Prediction of the Absolute Methane Emission Rate for Longwall Caving Extraction Based on Rock Mass Modelling—A Case Study

Abstract

:1. Introduction

- Empirical methods: Kirchgessner et al. [1] presented an equation based on the multilinear regression method, comprising the methane content emitted from a given coal seam, the coal extraction rate and the entire mine’s methane emission rate. Based on the historical data of underground mine-related methane emissions to the atmosphere in the United Kingdom, Creedy [2] summarized all the methane emissions from mines without methane drainage, from mines with drainage, from transported coal and from coal stored in stockyards on the surface. Lunarzewski [3] also proposed a function of the relationship between the coal extraction and the different variable empirical constants. The empirical method known as dynamic absolute longwall methane emission rate forecasting is commonly employed in Polish hard coal mining [4,5,6,7,8,9,10,11,12,13].

- Analytical methods: in Australia, the employed approach is the direct desorption method, which is based on measuring the methane content in coal samples [14].

- Statistical methods: Methane emission forecasting in China is generally based on the statistical method, which considers the historical methane emission data. The statistical approach adopts a number of assumptions concerning the geological conditions and the mining practices at the site encompassed by the forecasting [15]. Karacan and Olea [16] inferred the emission paths based on standard data obtained from the geophysical profiling of boreholes. The proposed technique was employed in the Black Warrior Basin, Alabama, using well logs from a series of boreholes aligned along a linear profile.

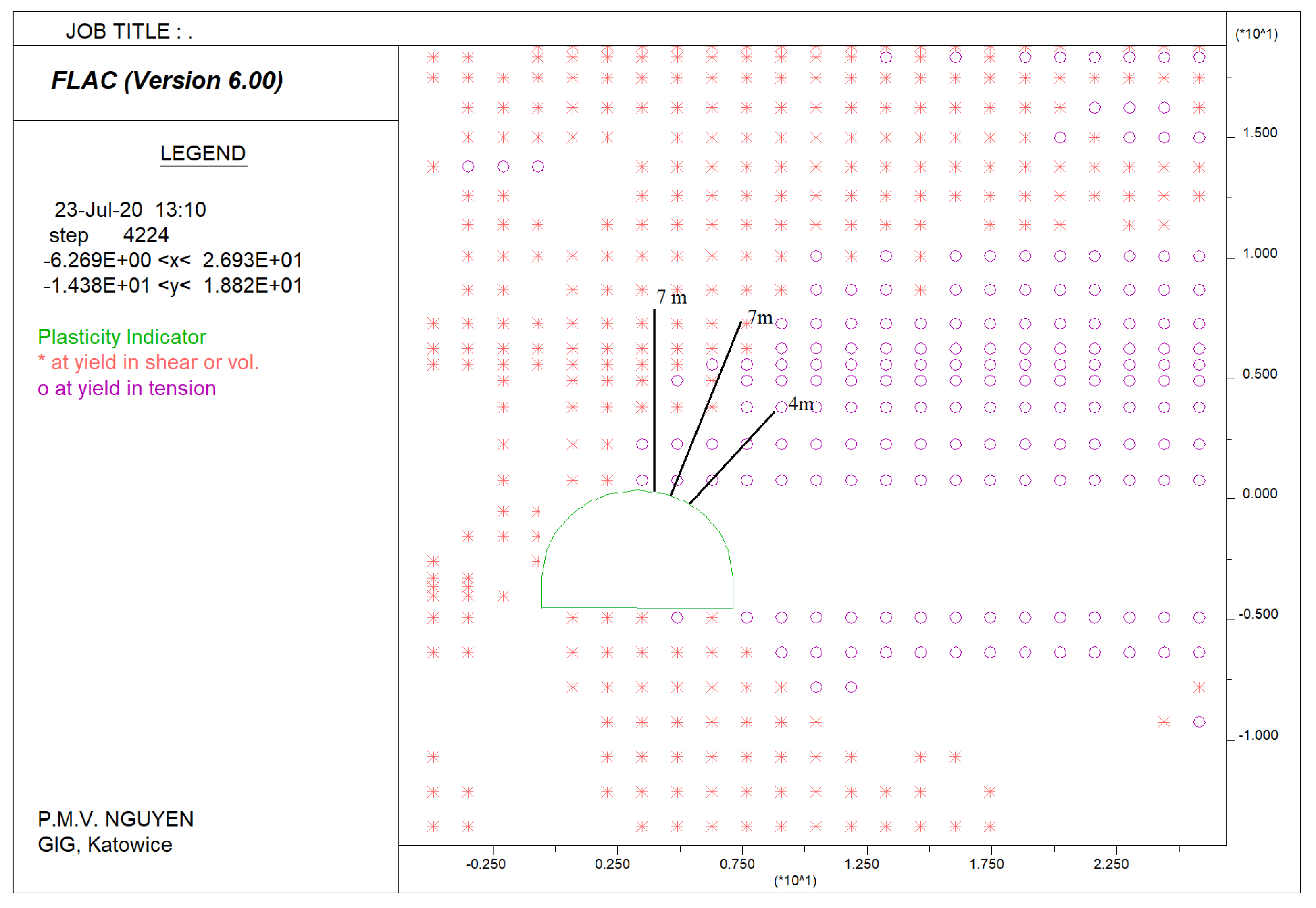

- Numerical methods: Many approaches were developed using computational fluid dynamics (CFD). Ren and Edwards [17] used laboratory data for simulating the methane flow through the rock strata surrounding a longwall panel, where the permeability is significantly dependent on the stresses generated by longwall mining. Kurnia et al. [18] simulated the behaviour of air flow and methane dispersion in a working. Results of numerical modelling were used for determining the influence of the caving zone on the methane concentration at the longwall entry [19,20]. More applications of CFD can be found in a number of studies [21,22,23,24,25]. Other approaches were based on finite difference method codes (FLAC2D). Karacan et al. [26] presented the application of geomechanical models for the purposes of inspecting the influence of the longwall length on the behaviour of the rock mass, the permeability variation, the methane emission and the design and performance of boreholes for methane drainage. Whittles et al. [27] described the construction and analysis of the results obtained from two- and three-dimensional geomechanical and gas flow models around a longwall in the United Kingdom. The numerical calculation results enabled the correct design of the orientation, length and support of the boreholes for gas drainage. They proposed a functional relationship that made it possible to forecast the intrinsic bulk permeability of a sheared coal measure rock based on the confining stress. Walentek and Wierzbiński [28] defined the influence of the destressing zones on the final forecasting methane emission rate and provided assessments of the rock mass geomechanical parameters on improving the result accuracy of the absolute methane emission rate from the analysed longwall panels. Others used the finite element method (COMSOL). Teng et al. [29] observed a growth in gas sorption and coal permeability under variable temperatures. They developed a model combining heat, gas and coal and applied it to a computational simulation of the thermal recovery of coal seam methane using COMSOL and MATLAB. Li et al. [30] also used COMSOL Multiphysics to reveal the law of air leakage as well as the gas distribution in a longwall caving zone under Y-type ventilation. Some studies also utilised artificial intelligence for the purposes of methane forecasting. Felka and Brodny [31] used a neuro-fuzzy network to forecast the concentration of methane in a longwall area. They presented the possibility of using artificial intelligence (AI) for forecasting models based on measurement data. Tutak and Brodny [32] presented a methodology for forecasting the methane concentration in a given mine area by means of the artificial neural network method. The forecasting model was constructed based on a multilayer perceptron (MLP) network. Karacan [33] and Karacan and Goodman [34] proposed a model based on principal component analysis (PCA) and an artificial neural network (ANN) to forecast the methane emissions in longwall areas in the United States.

