Abstract

Lignocellulosic biomass is an abundant resource that can be valorized for the production of bioenergy. However, studies aiming to quantify the amount of biogas production potential per km forest road are scarce in the literature. In this study, fresh pine needles, pine needle litter, pine branches, and pine bark were digested in batch reactors under mesophilic conditions after a grinding/milling pre-treatment. All samples were collected from a low-altitude Mediterranean Pinus forest (North Greece) adjacent to a category G forest road with a gentle slope. The methane yield of fresh pine needles was between 115 and 164 NmL g−1 volatile solids (VS), depending on the Pinus tree size. Pine needle litter produced a significantly lower methane yield (between 58 and 77 NmL g−1 VS), followed by pine bark (85 NmL g−1 VS) and pine branches (138 NmL g−1 VS). Considering the quantity of pine needle litter accumulated on adjacent forest roads (600 ± 200 g m−2), it was possible to calculate the biomethane production potential per km of forest road (up to 500 Nm3 km−1) if the biomass collected was disposed of at an anaerobic digestion facility. The results of the study demonstrate that residual forest biomass represents an additional resource for bioenergy production. Moreover, harvesting residual forest biomass can decrease the incidence of devastating summer forest fires and their disastrous consequences for the environment, the economy, and the local populations.

1. Introduction

Lignocellulosic biomass is a natural resource that can contribute to the European Union’s (EU) energy neutrality/independency targets. Lignocellulose is abundant, with an estimated global production of 200 bil tn yr−1, but only 10% of this yield is harvested from agricultural, grass, and forest land [1,2]. Agricultural residues (straw, stover, bagasse, cobs, stalks, etc.), municipal waste (paper, kitchen waste, garden residues, etc.), woodland trees (Eucalyptus, Populus, etc.), and dry energy grasses (Perennial, Napier, etc.) are the most common lignocellulosic biomasses used for bioenergy production [3]. Bioenergy from lignocellulosic biomass is currently produced by thermochemical conversions, such as gasification and pyrolysis [4,5,6,7].

Biogas production from lignocellulosic substrates remains largely unexploited; however, co-digestion with manure seems to be an attractive solution: for instance, in Denmark, it is expected to double biomethane production by 2030 [8]. In most anaerobic digestion studies, methane yield from lignocellulosic biomass was <250 NmL g−1 volatile solids (VS). The highest methane yield values (between 100 and 250 NmL g−1 VS) have been reported for leaves (e.g., fagus, oak, and phoenix tree) and wood samples (birch and poplar) [9,10,11,12,13,14]. Other biomass samples, such as those originating from maple wood, spruce, and pine bark and leaf litter [14,15,16,17] have been found to produce low methane (between 20 and 80 NmL g−1 VS). As expected, lignocellulose is resistant to degradation; consequently, additional pre-treatment may significantly increase methane yield and optimize the anaerobic digestion process [18,19].

Global warming adversely affects the frequency and severity of forest fires. The biomass accumulated on adjacent forest roads constitutes a major fuel source for summer wildfires. In Europe, about 65,000 fires occur annually, resulting in the conflagration of around 500,000 ha of forest and wildland, while 85% of the latter is located in the Mediterranean [20]. Harvesting residual biomass is vital to decreasing the incidence of wildfires. Simultaneously, the collected material can be valorized for fuel production, such as biogas, methane, or liquid biofuels [21]. Removal of lowland vegetation (e.g., shrubs and leaf litter) and tree pruning up to 3 m above ground are typical biomass harvesting activities. The collected material, however, is often disposed of in areas adjacent to the collection site rather than valorized (see Figure 1).

Figure 1.

(a) Map of Greece showing the location of the study site, (b) aerial overview of the Pinus forest, and (c) current practices of forest residual biomass disposal on forest roads.

The aim of this study was to evaluate the type and quantities of forest biomass accumulated in various points of the road network of a Mediterranean low-altitude Pinus forest, evaluate their biogas production potential, and calculate the biogas yield per km forest road, since relevant data were not found in the literature. Samples of fresh pine needles from different diameter trees, pine needle litter, and pine branches and bark were digested under mesophilic conditions after a grinding/milling pre-treatment. Data from both field and laboratory studies were used to calculate the biogas production potential per km of forest road if the collected material was disposed of at an anaerobic digestion facility. Finally, the experimental data were compared with similar results found in the literature.

2. Materials and Methods

2.1. Site and Field Work

The study site consisted of a low-altitude Mediterranean Pinus forest located in North Greece (Xanthi) (41°7′48″ N, 24°53′11″ E) (see Figure 1). Field campaigns were performed during the summer season aiming to quantify (a) the amount of pine needle litter accumulated on the forest floor and (b) the quantity of fresh pine needles and branches collected during tree-pruning operations (up to 3 m above ground) from different diameter trees (<10, 10–20, 20–30, 30–40, 40–50, and >50 cm). All samples were gathered on an adjacent Category G forest road, whose total length measured 5.0 km, deck width 7.95 m, and mean slope 9%. The material collected was transported to the laboratory for further examination.

