Controlling the Hydro-Swelling of Smectite Clay Minerals by Fe(III) Reducing Bacteria for Enhanced Oil Recovery from Low-Permeability Reservoirs

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of the Synthetic Cores

2.2. Preparation of the Flooding Fluids

2.3. Inhibiting and Reducing the Hydro-Swelling of Smectite Clay Minerals

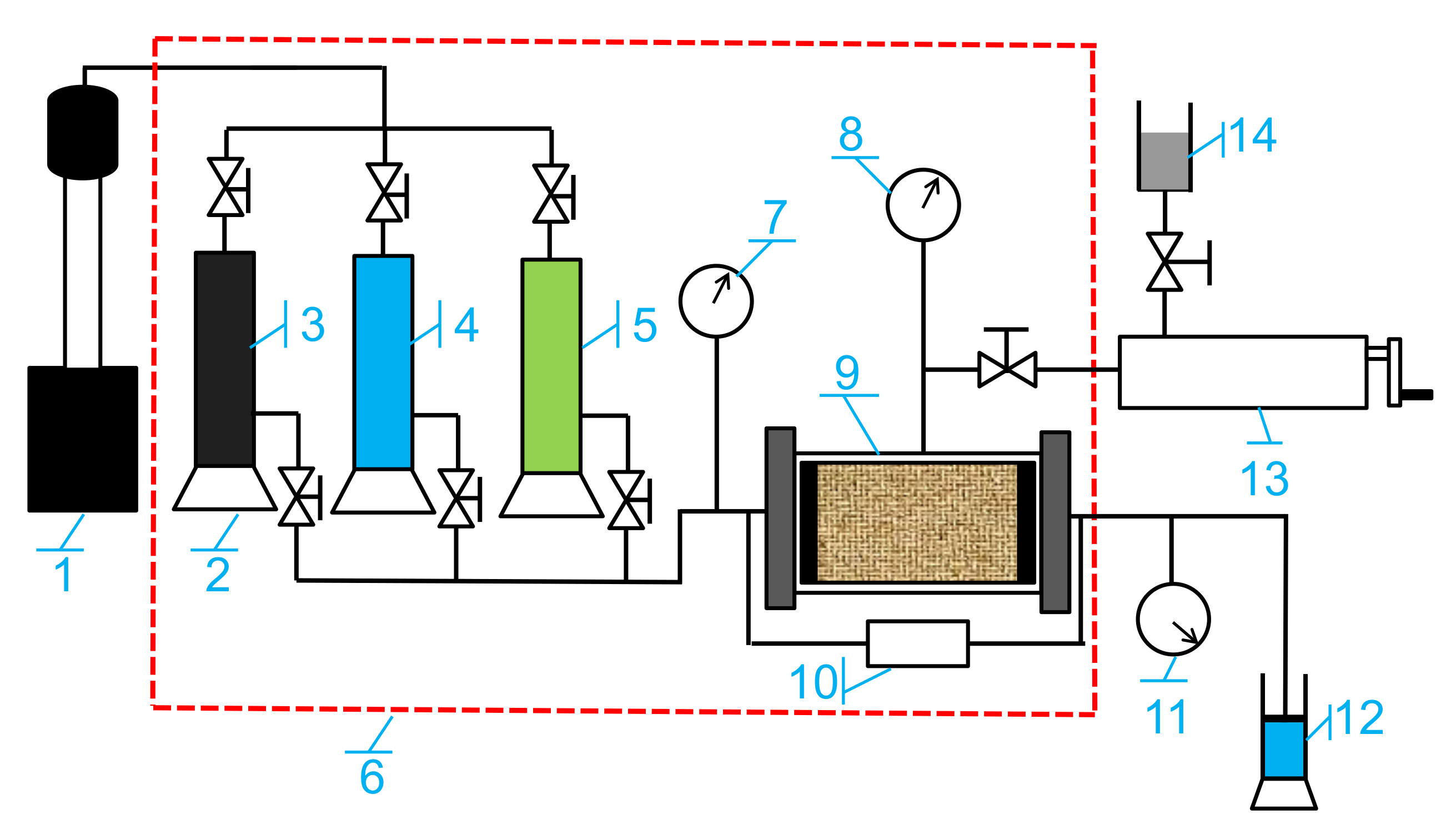

2.4. Core Displacement Tests to Evaluate the EOR

2.5. Analysis of Core Characteristic Parameters after Displacement Tests

3. Results

3.1. The Impact of FeRM on the Hydro-Swelling Properties of Core Plugs

3.2. The Impact of Temperature and Pressure on the Hydro-Swelling Reduction by FeRM

3.3. Evaluation of FeRM-EOR

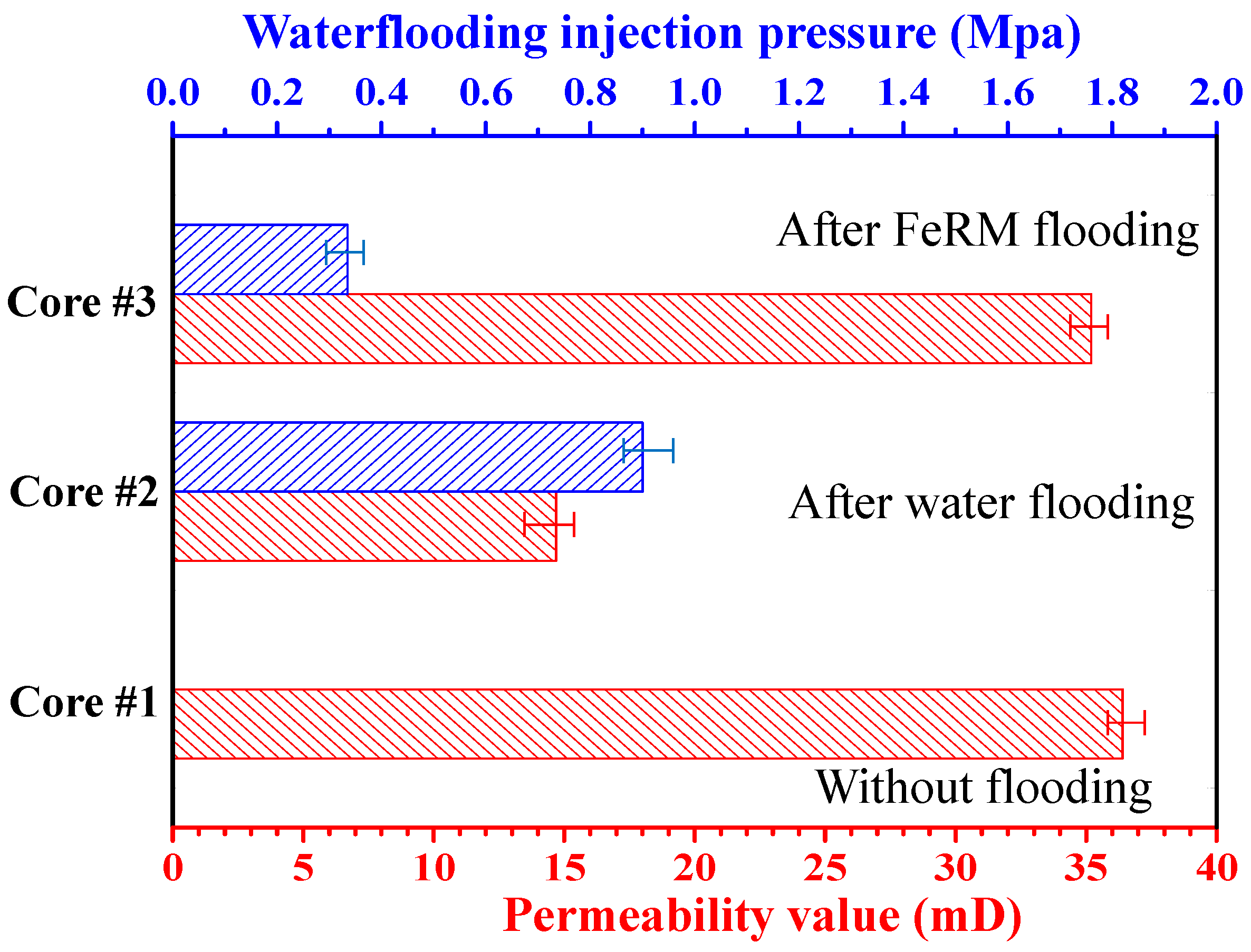

3.4. Changes in Permeability and Waterflooding Injection Pressure

3.5. Changes in Distribution and Structure of Core Pore-Throats

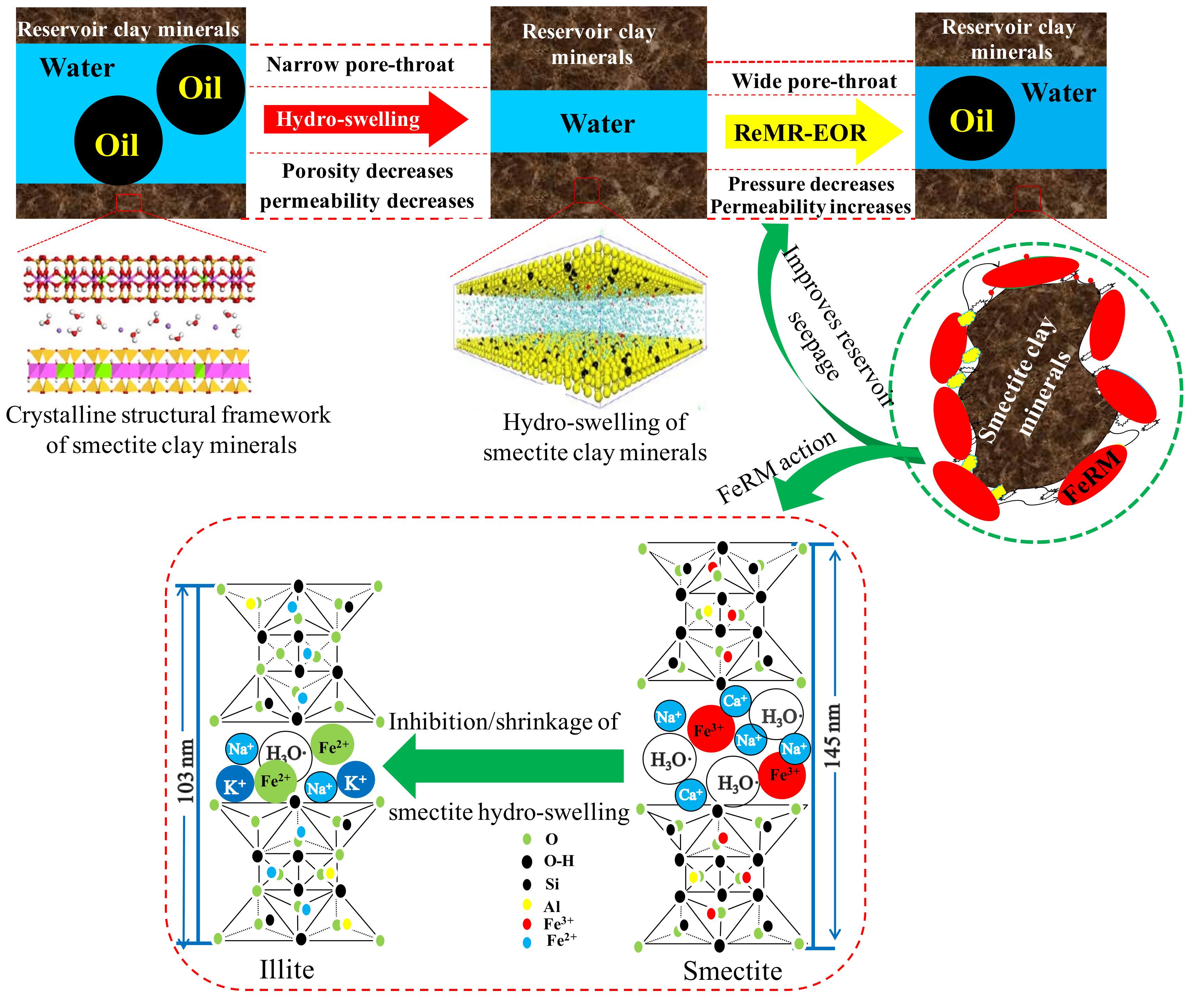

3.6. The Proposed Mechanism of FeRM-EOR

