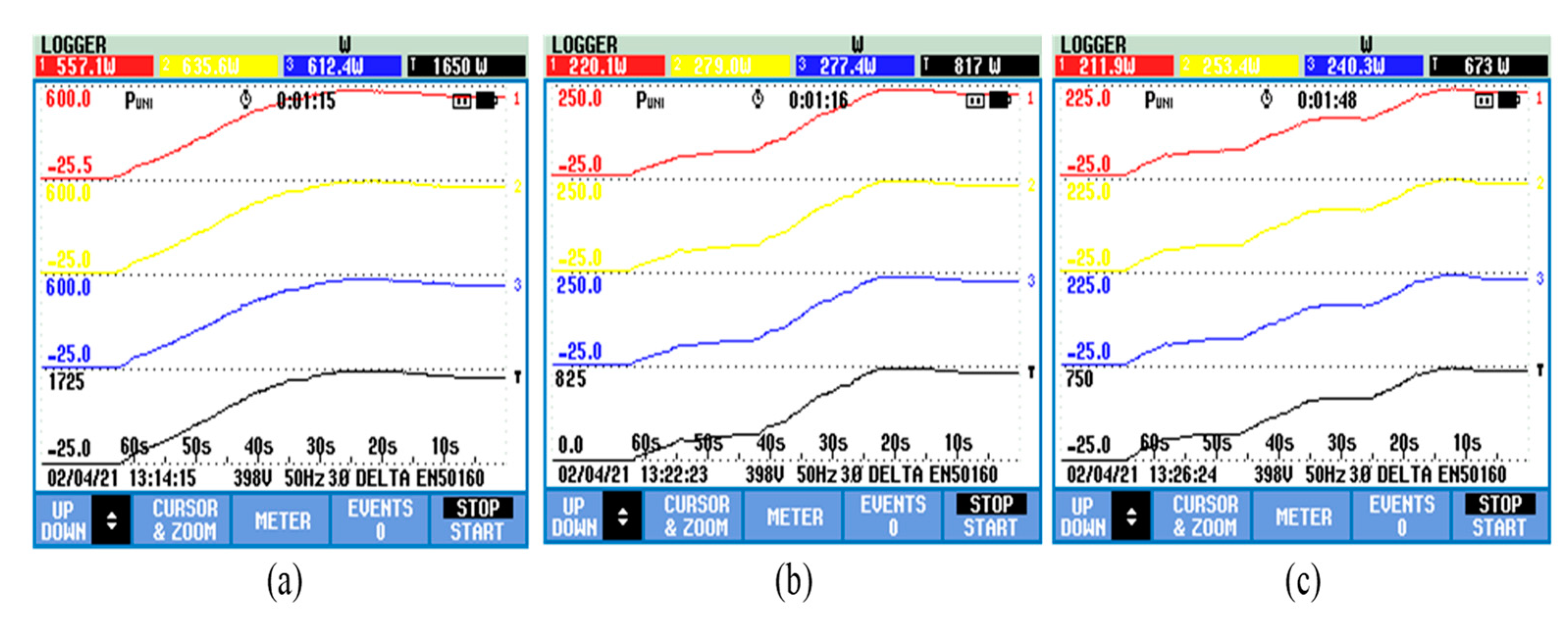

5.2. Experimental Result

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ANFIS | Adaptive neuro-fuzzy inference system |

