Tunnel Oxide Deposition Techniques and Their Parametric Influence on Nano-Scaled SiOx Layer of TOPCon Solar Cell: A Review

Abstract

:1. Introduction

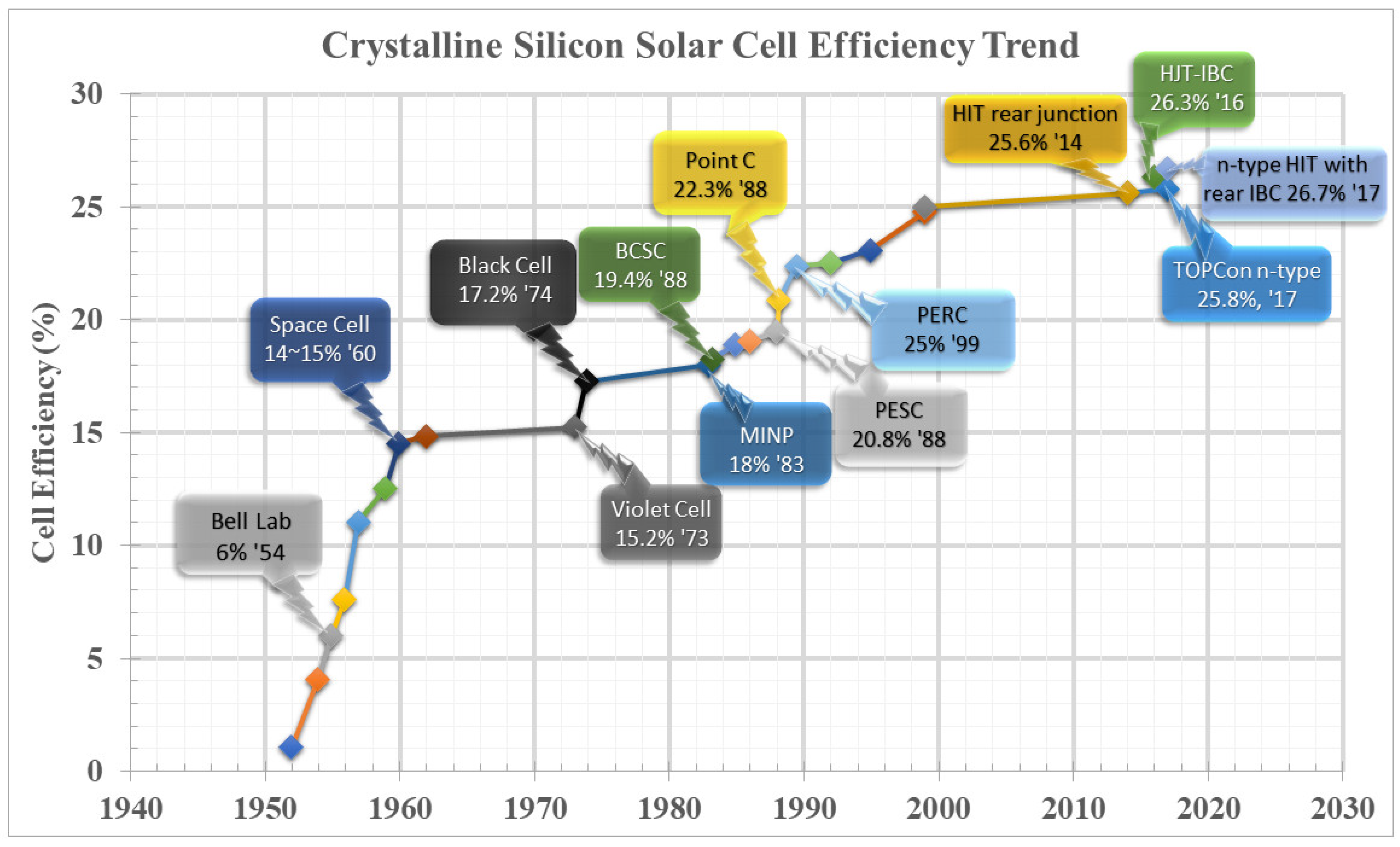

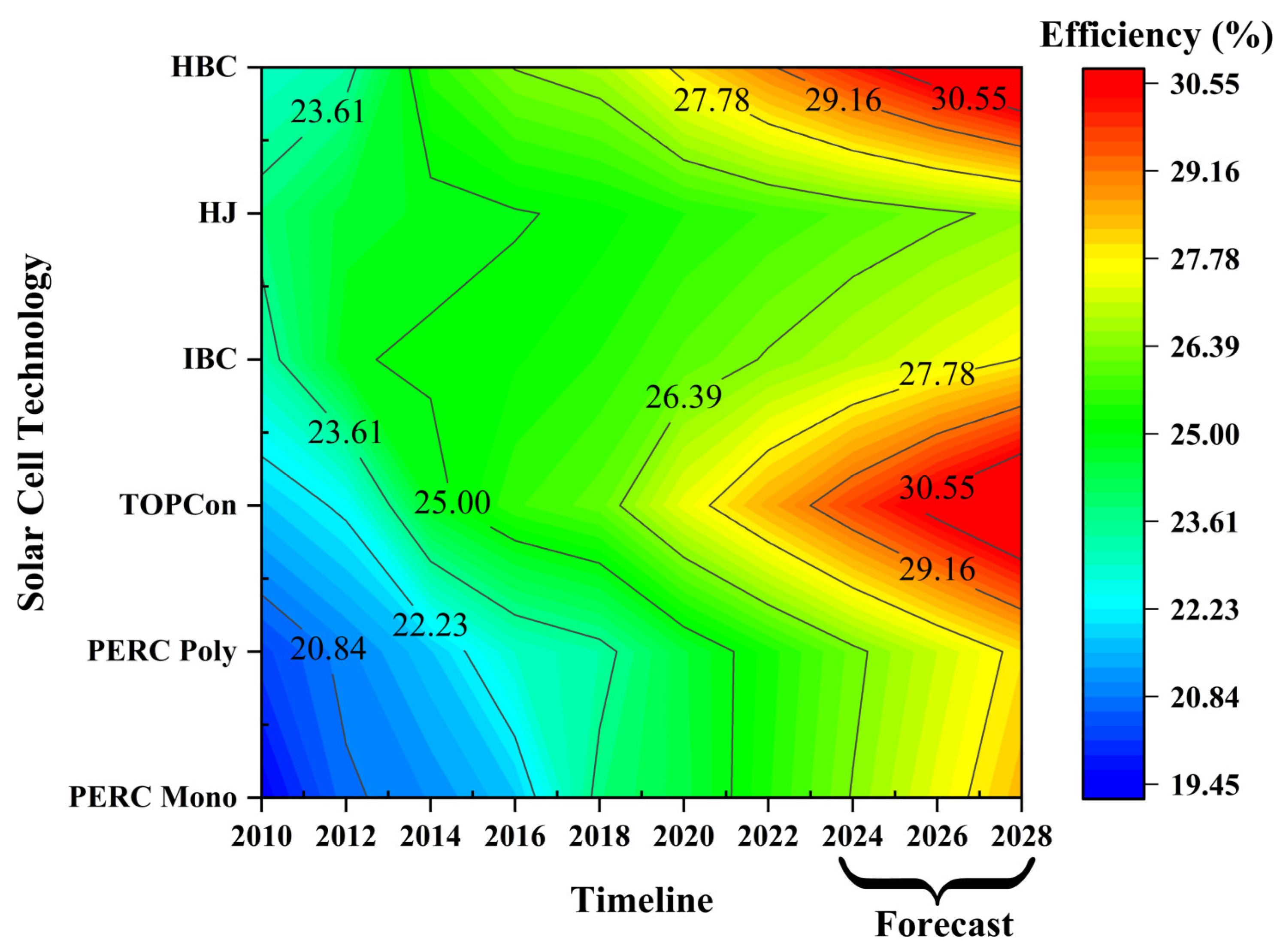

2. Development Progress of TOPCon Solar Cells

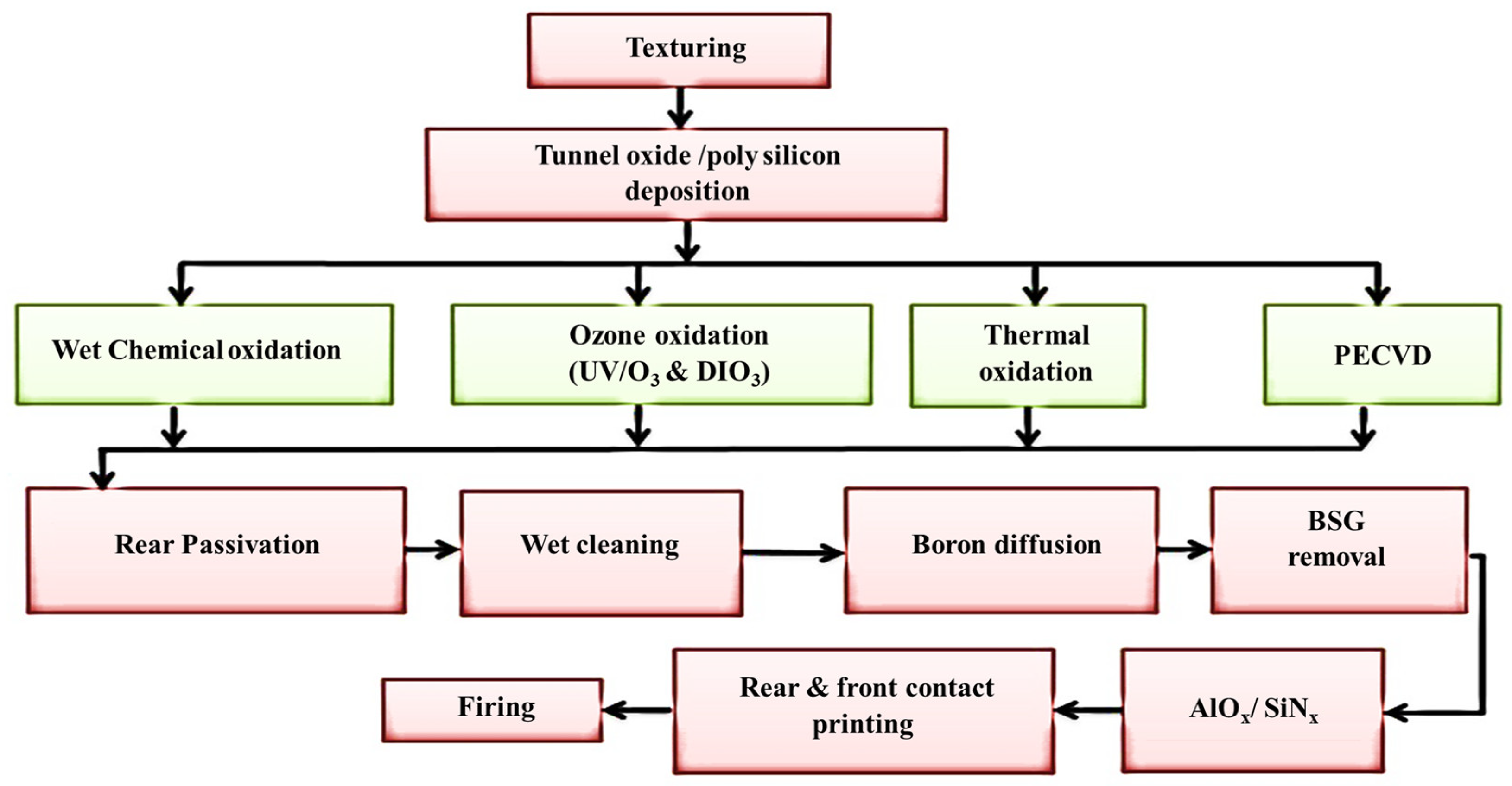

2.1. TOPCon Solar Cells Fabrication

2.2. Background of TOPCon Solar Cell Development Progress

- The ultimate oxides layer at the nano-scale assured the hanging bond that is found at a single crystal surface, consequently improving the conversion efficiency;

- Depending on the range of substrate conductivity, the oxide layer at nano-scale level permits instant transport of the holes or electrons;

- Owing to the importance of the high possibility of densely doped polysilicon conductivity, the junction resistivity can be reduced, and the output current might become better.

