Key Challenges for High Temperature Thermal Energy Storage in Concrete—First Steps towards a Novel Storage Design

Abstract

:1. Introduction

2. Innovative Concrete Formulations for High Temperature TES

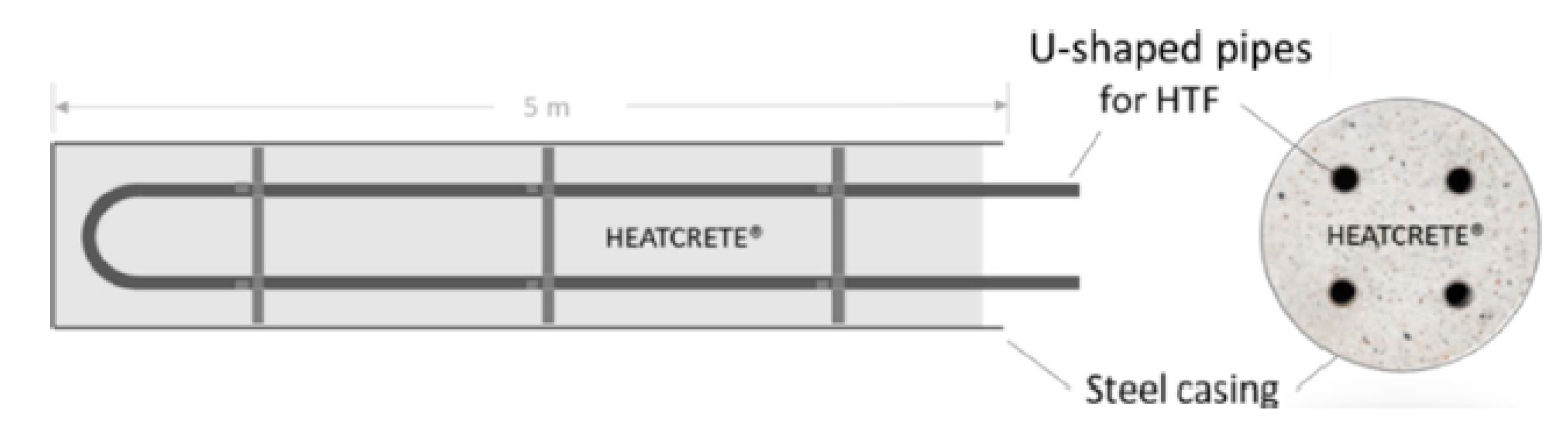

3. Conventional TES Concept

4. Challenges

- (i)

- On-site construction.

- (ii)

- Different thermal expansion coefficient of steel and concrete.

- (iii)

- Poor thermal conductivity of concrete.

- (iv)

- HTF thermal oil or molten salts with limited operating temperature range.

- (v)

- HTF thermal oil or molten salts in direct contact with concrete: migration of oil/salt in concrete.

