Clay Mineral Type and Content Control Properties of Fine-Grained CO2 Caprocks—Laboratory Insights from Strongly Swelling and Non-Swelling Clay–Quartz Mixtures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation and Characterization

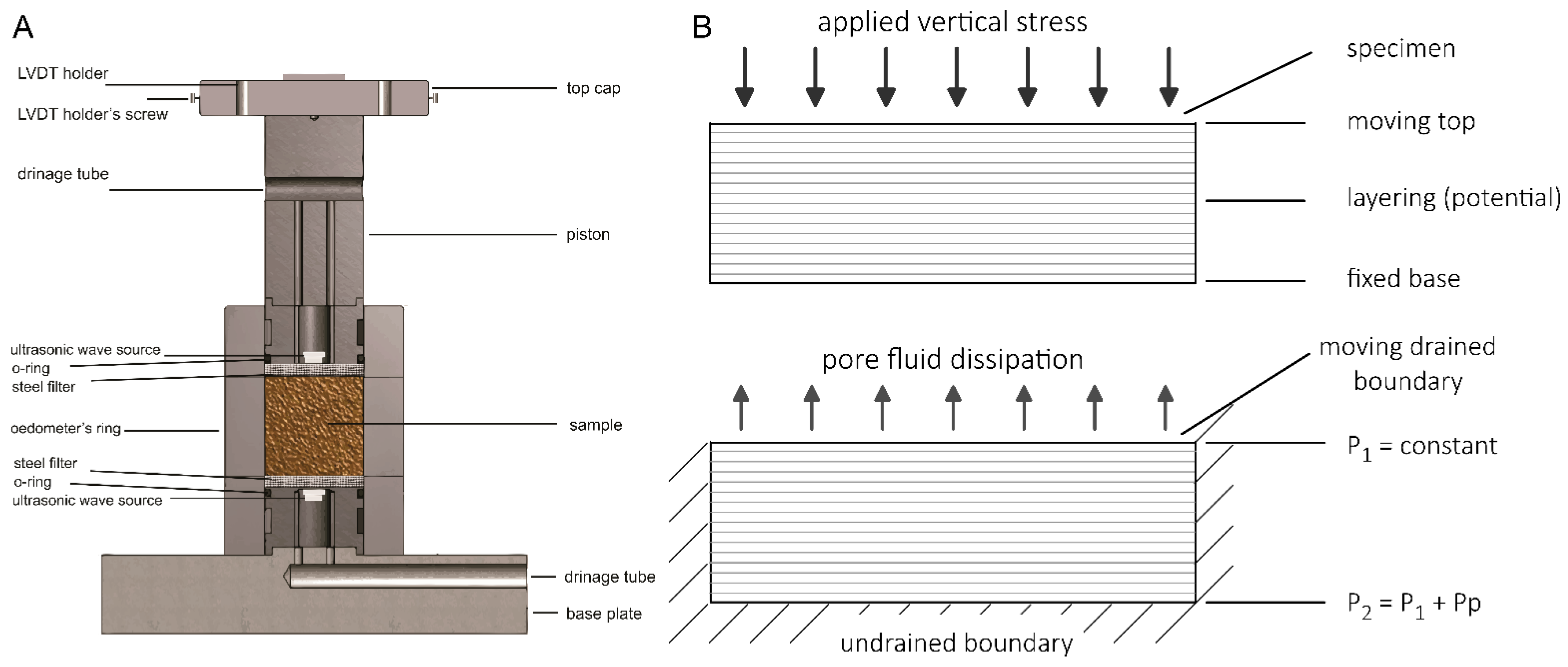

2.2. Laboratory Setup and Experimental Procedure

2.3. Vertical Permeability Measurement

3. Results and Discussion

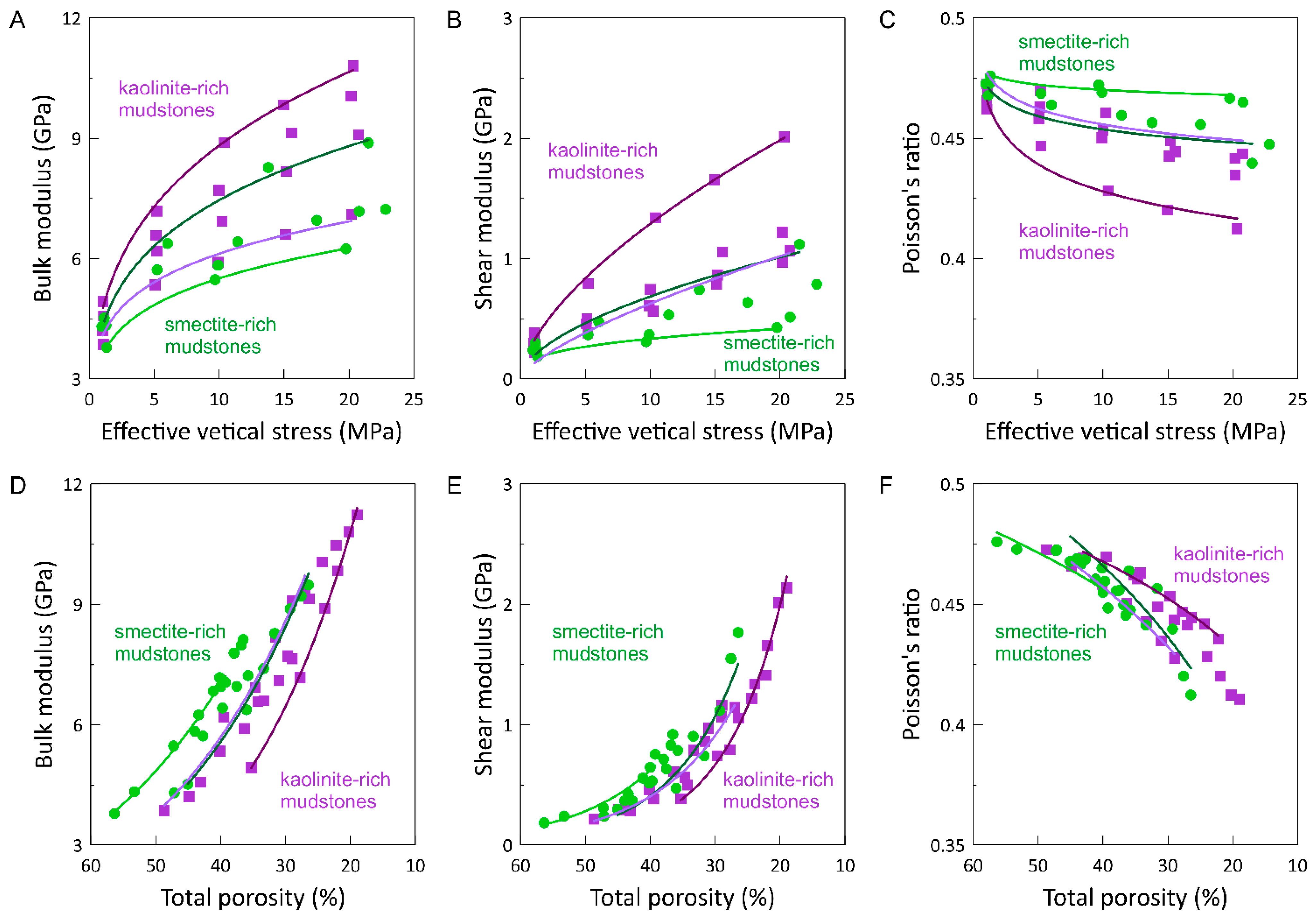

3.1. Changes in Rock Properties as a Function of Effective Stress

3.2. Changes in Rock Properties as a Function of Total Porosity

3.3. Changes in Elastic Moduli and Rock Physics Properties

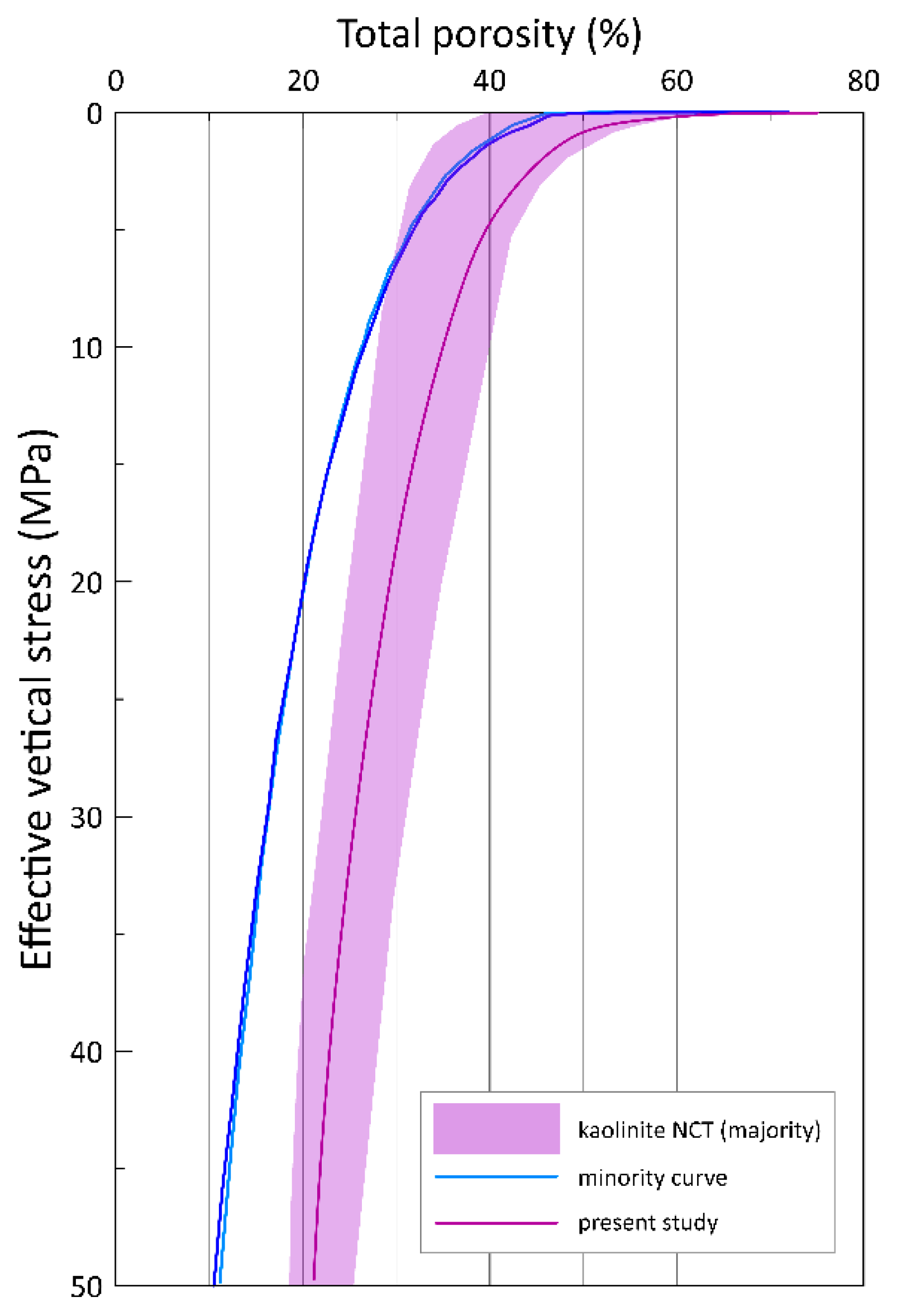

3.4. Inconsistencies in Published NCTs for Pure Kaolinite and Binary Quartz–Clay Mixtures

4. Implications for Top Seal Integrity

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Figure | Subplot | Equation | Kaolinite-Rich Binary Mixtures | Smectite-Rich Binary Mixtures | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lower Boundary Coefficients | Upper Boundary Coefficients | Lower Boundary Coefficients | Upper Boundary Coefficients | |||||||

