Novel Gas Turbine Challenges to Support the Clean Energy Transition

Abstract

:1. Introduction

- Excellent operational flexibility and maintainability;

- Relatively low investment costs;

- High electrical efficiencies.

- Mechanical: Pumped Hydro (PHS), Compressed Air (CAES), and Flywheel (FES);

- Electromechanical: Secondary Battery Lead-acid/NaS/Li-ion and Flow Battery;

- Electrical: Capacitor/Supercapacitor and Superconducting Magnetic (SMES);

- Thermochemical: Solar fuels and Solar hydrogen;

- Chemical: Hydrogen and Fuel cell/Electrolyzer;

- Thermal: Sensible/latent heat storage.

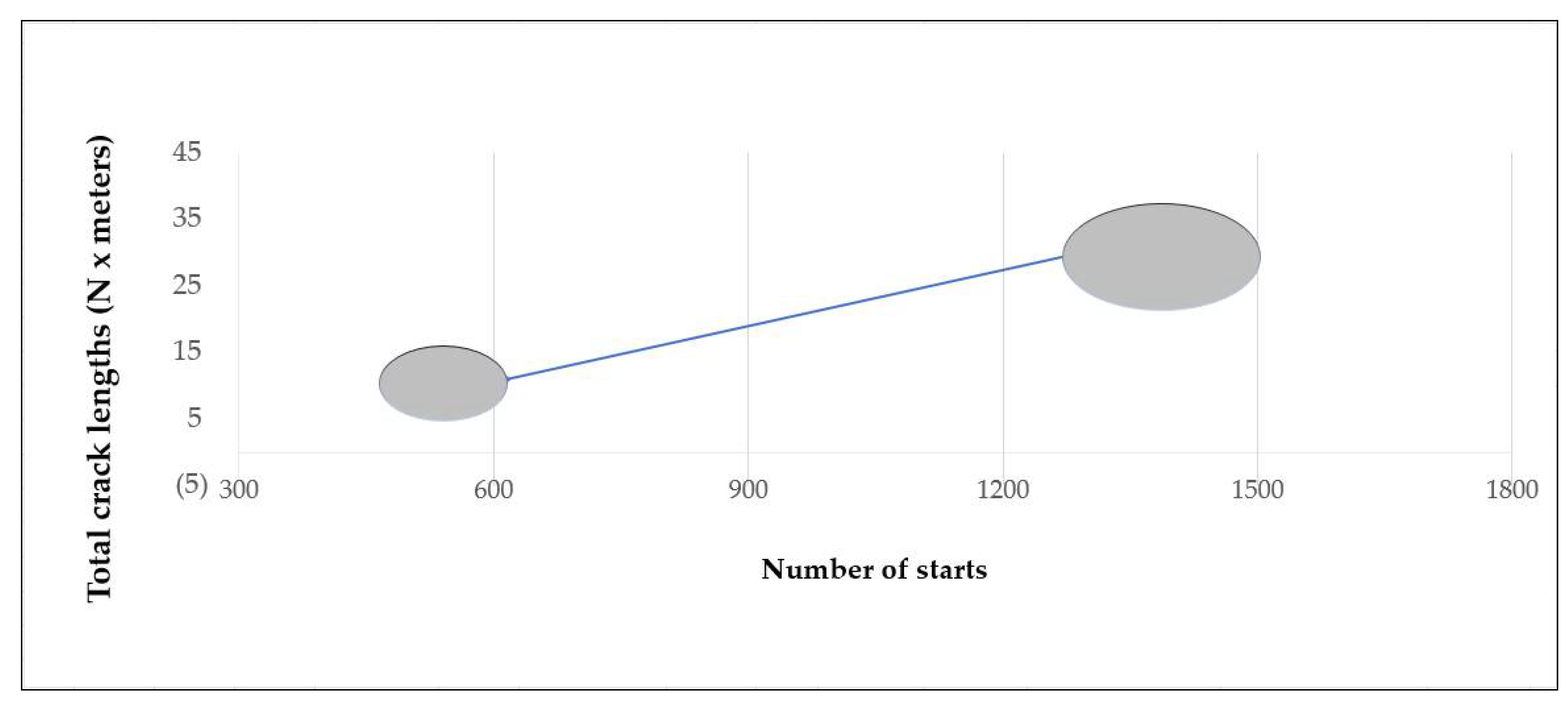

- Increase in starts;

- Fewer operating hours;

- More part load hours and load transients;

- Change for hot starts to cold starts;

- Shift to unpredictable and new load regimes.