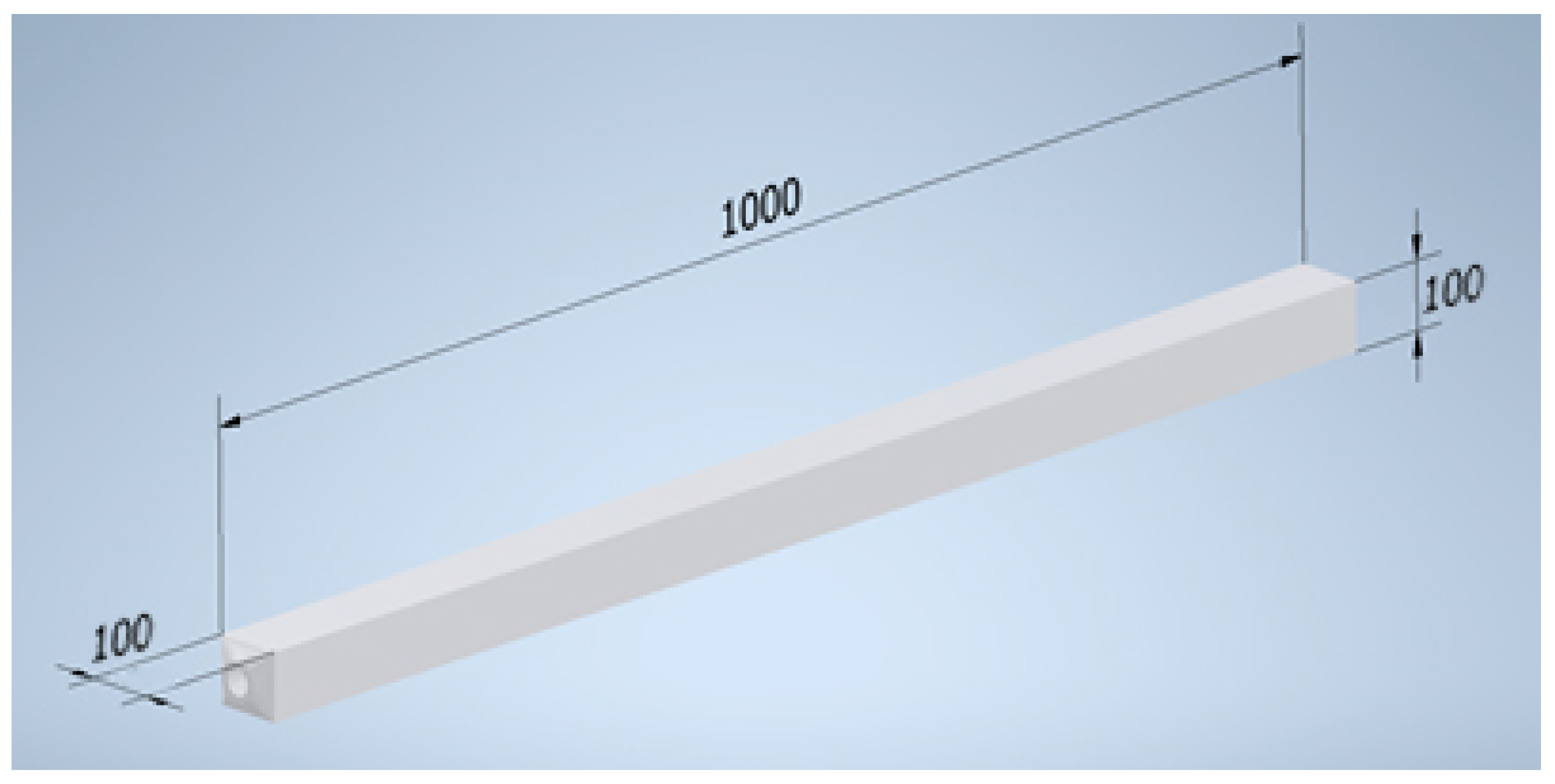

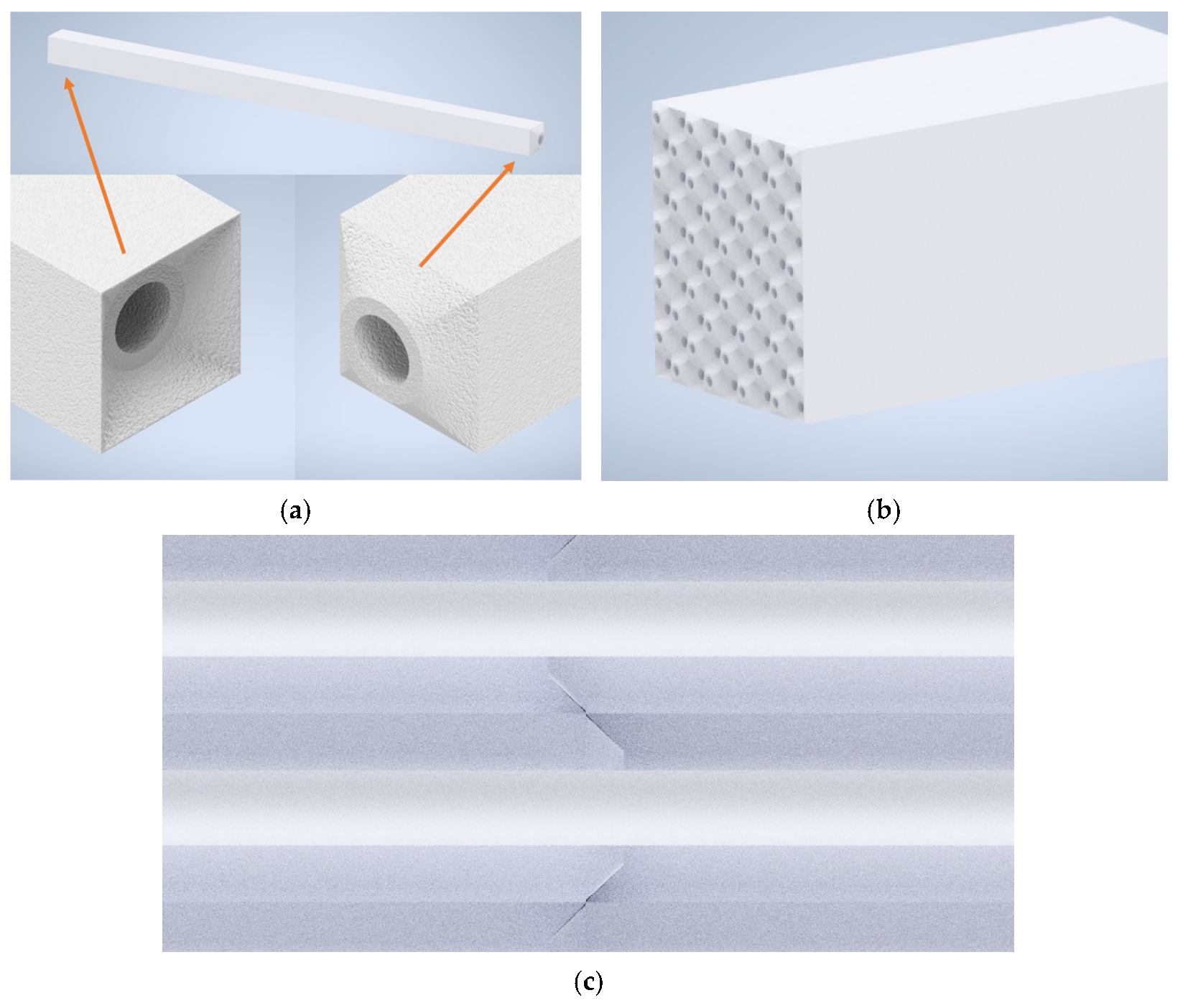

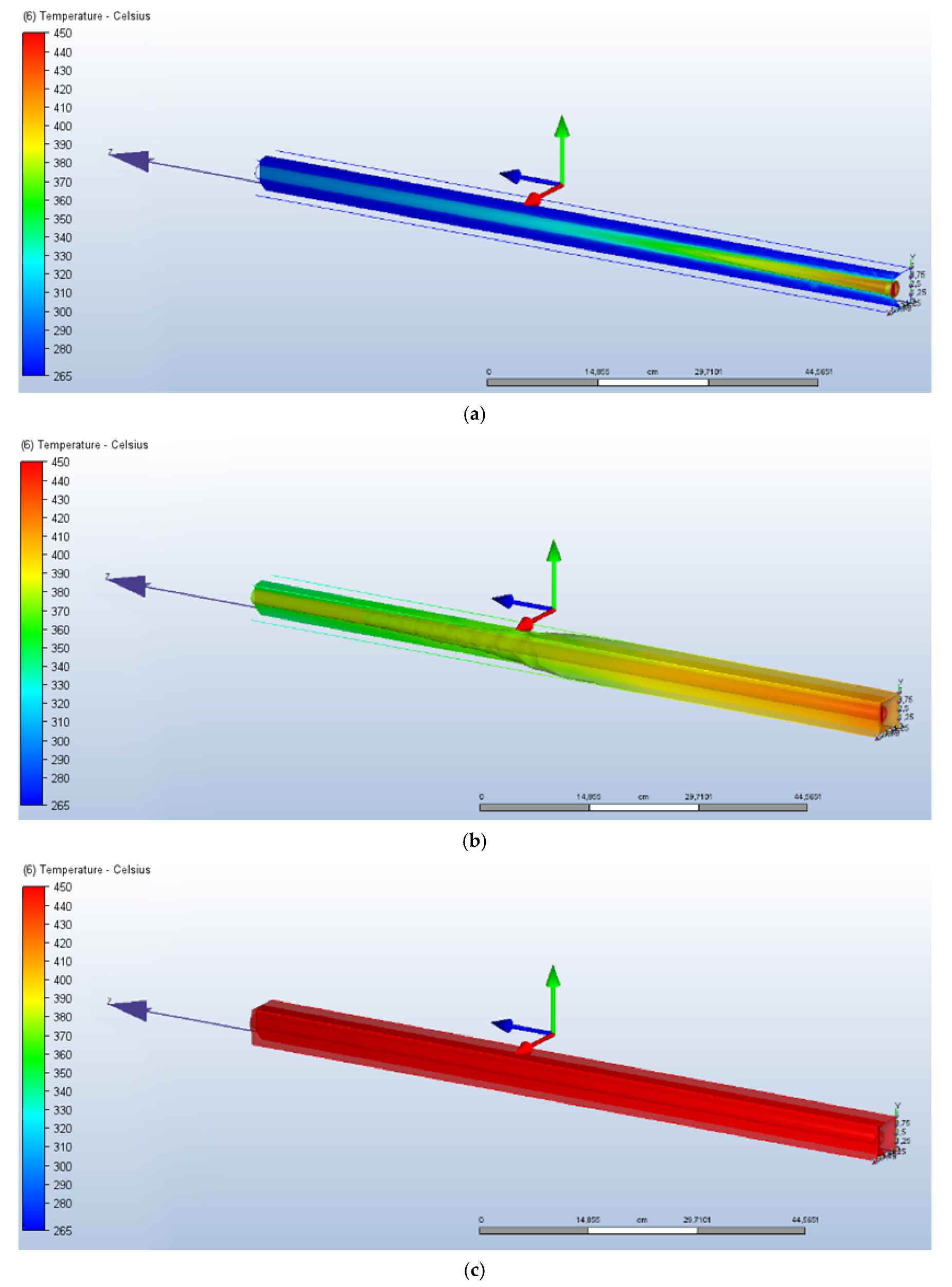

5. New Concept Proposal

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cabeza, L.F. 2-Advances in thermal energy storage systems: Methods and applications. In Advances in Thermal Energy Storage Systems; Elsevier: Amsterdam, The Netherlands, 2021; pp. 37–54. [Google Scholar] [CrossRef]

- Crespo, A.; Barreneche, C.; Ibarra, M.; Platzer, W. Latent thermal energy storage for solar process heat applications at medium-high temperatures—A review. Sol. Energy 2019, 192, 3–34. [Google Scholar] [CrossRef]

- Miró, L.; Gasia, J.; Cabeza, L.F. Thermal energy storage (TES) for industrial waste heat (IWH) recovery: A review. Appl. Energy 2016, 179, 284–301. [Google Scholar] [CrossRef] [Green Version]

- Miró, L.; McKenna, R.; Jäger, T.; Cabeza, L.F. Estimating the industrial waste heat recovery potential based on CO2 emissions in the European non-metallic mineral industry. Energy Effic. 2018, 11, 427–443. [Google Scholar] [CrossRef] [Green Version]

- REN21. Renewables 2020 Global Status Report; REN21: Paris, France, 2020. [Google Scholar]

- González-Roubaud, E.; Pérez-Osorio, D.; Prieto, C. Review of commercial thermal energy storage in concentrated solar power plants: Steam vs. molten salts. Renew. Sustain. Energy Rev. 2017, 80, 133–148. [Google Scholar] [CrossRef]