| a | b | a | b | a | b | a | b | |||

| Figure 3 | A | y = exp (a + b∗ln(x)) | 3.8660022 | −0.12582485 | 3.604363 | −0.18990982 | 4.0482839 | −0.082468556 | 3.8048668 | −0.118814 |

| B | −1.6264308 | −1.4806903 | −5.0742795 | −1.0291726 | −3.6129421 | −1.5440703 | −6.5994262 | −1.4030827 | ||

| C | 7.3226798 | 0.088211752 | 7.3677866 | 0.13741761 | 7.3050906 | 0.082131234 | 7.3514765 | 0.10892861 | ||

| D | 5.7056652 | 0.26926114 | 5.9981767 | 0.27632831 | 5.7428196 | 0.13130909 | 5.8591546 | 0.24165027 | ||

| Figure 4 | A | ln(y) = b∗x + a | −10.028926 | 0.098084803 | −14.185274 | 0.27424423 | −19.311332 | 0.22147957 | −17.236867 | 0.24334317 |

| B | 8.3119656 | −0.026209519 | 8.2279476 | −0.018581189 | 8.2808769 | −0.020270873 | 8.271686 | −0.016788725 | ||

| C | 7.8537623 | −0.05101014 | 7.7097782 | −0.038643926 | 7.7724375 | −0.041374261 | 7.7070976 | −0.034836206 | ||

| Figure 5 | A | y = exp (a + b∗ln(x)) | 1.4015981 | 0.1781668 | 1.5485299 | 0.27294465 | 1.2796649 | 0.18507085 | 1.4564052 | 0.24001766 |