- Combined methods: These approaches utilise one of the aforementioned methods as well as in situ measurements (monitoring) to determine the methane emission rates. Karacan [35] and Dougherty and Karacan [36] presented a “Methane Control and Prediction” software suite which was developed by means of various statistical mathematical approaches as well as artificial neural network prediction and classification methods. Dziurzyński and Wasilewski [37] carried out a computer simulation of the influence of the shearer operation and the methane flow during said operation on the dispersion of the air and methane mixture, and compared the simulation results with data recorded by automated gasometers during a measuring experiment. Dylong [38] described a proposed system enabling methane concentration measurements and forecasting in a longwall, and the application of knowledge regarding the concentrations to control the operation of the shearer. He also presented the results of a number of experimental studies that revealed the efficiency of the proposed system. Booth et al. [39] proposed a new method for methane emission forecasting that included the basic energy-related principles and computational techniques related to the degree of rock strata variation, the degree of stress variation, the failure mechanism and the degree of pressure variation with reference to space and time.

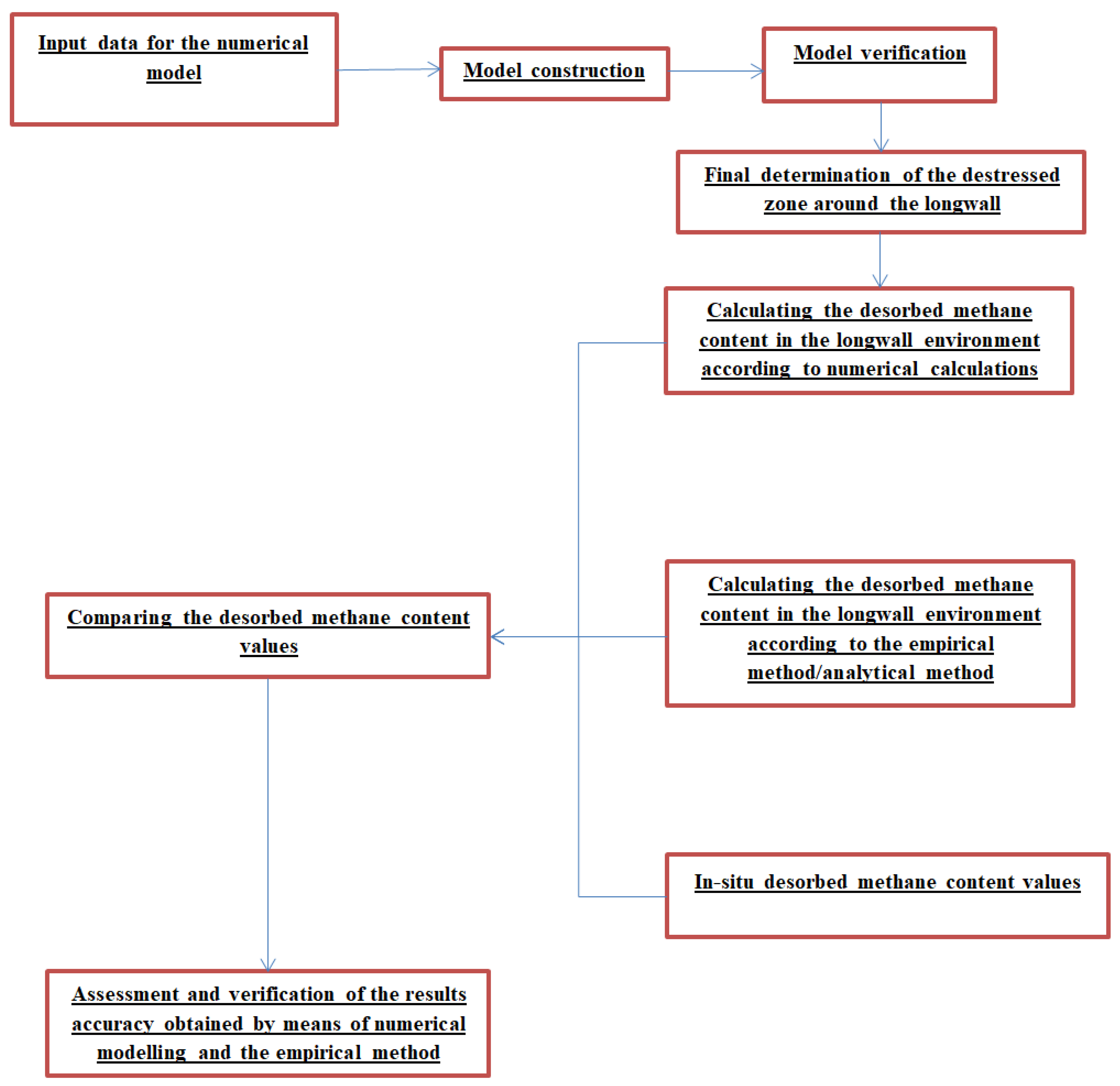

2. A Methodology for Forecasting the Absolute Methane Emission Rate in Longwall Caving Extraction

2.1. Empirical Method for Determination of Destressing Zone

- -

- For overlaying coal seams:

- -

- For underlaying coal seams:

- -

- For overlaying coal seams:

- -

- For underlaying coal seams:

