Study on Stress Evolution Law of Overburden under Repeated Mining in Long-Distance Double Upper Protective Layer

Abstract

:1. Introduction

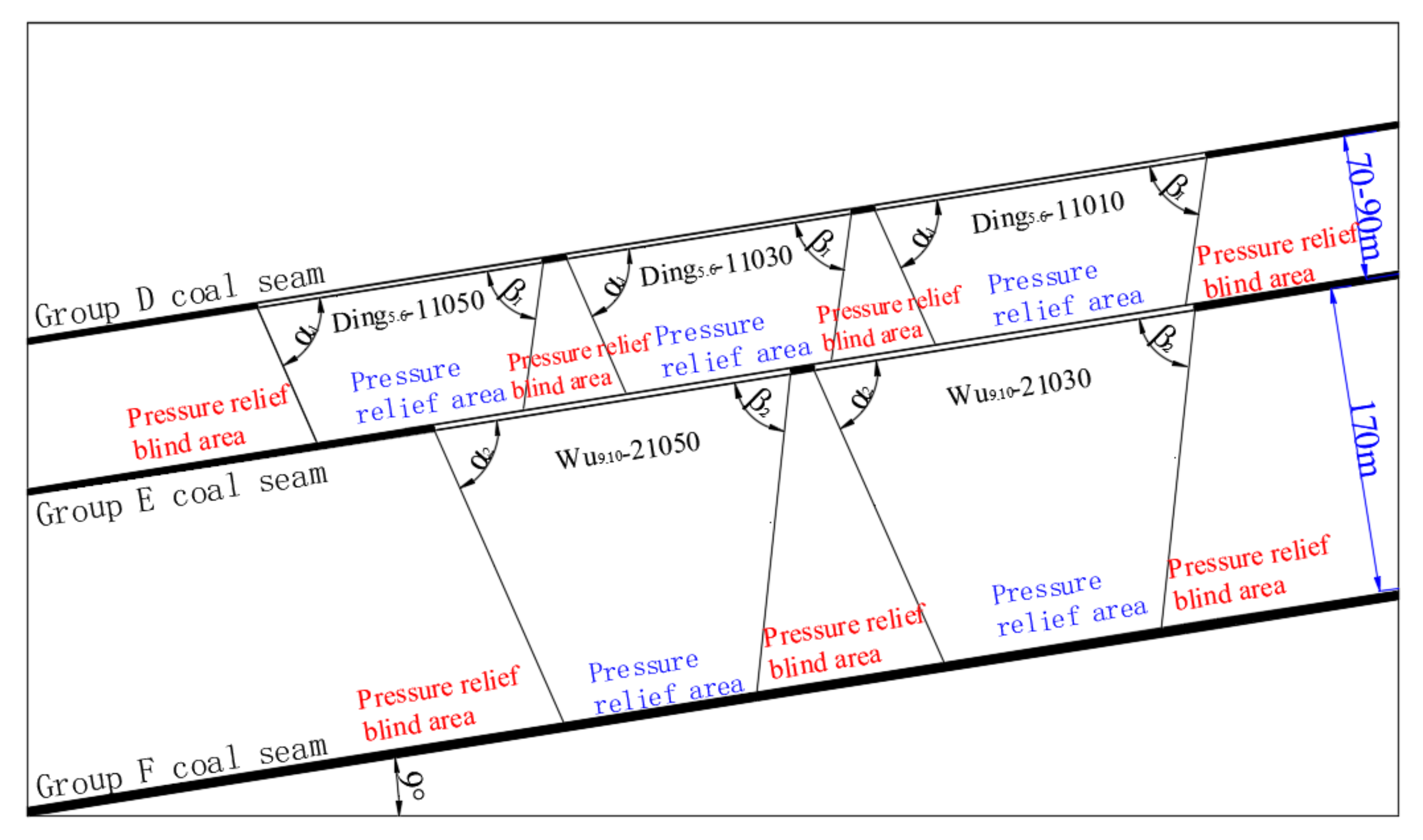

2. Similarity Materials Simulation Experiment of Long-Distance Coal Seam Group Superposition Mining

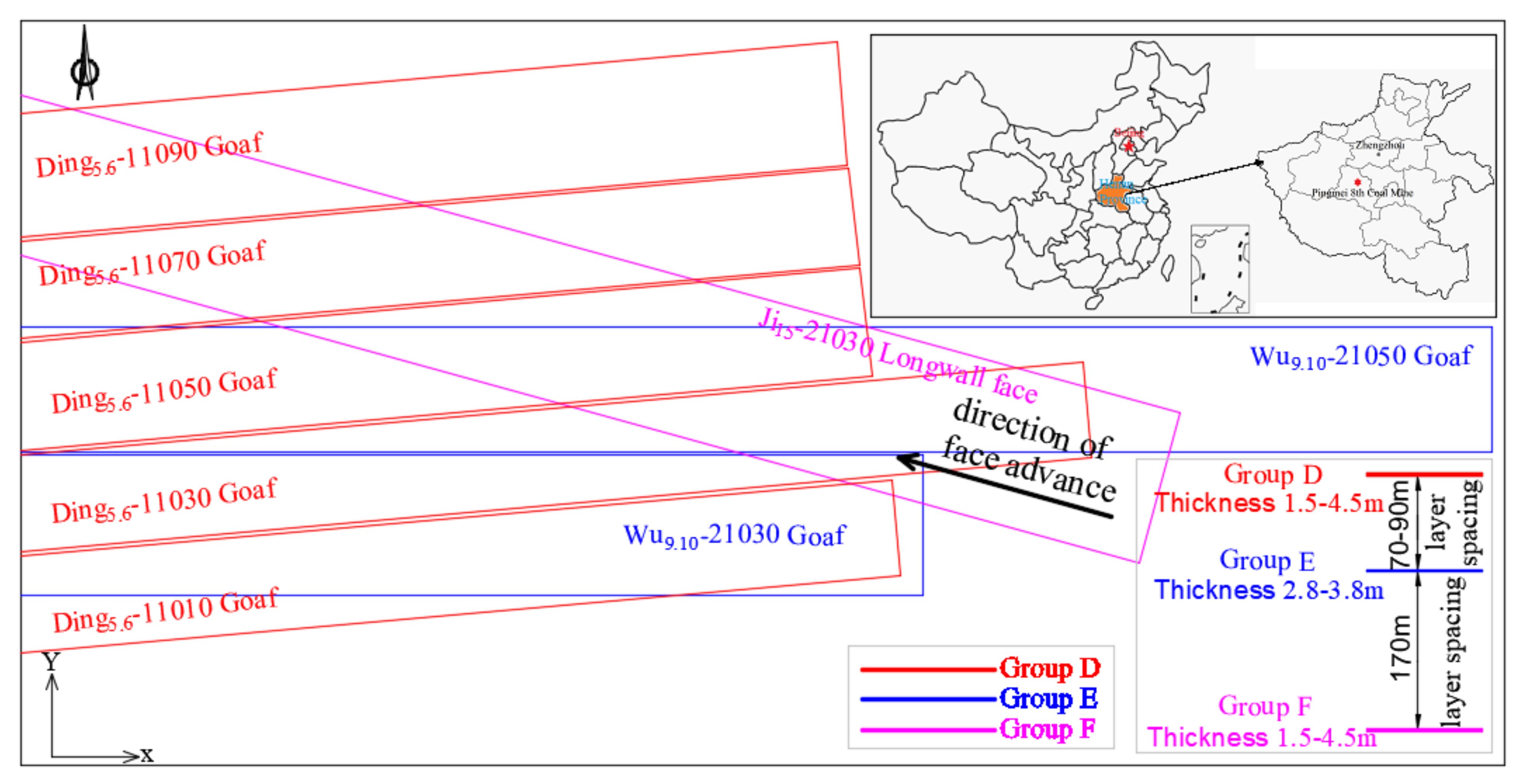

2.1. Project Background Overview

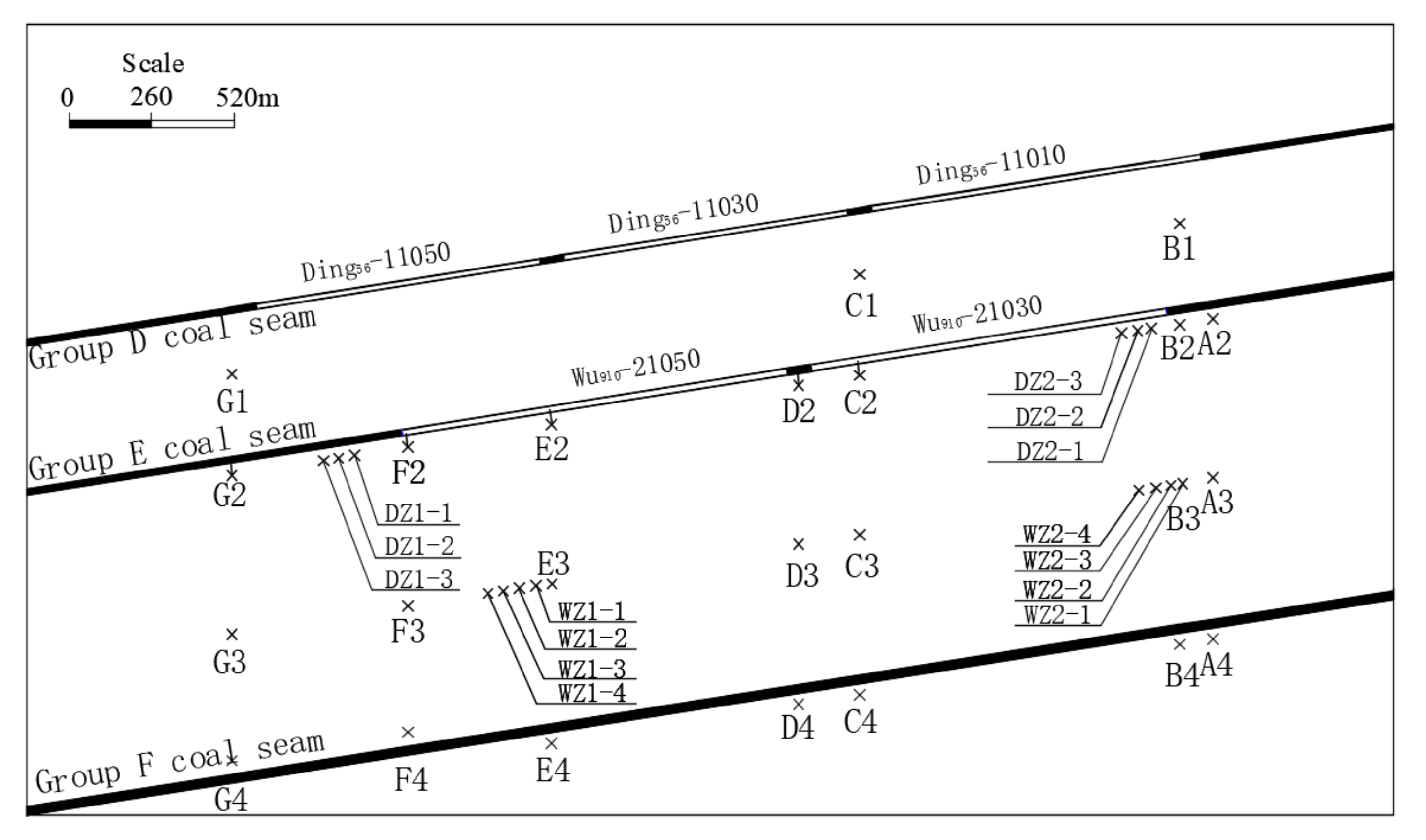

2.2. Program Design

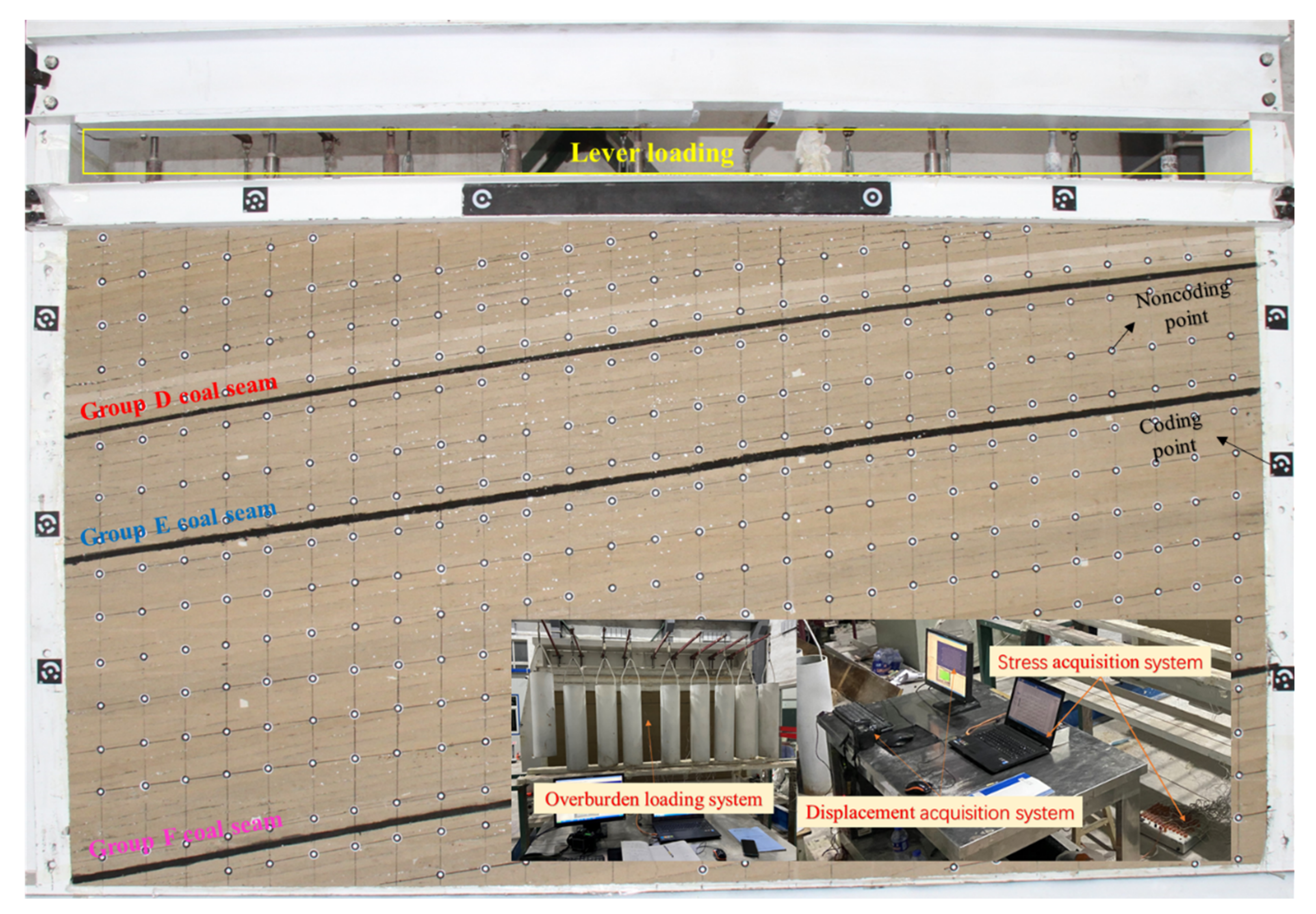

2.3. Model Establishment

3. Analysis of Experimental Results

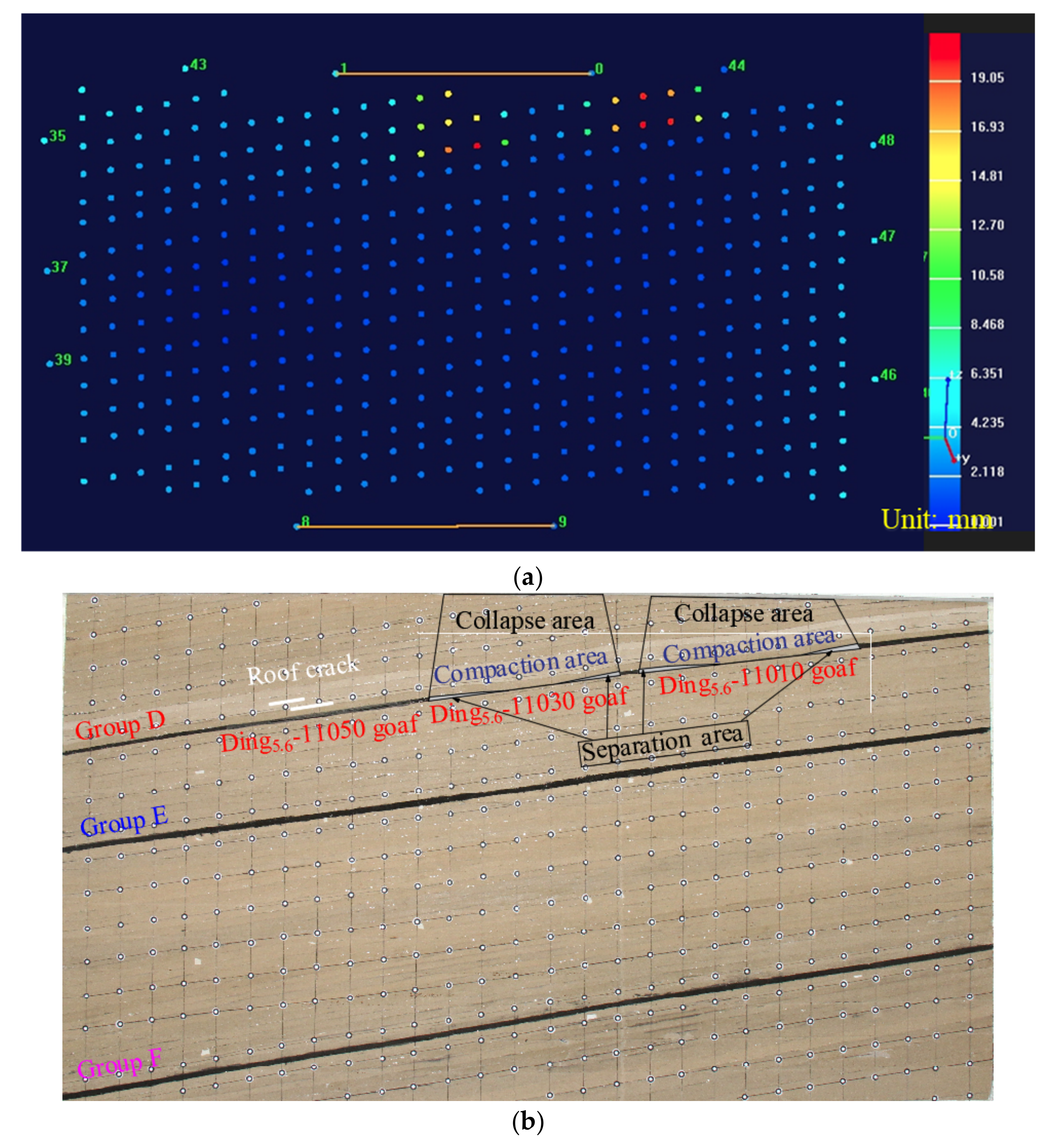

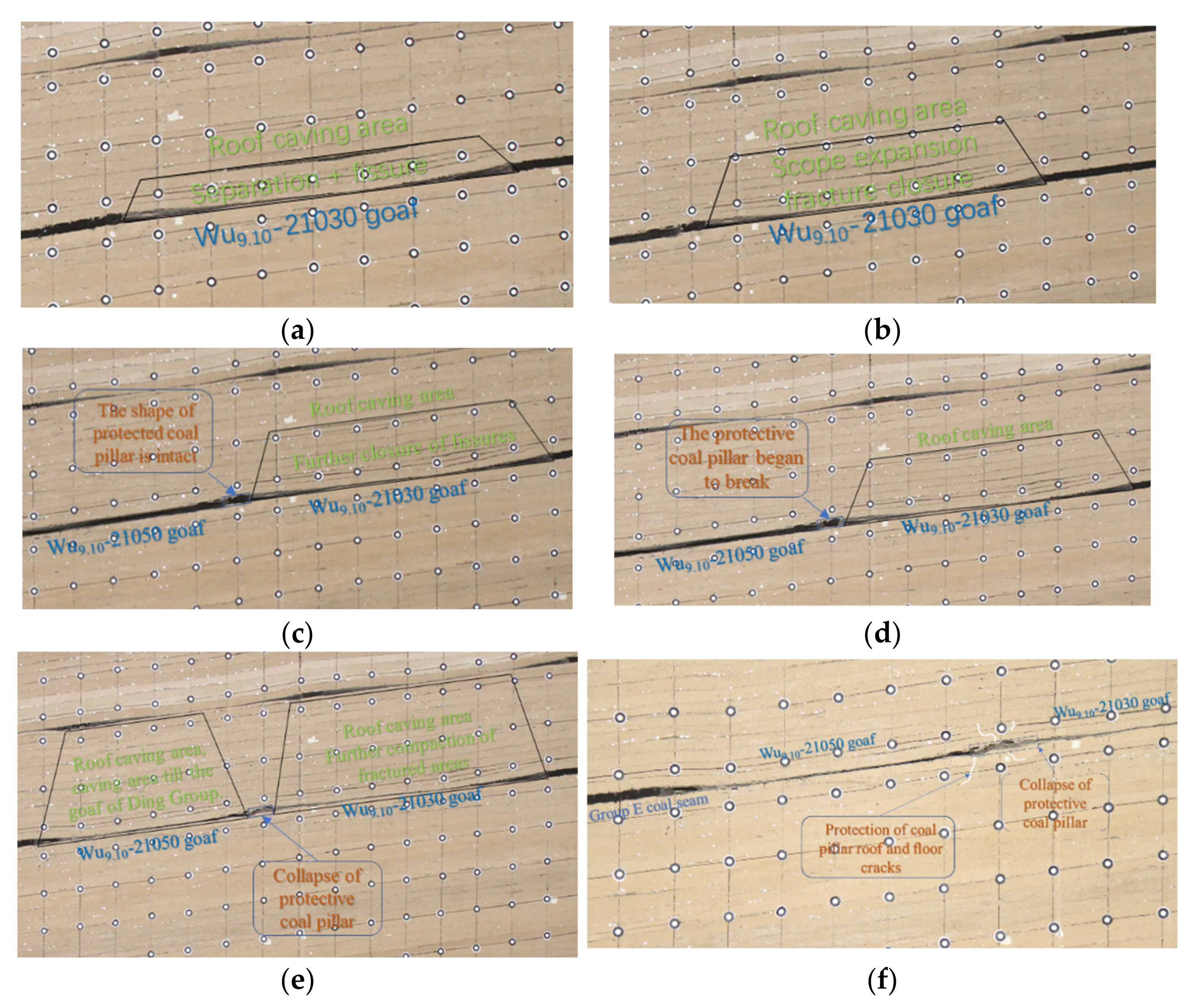