2.2. Forest Biomass Samples and Pre-Treatment

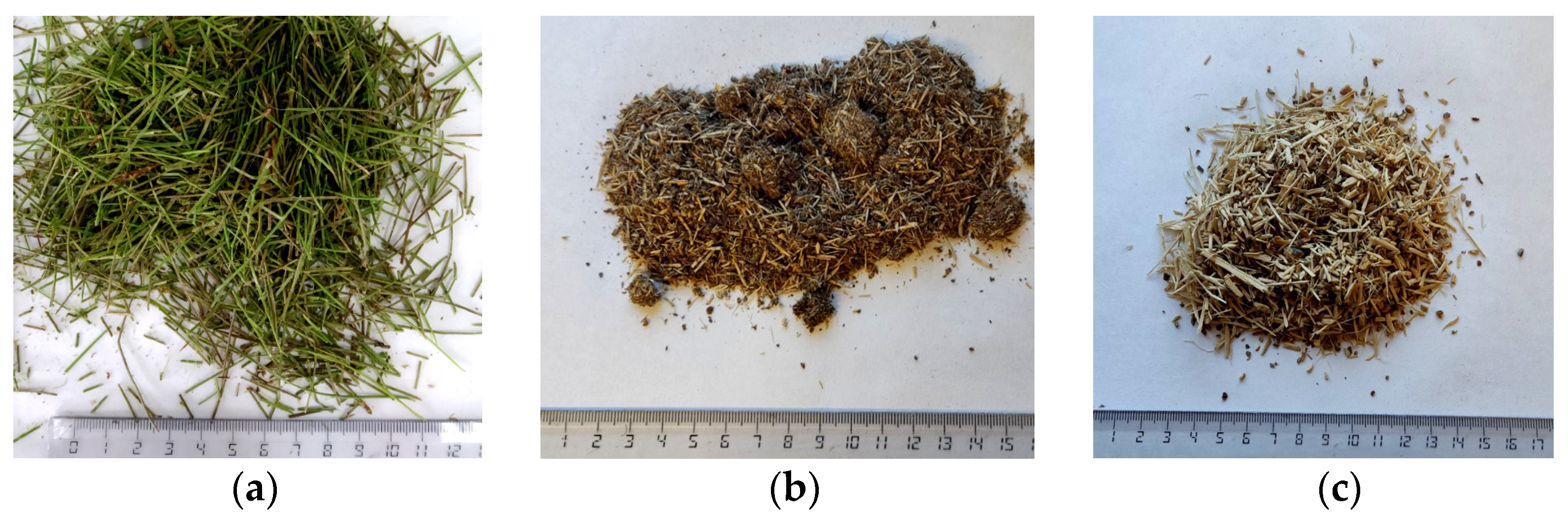

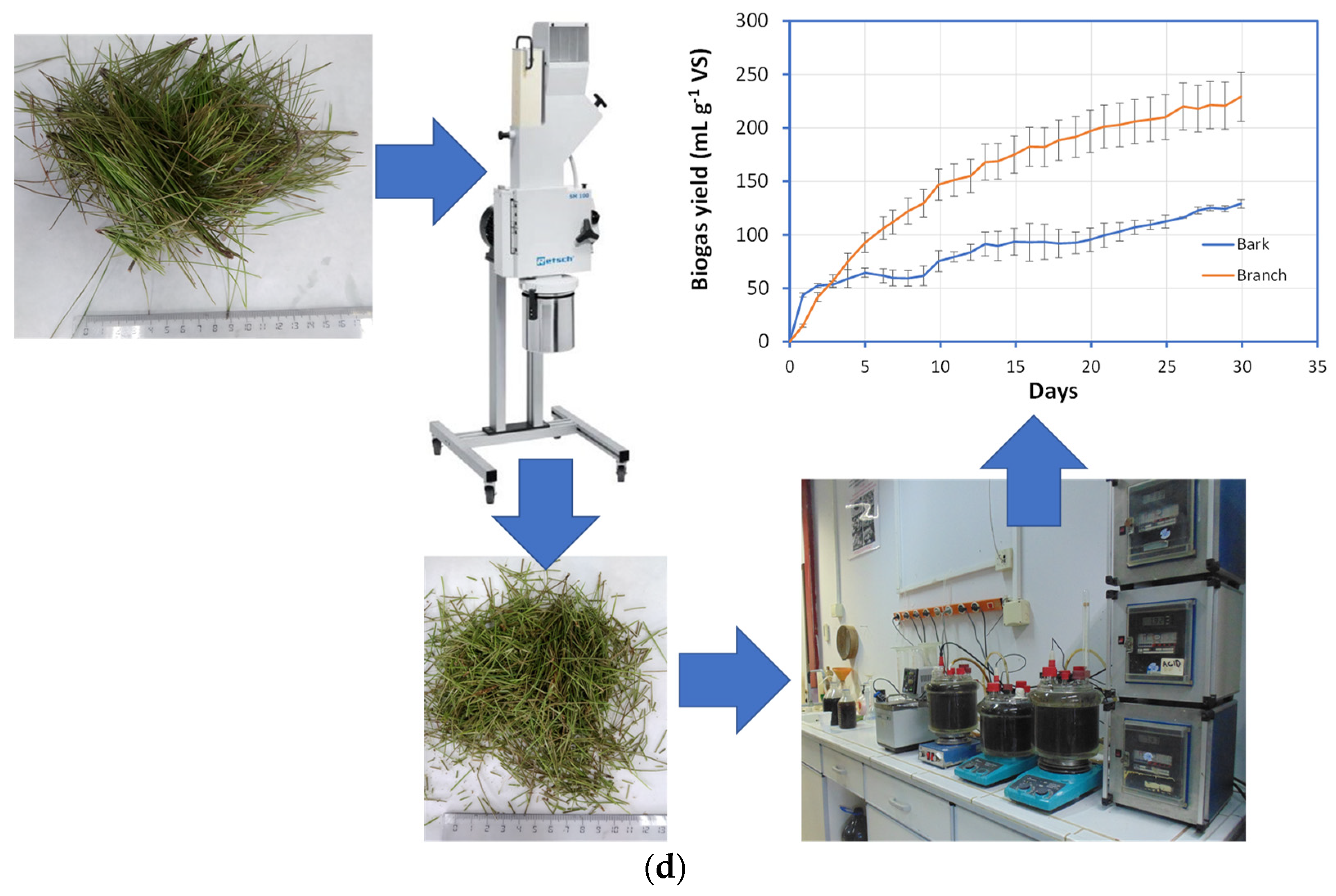

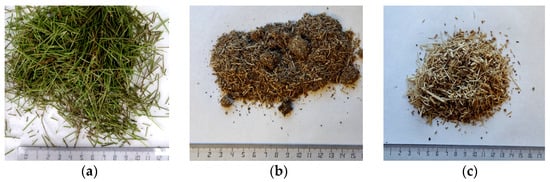

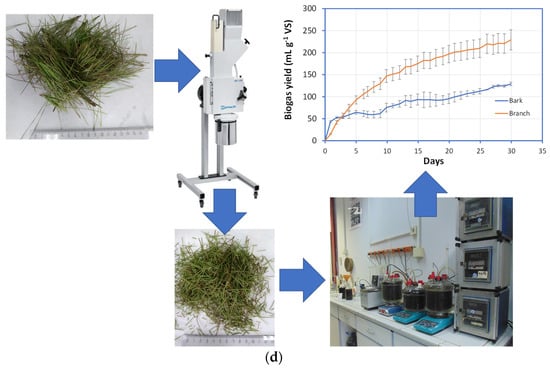

Forest biomass samples collected during the study consisted of (a) fresh pine needles from different diameter trees (see above), (b) pine needle litter, and (c) pine branches/bark. Prior to the anaerobic digestion, pine needles (fresh or littered) were ground using a kitchen blender at 3000 rpm, while pine branches were milled using an industrial mill (Retsch SM 100). The size of ground or milled biomass samples used for the anaerobic digestion experiments was <10 mm (Figure 2). The samples were characterized in terms of moisture content, total solids (TS), volatile solids (VS), and hexane extractable organics (HEO). All analyses were performed according to the Standard Methods [22].

Figure 2.

Photographic representation of (a) pine needles, (b) pine branches and (c) pine bark samples after grinding pre-treatment, and (d) the laboratory setup used for the anaerobic digestion assays.