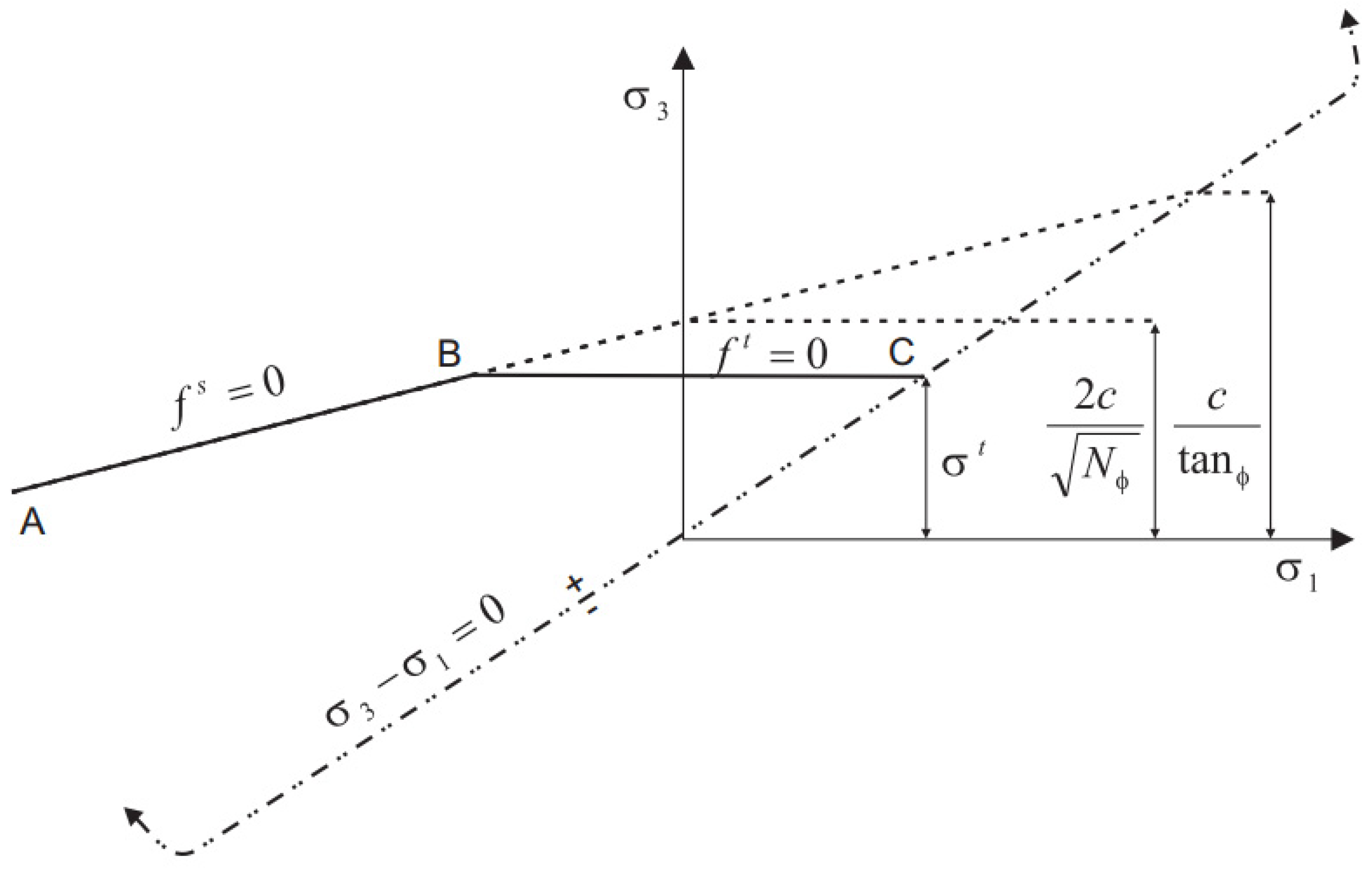

2.2. Brief Description of the FDM Software for Determination of Destressing Zone

2.3. Research Methodology

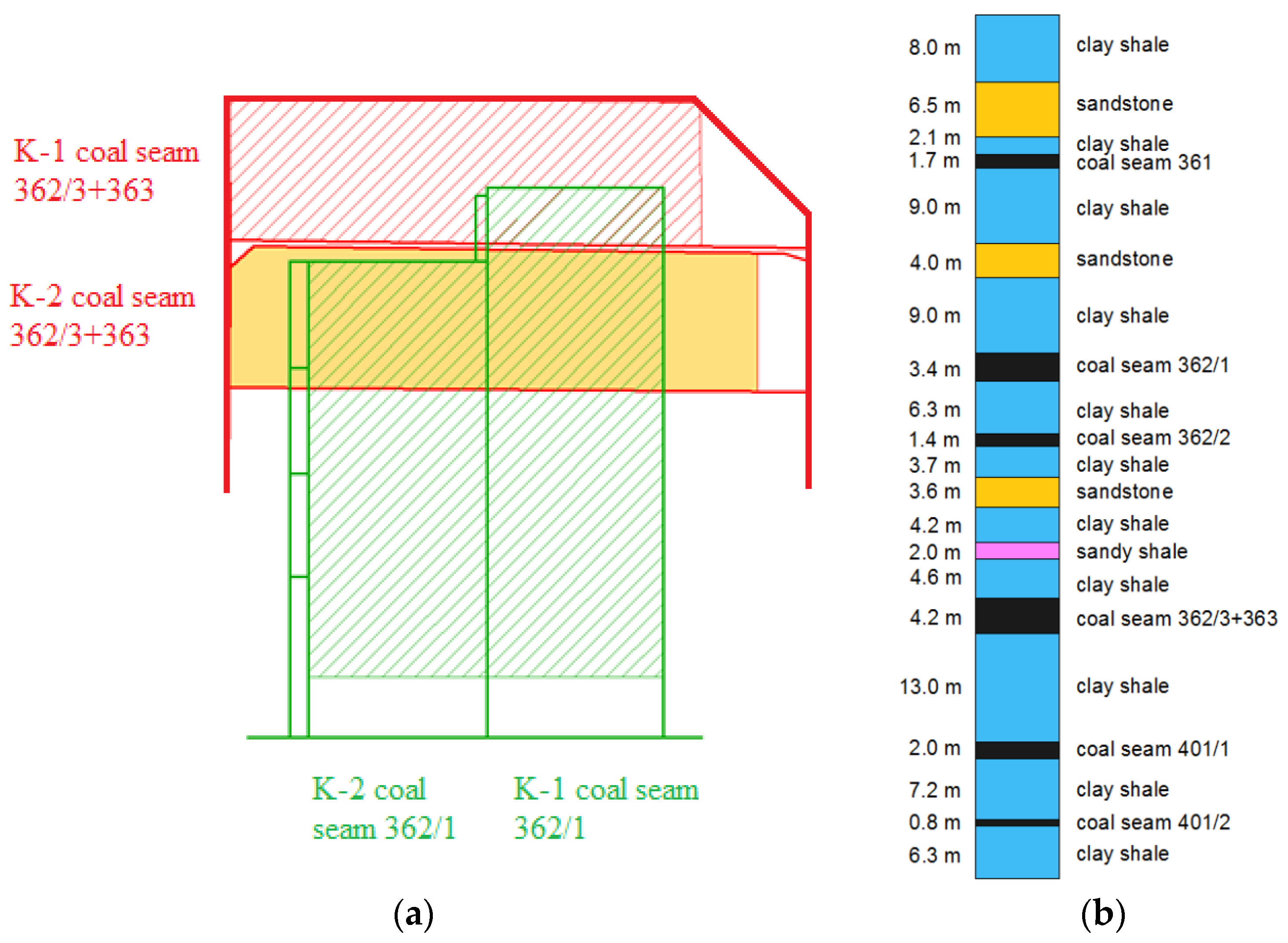

3. Case Study

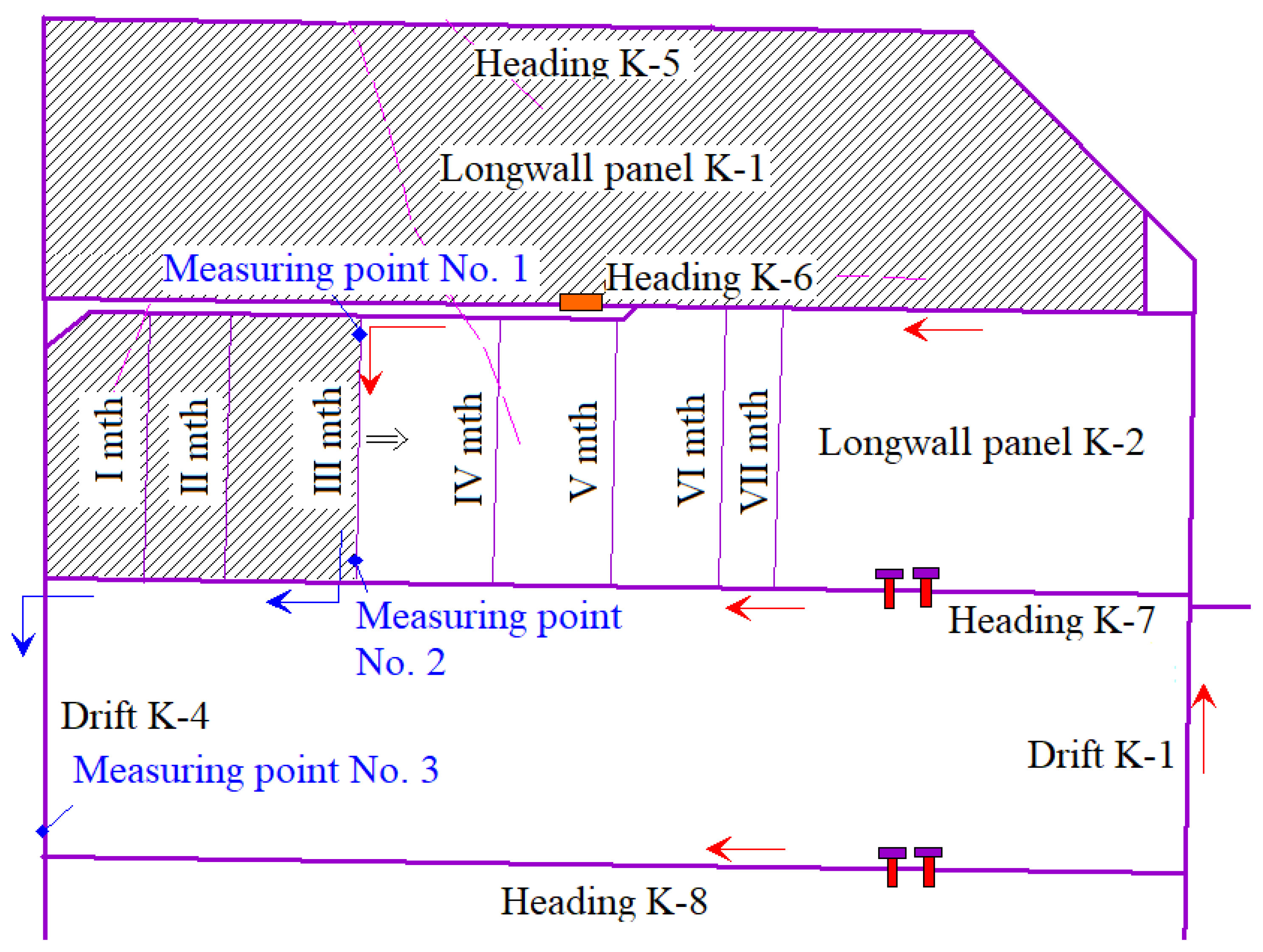

3.1. Description of the Geological and Mining Conditions of the Analysed Longwall

- -

- Roof rock:Claystone—31.5–63.2 MPa;Sandstone and mudstone—34.2–135.11 MPa;

- -

- Coal—3.03–11.9 MPa;

- -

- Floor—28.2–110.88 MPa.

