2. System Synthesis

In this work, the terminology commonly used for systems engineering is applied [

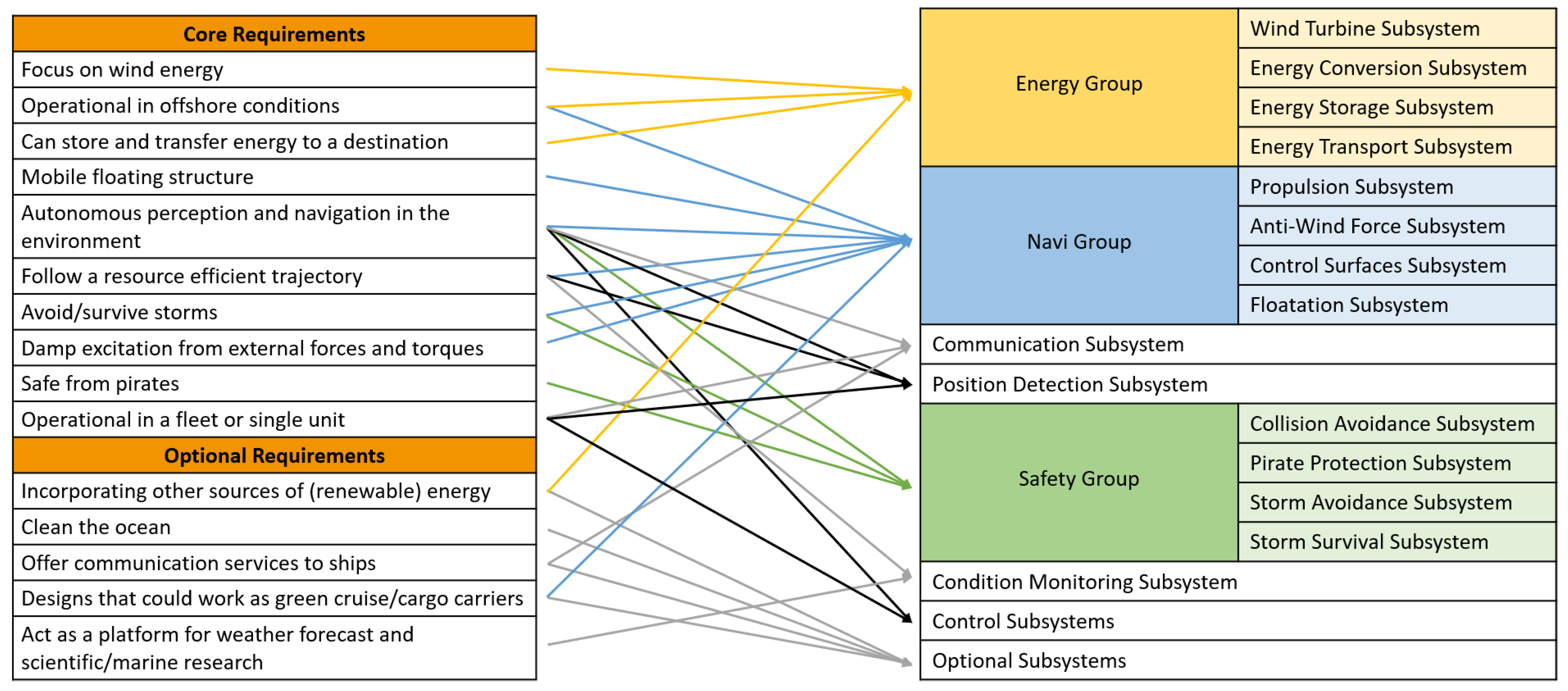

14]. The SailREC System is conceptualised by first revealing the requirements of a floating energy harvesting system. These requirements are then classified as core, optional, and generic requirements. The complete list of requirements is tabulated in

Appendix A. Then, the requirements are used to define the subsystems that would be required to fulfill them.

Figure 4 shows the requirements and the subsystems that are identified. The subsystems are described in more detail in the following.