| ANN | Artificial neural network |

| AI | Artificial intelligence |

| AEFA | Artificial electric field algorithm |

| BEP | Best efficiency point |

| BER | Best efficiency region |

| CP | Centrifugal pump |

| EPANET | Environmental Protection Agency Network |

| FIS | Fuzzy inference system |

| GA | Genetic algorithm |

| GRNN | General regression neural network |

| H | Total head |

| IM | Induction motor |

| J | Moment of inertia |

| MINLP | Mixed-integer nonlinear programming |

| MF | Membership function |

| N | Rotational speed |

| Nr | Rated speed |

| NN | Neural network |

| NPSHR | Net positive suction head |

| P | Number of pole pairs |

| P1 | Pump 1 |

| P2 | Pump 2 |

| P3 | Pump 3 |

| PCC | Point of common coupling |

| PQ | Power quality |

| Pb | Pump base water level |

| PAT | Position of turbine |

| PID | Proportional integral derivative |

| PSO-AIWA | Particle swarm optimization-adaptive inertia weight adjusting |

| PQA | Power quality analyzer |

| Q | Flowrate |

| SCIM | Squirrel cage induction motor |

| VSD | Variable speed drive |

| VFD | Variable frequency drive |

| V/F | Voltage/frequency |

| VVC+ | Voltage vector control |

| WNN | Wavelet neural network |

| A(Y) | Nonlinear function |

| MP | Passive/resistive torque of the pump |

| Mζ | Viscous torque |

| MMT | Active torque from the asynchronous motor |

| f | Network frequency |

| qv1 | Input flow |

| TL | Load torque |

| qv2 | Output water flow |

| ω | Angular velocity |

| kv | Valve constant |

| N0 | Nominal speed |

| Qp2, Qp3 | Flow ranges |

| p2 | Pressure valve 2 |

| Rm, Xm | Dissipative and reactive hydro-resistances |

| RΔH, XΔH | Losses of hydraulic head in CP’s spiral venting |

| RΔQ, XΔQ | Feedback on the CP’s head through the seal |

| Xt | Reactive hydro-resistance of the spiral part of the CP’s venting |

| XμH, XμQ | Finite number of the impeller’s blades on the pump’s pressure and volumetric fluid losses |

| H1 = (H1d + jH1q) | Phasor of rated head of ideal pump in non-functional mode |

| Q1, Q2, Qm | Phasors of rated volumetric fluid losses of ideal CP |

| H2(Q2) | Static head characteristics of hydraulic network |

| Hcpn, Qcpn | Nominal head and volumetric loss of fluid in CP |

| Scpn, Zcpn | Nominal power and module of hydraulic impedance of CP; |

| Per unit density of fluid | |

| g | Gravitational constant |

| H2 = (H2d + jH2q) | Phasor of hydraulic network head |

| H1n | Nominal head of idealized CP in no-load mode |

| Actual volumetric losses | |

| Actual head of real CP | |

| Rg2(Q2d, Q2q) = H2 (Q2)/Q2 | Hydraulic resistance of hydraulic network |

| Ncp | Mechanical power on the Shaft of CP |

| N2 | Hydraulic power on the output of CP |

| ωb | Base angular velocity |

| Rotor angular speed | |

| Stator and rotor resistance | |

| Mutual inductance | |

| Stator flux of d-axis and q-axis | |

| Rotor flux of d-axis and q-axis | |

| Flux linkages of stator and rotor | |

| Ppumpin | Pump input power |

| RS | Stator resistance |

| Rr | Rotor resistance |

| X1 and X2 | Stator and rotor leakage reactance |

| Xh | Main reactance |

| Rfe | Iron loss resistance |

| k | Operative stator/rotor turns ratio |

| μ(x) and μ(y) | Gaussian membership functions |

| ci | Fuzzy set breadth |

| σi | Training cost |

| wi | Normalized firing strength |

| pi, qi, and ri | Subsequent parameters for network’s training phase |

| S1 and S2 | Slip |

References

- Li, W.; Vaziri, V.; Aphale, S.S.; Dong, S.; Wiercigroch, M. Energy saving by reducing motor rating of sucker-rod pump systems. Energy 2021, 228, 120618. [Google Scholar] [CrossRef]

- de Souza, D.F.; da Guarda, E.L.A.; Sauer, I.L.; Tatizawa, H. Energy Efficiency Indicators for Water Pumping Systems in Multifamily Buildings. Energies 2021, 14, 7152. [Google Scholar] [CrossRef]

- Waide, P.; Brunner, C.U. Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems; IEA Energy Papers; OECD Publishing: Paris, France, 2011; pp. 1–132. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Wang, Z. A stochastic load demand-oriented synergetic optimal control strategy for variable-speed pumps in residential district heating or cooling systems. Energy Build. 2021, 238, 110853. [Google Scholar] [CrossRef]

- Wilson, A. The pump industry—past, present and future. World Pumps 2016, 2016, 36–38. [Google Scholar] [CrossRef]