2.3. Batch Anaerobic Digestion Assays

Batch anaerobic digestion of forest biomass samples was performed in 150 mL working volume reactors incubated in a water bath at 38 °C (Figure 2). The inoculum for the anaerobic digestion experiments was obtained from a full-scale digester treating agro-industrial wastes and energy crops. It was characterized by pH = 7.8, electrical conductivity (EC) = 22.7 mS cm−1, TS = 34.9 g L−1, VS = 22.3 g L−1, ammonia nitrogen (NH4-N) = 2411 mg L−1, and orthophosphates (PO4-P) = 83 mg L−1. The initial concentration of forest biomass VS was equal to 3 g VS L−1 corresponding to a substrate to inoculum ratio (SI) between 0.12 and 0.15 (VS basis). The batch reactors were initially flushed with nitrogen to remove oxygen from the headspace. Batch reactors were mixed manually once per day during the incubation period. Biogas production was recorded using a digital pressure meter (WIKA, Germany), while the biogas methane content was determined using an alkaline trap according to Eftaxias et al. [23]. Finally, the cumulative methane yield was fitted to a first-order kinetic model according to the following equation:

where

rS = K S

- rS = substrate consumption rate (kg VS m−3 d−1)

- K = first-order kinetic constant (d−1)

- S = substrate concentration (kg VS m−3)