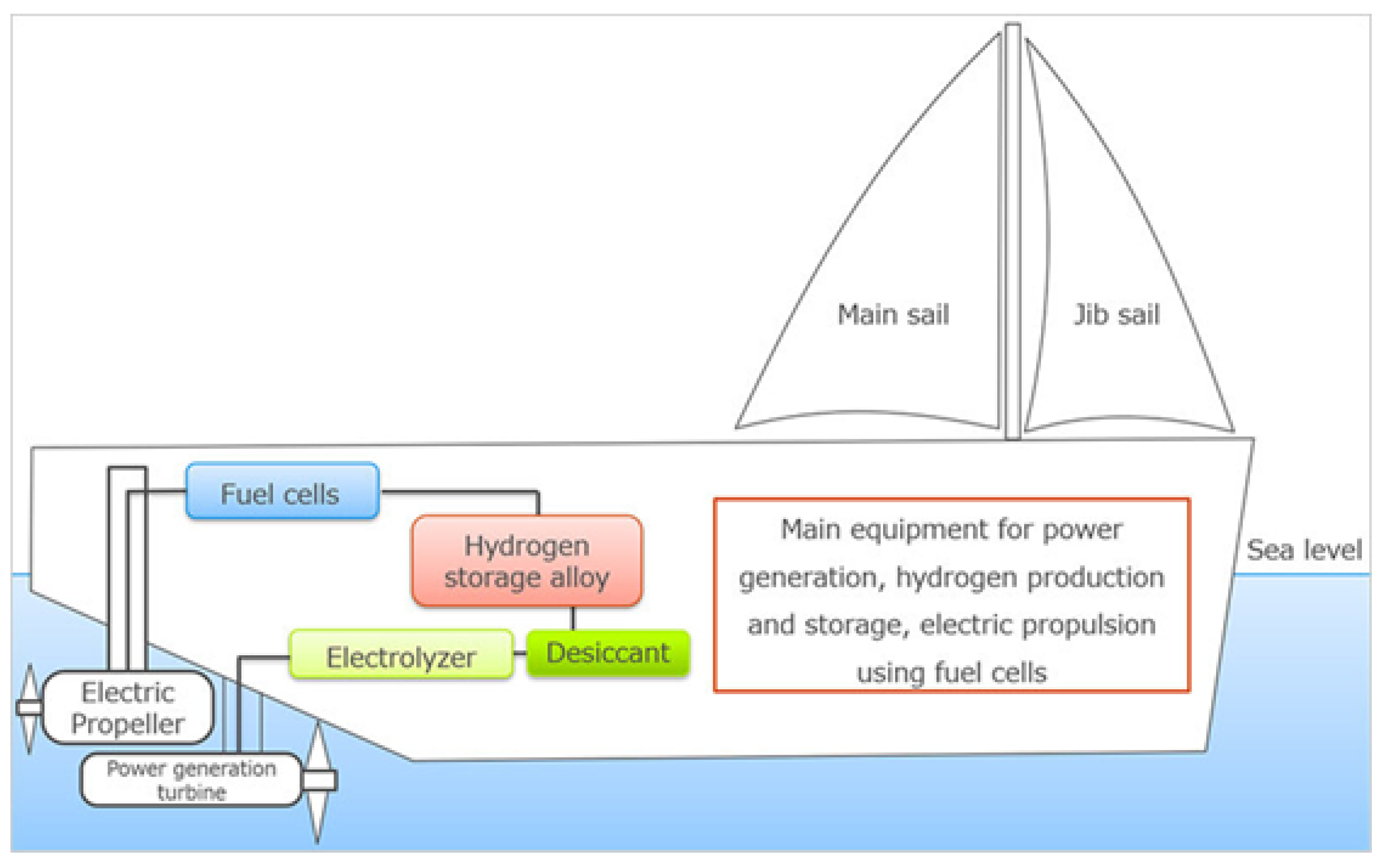

2.1. Energy Group

The Energy Group is comprised of subsystems which are part of the generation of energy as well as conversion, storage, and transport thereof.

The Wind Turbine Subsystem is the primary source of energy for a SailREC System as considered in this study. Due to the specific application of the wind turbine on a floating and moving SailREC System without any grid connection, the operational strategies and wind turbine control need to be adjusted.

The electricity generated by the Wind Turbine Subsystem and all other energy plants implemented on a SailREC System is converted by the

Energy Conversion Subsystem into renewable fuel. All components necessary for chemical energy conversion, such as electrolysers, storage of chemical precursors, and chemical reactors, belong to this subsystem. The conversion and storage of energy are further elaborated on in

Section 3.

The storage of the produced renewable fuel is taken over by the Energy Storage Subsystem.

All the hardware and software necessary to transfer the captured energy to a desired place (e.g., a port or a floating fuel station for ships) belongs to the Energy Transport Subsystem. There are many implementation options for this. In the case that a SailREC System travels on its own to a port to transfer the produced fuel, the Energy Transport Subsystem will likely consist of software for the most part. If, on the other hand, a tanker docks in the open ocean on to the SailREC System to pick up fuel, the tanker belongs to the subsystem.

2.2. Navi Group

The Navi Group is the set of subsystems necessary for making the SailREC System navigable and controllable and to keep it in a stable state of motion in all degrees of freedom.