- Ahn, K.U.; Park, S.H.; Hwang, S.; Choi, S.; Park, C.S. Optimal control strategies of eight parallel heat pumps using Gaussian process emulator. J. Build. Perform. Simul. 2019, 12, 650–662. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, Y.; Chen, G.; Zhan, Y.; Xu, G. Precise Determination of Power-Off Time of Intermittent Supply Technology Based on Fuzzy Control for Energy Saving of Beam Pumping Motor Systems. Electr. Power Components Syst. 2018, 46, 197–207. [Google Scholar] [CrossRef]

- Nikolenko, I.V.; Ryzhakov, A.N. Parallel operation mode optimization of different-type centrifugal pumps of a water supply booster pumping station. In Proceedings of the 2020 International Conference on Dynamics and Vibroacoustics of Machines (DVM), Samara, Russia, 16–18 September 2020. [Google Scholar] [CrossRef]

- Izquierdo, M.D.Z.; Jimenez, J.J.S.; Del Sol, A.M. Matlab software to determine the saving in parallel pumps optimal operation systems, by using variable speed. In Proceedings of the 2008 IEEE Energy 2030 Conference, Atlanta, GA, USA, 17–18 November 2008; Volume 2. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Q.; Wang, Y. An asynchronous distributed optimization method for energy saving of parallel-connected pumps in HVAC systems. Results Control Optim. 2020, 1, 100001. [Google Scholar] [CrossRef]

- Gruys, E. Bildbericht Nr. Magentorsion bei einem Schwein. Dtsch. Tierarztl. Wochenschr. 1974, 81, 411. [Google Scholar]

- Islam, A.; Singh, J.G.; Jahan, I.; Lipu, M.S.H.; Jamal, T.; Elavarasan, R.M.; Mihet-Popa, L. Modeling and Performance Evaluation of ANFIS Controller-Based Bidirectional Power Management Scheme in Plug-In Electric Vehicles Integrated With Electric Grid. IEEE Access 2021, 9, 166762–166780. [Google Scholar] [CrossRef]

- De Wrachien, D.; Mambretti, S.; Orsi, E.; Brebbia, C.A.; Ursino, N. Optimization of pump operations in a complex water supply network: New genetic algorithm frameworks. Int. J. Sustain. Dev. Plan. 2017, 12, 79–88. [Google Scholar] [CrossRef]

- Ekster, A. Optimization of Pump Station Operation Saves Energy and Reduces Carbon Footprint. Proc. Water Environ. Fed. 2009, 2009, 3762–3770. [Google Scholar] [CrossRef]

- Wu, P.; Lai, Z.; Wu, D.; Wang, L. Optimization Research of Parallel Pump System for Improving Energy Efficiency. J. Water Resour. Plan. Manag. 2015, 141, 04014094. [Google Scholar] [CrossRef]

- Moazeni, F.; Khazaei, J. Optimal energy management of water-energy networks via optimal placement of pumps-as-turbines and demand response through water storage tanks. Appl. Energy 2020, 283, 116335. [Google Scholar] [CrossRef]

- Sarmas, E.; Spiliotis, E.; Marinakis, V.; Tzanes, G.; Kaldellis, J.K.; Doukas, H. ML-based energy management of water pumping systems for the application of peak shaving in small-scale islands. Sustain. Cities Soc. 2022, 82, 103873. [Google Scholar] [CrossRef]

- Luna, T.; Ribau, J.; Figueiredo, D.; Alves, R. Improving energy efficiency in water supply systems with pump scheduling optimization. J. Clean. Prod. 2019, 213, 342–356. [Google Scholar] [CrossRef]

- Hieninger, T.; Schmidt-Vollus, R.; Schlücker, E. Improving energy efficiency of individual centrifugal pump systems using model-free and on-line optimization methods. Appl. Energy 2021, 304, 117311. [Google Scholar] [CrossRef]

- Hieninger, T.; Goppelt, F.; Schmidt-Vollus, R.; Schlücker, E. Energy-saving potential for centrifugal pump storage operation using optimized control schemes. Energy Effic. 2021, 14, 23. [Google Scholar] [CrossRef]

- Ping, X.; Yao, B.; Niu, K.; Yuan, M. A Machine Learning Framework With an Intelligent Algorithm for Predicting the Isentropic Efficiency of a Hydraulic Diaphragm Metering Pump in the Organic Rankine Cycle System. Front. Energy Res. 2022, 10, 1–14. [Google Scholar] [CrossRef]