- Fernández, A.G.; Gomez-Vidal, J.; Oró, E.; Kruizenga, A.; Solé, A.; Cabeza, L.F. Mainstreaming commercial CSP systems: A technology review. Renew. Energy 2019, 140, 152–176. [Google Scholar] [CrossRef]

- Laing-Nepustil, D.; Zunft, S. 4-Using concrete and other solid storage media in thermal energy storage systems. In Advances in Thermal Energy Storage Systems; Elsevier: Amsterdam, The Netherlands, 2021; pp. 83–110. [Google Scholar] [CrossRef]

- Laing, D.; Lehmann, D.; Fi, M.; Bahl, C. Test results of concrete thermal energy storage for parabolic trough power plants. J. Sol. Energy Eng. Trans. ASME 2009, 131, 0410071-6. [Google Scholar] [CrossRef] [Green Version]

- Boquera, L.; Castro, J.R.; Pisello, A.L.; Fabiani, C.; D’Alessandro, A.; Ubertini, F.; Cabeza, L.F. Thermal and mechanical performance of cement paste under high temperature thermal cycles. Sol. Energy Mater. Sol. Cells 2021, 231, 111333. [Google Scholar] [CrossRef]

- Alonso, M.C.; Vera-Agullo, J.; Guerreiro, L.; Flor-Laguna, V.; Sanchez, M.; Collares-Pereira, M. Calcium aluminate based cement for concrete to be used as thermal energy storage in solar thermal electricity plants. Cem. Concr. Res. 2016, 82, 74–86. [Google Scholar] [CrossRef]

- Laing, D.; Steinmann, W.-D.; Tamme, R.; Richter, C. Solid media thermal storage for parabolic trough power plants. Sol. Energy 2006, 80, 1283–1289. [Google Scholar] [CrossRef]

- Lucio-Martin, T.; Roig-Flores, M.; Izquierdo, M.; Alonso, M.C. Thermal conductivity of concrete at high temperatures for thermal energy storage applications: Experimental analysis. Sol. Energy 2021, 214, 430–442, Erratum in Sol. Energy 2021, 220, 1137–1138. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Lucio-Martin, T.; Alonso, M.C.; Guerreiro, L. Evolution of thermo-mechanical properties of concrete with calcium aluminate cement and special aggregates for energy storage. Cem. Concr. Res. 2021, 141, 106323. [Google Scholar] [CrossRef]

- Miliozzi, A.; Dominici, F.; Candelori, M.; Veca, E.; Liberatore, R.; Nicolini, D.; Torre, L. Development and Characterization of Concrete/PCM/Diatomite Composites for Thermal Energy Storage in CSP/CST Applications. Energies 2021, 14, 4410. [Google Scholar] [CrossRef]

- Rahjoo, M.; Goracci, G.; Martauz, P.; Rojas, E.; Dolado, J.S. Geopolymer Concrete Performance Study for High-Temperature Thermal Energy Storage (TES) Applications. Sustainability 2022, 14, 1937. [Google Scholar] [CrossRef]

- Laing, D.; Steinmann, W.-D.; Fiß, M.; Tamme, R.; Brand, T.; Bahl, C. Solid Media Thermal Storage Development and Analysis of Modular Storage Operation Concepts for Parabolic Trough Power Plants. J. Sol. Energy Eng. 2008, 130, 011006. [Google Scholar] [CrossRef]

- Ktistis, P.K.; Agathokleous, R.A.; Kalogirou, S.A. Experimental performance of a parabolic trough collector system for an industrial process heat application. Energy 2021, 215, 119288. [Google Scholar] [CrossRef]

- Martins, M.; Villalobos, U.; Delclos, T.; Armstrong, P.; Bergan, P.G.; Calvet, N. New Concentrating Solar Power Facility for Testing High Temperature Concrete Thermal Energy Storage. Energy Procedia 2015, 75, 2144–2149. [Google Scholar] [CrossRef] [Green Version]