All the components needed to accelerate the SailREC System in the water make up the Propulsion Subsystem. This facilitates location change, course correction during operation, avoidance of collisions with other vessels, staying away from the coast during storms, and more. It is not a requirement for the Propulsion Subsystem to have both Active and Passive Propulsion Components, however, it can be an advantage. Active Propulsion Components generate a force by themselves and not through an external potential. Their operation would necessitate the use of a power source, which could be stored renewable fuel or electric power. Passive Propulsion Components, on the other hand, generate a force through an external potential applied to the SailREC System. This could be a sail or a Flettner rotor. The Wind Turbine Subsystem itself creates a high thrust force and, hence, can also be used as a Passive Propulsion Component.

Movement of the SailREC System in wind direction decreases the resultant wind velocity on the wind turbine, which results in reduced power output. Thus, the Anti-Wind Force Subsystem compensates or reduces any force that is acting downwind on the system. Not all potential solutions are able to compensate for the wind turbine thrust, but only reduce it. While a water parachute could reduce the thrust, a keel may be able to completely compensate for the thrust in wind direction if the SailREC System would sail perpendicularly to the wind, similarly to a sailing ship.

The Control Surfaces Subsystem comprises surfaces that have fluid flowing over them. These are movable to control the state of motion by changing the angle of attack. The SailREC System can not only have control surfaces in the water but as well in the air. A control surface that likely needs to be implemented is a rudder. How many and which control surfaces will be used depends on the overall design of the SailREC System.

The Floatation Subsystem must be able to withstand the loads to which the SailREC System is subjected at sea, e.g., waves, currents, and overturning moments of the wind turbine. This is realised by the following components: The Buoyancy Component, which could simply be a ship hull, generates buoyancy for the whole system and, hence, compensates for the gravitational force. The Counter Torque Component compensates for torques, such as the torque generated by the thrust on the wind turbine and tower, or the torque applied to the rotor axis of the wind turbine. The Damping Component dampens the SailREC System’s angular oscillations and ensures a stable frequency response to external excitation, bringing the system back to an equilibrium state.

2.3. Communication Subsystem

A Communication Subsystem will be needed for the communication of the SailREC System with other interfaces, e.g., a control centre onshore, other SailREC Systems, ships, or vessels in the vicinity. The Communication Subsystem will be used for the transmission of telemetry data, which will include the sensor and condition monitoring data and can also include scientific data. The Communication Subsystem will be required to receive control commands from an external, onshore control centre. There is also the possibility of using the same transponders to act as an alternate network at sea for ship communication.

The hardware is mainly expected to comprise satellite communication and very high-frequency radio links. A combination of a low-cost and high-capacity, very small aperture service for use in most cases and an alternative service in the L-band can be an option. To ensure that the connection to shore is reliable, two independent communication channels with different systems and frequencies can be used. The end-to-end communication would need to be encrypted so as to protect it from access and threats arising from hostile parties [

15,

16].

2.4. Position Detection Subsystem

A Position Detection Subsystem is required for a SailREC System to localise itself, primarily for the safety of its own and other vessels. The subsystem will assist on a local level in detecting nearby or approaching vessels and on a global level in tracking them in the high seas. Thus, the Position Detection Subsystem plays a crucial part in making the SailREC System follow the desired trajectory. The positional information is also required for enabling the transfer of fuel in the case of a tanker docking to the SailREC System, or also making the decision of docking to a port if the system is navigating to one.

2.5. Safety Group

The high seas are territories where the deployment of any assets of value will need to be guarded from physical damage due to harsh conditions and theft.

The Collision Avoidance Subsystem is responsible for avoiding collisions with other vessels or other obstacles, such as sea banks. This would involve the use of both Communication and Position Detection Subsystems to detect its own and the positions of vessels in the vicinity, then communicate the expected path with others, involve the control centre if required, and also adapt the course to achieve a margin of safety from collision.

As a SailREC System has resources of value, including fuel or stored energy, machinery, and the material used for construction, it must be protected from theft by using a Pirate Protection Subsystem. Since the SailREC System is envisioned as autonomous, the possible solutions are a design that is hard to access by other parties and steal from, as well as a strategic deployment in areas of operation where hostile activity might be avoided.

The Storm Avoidance Subsystem is responsible for adapting the course of the SailREC System in such a way to avoid storms and other extreme environmental conditions. This subsystem also decides whether an expected storm is too dangerous and should be avoided or passed through. For this task, position data, global weather data, and data from other systems of its kind will likely be used.