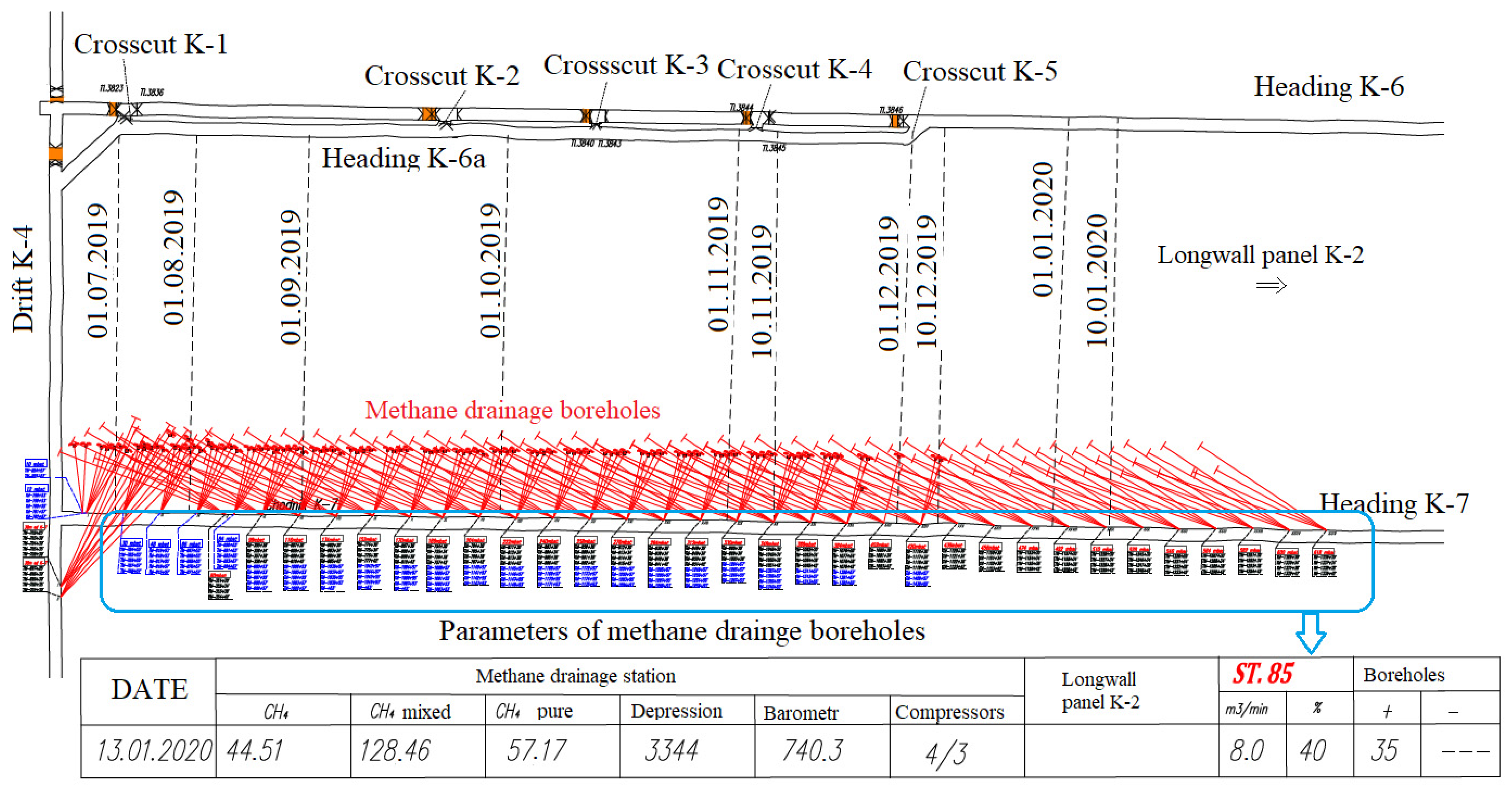

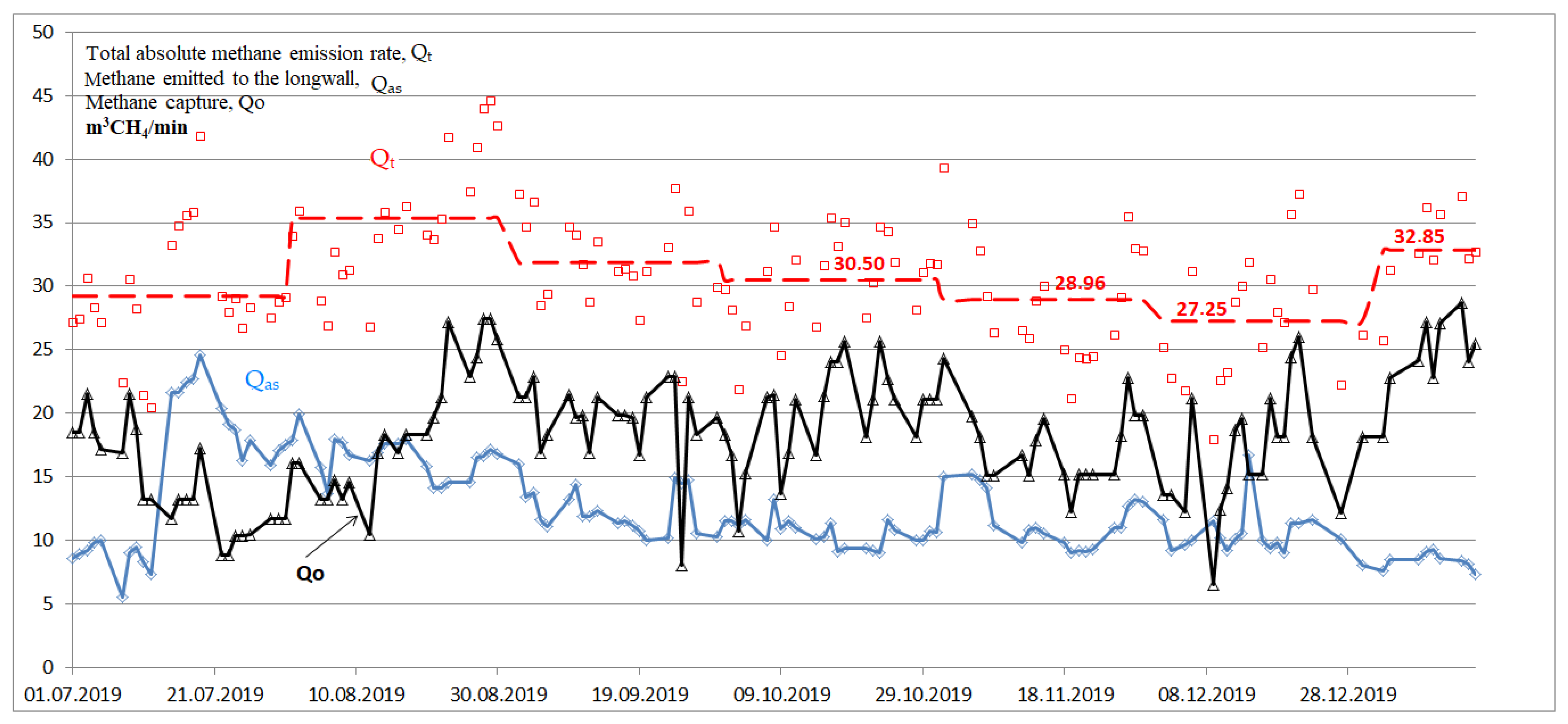

3.2. Description of the Ventilation and Methane Drainage Conditions in the K-2 Longwall, in the 362/3 + 363 Coal Seam

- -

- Methane emitted to the longwall environment;

- -

- Total absolute methane emission rate in the environment;

- -

- Methane flow to the longwall environment with the fresh air current;

- -

- Methane emissions to the longwall environment from the overlaying and underlaying deposits.

- -

- The methane capture ranged from 10 m3 CH4/min to 28 m3 CH4/min;

- -

- The methane emitted to the longwall area ranged from 5 m3 CH4/min to 25 m3 CH4/min;

- -

- The total absolute methane emission rate ranged from 20 m3 CH4/min to 45 m3 CH4/min.