- Lower efficiency due to the continuous start–stops and ramping;

- Cost increases;

- Shorter equipment life;

- Higher maintenance requirements.

2. Renewables and Flexibility Needs

- Penetration levels (as a ratio of peak load) of gas turbine-combined gas cycle (CCGT);

- Combined heat and power (CHP);

- Pumped hydropower;

- Hydroelectric power plants (Hydro);

- Interconnections.

- Daily needs are primarily driven by Photo Voltaic (PV) generation;

- Weekly needs are triggered through wind power generation, rather than PV;

- Annual needs are determined by seasonal variation in demand across the year and are dependent on the share of RESs. The type of RES has a major impact on the imbalance of the residual load between the seasons. In this case, the difference in the case of PV and wind energies can be significant. The summer season with peak PV production correlates with low consumption. In comparison, the winter where wind energy peaks, correlates with high demands. Therefore, annual flexibility need is less impacted as a result of increased wind shares. As a rule, a mix of two (or more) renewable sources would be desired as demonstrated by [46]: “Combination of different renewable-based sources such as PV and wind is very helpful for the reliability of the system”.

3. Present GT Lifing Criteria

- Fast start: depending on the gas turbine design, a fast start can typically be around 15 min from ignition to full load. General Electric (GE) specifies a peaking fast start, which for some units such as 7F.03 is less than 15 min and carries some maintenance factors due to increased thermal gradients in the rotor as reported by Beagle et al. [49].

- Peak load: the operation above base load, achieved by increasing the turbine inlet temperature (TIT).

- Hot, warm, and cold starts: these refer to the start-up, after a period of shutdown including less than 8, 8–48, and more than 48 h standstill (and cooling), respectively [50].

- Part load: is the operation below base load achieved by varying the fuel flow rate and the modulation of the inlet guide vane (IGV) in certain designs. The purpose of the air flow rate modulation is to enhance the heat recovery performance, thus increasing the combined cycle efficiency by maintaining a high turbine exhaust temperature [51].

- Flex start: during (faster) start-up and loading, specific modulations of the exhaust temperature and exhaust flows are allowed to limit the transient temperature effects imposed by the steam cycle (for combined cycle plants).

- Cycling: refers to the operation of electric-generating units at varying load levels, including on/off, load following, and minimum load operation, in response to changes in system load requirements.

Criteria Overview

- Hour-Based Factors: fuel type, peak load, and diluent (water or steam injection).

- Start-Based Factors: start type (conventional or fast peaking), start load (max. load achieved during a start cycle, e.g., part, base, or peak load), and shutdown type (normal cooldown, rapid cooldown, or trip).

4. Operational Flexibility Effects on GT Components

4.1. Fatigue–Creep Interaction

4.2. Thermal Mechanical Fatigue

4.3. Partial Load Operations

- Degradation of materials and coatings from cyclic-based loading and sustained transients such as increasing amounts of fatigue damage due to more frequent starts, load fluctuations, and faster loading ramp-ups;

- Inadequate inspection intervals primarily for combustion, expander parts, seals, and bearings;

- Lack of reliable lifing criteria for the most critical components such as the rotor and expander blades;

- Reduced reliability of high-temperature metallic and ceramic protective coatings.

5. New Limits

- Star–stop cycles;

- Reaction time;

- Low fixed and variable cost;

- Start-up capability;

- Operation range.

- Shorter start-up time and lower start-up costs: This is since shorter start-up times enable the plant to quickly reach full load and significantly improves the operational flexibility. The costs associated with the start-ups include more frequent maintenance and additional fuel consumption.

