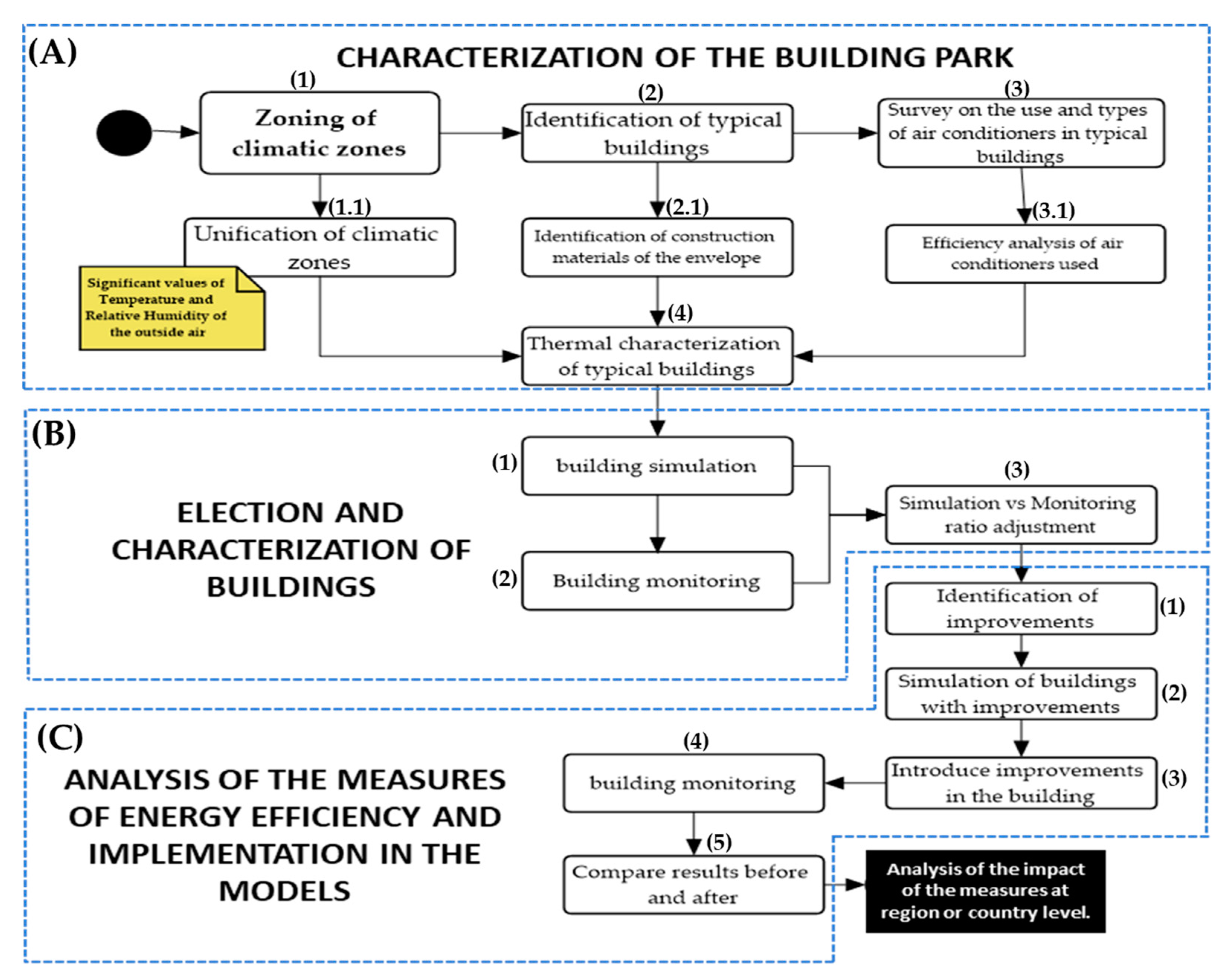

Figure 1.

Proposed methodology and detailed steeps for the evaluation of energy efficiency performance in tropical latitudes. Blocks (A–C) describe the steps to follow for the analysis of the impact of the measures at region or country level.

Figure 1.

Proposed methodology and detailed steeps for the evaluation of energy efficiency performance in tropical latitudes. Blocks (A–C) describe the steps to follow for the analysis of the impact of the measures at region or country level.

Figure 2.

Climatic classification of the provinces according to the significant influence of climatic conditions.

Figure 2.