2.3. Structure of TOPCon Solar Cell

2.4. Carrier Transportation Mechanisms at the Poly-Si/SiOx/c-Si Interfaces in the TOPCon Structure

3. Development of Nano-Scaled Oxide Layer on TOPCon Solar Cell

Polysilicon Doped Layer

4. Techniques for Deposition of Tunnel Oxide Layer on TOPCon Solar Cells

4.1. Chemical Oxidation

4.2. UV and DI Ozone Oxidation

4.3. Thermal Oxidation

4.4. Plasma Enhanced Chemical Vapor Deposition (PECVD)

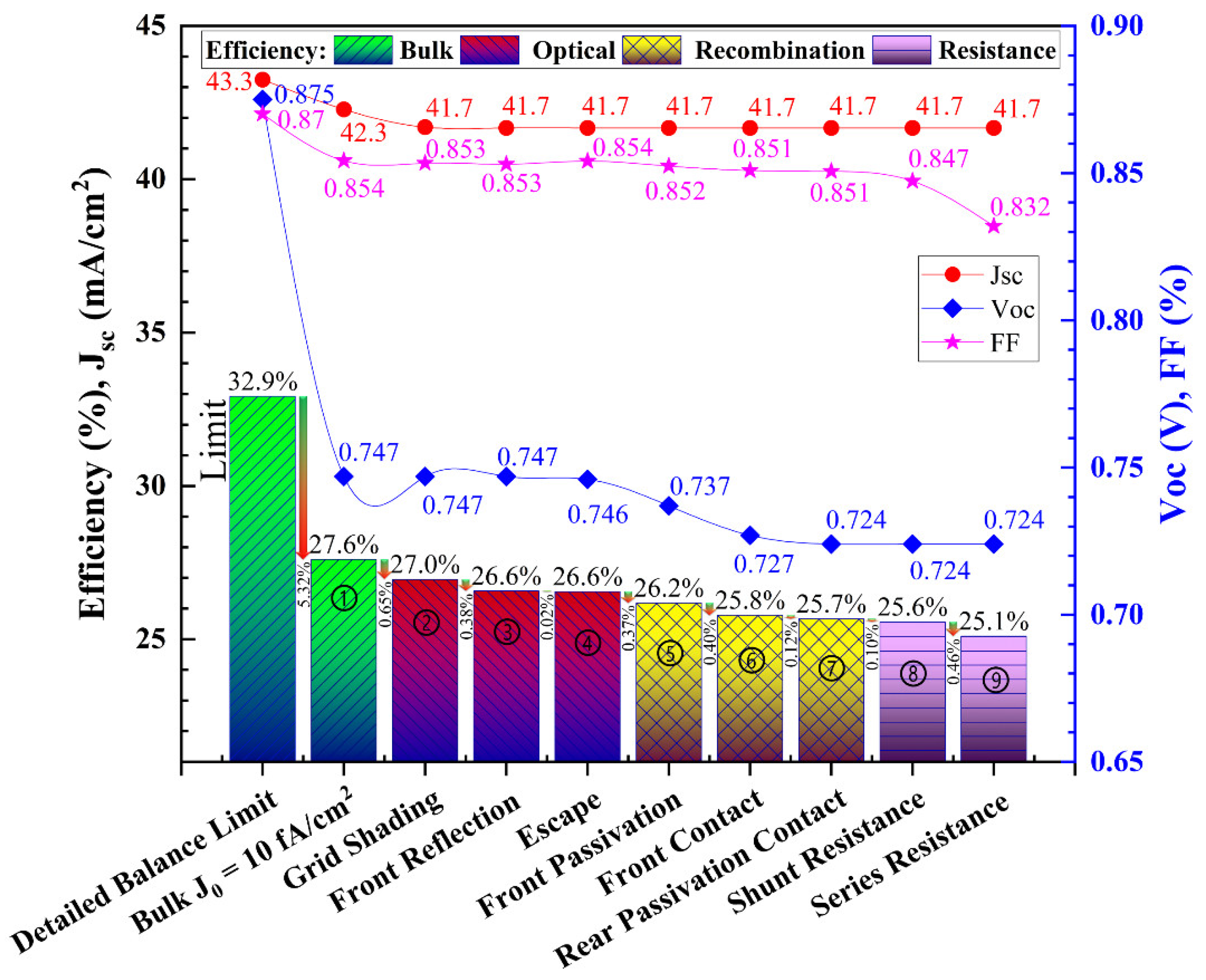

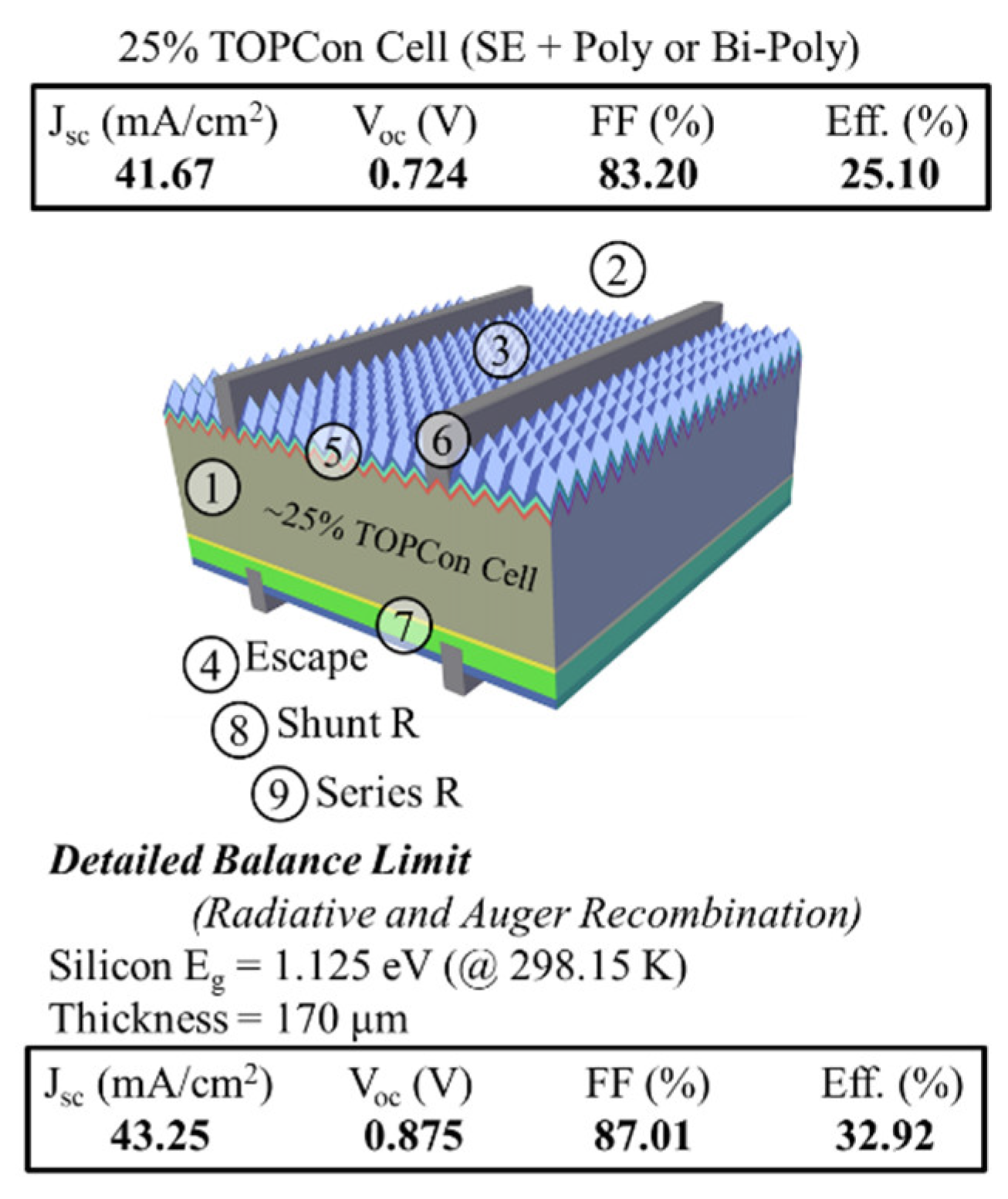

5. Analysis of Loss Factor

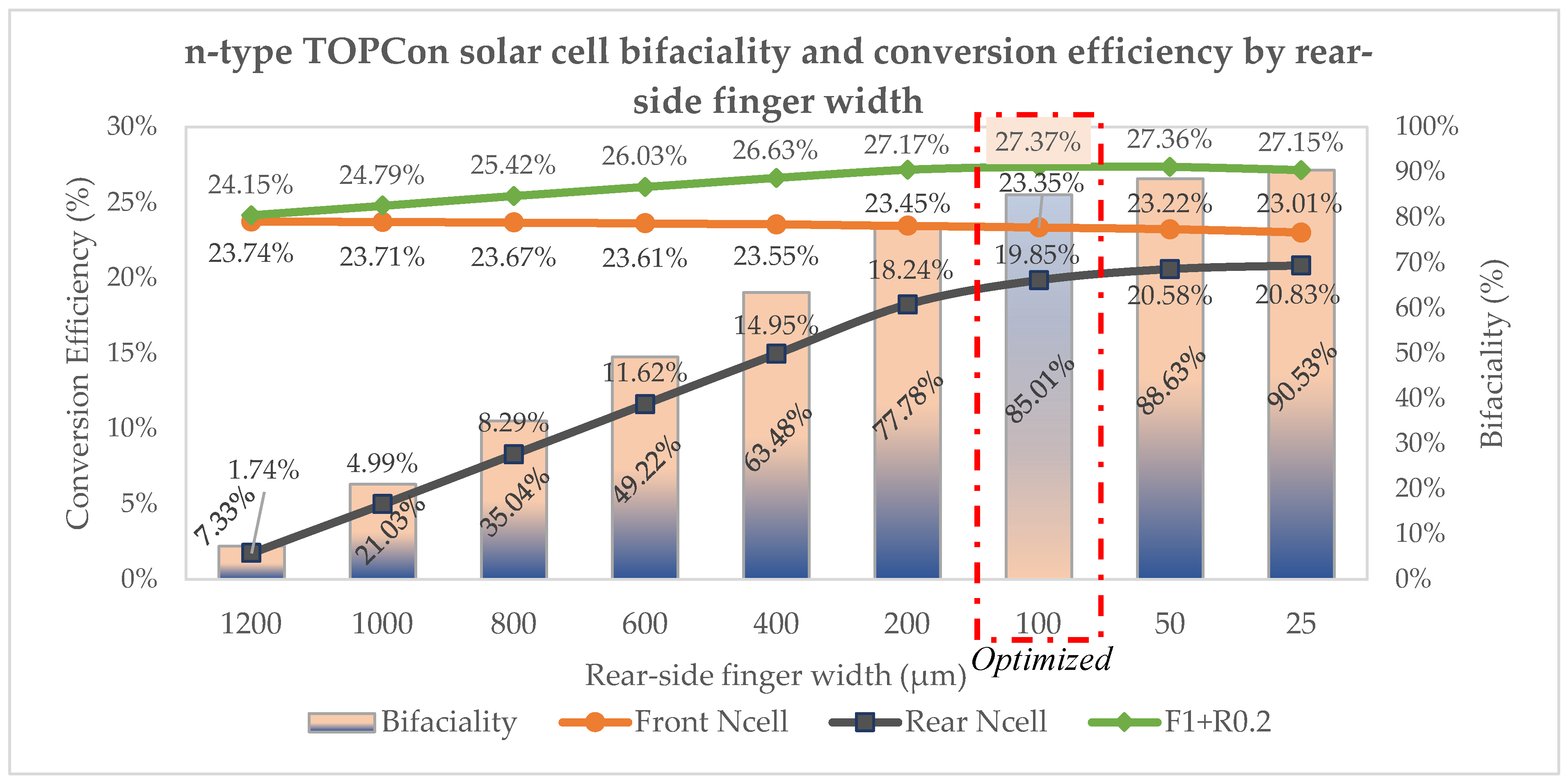

5.1. n-Type TOPCon Solar Cell TCAD Analysis and Conversion Efficiency with Bifaciality

5.2. Investigation of Interfuse Concentration

6. Perspective for the Future Research and Overview

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eriksen, R.; Engel, D.; Haugen, U.; Hodne, T.; Hovem, L.; Alvik, S.; Rinaldo, M. Energy Transition Outlook 2021: Technology Progress Report. 2021. Available online: https://www.dnv.com/Publications/energy-transition-outlook-2021-210847 (accessed on 14 March 2022).

- Aklin, M.; Bayer, P.; Harish, S.P.; Urpelainen, J. Does basic energy access generate socioeconomic benefits? A field experiment with off-grid solar power in India. Sci. Adv. 2017, 3, e1602153. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lovins, A.B. A bright future: The rise of solar energy and the path ahead for America’s renewable energy sector. Science 2015, 350, 169. [Google Scholar] [CrossRef]

- International Energy Agency Photovoltaic Power Systems Programme (IEA PVPS). Snapshot of Global Photovoltaic Markets. 2020. Available online: https://iea-pvps.org/wp-content/uploads/2020/04/IEA_PVPS_Snapshot_2020.pdf (accessed on 14 March 2022).