- Lower minimum load and improved part-load efficiency: Operating thermal plants at lower loads increases the bandwidth of their operation, increasing flexibility. Most thermal power plants experience a drastic reduction in their fuel efficiency at low loads, and therefore improving this is an important element of increasing flexibility.

- Higher ramp rate: The rate at which a plant can change its net power during operation is defined as the ramp rate. With higher ramp rates, the plant can quickly alter its production in line with system needs.

- Shorter minimum uptime and runtime: Reducing the minimum time that the plant must be kept running after start-up or remain closed after shutdown allows a plant to react more rapidly.

6. Discussion

- Fast startup and loading;

- Daily or weekly start/stop cycles;

- Variable peak loads and part loads while maintaining emissions compliance;

- Flexible start and loading strategies (temperature and flow) for steam cycle optimization;

- Fuel flexibility (natural gas and hydrogen mixtures and syngas);

- Standby and peak shaving units;

- Others, such as extended cold standby periods followed by fast starts.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bossman, T.; Barberi, P.; Fournié, L. Effect of High Shares of Renewables on Power Systems; Metis Studies, European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Cerri, G.; Gazzino, M.; Botta, F.; Salvini, C. Production planning with hot section life prediction for optimum gas turbine management. Int. J. Gas. Turbine Propuls. Power Syst. 2008, 2, 9–16. [Google Scholar] [CrossRef]

- Van den Bergh, K.; Delarue, K. Cycling of conventional power plants: Technical limits and actual costs. Energy Convers. Manag. 2015, 97, 70–77. [Google Scholar] [CrossRef]

- Michalski, J. The Role of Energy Storage Technologies for the Integration of Renewable Electricity into the German Energy System. Doctoral’s Dissertation, Technische Universität München, Munich, Germany, 2016. [Google Scholar]

- Guittet, M.; Capezzali, M.; Gaudard, L.; Romerio, F.; Vuille, F.; Avellan, F. Study of the drivers and asset management of pumped-storage power plants historical and geographical perspective. Energy 2016, 111, 560–579. [Google Scholar] [CrossRef]

- Lund, P.O.; Lindgren, J.; Mikkola, J.; Salpakari, J. Review of energy system flexibility measures to enable high levels of variable renewable electricity. Renew. Sustain. Energy Rev. 2015, 45, 785–807. [Google Scholar] [CrossRef] [Green Version]

- Sauer, D.U. Chapter 2-Classification of Storage Systems. In Electrochemical Energy Storage for Renewable Sources and Grid Balancing; Elsevier: Amsterdam, The Netherlands, 2015; pp. 13–21. [Google Scholar]

- Maton, J.P.; Zhao, L.; Brouwer, J. Dynamic modeling of compressed gas energy storage to complement renewable wind power intermittency. Int. J. Hydrogen Energy 2013, 38, 7867–7880. [Google Scholar] [CrossRef] [Green Version]

- Hadjipaschalis, I.; Poullikkas, A.; Efthimiou, V. Overview of current and future energy storage technologies for electric power applications. Renew. Sustain. Energy Rev. 2009, 13, 1513–1522. [Google Scholar] [CrossRef]

- Toledo, O.M.; Filho, D.O.; Diniz, A.S. Distributed photovoltaic generation and energy storage systems: A review. Renew. Sustain. Energy Rev. 2010, 14, 506–511. [Google Scholar] [CrossRef]

- Kazempour, S.J.; Moghaddam, M.P.; Haghifam, M.R.; Yousefi, G.R. Electric energy storage systems in a market-based economy: Comparison of emerging and traditional technologies. Renew. Energy 2009, 34, 2630–2639. [Google Scholar] [CrossRef]

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Appl. Energy 2015, 137, 511–536. [Google Scholar] [CrossRef] [Green Version]

- Rossi, A.; Stabile, M.; Puglisi, C.; Fabretti, D.; Merlo, M. Evaluation of the energy storage system Impact on the Italian ancillary market. Sustain. Energy 2019, 18, 100178. [Google Scholar] [CrossRef]