- Feng, X.; Qiu, B.; Wang, Y. Optimizing Parallel Pumping Station Operations in an Open-Channel Water Transfer System Using an Efficient Hybrid Algorithm. Energies 2020, 13, 4626. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Q.; Wang, Y. A Distributed Optimization Method for Energy Saving of Parallel-Connected Pumps in HVAC Systems. Energies 2020, 13, 3927. [Google Scholar] [CrossRef]

- Gu, X.; Li, T.; Liao, Z.; Yang, L.; Nie, L. Modeling and Optimization of Beam Pumping System Based on Intelligent Computing for Energy Saving. J. Appl. Math. 2014, 2014, 317130. [Google Scholar] [CrossRef] [Green Version]

- Abdelsalam, A.A.; Gabbar, H.A. Energy Saving and Management of Water Pumping Networks. Heliyon 2021, 7, e07820. [Google Scholar] [CrossRef] [PubMed]

- Sharabiani, V.R.; Kaveh, M.; Taghinezhad, E.; Abbaszadeh, R.; Khalife, E.; Szymanek, M.; Dziwulska-Hunek, A. Application of Artificial Neural Networks, Support Vector, Adaptive Neuro-Fuzzy Inference Systems for the Moisture Ratio of Parboiled Hulls. Appl. Sci. 2022, 12, 1771. [Google Scholar] [CrossRef]

- Cao, Y.; Mohammadzadeh, A.; Tavoosi, J.; Mobayen, S.; Safdar, R.; Fekih, A. A new predictive energy management system: Deep learned type-2 fuzzy system based on singular value decommission. Energy Rep. 2021, 8, 722–734. [Google Scholar] [CrossRef]

- Enayatollahi, H.; Sapin, P.; Unamba, C.; Fussey, P.; Markides, C.; Nguyen, B. A Control-Oriented ANFIS Model of Evaporator in a 1-kWe Organic Rankine Cycle Prototype. Electronics 2021, 10, 1535. [Google Scholar] [CrossRef]

- Subramaniam, U.; Elavarasan, R.M.; Raju, K.; Shanmugam, P. Sensorless parameter estimation of VFD based cascade centrifugal pumping system using automatic pump curve adaption method. Energy Rep. 2021, 7, 453–466. [Google Scholar] [CrossRef]

- Briceño-León, C.; Iglesias-Rey, P.; Martinez-Solano, F.; Mora-Melia, D.; Fuertes-Miquel, V. Use of Fixed and Variable Speed Pumps in Water Distribution Networks with Different Control Strategies. Water 2021, 13, 479. [Google Scholar] [CrossRef]

- Olszewski, P. Genetic optimization and experimental verification of complex parallel pumping station with centrifugal pumps. Appl. Energy 2016, 178, 527–539. [Google Scholar] [CrossRef]

- Hieninger, T.; Goppelt, F.; Schmidt-Vollus, R. On-line self-tuning for centrifugal pumps driven in parallel mode using dynamic optimization. In Proceedings of the 2018 18th International Conference on Mechatronics—Mechatronika (ME), Brno, Czech Republic, 5–7 December 2018. [Google Scholar]

- Van Erp, R.; Kampitsis, G.; Matioli, E. Efficient Microchannel Cooling of Multiple Power Devices With Compact Flow Distribution for High Power-Density Converters. IEEE Trans. Power Electron. 2019, 35, 7235–7245. [Google Scholar] [CrossRef]

- Ekta; Garg, V.K. Advance lighting and water pumping system using artificial intelligence. In Proceedings of the 2018 Fifth International Conference on Parallel, Distributed and Grid Computing (PDGC), Solan, India, 20–22 December 2018; pp. 669–675. [Google Scholar] [CrossRef]

- Viholainen, J.; Tamminen, J.; Ahonen, T.; Ahola, J.; Vakkilainen, E.; Soukka, R. Energy-efficient control strategy for variable speed-driven parallel pumping systems. Energy Effic. 2012, 6, 495–509. [Google Scholar] [CrossRef]

- Pechenik, M.; Burian, S.; Pushkar, M.; Zemlianukhina, H. Analysis of the Energy Efficiency of Pressure Stabilization Cascade Pump System. In Proceedings of the 2019 IEEE International Conference on Modern Electrical and Energy Systems (MEES), Kremenchuk, Ukraine, 23–25 September 2019; pp. 490–493. [Google Scholar] [CrossRef]