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Su, A.; Chen, H.H.; He, C. The characteristics of low permeability reservoirs, gas origin, generation, and charge in the central and western Xihu depression, East China Sea Basin. J. Nat. Gas Sci. Eng. 2018, 53, 94–109. [Google Scholar] [CrossRef]

- Dong, X.H.; Liu, H.Q.; Chen, Z.X.; Wu, K.; Lu, N.; Zhang, Q. Enhanced oil recovery techniques for heavy oil and oil sands reservoirs after steam injection. Appl. Energy 2019, 239, 1190–1211. [Google Scholar] [CrossRef]

- Chafale, A.; Kapley, A. Biosurfactants as microbial bioactive compounds in microbial enhanced oil recovery. J. Biotechnol. 2022, 352, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Baesso, R.C.; da Costa, A.C.A.; Lutterbach, M.T.S.; do Rosário, F.F. Biodegradability assessment of scale inhibitors from oil industry. Pet. Sci. Technol. 2022, 175, 1–15. [Google Scholar] [CrossRef]

- Khormali, A.; Petrakov, D.G.; Farmanzade, A.R. Prediction and inhibition of inorganic salt formation under static and dynamic conditions–Effect of pressure, temperature, and mixing ratio. Int. J. Technol. 2016, 7, 943–951. [Google Scholar] [CrossRef]

- Abbasi, S.; Khamehchi, E. Investigation of permeability decline due to coupled precipitation/dissolution mechanism in carbonate rocks during low salinity co-water injection. Energy. Rep. 2021, 7, 125–135. [Google Scholar] [CrossRef]

- Yuan, Z.; Liao, X.W.; Zhang, K.; Zhao, X.; Chen, Z. The effect of inorganic salt precipitation on oil recovery during CO2 flooding: A case study of Chang 8 block in Changqing oilfield, NW China. Pet. Explor. Dev. 2021, 48, 442–449. [Google Scholar] [CrossRef]

- Jiu, B.; Huang, W.H.; Li, Y.; He, M.Q. Influence of clay minerals and cementation on pore throat of tight sandstone gas reservoir in the eastern Ordos Basin, China. J. Nat. Gas Sci. Eng. 2021, 87, 103762. [Google Scholar] [CrossRef]

- Bavoh, C.B.; Ofei, T.N.; Lal, B.; Sharif, A.M.; Shahpin, M.H.B. Assessing the impact of an ionic liquid on NaCl/KCl/polymer water-based mud (WBM) for drilling gas hydrate-bearing sediments. J. Mol. Liq. 2019, 294, 111643. [Google Scholar] [CrossRef]

- Fu, L.P.; Liao, K.L.; Ge, J.J.; He, Y.F. Preparation and inhibition mechanism of bis-quaternary ammonium salt as shale inhibitor used in shale hydrocarbon production. J. Mol. Liq. 2020, 309, 113244. [Google Scholar] [CrossRef]

- Saleh, T.A.; Rana, A. Surface-modified biopolymer as an environment-friendly shale inhibitor and swelling control agent. J. Mol. Liq. 2021, 14, 117275. [Google Scholar] [CrossRef]

- Salles, F.; Douillard, J.M.; Bildstein, O.; Gaudin, C.; Prelot, B. Driving force for the hydration of the swelling clays: Case of montmorillonites saturated with alkaline-earth cations. J. Colloid Interface Sci. 2013, 395, 269–276. [Google Scholar] [CrossRef]