3. Results

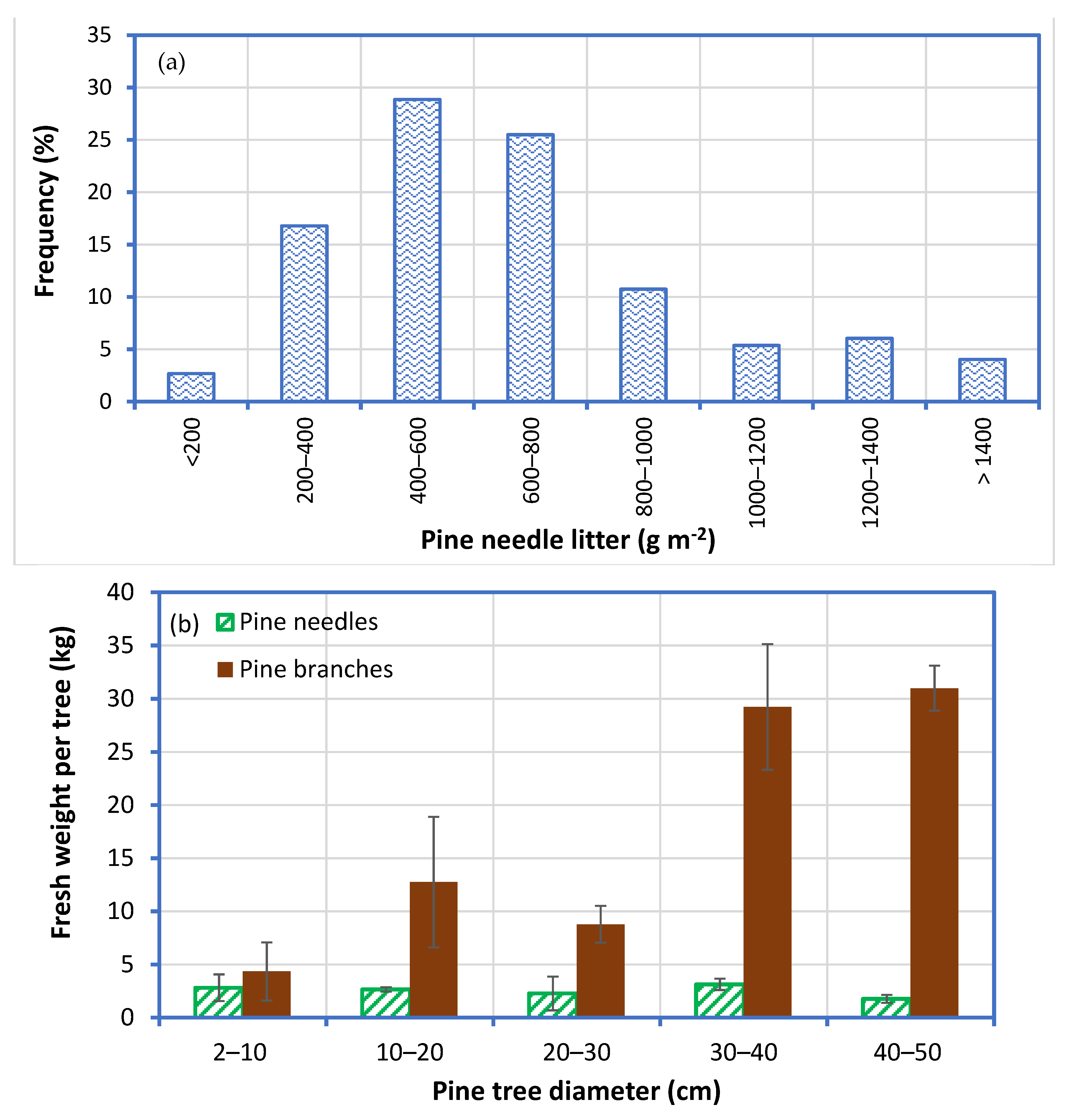

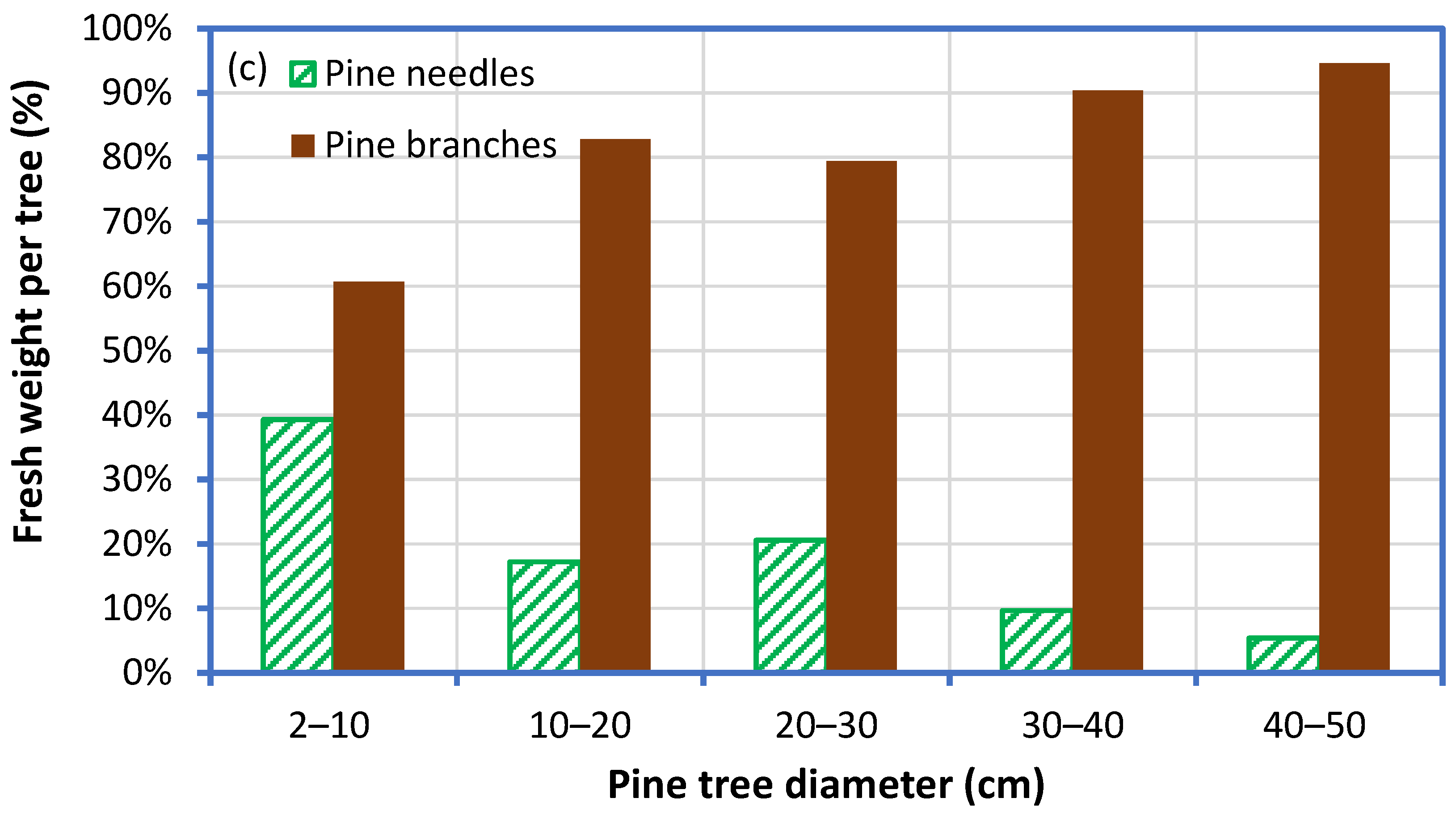

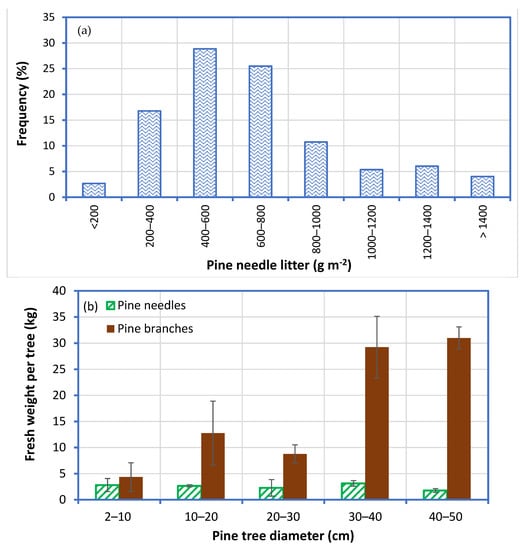

The quantity of fresh pine needles collected during tree-pruning operations was relatively constant at 2.62 ± 0.81 kg per pine tree independently of the tree diameter (see Figure 3b). By contrast, the quantity of branches increased from 4 to 31 kg per tree with increasing pine tree diameter (see Figure 3b). Under these conditions, pine branches represented 61 to 95% of the biomass fresh weight. The quantity of pine needle litter accumulated on the forest floor varied between 200 and 1000 g m−2 with an average value of 600 ± 200 g m−2 (see Figure 3a). Table 1 shows the composition of different forest biomass samples in terms of moisture content, volatile solids, and hexane extractable organics. Since sampling was performed during the summer season, pine needle litter was characterized by low moisture content (11% of fresh matter, FM). However, samples from the humified layer were moderately moist (45% FM). Fresh pine needles had an average moisture of 50.9 + 2.6% FM and VS content 95.9 + 0.5% TS. The HEO content of fresh pine needles was on average 6.0 + 1.1% VS. Pine bark was characterized by low moisture content (16.5% FM) and high HEO (7.8% VS).

Figure 3.

(a) Distribution of pine needle litter quantity accumulated on the forest floor and (b,c) quantity of fresh pine needles and branches collected from different diameter trees during tree pruning up to 3 m above ground (in kg of fresh matter (b) and as percentage (c)).

Table 1.

Physicochemical properties of fresh pine needles from different diameter trees, pine needle litter, pine branches, and pine bark.