- Engineer, O.; Water, F.R. Optimising pumping using variable speed drives. Future Boost. Pump Technol. 2017, 2017, 1–6. [Google Scholar]

- Xu, Y.; Guo, Z.; Yuan, C. Feasibility study of an integrated air source heat pump water heater/chillers and exhaust gas boiler heating system for swimming pool on luxury cruise ship. Energy Rep. 2021, 8, 1260–1282. [Google Scholar] [CrossRef]

- Lai, Z.; Li, Q.; Zhao, A.; Zhou, W.; Xu, H.; Wu, D. Improving Reliability of Pumps in Parallel Pump Systems Using Particle Swam Optimization Approach. IEEE Access 2020, 8, 58427–58434. [Google Scholar] [CrossRef]

- Zou, T.-H.; Ma, S.-Y. Analysis on energy saving of pumps movement adjustment in a closed cycle. In Proceedings of the 2010 Asia-Pacific Power and Energy Engineering Conference, Chengdu, China, 28–31 March 2010; pp. 1–4. [Google Scholar] [CrossRef]

- Shankar, V.A.; Subramaniyan, U.; Sanjeevikumar, P.; Holm-Nielsen, J.B.; Blaabjerg, F.; Paramasivam, S. Experimental Investigation of Power Signatures for Cavitation and Water Hammer in an Industrial Parallel Pumping System. Energies 2019, 12, 1351. [Google Scholar] [CrossRef] [Green Version]

- Fan, X.; Sun, H.; Yuan, Z.; Li, Z.; Shi, R.; Razmjooy, N. Multi-objective optimization for the proper selection of the best heat pump technology in a fuel cell-heat pump micro-CHP system. Energy Rep. 2020, 6, 325–335. [Google Scholar] [CrossRef]

- Arun Shankar, V.K.; Umashankar, U.; Paramasivam, S.; Hanigovszki, N. An Energy Efficient Control Algorithm for Parallel Pumping Industrial Motor Drives System. In Proceedings of the 2018 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Chennai, India, 18–21 December 2018. [Google Scholar] [CrossRef]

| Algorithm Type | Operation | Application |

|---|---|---|

| Genetic algorithm [13] | Significant progress has been made in the transition from a discrete to a continuous description of pump operation. | The procedure is random. Various situations with virtually comparable energy usage. |

| Pump stations optimization [14] | The established optimized schedule resulted in a 16KW*HR/MG energy reduction, which is over 25%. | Only fixed-speed motors were subjected to optimization. Manufacturer’s curves were used instead of actual performance curves. |

| The developed optimization model employs a genetic algorithm (GA) [15] | The GA and Lagrange multiples techniques were used to show a simple theoretical solution for optimizing the functioning of two identical pumps. | Recommending the most appropriate operating mode, This optimization model balances between efficiency and dependability. |

| Two mixed-integer nonlinear programming (MINLP) [16] | Determine the best quantity and position of turbine pumps (PATs). | Reduce energy generating costs in water-energy systems. |

| Energy management method [17] | The creation of a scheduling system and an ensemble of machine learning models for precisely forecasting RES production and energy usage. | Water pumping station operation hours are scheduled. Reduce the electricity usage. |

| Hybrid optimization method (EPANET) [18] | Water demand, and water storage risk, digital technologies may be used to improve the system with little investment in equipment or physical interaction. | Enhance the energy efficiency of a water delivery system. To obtain the sustainable water management system. |

| Model-free optimization [19] | The direct search strategy is typically the best solution for single pump systems. | The energy optimum of the single pump system. |

| Control optimization [20] | The impact of various system factors is investigated using twelve centrifugal pumps with nominal powers ranging from 1 to 120 kW. | To reduce the operational time, are critical for a cost-effective operation. |

| Wavelet neural network (WNN) with momentum term and particle swarm optimization-adaptive inertia weight adjusting (PSO-AIWA), [21] | When studying the time-varying features of the pump’s essential operational parameters, there are several constraints. | The evaluation of efficiency limits and optimum cycle parameters. |

| Efficient Hybrid Algorithm [22] | Parallel pumping station functioning in an open-channel water transfer system. | For real-time system optimization, the DA–SA–PSO is quite effective. |