The Storm Survival Subsystem is responsible for increasing the chance of survival if an environmental risk factor was underestimated by the Storm Avoidance Subsystem or to improve the stability if areas of extreme environmental conditions need to be passed through. Possible mechanisms may include floodable sections, increasing the draught of the system to reduce the centre of gravity, etc.

2.6. Condition Monitoring Subsystem

There must be sensors used along the SailREC System to track the health of critical subsystems. This can be monitored for safe operation and predictive maintenance of the system. The data acquired by the Condition Monitoring Subsystem is sent out to the control centre through the Communication Subsystem. The SailREC System could also have on-board sensors to monitor the weather, which can be used for trajectory planning, apart from using these data for research and science.

2.7. Control Subsystems

The Central Control Subsystem is the main decision unit of a SailREC System and ensures an autonomous fail-safe operation. The task of this subsystem is to coordinate the work and requirements of all subsystems with a focus on controlling the course of the system to maximise energy yield. It should also be able to keep the SailREC System in safe operation when possible subsystem failures occur.

There will be a need for a control centre onshore for the monitoring and operation of fleets of SailREC Systems. The facility will keep track of and set trajectories for the fleets based on global weather data and will have the ability to take over control from autonomous mode if required. The control centre will also communicate with ships making distress calls when they radio a SailREC System.

2.8. Optional Subsystems

The subsystems described next are optional and are not required for a SailREC System to work. Some of them might have a positive impact on the energy yield or lead to additional revenue.

An Ocean Cleanup Subsystem installed on the SailREC System can be used to clean oceans of floating plastics. A collection mechanism that does not require the use of any power would be ideal. The collected plastic can also be transferred to shore when fuel is transferred. Furthermore, to collect plastics, the subsystem can—depending on the design—increase the hydrodynamic drag in the wind direction, thereby acting as an Anti-Wind Force Subsystem. This would facilitate increased power production by the wind turbine.

The incorporation of additional energy sources, such as solar, wave, or even ocean thermal energy conversion, can be thought of. While such additional subsystems, falling into the Energy Group, will increase the energy output of the SailREC System, their utilisation might not result in a lower cost per unit of energy due to more costly and complex construction and design.

The SailREC System can also transport cargo during its usual operation. The optimal path for maximum energy yield may coincide in part with trading routes. So the transportation of cargo could bring additional revenue. Furthermore, as the mass of the whole system increases, the inertia is increased as well, which can lead to lower drift velocities and, thus, a higher effective wind speed at the wind turbine and, in turn, more generated power.

Just as with cargo, the concept can be extended to include the transport of people with a passenger module. Additional safety features might be required in this case.

An aquafarm incorporated into the SailREC System can also be used for carbon capture and to generate additional resources. The carbon capture can be performed by feeding farmed algae to a pyrolysis reactor.

3. Evaluation of the Energy Conversion Subsystem and Energy Storage Subsystem

In a SailREC System, the energy harvested needs to be converted and stored in chemical form. In

Section 3.1, the conversion of renewable power to hydrogen (liquid and gaseous), ammonia, and methanol are discussed as well as the state-of-the-art thereof.—Another option that could be of interest is methane, which, however, is omitted from the analysis. The reason for this decision is the advantages of methanol over methane, such as higher efficiency, lower cost of transportation, and higher volumetric energy density, even though the production costs of both are similar [

17].—A primary analysis using a trade study is performed for the choice of the fuel to store the energy (

Section 3.2).

3.1. Conversion Process

The starting step of all electric Power to X (P2X) conversion processes investigated is the generation of hydrogen, which is obtained by means of electrolysis of water (

Section 3.1.1). Then storage takes place either as hydrogen (liquid or gaseous) (

Section 3.1.2), or further conversion to ammonia (

Section 3.1.3) or methanol (

Section 3.1.4) using the Haber–Bosch process and methanol synthesis, respectively.—Hydrogen storage via physisorption, metal hydrides, and organic liquids containing molecules capable of reversibly releasing it are not investigated [

18].—A point to focus on would be that the processes of conversion to ammonia and methanol are assumed to be seaworthy and remotely operable on a small scale. This scale of production is not usually seen in plants that produce these fuels commercially.

3.1.1. Electrolysis

The SailREC System, as envisioned in this study, has seawater as a primary source of water. Since direct seawater electrolysis is not established yet, conventional polymer electrolyte membrane (PEM) or alkaline electrolysis of seawater might be performed after purification steps [

19]. Solid oxide electrolysers are still in the research and development phase in terms of technological maturity, apart from having the challenges of thermal cycling, chrome migration, and corrosion while offering higher electrical efficiency. Likewise, direct seawater electrolysis faces the challenge of designing selective electrodes that suppress chloride chemistry [

20]. The use of PEM electrolysers is foreseen, as they have a faster response to supply changes, higher power density, and less maintenance compared to alkaline electrolysers, though PEM electrolysers have a higher cost in the application. The electrolysers would be fed by purified water. The by-product of the purification of seawater is brine. This would have to be disposed of, and unlike in coastal waters, discharge in the high seas is not expected to have a negative impact on the environment, but further inspection of this and the legal regulations would be required.