| B | −2.0943057 | 0.70562619 | −1.1804517 | 0.62291463 | −1.8316319 | 0.3186028 | −1.6752392 | 0.56303121 | ||

| C | −0.76191432 | −0.037718901 | −0.738609 | −0.020471854 | −0.75029521 | −0.01735871 | −0.73956822 | −0.006554059 | ||

| D | ln(y) = b∗x + a | −0.041068431 | 3.3820241 | −0.051477194 | 3.4099259 | 3.4275793 | −0.036983438 | 3.3728576 | −0.041360769 | |

| E | 2.3407736 | −0.081132019 | 2.8757394 | −0.10934554 | 2.6979158 | −0.079317675 | 2.968095 | −0.096656714 | ||

| F | y = exp (a + b∗ln(x)) | −1.500971 | 0.19471909 | −1.1883243 | 0.11616354 | −1.3252217 | 0.1465476 | −1.5923159 | 0.22429785 | |

References

- Song, J.; Zhang, D. Comprehensive review of caprock-sealing mechanisms for geologic carbon sequestration. Environ. Sci. Technol. 2013, 47, 9–22. [Google Scholar] [CrossRef] [PubMed]

- Fazeli, H.; Nooraiepour, M.; Hellevang, H. Microfluidic Study of Fracture Dissolution in Carbonate-Rich Caprocks Subjected to CO2-Charged Brine. Ind. Eng. Chem. Res. 2020, 59, 450–457. [Google Scholar] [CrossRef]