- Kondoh, J.; Ishii, I.; Yamaguchi, H.; Murata, A.; Otani, K.; Sakuta, K.; Higuchi, N.; Sekine, S.; Kamimoto, M. Electrical energy storage systems for energy networks. Energy Convers. Manag. 2000, 41, 1863–1874. [Google Scholar] [CrossRef]

- Rydh, C.J.; Sandén, B.A. Energy analysis of batteries in photovoltaic systems. Part I: Performance and energy requirements. Energy Convers. Manag. 2005, 46, 1957–1979. [Google Scholar] [CrossRef]

- Dell, R.M.; Rand, D.A.J. Energy storage—a key technology for global energy sustainability. J. Power Sources 2001, 100, 2–17. [Google Scholar] [CrossRef]

- Hall, P.J.; Bain, E.J. Energy-storage technologies and electricity generation. Energy Policy 2008, 36, 4352–4355. [Google Scholar] [CrossRef] [Green Version]

- Sundararagavan, S.; Baker, E. Evaluating energy storage technologies for wind power integration. Sol. Energy 2012, 86, 2707–2717. [Google Scholar] [CrossRef]

- Denholm, P.; Margolis, R.M. Evaluating the limits of solar photovoltaics (PV) in electric power systems utilizing energy storage and other enabling technologies. Energy Policy 2007, 35, 4424–4433. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Zafirakis, D. Optimum energy storage techniques for the improvement of renewable energy sources-based electricity generation economic efficiency. Energy 2007, 32, 2295–2305. [Google Scholar] [CrossRef]

- González, A.; McKeogh, E.; Gallachóir, B.Ó. The role of hydrogen in high wind energy penetration electricity systems: The Irish case. Renew. Energy 2004, 29, 471–489. [Google Scholar] [CrossRef]

- Drury, E.; Denholm, P.; Sioshansi, R. The value of compressed air energy storage in energy and reserve markets. Energy 2011, 36, 4959–4973. [Google Scholar] [CrossRef]

- Nyamdash, B.; Denny, E.; O’Malley, M. The viability of balancing wind generation with large scale energy storage. Energy Policy 2010, 38, 7200–7208. [Google Scholar] [CrossRef]

- Nakhamkin, M.; Chirivolu, M.; Patel, M.; Byrd, S. Second generation of CAES technology–Performance, economics, renewable load management, green energy. In Proceedings of the Power-Gen International, Las Vegas, NV, USA, 8–10 December 2009. [Google Scholar]

- Salvini, C. Performance analysis of small size compressed air energy storage systems for power augmentation: Air injection and air injection/expander schemes. Heat Transf. Eng. 2018, 19, 304–315. [Google Scholar] [CrossRef]

- Razmi, A.R.; Afshar, H.H.; Pourahmadiyam, A.; Torabi, M. Investigation on a combined heat and power (CHP) system based on biomass and compressed air energy storage (CAES). Sustain. Energy Technol. Assess. 2021, 46, 101253. [Google Scholar] [CrossRef]

- Salvini, C. Performance assessment of CAES system integrated into a gas-steam combined plant. Energy Procedia 2017, 136, 264–269. [Google Scholar] [CrossRef]

- Ferreira, H.L.; Garde, R.; Fulli, G.; Kling, W.; Lopes, J.P. Characterisation of electrical energy storage technologies. Energy 2013, 53, 288–298. [Google Scholar] [CrossRef] [Green Version]

- Lund, H.; Salgi, G. The role of compressed air energy storage (CAES) in future sustainable energy systems. Energy Convers. Manag. 2009, 50, 1172–1179. [Google Scholar] [CrossRef]

- Igie, U.; Abbondanza, M.; Szymanski, A.; Nikolaidis, T. Impact of compressed air energy storage demands on gas turbine performance. J. Power Energy 2021, 235, 850–865. [Google Scholar] [CrossRef] [Green Version]