- Hoivik, N.; Greiner, C.; Barragan, J.; Iniesta, A.C.; Skeie, G.; Bergan, P.; Blanco-Rodriguez, P.; Calvet, N. Long-term performance results of concrete-based modular thermal energy storage system. J. Energy Storage 2019, 24, 100735. [Google Scholar] [CrossRef]

- Prieto, C.; Pérez Osorio, D.; Gonzalez-Roubaud, E.; Fereres, S.; Cabeza, L.F. Advanced Concrete Steam Accumulation Tanks for Energy Storage for Solar Thermal Electricity. Energies 2021, 14, 3896. [Google Scholar] [CrossRef]

- Ramos, D.C. El Sistema de Control del Hormigón en la Normativa Española: Evolución y Futuro; Asociación Española de Ingeniería Estructural (ACHE): Madrid, Spain, 2014. [Google Scholar]

- Asadi, I.; Shafigh, P.; Abu Hassan, Z.F.B.; Mahyuddin, N.B. Thermal conductivity of concrete—A review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Vignarooban, K.; Xu, X.; Arvay, A.; Hsu, K.; Kannan, A.M. Heat transfer fluids for concentrating solar power systems—A review. Appl. Energy 2015, 146, 383–396. [Google Scholar] [CrossRef]

- Prieto, C.; Ruiz-Cabañas, F.J.; Rodríguez-Sanchez, A.; Rubio Abujas, C.; Fernández, A.I.; Martínez, M.; Oró, E.; Cabeza, L.F. Effect of the impurity magnesium nitrate in the thermal decomposition of the solar salt. Sol. Energy 2019, 192, 186–192. [Google Scholar] [CrossRef]

- Bilal Awan, A.; Khan, M.N.; Zubair, M.; Bellos, E. Commercial parabolic trough CSP plants: Research trends and technological advancements. Sol. Energy 2020, 211, 1422–1458. [Google Scholar] [CrossRef]

- Autodesk. Autodesk Inventor. 2022. Available online: https://www.autodesk.es/products/inventor/overview (accessed on 19 May 2022).

- Autodesk. Autodesk CFD. 2022. Available online: https://www.autodesk.com/products/cfd/overview (accessed on 19 May 2022).

| Formulation | Cement | Water-Cement Ratio | Sand | Aggregate | Super- Plasticizer | Curing And Drying Protocol | Thermal Cycling | Compression Strength (MPa) | Porosity | Thermal Properties | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement paste | OPC | 0.34 | --- | --- | --- | 28 days curing in water | 20–200 °C 20–400 °C 20–600 °C 20–800 °C | Loss of stability in thermal cycling above 400 °C | Open porosity decreases with thermal cycles | Decrease in the thermal conductivity from 1 W/m·K to around 0.5 W/m·K after thermal cycling | [10] |

| Cement paste | CAC | 0.34 | --- | --- | --- | 28 days curing in water | 20–200 °C 20–400 °C 20–600 °C 20–800 °C | Decrease after first thermal cycle with stabilisation later on | Open porosity increased with temperature and thermal cycling | Lower thermal conductivity than OPC but higher heat capacity | [10] |

| Mortar | 70% CAC + 30% blast furnace slag (BFS) | 0.44 | Standard siliceous | --- | 1% | 3 days @105 °C | 290–550 °C | 72.67 ± 1.97 (after 7 days curing) | --- | --- | [11] |

| Concrete | Blast furnace cement | --- | --- | Iron oxides, flue ash, and other | --- | --- | --- | Medium material strength with several cracks | --- | 916 J/kg·K (@350 °C) 1.0 W/m·K (@350 °C) 9.3 ·10−6/K (@350 °C) | [12] |

| Concrete | 70% CAC + 30% blast furnace slag (BFS) | 0.5 | Standard siliceous | Natural from crash stone, silicon calcareous aggregate (SCA) | 0.8% | 3 days @105 °C | 290–550 °C | 50% decrease after first thermal cycle with stabilisation later on | 100% increase after thermal cycles | --- | [11] |

