Nonlinear Surface Conductivity Characteristics of Epoxy Resin-Based Micro-Nano Structured Composites

Abstract

:1. Introduction

2. Experimental

2.1. Tested Materials

2.2. Sample Preparation

- Surface treatment of nanostructured SiC. Surface treatment of nanostructured SiC using KH560 to increase the compatibility of the epoxy resin matrix with the nanostructured filler. After washing the modified nanoparticles in low mineralization water at pH = 7, the nanoparticles were vacuum-dried to remove moisture to obtain the modified nanostructured SiC (N-SiC).

- Organic treatment of MMT. A measuring cylinder was used to measure 300 mL of acid solution (prepared by injecting 0.8 mL of acetic acid into 800 mL of distilled water) and 40 g of nacreous montmorillonite raw clay into a three-necked flask. The flask was placed in an 80 °C water bath with ultrasonic shaking and stirring for 1 h. The solution was centrifuged three times using a centrifuge. The time of centrifugation treatment was set to 1 min, 2 min, and 2 min, respectively. Then, 2.8 g of octadecyl trimethyl ammonium chloride was added, followed by stirring with ultrasonic shaking for 2 h. After several rounds of standing, washing, filtering and then drying, grinding, and sieving, the organically modified MMT(O-MMT) was obtained.

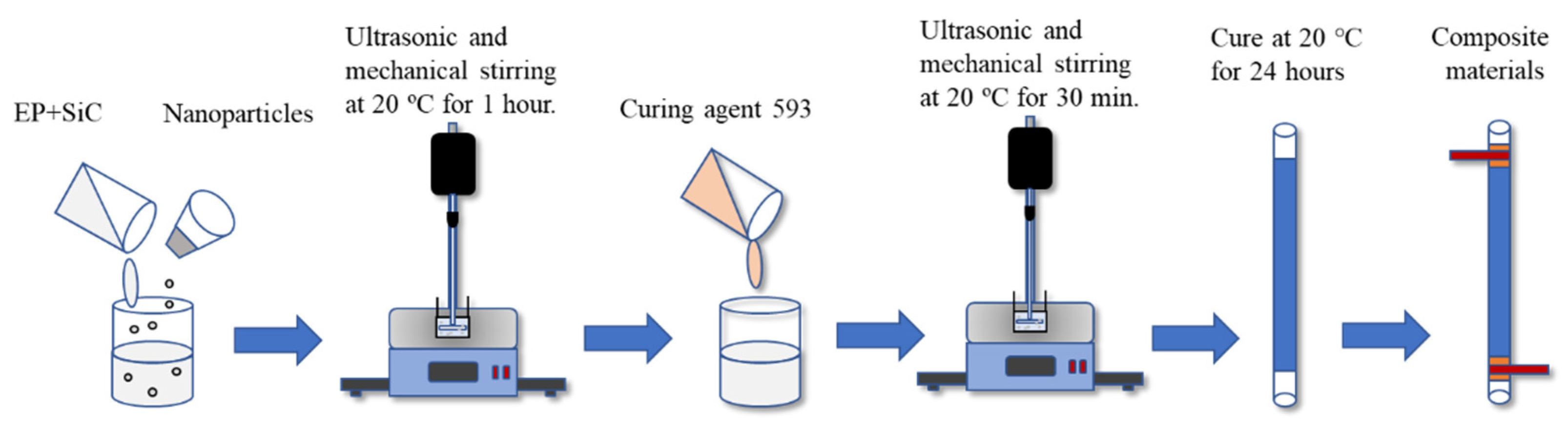

- Preparation of epoxy resin composite hybrid materials. The epoxy resin composites were mixed with 0.5, 1, 3, and 4 wt% nanoparticles by a mass fraction. The mixture was ultrasonically and mechanically stirred at room temperature (20 °C) at 2000 r/min for 1 h. Then, curing agent 593 was added to the mix (the amount of curing agent added was 10% of the mass of DECJ1345). The epoxy resin composite mixture was obtained by continuing ultrasonic mechanical stirring at 2000 r/min for 30 min at room temperature (20 °C).

- Preparation of micro-nano structured composite specimens. The blended mixture was evenly coated on the outer wall of the high-temperature resistant glass tube and cured at room temperature (20 °C) for 24 h to obtain a prefabricated sample of the glass tube. Copper conductive tape was wrapped around the top and bottom of the glass tube to perform sample coating. The copper conductive tape was wrapped around the copper wire and the copper wire was led out for the electrode to facilitate the test. The final composite samples to be tested were obtained with different nano-doped fillers and different mass fractions.