- Nooraiepour, M. Rock Properties and Sealing Efficiency in Fne-Grained Siliciclastic Caprocks—Implications for CCS and Petroleum Industry; University of Oslo: Oslo, Norway, 2018. [Google Scholar]

- Nooraiepour, M.; Haile, B.G.; Hellevang, H. Compaction and mechanical strength of Middle Miocene mudstones in the Norwegian North Sea–The major seal for the Skade CO2 storage reservoir. Int. J. Greenh. Gas Control 2017, 67, 49–59. [Google Scholar] [CrossRef]

- Nooraiepour, M.; Fazeli, H.; Miri, R.; Hellevang, H. Effect of CO2 Phase States and Flow Rate on Salt Precipitation in Shale Caprocks-A Microfluidic Study. Environ. Sci. Technol. 2018, 52, 6050–6060. [Google Scholar] [CrossRef]

- Falcon-Suarez, I.H.; Lichtschlag, A.; Marin-Moreno, H.; Papageorgiou, G.; Sahoo, S.K.; Roche, B.; Callow, B.; Gehrmann, R.A.S.; Chapman, M.; North, L. Core-scale geophysical and hydromechanical analysis of seabed sediments affected by CO2 venting. Int. J. Greenh. Gas Control 2021, 108, 103332. [Google Scholar] [CrossRef]

- Avseth, P.; Draege, A.; van Wijingaarden, A.J.; Johansen, T.A.; Jørstad, A. Shale rock physics and implications for AVO analysis: A North Sea demonstration. Lead. Edge (Tulsa, OK) 2008, 27, 788–797. [Google Scholar] [CrossRef]

- Avseth, P.; Mukerji, T.; Mavko, G.; Dvorkin, J. Rock-physics diagnostics of depositional texture, diagenetic alterations, and reservoir heterogeneity in high-porosity siliciclastic sediments and rocks-A review of selected models and suggested work flows. Geophysics 2010, 75, X75A31–X75A47. [Google Scholar] [CrossRef]

- Aplin, A.C.; Macquaker, J.H.S. Mudstone diversity: Origin and implications for source, seal, and reservoir properties in petroleum systems. Am. Assoc. Pet. Geol. Bull. 2011, 95, 2031–2059. [Google Scholar] [CrossRef]

- Avseth, P.; Flesche, H.; Van Wijngaarden, A.J. AVO classification of lithology and pore fluids constrained by rock physics depth trends. Lead. Edge (Tulsa, OK) 2003, 22, 1004–1011. [Google Scholar] [CrossRef]

- Loseth, H.; Wensaas, L.; Gading, M.; Duffaut, K.; Springer, M. Can hydrocarbon source rocks be identified on seismic data? Geology 2011, 39, 1167–1170. [Google Scholar] [CrossRef] [Green Version]

- Nooraiepour, M.; Mondol, N.H.; Hellevang, H.; Bjørlykke, K. Experimental mechanical compaction of reconstituted shale and mudstone aggregates: Investigation of petrophysical and acoustic properties of SW Barents Sea cap rock sequences. Mar. Pet. Geol. 2017, 80, 265–292. [Google Scholar] [CrossRef] [Green Version]

- Haile, B.G.; Klausen, T.G.; Czarniecka, U.; Xi, K.; Jahren, J.; Hellevang, H. How are diagenesis and reservoir quality linked to depositional facies? A deltaic succession, Edgeøya, Svalbard. Mar. Pet. Geol. 2018, 92, 519–546. [Google Scholar] [CrossRef]

- Bjørlykke, K.; Høeg, K. Effects of burial diagenesis on stresses, compaction and fluid flow in sedimentary basins. Mar. Pet. Geol. 1997, 14, 267–276. [Google Scholar] [CrossRef]

- Bjørlykke, K. Clay mineral diagenesis in sedimentary basins-A key to the prediction of rock properties. Examples from the North Sea Basin. Clay Miner. 1998, 33, 14–34. [Google Scholar] [CrossRef]

- Bjørlykke, K. Compaction of sedimentary rocks: Shales, sandstones and carbonates. In Petroleum Geoscience: From Sedimentary Environments to Rock Physics, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 351–360. ISBN 9783642341328. [Google Scholar]

- Storvoll, V.; Brevik, I. Identifying time, temperature, and mineralogical effects on chemical compaction in shales by rock physics relations. Lead. Edge 2008, 27, 750–756. [Google Scholar] [CrossRef]

- Dutta, N.C. Deepwater geohazard prediction using prestack inversion of large offset P-wave data and rock model. Lead. Edge (Tulsa, OK) 2002, 21, 193–198. [Google Scholar] [CrossRef]

- Goulty, N.R.; Sargent, C.; Andras, P.; Aplin, A.C. Compaction of diagenetically altered mudstones—Part 1: Mechanical and chemical contributions. Mar. Pet. Geol. 2016, 77, 703–713. [Google Scholar] [CrossRef] [Green Version]

- Lahann, R. Impact of Smectite Diagenesis on Compaction Modeling and Compaction Equilibrium. Press. Regimes Sediment. Basins Their Predict. 2001, 76, 61–72. [Google Scholar]

