A Log-Logistic Predictor for Power Generation in Photovoltaic Systems

Abstract

:1. Introduction

1.1. Impact of Soiling on Power Generation in Photovoltaic Systems

1.2. Related Work

1.3. Statistical Methodology for Soiling Estimation

2. Materials and Methods

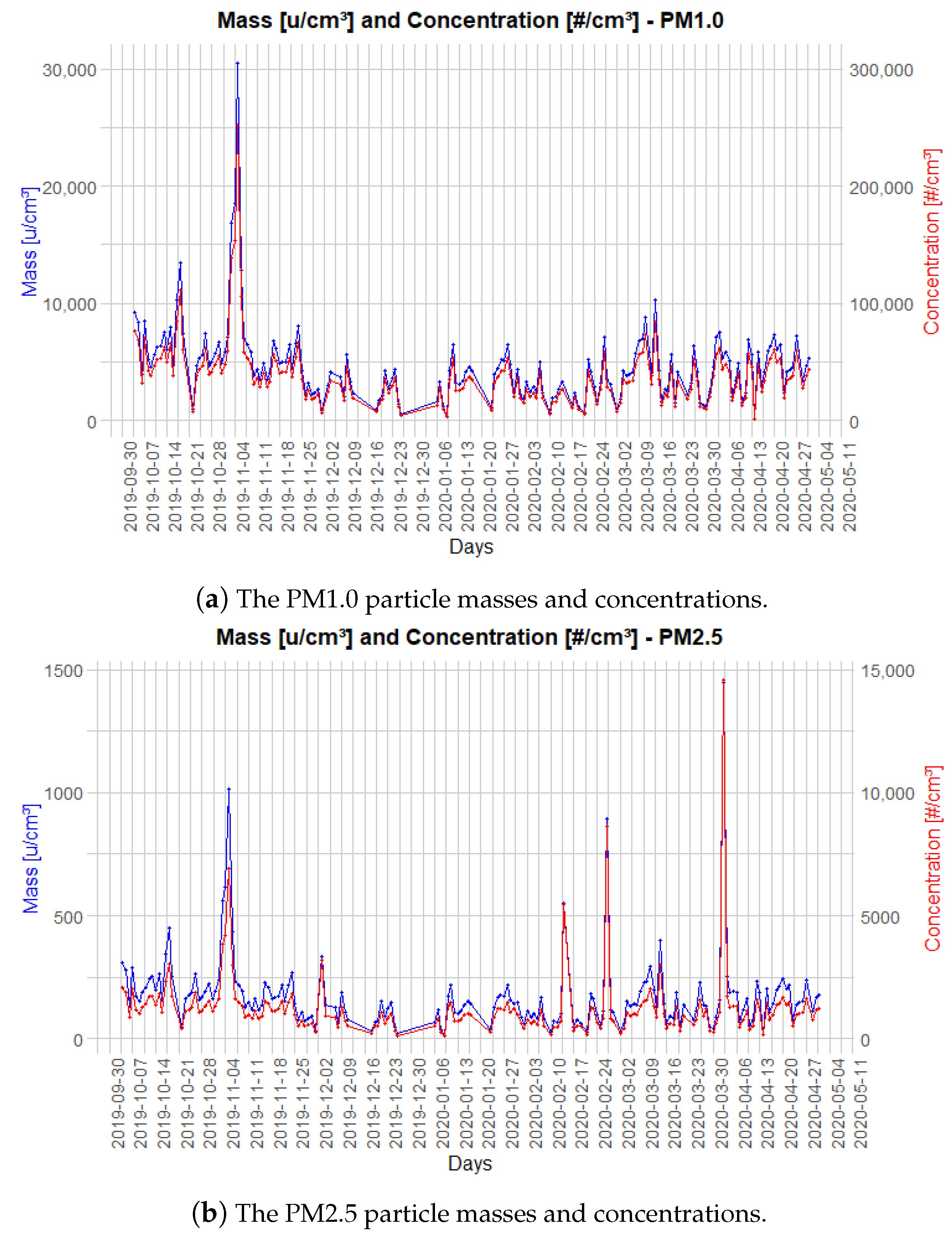

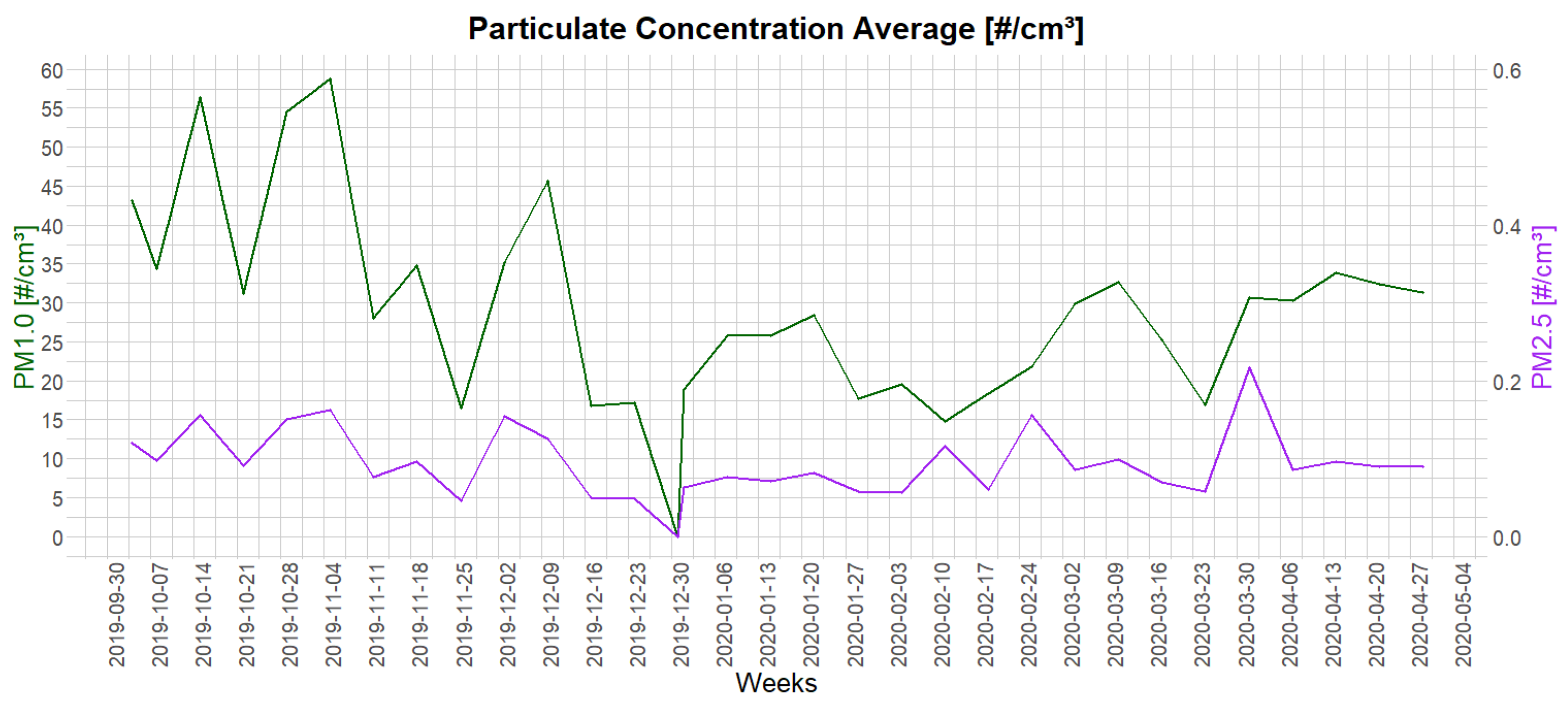

2.1. Estimation of Accumulated Particle Mass

- M is the accumulated mass in the time interval (g/);

- t is the time interval in seconds;

- v is the particulate deposition speed (g/m);

- C is the particulate concentration in the environment (g/);

- is the PV module angle;

- 10−2.5 is the index of the particles from 10 μm to 2.5 μm;

- 2.5 is the index of particles less than 2.5 μm.