- Chapin, D.M.; Fuller, C.S.; Pearson, G.L. A new silicon p-n junction photocell for converting solar radiation into electrical power. J. Appl. Phys. 1954, 25, 676–677. [Google Scholar] [CrossRef]

- Ghosh, D.K.; Bose, S.; Das, G.; Acharyya, S.; Nandi, A.; Mukhopadhyay, S.; Sengupta, A. Fundamentals, Present Status and Future Perspective of TOPCon Solar Cells: A Comprehensive Review. Surf. Interfaces 2022, 30, 101917. [Google Scholar] [CrossRef]

- Kim, S.; Kim, T.; Jeong, S.; Cha, Y.; Kim, H.; Park, S.; Ju, M.; Yi, J. Passivating Contact Properties based on SiOX/poly-Si Thin Film Deposition Process for High-efficiency TOPCon Solar Cells. New Renew. Energy 2022, 18, 29–34. [Google Scholar] [CrossRef]

- Green, M.A. The path to 25% silicon solar cell efficiency: History of silicon cell evolution. Prog. Photovolt. Res. Appl. 2009, 17, 183–189. [Google Scholar] [CrossRef]

- Yoshikawa, K.; Kawasaki, H.; Yoshida, W.; Irie, T.; Konishi, K.; Nakano, K.; Uto, T.; Adachi, D.; Kanematsu, M.; Uzu, H.; et al. Silicon heterojunction solar cell with interdigitated back contacts for a photoconversion efficiency over 26%. Nat. Energy 2017, 2, 17032. [Google Scholar] [CrossRef]

- Allen, T.G.; Bullock, J.; Yang, X.; Javey, A.; de Wolf, S. Passivating contacts for crystalline silicon solar cells. Nat. Energy 2019, 4, 914–928. [Google Scholar] [CrossRef]

- Yablonovitch, E.; Gmitter, T.; Swanson, R.M.; Kwark, Y.H. A 720 mV open circuit voltage SiOx: C-Si: SiOx double heterostructure solar cell. Appl. Phys. Lett. 1985, 47, 1211–1213. [Google Scholar] [CrossRef]

- Feldmann, F.; Bivour, M.; Reichel, C.; Hermle, M.; Glunz, S.W. A Passivated Rear Contact for High-Efficiency n-Type Silicon Solar Cells Enabling High Vocs and FF > 82%. In Proceedings of the 28th European PV Solar Energy Conference and Exhibition, Villepinte, France, 30 September 2013; pp. 988–992. [Google Scholar]

- Feldmann, F.; Steinhauser, B.; Arya, V.; Büchler, A.; Brand, A.A.; Kluska, S.; Glunz, S.W. Evaluation of TOPCon technology on large area solar cells. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25 September 2017; pp. 1–3. [Google Scholar]

- Liu, J.; Yao, Y.; Xiao, S.; Gu, X. Review of status developments of high-efficiency crystalline silicon solar cells. J. Phys. D Appl. Phys. 2018, 51, 123001. [Google Scholar] [CrossRef]

- Shaw, V. The Weekend Read: Life after PERC. Available online: https://www.pv-magazine.com/2021/05/08/the-weekend-read-life-after-perc/ (accessed on 14 March 2022).

- Lu, M.; Mikeska, K.R.; Ni, C.; Zhao, Y.; Chen, F.; Xie, X.; Zhang, C. Screen-Printable Conductor Metallizations for Industrial n-TOPCon Crystalline Silicon Solar Cells. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), San Juan, Puerto Rico, 20–25 June 2021; pp. 954–957. [Google Scholar]

- Hermle, M. Silicon Solar Cells–Current Production and Future Concepts. Fraunhofer Institute for Solar Energy Systems ISE. 2017, pp. 1–46. Available online: https://www.helmholtz-berlin.de/media/media/projekte/hercules/hercules-m36-workshop/2016-10-10-hermle-berlin-bessy-pdf.pdf (accessed on 14 March 2022).

- Stenzel, F.; Lee, B.G.; Cieslak, J.; Schwabedissen, A.; Wissen, D.; Geißler, S.; Rudolph, T.; Faulwetter-Quandt, B.; Hönig, R.; Wasmer, S.; et al. Exceeding 23% and Mass Production of p-Cz Q. ANTUM Bifacial Solar Cells. In Proceedings of the 36th European Photovoltaic Solar Energy Conference and Exhibition, Marseille, France, 9 December 2019; pp. 96–99. [Google Scholar]

- Rahman, M.Z. Advances in surface passivation and emitter optimization techniques of c-Si solar cells. Renew. Sustain. Energy Rev. 2014, 30, 734–742. [Google Scholar] [CrossRef]

- Feldmann, F.; Bivour, M.; Reichel, C.; Hermle, M.; Glunz, S.W. Passivated rear contacts for high-efficiency n-type Si solar cells providing high interface passivation quality and excellent transport characteristics. Sol. Energy Mater. Sol. Cells 2014, 120, 270–274. [Google Scholar] [CrossRef]

- Cousins, P.J.; Smith, D.D.; Luan, H.C.; Manning, J.; Dennis, T.D.; Waldhauer, A.; Wilson, K.E.; Harley, G.; Mulligan, W.P. Generation 3: Improved performance at lower cost. In Proceedings of the 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; pp. 275–278. [Google Scholar]

- Richter, A.; Benick, J.; Feldmann, F.; Fell, A.; Hermle, M.; Glunz, S.W. n-Type Si solar cells with passivating electron contact: Identifying sources for efficiency limitations by wafer thickness and resistivity variation. Sol. Energy Mater. Sol. Cells 2017, 173, 96–105. [Google Scholar] [CrossRef]

- Green, M.A.; Hishikawa, Y.; Dunlop, E.D.; Levi, D.H.; Hohl-Ebinger, J.; Ho-Baillie, A.W. Solar cell efficiency tables (version 51). Prog. Photovolt. 2018, 26, 3–12. [Google Scholar] [CrossRef] [Green Version]

- Haase, F.; Hollemann, C.; Schäfer, S.; Merkle, A.; Rienäcker, M.; Krügener, J.; Brendel, R.; Peibst, R. Laser contact openings for local poly-Si-metal contacts enabling 26.1%-efficient POLO-IBC solar cells. Sol. Energy Mater. Sol. Cells 2018, 186, 184–193. [Google Scholar] [CrossRef]

- Stodolny, M.K.; Lenes, M.; Wu, Y.; Janssen, G.J.M.; Romijn, I.G.; Luchies, J.R.M.; Geerligs, L.J. n-Type polysilicon passivating contact for industrial bifacial n-type solar cells. Sol. Energy Mater. Sol. Cells 2016, 158, 24–28. [Google Scholar] [CrossRef]

- Nandakumar, N.; Rodriguez, J.; Kluge, T.; Groβe, T.; Fondop, L.; Padhamnath, P.; Balaji, N.; König, M.; Duttagupta, S. Approaching 23% with large-area monoPoly cells using screen-printed and fired rear passivating contacts fabricated by inline PECVD. Prog. Photovolt. Res. Appl. 2019, 27, 107–112. [Google Scholar] [CrossRef]

- Merkle, A.; Seren, S.; Knauss, H.; Min, B.; Steffens, J.; Terheiden, B.; Brendel, R.; Peibst, R. Atmospheric Pressure Chemical Vapor Deposition of In-Situ Doped Amorphous Silicon Layers for Passivating Contacts. In Proceedings of the 35th European Photovoltaic Solar Energy Conference and Exhibition, Brussels, Belgium, 27 September 2018; pp. 785–791. [Google Scholar]

- Deng, S. Polysilicon Contacts for Next-Generation Industrial Silicon Solar Cells. UNSW. 2019. Available online: https://unsworks.unsw.edu.au/entities/publication/3218ed31-21bd-4acc-b5a8-499fd69847fd (accessed on 14 March 2022).