2.3. Test Method and Principle

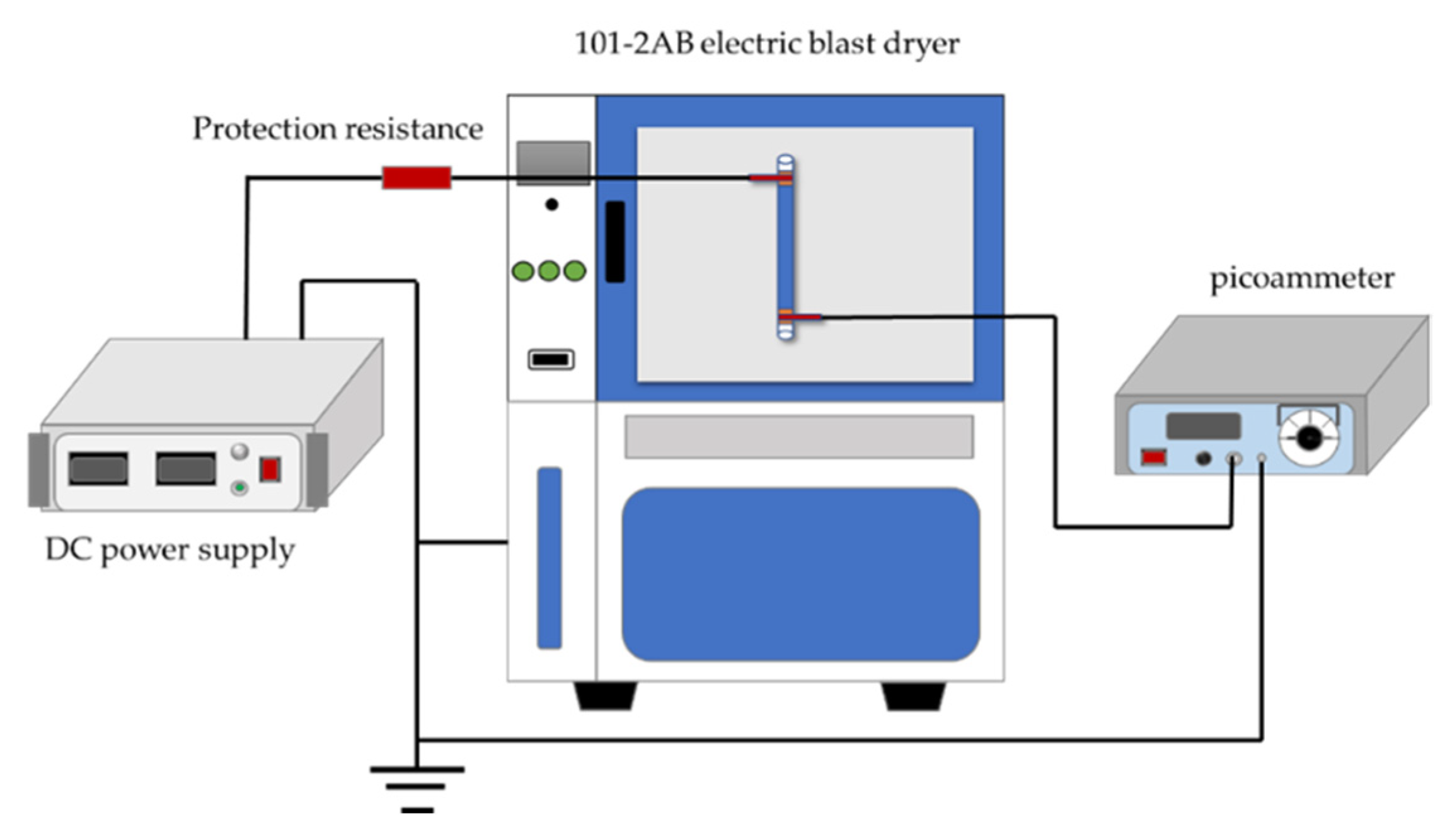

2.3.1. DC Surface Conductivity

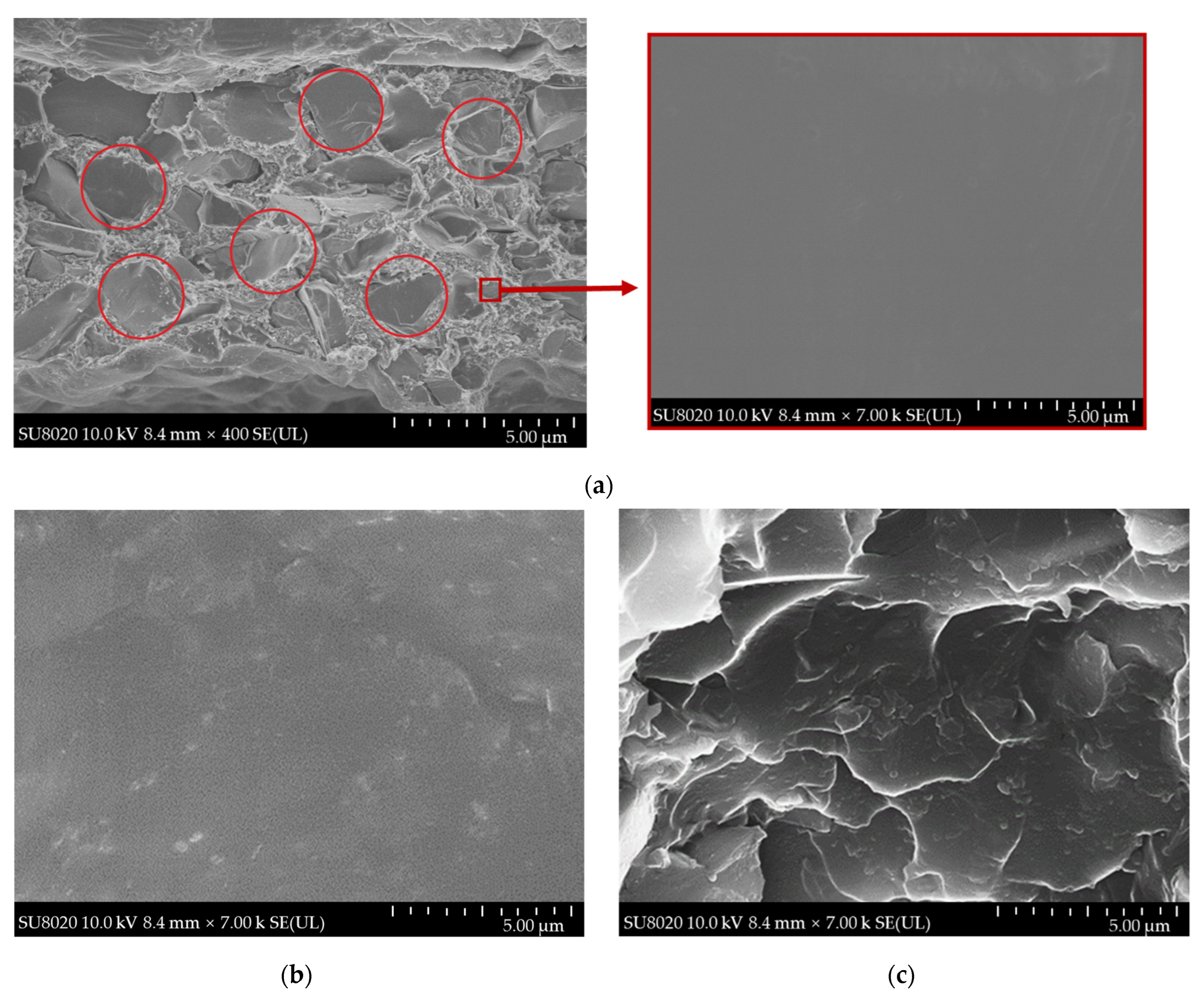

2.3.2. Cross-Sectional Characterization

3. Results and Discussion

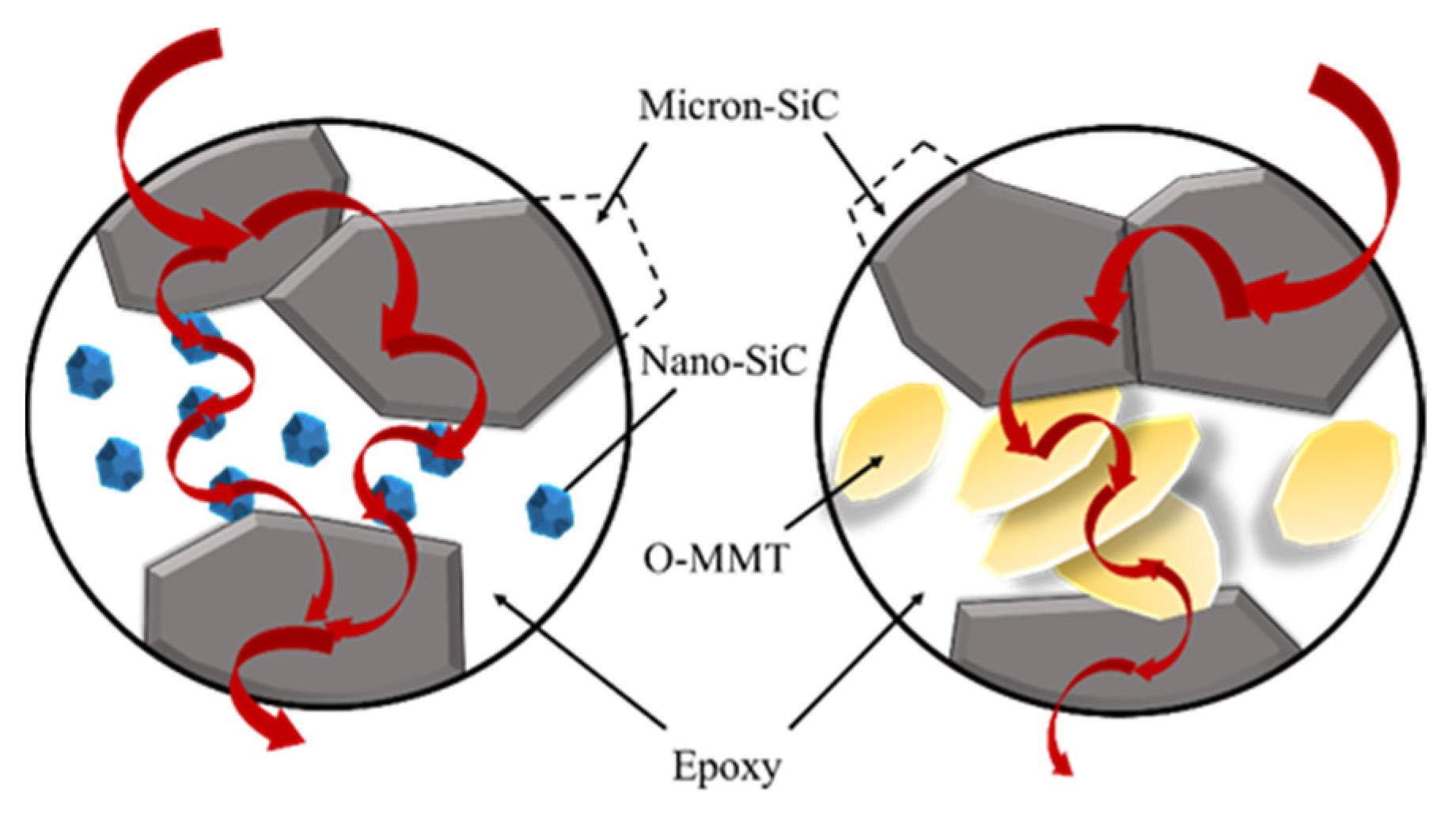

3.1. Morphology of Micro-Nano Structured Composites

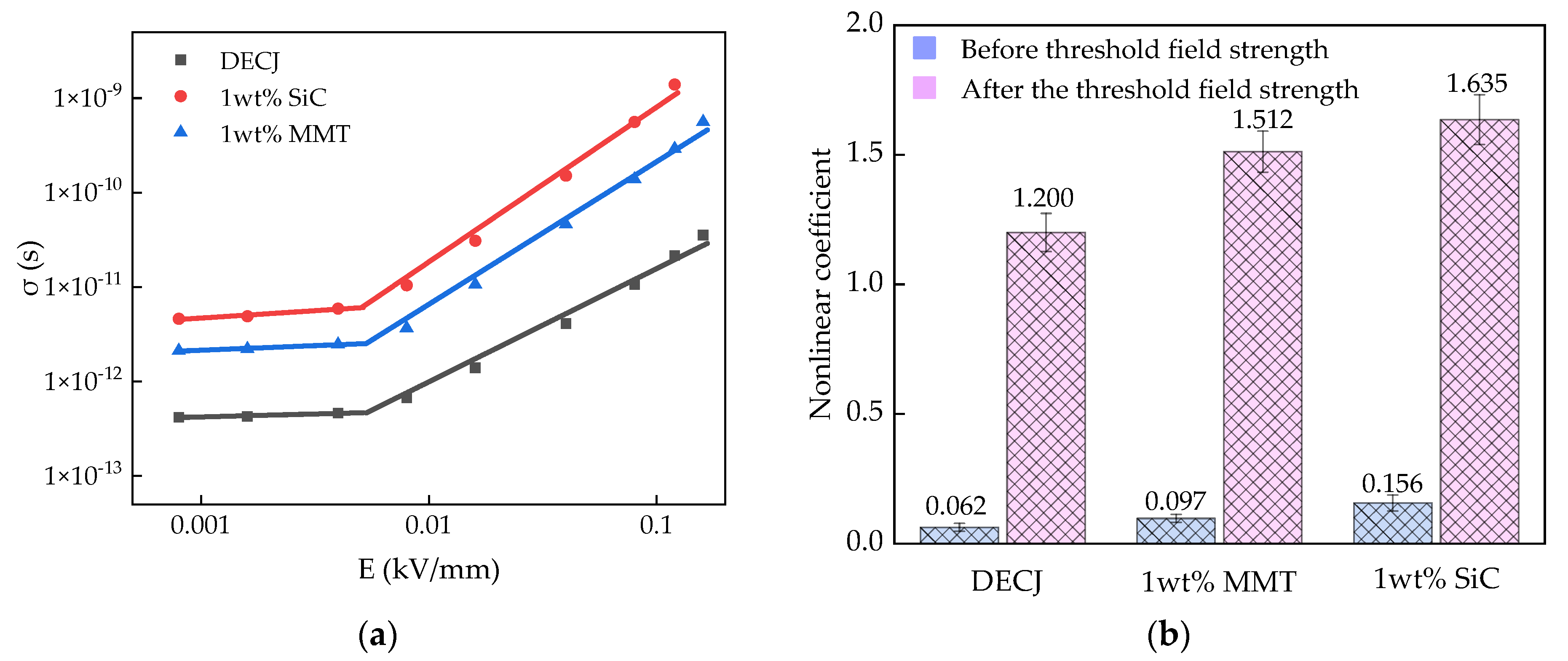

3.2. Effect of Packing Type on Surface Conductivity Characteristics

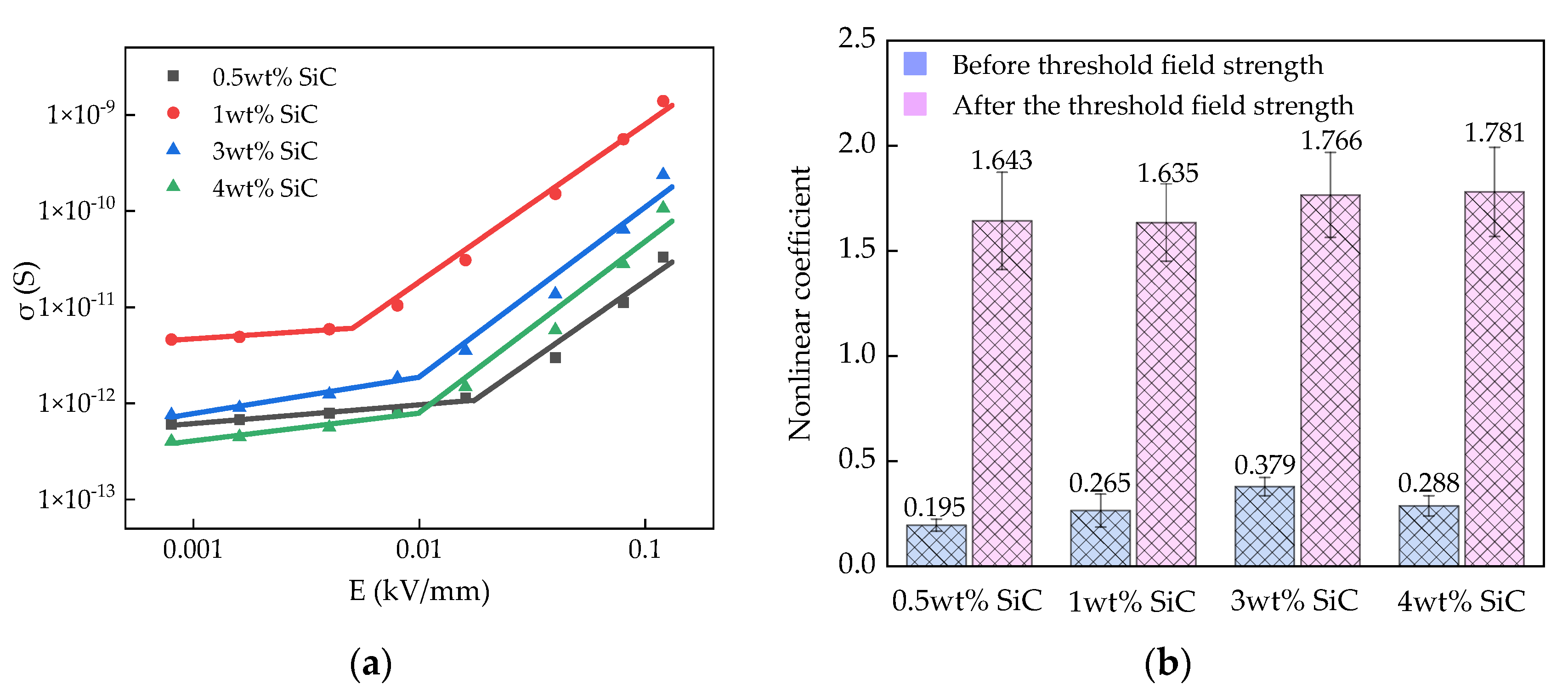