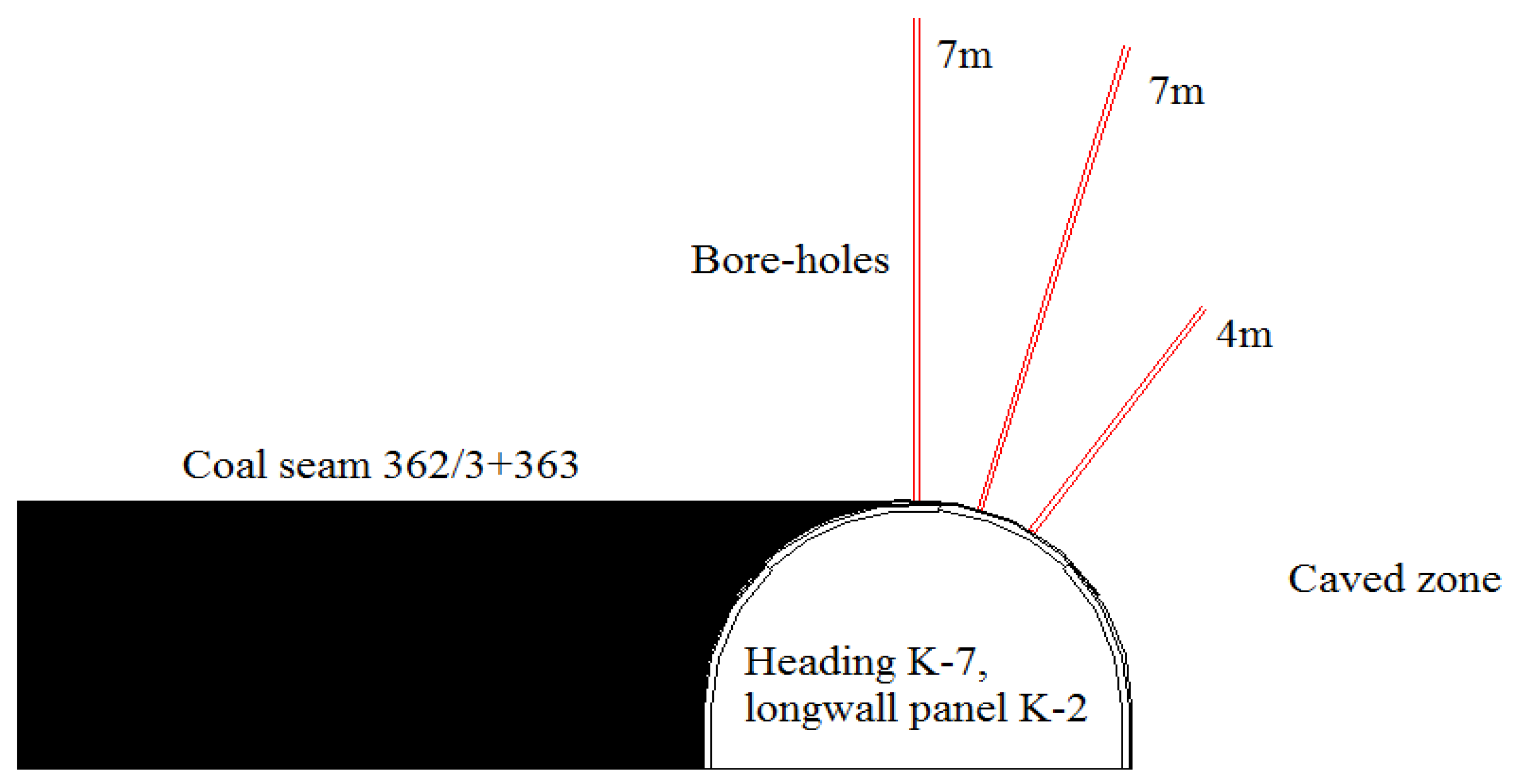

3.3. In Situ Measurements

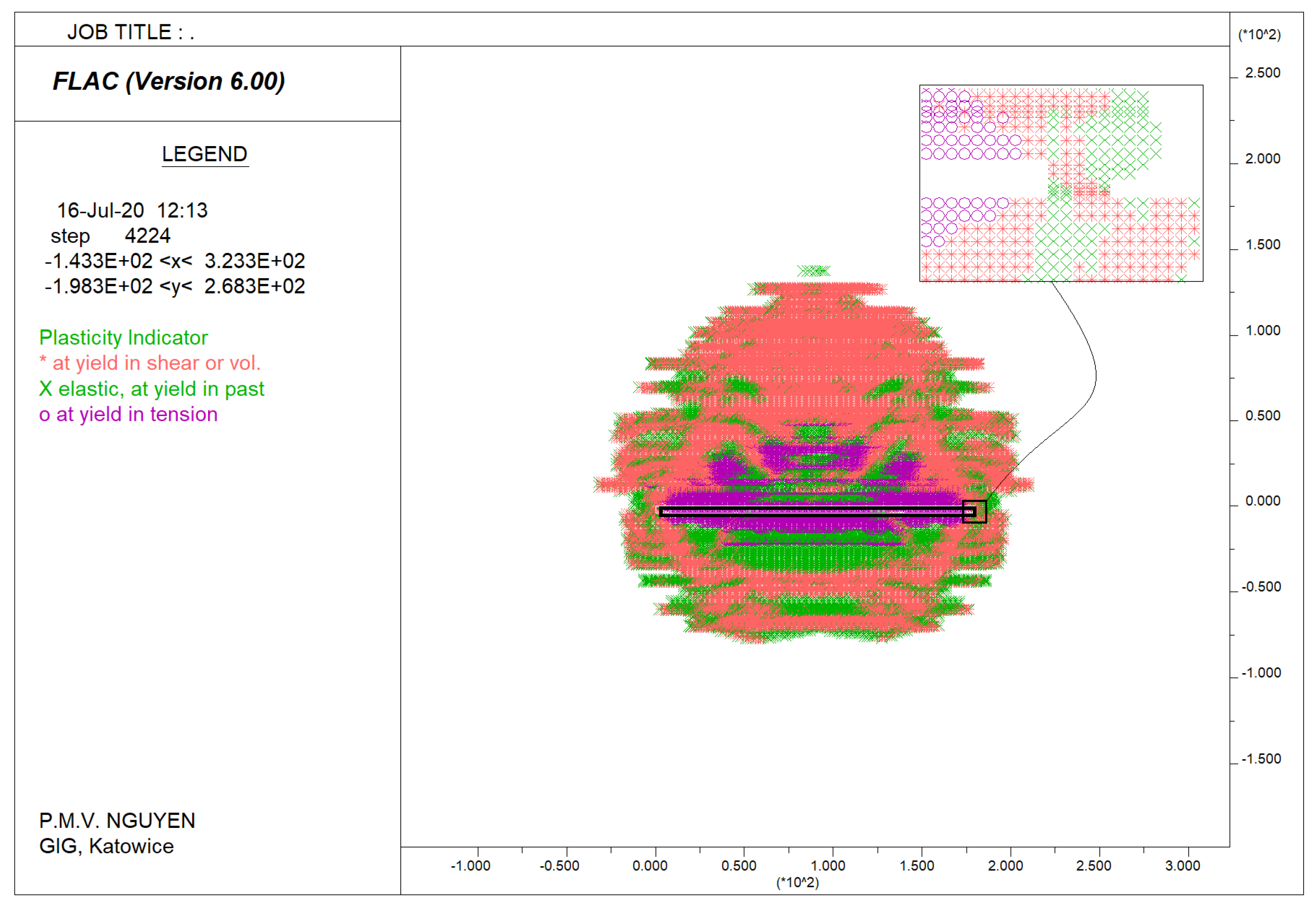

4. Numerical Modelling

4.1. Model Description

4.2. Numerical Model Verification

5. Result Analysis and Discussions

5.1. Comparison of the Destressing Zone Obtained from Numerical Calculations and the Empirical Method

5.2. Field Measurements of Methane Emission and Comparative Analysis of Total Absolute Methane Emission Rate Forcasted by Numerical Modelling and Empirical Method

5.3. Discussions

6. Conclusions

- -

- Numerical calculations based on the finite difference method (FLAC2D) can be a useful tool to determine the destressing zone, with the possibility of taking the number of geomechanical parameters into account. This method improved the accuracy of the absolute methane emission rate prediction by reducing the relative error from 55% to 12% in the case of forecasting the methane emission rates from adjacent strata, and from 39% to 13% in the case of forecasting the total captured methane emission.

- -

- The results confirm the key role of in situ measurements in the verification of rock mass models and assessments of the numerical modelling results.

- -

- The results indicate the influence of the geomechanical parameters of the rock mass on predicting the results of the total absolute methane emission rates.

- -

- The proposed methodology using numerical modelling and in situ measurements managed to predict the absolute methane emission rate with high accuracy for a case study in the Pniówek coal mine. It is suggested to apply the proposed calculation algorithm to various cases with various geo-mining conditions in order to confirm its efficiency.

- -

- Due to the influence of the longwall length and the ventilation method (arrangement of workings) on the methane emission, three-dimensional numerical modelling would achieve a higher accuracy of the results.

- -

- It is recommended to calibrate a general geomechanical model for a specific location (longwall panel or mined coal seam section), which may serve as the basis for the forecasting of specific issues related to the flow of methane or other gases in individual longwall panels in that particular mine.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kirchgessner, A.D.; Piccot, S.D.; Winkler, J.D. Estimate of global methane emissions from coal mines. Chemosphere 1993, 26, 453–472. [Google Scholar] [CrossRef]