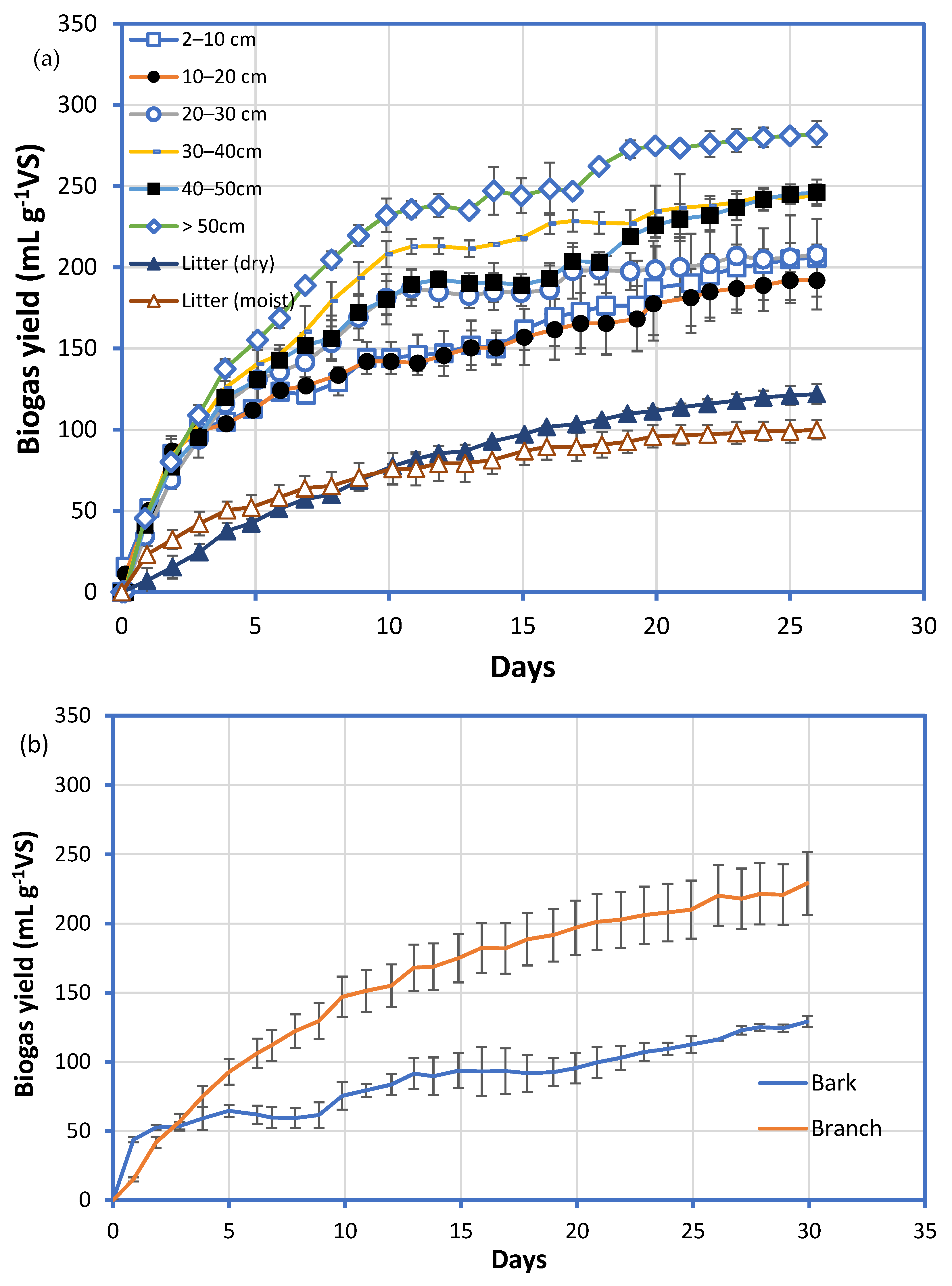

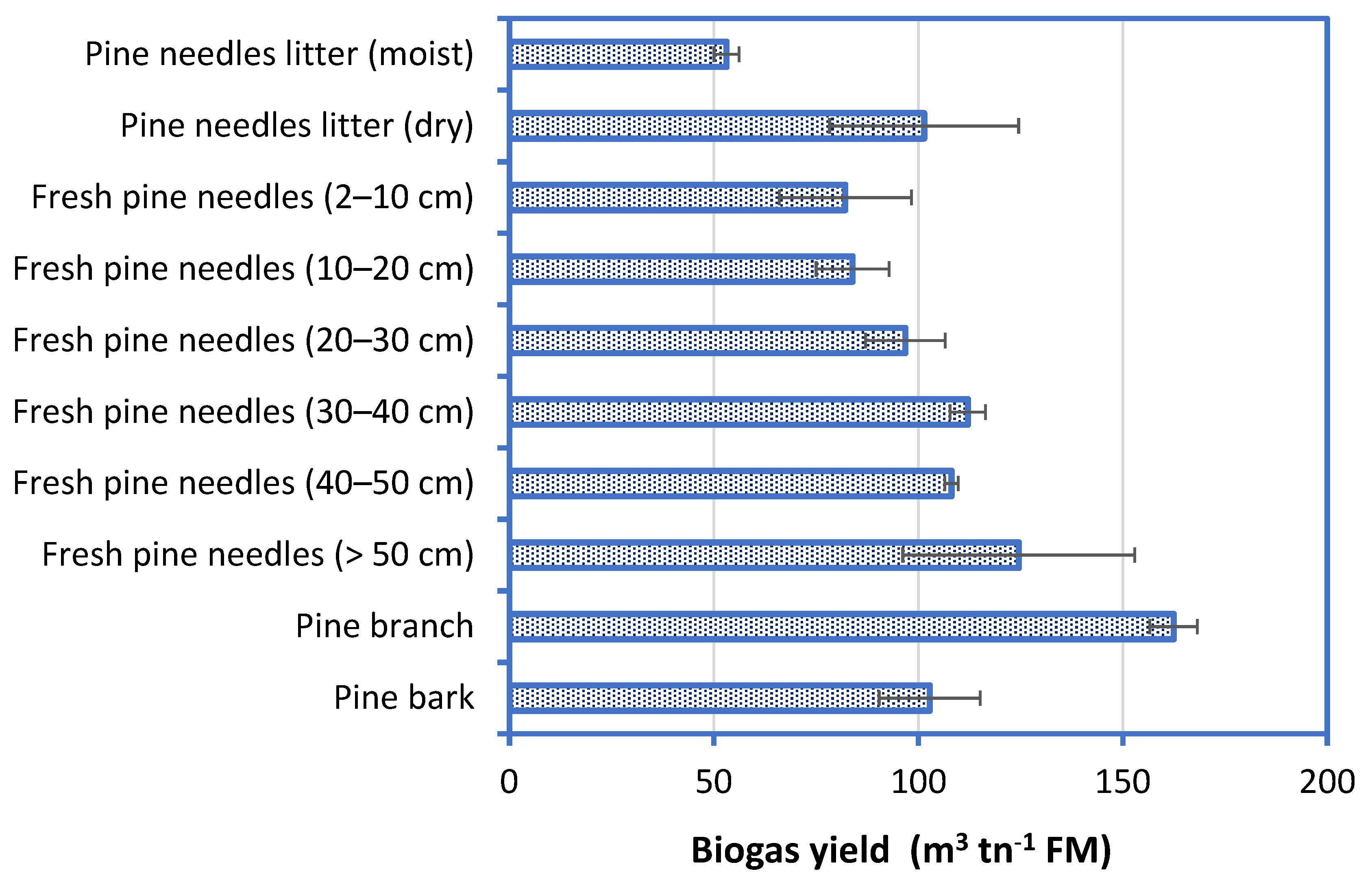

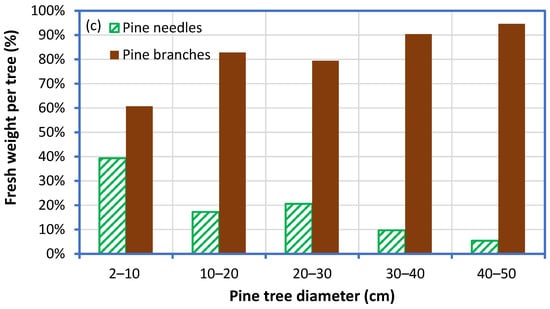

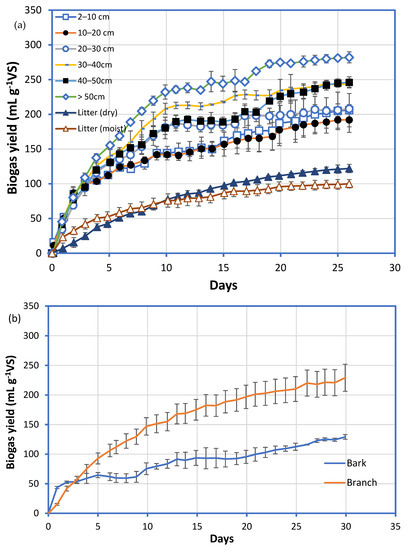

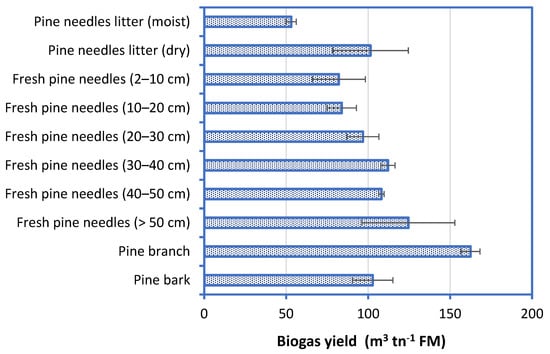

Figure 4 illustrates the cumulative biogas yield during mesophilic anaerobic digestion of different forest biomass samples after the grinding/milling pre-treatment. The biogas yield varied between 190 and 280 mL g−1 VS for fresh pine needles and between 100 and 120 mL g−1 VS for pine needle litter. Biogas yield from fresh pine needles increased with increasing pine tree diameter. Pine branches produced high biogas yield values (230 mL g−1 VS), similar to fresh pine needles. Unlike pine branches, pine bark samples displayed low biodegradability, as demonstrated by the respective biogas yield (130 mL g−1 VS) and the first-order kinetic constant (0.071 d−1) (see Table 2). Based on the above, the biogas yield per kg of forest biomass fresh matter (FM) was estimated around 100 m3 tn−1 FM (see Figure 5). The biogas methane content ranged from 59 to 66% in all experiments.