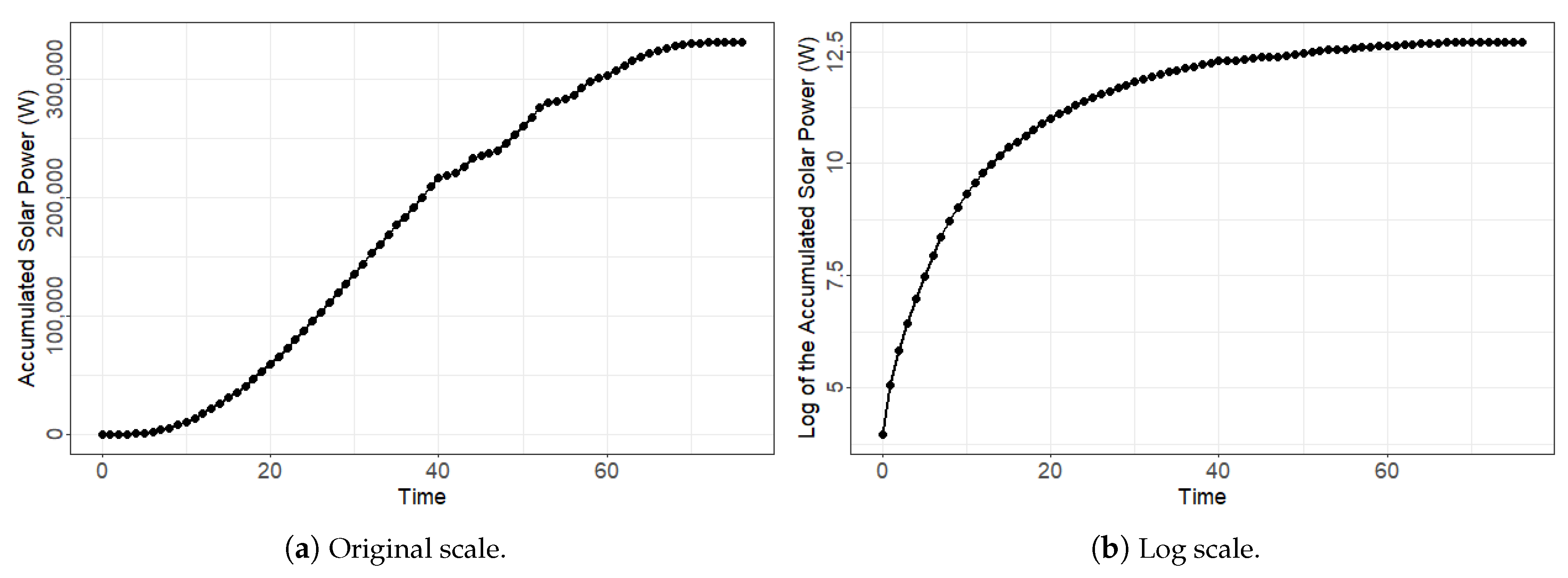

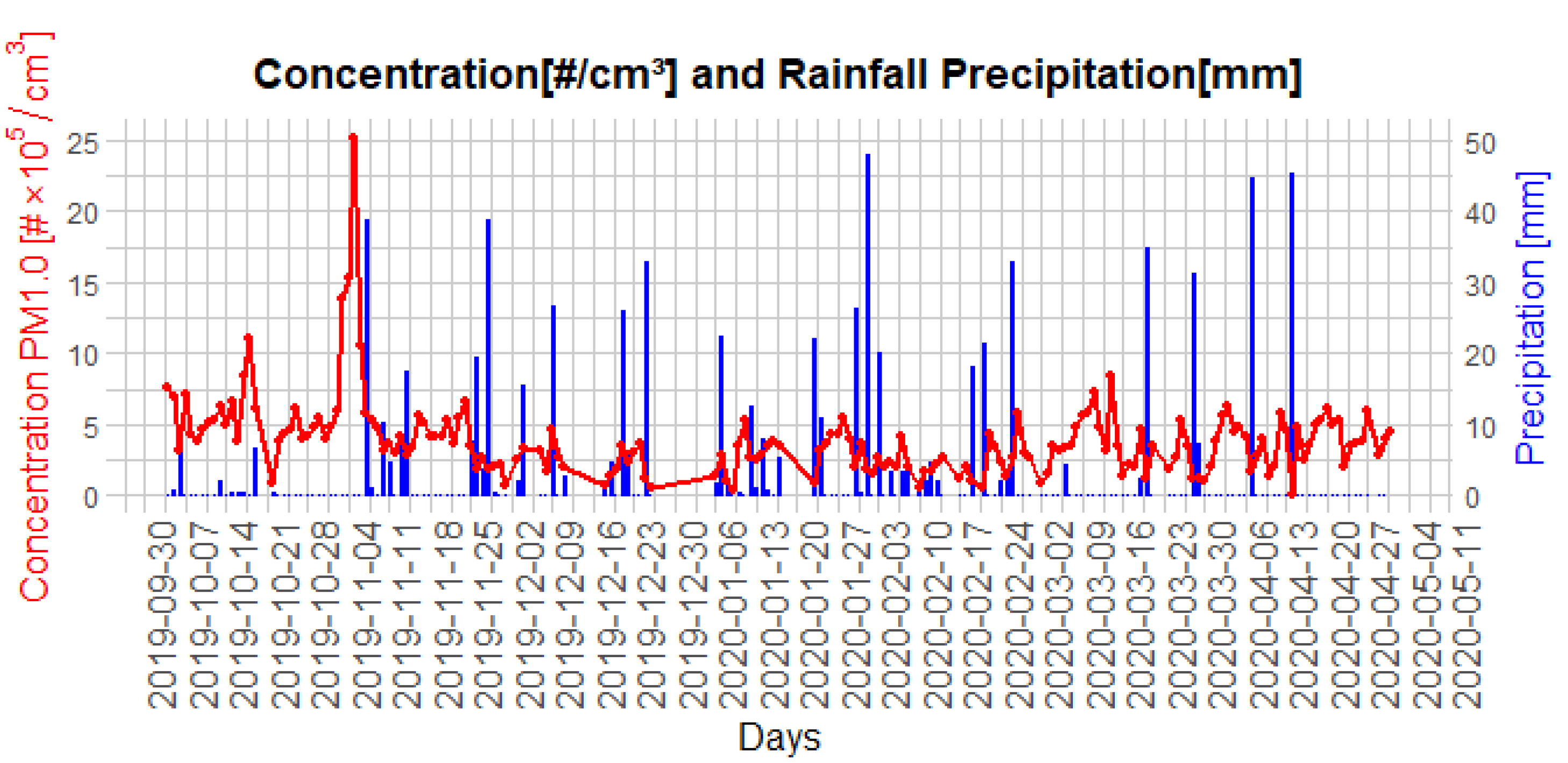

2.2. Dataset and Statistical Modeling

2.3. Nonlinear Mixed-Effects Model

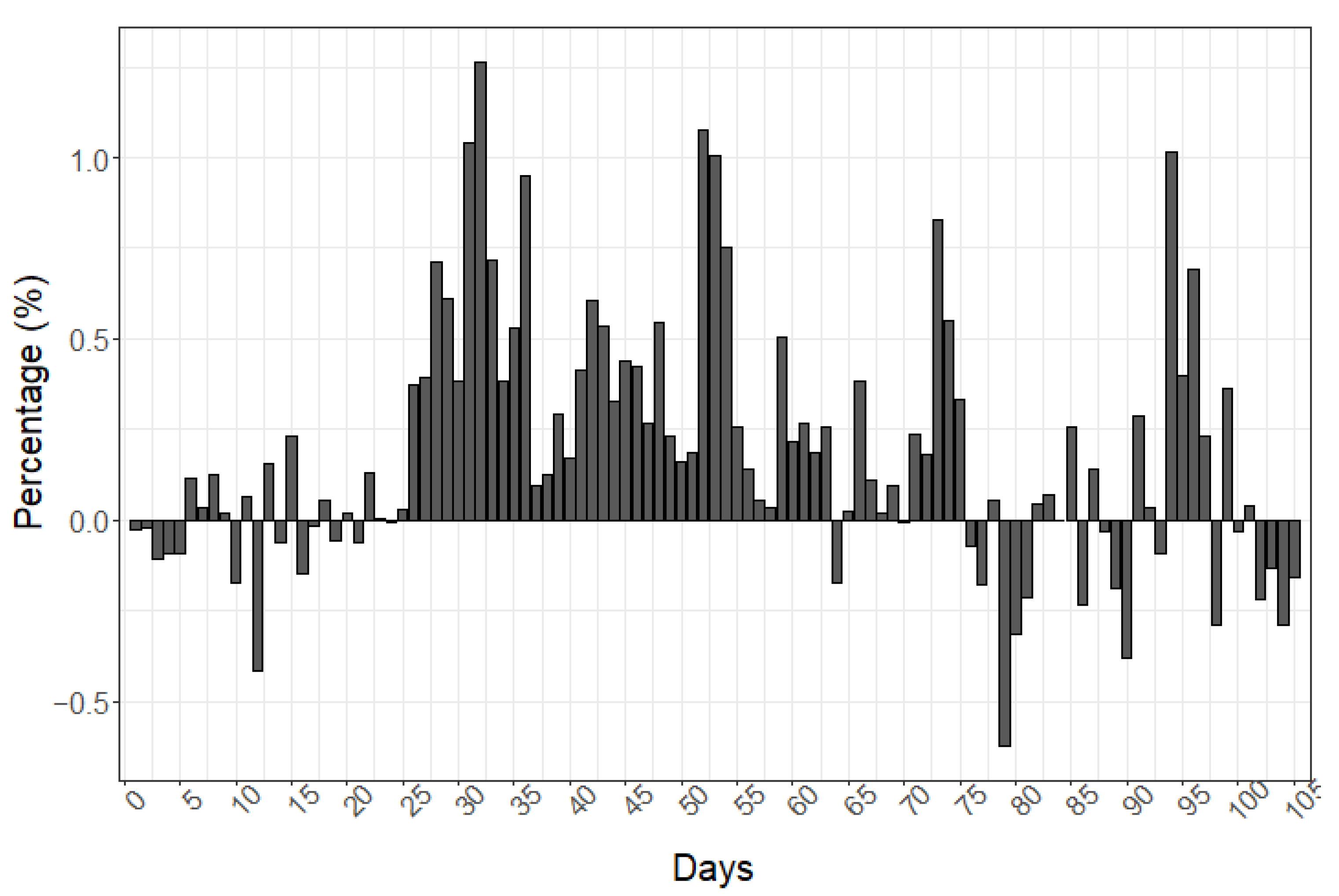

3. Results and Discussion

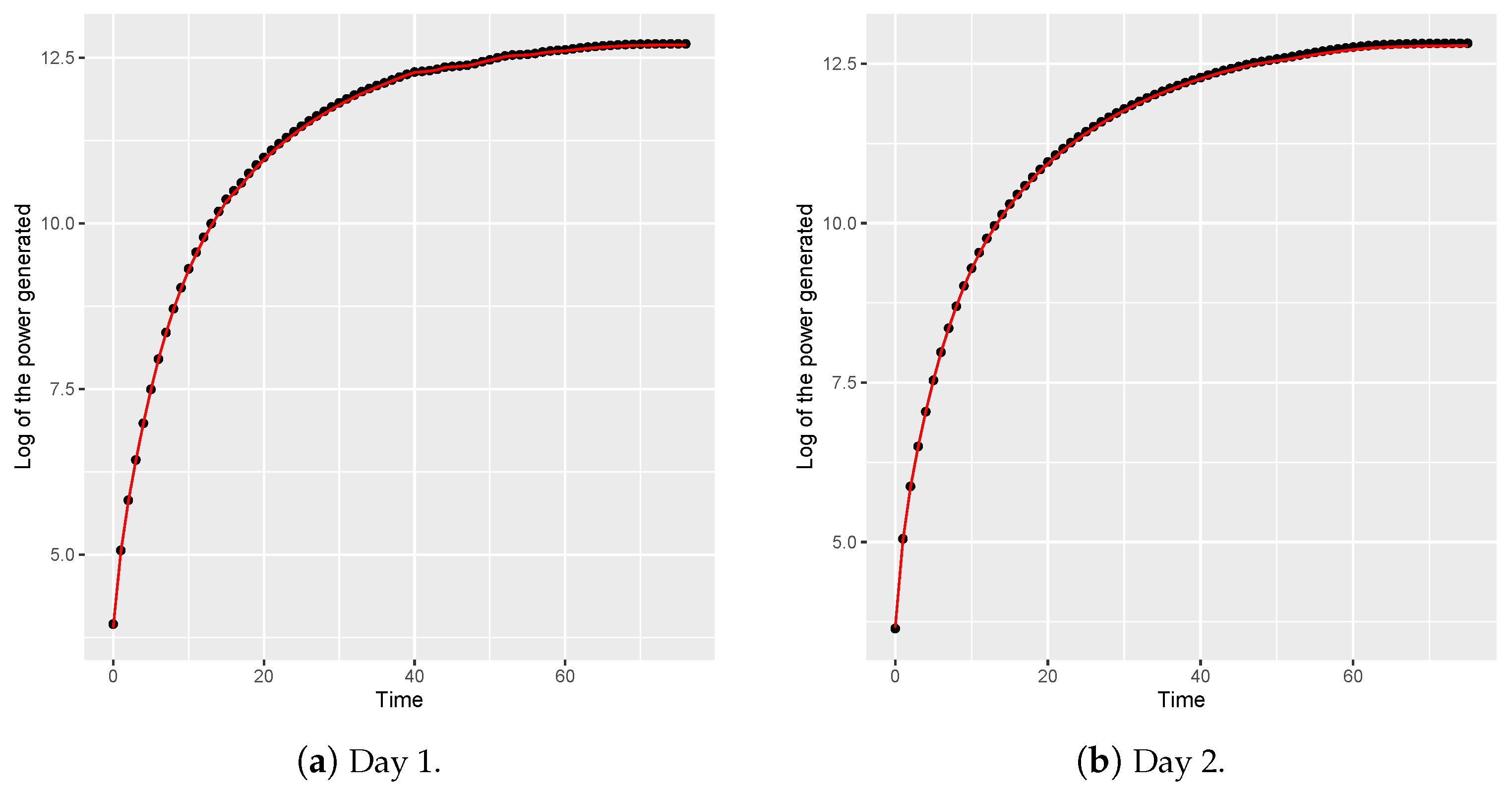

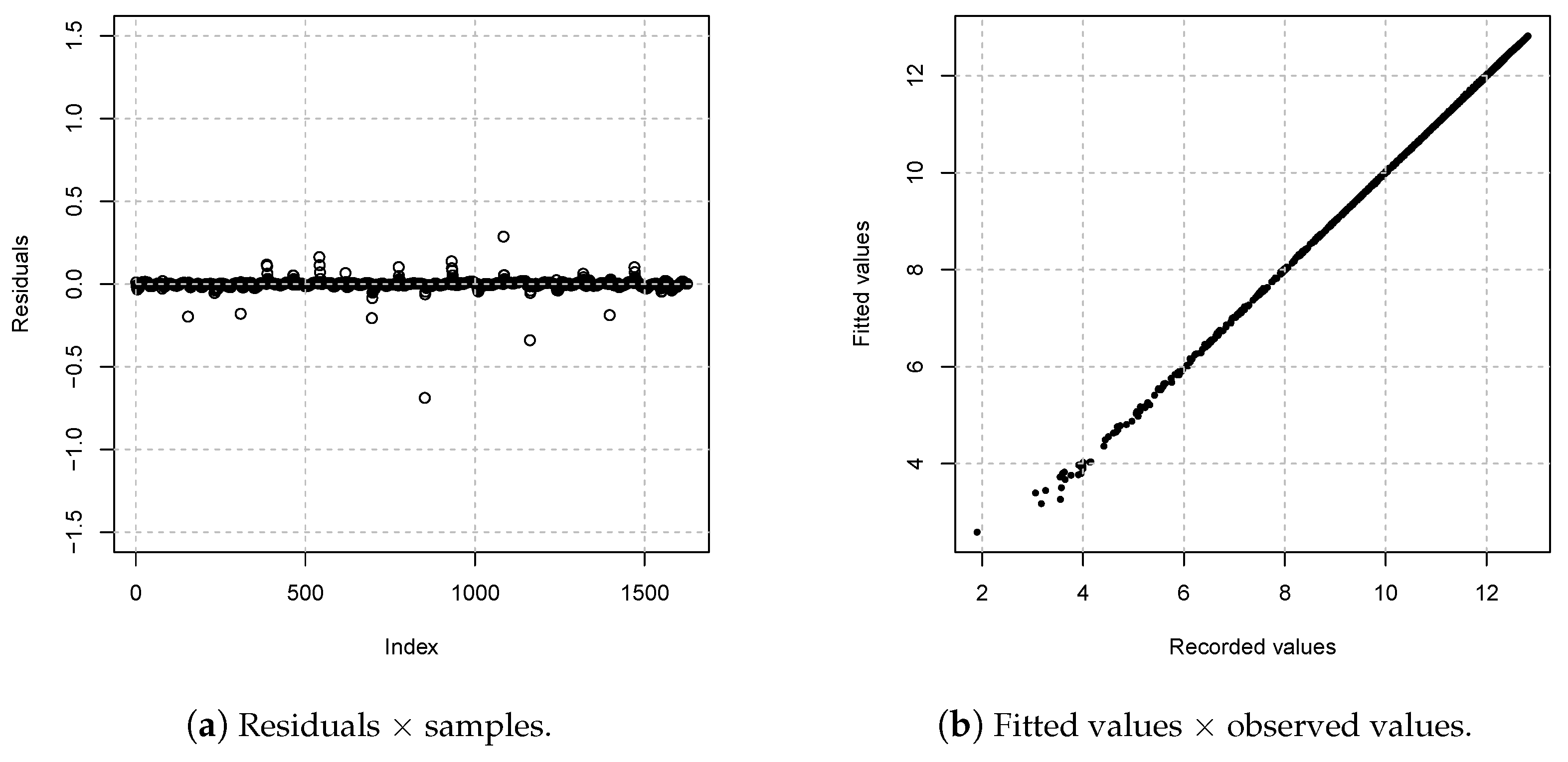

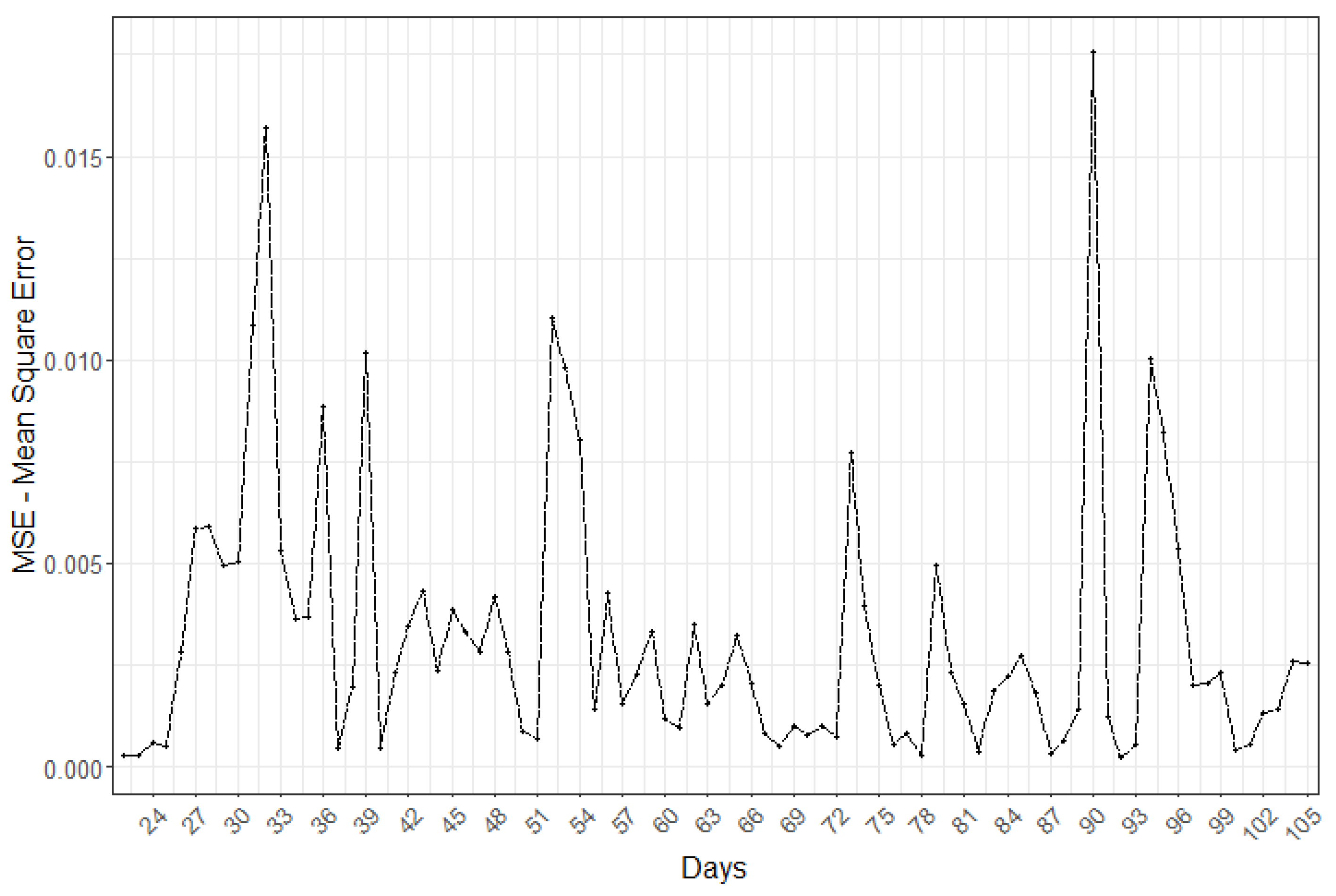

3.1. Fitted Model

3.2. Model Validation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AIC | Akaike information criterion |

| ANN | Artificial neural network |

| AWS | Amazon Web Services |

| BIC | Bayesian information criterion |

| BNN | Bayesian neural network |

| CI | Cleanness index |

| CNN | Convolutional neural network |

| FAMEZ | Faculty of Veterinary Medicine and Animal Science |

| MENA | Middle East and North Africa |

| MLR | Multilinear regression |

| MPPT | Maximum power point tracker |

| MSE | Mean squared error |

| NLME | Nonlinear mixed-effects |

| p-Si | Polycrystalline silicon |

| PV | Photovoltaic |

| PM1.0 | Particles less than 1.0 μm in diameter |

| PM2.5 | Particles less than 2.5 μm in diameter |

| PM4.0 | Particles less than 4.0 μm in diameter |

| PM10.0 | Particles less than 10.0 μm in diameter |

| PRM | Polynomial regression model |

References

- Catelani, M.; Ciani, L.; Cristaldi, L.; Faifer, M.; Lazzaroni, M.; Rossi, M. Characterization of photovoltaic panels: The effects of dust. In Proceedings of the IEEE International Energy Conference and Exhibition, Florence, Italy, 9–12 September 2012; pp. 45–50. [Google Scholar]