- Aghdam, S.K.; Aghdam, A.; Ahmadi, M. A laboratory study of a novel bio-based nonionic surfactant to mitigate clay swelling. Petroleum 2021, 7, 178–187. [Google Scholar] [CrossRef]

- Zhan, Y.W.; Fu, W.J.; Xing, Y.C.; Ma, X.; Chen, C. Advances in versatile anti-swelling polymer hydrogels. Mater. Sci. Eng. 2021, 127, 112208. [Google Scholar] [CrossRef]

- Chuprakov, D.; Bekerov, I.; Iuldasheva, A. Productivity of hydraulic fractures with heterogeneous proppant placement and acid-0etched walls. Appl. Eng. Sci. 2020, 3, 100018. [Google Scholar]

- Becattini, V.; Motmans, Z.; Madonna, C.; Haselbacher, A.; Steinfeld, A. Experimental investigation of the thermal and mechanical stability of rocks for high-temperature thermal-energy storage. Appl. Energy 2017, 230, 373–389. [Google Scholar] [CrossRef]

- Blanc, P.; Gherardi, F.; Marty, N.C.M.; Gailhanou, H.; Gaboreau, S.; Letat, B.; Geloni, C.; Gaucher, E.C.; Made, B. Thermodynamics for clay minerals: Calculation tools and application to the case of illite/smectite interstratified minerals. Appl. Geochem. 2021, 130, 104986. [Google Scholar] [CrossRef]

- Gaol, C.L.; Ganzer, L.; Mukherjee, S.; Alkan, H. Parameters govern microbial enhanced oil recovery (MEOR) performance in real-structure micromodels. J. Pet. Sci. Eng. 2021, 205, 108814. [Google Scholar] [CrossRef]

- Neshatian, M.; Holcroft, J.; Kishen, A.; Souza, G.D.; Ganss, B. Promoting mineralization at biological interfaces Ex vivo with novel amelotin-based bio-nano complexes. Mater. Today Bio 2022, 14, 100255. [Google Scholar] [CrossRef]

- Cui, K.; Sun, S.S.; Xiao, M.; Liu, T.; Xu, Q.; Dong, H.; Wang, D.; Gong, Y.; Hou, J.; Zhang, Z.Z.; et al. Microbial mineralization of montmorillonite in low permeability oil reservoirs for microbial enhanced oil recovery. Appl. Environ. Microbiol. 2018, 84, e00176. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Dong, H.L.; Seabaugh, J.; Newell, S.W.; Eberl, D.D. Role of microbes in the smectite-to-illite reaction. Science 2004, 303, 830–832. [Google Scholar] [CrossRef] [Green Version]

- Cai, Y.D.; Li, Q.; Liu, D.M.; Zhou, Y.; Lv, D. Insights into matrix compressibility of coals by mercury intrusion porosimetry and N2 adsorption. Int. J. Coal Geol. 2018, 200, 199–212. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.Y.; An, X.B.; Wang, J.; Fan, J.M.; Kang, X.; Tan, X.; Li, W. A quantitative evaluation for well pattern adaptability in ultra-low permeability oil reservoirs: A case study of Triassic Chang 6 and Chang 8 reservoirs in Ordos Basinl. Pet. Explor. Dev. 2018, 45, 499–506. [Google Scholar] [CrossRef]

- Omidpour, A.; Mahboubi, A.; Moussavi-Harami, R.; Rahimpour-Bonab, H. Effects of dolomitization on porosity-Permeability distribution in depositional sequences and its effects on reservoir quality, a case from Asmari Formation, SW Iran. J. Pet. Sci. Eng. 2022, 208, 109348. [Google Scholar] [CrossRef]

- Xiao, M.; Zhang, Z.Z.; Wang, J.X.; Zhang, G.Q.; Luo, Y.J.; Song, Z.Z.; Zhang, J.Y. Bacterial community diversity in a low-permeability oil reservoir and its potential for enhancing oil recovery. Bioresource Technol. 2013, 147, 110–116. [Google Scholar] [CrossRef]