Figure 4.

Cumulative biogas yield for (a) fresh pine needles and pine needle litter, and (b) pine bark and branches.

Table 2.

First-order kinetic constants and methane yield for fresh pine needles, pine needle litter, pine bark, and pine branches.

Figure 5.

Summary of biogas yield values per tn fresh matter (FM) for different pinus forest biomass samples.

4. Discussion

The genus Pinus (family Pinaceae) is the most popular species in the Northern Hemisphere, with around 111 different sub-species [24]. It represents 10% of the total forest cover in the Mediterranean basin [25]. The southernmost European natural and planted pine forests are among the most vulnerable to warming-induced drought decline [26,27,28]. Furthermore, climate models forecast an increase in the intensity and frequency of extreme climate events, such as droughts [28].

Harvesting residual forest biomass can decrease the incidence of devastating summer forest fires and their disastrous consequences for the environment, the economy, and the local populations [21,29]. To mitigate the potential for wildfires, measures include thinning of existing plantation, reducing fuel plants, and creating fire safety zones [30]. It is common practice, however, especially in regions that do not have a strong woody biomass market, to dispose of forest residues unutilized on forest roads [31]. This practice can contribute to the creation of an excessive fuel load on the forest floor, thereby increasing the risk of fire [31].

Forest biomass residues, such as limbs, tops, and small non-commercial trees removed during forest management activities represent an additional source of woody biomass for bioenergy production [32]. Table 3 shows the methane yield of different forest biomass samples based on a literature review. The data were selected from mesophilic anaerobic digestion studies involving a grinding or milling pre-treatment. The results demonstrate a wide range of methane yield values from 17 to 230 NmL g−1 VS, i.e., within the same range as the results from this work. The highest methane yield values were recorded for birch wood samples and different types of leaves (phoenix tree, oak leaves, pine needles). Low methane yield values were reported for spruce wood samples and wood bark samples (pine, spruce, maple). The first-order kinetic constants ranged between 0.07 and 0.12 d−1 for all substrates examined, similar to fallen leaves, yard wastes, maple wood, pine wood, and poplar residues (0.04 to 0.09 d−1) found in the literature [14,15].

Table 3.

Physicochemical properties, reactor operating conditions and Biochemical Methane Potential (BMP) of forest biomass samples after grinding/milling pre-treatment.

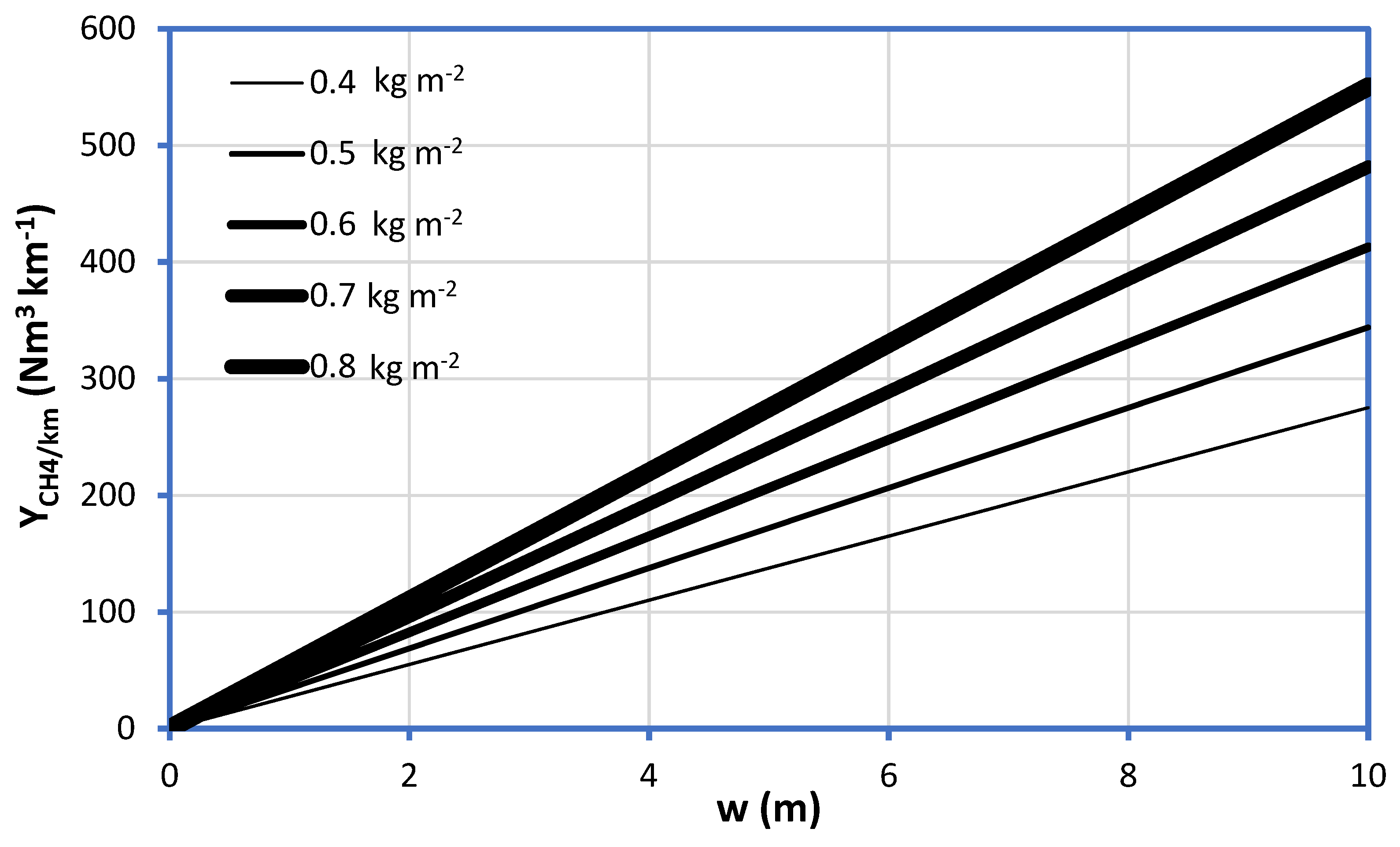

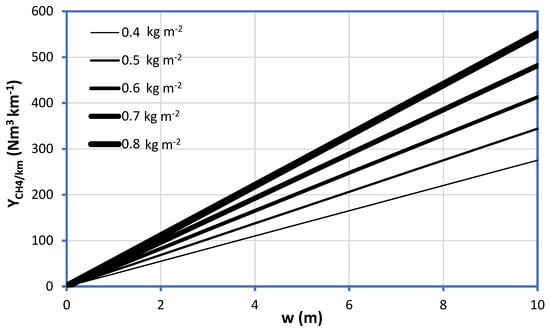

Considering the data obtained from the laboratory and field studies, it was possible to calculate the amount of biomethane generated per km of forest road, when the biomass was disposed of in an anaerobic digestion facility. The following equation was used for the pine needle litter [12]:

where

YCH4/km = 1000 × YCH4/VS × vs. × d × w,

- YCH4/km = methane yield per km of forest road (Nm3 km−1)