- Stodolny, M.K.; Anker, J.; Geerligs, B.L.; Janssen, G.J.; Van De Loo, B.W.; Melskens, J.; Santbergen, R.; Isabella, O.; Schmitz, J.; Lenes, M.; et al. Material properties of LPCVD processed n-type polysilicon passivating contacts and its application in PERPoly industrial bifacial solar cells. Energy Procedia 2017, 124, 635–642. [Google Scholar] [CrossRef]

- Padhamnath, P.; Wong, J.; Nagarajan, B.; Buatis, J.K.; Ortega, L.M.; Nandakumar, N.; Khanna, A.; Shanmugam, V.; Duttagupta, S. Metal contact recombination in monoPoly™ solar cells with screen-printed & fire-through contacts. Sol. Energy Mater. Sol. Cells 2019, 192, 109–116. [Google Scholar]

- Feldmann, F.; Reichel, C.; Müller, R.; Hermle, M. The application of poly-Si/SiOx contacts as passivated top/rear contacts in Si solar cells. Sol. Energy Mater. Sol. Cells 2017, 159, 265–271. [Google Scholar] [CrossRef]

- Mekhilef, S.; Safari, A.; Mustaffa, W.; Saidur, R.; Omar, R.; Younis, M. Solar energy in Malaysia: Current state and prospects. Renew. Sustain. Energy Rev. 2012, 16, 386–396. [Google Scholar] [CrossRef]

- Chen, D.; Chen, Y.; Wang, Z.; Gong, J.; Liu, C.; Zou, Y.; He, Y.; Wang, Y.; Yuan, L.; Lin, W.; et al. 24.58% total area efficiency of screen-printed, large area industrial silicon solar cells with the tunnel oxide passivated contacts (i-TOPCon) design. Sol. Energy Mater. Sol. Cells 2019, 206, 110258. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, D.; Liu, C.; Wang, Z.; Zou, Y.; He, Y.; Wang, Y.; Yuan, L.; Gong, J.; Lin, W.; et al. Mass production of industrial tunnel oxide passivated contacts (i-TOPCon) silicon solar cells with average efficiency over 23% and modules over 345 W. Prog. Photovolt. Res. Appl. 2019, 27, 827–834. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, A.; Green, M.A. 24.5% Efficiency silicon PERT cells on MCZ substrates and 24.7% efficiency PERL cells on FZ substrates. Prog. Photovolt. Res. Appl. 1999, 7, 471–474. [Google Scholar] [CrossRef]

- Schmidt, J.; Merkle, A.; Brendel, R.; Hoex, B.; van de Sanden, M.C.M.; Kessels, W.M.M. Surface passivation of high-efficiency silicon solar cells by atomic-layer-deposited Al2O3. Prog. Photovolt. Res. Appl. 2008, 16, 461–466. [Google Scholar] [CrossRef]

- Petrova, V. JinkoSolar Hits 22.04% Conversion Efficiency Multi-Si PV Cells. Available online: https://renewablesnow.com/news/jinkosolar-hits-2204-conversion-efficiency-for-multi-si-pv-cells-585575/ (accessed on 14 March 2022).

- Osborne, M. LONGi Sol. Has Bifacial Mono-PERC Sol. Cell World Rec. Verif. 24.06%. Available online: https://www.pv-tech.org/longi-solar-has-bifacial-mono-perc-solar-cell-world-record-verified-at-24.0/ (accessed on 14 March 2022).

- Carolus, J.; Tsanakas, J.A.; van der Heide, A.; Voroshazi, E.; de Ceuninck, W.; Daenen, M. Physics of potential-induced degradation in bifacial p-PERC solar cells. Sol. Energy Mater. Sol. Cells 2019, 200, 109950. [Google Scholar] [CrossRef] [Green Version]

- Varshney, U.; Li, W.M.; Li, X.; Chan, C.; Hoex, B. Impact of wafer properties and production processes on the degradation in industrial PERC solar cells. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, New York, NY, USA, 6 June 2020; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2020; pp. 803–806. [Google Scholar]

- Rehman, A.U.; Lee, S.H. Advancements in n-type base crystalline silicon solar cells and their emergence in the photovoltaic industry. Sci. World J. 2013, 2013, 470347. [Google Scholar] [CrossRef]

- Adachi, D.; Hernandez, J.L.; Yamamoto, K. Impact of carrier recombination on fill factor for large area heterojunction crystalline silicon solar cell with 25.1% efficiency. Appl. Phys. Lett. 2015, 107, 233506. [Google Scholar] [CrossRef]

- Feldmann, F.; Bivour, M.; Reichel, C.; Steinkemper, H.; Hermle, M.; Glunz, S.W. Tunnel oxide passivated contacts as an alternative to partial rear contacts. Sol. Energy Mater. Sol. Cells 2014, 131, 46–50. [Google Scholar] [CrossRef]

- Tao, Y.; Madani, K.; Cho, E.; Rounsaville, B.; Upadhyaya, V.; Rohatgi, A. High-efficiency selective boron emitter formed by wet chemical etch-back for n-type screen-printed Si solar cells. Appl. Phys. Lett. 2017, 110, 021101. [Google Scholar] [CrossRef]

- Matsushita, T.; Aoki, T.; Otsu, T.; Yamoto, H.; Hayashi, H.; Okayama, M.; Kawana, Y.J. Semi-insulating polycrystalline-silicon (SIPOS) passivation technology. Jpn. J. Appl. Phys. 1976, 15, 35. [Google Scholar] [CrossRef] [Green Version]

- Richter, A.; Benick, J.; Feldmann, F.; Fell, A.; Steinhauser, B.; Polzin, J.I.; Tucher, N.; Murthy, J.N.; Hermle, M.; Glunz, S.W. September. Both sides contacted silicon solar cells: Options for approaching 26% efficiency. In Proceedings of the 36th European PV Solar Energy Conference and Exhibition, Marseille, France, 9–13 September 2019; pp. 9–13. [Google Scholar]

- Rienacker, M.; Merkle, A.; Romer, U.; Kohlenberg, H.; Krugener, J.; Brendel, R.; Peibst, R. Recombination behavior of photolithography-free back junction back contact solar cells with carrier-selective polysilicon on oxide junctions for both polarities. Energy Procedia 2016, 92, 412–418. [Google Scholar] [CrossRef] [Green Version]

- Yousuf, H.; Khokhar, M.Q.; Chowdhury, S.; Pham, D.P.; Kim, Y.; Ju, M.; Cho, Y.; Cho, E.C.; Yi, J. A Review on TOPCon Solar Cell Technology. Curr. Photovolt. Res. 2021, 9, 75–83. [Google Scholar]

- Masuko, K.; Shigematsu, M.; Hashiguchi, T.; Fujishima, D.; Kai, M.; Yoshimura, N.; Yamaguchi, T.; Ichihashi, Y.; Mishima, T.; Matsubara, N.; et al. Achievement of more than 25% conversion efficiency with crystalline silicon heterojunction solar cell. IEEE J. Photovolt. 2014, 4, 1433–1435. [Google Scholar] [CrossRef]

- Richter, A.; Muller, R.; Benick, J.; Feldmann, F.; Steinhauser, B.; Reichel, C.; Fell, A.; Bivour, M.; Hermle, M.; Glunz, S.W. Design rules for high-efficiency both-sides-contacted silicon solar cells with balanced charge carrier transport and recombination losses. Nat. Energy 2021, 6, 429–438. [Google Scholar] [CrossRef]

- Glunz, S.W.; Feldmann, F.; Richter, A.; Bivour, M.; Glunz, S.W.; Feldmann, F.; Richter, A.; Bivour, M.; Reichel, C.; Steinkemper, H.; et al. The irresistible charm of a simple current flow pattern–25% with a solar cell featuring a full-area back contact. In Proceedings of the 31st European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 14–18 September 2015; pp. 259–263. [Google Scholar]

- Feldmann, F.; Nogay, G.; Loper, P.; Young, D.L.; Lee, B.G.; Stradins, P.; Hermle, M.; Glunz, S.W. Charge carrier transport mechanisms of passivating contacts studied by temperature-dependent JV measurements. Sol. Energy Mater. Sol. Cells 2018, 178, 15–19. [Google Scholar] [CrossRef]

- Wietler, T.F.; Tetzlaff, D.; Krugener, J.; Rienacker, M.; Haase, F.; Larionova, Y.; Brendel, R.; Peibst, R. Pinhole density and contact resistivity of carrier selective junctions with polycrystalline silicon on oxide. Appl. Phys. Lett. 2017, 110, 253902. [Google Scholar] [CrossRef]

- Rui, Z.; Zeng, Y.; Guo, X.; Yang, Q.; Wang, Z.; Shou, C.; Ding, W.; Yang, J.; Zhang, X.; Wang, Q.; et al. On the passivation mechanism of poly-silicon and thin silicon oxide on crystal silicon wafers. Sol. Energy 2019, 194, 18–26. [Google Scholar] [CrossRef]

- Steinkemper, H.; Feldmann, F.; Bivour, M.; Hermle, M. Numerical simulation of carrier-selective electron contacts featuring tunnel oxides. IEEE J. Photovolt. 2015, 5, 1348–1356. [Google Scholar] [CrossRef]

- Fırat, M.; Radhakrishnan, H.S.; Payo, M.R.; Choulat, P.; Badran, H.; van der Heide, A.; Govaerts, J.; Duerinckx, F.; Tous, L.; Hajjiah, A.; et al. Large-area bifacial n-TOPCon solar cells with in situ phosphorus-doped LPCVD poly-Si passivating contacts. Sol. Energy Mater. Sol. Cells 2022, 236, 111544. [Google Scholar] [CrossRef]