- Fayoyiwa, A.D.; Hirvi, J.T.; Pakkanen, T.A. Roles of alkaline-earth cation species in the swelling pressure of smectites-A computational study. Chem. Phys. Lett. 2020, 735, 137602. [Google Scholar] [CrossRef]

- Pentráková, L.; Su, K.; Pentrak, M.; Stuck, J.W. A review of microbial redox interactions with structural Fe in clay minerals. Clay Miner. 2013, 48, 543–560. [Google Scholar] [CrossRef]

- Liu, D.; Wang, F.P.; Dong, H.L.; Wang, H.; Zhao, L.; Huang, L.; Wu, L. Biological reduction of structural Fe(III) in smectites by a marine bacterium at 0.1 and 20 MPa. Chem. Geol. 2016, 438, 1–10. [Google Scholar] [CrossRef]

- Liu, D.; Dong, H.; Bishop, M.E.; Zhang, J.; Wang, J.; Xie, S.; Wang, S.; Huang, D.; Eberl, D.D. Microbial reduction of structural iron in interstratified illite-smectite minerals by a sulfate-reducing bacterium. Geobiology 2012, 10, 150–162. [Google Scholar] [CrossRef]

- Cui, K.; Zhang, Z.Y.; Zhang, Z.Z.; Sun, S.; Li, H.; Fu, P. Stimulation of indigenous microbes by optimizing the water cut in low permeability reservoirs for green and enhanced oil recovery. Sci. Rep. 2019, 9, 15772. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, H.; Sheng, G.L.; Li, H.A.; Xu, L.; Zhou, Y. A rapid waterflooding optimization method based on INSIM-FPT data-driven model and its application to three-dimensional reservoirs. Fuel 2021, 292, 120219. [Google Scholar] [CrossRef]

- Luo, L.; Cheng, S.Q. In-situ characterization of nonlinear flow behavior of fluid in ultra low permeability oil reservoirs. J. Pet. Sci. Eng. 2021, 203, 108573. [Google Scholar] [CrossRef]

- Li, G.L.; Zhou, C.H.; Fiore, S.; Yu, W.H. Interactions between microorganisms and clay minerals: New insights and broader applications. Appl. Clay Sci. 2019, 177, 91–113. [Google Scholar] [CrossRef]

- Deng, H.C.; Fu, M.Y.; Zhou, W.; Zhang, L.; Xie, X.; Li, Y.; Wang, D. The pores evolution of lacustrine shale induced by smectite-to-illite conversion and hydrocarbon generation: Upper Triassic Yanchang Formation, Ordos Basin, China. J. Pet. Sci. Eng. 2021, 202, 108460. [Google Scholar]

- Ghalamzan, F.; Rosa, J.D.; Gajo, A.; Maio, C.D. Swelling and swelling pressure of a clayey soil: Experimental data, model simulations and effects on slope stability. Eng. Geol. 2022, 297, 106512. [Google Scholar] [CrossRef]

- Rouquerol, J.; Avnir, D.; Fairbridge, C.W.; Everett, D.H.; Haynes, J.M.; Pernicone, N.; Ramsay, J.D.F.; Sing, K.S.W.; Unger, K.K. Recommendations for the characterization of porous solids. Appl. Chem. 1994, 66, 1739–1758. [Google Scholar] [CrossRef]

- Fernandez, A.T.; Orlandi, S.; Codevilla, M.; Teresa, M.; Piqué, T.; Manzanal, D. Performance of calcium lignosulfonate as a stabiliser of highly expansive clay. Transp. Geotech. 2021, 27, 100469. [Google Scholar] [CrossRef]

- Idiart, A.; Laviña, M.; Cochepin, B.; Pasteau, A. Hydro-chemo-mechanical modeling of long-term evolution of bentonite swelling. Appl. Clay Sci. 2021, 195, 10717. [Google Scholar]