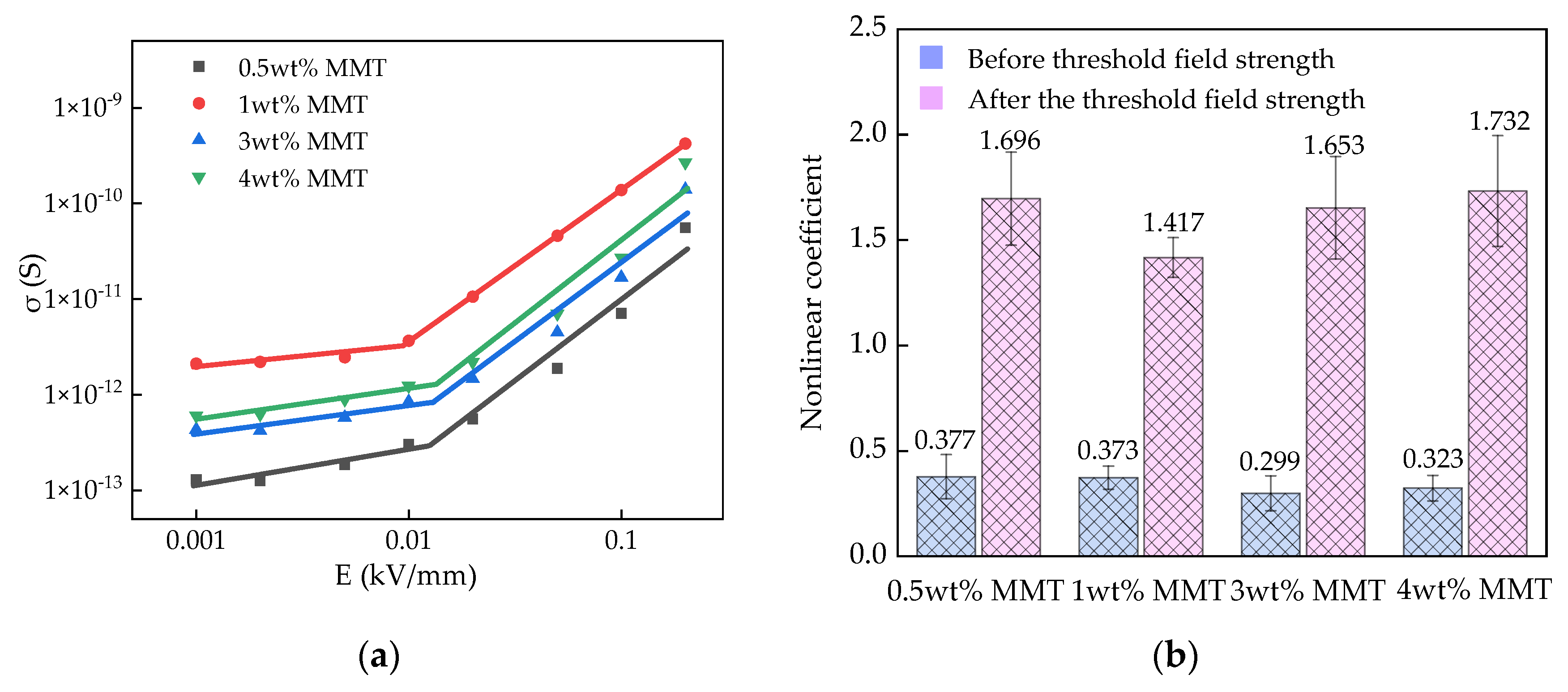

3.3. Effect of Nanoparticle Content on Electrical Surface Conductivity Characteristics

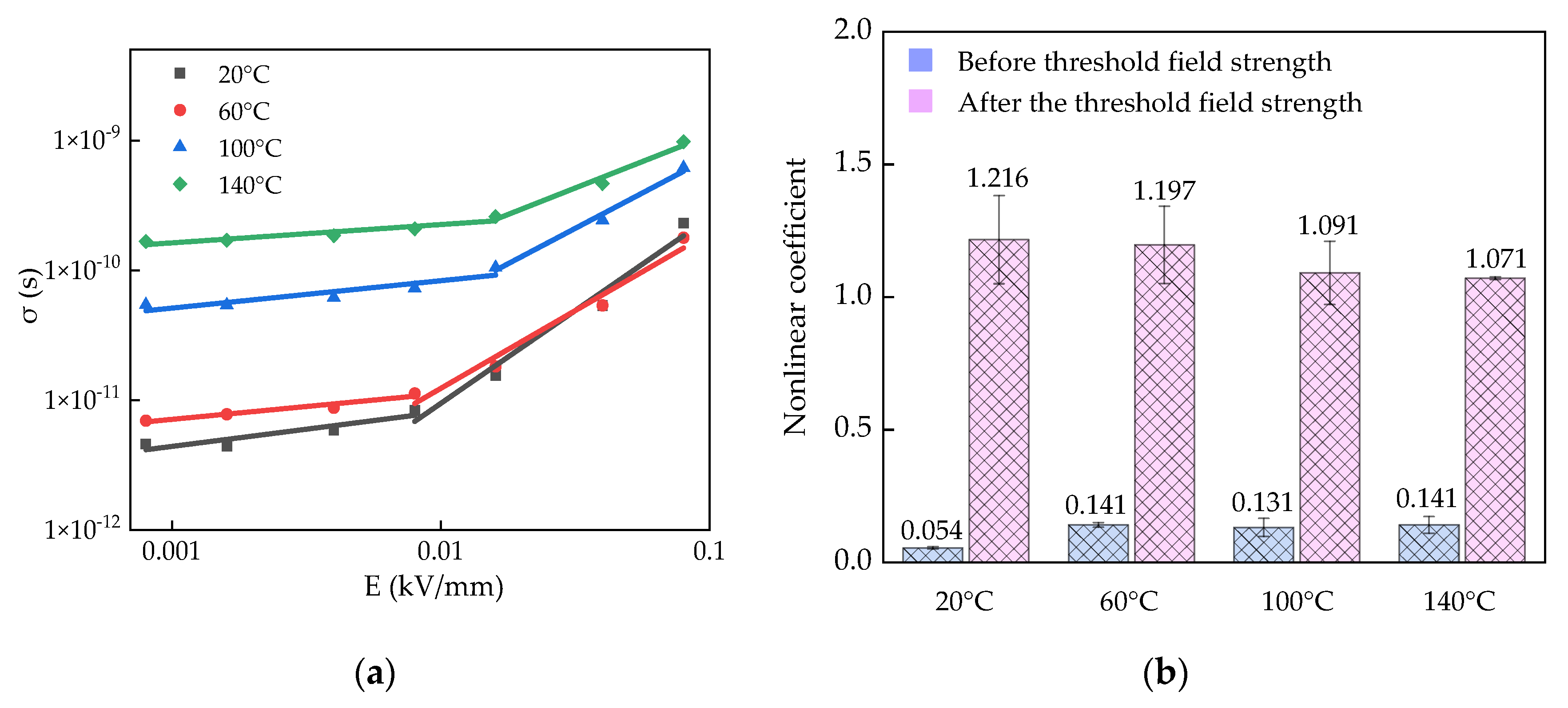

3.4. Effect of Temperature on Nonlinear Surface Conductivity Properties of Micro-Nano Composites

4. Conclusions

- After doping with nanofillers, the surface conductivity of the micro-nano composites was significantly higher than that of the micron composites before doping. The surface conductivity and nonlinear coefficients of SiC-doped micro-nano composites were more excellent than those of micro-nano composites doped with a nano-sheet structure O-MMT. The nonlinear coefficient was improved by 36.25% in the epoxy composites by doping SiC nanoparticles with a content of 1 wt%.

- The surface conductivity of the micro-nanocomposites showed a trend of increasing and then decreasing with the increase of nanostructured SiC and O-MMT contents after the threshold field strength. The highest surface conductivity of the micro-nanocomposites was observed at 1 wt% of both nanostructured SiC and O-MMT content, and the threshold electric field intensity shifted backward relative to the doping concentration at 0.5 wt%. The threshold field strengths are the same for doping concentrations of 3 wt% and 4 wt%. The surface conductivity of the O-MMT doped micro-nanocomposites was highest at 1 wt% of O-MMT content, and the threshold field strength was essentially constant with increasing doping concentration. The nonlinear coefficients of the two micro-nano composites show a similar pattern, and the nonlinear coefficients after the threshold field strength vary significantly concerning the nonlinearity before the threshold field strength. The nonlinear coefficient reaches 1.781 at a doped nanostructured SiC content of 4 wt%.