3.1.2. Hydrogen

Hydrogen (H

2) is a clean energy carrier, has a high gravimetric energy density, and can be used in fuel cells and combustion engines to get back energy, where the former has higher efficiency than the latter but does not reach the efficiency of batteries. The challenges in hydrogen-based storage are that it is expensive and the fact that it is the least dense element, which creates the need for either compression or liquefaction owing to volumetric constraints. Storage of hydrogen as a high-pressure gas (H

2(g)) requires the use of composite materials for the vessel, whereas the liquefaction process for obtaining liquid hydrogen (H

2(l)) is energy-intensive [

21].

3.1.3. Ammonia

Ammonia (NH

3) is also a clean energy carrier in the sense that it does not release carbon dioxide at the point of use as an energy source. It can be used to generate energy with conventional technologies with modifications (e.g., ammonia can be reformed to yield hydrogen and nitrogen, which can be used in internal combustion engines [

22], gas turbines, and alkaline fuel cells without further purification [

23]). It has half the energy density of gasoline and is easier to store than liquid or gaseous hydrogen. Although toxic and corrosive, the transmission and storage technologies are mature. The Haber–Bosch process is considered for synthesis, and the nitrogen (N

2) needed for this can be separated from air using pressure swing absorption (PSA). The process of electrochemical synthesis of ammonia is not explored since the yield rates and efficiencies are still low and below commercially viable levels. Furthermore, the Haber–Bosch process is not flexible—it is optimised for continuous operation. If the process is run at uneven intervals, there are risks of lower catalyst and equipment lifetime due to thermal cycling and reduced production efficiency. A hydrogen and nitrogen buffer would be required in the SailREC System to take care of renewable energy intermittency. Another approach might be to make the process vary its output just as with energy by plant design and operation techniques. This capability to turn down could be a better solution if possible [

23,

24,

25,

26].

3.1.4. Methanol

Methanol (CH

3OH) is another option as an energy carrier. It is liquid at room temperature and has advantages due to its compatibility with existing infrastructure—including tanks, pipelines, and fuelling stations—as well as its suitability for application in combustion engines [

27]. The carbon dioxide (CO

2) for the production of methanol can be sourced from carbon capture from processes releasing it, such as cement manufacturing, steel-making, or biomass and power plants, or even obtained through direct air capture (DAC), which can be either onshore or locally at the SailREC System (there are containerised solutions available for DAC, which might be well suited for application in the SailREC System [

28]). For nitrogen, separation from air is competitively easier than for carbon dioxide due to the higher concentration of the former in the atmosphere (78% for N

2, <0.5% for CO

2). DAC of carbon dioxide is still under development and is not competitive enough with flue gas capture on a commercial level [

29]. If DAC at the SailREC System is not used, then the transport of carbon dioxide to the system and its storage will need to be addressed. The conversion reaction is not flexible enough to account for the power intermittency and it follows that buffers for the feed-stocks will be required just as in the case of the Haber–Bosch process for ammonia.

3.2. Trade Study

A trade study is conducted because the choice of the fuel to use as energy storage is highly complex. To do so, an abstract representation of the system and underlying processes is made (cf.

Appendix B for more details). The steps included are the harvesting of energy by a wind turbine, required conversions to chemical sources, storage on the SailREC System, followed by transport, and the final use of the energy in the form of heat and electricity. Similar chains of production, transport, and use of the different fuels are followed to make comparisons between the options possible. The flow chart for liquid hydrogen is presented in

Figure 5. The hydrogen gas generated after electrolysis is liquefied and stored as a liquid on-board in Dewar tanks (cf.

Appendix B.1 for further details on the storage tank) at 20.68 K (i.e., −252.47 °C) at a pressure of 4 bar. The liquefier consumes 10 kWh for the liquefaction of 1 kg of hydrogen. Thus, the efficiency of the block is calculated as 70%. The flow charts for gaseous hydrogen, ammonia, and methanol can be found in the

Appendix B.2. Overall, the trade study is conducted for a specific use case, as summarised in

Table A2 in the

Appendix B.3.