- Viana, T.; Rüther, R.; Martins, F.; Pereira, E. Assessing the potential of concentrating solar photovoltaic generation in Brazil with satellite-derived direct normal irradiation. Sol. Energy 2011, 85, 486–495. [Google Scholar] [CrossRef]

- Asmelash, E.; Prakash, G.; Kadir, M. Webinar Series—Wind and Solar PV—What We Need by 2050. 2020. Available online: https://bit.ly/3LJJ63r (accessed on 17 October 2021).

- Ribeiro, K.; Santos, R.; Saraiva, E.; Rajagopal, R. A Statistical Methodology to Estimate Soiling Losses on Photovoltaic Solar Plants. J. Sol. Energy Eng. 2021, 143, 064501. [Google Scholar] [CrossRef]

- Hickel, B.M.; Deschamps, E.M.; Nascimento, L.; Rüther, R.; Simões, G.C. Análise da Influência do Acúmulo de Sujeira Sobre Diferentes Tecnologias de módulos FV: Revisão e medições de campo. In Proceedings of the VI Congresso Brasileiro de Energia Solar, Belo Horizonte, Brazil, 4–7 April 2016. [Google Scholar]

- Zorrilla-Casanova, J.; Philiougine, M.; Carretero, J.; Bernaola, P.; Carpena, P.; Mora-López, L.; Sidrach-de Cardona, M. Analysis of dust losses in photovoltaic modules. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011; pp. 8–13. [Google Scholar]

- Dunn, L. PV module soiling measurement uncertainty analysis. In Proceedings of the 39th Photovoltaic Specialists Conference (PVSC), Tampa, FL, USA, 16–21 June 2013; pp. 658–663. [Google Scholar]

- Sinha, P.; Hayes, W.; Littmann, B.; Ngan, L.; Znaidi, R. Environmental variables affecting solar photovoltaic energy generation in Morocco. In Proceedings of the 2014 International Renewable and Sustainable Energy Conference (IRSEC), Ouarzazate, Morocco, 17–19 October 2014; pp. 230–234. [Google Scholar]

- Fernández-Solas, Á.; Montes-Romero, J.; Micheli, L.; Almonacid, F.; Fernández, E.F. Estimation of soiling losses in photovoltaic modules of different technologies through analytical methods. Energy 2022, 244, 123173. [Google Scholar] [CrossRef]

- Zsiborács, H.; Zentkó, L.; Pintér, G.; Vincze, A.; Baranyai, N.H. Assessing shading losses of photovoltaic power plants based on string data. Energy Rep. 2021, 7, 3400–3409. [Google Scholar] [CrossRef]

- de Oliveira, A.K.V.; Aghaei, M.; Rüther, R. Automatic Inspection of Photovoltaic Power Plants Using Aerial Infrared Thermography: A Review. Energies 2022, 15, 2055. [Google Scholar] [CrossRef]

- Mehta, S.; Azad, A.P.; Chemmengath, S.A.; Raykar, V.; Kalyanaraman, S. DeepSolarEye: Power Loss Prediction and Weakly Supervised Soiling Localization via Fully Convolutional Networks for Solar Panels. In Proceedings of the 2018 IEEE Winter Conference on Applications of Computer Vision (WACV), Lake Tahoe, NV, USA, 12–15 March 2018; pp. 333–342. [Google Scholar]

- García Márquez, F.P.; Segovia Ramírez, I. Condition monitoring system for solar power plants with radiometric and thermographic sensors embedded in unmanned aerial vehicles. Measurement 2019, 139, 152–162. [Google Scholar] [CrossRef]

- Herraiz, Á.H.; Marugán, A.P.; Márquez, F.P.G. Photovoltaic plant condition monitoring using thermal images analysis by convolutional neural network-based structure. Renew. Energy 2020, 153, 334–348. [Google Scholar] [CrossRef]

- Pavan, A.M.; Mellit, A.; De Pieri, D.; Kalogirou, S.A. A comparison between BNN and regression polynomial methods for the evaluation of the effect of soiling in large scale photovoltaic plants. Appl. Energy 2013, 108, 392–401. [Google Scholar] [CrossRef]

- Pavan, A.M.; Mellit, A.; De Pieri, D. The effect of soiling on energy production for large-scale photovoltaic plants. Sol. Energy 2011, 85, 1128–1136. [Google Scholar] [CrossRef]

- Javed, W.; Guo, B.; Figgis, B. Modeling of photovoltaic soiling loss as a function of environmental variables. Sol. Energy 2017, 157, 397–407. [Google Scholar] [CrossRef]

- Hammad, B.; Al-Abed, M.; Al-Ghandoor, A.; Al-Sardeah, A.; Al-Bashir, A. Modeling and analysis of dust and temperature effects on photovoltaic systems’ performance and optimal cleaning frequency: Jordan case study. Renew. Sustain. Energy Rev. 2018, 82, 2218–2234. [Google Scholar] [CrossRef]