- Yan, D.; Cuevas, A.; Bullock, J.; Wan, Y.; Samundsett, C. Phosphorus-diffused polysilicon contacts for solar cells. Sol. Energy Mater. Sol. Cells 2015, 142, 75–82. [Google Scholar] [CrossRef]

- Rohatgi, A.; Zimbardi, F.; Rounsaville, B.; Benick, J.; Stradins, P.; Norman, A.; Lee, B.; Upadhyaya, A.; Ok, Y.W.; Tao, Y.; et al. Overcoming the Fundamental Bottlenecks to a New World-Record Silicon Solar Cell; Final Technical Report (No. DOE-GT-6336); Georgia Institute of Technology: Atlanta, GA, USA, 2017. [Google Scholar]

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Hinken, D.; Rauer, M.; Hao, X. Solar cell efficiency tables (Version 60). Prog. Photovolt. Res. Appl. 2022, 30, 687–701. [Google Scholar] [CrossRef]

- Younis, I.M. Cost Benefit Analysis of Photovoltaic Technology Adoption at Rest and Service Area for Malaysia Highway. Ph.D. Thesis, Universiti Teknologi Malaysia, Johor, Malaysia, 2019. [Google Scholar]

- Lauinger, T.; Schmidt, J.; Aberle, A.G.; Hezel, R. Record low surface recombination velocities on 1 Ω cm p-silicon using remote plasma silicon nitride passivation. Appl. Phys. Lett. 1996, 68, 1232–1234. [Google Scholar] [CrossRef]

- Grant, N.E.; Markevich, V.P.; Mullins, J.; Peaker, A.R.; Rougieux, F.; Macdonald, D.; Murphy, J.D. Permanent annihilation of thermally activated defects which limit the lifetime of float-zone silicon. Phys. Status Solidi (A) 2016, 213, 2844–2849. [Google Scholar] [CrossRef] [Green Version]

- Steinhauser, B.; Feldmann, F.; Polzin, J.I.; Tutsch, L.; Arya, V.; Grübel, B.; Fischer, A.; Moldovan, A.; Benick, J.; Richter, A.; et al. Large area TOPCon Technology Achieving 23.4% Efficiency. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 1507–1510. [Google Scholar]

- Lindekugel, S.; Lautenschlager, H.; Ruof, T.; Reber, S. Plasma Hydrogen Passivation for Crystalline Silicon Thin-Films. In Proceedings of the 23rd European Photovoltaic Solar Energy Conference, Valencia, Spain, 1–5 September 2008; pp. 2232–2235. [Google Scholar]

- Richter, A.; Glunz, S.W.; Werner, F.; Schmidt, J.; Cuevas, A. Improved quantitative description of Auger recombination in crystalline silicon. Phys. Rev. 2012, 86, 165202. [Google Scholar] [CrossRef] [Green Version]

- Feldmann, F.; Fellmeth, T.; Steinhauser, B.; Nagel, H.; Ourinson, D.; Mack, S.; Lohmüller, E.; Polzin, J.I.; Benick, J.; Richter, A.; et al. Large Area TOPCon Cells Realized by a PECVD Tube Process. In Proceedings of the 36th European Photovoltaic Solar Energy Conference and Exhibition, Lisbon, Portugal, 10 September 2021. [Google Scholar]

- Haase, F.; Kiefer, F.; Schafer, S.; Kruse, C.; Krugener, J.; Brendel, R.; Peibst, R. Interdigitated back contact solar cells with polycrystalline silicon on oxide passivating contacts for both polarities. Jpn. J. Appl. Phys. 2017, 56, 08MB15. [Google Scholar] [CrossRef]

- Folchert, N.; Rienacker, M.; Yeo, A.A.; Min, B.; Peibst, R.; Brendel, R. Temperature-dependent contact resistance of carrier selective Poly-Si on oxide junctions. Sol. Energy Mater. Sol. Cells 2018, 185, 425–430. [Google Scholar] [CrossRef]

- Peibst, R.; Romer, U.; Larionova, Y.; Rienacker, M.; Merkle, A.; Folchert, N.; Reiter, S.; Turcu, M.; Min, B.; Krugener, J.; et al. Working principle of carrier selective poly-Si/c-Si junctions: Is tunnelling the whole story? Sol. Energy Mater. Sol. Cells 2016, 158, 60–67. [Google Scholar] [CrossRef]

- Zhang, Z.; Zeng, Y.; Jiang, C.S.; Huang, Y.; Liao, M.; Tong, H.; Al-Jassim, M.; Gao, P.; Shou, C.; Zhou, X.; et al. Carrier transport through the ultrathin silicon-oxide layer in tunnel oxide passivated contact (TOPCon) c-Si solar cells. Sol. Energy Mater. Sol. Cells 2018, 187, 113–122. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, W.; Yuan, N.; Li, Y.; Zhang, Y.; Ding, J. Influence of SiOx film thickness on electrical performance and efficiency of TOPCon solar cells. Sol. Energy Mater. Sol. Cells 2020, 208, 110423. [Google Scholar] [CrossRef]

- Zeng, Y.; Tong, H.; Quan, C.; Cai, L.; Yang, Z.; Chen, K.; Yuan, Z.; Wu, C.H.; Yan, B.; Gao, P.; et al. Theoretical exploration towards high-efficiency tunnel oxide passivated carrier-selective contacts (TOPCon) solar cells. Sol. Energy 2017, 155, 654–660. [Google Scholar] [CrossRef]

- Lenes, M.; Naber, R.C.G.; Luchies, J.R.M. LPCVD Polysilicon Passivated Contacts for Different Solar Cell Concepts. In Proceedings of the 6th Silicon PV Conference, Chambery, France, 7 March 2016. [Google Scholar]

- Limodio, G.; Yang, G.; Ge, H.; Procel, P.; de Groot, Y.; Mazzarella, L.; Isabella, O.; Zeman, M. Front and rear contact Si solar cells combining high and low thermal budget Si passivating contacts. Sol. Energy Mater. Sol. Cells. 2019, 194, 28–35. [Google Scholar] [CrossRef]

- Wen, Y.; Tu, H.T.C.; Ohdaira, K. Tunnel nitride passivated contacts for silicon solar cells formed by catalytic CVD. Jpn. J. Appl. Phys. 2021, 60, SBBF09. [Google Scholar] [CrossRef]

- Köhler, M.; Pomaska, M.; Lentz, F.; Finger, F.; Rau, U.; Ding, K.A.C.S. Wet-chemical preparation of silicon tunnel oxides for transparent passivated contacts in crystalline silicon solar cells. ACS Appl. Mater. Interfaces 2018, 10, 14259–14263. [Google Scholar] [CrossRef] [PubMed]

- Tong, H.; Liao, M.; Zhang, Z.; Wan, Y.; Wang, D.; Quan, C.; Cai, L.; Gao, P.; Guo, W.; Lin, H.; et al. A strong-oxidizing mixed acid derived high-quality silicon oxide tunneling layer for polysilicon passivated contact silicon solar cell. Sol. Energy Mater. Sol. Cells 2018, 188, 149. [Google Scholar] [CrossRef]

- Matsumoto, T.; Nakajima, H.; Irishika, D.; Nonaka, T.; Imamura, K.; Kobayashi, H. Ultrathin SiO2 layer formed by the nitric acid oxidation of Si (NAOS) method to improve the thermal-SiO2/Si interface for crystalline Si solar cells. Appl. Surf. Sci. 2017, 395, 56–60. [Google Scholar] [CrossRef]

- Tetzlaff, D.; Krugener, J.; Larionova, Y.; Reiter, S.; Turcu, M.; Peibst, R.; Hohne, U.; Kahler, J.D.; Wietler, T. Evolution of oxide disruptions: The (W)hole story about poly-Si/c-Si passivating contacts. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, New York, NY, USA, 27 May 2020; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2016; pp. 221–224. [Google Scholar]

- Moldovan, A.; Feldmann, F.; Zimmer, M.; Rentsch, J.; Benick, J.; Hermle, M. Tunnel oxide passivated carrier-selective contacts based on ultra-thin SiO2 layers. Sol. Energy Mater. Sol. Cells 2015, 142, 123–127. [Google Scholar] [CrossRef]

- Ichimura, S.; Nonaka, H.; Morikawa, Y.; Noyori, T.; Nishiguchi, T.; Kekura, M.J. Development of a continuous generation/supply system of highly concentrated ozone gas for low-temperature oxidation process. J. Vac. Sci. Technol. A Vac. Surf. Film. 2004, 22, 1410–1414. [Google Scholar] [CrossRef]