- YCH4/VS = methane yield per kg VS of pine needle litter (Nm3 kg−1 VS)

- VS = pine needle litter VS content (kg VS kg−1 FM)

- d = pine needle litter bulk density (kg m−2)

- w = vertical distance of pine needle litter accumulation on adjacent forest road (m)

Figure 6 shows the methane yield per km of forest road as a function of the vertical distance of pine needle litter collection on adjacent forest road and the litter bulk density. The data demonstrate that it is possible to recover up to 500 Nm3 of methane for each km of forest road. Considering that methane is used for electricity production, the economic benefit can be calculated equal to (500 Nm3 CH4 km−1) × (4 kWh m−3 CH4) × (0.20 € kWh−1) = 400 € km−1 forest road. In a similar study, Kantartzis et al. [12] reported that the quantity of methane recovered per km of forest road for a Fagus Sylvatica forest amounted to 1000 Nm3 km−1. In this case, Fagus leaf litter had an increased bulk density (1200 to 1600 g m−2) and generated a higher methane yield (80 NmL g−1 VS) compared to pine needles. Biogas recovery per km of forest road, however, can be further increased if tree pruning and low vegetation biomass (such as bushes and shrubs) are also included. For an objective assessment, nonetheless, one should consider the costs for biomass collection, pre-treatment and transportation, as well as the depreciation and operational expenses of the anaerobic digestion facility [35,36].

Figure 6.

Methane yield per km of forest road as a function of the vertical distance (w) of pine needle litter collection on adjacent forest road and for different pine needle litter bulk densities.

5. Conclusions

The results of this study demonstrate that forest biomass can be valorized in anaerobic digestion facilities for the production of biogas. The highest biogas yield values were recorded for fresh pine needles and pine branches. Pine bark samples displayed low biodegradability, on a par with pine needle litter. The quantity of pine needle litter accumulated on the forest floor was significant and could contribute to the recovery of up to 500 Nm3 methane per km of forest road, if the material was disposed of at an anaerobic digestion facility. A side benefit of this approach would be the reduction or elimination of the risk of forest fires.

Author Contributions

Conceptualization, V.D.; methodology, V.D. and A.E.; field studies, C.D. and A.K.; laboratory studies A.E., E.A.P. and C.M.; data curation, V.D. and A.E.; writing—original draft preparation, V.D.; writing—review and editing, V.D., A.E., E.A.P. and A.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded under the project, “Development of a fire prediction and early-warning system for historic centers and old cities in contact with suburban forests”, funded by the GREEN FUND under the program “Natural Environment and Innovative Actions 2020”, Priority axis 2: Smart Cities.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Xu, N.; Liu, S.; Xin, F.; Zhou, F.; Jia, H.; Xu, J.; Jiang, M.; Dong, W. Biomethane Production from Lignocellulose: Biomass Recalcitrance and Its Impacts on Anaerobic Digestion. Front. Bioeng. Biotechnol. 2019, 7, 191. [Google Scholar] [CrossRef] [PubMed]

- Dahmen, N.; Lewandowski, I.; Zibek, S.; Weidtmann, A. Integrated lignocellulosic value chains in a growing bioeconomy: Status quo and perspectives. GCB Bioenergy 2018, 11, 107–117. [Google Scholar] [CrossRef] [Green Version]

- Dahunsi, S.O.; Enyinnaya, M. The bioenergy potentials of Lignocelluloses. In Energy Conversion: Current Technologies and Future Trends; Al-Bahadly, I.H., Ed.; InTechOpen: London, UK, 2018; pp. 93–104. [Google Scholar] [CrossRef] [Green Version]

- Dhyani, V.; Bhaskar, T. A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew. Energy 2018, 129, 695–716. [Google Scholar] [CrossRef]

- Canabarro, N.; Soares, J.F.; Anchieta, C.G.; Kelling, C.; Mazutti, M.A. Thermochemical processes for biofuels production from biomass. Sustain. Chem. Process. 2013, 1, 22. [Google Scholar] [CrossRef] [Green Version]

- Nanda, S.; Kozinski, A.J.; Dalai, K.A. Lignocellulosic biomass: A review of conversion technologies and fuel products. Curr. Biochem. Eng. 2016, 3, 24–36. [Google Scholar] [CrossRef]

- Zadeh, E.Z.; Abdulkhani, A.; Aboelazayem, O.; Saha, B. Recent insights into lignocellulosic biomass pyrolysis: A critical review on pretreatment, characterization, and products upgrading. Processes 2020, 8, 799. [Google Scholar] [CrossRef]

- Nielsen Sander, B. Offsetting methane emissions from agriculture. In Proceedings of the European Biogas Conference, EBA, Brussels, Belgium, 26–27 October 2021. [Google Scholar]

- Elsayed, M.; Blel, W.; Soliman, M.; Andres, Y.; Hassan, R. Semi-continuous co-digestion of sludge, fallen leaves, and grass performance. Energy 2021, 221, 119888. [Google Scholar] [CrossRef]

- Klavins, A.; Dubrocskis, V.; Plume, I. Effectiveness of usage of straw and oak leave pellets for biogas production. Eng. Rur. Dev. 2020, 2020, 1900–1906. [Google Scholar] [CrossRef]

- Mu, L.; Zhang, L.; Ma, J.; Zhu, K.; Chen, C.; Li, A. Enhancement of anaerobic digestion of phoenix tree leaf by mild alkali pretreatment: Optimization by Taguchi orthogonal design and semi-continuous operation. Bioresour. Technol. 2020, 313, 123634. [Google Scholar] [CrossRef]

- Kantartzis, A.; Daoutis, C.; Eftaxias, A.; Arabatzis, G.; Diamantis, V. Biomass residues adjacent forest roads in two different forest species (Fagus sylvatica and Pinus brutia): Quantities and evaluation of their biogas production potential. IOP Conf. Ser. Earth Environ. Sci. 2021, 899, 012030. [Google Scholar] [CrossRef]

- Vivenkanand, V.; Olsen, E.F.; Eijsink, V.G.H.; Horn, S.J. Effect of different steam explosion conditions on methane potential and enzymatic saccharification of birch. Bioresour. Technol. 2013, 127, 343–349. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; He, M.; Ren, Y.; Ma, L.; Luo, Y.; Sheng, H.; Xiang, Y.; Zhang, H.; Li, Q.; An, L. Anaerobic digestion of poplar processing residues for methane production after alkaline treatment. Bioresour. Technol. 2013, 134, 347–352. [Google Scholar] [CrossRef] [PubMed]