- Al Siyabi, I.; Al Mayasi, A.; Al Shukaili, A.; Khanna, S. Effect of soiling on solar photovoltaic performance under desert climatic conditions. Energies 2021, 14, 659. [Google Scholar] [CrossRef]

- Lindstrom, M.J.; Bates, D.M. Newton—Raphson and EM algorithms for linear mixed-effects models for repeated-measures data. J. Am. Stat. Assoc. 1988, 83, 1014–1022. [Google Scholar]

- El-Shobokshy, M.S.; Hussein, F.M. Effect of dust with different physical properties on the performance of photovoltaic cells. Sol. Energy 1993, 51, 505–511. [Google Scholar] [CrossRef]

- Hupa, L.; Bergman, R.; Fröberg, L.; Vane-Tempest, S.; Hupa, M.; Kronberg, T.; Pesonen-Leinonen, E.; Sjöberg, A.M. Chemical resistance and cleanability of glazed surfaces. Surf. Sci. 2005, 584, 113–118. [Google Scholar] [CrossRef]

- Coello, M.; Boyle, L. Simple model for predicting time series soiling of photovoltaic panels. IEEE J. Photovolt. 2019, 9, 1382–1387. [Google Scholar] [CrossRef]

- Blumberg, A. Logistic growth rate functions. J. Theor. Biol. 1968, 21, 42–44. [Google Scholar] [CrossRef]

- Davidian, M.; Giltinan, D.M. Nonlinear Models for Repeated Measurement Sdata; CRC Press: Boca Raton, FL, USA, 1995; Volume 62. [Google Scholar]

- Xu, P.; Shen, Y.; Fukuda, Y.; Liu, Y. Variance component estimation in linear inverse ill-posed models. J. Geod. 2006, 80, 69–81. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2021. [Google Scholar]

- R Core Team. nlme: Linear and Nonlinear Mixed Effects Models. R Package Version 3.1-141. 2019. Available online: http://CRAN.R-Project.Org/Package=Nlme (accessed on 6 April 2022).

| Variable | Measurements | ||||||

|---|---|---|---|---|---|---|---|

| Min. | 1st Q. | Median | Average | S. Deviation | 3rd Q. | Max. | |

| Power | 2.77 | 997.19 | 3616.73 | 3858.56 | 2882.368 | 6528.59 | 8475.12 |

| Irradiance | 0.10 | 118.60 | 420.40 | 470.50 | 362.37 | 799.30 | 1197.20 |

| Temperature | 19.15 | 27.63 | 31.36 | 30.80 | 4.67649 | 34.71 | 39.34 |

| Accumulated Mass | 0.1387 | 0.1971 | 0.2599 | 0.2768 | 0.08948 | 0.3720 | 0.3920 |

| Variable | Variable | ||

|---|---|---|---|

| Irradiance | Temperature | Accumulated Mass | |

| Irradiance | 1 | 0.6754 | −0.2226 |

| Temperature | 0.6754 | 1 | −0.5231 |

| Accumulated Mass | −0.2226 | −0.5231 | 1 |

| Criteria | Model | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MSE | 0.0037 | 0.3334 | 0.2181 | 0.2998 | 0.2338 | 0.2056 | 0.218 | 0.2119 | 0.1889 | 0.0007 |

| AIC | −4495.575 | 2834.605 | 2245.463 | 2730.587 | 2351.410 | 2191.774 | 2248.816 | 2234.820 | 2090.743 | −15,395.292 |

| BIC | −4474.002 | 2856.177 | 2272.429 | 2757.554 | 2378.466 | 2229.527 | 2286.569 | 2272.573 | 2144.675 | −15,325.179 |

| Parameter | Estimate | Std. Error | DF | t-Value | p-Value |

|---|---|---|---|---|---|

| 6.7092 | 0.2823 | 1598 | 23.7691 | 0.0000 | |

| 0.6577 | 0.0210 | 1598 | 31.3600 | 0.0000 | |

| 0.0696 | 0.0383 | 1598 | 1.8162 | 0.0695 | |

| 4.9754 | 0.2696 | 1598 | 18.4537 | 0.0000 | |

| −0.4143 | 0.0162 | 1598 | −25.6015 | 0.0000 | |

| 0.1148 | 0.0549 | 1598 | 2.0936 | 0.0365 | |

| 0.0009 | 0.0001 | 1598 | 9.4311 | 0.0000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Souza, G.; Santos, R.; Saraiva, E. A Log-Logistic Predictor for Power Generation in Photovoltaic Systems. Energies 2022, 15, 5973. https://doi.org/10.3390/en15165973

Souza G, Santos R, Saraiva E. A Log-Logistic Predictor for Power Generation in Photovoltaic Systems. Energies. 2022; 15(16):5973. https://doi.org/10.3390/en15165973

Chicago/Turabian StyleSouza, Guilherme, Ricardo Santos, and Erlandson Saraiva. 2022. "A Log-Logistic Predictor for Power Generation in Photovoltaic Systems" Energies 15, no. 16: 5973. https://doi.org/10.3390/en15165973

APA StyleSouza, G., Santos, R., & Saraiva, E. (2022). A Log-Logistic Predictor for Power Generation in Photovoltaic Systems. Energies, 15(16), 5973. https://doi.org/10.3390/en15165973