Climatic classification of the provinces according to the significant influence of climatic conditions.

Figure 3.

Changed to: View of building types identified in the division of each climatic in

Figure 2 (A–H) zone of the case under study in DR.

Figure 3.

Changed to: View of building types identified in the division of each climatic in

Figure 2 (A–H) zone of the case under study in DR.

Figure 4.

Plan view of the building within the air temperature and relative humidity sensors’ locations.

Figure 4.

Plan view of the building within the air temperature and relative humidity sensors’ locations.

Scheme 1.

Climatic parameters collected in the representative building during the monitoring period.

Scheme 1.

Climatic parameters collected in the representative building during the monitoring period.

Scheme 2.

Data of outside temperature and relative humidity for the calculated typical day.

Scheme 2.

Data of outside temperature and relative humidity for the calculated typical day.

Scheme 3.

Data for indoor temperature and relative humidity for the calculated typical day.

Scheme 3.

Data for indoor temperature and relative humidity for the calculated typical day.

Scheme 4.

Data of energy consumption A/C.

Scheme 4.

Data of energy consumption A/C.

Scheme 5.

Data of outside temperature (°C).

Scheme 5.

Data of outside temperature (°C).

Scheme 6.

Monthly electric energy consumption in the selected building type.

Scheme 6.

Monthly electric energy consumption in the selected building type.

Figure 5.

View of the façades of the model of the F. Mancebo building in DesignBuilder.

Figure 5.

View of the façades of the model of the F. Mancebo building in DesignBuilder.

Figure 6.

Wall-section of a typical building.

Figure 6.

Wall-section of a typical building.

Scheme 7.

Heat flow by conduction plus convection in the front façade of the F. Mancebo building for one average day.

Scheme 7.

Heat flow by conduction plus convection in the front façade of the F. Mancebo building for one average day.

Scheme 8.

Heat flow by conduction plus convection through the right side of the building.

Scheme 8.

Heat flow by conduction plus convection through the right side of the building.

Scheme 9.

Heat flow by conduction plus convection through the rear façade of the building.

Scheme 9.

Heat flow by conduction plus convection through the rear façade of the building.

Scheme 10.

Transfer of heat by radiation through the front façade of the building in working hours for a typical day.

Scheme 10.

Transfer of heat by radiation through the front façade of the building in working hours for a typical day.

Scheme 11.

Transfer of heat by radiation through the lateral façade during work hours on a typical day.

Scheme 11.

Transfer of heat by radiation through the lateral façade during work hours on a typical day.

Scheme 12.

Transfer of heat by radiation through the rear wall during working hours on a typical day.

Scheme 12.

Transfer of heat by radiation through the rear wall during working hours on a typical day.

Scheme 13.

Simulated vs. calculated heat flow of the front wall of the F. Mancebo building for a typical day.

Scheme 13.

Simulated vs. calculated heat flow of the front wall of the F. Mancebo building for a typical day.

Scheme 14.

Simulated vs. calculated heat flow through the front window of the F. Mancebo building for a typical day.

Scheme 14.

Simulated vs. calculated heat flow through the front window of the F. Mancebo building for a typical day.

Scheme 15.

Simulated vs. calculated heat flow in the side window of the F. Mancebo building for a typical day.

Scheme 15.

Simulated vs. calculated heat flow in the side window of the F. Mancebo building for a typical day.

Scheme 16.

Simulated vs. monitoring energy consumption of the air conditioning units (A/C).

Scheme 16.

Simulated vs. monitoring energy consumption of the air conditioning units (A/C).

Figure 7.

Modeling in SketchUp of the F. Mancebo building.

Figure 7.

Modeling in SketchUp of the F. Mancebo building.

Figure 8.

Modeling in SketchUp of the F. Mancebo building with the proposed strategies.

Figure 8.

Modeling in SketchUp of the F. Mancebo building with the proposed strategies.

Figure 9.

View of the F. Mancebo building before and after the energy efficiency strategies.

Figure 9.

View of the F. Mancebo building before and after the energy efficiency strategies.

Scheme 17.

Daily electricity consumption (kWh) of AC units in the F. Mancebo building in the eight different climatic zones of the DR, before implantation of EESs E.

Scheme 17.

Daily electricity consumption (kWh) of AC units in the F. Mancebo building in the eight different climatic zones of the DR, before implantation of EESs E.

Scheme 18.