3.1. Overburden Movement Law of Long-Distance Coal Seam Group Overlapping Mining

3.1.1. Overburden Movement Law after Mining Group D Coal Seam

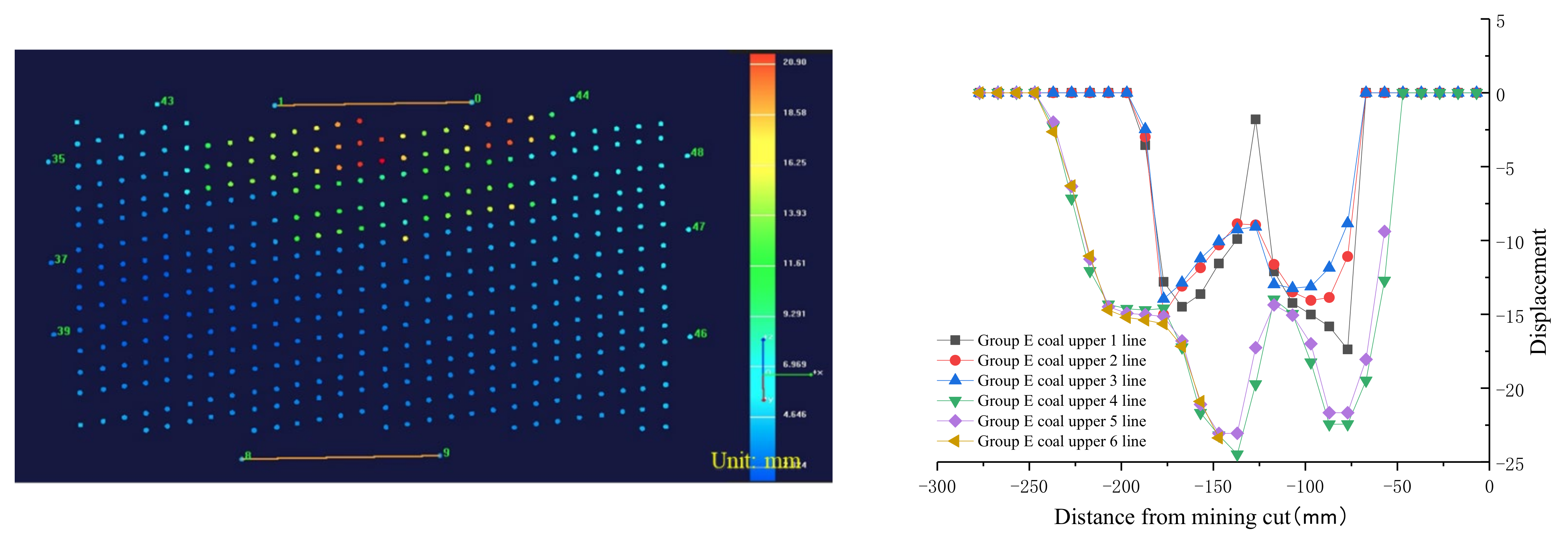

3.1.2. Overburden Movement Law after Mining Group E Coal Seam

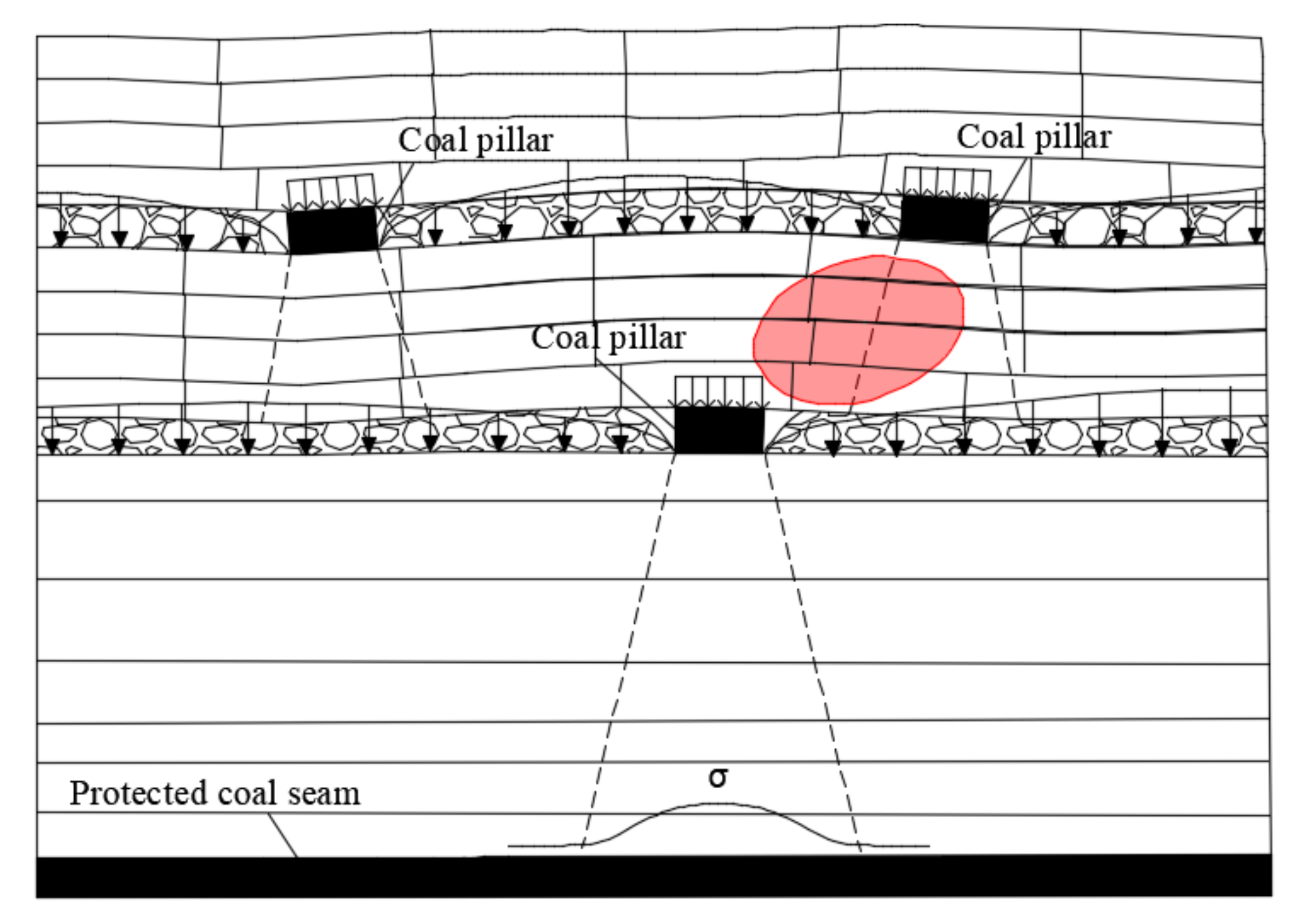

3.1.3. Mechanical Structure Analysis of Protective Layer

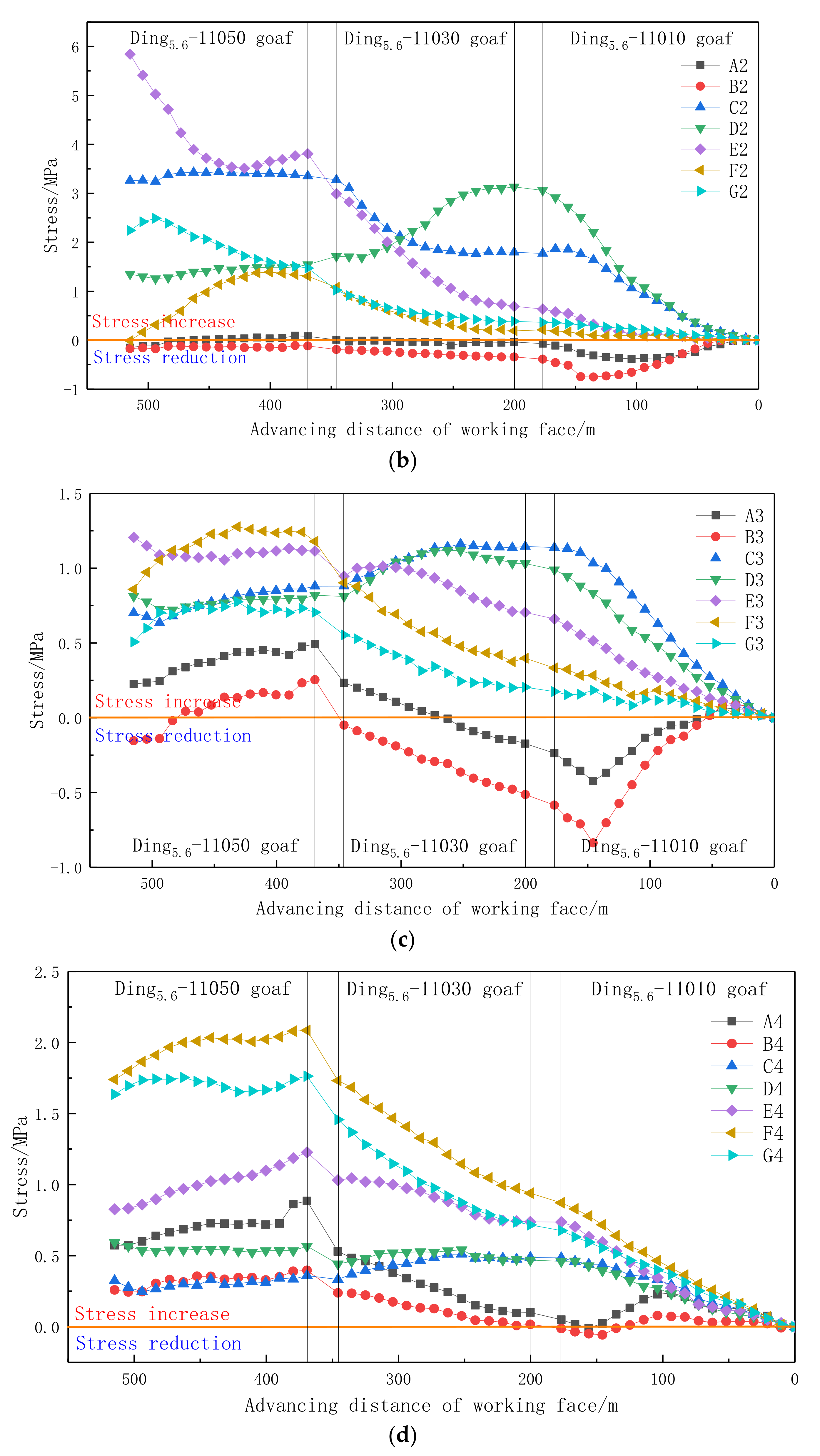

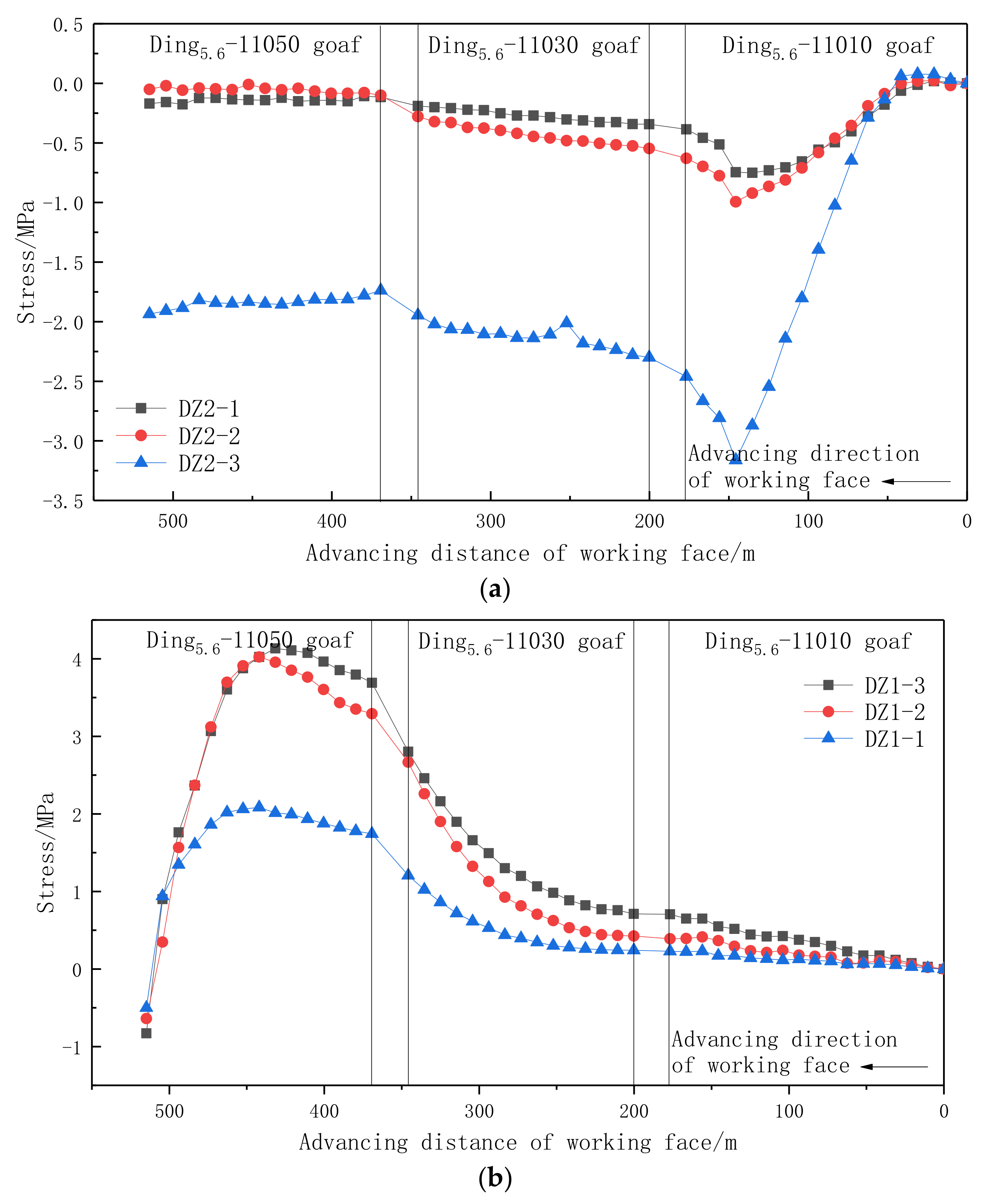

3.2. The Temporal and Spatial Evolution Law of Overburden Stress

3.2.1. Stress Evolution Law of Different Layers of Mining Floor in Group D Coal Seam