- Day-Stirrat, R.J.J.; McDonnell, A.; Wood, L.J.J. Diagenetic and Seismic concerns associated with interpretation of deeply buried “mobile shales”. AAPG Mem. 2010, 93, 5–27. [Google Scholar] [CrossRef]

- Milliken, K.L.; Day-Stirrat, R.J. Cementation in mudrocksz: Brief review with examples from cratonic basin mudrocks. AAPG Mem. 2013, 133–150. [Google Scholar] [CrossRef]

- Chilingarian, G.V.; Rieke Iii, H.H.; Donaldson, E.C. Chapter 2 Compaction of argillaceous sediments. Dev. Pet. Sci. 1995, 41, 47–164. [Google Scholar]

- Giles, M.R.R.; Indrelid, S.L.; James, D.M.D. Compaction—The great unknown in basin modelling. Geol. Soc. Lond. Spec. Publ. 1998, 141, 15–43. [Google Scholar] [CrossRef]

- Bachrach, R. Mechanical compaction in heterogeneous clastic formations from plastic-poroelastic deformation principles: Theory and applications. Geophys. Prospect. 2016. [Google Scholar] [CrossRef]

- Nooraiepour, M.; Mondol, N.H.; Hellevang, H. Permeability and physical properties of semi-compacted fine-grained sediments—A laboratory study to constrain mudstone compaction trends. Mar. Pet. Geol. 2019, 102, 590–603. [Google Scholar] [CrossRef]

- Ma, X.; Zoback, M.D. Laboratory experiments simulating poroelastic stress changes associated with depletion and injection in low-porosity sedimentary rocks. J. Geophys. Res. Solid Earth 2017, 122, 2478–2503. [Google Scholar] [CrossRef]

- Vernik, L.; Kachanov, M. Modeling elastic properties of siliciclastic rocks. Geophysics 2010, 75, E171–E182. [Google Scholar] [CrossRef]

- Athy, L.F. Density, Porosity and Compaction of Sedimentary Rocks. Am. Assoc. Pet. Geol. Bull. 1930, 14, 1–24. [Google Scholar]

- Velde, B. Compaction trends of clay-rich deep sea sediments. Mar. Geol. 1996, 133, 193–201. [Google Scholar] [CrossRef]

- Schneider, J.; Flemings, P.B.B.; Day-Stirrat, R.J.J.; Germaine, J.T.T. Insights into pore-scale controls on mudstone permeability through resedimentation experiments. Geology 2011, 39, 1011–1014. [Google Scholar] [CrossRef]

- Peltonen, C.; Marcussen, Ø.; Bjørlykke, K.; Jahren, J. Clay mineral diagenesis and quartz cementation in mudstones: The effects of smectite to illite reaction on rock properties. Mar. Pet. Geol. 2009, 26, 887–898. [Google Scholar] [CrossRef]

- Marcussen, Ø.; Faleide, J.I.; Jahren, J.; Bjørlykke, K. Mudstone compaction curves in basin modelling: A study of Mesozoic and Cenozoic Sediments in the northern North Sea. Basin Res. 2010, 22, 324–340. [Google Scholar] [CrossRef]

- Vernik, L.; Nur, A. Petrophysical classification of siliciclastics for lithology and porosity prediction from seismic velocities. Am. Assoc. Pet. Geol. Bull. 1992, 76, 1295–1309. [Google Scholar]

- Winkler, K.W. Contact stiffness in granular porous materials: Comparison between theory and experiment. Geophys. Res. Lett. 1983, 10, 1073–1076. [Google Scholar] [CrossRef]

- Bernabé, Y.; Fryer, D.T.T.; Hayes, J.A.A. The effect of cement on the strength of granular rocks. Geophys. Res. Lett. 1992, 19, 1511–1514. [Google Scholar] [CrossRef]

- Han, D.-H.H.; Batzle, M. Velocities of deepwater reservoir sands. Lead. Edge (Tulsa, OK) 2006, 25, 460–466. [Google Scholar] [CrossRef]

- Mavko, G.; Mukerji, T.; Dvorkin, J. The Rock Physics Handbook: Tools for Seismic Analysis of Porous Media, 2nd ed.; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Wissa, A.E.; Christian, J.T.; Davis, E.H.; Heiberg, S. Consolidation at constant rate of strain. ASCE J. Soil Mech. Found. Div. 1971, 97, 1393–1413. [Google Scholar] [CrossRef]

- ASTM Standard D4186-06. Test Method for One-Dimensional Consolidation Properties of Saturated Cohesive Soils Using Controlled-Strain Loading 2006. ASTM: West Conshohocken, PA, USA, 2006.