- The surface conductivity of the micro-nanocomposites doped with nanostructured SiC and O-MMT increased continuously with increasing temperature at both low and high fields. However, the nonlinear coefficients of the composites doped with nanostructured SiC showed a trend of gradual decrease. The nonlinearity coefficient gradually decreases from 1.216 to 1.071 between 20 °C and 140 °C. The nonlinear coefficients of the O-MMT doped composite specimens varied less significantly, all fluctuating above and below 1.487 ± 0.028.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Haque, S.K.M.; Ardila-Rey, J.A.; Umar, Y.; Mas’ud, A.A.; Muhammad-Sukki, F.; Jume, B.H.; Rahman, H.; Bani, N.A. Application and Suitability of Polymeric Materials as Insulators in Electrical Equipment. Energies 2021, 14, 2758. [Google Scholar] [CrossRef]

- Lenko, D.; Schlögl, S.; Bichler, S.; Lemesch, G.; Ramsauer, F.; Ladstätter, W.; Rosc, J.; Kern, W. New Approaches towards the Investigation on Defects and Failure Mechanisms of Insulating Composites Used in High Voltage Applications. Compos. Part B Eng. 2014, 58, 83–90. [Google Scholar] [CrossRef]

- Alam, H.S.; Djunaedi, I.; Soetraprawata, D. Remaining Life Assessment of the Generator Stator Insulation: A Case Study on Suralaya Coal Fired Power Plant in Indonesia. Appl. Mech. Mater. 2015, 799–800, 1344–1348. [Google Scholar] [CrossRef]

- Xie, J.; Hu, J.; He, J.; Guo, Z.; Yin, Y. Simulation Analyse of Modification Effect of Nonlinear Composites on Nonuniform Electrical Fields. Gaodianya Jishu/High Volt. Eng. 2014, 40, 741–750. [Google Scholar] [CrossRef]

- IEEE Dielectrics and Electrical Insulation Society. Annual IEEE Computer Conference. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Shenzhen, China, 20–23 October 2013; Ming Wah International Conference Center: Shenzhen, China, 2013. ISBN 9781479925971. [Google Scholar]

- Hu, H.; Zhang, X.; Zhang, D.; Gao, J.; Hu, C.; Wang, Y. Study on the Nonlinear Conductivity of SiC/ZnO/Epoxy Resin Micro- and Nanocomposite Materials. Materials 2019, 12, 761. [Google Scholar] [CrossRef] [Green Version]

- Shao, T.; Liu, F.; Hai, B.; Ma, Y.; Wang, R.; Ren, C. Surface Modification of Epoxy Using an Atmospheric Pressure Dielectric Barrier Discharge to Accelerate Surface Charge Dissipation. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1557–1565. [Google Scholar] [CrossRef]

- Tu, Y.; Zhou, F.; Jiang, H.; Bai, F.; Wang, C.; Lin, J.; Cheng, Y. Effect of Nano-TiO2/EP Composite Coating on Dynamic Characteristics of Surface Charge in Epoxy Resin. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1308–1317. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, X.; Liu, Y.; Guo, L.; Gao, J. Optimization of the Electric Field Distribution at the End of the Stator in a Large Generator. Energies 2018, 11, 2510. [Google Scholar] [CrossRef] [Green Version]

- Du, B.X.; Liang, H.C.; Li, J.; Zhang, C. Temperature Dependent Surface Potential Decay and Flashover Characteristics of Epoxy/SiC Composites. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 631–638. [Google Scholar] [CrossRef]

- Can-Ortiz, A.; Laudebat, L.; Valdez-Nava, Z.; Diaham, S. Nonlinear Electrical Conduction in Polymer Composites for Field Grading in High-Voltage Applications: A Review. Polymers 2021, 13, 1370. [Google Scholar] [CrossRef]

- Yang, X.; Hu, J.; He, J. Adjusting Nonlinear Characteristics of ZnO-Silicone Rubber Composites by Controlling Filler’s Shape and Size. In Proceedings of the 2016 IEEE International Conference on Dielectrics (ICD 2016), Montpellier, France, 3–7 July 2016; Institute of Electrical and Electronics Engineers Inc.: Manhattan, NY, USA, 2016; Volume 1, pp. 313–317. [Google Scholar]

- Liu, C.; Zheng, Y.; Zhang, B.; Zheng, X.; Hu, S.; Han, K. Review of Nonlinear Conductivity Theory Research of Modified Composite Materials. IEEE Access 2019, 7, 50536–50548. [Google Scholar] [CrossRef]

- Katayama, J.; Ohki, Y.; Fuse, N.; Kozako, M.; Tanaka, T. Effects of Nanofiller Materials on the Dielectric Properties of Epoxy Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 157–165. [Google Scholar] [CrossRef]

- Ramu, T.; Nagamani, H. Alumina and Silica Based Epoxy Nano-Composites for Electrical Insulation. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 236–243. [Google Scholar] [CrossRef]

- Yang, G.; Guo, Y.; Wang, D.; Wang, S.; Jia, R.; Li, P. Dielectric Characteristics of Epoxy Composites Modified with Nano ZnO in Non-Uniform Electrical Field. Gaodianya Jishu/High Volt. Eng. 2017, 43, 2825–2830. [Google Scholar] [CrossRef]