3.2.2. Stress Evolution Law of Different Layers of Mining Floor in Group E Coal Seam

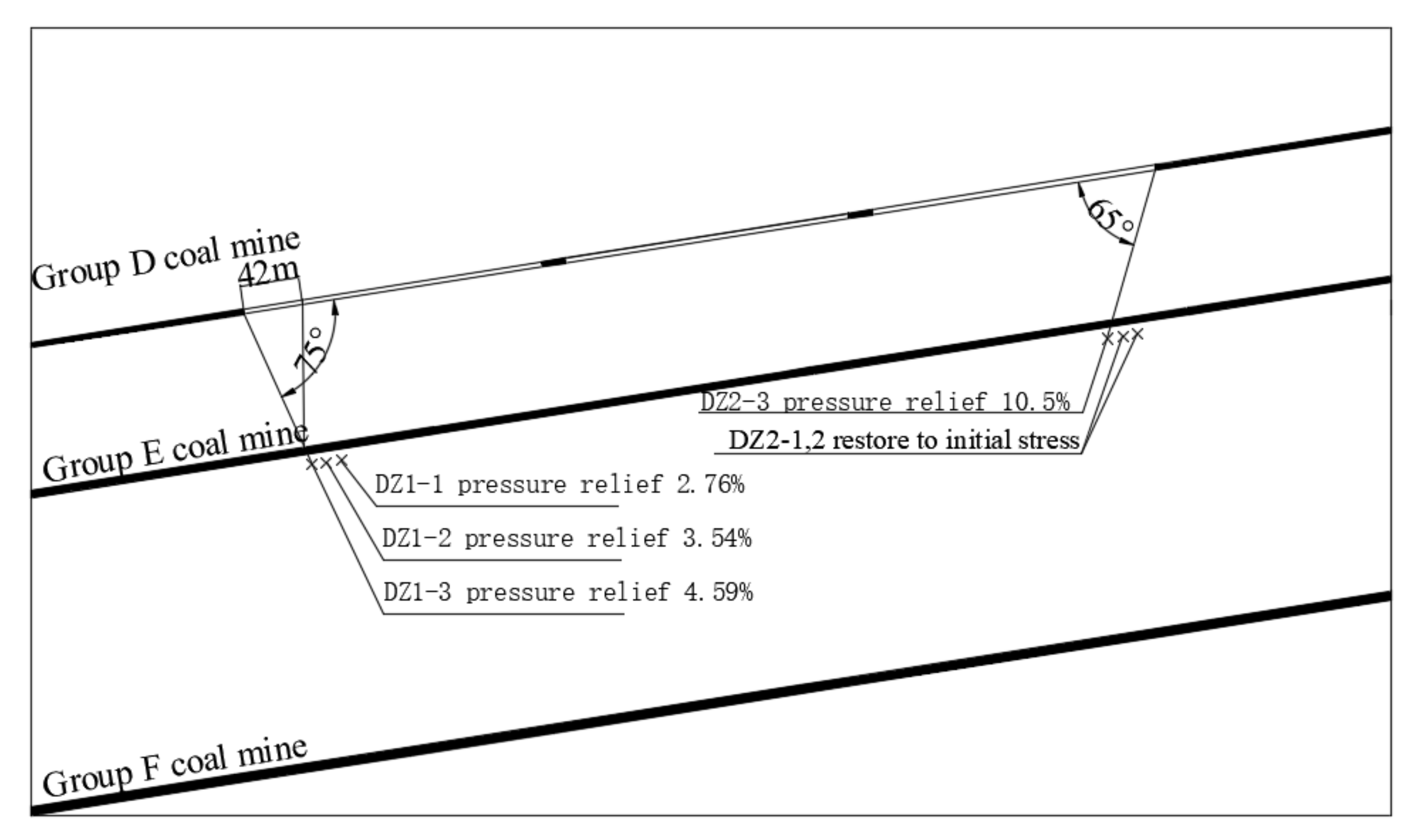

3.3. Determination of Pressure-Relief Angle of Protective Layer in Group D and E Coal Seams

3.4. Field Verification

4. Treatment and Mining Optimization Scheme of Protected Layer

- (1)

- Enhanced Extraction

- (2)

- Optimization of working face layout

- (3)

- Optimization of Roadway layout

- (4)

- Strengthen monitoring

5. Conclusions

- (1)

- Pressure relief is a dynamic process. The goaf formed after the rock movement is stable after the mining of the working