Assessment Criteria of Changes in Health Index Values over Time—A Transformer Population Study

Abstract

:1. Introduction

- Electrical parameters (turns ratio, winding resistance);

- Insulation properties (insulation resistance, dielectric dissipation of windings, and moisture content evaluation within solid insulation using polarization methods);

- Mechanical integrity (frequency response analysis, leakage reactance);

- Accessory check (on-load tap changer diagnostics, bushing assessment).

- Simulations of the algorithm output based on different criteria to determine the magnitude of typical internal faults detectable through oil analysis;

- Evaluation of the score changes observed within the population;

- Recommendation of alarm and pre-failure thresholds based on the observed and simulated results.

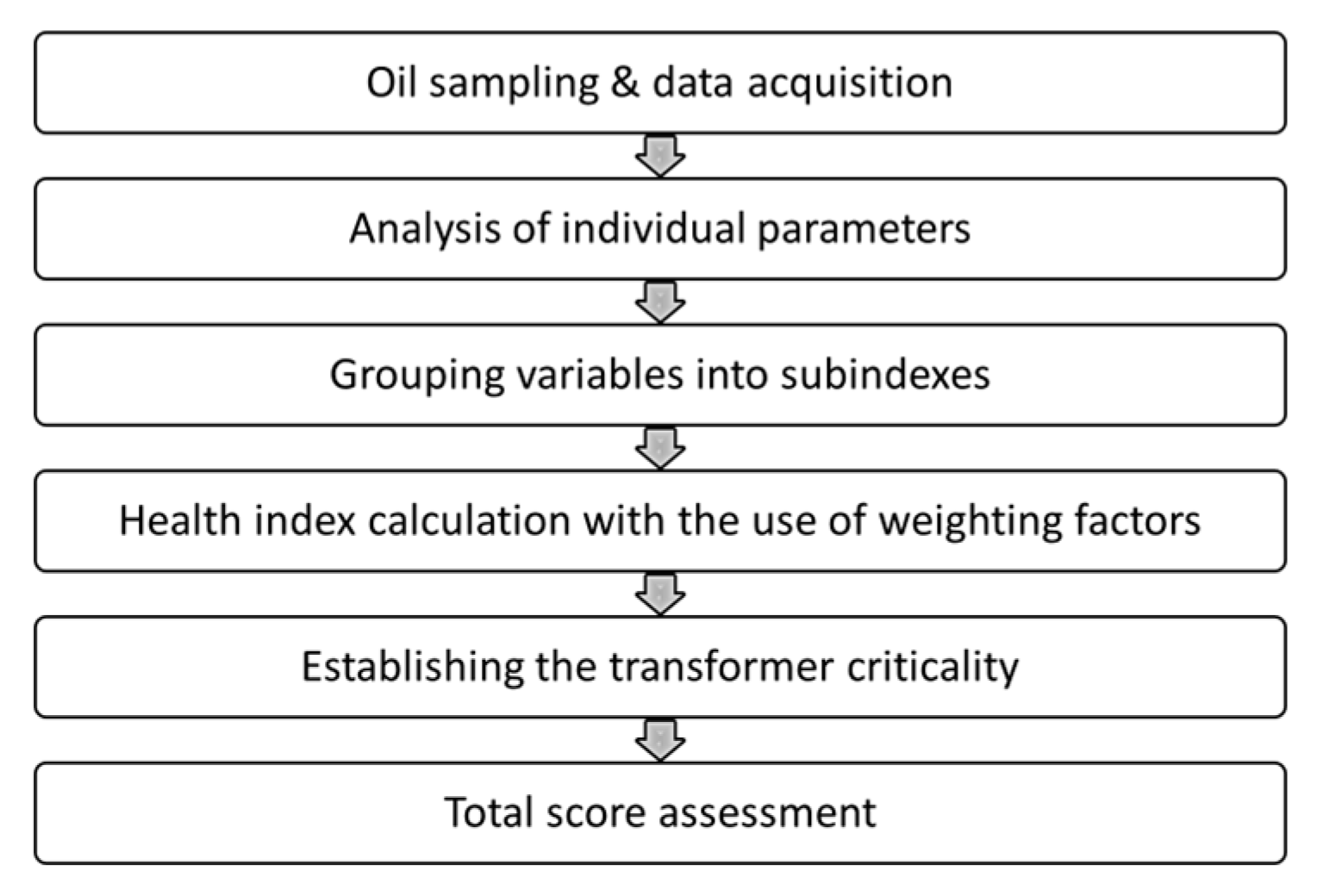

2. Materials and Methods

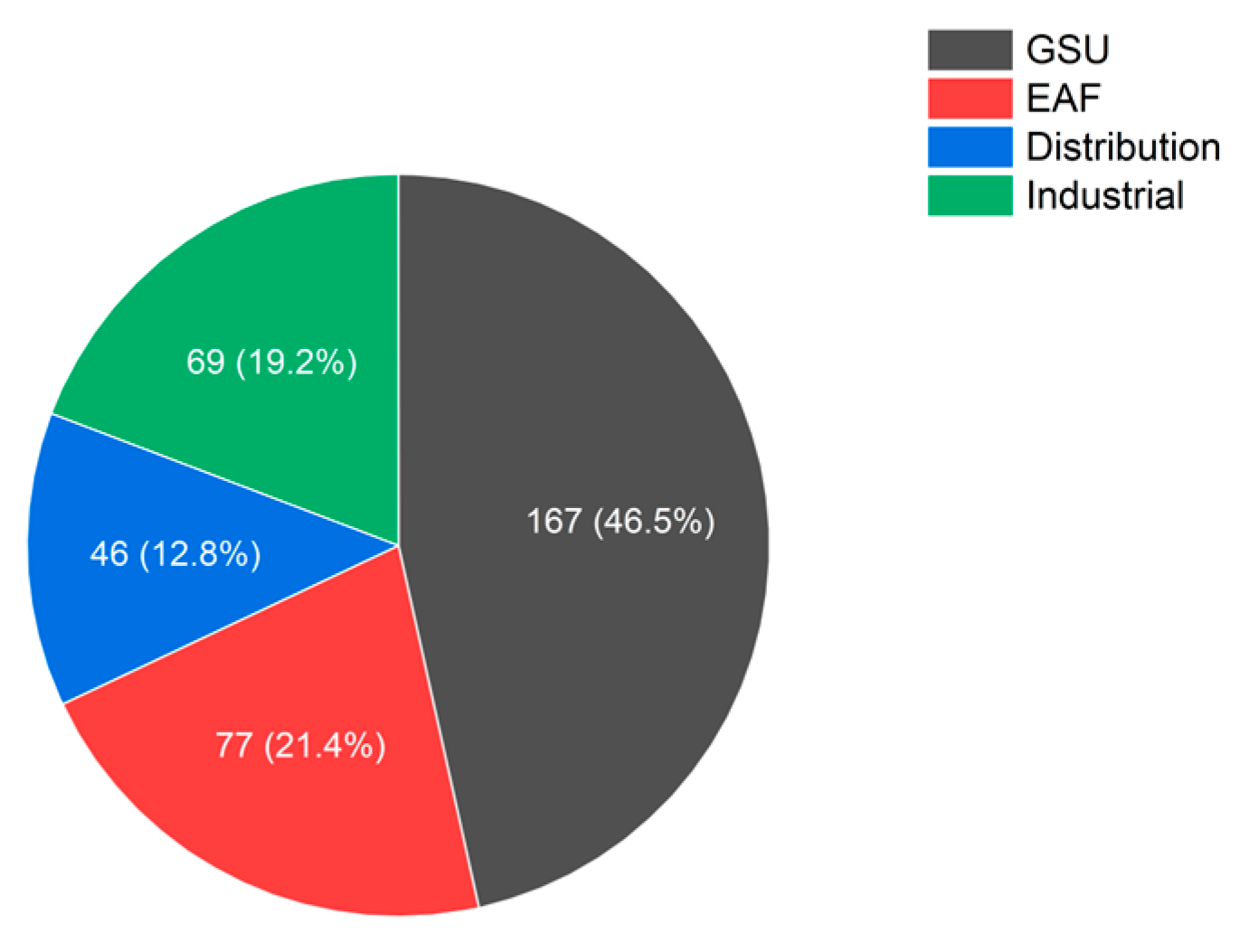

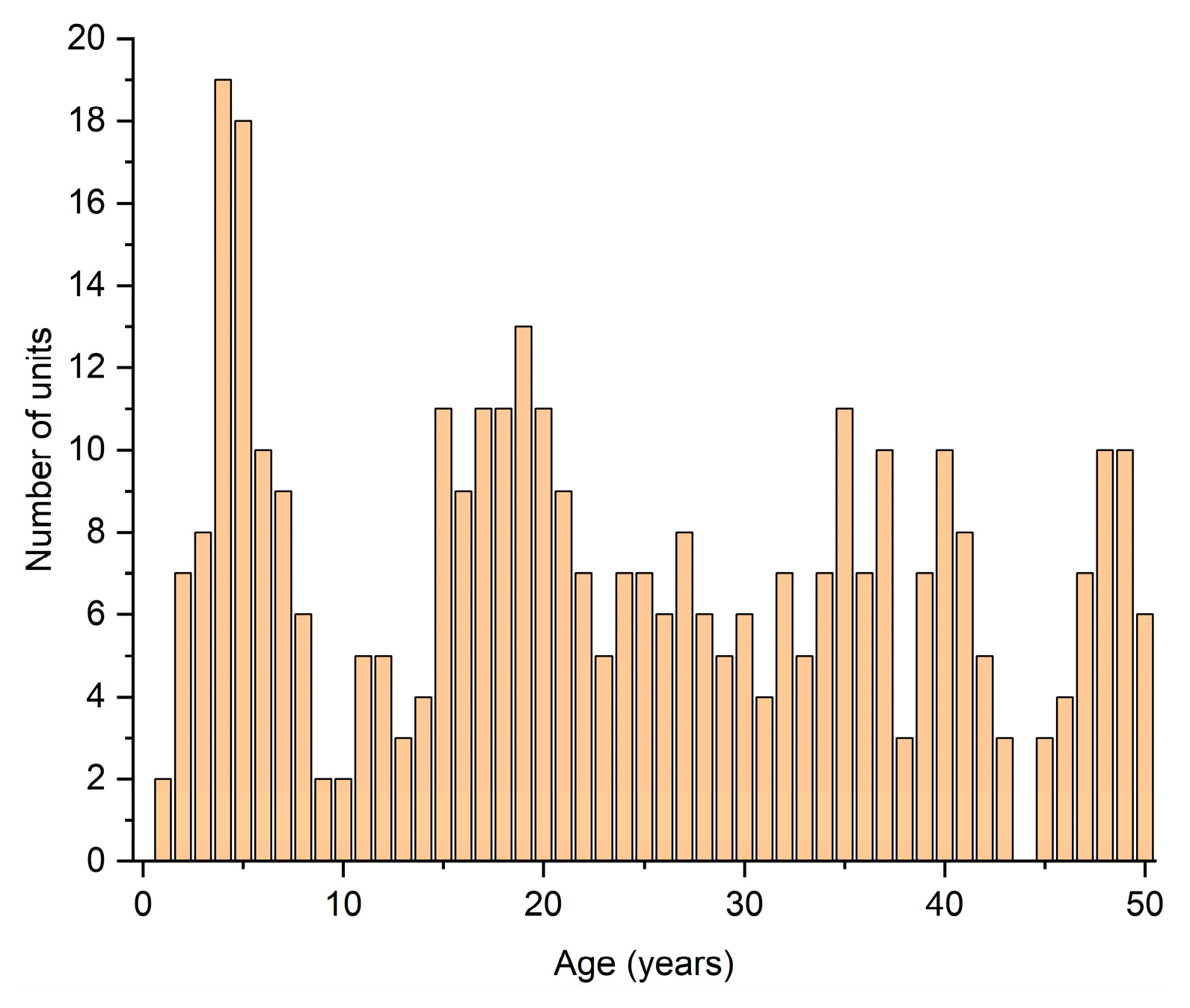

2.1. Study Group

2.2. The Health Index Adopted for the Study

3. Study Considerations

4. Results

4.1. The Simulation of Changes in Dissolved Gas Content

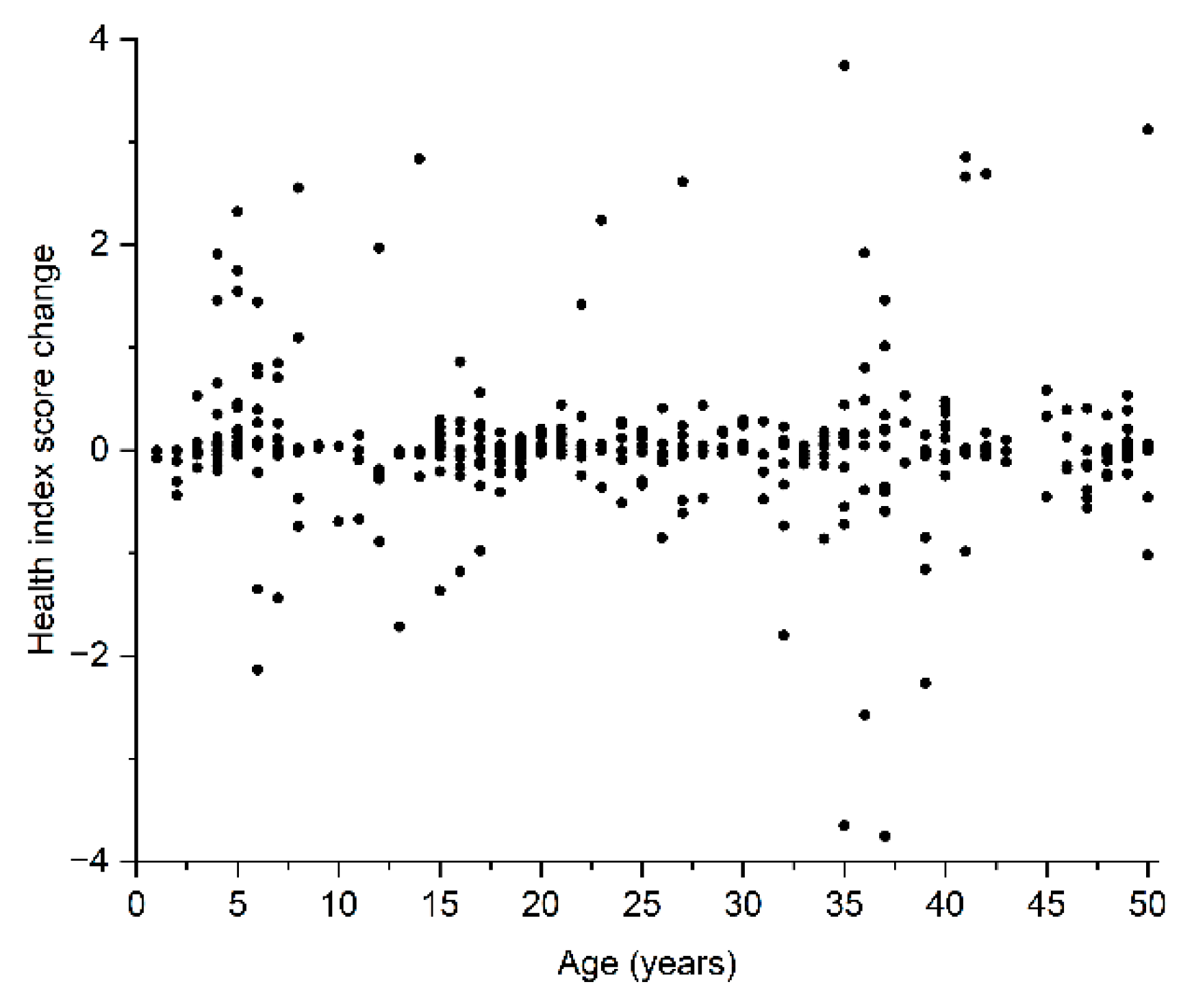

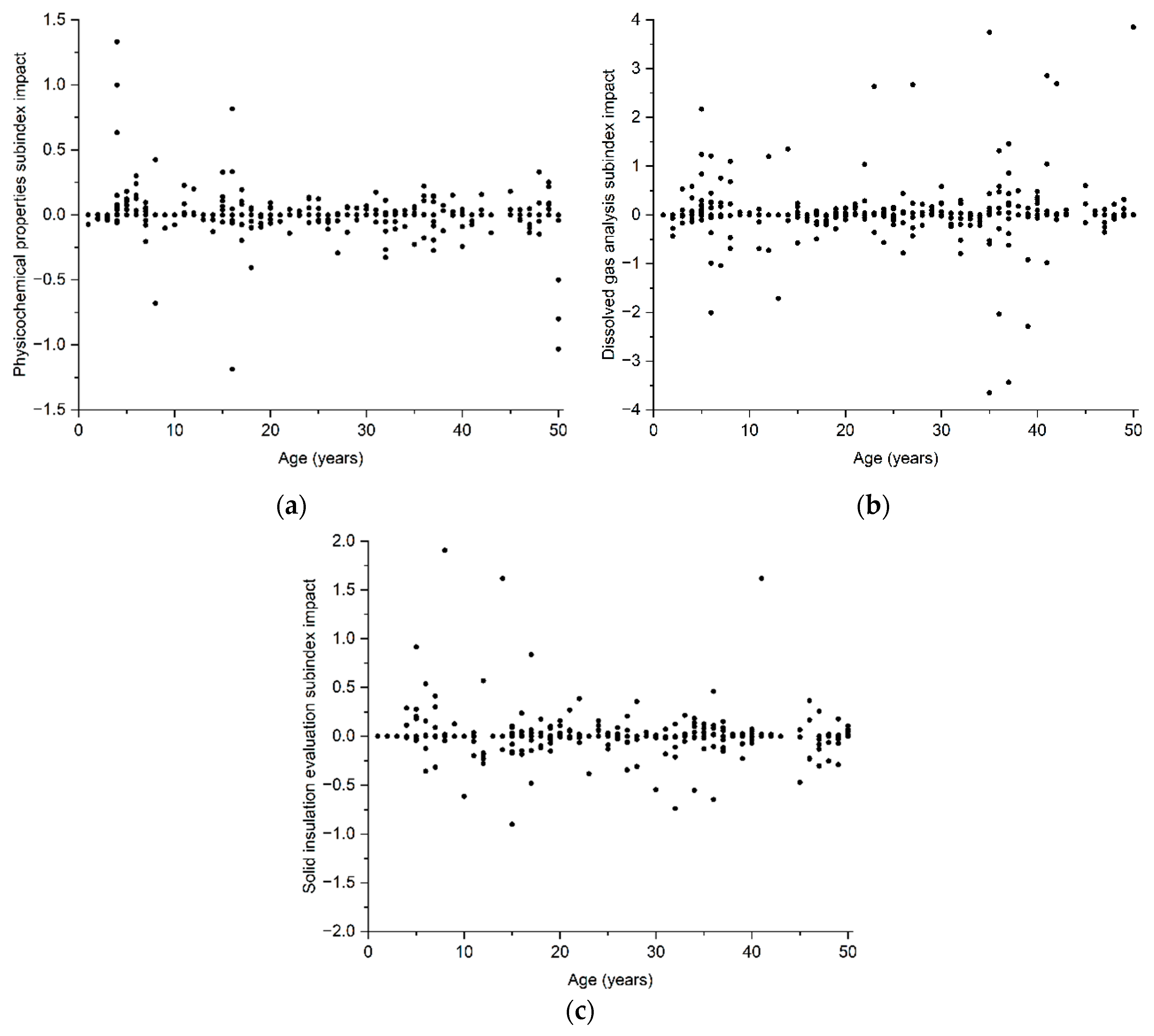

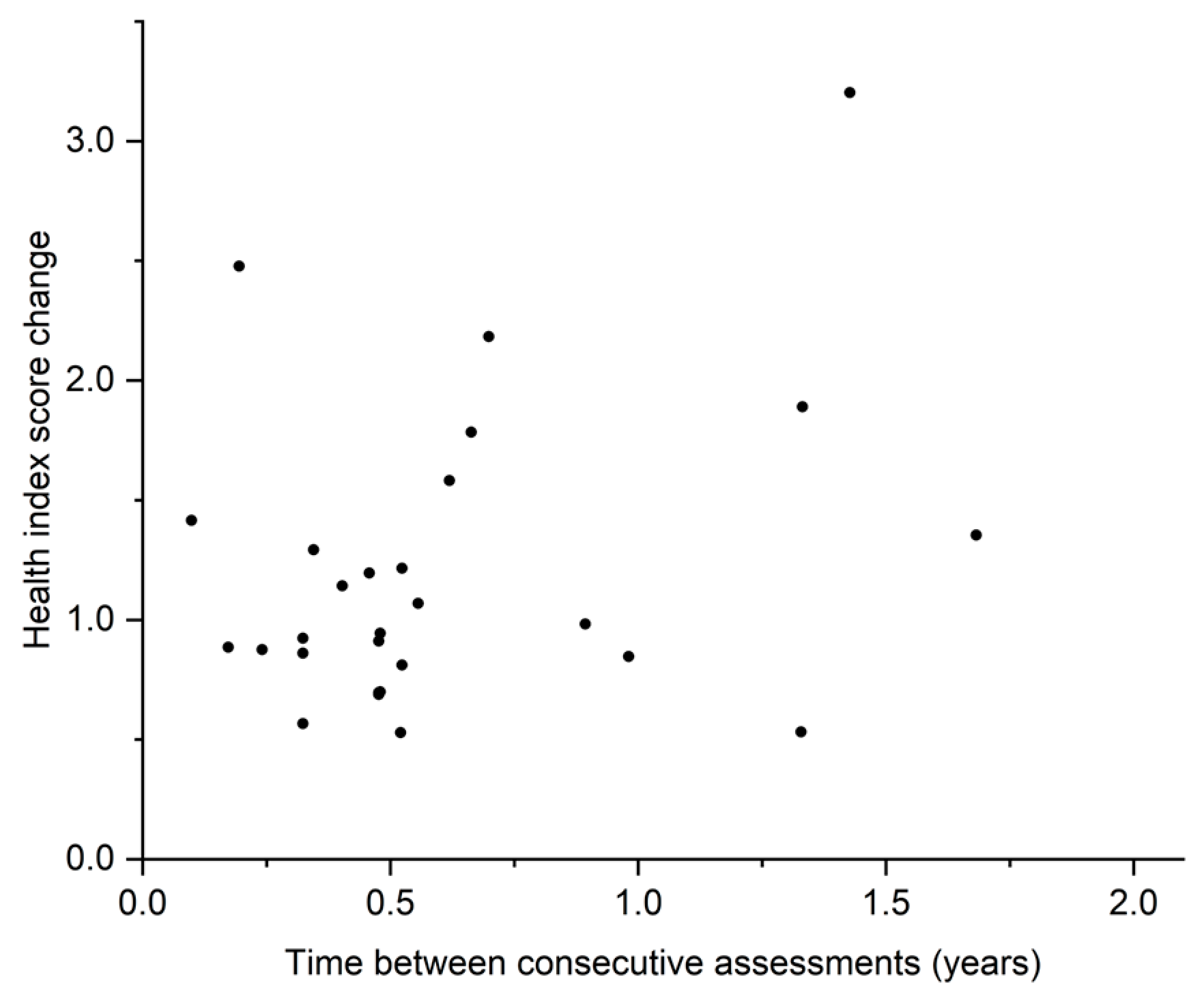