Daily electricity consumption (kWh) of AC units of the F. Mancebo building in the eight different climatic zones of the DR, after implementation of EESs.

Scheme 18.

Daily electricity consumption (kWh) of AC units of the F. Mancebo building in the eight different climatic zones of the DR, after implementation of EESs.

Scheme 19.

Comparison of the simulation of the heat flows in the front window before and after the implementation of the strategies for a typical day.

Scheme 19.

Comparison of the simulation of the heat flows in the front window before and after the implementation of the strategies for a typical day.

Scheme 20.

Comparison of the heat flow simulation in the lateral window before and after the implementation of F strategy for a typical day.

Scheme 20.

Comparison of the heat flow simulation in the lateral window before and after the implementation of F strategy for a typical day.

Scheme 21.

Temperatures inside the building before and after the efficiency strategies for a typical day.

Scheme 21.

Temperatures inside the building before and after the efficiency strategies for a typical day.

Scheme 22.

Relative humidity inside the building before and after the energy efficiency strategies for a typical day.

Scheme 22.

Relative humidity inside the building before and after the energy efficiency strategies for a typical day.

Scheme 23.

Simulated and monitored consumption of electric energy by the A/C before and after the energy efficiency strategies.

Scheme 23.

Simulated and monitored consumption of electric energy by the A/C before and after the energy efficiency strategies.

Scheme 24.

Simulated and monitored consumption of electric energy by the A/C after the implementation of the energy efficiency strategies.

Scheme 24.

Simulated and monitored consumption of electric energy by the A/C after the implementation of the energy efficiency strategies.

Scheme 25.

Difference between modeled vs. monitored forecasts with indoor temperature.

Scheme 25.

Difference between modeled vs. monitored forecasts with indoor temperature.

Scheme 26.

Investment recovery period for the implementation of energy efficiency strategies on the premises.

Scheme 26.

Investment recovery period for the implementation of energy efficiency strategies on the premises.

Table 1.

Comparison among items commonly used in different SCSs and items used in this studio.

Table 1.

Comparison among items commonly used in different SCSs and items used in this studio.

| SCS | Items | Used in This Studio? |

|---|

| LEED | Minimum Energy Yield | YES |

| LEED | Optimized Energy Performance | YES |

| LEED | On-site Renewable Energy | NO |

| LEED | Green energy | NO |

| BREEAM | Energy demand for heating and cooling | YES |

| BREEAM | Primary energy consumption | NO |

| BREEAM | Total CO2 emissions | YES |

| DGNB | Non-renewable primary energy requirement | YES |

| DGNB | Total Energy Decrease Requirement | YES |

| DGNB | Renewable primary energy | NO |

| HQE | Reducing energy demand through architectural design | YES |

| HQE | Reduction of primary energy consumption | NO |

| HQE | Reduction of polluting emissions into the atmosphere | YES |

Table 2.

Percentage of glass in the building’s façades.

Table 2.

Percentage of glass in the building’s façades.

| % of Glass with Respect to the Wall of the Façade |

|---|

| View | % of Glass | Orientation |

|---|

| Front façade | 28.35% | 258°—South West |

| Lateral façade | 7.56% | 177°—South |

| Rear façade | 7.56% | 93°—East |

Table 3.

Characteristics and properties of the construction materials in the F. Mancebo building.

Table 3.

Characteristics and properties of the construction materials in the F. Mancebo building.

| Material | Thickness (m) | Thermal Conductivity (W/m·K) | Density (kg/m3) | Specific Heat (J/kg·k) |

|---|

| Concrete Block | 0.15 | 1.18 | 1230 | 1000 |

| Mortar | 0.02 | 1.3 | 1900 | 1000 |

| Concrete ceiling | 0.04 | 1.65 | 2300 | 1000 |

| Single glass | 0.03 | 1.05 | 2530 | 800 |

| Aluminum (frames) | 0.01 | 207 | 2700 | 880 |

Table 4.

Emissivity values ɛ of the various building materials in the DR.

Table 4.

Emissivity values ɛ of the various building materials in the DR.

| Material | Emissivity ε |

|---|

| Concrete blocks | 0.9 |

| Concrete ceiling | 0.88 |

| Mortar | 0.93 |

| White paint | 0.93 |

| Simple glass | 0.9 |

| Aluminum (frames) | 0.03 |

Table 5.

Annual consumption of electrical energy in the type of building selected.

Table 5.