- Creedy, D.P. Methane emissions from coal related resources in Britain: Development of a methodology. Chemosphere 1993, 26, 419–439. [Google Scholar] [CrossRef]

- Lunarzewski, L.W. Gas emissions prediction and recovery in underground coal mines. Int. J. Coal Geol. 1998, 35, 117–145. [Google Scholar] [CrossRef]

- Badura, H. Short-Term Prediction Methods for Methane Concentration at the Outlets from Caving Longwall Areas at Coal Mines; Politechnika Śląska: Gliwice, Poland, 2013. [Google Scholar]

- Szlązak, N.; Obracaj, D.; Swolkień, J. Methane drainage from roof strata using an overlying drainage gallery. Int. J. Coal Geol. 2014, 136, 99–115. [Google Scholar] [CrossRef]

- Krause, E. Short-term predictions of methane emissions during longwall mining. Arch. Min. Sci. 2015, 60, 581–594. [Google Scholar] [CrossRef]

- Koptoń, H. Review and verification of methods of absolute methane content prediction of roadway workings driven by means of heading machines in hard coal mines. Res. Rep. Min. Environ. 2007, 4, 51–64. (In Polish) [Google Scholar]

- Krause, E.; Krzystolik, P.; Łukowicz, K. Recognition, Forecasting, Control and Combating Methane Hazard in Hard Coal Mines; GIG: Katowice, Poland, 2001. [Google Scholar]

- Tarnowski, J. Mine working gas content forecasting method development. Arch. Górnictwa 1981, 26, 4. (In Polish) [Google Scholar]

- Krause, E.; Łukowicz, K. Dynamic Prediction of Absolute Methane Emissions on Longwalls; Technical Guide; GIG: Katowice, Poland, 2000. (In Polish) [Google Scholar]

- Krause, E.; Łukowicz, K. Gas hazard. In Occupational Safety in Hard Coal Mines; Konopko, W., Ed.; Central Mining Institute: Katowice, Poland, 2013. (In Polish) [Google Scholar]

- Koptoń, H. Method of prognosing absolute methane content in dog headings driven with heading machine in coal mines. Res. Rep. Min. Environ. 2009, 8, 53–72. (In Polish) [Google Scholar]

- Koptoń, H. Mathematical model of prediction of methane emissions into a drift crossing a coal seam. Pr. Nauk. GIG Kwart. Górnictwo Sr. 2011, 51–64. (In Polish) [Google Scholar]

- AS3980-1999; Australian Standards. Guide to the Determination of Gas Content of Coal—Direct Desorption Method. Standards Australia (Standards Association of Australia): Homebush, NSW, Australia, 2013.