- Welch, M. Improving the flexibility and efficiency of gas turbine-based distributed power plant. In Proceedings of the Future of Gas. Turbine Technology 8th international Gas. Turbine Conference, 08-IGTC16, Brussels, Belgium, 12–13 October 2016. [Google Scholar]

- Impram, S.; Nese, S.V.; Oral, B. Challenges of renewable energy penetration on power system flexibility: A survey. Energy Strategy Rev. 2020, 31, 100539. [Google Scholar] [CrossRef]

- Yasuda, Y.; Ardal, A.R.; Carlini, E.M.; Estanqueiro, A.; Flynn, D.; Gomez-Lázaro, E.; Holttinen, H.; Kiviluoma, J.; van Hulle, F.; Kondoh, J.; et al. Flexibility chart: Evaluation on diversity of flexibility in various areas. In Proceedings of the 12th International Workshop on Large-Scale Integration of Wind Power into Power Systems as well as on Transmission Networks for Offshore Wind Power Plants, Book of Proceedings, London, UK, 22–24 October 2013. [Google Scholar]

- Naser, I.S.; Garba, A.; Anaya-Lara, O.; Lo, K.L. Voltage stability of transmission network with different penetration levels of wind generation. In Proceedings of the 45th International Universities Power Engineering Conference (UPEC2010), Cardiff, UK, 31 August–3 September 2010; pp. 1–5. [Google Scholar]

- Meegahapola, L.; Flynn, D. Impact on transient and frequency stability for a power system at very high wind penetration. In Proceedings of the IEEE PES General Meeting, Minneapolis, MN, USA, 25–29 July 2010; pp. 1–8. [Google Scholar]

- Zhang, Y.; Zhu, S.; Sparks, R.; Green, I. Impacts of solar PV generators on power system stability and voltage performance. In Proceedings of the 2012 IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012; pp. 1–7. [Google Scholar]

- Niu, S.; Zhang, Z.; Ke, X.; Zhang, G.; Huo, C.; Qin, B. Impact of renewable energy penetration rate on power system transient voltage stability. Energy Rep. 2022, 8, 487–492. [Google Scholar] [CrossRef]

- Eftekharnejad, S.; Vittal, V.; Heydt, G.T.; Keel, B.; Loehr, J. Impact of increased penetration of photovoltaic generation on power systems. IEEE Trans. Power Syst. 2013, 28, 893–901. [Google Scholar] [CrossRef]

- Alquthami, T.; Ravindra, H.; Faruque, M.O.; Steurer, M.; Baldwin, T. Study of photovoltaic integration impact on system stability using custom model of PV arrays integrated with PSS/E. N. Am. Power Symp. 2010, 2010, 1–8. [Google Scholar]

- Eser, P.; Singh, A.; Chokani, N.; Abhari, R.S. Effect of increased renewables generation on operation of thermal power plants. Appl. Energy 2016, 164, 723–732. [Google Scholar] [CrossRef]

- Feldmuller, A.; Zimmerer, T.; Roehr, F. From Base to Cycling Operation. Siemens energy. In Proceedings of the Power-Gen Europe 2015, Amsterdam, The Netherlands, 9–11 June 2015. [Google Scholar]

- Lukowicz, H.; Rusin, A. The impact of the control method of cyclic operation on the power unit efficiency and life. Energy 2018, 150, 565–574. [Google Scholar] [CrossRef]

- Turconi, R.; O’Dwyer, C.; Flynn, D.; Astrup, T. Emissions from cycling of thermal power plants in electricity systems with high penetration of wind power: Life cycle assessment for Ireland. Appl. Energy 2014, 131, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Arias, B. An analysis of the operation of a flexible oxy-fired CFB power plant integrated with a thermal energy storage system. Int. J. Greenh. Gas. Control. 2016, 45, 172–180. [Google Scholar] [CrossRef]

- Farhat, H.; Salvini, C. New lifing criterion for land-based gas turbines in flexible operation mode. Energy Rep. 2020, 8, 379–385. [Google Scholar] [CrossRef]