- Nishiguchi, T.; Saitoh, S.; Kameda, N.; Morikawa, Y.; Kekura, M.; Nonaka, H.J. Rapid oxidation of silicon using UV-light irradiation in low-pressure, highly concentrated ozone gas below 300 C. Jpn. J. Appl. Phys. 2007, 46, 2835. [Google Scholar] [CrossRef]

- Chao, S.C.; Pitchai, R.; Lee, Y.H. Enhancement in thermal oxidation of silicon by ozone. J. Electrochem. Soc. 1989, 136, 2751. [Google Scholar] [CrossRef]

- Nakamura, K.J.; Ichimura, S. Vibrational Spectroscopic Study of the Interface of SiO2/Si (100) Fabricated by Highly Concentrated Ozone: Direct Evidence for Less Strained Si–O–Si Bond Angle. Jpn. J. Appl. Phys. 2005, 44, 7602. [Google Scholar] [CrossRef]

- Kurokawa, A.; Nakamura, K.; Ichimura, S.; Moon, D.W. Reduction of the interfacial Si displacement of ultrathin SiO2 on Si(100) formed by atmospheric-pressure ozone. Appl. Phys. Lett. 2000, 76, 493–495. [Google Scholar] [CrossRef]

- Fink, C.K.; Nakamura, K.; Ichimura, S.; Jenkins, S.J. Silicon oxidation by ozone. J. Phys. Condens. Matter 2009, 21, 183001. [Google Scholar] [CrossRef] [PubMed]

- Kameda, N.; Nishiguchi, T.; Morikawa, Y.; Kekura, M.; Nonaka, H.; Ichimura, S. High quality gate dielectric film on poly-silicon grown at room temperature using UV light excited ozone. J. Electrochem. Soc. 2007, 154, H769. [Google Scholar] [CrossRef]

- Moldovan, A.; Feldmann, F.; Krugel, G.; Zimmer, M.; Rentsch, J.; Hermle, M.; Roth-Folsch, A.; Kaufmann, K.; Hagendorf, C. Simple cleaning and conditioning of silicon surfaces with UV/ozone sources. Energy Procedia 2014, 55, 834–844. [Google Scholar] [CrossRef]

- Angermann, H.; Wolke, K.; Gottschalk, C.; Moldovan, A.; Roczen, M.; Fittkau, J.; Zimmer, M.; Rentsch, J. Electronic interface properties of silicon substrates after ozone based wet-chemical oxidation studied by SPV measurements. Appl. Surf. Sci. 2012, 258, 8387–8396. [Google Scholar] [CrossRef]

- van der Vossen, R.; Feldmann, F.; Moldovan, A.; Hermle, M. Comparative study of differently grown tunnel oxides for p-type passivating contacts. Energy Procedia 2017, 124, 448–454. [Google Scholar] [CrossRef]

- Moldovan, A.; Feldmann, F.; Kaufmann, K.; Richter, S.; Werner, M.; Hagendorf, C.; Zimmer, M.; Rentsch, J.; Hermle, M. Tunnel oxide passivated carrier-selective contacts based on ultra-thin SiO2 layers grown by photo-oxidation or wet-chemical oxidation in ozonized water. In Proceedings of the IEEE 42nd Photovoltaic Specialist Conference (PVSC), New Oreleans, LA, USA, 14–19 June 2015; pp. 1–6. [Google Scholar]

- Starodub, D.; Gusev, E.P.; Garfunkel, E.; Gustafsson, T. Silicon oxide decomposition and desorption during the thermal oxidation of silicon. Surf. Rev. Lett. 1999, 6, 45–52. [Google Scholar] [CrossRef]

- Hattori, T. Chemical Structures of the SiO2Si Interface. Crit. Rev. Solid State Mater. Sci. 1995, 20, 339–382. [Google Scholar] [CrossRef]

- Kale, A.S.; Nemeth, W.; Nanayakkara, S.U.; Guthrey, H.; Page, M.; Al-Jassim, M.; Agarwal, S.; Stradins, P. Tunneling or Pinholes: Understanding the Transport Mechanisms in SiOx Based Passivated Contacts for High-Efficiency Silicon Solar Cells. In Proceedings of the IEEE 7th World Conf. Photovoltaic Energy Conversion, WCPEC 2018, Waikoloa Village, HI, USA, 5 January 2018; pp. 3473–3476. [Google Scholar]

- Liu, C.P.; Chang, M.W.; Chuang, C.L. Effect of rapid thermal oxidation on structure and photoelectronic properties of silicon oxide in monocrystalline silicon solar cells. Curr. Appl. Phys. 2014, 14, 653–658. [Google Scholar] [CrossRef]

- Liao, S.S.; Lin, Y.C.; Chuang, C.L.; Chang, E.Y. Efficiency enhancement of multicrystalline silicon solar cells by inserting two-step growth thermal oxide to the surface passivation layer. Int. J. Photoenergy 2017, 2017, 9503857. [Google Scholar] [CrossRef] [Green Version]

- Rehman, A.u.; Iqbal, M.Z.; Bhopal, M.F.; Khan, M.F.; Hussain, F.; Iqbal, J.; Khan, M.; Lee, S.H. Development and prospects of surface passivation schemes for high-efficiency c-Si solar cells. Sol. Energy 2018, 166, 90–97. [Google Scholar] [CrossRef]

- Mazzarella, L.; Kolb, S.; Kirner, S.; Calnan, S.; Korte, L.; Stannowski, B.; Rech, B.; Schlatmann, R. Optimization of PECVD process for ultra-thin tunnel SiO x film as passivation layer for silicon heterojunction solar cells. In Proceedings of the IEEE 43rd Photovoltaic Specialists Conference (PVSC), San Diego, CA, USA, 5–10 June 2016; pp. 2955–2959. [Google Scholar]

- Antonenko, A.K.; Volodin, V.A.; Efremov, M.D.; Zazulya, P.S.; Kamaev, G.N.; Marin, D.V. Oxidation kinetics of a silicon surface in a plasma of oxygen with inert gases. Optoelectron. Instrum. Data Process. 2011, 475, 459–464. [Google Scholar] [CrossRef]

- Gismatulin, A.A.; Kamaev, G.N.; Antonenko, A.K.; Arzhannikova, S.A.; Volodin, V.A.; Efremov, M.D.; Gileva, A.S. Nanoscale Si/SiO2 multilayer structures produced by plasma-chemical technology. In Proceedings of the International School and Seminar on Modern Problems of Nanoelectronics, Micro- and Nanosystem Technologies, Novosibirsk, Russia, 28–31 October 2009; pp. 81–83. [Google Scholar]

- Mandal, N.C.; Biswas, S.; Acharya, S.; Panda, T.; Sadhukhan, S.; Sharma, J.R.; Nandi, A.; Bose, S.; Kole, A.; Das, G.; et al. Study of the properties of SiOx layers prepared by different techniques for rear side passivation in TOPCon solar cells. Mater. Sci. Semicond. Process. 2020, 119, 105163. [Google Scholar] [CrossRef]

- Huang, Y.; Liao, M.; Wang, Z.; Guo, X.; Jiang, C.; Yang, Q.; Yuan, Z.; Huang, D.; Yang, J.; Zhang, X.; et al. Ultrathin silicon oxide prepared by in-line plasma-assisted N2O oxidation (PANO) and the application for n-type polysilicon passivated contact. Sol. Energy Mater. Sol. Cells 2020, 208, 110389. [Google Scholar] [CrossRef]

- Gao, T.; Yang, Q.; Guo, X.; Huang, Y.; Zhang, Z.; Wang, Z.; Liao, M.; Shou, C.; Zeng, Y.; Yan, B.; et al. An industrially viable TOPCon structure with both ultra-thin SiOx and n+-poly-Si processed by PECVD for p-type c-Si solar cells. Sol. Energy Mater. Sol. Cells 2019, 200, 109926. [Google Scholar] [CrossRef]

- Park, C.; Balaji, N.; Ahn, S.; Park, J.; Cho, E.C.; Yi, J. Effects of tunneling oxide defect density and inter-diffused carrier concentration on carrier selective contact solar cell performance: Illumination and temperature effects. Sol. Energy 2020, 211, 62–73. [Google Scholar] [CrossRef]

- Römer, U.; Peibst, R.; Ohrdes, T.; Lim, B.; Krügener, J.; Bugiel, E.; Wietler, T.; Brendel, R. Recombination behavior and contact resistance of n+ and p+ poly-crystalline Si/mono-crystalline Si junctions. Sol. Energy Mater. Sol. Cells 2014, 131, 85–91. [Google Scholar] [CrossRef]