The trade parameters used in the trade study, along with their values and weights (considering a range of 1–10), are listed in

Table 1. As technology in the energy sector is very cost-driven, the trade parameter levelised cost of energy (LCOE) is given the highest weight of 10. Having the main motivation of a SailREC System of delivering clean energy in mind, 7 is assigned as the weight for the trade parameter on environmental friendliness. Another trade parameter is the partial load capability, which is the ability to produce fuel with interruptions in input power. Fuels requiring chemical reactors and intermediate steps would be at a disadvantage in this assessment. The weight for the partial load capability is set higher than the remaining ones because power harvested in a SailREC System could be subject to periodic stopping. Considering the fact that the weight of the fuel itself and its storage containment needs to be carried by the SailREC System, the trade parameter displaced water volume—referring solely to the specific fuel and storage tank (in future studies, the weight of the production facilities, auxiliary systems, etc. of the fuel can also be taken into account)—is defined, since fuel which requires more displaced water volume may also require a more challenging design of the entire SailREC System. Further trade parameters are the technology readiness level (TRL) of the systems finding use in the Energy Conversion and Storage Subsystems as well as the safety of maintenance personnel. Finally, the transport infrastructure readiness level in 2032 is thought of as a measure of the maturity of infrastructure ten years from now, for transporting the fuel through pipelines, rail tracks, etc., and connecting ports (where SailREC Systems would offload) with points of use inland.

Only for the trade parameters LCOE and displaced water volume are values calculated (cf.

Appendix B.1 for further details on the calculation of LCOE), which, however, are not intended to represent exact values but rather serve as indicative measures that can be used for comparison within the trade study. For the remaining trade parameters, the values are quantified by ranking. This is achieved by distributing the values from 1 to 4, with 1 representing the worst-scoring fuel and 4 the best-scoring one. This ranking is based on literature research and discussions with, among others, experts from the Department Hydrogen Labs and Field Tests of the Fraunhofer Institute for Wind Energy Systems IWES. For the evaluation of the trade study, the values are normalised for each trade parameter. Subsequently, the normalised values are multiplied by their respective weights. Finally, the sum of all weighted values across the parameters reflects the score for each fuel. Upon this, the best ranked fuel option turns out to be liquid hydrogen, followed by gaseous hydrogen, methanol, and then ammonia (cf.

Table 1).

The span of values in the scaled and weighted final score gives a picture of how each fuel will perform against the others according to the selected trade parameters. The values range from 18.04 for ammonia to 29.44 for liquid hydrogen. Furthermore, the values for liquid and gaseous hydrogen are close to each other at 29.44 and 27.27, respectively, which is also the case for ammonia (18.04) and methanol (20.14). Finally, it can be seen that the values of ammonia and methanol are just about two-thirds of the values for hydrogen (liquid and gaseous).

As mentioned earlier, it is very complex to decide which fuel is most suitable. The trade study provides a framework for making this decision, although the result may not be completely objective and unequivocal. In the following, some critical points of view and areas of improvement for the trade study are addressed. The fuel options explored sometimes have their own niche use cases (e.g., ammonia is used for the production of fertiliser); in the study, only the use of fuel for heat and electricity generation is taken into consideration. The fuel ending up with a lower score in this trade study might not make it a bad choice for it to be produced on a SailREC System if another application of the generated chemical is the aim. The projected future demand for each fuel, which is used not only for power generation but also as a feed stock for other chemicals and similar applications, could be explored in further studies. Furthermore, when referring to the trade parameter LCOE, it should be clear that a value for each fuel is calculated, which, however, does not correspond to the market price of the fuel. It is just an indicative value and, hence, all the CAPEX and OPEX are not meticulously charted but can still be used for comparison of fuels. The abstraction made in the flow charts is fundamental in nature; detailed design and modelling can be performed in further studies:

For example, in the abstract representation of the model, the process for desalination as well as PSA and DAC—in the case of ammonia and methanol, respectively (cf.

Appendix B.2)—are not taken into consideration;

Furthermore, the model can be adapted for a more detailed investigation of seaborne transport and the use of pipelines and railways for transportation on land instead of trucks;

The processes used (such as liquefier, Haber–Bosch process, etc.) are taken to be continuous processes and are assumed to be performed on the scale of the power rating of the SailREC System. From an engineering perspective, the processes could be considered batch processes. This is not modelled accordingly in the trade study. Considering buffer storage between processes and aptly power-rated processes would need further exploration.

Finally, the trade study is subjective in the choice of parameters, the weights assigned to those, and the varied assumptions used in the spreadsheet calculations (cf.

Appendix B.1). Under a different set of these, the ranking of fuels may vary. For reasons of simplicity, in this study, some of the assumptions are made to allow comparison of the different fuel options and might not represent the optimal design decision for each of them.