| Concrete | 70% CAC + 30% blast furnace slag (BFS) | 0.57 | Standard siliceous | Natural SCA + industrial waste slag | 0.8% | 3 days @105 °C | 290–550 °C | 50% decrease after first thermal cycle with stabilisation later on | 100% increase after thermal cycles | --- | [11] |

| Concrete | CAC | 0.43 | --- | Basalt 0–6 mm | 0.9% | Left @95% RH and @20 °C until testing | 300–600 °C | --- | --- | 1.2–2 W/m·K Decrease of 20–40% in the thermal conductivity after first thermal cycle | [13] |

| Concrete | CAC | 0.43 | --- | CAT 0.25–4 mm | 0.9% | Left @95% RH and @20 °C until testing | 300–600 °C | --- | --- | 1.2–2 W/m·K Decrease of 20–40% in the thermal conductivity after first thermal cycle | [13] |

| Concrete | CAC | 0.43 | --- | Slag 0.25–2 mm | 0.9% | Left @95% RH and @20 °C until testing | 300–600 °C | --- | --- | 1.2–2 W/m·K Decrease of 20–40% in the thermal conductivity after first thermal cycle | [13] |

| Concrete | CAC | 0.43 | --- | Slat 3–7 mm | 0.9% | Left @95% RH and @20 °C until testing | 300–600 °C | --- | --- | 1.2–2 W/m·K Decrease of 20–40% in the thermal conductivity after first thermal cycle | [13] |

| Concrete | CAC | 0.43 | --- | Calcareous 0–6 mm | 0.9% | Left @95% RH and @20 °C until testing | 300–600 °C | --- | --- | 1.2–2 W/m·K Decrease of 20–40% in the thermal conductivity after first thermal cycle | [13] |

| Concrete | CAC | 0.43 | --- | Siliceous 0–3 mm | 0.9% | Left @95% RH and @20 °C until testing | 300–600 °C | --- | --- | Up to 5 W/m·K Decrease of 50% in the thermal conductivity after first thermal cycle | [13] |

| Concrete | CAC | 0.43 | --- | Siliceous + polypropylene fibres | 1% | Left @95% RH and @20 °C until testing | 300–600 °C | Loss of 74% after one thermal cycle | --- | Decrease of 50% in the thermal conductivity after first thermal cycle | [14] |

| Concrete | CAC | 0.43 | --- | Calcium aluminate (CAT) + polypropylene fibres | 1% | Left @95% RH and @20 °C until testing | 300–600 °C | Loss of 63% after one thermal cycle | 1.6–2 µm Increase to 24–27 µm after thermal cycling | Decrease of 50% in the thermal conductivity after first thermal cycle | [14] |

| Concrete | CAC | 0.43 | --- | CAT + crushed basalt + polypropylene fibres | 1% | Left @95% RH and @20 °C until testing | 300–600 °C | Loss of 69% after one thermal cycle | 0.7 µm Increase to 24–27 µm after thermal cycling | Decrease of 50% in the thermal conductivity after first thermal cycle | [14] |

| Concrete | CAC | 0.43 | --- | CAT + crushed basalt + 15% waste slag + polypropylene fibres | 1% | Left @95% RH and @20 °C until testing | 300–600 °C | Loss of 69% after one thermal cycle | 1.6–2 µm Increase to 24–27 µm after thermal cycling | Decrease of 50% in the thermal conductivity after first thermal cycle | [14] |

| Concrete | CAC | 0.43 | --- | CAT + crushed basalt + 30% waste slag + polypropylene fibres | 1% | Left @95% RH and @20 °C until testing | 300–600 °C | Loss of 61% after 1 thermal cycle | 1.6–2 µm Increase to 24–27 µm after thermal cycling | Decrease of 50% in the thermal conductivity after first thermal cycle | [14] |