- Kyokawa, H. A double structure model for hydro-mechano-chemical behavior of expansive soils based on the surface phenomena of mineral crystals. Eng. Geol. 2021, 299, 106366. [Google Scholar] [CrossRef]

- Eghbalian, M.; Wa, R.; Pouragha, M. Multi-scale description of hydro-mechanical coupling in swelling clays. Part II: Poroplasticity. Mech. Mater. 2022, 171, 104357. [Google Scholar] [CrossRef]

| Core Number | Diameter (cm) | Length (cm) | Pore Quality (g) | Porosity (%) | Gas Permeability (mD) | Water Permeability (mD) | Smectite Clay Mineral Content (%) |

|---|---|---|---|---|---|---|---|

| #1 | 2.50 | 9.65 | 1.664 | 8.47 | 37.65 | 2.51 | 7–8 |

| #2 | 2.50 | 9.65 | 1.617 | 8.43 | 35.65 | 2.38 | 7–8 |

| #3 | 2.50 | 9.65 | 1.638 | 8.45 | 36.65 | 2.43 | 7–8 |

| Core Number | Pretreatment | Displacement Tests | Objectives |

|---|---|---|---|

| #1 | Without treatment | Without flooding | Blank control |

| #2 | Hydration + crude oil | Waterflooding (without FeRM) | Experimental control |

| #3 | Hydration + crude oil | Microbial flooding (5% FeRM) | To investigate the inhibition/shrinkage effects of FeRM |

| Core Number | Pore-Throat Coefficient | Structure Coefficient | Pore-Throat Sorting Coefficient | Average Pore-Throat Radius | Pore-Throat Radius <0.01 μm, % | Pore-Throat Radius 0.01–0.05 μm, % |

|---|---|---|---|---|---|---|

| #1 | 6.28 | 3.67 | 1.32 | 12.853 | 40.88 | 44.50 |

| #2 | 5.82 | 2.55 | 1.76 | 9.113 | 49.95 | 37.98 |

| #3 | 6.49 | 4.55 | 1.38 | 11.965 | 44.15 | 42.48 |

| Pore-Throat Radius >0.05 μm, % | Capillary Pressure (10%), Mpa | Capillary Pressure (30%), Mpa | Capillary Pressure (50%), Mpa | Pore-Throat Radius (10%), μm | Pore-Throat Radius (30%), μm | Pore-Throat Radius (50%), μm |

| 14.62 | 0.034 | 0.052 | 0.069 | 22.321 | 14.059 | 10.119 |

| 12.07 | 0.041 | 0.056 | 0.087 | 20.327 | 13.066 | 8.466 |

| 13.57 | 0.032 | 0.047 | 0.063 | 22.942 | 15.831 | 11.611 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, K.; Wang, C.; Li, L.; Zou, J.; Huang, W.; Zhang, Z.; Wang, H.; Guo, K. Controlling the Hydro-Swelling of Smectite Clay Minerals by Fe(III) Reducing Bacteria for Enhanced Oil Recovery from Low-Permeability Reservoirs. Energies 2022, 15, 4393. https://doi.org/10.3390/en15124393

Cui K, Wang C, Li L, Zou J, Huang W, Zhang Z, Wang H, Guo K. Controlling the Hydro-Swelling of Smectite Clay Minerals by Fe(III) Reducing Bacteria for Enhanced Oil Recovery from Low-Permeability Reservoirs. Energies. 2022; 15(12):4393. https://doi.org/10.3390/en15124393

Chicago/Turabian StyleCui, Kai, Chengjun Wang, Li Li, Jungang Zou, Weihong Huang, Zhongzhi Zhang, Heming Wang, and Kun Guo. 2022. "Controlling the Hydro-Swelling of Smectite Clay Minerals by Fe(III) Reducing Bacteria for Enhanced Oil Recovery from Low-Permeability Reservoirs" Energies 15, no. 12: 4393. https://doi.org/10.3390/en15124393