face promote the stress of the existing coal seam to return to the original in situ stress value. Under the condition of superposition and staggered mining of working faces of Group D and Group E, the stress concentration phenomenon of coal pillar between working faces of Group D or Group E in the mining process of upper and lower layers of working face is weakened, playing the effect of mutual shielding.

- (2)

- The mining of Group D coal seam has a certain impact on Group E coal seam. The maximum pressure-relief ratio is 4.7%. The coal pillar left after mining causes stress concentration in Group E coal seam, and the maximum stress concentration factor is 1.37. The maximum influence depth of the floor can reach 182 m. After the mining of Group D coal seam is completed, the pressure-relief angle of Group E coal seam in the protective layer is 65° on the upper side and 75° on the lower side. The distance behind the vertical projection of Group D working face is 42 m.

- (3)

- The superimposed mining of Group D and Group E will affect the stress distribution of Group F coal seam. In the mining process of Group E coal seam, 101 m of the floor is affected by the different structure of the overlying superimposed goaf and coal pillar. The maximum pressure-relief ratio is 5.3%. The overlying coal pillar has little impact on Group I coal seam. After the mining of Group E coal seam is completed, the upper side of the protective layer has been affected by the protection of the double protective layer. The pressure-relief angle can reach 88°, the pressure-relief angle of the lower side is greater than 78°, and the distance behind the vertical projection of the working face of Group E is less than 61 m. The mining of the double protective layer can expand the protective layer.