- Adams, A.L. Laboratory Evaluation of the Constant Rate of Strain and Constant Head Techniques for Measurement of the Hydraulic Conductivity of Fine Grained Soils; Massachusetts Institute of Technology: Cambridge, MA, USA, 2011. [Google Scholar]

- Moghadam, J.N.; Nooraiepour, M.; Hellevang, H.; Mondol, N.H.; Aagaard, P. Relative permeability and residual gaseous CO2 saturation in the Jurassic Brentskardhaugen Bed sandstones, Wilhelmøya Subgroup, western central Spitsbergen, Svalbard. Nor. J. Geol. 2019, 99, 317–328. [Google Scholar] [CrossRef]

- Nooraiepour, M.; Bohloli, B.; Park, J.; Sauvin, G.; Skurtveit, E.; Mondol, N.H.H. Effect of brine-CO2 fracture flow on velocity and electrical resistivity of naturally fractured tight sandstones. Geophysics 2018, 83, WA37–WA48. [Google Scholar] [CrossRef] [Green Version]

- Gamage, K.; Screaton, E.; Bekins, B.; Aiello, I. Permeability–porosity relationships of subduction zone sediments. Mar. Geol. 2011, 279, 19–36. [Google Scholar] [CrossRef]

- Daigle, H.; Screaton, E.J.J. Evolution of sediment permeability during burial and subduction. Geofluids 2015, 15, 84–105. [Google Scholar] [CrossRef]

- Yang, Y.; Aplin, A.C. A permeability–porosity relationship for mudstones. Mar. Pet. Geol. 2010, 27, 1692–1697. [Google Scholar] [CrossRef]

- Brigatti, M.F.F.; Galán, E.; Theng, B.K.G. Structure and Mineralogy of Clay Minerals. In Handbook of Clay Science; Elsevier: Amsterdam, The Netherlands, 2013; Volume 5, pp. 21–81. [Google Scholar]

- Avseth, P.; Mukerji, T.; Mavko, G. Quantitative Seismic Interpretation: Applying Rock Physics Tools to Reduce Interpretation Risk; ProQuest: Morrisville, NC, USA, 2005; Volume 9780521816, ISBN 9780511600074. [Google Scholar]

- Brigatti, M.F.F.; Galán, E.; Theng, B.K.G.K.G.; Schoonheydt, R.A.; Johnston, C.T.; Bergaya, F. 1—Clay minerals and their surfaces. In Surface and Interface Chemistry of Clay Minerals; Schoonheydt, R., Johnston, C.T., Bergaya, F.B.T.-D., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; Volume 9, pp. 1–21. ISBN 1572-4352. [Google Scholar]

- Bergaya, F.; Lagaly, G. Chapter 1—General Introduction: Clays, Clay Minerals, and Clay Science. In Handbook of Clay Science; Bergaya, F., Lagaly, G.B.T.-D., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; Volume 5, pp. 1–19. ISBN 1572-4352. [Google Scholar]

- Haigh, S.K.; Vardanega, P.J. Fundamental basis of single-point liquid limit measurement approaches. Appl. Clay Sci. 2014, 102, 8–14. [Google Scholar] [CrossRef] [Green Version]

- Emmerich, K. Chapter 2.13—Full Characterization of Smectites. In Handbook of Clay Science; Bergaya, F., Lagaly, G.B.T.-D., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; Volume 5, pp. 381–404. ISBN 1572-4352. [Google Scholar]

- Castagna, J.P.; Batzle, M.L.; Eastwood, R.L. Relationships between compressional-wave and shear-wave velocities in clastic silicate rocks. Geophysics 1985, 50, 571–581. [Google Scholar] [CrossRef]

- Greenberg, M.L.; Castagna, J.P. Shear-wave velocity estimation in porous rocks: Theoretical formulation, preliminary verification and applications. Geophys. Prospect. 1992, 40, 195–209. [Google Scholar] [CrossRef]

- Beloborodov, R.; Pervukhina, M.; Han, T.; Josh, M. Experimental Characterization of Dielectric Properties in Fluid Saturated Artificial Shales. Geofluids 2017, 2017, 1019461. [Google Scholar] [CrossRef] [Green Version]

- Chilingar, G.V.; Knight, L. Relationship Between Pressure and Moisture Content of Kaolinite, Illite, and Montmorillonite Clays1. Am. Assoc. Pet. Geol. Bull. 1960, 44, 101–106. [Google Scholar] [CrossRef]

- von Engelhardt, W.; Gaida, K.H. Concentration changes of pore solutions during compaction of clay sediments. J. Sediment. Res. 1963, 33, 919–930. [Google Scholar] [CrossRef]

- Brown, P.R. Compaction of fine-grained terrigenous and carbonate sediments: A review. Bull. Can. Pet. Geol. 1969, 17, 486–495. [Google Scholar]

- Marion, D.; Nur, A.; Yin, H.; Han, D. Compressional velocity and porosity in sand-clay mixtures. Geophysics 1992, 57, 554–563. [Google Scholar] [CrossRef]

- Robinet, J.C.; Pakzad, M.; Plas, F. Un modèle rhéologique pour les argiles gonflantes. Rev. Française Géotechnique 1994, 68, 57–67. [Google Scholar] [CrossRef] [Green Version]

- Vasseur, G.; Djeran-Maigre, I.; Grunberger, D.; Rousset, G.; Tessier, D.; Velde, B. Evolution of structural and physical parameters of clays during experimental compaction. Mar. Pet. Geol. 1995, 12, 941–954. [Google Scholar] [CrossRef]