| Distributed optimal control algorithm [23] | The pump optimization issue in a distributed fashion, achieving the lowest possible pump energy usage while ensuring convergence. | Energy savings potential, convergence assurance, and adaptability. |

| Regression neural network (GRNN) algorithm [24] | This approach does not need any modifications to the original equipment; it just attempts to make the device function in an energy-saving mode. | The optimal conditions result in a 5.34% oil yield and a 3.75% reduction in electric power usage. |

| Artificial electric field algorithm [25] | It is an iterative process including an optimization algorithm and the EPANET hydraulic simulator. | Its findings reveal that AEFA is superior in terms of convergence and cost savings. |

| Setpoint Flowrate (lph) | Pump 1 | Pump 2 | Pump 3 |

|---|---|---|---|

| 1 to 1703 lph | ON | OFF | OFF |

| 1703 to 3285 lph | ON | ON | OFF |

| Above 3285 lph | ON | ON | ON |

| Particular | Values |

|---|---|

| Rated power | 0.55 kW/0.75 HP |

| Rated voltage | 415 V |

| Frequency | 50 Hz |

| Rated current | 1.7 A |

| Head | 23.5 m |

| Nominal speed | 2800 rpm |

| Motor selection | Asynchronous |

| Configuration mode | Open-loop |

| Motor control principle | V/F |

| Overload mode | Normal torque |

| Clockwise direction | Normal |

| Pump type | Centrifugal |

| ISC | 3.3 A |

| Head range | 18/25 m |

| Discharge | 2000 (Lph) |

| Duty type | S1 |

| Pipe size | 25 × 25 mm |

| Model | PH2-30 CI |

| INSUL | CLASS ‘F’ |

| Stator resistance (RS) | 13.1083 Ohm |

| Rotor resistance (Rr) | 11.9789 Ohm |

| Stator and rotor leakage reactance (X1 and X2) | 11.3003 Ohm |

| Main reactance (Xh) | 212.7426 Ω |

| Iron loss resistance (Rfe) | 5182.820 Ω |

| Number of pole pair | 2 |

| Simulation type | Continuous (or) discrete |

| Port configuration | Torque |

| Stator and rotor inductance | 0.035969972 H |

| Mutual inductance | 0.677180727 H |

| Load | 1/4 | 1/2 | 1/3 | Full |

|---|---|---|---|---|

| Efficiency (%) | 72 | 75 | 77 | 78 |

| Power factor (%) | 68 | 70 | 75 | 81 |

| Flowrate (p.u) | Power Consumption Rate for Simulation (%) | Power Consumption Rate for Experimental Set Up (%) | ||||

|---|---|---|---|---|---|---|

| P1 | P1 + P2 | P1 + P2 + P3 | P1 | P1 + P2 | P1 + P2 + P3 | |

| 0.2 | 49.1% | 72% | 100% | 53.2% | 76.7% | 100% |

| 0.4 | 97.5% | 84.3% | 100% | 95.1% | 79.2% | 100% |

| 0.6 | 100% | 63.7% | 65.9% | 100% | 65% | 69.2% |

| 0.8 | 100% | 55.9% | 52.2% | 100% | 57.9% | 54% |

| 1 | 100% | 51.9% | 45.1% | 100% | 55% | 47.4% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baranidharan, M.; Singh, R.R. AI Energy Optimal Strategy on Variable Speed Drives for Multi-Parallel Aqua Pumping System. Energies 2022, 15, 4343. https://doi.org/10.3390/en15124343

Baranidharan M, Singh RR. AI Energy Optimal Strategy on Variable Speed Drives for Multi-Parallel Aqua Pumping System. Energies. 2022; 15(12):4343. https://doi.org/10.3390/en15124343

Chicago/Turabian StyleBaranidharan, Manickavel, and Rassiah Raja Singh. 2022. "AI Energy Optimal Strategy on Variable Speed Drives for Multi-Parallel Aqua Pumping System" Energies 15, no. 12: 4343. https://doi.org/10.3390/en15124343

APA StyleBaranidharan, M., & Singh, R. R. (2022). AI Energy Optimal Strategy on Variable Speed Drives for Multi-Parallel Aqua Pumping System. Energies, 15(12), 4343. https://doi.org/10.3390/en15124343