- (4)

- Through field verification, it can be seen that when the coal seam of Group D protects the coal seam of Group E, the gas content is reduced by 40.6%, the gas pressure is reduced by 54.5%, and the coal seam permeability is increased by 12.4 times. When the coal seam of Group D and E protect the coal seam of Group F, the gas content is reduced by 34.7%, the gas pressure is reduced by 23.5%, and the coal seam permeability is increased by 4.3 times.

Author Contributions

Funding

Conflicts of Interest

References

- Yang, W.; Lin, B.Q.; Qu, Y.A.; Zhao, S.; Zhai, C.; Jia, L.L.; Zhao, W.Q. Mechanism of strata deformation under protective seam and its application for relieved methane control. Int. J. Coal Geol. 2011, 85, 300–306. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, Y.; Liu, Q.; Jiang, J.; Li, W.; Zhang, K. Numerical assessment of CMM drainage in the remote unloaded coal body: Insights of geostress-relief gas migration and coal permeability. J. Nat. Gas Sci. Eng. 2017, 45, 487–501. [Google Scholar] [CrossRef]

- Sun, P.; Sun, H.; Lin, F.; Yang, X.; Jiang, W.; Wu, W.; Jia, Q. Experimental study on the ratio model of similar materials in the simulation test of coal and gas outburst. Sci. Rep. 2021, 11, 13513. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Song, D.; He, X.; Li, Z.; Liu, H.; Wang, W. Investigation on micro-surface adhesion of coals and implications for gas occurrence and coal and gas outburst mechanism. J. Nat. Gas Sci. Eng. 2021, 94, 104115. [Google Scholar] [CrossRef]

- Wang, L.; Lu, Z.; Chen, D.P.; Liu, Q.Q.; Chu, P.; Shu, L.Y.; Wen, Z.J. Safe strategy for coal and gas outburst prevention in deep-and-thick coal seams using a soft rock protective layer mining. Saf. Sci. 2020, 129, 104800. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, R.; Xie, H.; Gao, M.; Xie, J. Mining-induced coal permeability change under different mining layouts. Rock Mech. Rock Eng. 2016, 49, 3753–3768. [Google Scholar] [CrossRef]

- Yang, M.Q.; Xie, H.P.; Gao, M.Z.; He, Z.Q.; Li, C.; Xie, J.; Yang, B.G. On distribution characteristics of the temperature field and gas seepage law of coal in deep mining. Therm. Sci. 2020, 24, 3923–3931. [Google Scholar] [CrossRef]

- State Administration of Coal Mine Safety. Detailed Rules for Prevention and Control of Coal and Gas Outburst; China Coal Industry Publishing House: Beijing, China, 2019. [Google Scholar]

- Gao, R.; Yu, B.; Xia, H.; Duan, H. Reduction of stress acting on a thick, deep coal seam by protective-seam mining. Energies 2017, 10, 1209. [Google Scholar] [CrossRef] [Green Version]

- Sun, Q.; Zhang, J.; Zhang, Q.; Yin, W.; Germain, D. A protective seam with nearly whole rock mining technology for controlling coal and gas outburst hazards: A case study. Nat. Hazards 2016, 84, 1793–1806. [Google Scholar] [CrossRef]

- Jin, K.; Cheng, Y.; Wang, W.; Liu, H.; Liu, Z.; Zhang, H. Evaluation of the remote lower protective seam mining for coal mine gas control: A typical case study from the Zhuxianzhuang Coal Mine, Huaibei Coalfield, China. J. Nat. Gas Sci. Eng. 2016, 33, 44–55. [Google Scholar] [CrossRef] [Green Version]

- Jia, T.; Zhang, Z.; Tang, C.; Zhang, Y. Numerical simulation of stress-relief effects of protective layer extraction. Arch. Min. Sci. 2013, 58, 521–540. [Google Scholar]

- Wang, H.; Cheng, Y.; Yuan, L. Gas outburst disasters and the mining technology of key protective seam in coal seam group in the Huainan coalfield. Nat. Hazards 2013, 67, 763–782. [Google Scholar] [CrossRef]

- Noack, K. Control of gas emissions in underground coal mines. Int. J. Coal Geol. 1998, 35, 57–82. [Google Scholar] [CrossRef]

- Flores, R.M. Coalbed methane: From hazard to resource. Int. J. Coal Geol. 1998, 35, 3–26. [Google Scholar] [CrossRef]

- Li, Q.M. The Damage and Seepage Flow Characteristics of Coal under Conditions of Poly-Protection and the Rationality Evaluation of the Coal Mining and Excavation Deployment. Ph.D. Thesis, Chongqing University, Chongqing, China, 2019. [Google Scholar]

- Li, S.Q.; He, X.Q.; Li, S.Q.; Zhang, S.J.; Yan, Z.; Jie, Q.X. Experimental research on strata movement and fracture dynamic evolution of double pressure-relief mining in coal seams group. J. China Coal Soc. 2013, 38, 2146–2152. [Google Scholar]

- Li, M.; Qu, C.; Lin, B.Q.; Liao, K.B.; Jia, H.Q.; Zhang, J. Study on space-time evolution of stress under double pressure relief in composite coal seam group. Saf. Coal Mines 2015, 46, 39–43. [Google Scholar]

- Kong, X.Y.; Yang, K.; Lu, W. Floor failure mechanism and engineering application of downward mining of the large dip angle coal seam group. Chin. J. Undergr. Space Eng. 2015, 11, 394–400. [Google Scholar]

- Cheng, Z.H.; Qi, Q.X.; Li, H.Y.; Zhang, L.; Liu, X.G. Evolution of the superimposed mining induced stress-fissure field under extracting of close distance coal seam group. J. China Coal Soc. 2016, 41, 367–375. [Google Scholar]

- Yang, W.; Lin, B.Q.; Qu, Y.A.; Li, Z.W.; Zhai, C.; Jia, L.L.; Zhao, W.Q. Stress evolution with time and space during mining of a coal seam. Int. J. Rock Mech. Min. Sci. 2011, 48, 1145–1152. [Google Scholar] [CrossRef]

- Xiong, Y.; Kong, D.; Wen, Z.; Wu, G.; Liu, Q. Analysis of coal face stability of lower coal seam under repeated mining in close coal seams group. Sci. Rep. 2022, 12, 509. [Google Scholar] [CrossRef]

- Zhang, C.; Feng, R.; Zhang, X.; Shen, W. Numerical Study on Stress Relief and Fracture Distribution Law of Floor in Short-Distance Coal Seams Mining: A Case Study. Geotech. Geol. Eng. 2021, 39, 437–450. [Google Scholar] [CrossRef]

- Jiang, J.; Cheng, Y.; Zhang, P.; Jin, K.; Cui, J.; Du, H. CBM drainage engineering challenges and the technology of mining protective coal seam in the Dalong Mine, Tiefa Basin, China. J. Nat. Gas Sci. Eng. 2015, 24, 412–424. [Google Scholar] [CrossRef]

- Tu, Q.; Cheng, Y. Stress evolution and coal seam deformation through the mining of a remote upper protective layer. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 338–348. [Google Scholar] [CrossRef]