- Djéran-Maigre, I.; Tessier, D.; Grunberger, D.; Velde, B.; Vasseur, G. Evolution of microstructures and of macroscopic properties of some clays during experimental compaction. Mar. Pet. Geol. 1998, 15, 109–128. [Google Scholar] [CrossRef]

- Beloborodov, R.; Pervukhina, M.; Lebedev, M. Compaction trends of full stiffness tensor and fluid permeability in artificial shales. Geophys. J. Int. 2018, 212, 1687–1693. [Google Scholar] [CrossRef] [Green Version]

- Glover, P.W.J.; Luo, M. The Porosity and Permeability of Binary Grain Mixtures. Transp. Porous Media 2020, 132, 1–37. [Google Scholar] [CrossRef] [Green Version]

- Yin, H. Acoustic Velocity and Attenuation of Rocks: Isotropy, Intrinsic Anisotropy, and Stress-Induced Anisotropy; Stanford University: Stanford, CA, USA, 1992. [Google Scholar]

- Dewhurst, D.N.; Aplin, A.C.; Sarda, J.-P.; Yang, Y. Compaction-driven evolution of porosity and permeability in natural mudstones: An experimental study. J. Geophys. Res. Solid Earth 1998, 103, 651–661. [Google Scholar] [CrossRef]

- Revil, A.; Grauls, D.; Brévart, O. Mechanical compaction of sand/clay mixtures. J. Geophys. Res. Solid Earth 2002, 107, 2293. [Google Scholar] [CrossRef]

- Pitman, T.D.; Robertson, P.K.; Sego, D.C. Influence of fines on the collapse of loose sands. Can. Geotech. J. 1994, 31, 728–739. [Google Scholar] [CrossRef]

- Thevanayagam, S.; Mohan, S. Intergranular state variables and stress–strain behaviour of silty sands. Géotechnique 2000, 50, 1–23. [Google Scholar] [CrossRef]

- Knoll, D.M.; Knight, R. Relationships between Dielectric and Hydrogeologic Properties of Sand-Clay Mixtures. In Proceedings of the Fifth International Conferention on Ground Penetrating Radar, Kitchener, ON, Canada, 12 June 1994. [Google Scholar] [CrossRef]

- Beloborodov, R.; Pervukhina, M.; Luzin, V.; Delle Piane, C.; Clennell, M.B.; Zandi, S.; Lebedev, M. Compaction of quartz-kaolinite mixtures: The influence of the pore fluid composition on the development of their microstructure and elastic anisotropy. Mar. Pet. Geol. 2016, 78, 426–438. [Google Scholar] [CrossRef]

- Mondol, N.H.H. Porosity and permeability development in mechanically compacted silt-kaolinite mixtures. In Proceedings of the 2009 SEG Annual Meeting, Houston, TX, USA, 25–30 October 2009; Volume 28, pp. 2139–2143. [Google Scholar]

- Fawad, M.; Mondol, N.H.; Jahren, J.; Bjørlykke, K. Microfabric and rock properties of experimentally compressed silt-clay mixtures. Mar. Pet. Geol. 2010, 27, 1698–1712. [Google Scholar] [CrossRef]

- Mondol, N.H.; Bjørlykke, K.; Jahren, J.; Høeg, K. Experimental mechanical compaction of clay mineral aggregates-Changes in physical properties of mudstones during burial. Mar. Pet. Geol. 2007, 24, 289–311. [Google Scholar] [CrossRef]

- Mondol, N.; Bjørlykke, K.; Jahren, J. Experimental Compaction of Kaolinite Aggregates—Effects of Grain Size on Mudrock Properties. In Proceedings of the 70th EAGE Conference and Exhibition incorporating SPE EUROPEC 2008, Rome, Italy, 9 June 2008; p. cp-40-00284. [Google Scholar]

- Michael, K.; Golab, A.; Shulakova, V.; Ennis-King, J.; Allinson, G.; Sharma, S.; Aiken, T. Geological storage of CO2 in saline aquifers—A review of the experience from existing storage operations. Int. J. Greenh. Gas Control 2010, 4, 659–667. [Google Scholar] [CrossRef]

- Liu, F.; Lu, P.; Griffith, C.; Hedges, S.W.; Soong, Y.; Hellevang, H.; Zhu, C. CO2–brine–caprock interaction: Reactivity experiments on Eau Claire shale and a review of relevant literature. Int. J. Greenh. Gas Control 2012, 7, 153–167. [Google Scholar] [CrossRef] [Green Version]

- Karstunen, M.; Koskinen, M. Plastic anisotropy of soft reconstituted clays. Can. Geotech. J. 2008, 45, 314–328. [Google Scholar] [CrossRef] [Green Version]

- Yin, Z.-Y.; Hattab, M.; Hicher, P.-Y. Multiscale modeling of a sensitive marine clay. Int. J. Numer. Anal. Methods Geomech. 2011, 35, 1682–1702. [Google Scholar] [CrossRef]

- Burland, J.B. On the compressibility and shear strength of natural clays. Geotechnique 1990, 40, 329–378. [Google Scholar] [CrossRef]