4. Investigations on the Propulsion Subsystem

The Propulsion Subsystem shall serve for navigation (e.g., for course correction, driving to a port, etc.) and stabilisation (i.e., to keep the SailREC System stable under dynamic forces, for example, under extreme weather conditions).

The overall stability of the SailREC System should be ensured using passive means, while powered propellers would provide support in the case of adverse conditions where a higher degree of precision and faster response time is essential. The requirements for the Propulsion Subsystem in terms of stabilisation may be similar to those for dynamic positioning (DP) [

30]. DP is used in drilling and oil and gas exploration vessels. For instance, when used in floating production storage and offloading vessels, which are usually moored, the DP system assists in position mooring when there are severe environmental conditions [

31]. This system relies heavily on the Control Subsystems and the Position Detection Subsystem to produce control outputs that actuate the propellers to maintain a specific position or heading.

The general navigation of the SailREC System to follow a trajectory should not happen by means of powered propellers. Some potential sailing strategies are described in

Section 5. Wind assisted propulsion, such as by wind sails or Flettner rotors, can also be used to manipulate the motion around a trajectory and at the same time reduce fuel consumption, as demonstrated in applications in container ships [

8]. The use of active propulsion should be kept to a minimum to reduce the energy required for navigation.

In the following, it is elaborated in more detail on propellers (

Section 4.1) and the prime mover (

Section 4.2).

4.1. Propeller

For the navigating procedures, screw-type propellers could be used. An exhaustive list of various propulsion systems can be found in the book by Carlton [

32].

For the stabilisation procedures, propellers typically applied in DP applications are foreseen to be used. These are mainly azipod or cycloidal propellers, as they have a high degree of manoeuvrability and shorter positioning times compared to other propellers. Thus, a probable Propulsion Subsystem solution for the SailREC System would be a combination of a screw propeller—as a main propeller for the navigation procedure—and multiple propellers, which might be combinations of azimuth mounted and cycloidal type propellers, for the stabilisation procedures. To decrease the overall cost of the subsystem, the design might settle on some simpler configurations. Further studies on the Control Subsystems and propeller configuration of the SailREC System would be required.

4.2. Prime Mover and Fuel

The mechanical means of powering the propulsion is provided broadly by two-stroke engines. These engines have higher efficiencies and can be coupled directly with the propellers when compared with four-stroke engines.—The four-stroke engines have higher power densities and lower height requirements, though they will need a reduction gear to reduce the high speed of rotation before coupling with the propeller [

33].—These engines mainly use diesel currently, but a development towards the use of alternative fuel is being made where propulsion powered by hydrogen, methanol, or ammonia is used. In a SailREC System, these are the very fuels that could be produced and would be used in the engines. With higher demands for more efficient and cleaner ships, hybrid technology (i.e., additional use of batteries) is also being adopted and integrated into the marine industry. The use of battery technology is shown to reduce the annual operational cost of ships as compared with diesel-mechanical propulsion systems [

34]. This is—apart from the target of environmental friendliness and carbon neutrality—a sound argument for designing a propulsion system which is powered electrically rather than just chemically.

A possible electric propulsion architecture that can be used in a SailREC System is shown in

Figure 6. The wind turbine feeds the power bus with energy, which is used by the electrolyser and in the conversion processes (Haber reactor or methanol synthesis reactor). The energy will also be used by other subsystems and auxiliary systems. Part of the energy is stored in the electrical form in batteries, which can be used to feed the bus. The bus can also be energised by using the stored fuel through a chemical to power conversion (X2P) when required. The whole control of power on the bus should be monitored by a power management system. The prime movers for the propellers are electric motors, and they source power from the bus. The SailREC System will require a battery (or other storage technology) to conserve energy to supply power for conversion processes that would need power when the wind turbine is not generating (enough) power, as the processes may not be flexible enough to be turned up and down depending on the fluctuating supply of power. The power bus can be based on AC (alternating current) or DC (direct current); currently, AC-based applications are more prevalent for marine applications. The study by Chai et al. [

35] has shown benefits in the use of DC-based systems—in both electrical performance and fuel efficiency—in a diesel–electric marine vessel. The challenge would be the safety of the system, as designing protection devices for DC applications is of increased difficulty.

7. Discussion and Outlook

In this section, the concept design from

Section 6 is put into the context of the existing systems mentioned in

Section 1.1. Based on this, the properties of the concept design and its limitations are discussed, and future steps required to develop the concept design further are pointed out.