Annual consumption of electrical energy in the type of building selected.

| Year | Electricity Consumption (kWh/Year) |

|---|

| 2019 | 4616 |

| 2020 | 4303 |

| 2021 | 4176 |

Table 6.

Energy Efficiency Strategies in buildings concerning the envelope.

Table 6.

Energy Efficiency Strategies in buildings concerning the envelope.

| EES | Description | Intrusion Degree (1–5) | Implementation Time (Months) | Unitary Cost ($/m2) | Index of Availability in DR (1–10) |

|---|

| A | Change to windows with double glazed glass 4/16/4 | 4 | 1 | 300 | 1 |

| B | Vinyl film application in windows | 1 | 0.1 | 26 | 10 |

| C | Black shade painted film in windows | 1 | 0.1 | 16 | 10 |

| D | Nano ceramic paint | 1 | 0.1 | 24 | 6 |

| E | Application of white acrylic paint as a base | 2 | 0.15 | 8.7 | 10 |

| F | Canvas awnings for windows | 2 | 0.1 | 150 | 10 |

| G | Aluminum awnings for windows | 2 | 0.1 | 111 | 10 |

| H | Energy retrofitting of opaque vertical enclosures | 5 | 3 | 1080 | 7 |

| I | Landscaped roof | 4 | 1.5 | 3039 | 6 |

Table 7.

EES affecting the air conditioning system.

Table 7.

EES affecting the air conditioning system.

| EES | Power (kW) | SEER | Unitary Cost (USD/ud) |

|---|

| J | 3.51 | “4.60 ≤ SEER < 5.10” | 396.55 |

| 3.51 | “5.10 ≤ SEER < 5.60” | 413.79 |

| 3.51 | “5.60 ≤ SEER < 6.10” | 465.52 |

| 3.51 | “6.10 ≤ SEER < 8.50” | 655.17 |

| 3.51 | “SEER > 8.50” | 775.86 |

Table 8.

Chosen EES.

| EES | Zones of the Building Where Will be Implemented | Total Cost (USD) |

|---|

| B | Right and front facades | 81.35 |

| F | Right facade | 127.12 |

Table 9.

Criteria for selecting alternatives to implement in the building of the case under study.

Table 9.

Criteria for selecting alternatives to implement in the building of the case under study.

| | Table Summarizing the Alternatives |

|---|

| | Provider 1 | Provider 2 | Provider 3 | Provider 4 |

|---|

| Type of Awning | Aluminum | Canvas | Canvas | Aluminum | Canvas | Canvas |

|---|

| Cost of Product (USD) | 99.15 | 133.33 | 186.32 | 185.3 | 224.62 | 246.15 |

| Emissivity of the material | 0.04 | 0.77 | 0.77 | 0.04 | 0.77 | 0.77 |

| Thermal Conductivity (W/mK) | 207 | 0.034 | 0.034 | 2207 | 0.034 | 0.034 |

| Impermeability and Dust Repellence | 1–10 | 1–10 | 1–10 | 1–10 | 1–10 | 1–10 |

| Ease of maintenance | 1–10 | 1–10 | 1–10 | 1–10 | 1–10 | 1–10 |

Table 10.

Selection criteria for alternatives to be implemented in the front window of the case under study.

Table 10.

Selection criteria for alternatives to be implemented in the front window of the case under study.

| | Summary Table for the Choice of Front Window Protection |

|---|

| | Provider 5 | Provider 6 |

|---|

| Vinyl Type | Microperforated | Full Vinyl | Microperforated | Full Vinyl |

|---|

| Product cost (USD m2) | 26 | 24 | 29 | 26 |

| Emissivity of the material | 0.94 | 0.94 | 0.94 | 0.94 |

| Thermal Conductivity (W/mK) | 0.25 | 0.12 | 0.29 | 0.16 |

| Materia | PVC polymeric | PVC polymeric | PVC monomeric | PVC monomeric |

| Thickness (mm) | 0.0016 | 0.0016 | 0.0014 | 0.0014 |

| Size of holes to allow vision (mm) | 1.60 | 0 | 1.65 | 0 |

| Useful Life (years) | 6 | 7 | 3 | 5 |

Table 11.

Monthly electric energy consumption (kWh) before and after the implementation of the EESs in each one of the climatic zones.

Table 11.