- Hicher, P.Y.; Wahyudi, H.; Tessier, D. Microstructural analysis of inherent and induced anisotropy in clay. Mech. Cohesive-Frictional Mater. 2000, 5, 341–371. [Google Scholar] [CrossRef]

- Wheeler, S.J.S.J.; Näätänen, A.; Karstunen, M.; Lojander, M. An anisotropic elastoplastic model for soft clays. Can. Geotech. J. 2003, 40, 403–418. [Google Scholar] [CrossRef]

- Falcon-Suarez, I.H.; Amalokwu, K.; Delgado-Martin, J.; Callow, B.; Robert, K.; North, L.; Sahoo, S.K.; Best, A.I. Comparison of stress-dependent geophysical, hydraulic and mechanical properties of synthetic and natural sandstones for reservoir characterization and monitoring studies. Geophys. Prospect. 2019, 67, 784–803. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.; Ning, Z.; Zhao, T.; Zhang, R.; Wang, Q. Effects of mineralogy on petrophysical properties and permeability estimation of the Upper Triassic Yanchang tight oil sandstones in Ordos Basin, Northern China. Fuel 2016, 186, 328–338. [Google Scholar] [CrossRef]

- Nooraiepour, M.; Masoudi, M.; Hellevang, H. Probabilistic nucleation governs time, amount, and location of mineral precipitation and geometry evolution in the porous medium. Sci. Rep. 2021, 11. [Google Scholar] [CrossRef] [PubMed]

- Nooraiepour, M.; Masoudi, M.; Shokri, N.; Hellevang, H. Probabilistic Nucleation and Crystal Growth in Porous Medium: New Insights from Calcium Carbonate Precipitation on Primary and Secondary Substrates. ACS Omega 2021, 6, 28072–28083. [Google Scholar] [CrossRef]

- Deng, H.; Poonoosamy, J.; Molins, S. A reactive transport modeling perspective on the dynamics of interface-coupled dissolution-precipitation. Appl. Geochem. 2022, 137, 105207. [Google Scholar] [CrossRef]

- Chapuis, R.P.; Aubertin, M. On the use of the Kozeny–Carman equation to predict the hydraulic conductivity of soils. Can. Geotech. J. 2003, 40, 616–628. [Google Scholar] [CrossRef]

- Civan, F.; Rai, C.S.S.; Sondergeld, C.H.H. Shale-Gas Permeability and Diffusivity Inferred by Improved Formulation of Relevant Retention and Transport Mechanisms. Transp. Porous Media 2011, 86, 925–944. [Google Scholar] [CrossRef]

- Revil, A.; Cathles, L.M., III; Cathles, L.M. Permeability of shaly sands. Water Resour. Res. 1999, 35, 651–662. [Google Scholar] [CrossRef]

| Binary Mixtures | Compaction | Initial Parameters | |||||

|---|---|---|---|---|---|---|---|

| Clay Fraction | Quartz * Fraction | Quartz: Clay wt [%] | Effective Stress [MPa] | Initial Height [mm] | Brine-Sat. Mass [gr] | Dry Mass [gr] | |

| kaolinite-rich | kaolinite | --- | 0:100 | 25 | 31.09 | 87.69 | 39.97 |

| kaolinite | silt + VFS | 15:85 | 25 | 32.54 | 90.53 | 38.51 | |

| kaolinite | silt + VFS | 50:50 | 25 | 34.89 | 100.37 | 47.45 | |

| kaolinite | silt + VFS | 85:15 | 25 | 31.9 | 95.93 | 49.4 | |

| smectite-rich | smectite | --- | 0:100 | 25 | 33.23 | 88.27 | 32.64 |

| smectite | silt + VFS | 15:85 | 25 | 33.96 | 91.7 | 37.28 | |

| smectite | silt + VFS | 50:50 | 25 | 32.29 | 87.7 | 35.49 | |

| smectite | silt + VFS | 85:15 | 25 | 33.99 | 100.56 | 48.49 | |

| pure kaolinite | kaolinite | --- | 0:100 | 50 | 31.15 | 87.86 | 40.03 |

| kaolinite | --- | 0:100 | 50 | 31.11 | 87.84 | 40.00 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nooraiepour, M. Clay Mineral Type and Content Control Properties of Fine-Grained CO2 Caprocks—Laboratory Insights from Strongly Swelling and Non-Swelling Clay–Quartz Mixtures. Energies 2022, 15, 5149. https://doi.org/10.3390/en15145149

Nooraiepour M. Clay Mineral Type and Content Control Properties of Fine-Grained CO2 Caprocks—Laboratory Insights from Strongly Swelling and Non-Swelling Clay–Quartz Mixtures. Energies. 2022; 15(14):5149. https://doi.org/10.3390/en15145149

Chicago/Turabian StyleNooraiepour, Mohammad. 2022. "Clay Mineral Type and Content Control Properties of Fine-Grained CO2 Caprocks—Laboratory Insights from Strongly Swelling and Non-Swelling Clay–Quartz Mixtures" Energies 15, no. 14: 5149. https://doi.org/10.3390/en15145149