- Tetzlaff, D.; Krügener, J.; Larionova, Y.; Reiter, S.; Turcu, M.; Haase, F.; Brendel, R.; Peibst, R.; Höhne, U.; Kähler, J.D.; et al. A simple method for pinhole detection in carrier selective POLO-junctions for high efficiency silicon solar cells. Sol. Energy Mater. Sol. Cells 2017, 173, 106–110. [Google Scholar] [CrossRef]

- Kale, A.S.; Nemeth, W.; Guthrey, H.; Kennedy, E.; Norman, A.G.; Page, M.; Al-Jassim, M.; Young, D.L.; Agarwal, S.; Stradins, P. Understanding the charge transport mechanisms through ultrathin SiO x layers in passivated contacts for high-efficiency silicon solar cells. Appl. Phys. Lett. 2019, 114, 083902. [Google Scholar] [CrossRef]

- Lu, L.; Zeng, Y.; Liao, M.; Zheng, J.; Lin, Y.; Feng, M.; Zhi, Y.; He, H.; Ding, W.; Shou, C.; et al. Dopant diffusion through ultrathin AlOx and AlOx/SiOx tunnel layer in TOPCon structure and its impact on the passivation quality on c-Si solar cells. Sol. Energy Mater. Sol. Cells 2021, 223, 110970. [Google Scholar] [CrossRef]

- Kaur, G.; Dutta, T.; Sridharan, R.; Zheng, X.; Danner, A.; Stangl, R. Can interface charge enhance selectivity in tunnel layer passivated contacts? Using negatively charged aluminium oxide capped with dopant free PEDOT or boron doped polysilicon. Sol. Energy Mater. Sol. Cells 2021, 221, 110857. [Google Scholar] [CrossRef]

- Kaur, G.; Dutta, T.; Zheng, X.; Danner, A.; Stangl, R. Can interface charge enhance carrier selectivity in tunnel-layer/poly-Si passivated contacts? In Proceedings of the 47th IEEE Photovoltaic Specialists Conference (PVSC) IEEE, Calgary, OR, Canada, 21 August 2020; pp. 438–442. [Google Scholar]

- Anand, N.; Kale, P. Optimization of TOPCon Structured Solar Cell Using AFORS-HET. Trans. Electr. Electron. Mater. 2021, 22, 160–166. [Google Scholar] [CrossRef]

- Attafi, D.; Meftah, A.; Boumaraf, R.; Labed, M. Enhancement of silicon solar cell performance by introducing selected defects in the SiO2 passivation layer. Optik 2021, 229, 166206. [Google Scholar] [CrossRef]

- Singh, P.; Raman, A.; Kumar, N. Spectroscopic and simulation analysis of facile PEDOT: PSS layer deposition-silicon for perovskite solar cell. Silicon 2020, 12, 1769–1777. [Google Scholar] [CrossRef]

- Richter, S.; Kaufmann, K.; Naumann, V.; Werner, M.; Graff, A.; Großer, S.; Moldovan, A.; Zimmer, M.; Rentsch, J.; Bagdahn, J.; et al. High-resolution structural investigation of passivated interfaces of silicon solar cells. Sol. Energy Mater. Sol. Cells 2015, 142, 128–133. [Google Scholar] [CrossRef]

- Mehmood, H.; Nasser, H.; Tauqeer, T.; Turan, R. Numerical analysis of dopant-free asymmetric silicon heterostructure solar cell with SiO2 as passivation layer. Int. J. Energy Res. 2020, 44, 10739–10753. [Google Scholar] [CrossRef]

| Cell Structure | Unit | Value | JSC (mA/cm2) | VOC (V) | FF (%) | Eff. (%) | Eff. Loss (%) | Remark | ||

|---|---|---|---|---|---|---|---|---|---|---|

| SRH Bulk | ① | Bulk J0 | fA/cm2 | 10 | 43.25 | 0.747 | 85.42 | 27.60 | 5.32 | ITRPV 2019 Report |

| Optical Loss | ② | Shading | % | 2.25 | 42.28 | 0.747 | 85.34 | 26.95 | 0.65 | Finger Width = 20 μm, Thickness = 20 μm, # of Finger = 190 ea Dual printing, Busbar = 0.3 mm (12BB), Reflected Absorption Grid |

| ③ | Front Reflectance | % | 2.26 | 41.70 | 0.747 | 85.30 | 26.57 | 0.38 | Textured + Boron emitter + Multi-Layer ARC | |

| ④ | Escape | % | 0.07 | 41.67 | 0.746 | 85.41 | 26.55 | 0.02 | Absorption missing at longwave length | |

| Recombination Loss | ⑤ | Front Passivation | fA/cm2 | 4.4 | 41.67 | 0.737 | 85.24 | 26.18 | 0.37 | J0, full surface = 4.5 fA/cm2 (@200 Ω/sq.) Textured + Boron emitter + Passivation with Single ARC |

| ⑥ | Front Contact | fA/cm2 | 6.89 | 41.67 | 0.727 | 85.09 | 25.78 | 0.40 | J0, full contact = 300 fA/cm2, (@40 Ω/sq.) Contact Fraction = 2.30% (dual printing) | |

| ⑦ | Rear Passivating Contact | fA/cm2 | 2.5 | 41.67 | 0.724 | 85.06 | 25.66 | 0.11 | J0, full contact = 2.5 fA/cm2 Polished + Oxide + Poly-Si (Optimized Process with SiNx Coating) | |

| Electrical Loss | ⑧ | Shunt Resistance | Ωcm2 | 4000 | 41.67 | 0.724 | 84.73 | 25.56 | 0.10 | Selective emitter (200 Ω/sq./40 Ω/sq.) |

| ⑨ | Series Resistance | mΩcm2 | 290.9 | 41.67 | 0.724 | 83.20 | 25.10 | 0.46 | Wafer resistivity = 5 Ωcm, Contact Resistivity = 1.5 mΩ cm2 |

| Methods of Oxidation | Thickness of SiOx (nm) | Tannealing (°C) | Parameters of the Solar Cell | Ref |

|---|---|---|---|---|

| Wet chemical | 1.2 | 950 | Voc = 714 mV; J0 = 20 fA/cm2 | [105] |

| 1.3–1.5 | 800–900 | Voc = 719 mV; Eff = 24.9% | [80] | |

| Thermal oxidation | 1.7 1.5 | 800–1000 850 | J0 = 50 fA/cm2 Voc = 705 mV; FF = 75.1%; Rser = 0.86 Ω cm2 | [106] [107] |

| PECVD UV/O3 | 1.55 2.5 1.1–1.4 2.0 1.2–1.4 | 850 800 880 850–880 900 | Voc = 687 mV; FF = 81.09%; Eff = 22.5% J0 = 3.4 fA/cm2 iVoc = 730 mV; J0 = 4.3 fA/cm2 iVoc = 724 mV; J0 = 3 fA/cm2 Voc = 719 mV; J0 = 20 fA/cm2 | [71] [106] [78] [103] [80,90] |

| DIO3 | 1.3–1.4 | 900 | Voc = 715 mV; J0 = 35 fA/cm2; ρc = 22 mΩ cm2 | [80,90] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yousuf, H.; Khokhar, M.Q.; Zahid, M.A.; Rabelo, M.; Kim, S.; Pham, D.P.; Kim, Y.; Yi, J. Tunnel Oxide Deposition Techniques and Their Parametric Influence on Nano-Scaled SiOx Layer of TOPCon Solar Cell: A Review. Energies 2022, 15, 5753. https://doi.org/10.3390/en15155753

Yousuf H, Khokhar MQ, Zahid MA, Rabelo M, Kim S, Pham DP, Kim Y, Yi J. Tunnel Oxide Deposition Techniques and Their Parametric Influence on Nano-Scaled SiOx Layer of TOPCon Solar Cell: A Review. Energies. 2022; 15(15):5753. https://doi.org/10.3390/en15155753

Chicago/Turabian StyleYousuf, Hasnain, Muhammad Quddamah Khokhar, Muhammad Aleem Zahid, Matheus Rabelo, Sungheon Kim, Duy Phong Pham, Youngkuk Kim, and Junsin Yi. 2022. "Tunnel Oxide Deposition Techniques and Their Parametric Influence on Nano-Scaled SiOx Layer of TOPCon Solar Cell: A Review" Energies 15, no. 15: 5753. https://doi.org/10.3390/en15155753

APA StyleYousuf, H., Khokhar, M. Q., Zahid, M. A., Rabelo, M., Kim, S., Pham, D. P., Kim, Y., & Yi, J. (2022). Tunnel Oxide Deposition Techniques and Their Parametric Influence on Nano-Scaled SiOx Layer of TOPCon Solar Cell: A Review. Energies, 15(15), 5753. https://doi.org/10.3390/en15155753