- Jeon, Y.; Hong, S.K.; Kim, M. Effect of Filler Concentration on Tracking Resistance of ATH-Filled Silicone Rubber Nanocomposites. Energies 2019, 12, 2401. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Yin, G.; Chen, G.; Li, J.; Bai, S.; Zhong, L.; Zhang, Y.; Lei, Q. Short-Term Breakdown and Long-Term Failure in Nanodielectrics: A Review. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1523–1535. [Google Scholar] [CrossRef] [Green Version]

- Castellon, J.; Nguyen, H.N.; Agnel, S.; Toureille, A.; Frechette, M.; Savoie, S.; Krivda, A.; Schmidt, L.E. Electrical Properties Analysis of Micro and Nano Composite Epoxy Resin Materials. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 651–658. [Google Scholar] [CrossRef]

- Roy, M.; Nelson, J.K.; MacCrone, R.K.; Schadler, L.S.; Reed, C.W.; Keefe, R.; Zenger, W. Polymer Nanocomposite Dielectrics—The Role of the Interface. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 629–642. [Google Scholar] [CrossRef]

- Tanaka, T.; Montanari, G.C.; Mülhaupt, R. Polymer Nanocomposites as Dielectrics and Electrical Insulation- Perspectives for Processing Technologies, Material Characterization and Future Applications. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 763–784. [Google Scholar] [CrossRef]

- Tanaka, T. Dielectric Nanocomposites with Insulating Properties. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 914–928. [Google Scholar] [CrossRef]

- Roling, B.; Patro, L.N.; Burghaus, O.; Gräf, M. Nonlinear Ion Transport in Liquid and Solid Electrolytes. Eur. Phys. J. Spec. Top. 2017, 226, 3095–3112. [Google Scholar] [CrossRef]

- Han, Y.; Min, D.; Li, S. Nonlinear Conduction and Surface Potential Decay of Epoxy/SiC Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3154–3164. [Google Scholar] [CrossRef]

- Wang, X.; Nelson, J.; Schadler, L.; Hillborg, H. Mechanisms Leading to Nonlinear Electrical Response of a Nano P-SiC/Silicone Rubber Composite. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1687–1696. [Google Scholar] [CrossRef]

- Han, Y.; Li, S.; Frechette, M.; Min, D. Nonlinear Conductivity of Polymer Nanocomposites: A Study on Epoxy Resin/Silicon Carbide Materials. IEEE Nanotechnol. Mag. 2018, 12, 23–32. [Google Scholar] [CrossRef]

| Name | Notation | Production Manufacturer | Remarks |

|---|---|---|---|

| Epoxy resin composites | DECJ1345 | Dongfang Electric Corporation Limited, Chengdu, China | Epoxy resin blended with micron silicon carbide (72 wt%) |

| Curing agent | 593 | Dongfang Electric Corporation Limited, Chengdu, China | Diethylenetriamine and butyl glycidyl ether |

| Nano silicon carbide | SiC | Beijing Deke Daojin Science and Technology Co., Ltd., Beijing, China | Average particle size of 30 nm |

| Montmorillonite | MMT | Qinghe Chemical Factory, Zhangjiakou, Hebei, China | Average layer spacing of 1.25 nm |

| Octadecyl trimethyl ammonium chloride | S817662 | Shanghai Macklin Biochemical Co., Ltd., Shanghai, China | |

| Silane coupling agent | KH560 | Saen Chemical Technology (Shanghai) Co., Ltd., Shanghai, China |

| Number | Specimen Code | Specimen Formulation |

|---|---|---|

| 1 | DECJ | DECJ1345 |

| 2 | 0.5 wt% SiC | DECJ1345 + 0.5 wt% N-SiC |

| 3 | 1 wt% SiC | DECJ1345 + 1 wt% N-SiC |

| 4 | 3 wt% SiC | DECJ1345 + 3 wt% N-SiC |

| 5 | 4 wt% SiC | DECJ1345 + 4 wt% N-SiC |

| 6 | 0.5 wt% MMT | DECJ1345 + 0.5 wt% O-MMT |

| 7 | 1 wt% MMT | DECJ1345 + 1 wt% O-MMT |

| 8 | 3 wt% MMT | DECJ1345 + 3 wt% O-MMT |

| 9 | 4 wt% MMT | DECJ1345 + 4 wt% O-MMT |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, N.; Sun, J.; Li, Y.; Lv, X.; Gao, J.; He, M.; Zhang, Y. Nonlinear Surface Conductivity Characteristics of Epoxy Resin-Based Micro-Nano Structured Composites. Energies 2022, 15, 5374. https://doi.org/10.3390/en15155374

Guo N, Sun J, Li Y, Lv X, Gao J, He M, Zhang Y. Nonlinear Surface Conductivity Characteristics of Epoxy Resin-Based Micro-Nano Structured Composites. Energies. 2022; 15(15):5374. https://doi.org/10.3390/en15155374

Chicago/Turabian StyleGuo, Ning, Jiaming Sun, Yunlei Li, Xiaoyu Lv, Junguo Gao, Mingpeng He, and Yue Zhang. 2022. "Nonlinear Surface Conductivity Characteristics of Epoxy Resin-Based Micro-Nano Structured Composites" Energies 15, no. 15: 5374. https://doi.org/10.3390/en15155374

APA StyleGuo, N., Sun, J., Li, Y., Lv, X., Gao, J., He, M., & Zhang, Y. (2022). Nonlinear Surface Conductivity Characteristics of Epoxy Resin-Based Micro-Nano Structured Composites. Energies, 15(15), 5374. https://doi.org/10.3390/en15155374