The concept design from

Section 6 implements, such as the FARWIND energy ship and the proposed wind farm by the NIES, a kind of Beam Reach sailing strategy, as all designs are expected to reach their peak power when the wind comes from a beam. Another property that all proposals share is a catamaran-style floating platform. The concept design from

Section 6 and the wind farm from the NIES use both primarily or only wind turbines to generate electricity [

3]. The NIES concept incorporates 11 wind turbines [

3] instead of one for the concept design. On the other hand, the FARWIND energy ship uses only hydrokinetic turbines to generate electricity. A hydrokinetic turbine is also intended to be implemented by the concept from

Section 6, but not as the primary electricity generator. By comparing the sizes, the NIES proposal stands out with a length of around 2 km [

3]. The concept design (74.3 m) and the FARWIND energy ship (31.7 m) [

5] are on a much smaller scale. The same relationship holds for the electrical power output. The FARWIND energy ship with its two hydro turbines has a rated power of 1.8 MW [

5], the concept design generates with its single wind turbine 4 MW (the electricity generated by the Propulsion Subsystem in generation mode—acting as a hydro turbine—is neglected), and the NIES wind farm 55 MW with its 11 wind turbines [

3]. Concerning manoeuvrability, Tsujimoto et al. [

3] state that a turning operation takes a few hours. The FARWIND energy ship and the concept design are expected to be much more manoeuvrable, simply because they are much smaller. The FARWIND energy ship’s manoeuvrability in operation is expected to be better than that of the concept design. The reason for this is seen in the Flettner rotors, which can be adjusted very fast to a new wind direction compared to the limiting rotational speed of the wind turbine rotor. The difference in manoeuvrability can not be quantified at the moment, nor can it be answered if the expected reduced manoeuvrability compared to the FARWIND energy ship is a measurable drawback for the capacity factor of the concept design. This might depend on the number of fast course changes during operation. The concept design is, compared to the other two designs, still in a very conceptual phase and introduces many new untested ideas, as is the aim of this study. The open question of how well these ideas would work in reality is, for example, applicable to the liquid hydrogen storage containers. Susiso Frontier, the world’s first liquid hydrogen transport ship, entered service in 2020 [

47]. The ship has a 1250 m

3 large vacuum-insulated liquid hydrogen storage tank [

47]. It can not be said how well this technology can be adapted for the proposed storage containers. It also needs to be investigated in detail whether the Floatation Subsystem, with its smaller and larger buoyancy bodies, can provide sufficient stability even in extreme wave conditions. Further technical and economic studies are necessary to judge the suitability of the concept. For example, the sailing properties and energy performance, which are not explored at all and are just based on a conservative guess, can be investigated. All parts of the construction, being below or at the waterline, could be analysed in a CFD simulation. For this, in particular, the interaction with waves should be explored. It might also be important to simulate the concept design as a whole system to investigate the coupled dynamics and responses.

8. Conclusions

This paper introduces the concept of a SailREC System as a technology to rapidly build up the production of renewable fuels without barriers to growth, as the oceans are very large. A SailREC System is generically defined by the subsystems identified in this paper, so that any SailREC System is describable. Subsystems with close interfaces to each other are grouped. A SailREC System needs, for example, subsystems from the Energy Group to convert and store energy generated by the Wind Turbine Subsystem. Further subsystems—belonging to the Navi Group—are required to provide ship-like properties to move and steer, but also to improve the energy efficiency of the wind turbine. Other subsystems enable remote control and autonomous operation or provide safety. Within this study, some subsystems are investigated in more detail. Coming under the Energy Group, ammonia, methanol, gaseous hydrogen, and liquid hydrogen are being investigated as options for the fuel to be produced on board. A trade study, focusing mainly on LCOE (as a result of supply chain modelling) but also addressing, among others, infrastructure readiness level in 2032 and environmental friendliness, reveals that liquid hydrogen, closely followed by gaseous hydrogen, ranks first, whereas methanol and ammonia score just about two-thirds of the highest value. A further focus is placed on the sailing strategy and three alternatives are investigated, including the assessment of their effects on the effective electrical power being generated by the system. In conclusion, the highest capacity factor, though the highest technical challenge, is expected with a strategy where the wind comes from a beam. Based on the identified subsystems and detailed investigations, a concept design is developed that features a 4 MW wind turbine and converts energy into liquid hydrogen stored in double-walled, vacuum-insulated containers that are meant to be easily transportable, utilising existing infrastructure. The overall appearance of the proposed SailREC System is that of a catamaran with the wind turbine in the middle of the beam. This specific concept design shows some similarities as well as some differences compared to other existing ideas for comparable system technologies. Overall, the presented concept study serves as a basis for further in-depth investigations into individual subsystems and a detailed system design. The elaborated technology of SailREC Systems may pave the way to future offshore renewable energy research and development.