| Concrete | Cement | 0.32 | 9% washed sand 0-4 mm | Aggregate + metal and synthetic fibres | 0.43% | 28 days in a tank @100% HR and @15-20 °C | 50–200 °C 50–300 °C 50–400 °C (1 cycle) | Higher values at low temperature | Density was characterised | Specific heat is constant with temperature treatment Thermal conductivity around 2 W/m·K | [15] |

| Concrete/PCM | Cement | 0.37-0.41 | 9% washed sand 0-4 mm | Aggregate + metal and synthetic fibres + PCM impregnate in porous material | 0.43% | 28 days in a tank @100% HR and @15-20 °C | 50–200 °C 50–300 °C 50–400 °C (1 cycle) | PCM content helps in maintaining higher values after thermal treatment | Density was characterised | Specific heat increases with temperature treatment Thermal conductivity decreases strongly with PCM content | [15] |

| Geopolymer concrete | 20% OPC + 80% inorganic geopolymer | 0.6 | --- | Steel slag | --- | 1 day @100% RH + 28 days @room temperature | --- | --- | --- | More stable thermal properties than OPC as temperature increases | [16] |

| HTF | Melting Point (°C) | Stability Limit (°C) | Viscosity (Pa·s) | Thermal Conductivity (W/m·K) | Heat Capacity (kJ/kg·K) |

|---|---|---|---|---|---|

| Air | --- | --- | 0.00003 (@ 600 °C) | 0.06 (@ 600 °C) | 1.12 (@ 600 °C) |

| Water/steam | 0 | --- | 0.00133 (@ 600 °C) | 0.08 (@ 600 °C) | 2.42 (@ 600 °C) |

| Thermal oils | −20 | 300 | --- | ~0.1 | --- |

| Mineral oil | −20 | 350 | --- | ~0.1 | --- |

| Synthetic oil | −20 | 400 | --- | ~0.1 | --- |

| Biphenyl/diphenyl oxide | 12 | 393 | 0.00059 (@ 300 °C) | ~0.01 (@ 300 °C) | 1.93 (@ 300 °C) |

| Solar salt (60 wt.% NaNO3-40 wt.% KNO3) | 220 | 600 | 0.00326 (@ 300 °C) | 0.55 (@ 400 °C) | 1.1 (@ 600 °C) |

| Property | Concrete |

|---|---|

| Thermal conductivity x, y, z direction [W/m·K] | 1.01 |

| Density [kg/m3] | 2306 |

| Specific heat [kJ/kg·K] | 0.837 |

| Emissivity [-] | 0.95 |

| Transmissivity [-] | 0 |

| Electrical resistivity [ohm·m] | 0 |

| Wall roughness | 0 |

| Property | Air |

|---|---|

| Density | Equation of state |

| Viscosity [poise] | 0.0001817 |

| Thermal conductivity [W/m·K] | 0.02563 |

| Specific heat [kJ/kg·K] | 1.004 |

| Compressibility [Cp/Cv] | 1.4 |

| Emissivity | 1 |

| Wall roughness | 0 |

| Parameter | Value |

|---|---|

| Resolution factor | 1 |

| Edge growth rate | 1.1 |

| Minimum points on edge | 2 |

| Points on longest edge | 10 |

| Surface limiting aspect ratio | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabeza, L.F.; Vérez, D.; Zsembinszki, G.; Borri, E.; Prieto, C. Key Challenges for High Temperature Thermal Energy Storage in Concrete—First Steps towards a Novel Storage Design. Energies 2022, 15, 4544. https://doi.org/10.3390/en15134544

Cabeza LF, Vérez D, Zsembinszki G, Borri E, Prieto C. Key Challenges for High Temperature Thermal Energy Storage in Concrete—First Steps towards a Novel Storage Design. Energies. 2022; 15(13):4544. https://doi.org/10.3390/en15134544

Chicago/Turabian StyleCabeza, Luisa F., David Vérez, Gabriel Zsembinszki, Emiliano Borri, and Cristina Prieto. 2022. "Key Challenges for High Temperature Thermal Energy Storage in Concrete—First Steps towards a Novel Storage Design" Energies 15, no. 13: 4544. https://doi.org/10.3390/en15134544