Monthly electric energy consumption (kWh) before and after the implementation of the EESs in each one of the climatic zones.

| Climatic Zone | Province | Implemented EESs | Average Monthly Energy Consumption before Implementation of EESs (KWh) | Average Monthly Energy Consumption after Implementation of EESs (KWh) | Percentage of the Energy Consumption Reduction |

|---|

| A | San Juan | H, E | 1433 | 948 | 41% |

| B | Monseñor Nouel (Bonao) | F, H, E | 93.12 | 58 | 47% |

| C | San José de Ocoa | F, H, E | 84.72 | 34 | 50% |

| D | Santiago | E, H | 2326 | 2072 | 12% |

| E | San Francisco de Macorís | F, H, E | 103 | 84 | 20% |

| F | Pedernales | B, H, E | 2264 | 2104 | 7% |

| G | La Altagracia (Punta Cana) | C, H, E | 2552 | 2068 | 13% |

| H | La Romana | F, H, E | 1237 | 1174 | 5% |

Table 12.

Results of the simulation of the F. Mancebo building in the eight different climatic zones.

Table 12.

Results of the simulation of the F. Mancebo building in the eight different climatic zones.

| Climatic Zone | Location in the Country | Province | Daily Electricity Consumption (kWh) before Implementation | Daily Electricity Consumption (kWh) after Implementation | Reduction (%) |

|---|

| A | Southwest | San Juan | 6.58 | 3.52 | 37% |

| B | North | Monseñor Nouel (Bonao) | 2.92 | 1.23 | 48% |

| C | Southwest | San José de Ocoa | 5.56 | 2.78 | 40% |

| D | North | Santiago | 4.56 | 2.47 | 36% |

| E | North | San Francisco de Macorís | 5.65 | 3.43 | 30% |

| F | Southwest | Pedernales | 7.22 | 5.05 | 22% |

| G | East | La Altagracia (Punta Cana) | 3.44 | 1.41 | 49% |

| H | Southwest | La Romana | 6.58 | 3.55 | 36% |

Table 13.

Hourly energy consumption for the three considered scenarios.

Table 13.

Hourly energy consumption for the three considered scenarios.

| Time | Scenario 1 kWh | Scenario 2 kWh | Scenario 3 kWh |

|---|

| 7:00–7:30 | 0.00 | 0.16 | 0.17 |

| 7:30–8:00 | 0.00 | 0.15 | 0.15 |

| 8:00–8:30 | 0.26 | 0.19 | 0.19 |

| 8:30–9:00 | 0.22 | 0.18 | 0.18 |

| 9:00–9:30 | 0.20 | 0.17 | 0.17 |

| 9:30–10:00 | 0.25 | 0.23 | 0.24 |

| 10:00–10:30 | 0.31 | 0.31 | 0.31 |

| 10:30–11:00 | 0.37 | 0.37 | 0.37 |

| 11:00–11:30 | 0.41 | 0.41 | 0.41 |

| 11:30–12:00 | 0.43 | 0.42 | 0.42 |

| 12:00–12:30 | 0.43 | 0.42 | 0.42 |

| 12:30–13:00 | 0.00 | 0.35 | 0.00 |

| 13:00–13:30 | 0.00 | 0.33 | 0.00 |

| 13:30–14:00 | 0.00 | 0.32 | 0.00 |

| 14:00–14:30 | 0.36 | 0.32 | 0.33 |

| 14:30–15:00 | 0.32 | 0.29 | 0.29 |

| 15:00–15:30 | 0.28 | 0.25 | 0.25 |

| 15:30–16:00 | 0.27 | 0.24 | 0.24 |

| 16:00–16:30 | 0.26 | 0.24 | 0.24 |

| 16:30–17:00 | 0.26 | 0.24 | 0.24 |

| 17:00–30:30 | 0.26 | 0.24 | 0.24 |

| Total kWh for a Working day | 4.89 | 5.83 | 4.86 |

Table 14.

Comparison among different EESs used by different researchers using saved energy (%) and its unit cost ($/%).

Table 14.

Comparison among different EESs used by different researchers using saved energy (%) and its unit cost ($/%).

| Research | EES | Saved Energy (%) | Unit Cost (USD/%) |

| Hong Kong [13] | Change AC units | 19% | 1947 |

| Teheran [14] | Changing facades | 53% | 4528 |

| Semnan-Irán [23] | Energy retrofitting of opaque vertical enclosures | 18% | 14,810 |

| Singapore [42] | Change of lighting and AC units | 40% | 812 |

| Case Study | Painting facade

Shading windows | 37% | 166 |