- Chen, H.; Cheng, Y.; Ren, T.; Zhou, H.; Liu, Q. Permeability distribution characteristics of protected coal seams during unloading of the coal body. Int. J. Rock Mech. Min. Sci. 2014, 71, 105–116. [Google Scholar] [CrossRef]

- Karacan, C.O.; Olea, R.A. Inference of strata separation and gas emission paths in longwall overburden using continuous wavelet transform of well logs and geostatistical simulation. J. Appl. Geophys. 2014, 105, 147–158. [Google Scholar] [CrossRef] [Green Version]

- Ren, T.X.; Edwards, J.S. Three-dimensional computational fluid dynamics modelling of methane flow through permeable strata around a longwall face. Min. Technol. 2000, 109, 41–48. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. CFD simulation of methane dispersion and innovative methane management in underground mining faces. Appl. Math. Model. 2014, 38, 346–3484. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J. Analysis of influence of goaf sealing from tailgate on the methane concentration at the outlet from the longwall. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 042025. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M.; John, A. Analysis of influence of types of rocks forming the goaf with caving on the physical parameters of air stream flowing through these gob and adjacent headings. Mechanics 2018, 24, 43–49. [Google Scholar] [CrossRef] [Green Version]

- Mishra, D.P.; Kumar, M.; Panigrahi, D.C. Dispersion of methane in tailgate of a retreating longwall mine: A computational fluid dynamics study. Environ. Earth Sci. 2016, 75, 475. [Google Scholar] [CrossRef]

- Wierzbiński, K. The use of CFD methods for predicting the three-dimensional field of methane concentration in the ventilation roadway—Development and validation of numerical models 3D. Przegląd Górniczy 2016, 2, 44–55. (In Polish) [Google Scholar]

- Sasmito, A.P.; Birgersson, E.; Ly, H.C.; Mujumdar, A.S. Some approaches to improve ventilation system in underground coal mines environment—A computational fluid dynamic study. Tunn. Undergr. Sp. Technol. 2013, 34, 82–95. [Google Scholar] [CrossRef]

- Wala, A.M.; Vytla, S.; Taylor, C.D.; Huang, G. Mine face ventilation: A comparison of CFD results against benchmark experiments for the CFD code validation. Min. Eng. 2007, 59, 1–7. [Google Scholar]

- Branny, M. Computer simulation of flow of air and methane mixture in the longwall-return crossing zone. Arch. Min. Sci. 2006, 51, 133–145. [Google Scholar]

- Karacan, C.O.; Diamond, W.P.; Esterhuizen, G.S.; Schatzel, S.J. Numerical analysis of the impact of longwall panel width on methane emissions and performance of gob gas ventholes. In Proceedings of the International Coalbed Methane Symposium, Tuscaloosa, AL, USA, 17–19 May 2005; pp. 1–28. [Google Scholar]

- Whittles, D.N.; Lowndes, I.S.; Kingman, S.W.; Yates, C.; Jobling, S. Influence of geotechnical factors on gas flow experienced in a UK longwall coal mine panel. Int. J. Rock Mech. Min. Sci. 2006, 43, 369–387. [Google Scholar] [CrossRef]

- Walentek, A.; Wierzbiński, K. Influence of rock geomechanical parameters on increased longwall absolute methane emission rate forecasting accuracy. Arch. Min. Sci. 2020, 65, 641–664. [Google Scholar] [CrossRef]

- Teng, T.; Wang, Y.; He, X.; Chen, P. Mathematical modelling and simulation on the stimulation interactions in coalbed methane thermal recovery. Processes 2019, 7, 526. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Wu, B.; Lei, B.; Huang, Q. Study on air leakage and gas distribution in goaf of Y-type ventilation system. J. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–14. [Google Scholar] [CrossRef]

- Felka, D.; Brodny, J. Application of Neural-Fuzzy system in prediction of Methane hazard. In Proceedings of the International Conference on Intelligent Systems in Production Engineering and Maintenance, Wroclaw, Poland, 28–29 September 2017; pp. 151–160. [Google Scholar]

- Tutak, M.; Brodny, J. Predicting methane concentration in longwall regions using artificial neural networks. Int. J. Environ. Res. Public Health 2019, 16, 1406. [Google Scholar] [CrossRef] [Green Version]

- Karacan, C. Modelling and prediction of ventilation methane emissions of U.S. longwall mines using supervised Artificial Neural Networks. Int. J. Coal Geol. 2008, 73, 371–387. [Google Scholar] [CrossRef]

- Karacan, C.; Goodman, G.V. Artificial neural networks to determine ventilation emissions and optimum degasification strategies for longwall mines. In Proceedings of the 12th U.S./North American Mine Ventilation Symposium, Reno, NV, USA, 9–12 June 2008; pp. 321–329. [Google Scholar]

- Karacan, C.O. Methane Control and Prediction (MCP) Software (Version 2.0). 2010. Available online: https://www.cdc.gov/niosh/mining/products/product180.htm (accessed on 26 May 2022).

- Dougherty, H.; Karacan, C.O. A new methane control and prediction software suite for longwall mines. Comput. Geosci. 2011, 37, 1490–1500. [Google Scholar] [CrossRef]

- Dziurzyński, W.; Wasilewski, S. Assessment of methane outburst hazard in the area of longwalls based on gas sensing electrode and computer simulation of the flow of air-and-methane mixture. Przegląd Górniczy 2012, 12, 28–34. (In Polish) [Google Scholar]

- Dylong, A. A monitoring and prediction of methane emission in the longwall and possibilities to control the longwall system. Min. Inform. Autom. Electr. Eng. 2016, 54, 5–14. [Google Scholar]

- Booth, P.; Nemcik, J.; Ren, T. A critical review and new approach for determination of transient gas emission behaviour in underground coal mines. In Proceedings of the 16th Coal Operation’s Conference, Cape Town, South Africa, 10–12 February 2016; University of Wollongong: Wollongong, NSW, Australia; pp. 367–379.

- Itasca Consulting Group Inc. FLAC (2-Dimensional Finite Difference Code), Version 6.0, Minneapolis. 2008. Available online: https://www.itascacg.com/ (accessed on 5 May 2008).

- Rajwa, S.; Janoszek, T.; Prusek, S. Influence of canopy ratio of powered roof support on longwall working stability—A case study. Int. J. Min. Sci. and Technol. 2019, 29, 591–598. [Google Scholar] [CrossRef]

- Rajwa, S. The Influence of the Geometrical Construction of the Powered Roof Support on the Loss of a Longwall Working Stability Based on the Practical Experience. Arch. Min. Sci. 2020, 65, 511–529. [Google Scholar] [CrossRef]

- Rajwa, S.; Janoszek, T.; Prusek, S. Model tests of the effect of active roof support on the working stability of a longwall. Comput. Geotech. 2020, 118, 103302. [Google Scholar] [CrossRef]

- Janoszek, T. The assessment of longwall working stability based on the Mohr-Coulomb stress criterion–numerical analysis. Arch. Min. Sci. 2020, 65, 493–509. [Google Scholar] [CrossRef]

- Nguyen, P.M.V.; Rotkegel, M.; Do Van, H. Analysis of Behaviour of the Steel Arch Support in the Geological and Mining Conditions of the Cam Pha Coal Basin, Vietnam. Arch. Min. Sci. 2020, 65, 551–567. [Google Scholar] [CrossRef]