- Rakhshani, E.; Rouzbehi, K.; Sánchez, A.J.; Tobar, A.C.; Pouresmaeil, E. Integration of Large Scale PV-Based Generation into Power Systems: A Survey. Energies 2019, 12, 1425. [Google Scholar] [CrossRef] [Green Version]

- Obi, M.; Bass, R. Trends and challenges of grid-connected photovoltaic systems—A review. Renew. Sustain. Energy Rev. 2016, 58, 1082–1094. [Google Scholar] [CrossRef]

- Dounis, A.I.; Kofinas, P.; Alafodimos, C.; Tseles, D. Adaptive fuzzy gain scheduling PID controller for maximum power point tracking of photovoltaic system. Renew. Energy 2013, 60, 202–214. [Google Scholar] [CrossRef]

- Beagle, D.; Moran, B.; McDufford, M.; Merine, M. Heavy-Duty Gas Turbine Operating and Maintenance Considerations; GER-3620P; GE Power: Atlanta, GA, USA, 2021. [Google Scholar]

- Angerer, M.; Kahlert, S.; Spliethoff, H. Transient simulation and fatigue evaluation of fast gas turbine startups and shutdowns in a combined cycle plant with an innovative thermal buffer storage. Energy 2017, 130, 246–257. [Google Scholar] [CrossRef]

- Cerri, G.; Mazzoni, S.; Salvini, C. Steam Cycle simulator for CHP plants. In Proceedings of the ASME Turbo Expo, ASME Turbo Expo 203: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013; Volume 2. [Google Scholar]

- Keatley, P.; Shibli, A.; Hewitt, N.J. Estimating power plant start costs in cyclic operation. Appl. Energy 2013, 111, 550–557. [Google Scholar] [CrossRef]

- Kumar, N.; Besuner, S.; Lefton, S.; Agan, D.; Hilleman, D. Power Plant Cycling Costs; Intertek APTECH Sunnyvale: Sunnyvale, CA, USA, 2012. [Google Scholar]

- Reyhani, M.; Alizadeh, M.; Fathi, A.; Khaledi, H. Turbine blade temperature calculation and life estimation—A sensitivity analysis. Propuls. Power Res. 2013, 2, 148–161. [Google Scholar] [CrossRef] [Green Version]

- Dogan, B. Plant Component Assessment for Creep-Fatigue Damage: Component Assessment Methodologies; EPRI: Palo Alto, CA, USA, 2009. [Google Scholar]

- Gandy, D. Program on Technology Innovation: The State-of-Knowledge Report on Creep-Fatigue Interaction; EPRI: Palo Alto, CA, USA, 2008; p. 101 6489.

- Jones, J. Thermo-Mechanical Fatigue-In the Gas Turbine Engine; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Are Simple Cycles or Combined Cycles Better for Renewable Power Integration? Power Magazine. 2015. Available online: https://www.powermag.com/are-simple-cycles-or-combined-cycles-better-for-renewable-power-integration/ (accessed on 29 June 2021).

- Linkenheil, C.P.; Küchle, I.; Kurth, T.; Huneke, F. Flexibility Needs and Options for Europe’s Future Electricity System; EUGINE-European Engine Power Plants Association: Berlin, Germany, 2017. [Google Scholar]

- Anisie, A.; Fransisco, B. Innovation Landscape Brief: Flexibility in Conventional Power Plants; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farhat, H.; Salvini, C. Novel Gas Turbine Challenges to Support the Clean Energy Transition. Energies 2022, 15, 5474. https://doi.org/10.3390/en15155474

Farhat H, Salvini C. Novel Gas Turbine Challenges to Support the Clean Energy Transition. Energies. 2022; 15(15):5474. https://doi.org/10.3390/en15155474

Chicago/Turabian StyleFarhat, Hiyam, and Coriolano Salvini. 2022. "Novel Gas Turbine Challenges to Support the Clean Energy Transition" Energies 15, no. 15: 5474. https://doi.org/10.3390/en15155474