- Yuan, Z.; Shao, Y.; Zhu, Z. Similar material simulation study on protection effect of steeply inclined upper protective layer mining with varying interlayer distances. Adv. Civ. Eng. 2019, 2019, 9849635. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Y.P.; Wang, H.F.; Wang, L.; Zhou, H.X.; Liu, H.Y.; Liu, H.B.; Li, W. Theories and Engineering Applications on Coal Mine Gas Control; China University of Mining and Technology Press: Xuzhou, China, 2010. [Google Scholar]

- Wang, Y.Q.; Wang, X.; Zhang, J.S.; Yang, B.S.; Zhu, W.J.; Wang, Z.P. Similar experimental study on retaining waterproof coal pillar in composite strata mining. Sci. Rep. 2022, 12, 1366. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Hou, C.; Hou, J. Numerical and similarity simulation study on the protection effect of composite protective layer mining with gently inclined thick coal seam. Shock. Vib. 2021, 2021, 6679199. [Google Scholar] [CrossRef]

- Kissell, F.N.; Diamond, W.P.; Beiter, D.A.; Taylor, C.D.; Goodman, G.V.R.; Cecala, A.B.; Urosek, J.E.; Francart, W.J.; Thakur, P.C.; Ulery, J.P.; et al. Handbook for Methane Control in Mining; Pittsburgh Research Laboratory (National Institute for Occupational Safety and Health): Cincinnati, OH, USA, 2006. Available online: https://stacks.cdc.gov/view/cdc/6882 (accessed on 27 April 2022).

| Group | 1 | 2 | 3 | 4 | Vertical Line Position |

|---|---|---|---|---|---|

| A | —— | A2 | A3 | A4 | Ding5.6-11010 opening line projection right 30 m |

| B | B1 | B2 | B3 | B4 | Wu9.10-21030 opening line projection left 6 m |

| C | C1 | C2 | C3 | C4 | Coal pillar between Ding5.6-11010 and Ding5.6-11030 |

| D | —— | D2 | D3 | D4 | Coal pillar between Wu9.10-21030 and Wu9.10-21050 |

| E | —— | E2 | E3 | E4 | Coal pillar between Ding5.6-11030 and Ding5.6-11050 |

| F | —— | F2 | F3 | F4 | Wu9.10-21030 stopping line projection left 13.5 m |

| G | G1 | G2 | G3 | G4 | Ding5.6-11050 stopping line projection left 13.5 m |

| Location of survey line along the floor | Group D coal seam floor 40 m | Group E coal seam floor 6 m | Group E coal seam floor 101 m | Group F coal seam roof or floor 6 m | Remarks: DZ, WZ are stress-monitoring points for pressure-relief angle inspection |

| Rock Character | Model Thickness /cm | Prototype Compressive Strength /MPa | Model Compressive Strength /MPa | Model Density /cm3 | Ratio Number |

|---|---|---|---|---|---|

| Sandy mudstone | 12 | 40 | 0.13 | 1.6 | 437 |

| Fine sandstone | 4 | 60 | 0.20 | 1.6 | 437 |

| Mudstone | 10 | 20 | 0.07 | 1.6 | 573 |

| Sandy mudstone | 3 | 30 | 0.10 | 1.6 | 437 |

| Medium sandstone | 4 | 90 | 0.30 | 1.6 | 337 |

| Sandy mudstone | 2 | 30 | 0.10 | 1.6 | 437 |

| Ding5.6 coal seam | 1.1 | 5.29 | 0.02 | 1.6 | 773 |

| Medium sandstone | 4 | 57.5 | 0.19 | 1.6 | 437 |

| Sandy mudstone | 8 | 85 | 0.28 | 1.6 | 437 |

| Medium sandstone | 2 | 105 | 0.35 | 1.6 | 437 |

| Sandy mudstone | 5 | 20 | 0.07 | 1.6 | 437 |

| Medium sandstone | 2 | 105 | 0.35 | 1.6 | 437 |

| Sandy mudstone | 2 | 20 | 0.07 | 1.6 | 437 |

| Medium sandstone | 4 | 45 | 0.15 | 1.6 | 437 |

| Wu9.10 coal seam | 1.3 | 5.29 | 0.02 | 1.6 | 773 |

| Mudstone | 2 | 15 | 0.05 | 1.6 | 573 |

| Medium sandstone | 6 | 105 | 0.35 | 1.6 | 437 |

| Mudstone | 4 | 15 | 0.05 | 1.6 | 573 |

| Medium sandstone | 2 | 105 | 0.35 | 1.6 | 437 |

| Mudstone | 12 | 15 | 0.05 | 1.6 | 573 |

| Fine sandstone | 6 | 95 | 0.32 | 1.6 | 437 |

| Mudstone | 16 | 15 | 0.05 | 1.6 | 573 |

| Medium sandstone | 2 | 105 | 0.35 | 1.6 | 437 |

| Mudstone | 2 | 15 | 0.05 | 1.6 | 573 |

| Fine sandstone | 8 | 95 | 0.32 | 1.6 | 437 |

| Sandy mudstone | 6 | 25 | 0.08 | 1.6 | 473 |

| Ji15 coal seam | 1.7 | 5.29 | 0.02 | 1.6 | 773 |

| Sandy mudstone | 2 | 40 | 0.13 | 1.6 | 437 |

| Fine sandstone | 2 | 50 | 0.17 | 1.6 | 437 |

| Muddy tuff | 18 | 45 | 0.15 | 1.6 | 573 |

| Limestone | 18 | 60 | 0.20 | 1.6 | 537 |

| Test Content | Gas Content (m3/t) | Gas Pressure (MPa) | Coal Seam Permeability Coefficient (m2/(MPa·d)) |

|---|---|---|---|

| Original area of coal seam in Group E | 9.9 | 1.1 | 0.157 |

| Original area of coal seam in Group F | 9.71 | 3.4 | 0.012 |

| Group D protected area | 5.88 | 0.5 | 1.945 |

| Group D and E protected area | 6.34 | 2.6 | 0.052 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, S.-J.; Liang, B.; Sun, W.-J.; Shi, Z.-S.; Hao, J.-F.; Wang, B.-F.; Zhang, X.-Y. Study on Stress Evolution Law of Overburden under Repeated Mining in Long-Distance Double Upper Protective Layer. Energies 2022, 15, 4459. https://doi.org/10.3390/en15124459

Fang S-J, Liang B, Sun W-J, Shi Z-S, Hao J-F, Wang B-F, Zhang X-Y. Study on Stress Evolution Law of Overburden under Repeated Mining in Long-Distance Double Upper Protective Layer. Energies. 2022; 15(12):4459. https://doi.org/10.3390/en15124459

Chicago/Turabian StyleFang, Sheng-Jie, Bing Liang, Wei-Ji Sun, Zhan-Shan Shi, Jian-Feng Hao, Bei-Fang Wang, and Xiao-Yong Zhang. 2022. "Study on Stress Evolution Law of Overburden under Repeated Mining in Long-Distance Double Upper Protective Layer" Energies 15, no. 12: 4459. https://doi.org/10.3390/en15124459

APA StyleFang, S.-J., Liang, B., Sun, W.-J., Shi, Z.-S., Hao, J.-F., Wang, B.-F., & Zhang, X.-Y. (2022). Study on Stress Evolution Law of Overburden under Repeated Mining in Long-Distance Double Upper Protective Layer. Energies, 15(12), 4459. https://doi.org/10.3390/en15124459