- Nguyen, P.M.V.; Olczak, T.; Rajwa, S. An investigation of longwall failure using 3D numerical modelling—A case study at a copper mine. Studia Geotech. Et Mech. 2021, 43, 389–410. [Google Scholar] [CrossRef]

- Majcherczyk, T.; Malkowski, P.; Niedbalski, Z. Describing quality of rocks around underground headings: Endoscopic observations of fractures. In Proceedings of the International Symposium of the International Society for Rock Mechanics, Eurock 2005, Brno, Czech Republic, 18–20 May 2005; pp. 355–360. [Google Scholar]

- Malkowski, P.; Majcherczyk, T.; Niedbalski, Z. Endoscopic method of rockmass quality evaluation-new experiences. In Proceedings of the 42nd U.S. Rock Mechanics 2nd U.S.-Canada Rock Mechanics Symposium, San Francisco, CA, USA, 29 June–2 July 2008. [Google Scholar]

- Walentek, A. Analysis of the Applicability of the Convergence Control Method for Gateroad Design Based on Conducted Underground Investigations. Arch. Min. Sci. 2019, 64, 765–783. [Google Scholar] [CrossRef]

- Biliński, A. Method of Selection of Longwall Face and Roadway Supports for the Panelling Conditions; Prace naukowe Monografie; CMG KOMAG: Gliwice, Poland, 2005. (In Polish) [Google Scholar]

| Rock Type | Young’s Modulus E, GPa | Poisson’s Ratio υ | Tensile Strength , MPa | Cohesion c, MPa | Angle of Internal Friction θ, ° |

|---|---|---|---|---|---|

| Coal | 2.50 | 0.30 | 0.039 | 0.54 | 24 |

| Silty shale | 4.50 | 0.25 | 0.074 | 0.75 | 27 |

| Sandstone | 10.5 | 0.22 | 0.240 | 1.90 | 33 |

| Longwall Length Ls, m | Upper Destressing (Desorption) Zone Range, hg | Lower Destressing (Desorption) Zone Range, hd | ||

|---|---|---|---|---|

| Empirical Method | FDM | Empirical Method | FDM | |

| 186 | 128 | 133 | 48 | 72 |

| Measurement Results | Calculation Results | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Measurement Date, Month | Longwall Face Distance | Average Daily Output, Wd | Q1 | n1 | Q2 | n2 | Q3 | n3 | Qo | Qt | Qas |

| - | m | Mg/d | m3/min | % CH4 | m3/min | % CH4 | m3/min | % CH4 | m3 CH4/min | m3 CH4/min | m3 CH4/min |

| 3rd | 220 | 3178 | 1370 | 0.43 | 1370 | 0.84 | 2970 | 0.86 | 12.2 | 31.85 | 26.23 |

| 4th | 325 | 3698 | 1370 | 0.30 | 1370 | 0.89 | 2975 | 0.80 | 10.8 | 30.49 | 22.41 |

| 5th | 405 | 3009 | 1370 | 0.22 | 1370 | 0.59 | 2985 | 0.68 | 11.7 | 28.98 | 23.92 |

| 6th | 485 | 2710 | 1375 | 0.27 | 1375 | 0.61 | 2990 | 0.68 | 10.6 | 27.22 | 22.54 |

| 7th | 520 | 2371 | 1375 | 0.21 | 1375 | 0.69 | 2985 | 0.92 | 8.3 | 32.87 | 26.27 |

| Month | Average Daily Output, Wd | Measured Qc(rej) | Method | Forecast Qt | Difference | Relative Error, % |

|---|---|---|---|---|---|---|

| - | Mg/d | m3/min | - | m3/min | m3/min | |

| 3rd | 3178 | 31.85 | Empirical | 29.29 | −2.56 | 8 |

| FDM | 42.84 | 10.99 | 35 | |||

| 4th | 3698 | 30.49 | Empirical | 19.38 | −11.11 | 36 |

| FDM | 33.26 | 2.77 | 9 | |||

| 5th | 3009 | 28.98 | Empirical | 25.87 | −3.11 | 11 |

| FDM | 38.97 | 9.99 | 34 | |||

| 6th | 2710 | 27.22 | Empirical | 20.36 | −6.86 | 25 |

| FDM | 31.91 | 4.69 | 17 | |||

| 7th | 2371 | 32.87 | Empirical | 17.44 | −15.43 | 47 |

| FDM | 28.14 | −4.73 | 14 | |||

| Average error of forecasts | Empirical | −7.8 | 0.25 | |||

| FDM | 4.8 | 0.22 | ||||

| Month | Average Daily Output, Wd | Measured Q(des) | Method | Forecast Qas | Difference | Relative Error |

|---|---|---|---|---|---|---|

| - | Mg/d | m3/min | - | m3/min | m3/min | |

| 3rd | 3178 | 26.23 | Empirical | 14.40 | −11.83 | 45 |

| FDM | 25.70 | −0.53 | 2 | |||

| 4th | 3698 | 22.41 | Empirical | 8.67 | −13.74 | 61 |

| FDM | 20.23 | −2.18 | 10 | |||

| 5th | 3009 | 23.92 | Empirical | 12.67 | −11.25 | 47 |

| FDM | 23.56 | −0.36 | 1 | |||

| 6th | 2710 | 22.54 | Empirical | 9.96 | −12.58 | 56 |

| FDM | 19.58 | −2.96 | 13 | |||

| 7th | 2371 | 26.27 | Empirical | 8.59 | −17.68 | 67 |

| FDM | 17.52 | −8.75 | 33 | |||

| Average error of forecasts | Empirical | −13.42 | 0.55 | |||

| FDM | −2.96 | 0.12 | ||||

| Total Captured Methane Emission | Total Predicted Value of Methane Emission by Empirical Method | Difference | Relative Error of Empirical Results | Total Predicted Value of Methane Emission by FDM | Difference | Relative Error of FDM Results |

|---|---|---|---|---|---|---|

| m3/min | m3/min | m3/min | % | m3/min | m3/min | % |

| 58.08 | 43.69 | −14.39 | 25 | 68.54 | 10.46 | 18 |

| 52.90 | 28.05 | −24.85 | 47 | 53.49 | 0.59 | 1 |

| 52.90 | 38.54 | −14.36 | 27 | 62.53 | 9.63 | 18 |

| 49.76 | 30.32 | −19.44 | 39 | 51.49 | 1.73 | 3 |

| 59.14 | 26.03 | −33.11 | 56 | 45.66 | −13.48 | 23 |

| Average value | 39 | 13 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, P.M.V.; Walentek, A.; Wierzbiński, K.; Zmarzły, M. Prediction of the Absolute Methane Emission Rate for Longwall Caving Extraction Based on Rock Mass Modelling—A Case Study. Energies 2022, 15, 4958. https://doi.org/10.3390/en15144958

Nguyen PMV, Walentek A, Wierzbiński K, Zmarzły M. Prediction of the Absolute Methane Emission Rate for Longwall Caving Extraction Based on Rock Mass Modelling—A Case Study. Energies. 2022; 15(14):4958. https://doi.org/10.3390/en15144958

Chicago/Turabian StyleNguyen, Phu Minh Vuong, Andrzej Walentek, Krystian Wierzbiński, and Marian Zmarzły. 2022. "Prediction of the Absolute Methane Emission Rate for Longwall Caving Extraction Based on Rock Mass Modelling—A Case Study" Energies 15, no. 14: 4958. https://doi.org/10.3390/en15144958