- Brown, D.; Shi, J.; Li, Y. Comparison of solid-state to liquid anaerobic digestion of lignocellulosic feedstocks for biogas production. Bioresour. Technol. 2012, 124, 379–386. [Google Scholar] [CrossRef]

- Rasi, S.; Kilpelainen, P.; Rasa, K.; Korpinen, R.; Raitanen, J.E.; Vainio, M.; Kitunen, V.; Pulkkinen, H.; Jyske, T. Cascade processing of softwood bark with hot water extraction, pyrolysis and anaerobic digestion. Bioresour. Technol. 2019, 292, 121893. [Google Scholar] [CrossRef] [PubMed]

- Salehian, P.; Karimi, K. Alkali pretreatment for improvement of biogas and ethanol production from different waste parts of pine tree. Ind. Eng. Chem. Res. 2012, 52, 972–978. [Google Scholar] [CrossRef]

- Isikgor, H.F.; Becer, R. Lignocellulosic biomass: A sustainable platform for the production of bio-based chemicals and polymers. Polym. Chem.-UK 2015, 6, 4497–4559. [Google Scholar] [CrossRef] [Green Version]

- Sayara, T.; Sánchez, A. A Review on Anaerobic Digestion of Lignocellulosic Wastes: Pretreatments and Operational Conditions. Appl. Sci. 2019, 9, 4655. [Google Scholar] [CrossRef] [Green Version]

- Ayanz, M.S.J.; Schulte, E.; Schmuck, G.; Camia, A.; Strobl, P.; Liberta, G.; Giovando, C.; Boca, R.; Sedano, F.; Kempeneers, P.; et al. Comprehensive monitoring of wildfires in Europe: The European Forest Fire Information System (EFFIS). In Approaches to Managing Disaster-Assessing Hazards, Emergencies and Disaster Impacts; Tiefenbacher, J., Ed.; InTechOpen: London, UK, 2012; pp. 87–108. [Google Scholar] [CrossRef] [Green Version]

- Rijo, B.; Soares Dias, A.P.; Ramos, M.; Ameixa, M. Valorization of forest waste biomass by catalyzed pyrolysis. Energy 2021, 243, 122766. [Google Scholar] [CrossRef]

- Rice, E.W.; Baird, R.B.; Eaton, A.D. Standard Methods for the Examination of Water and Wastewater; American Public Health Association (APHA), American Water Works Association, Water Environment Federation: Washington, DC, USA, 1999. [Google Scholar]

- Eftaxias, A.; Diamantis, V.; Michailidis, C.; Stamatelatou, K.; Aivasidis, A. The role of emulsification as pre-treatment on the anaerobic digestion of oleic acid: Process performance, modeling and sludge metabolic properties. Biomass Conv. Bioref. 2021, 11, 251–260. [Google Scholar] [CrossRef]

- Choung, Y.; Lee, J.; Cho, S.; Noh, J. Review on the succession process of Pinus densiflora forests in South Korea: Progressive and disturbance-driven succession. J. Ecol. Environ. 2020, 44, 16. [Google Scholar] [CrossRef]

- Rodriguez- Vallejo, C.; Navarro-Cerrillo, M.R.; Manzanedo, D.R.; Rodriguez, P.G.; Gazol, A.; Camarrero, J.J. High resilience, but low viability, of pine plantations in the face of a shift towards a drier climate. For. Ecol. Manag. 2021, 479, 118537. [Google Scholar] [CrossRef]

- Sánchez-Salguero, R.; Camarero, J.J.; Dobbertin, M.; Fernández-Cancio, A.; Vilà-Cabrera, A.; Manzanedo, R.D.; Zavala, M.A.; Navarro-Cerrillo, R.M. Contrasting vulnerability and resilience to drought-induced decline of densely planted vs. natural rear-edge Pinus. nigra forests. For. Ecol. Manag. 2013, 310, 956–967. [Google Scholar] [CrossRef]

- Zeng, X.; Wei, C.; Liu, X.; Zhang, L. Qinghai spruce (Picea crassifolia) and Chinese pine (Pinus tabuliformis) show high vulnerability and similar resilience to early- growing- season drought in the Helan Mountains, China. Ecol. Indic. 2020, 110, 105871. [Google Scholar] [CrossRef]

- Sidor, G.C.; Camarero, J.; Popa, I.; Badea, O.; Apostol, N.E.; Vlad, R. Forest vulnerability to extreme climatic events in Romanian Scots pine forests. Sci. Total Environ. 2019, 678, 721–727. [Google Scholar] [CrossRef]

- Sanseverino-Gofrin, V.; Garbolino, E.; Hinojos-Mendoza, G. Evolution of the legal prevention measures concerning forest fire risk in a context of climate change. Saf. Sci. 2017, 97, 73–80. [Google Scholar] [CrossRef]

- Moghli, A.; Santana, M.V.; Soliveres, S.; Jaime Baeza, M. Thinning and plantation of resprouting species redirect overstocked pine stands towards more functional communities in the Mediterranean basin. Sci. Total Environ. 2022, 806, 150715. [Google Scholar] [CrossRef]

- Kizha, A.R.; Han, H.S. Processing and sorting forest residues: Cost, productivity and managerial impacts. Biomass Bioenergy 2016, 93, 97–106. [Google Scholar] [CrossRef] [Green Version]

- Jones, G.; Loeffler, D.; Calkin, D.; Chung, W. Forest treatment residues for thermal energy compared with disposal by onsite burning: Emissions and energy return. Biomass Bioenergy 2010, 34, 737–746. [Google Scholar] [CrossRef]

- Panigrahi, S.; Sharma, H.B.; Tiwari, B.R.; Krishna, N.V.; Ghangerkar, M.M.; Dubey, B.K. Insight into understanding the performance of electrochemical pretreatment on improving anaerobic biodegradability of yard waste. Renew. Energy 2021, 180, 1166–1178. [Google Scholar] [CrossRef]

- Yao, Y.; Chen, S.; Kafle, G.K. Importance of “weak-base” poplar wastes to process performance and methane yield in solid-state anaerobic digestion. J. Environ. Manag. 2017, 193, 423–429. [Google Scholar] [CrossRef]

- Vlachokostas, C.; Achillas, A.; Diamantis, V.; Michailidou, A.V.; Baginetas, K.; Aidonis, D. Supporting decision making to achieve circularity via a biodegradable waste-to-bioenergy and compost facility. J. Environ. Manag. 2021, 285, 112215. [Google Scholar] [CrossRef] [PubMed]

- Diamantis, V.; Eftaxias, A.; Stamatelatou, K.; Noutsopoulos, C.; Vlachokostas, C.; Aivasidis, A. Bioenergy in the era of circular economy: Anaerobic digestion technological solutions to produce biogas from lipid-rich wastes. Renew. Energy 2021, 168, 438–447. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).