4.2. The Health Index Score Changes in the Population

4.3. The Highest Recorded Increases in the Health Index Values

4.4. The Highest Recorded Decreases in the Health Index Values

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Object | Age | HI Change | HIOIL Change | HIDGA Change | HIISO Change | Testing Interval in Days | Significant Changes |

|---|---|---|---|---|---|---|---|

| T1 | 8 | 0.98 | 0.00 | 0.98 | 0.00 | 326 | DGA (CH4, C2H6, C2H4) |

| T2 | 27 | 1.20 | 0.00 | 1.23 | −0.03 | 167 | DGA (CH4, C2H6, C2H4) |

| T3 | 50 | 2.18 | −0.56 | 2.69 | 0.05 | 255 | DGA (H2, CH4, C2H6, C2H4, C2H2) |

| T4 | 16 | 0.85 | 0.80 | 0.00 | 0.05 | 358 | BDV and WC |

| T5 | 41 | 0.86 | 0.00 | 0.34 | 0.52 | 118 | DGA (CH4, C2H6, CO, CO2) |

| T6 | 35 | 1.29 | 0.00 | 1.29 | 0.00 | 126 | DGA (H2, C2H2) |

| T7 | 36 | 1.07 | 0.08 | 0.73 | 0.26 | 203 | DGA (H2, C2H6, C2H4, C2H2, CO2) |

| T8 | 37 | 0.70 | −0.04 | 0.70 | 0.04 | 175 | DGA (C2H6, C2H4, C2H2) |

| T9 | 41 | 0.92 | 0.00 | 0.92 | 0.00 | 118 | DGA (H2, C2H6, C2H4, C2H2) |

| T10 | 12 | 0.94 | 0.09 | 0.58 | 0.27 | 175 | DGA (CH4, C2H6, CO) |

| T11 | 35 | 0.89 | 0.16 | 0.56 | 0.17 | 63 | DGA (H2, CH4, C2H6, C2H4, C2H2, CO, CO2) |

| T12 | 37 | 0.53 | 0.05 | 0.45 | 0.03 | 190 | DGA (C2H6, C2H4, C2H2, CO2) |

| T13 | 37 | 1.42 | 0.05 | 1.20 | 0.17 | 36 | DGA (H2, CH4, C2H6, C2H4, C2H2, CO, CO2) |

| T14 | 35 | 0.88 | 0.12 | 0.47 | 0.29 | 88 | DGA (H2, CH4, C2H6, C2H4, C2H2, CO, CO2) |

| T15 | 22 | 1.89 | 0.00 | 1.38 | 0.51 | 486 | DGA (H2, CH4, C2H6, C2H4, CO, CO2) |

| T16 | 6 | 1.35 | 0.00 | 0.45 | 0.90 | 614 | DGA (CH4, C2H4) and 2-FAL |

| T17 * | 42 | 1.78 | 0.00 | 1.78 | 0.00 | 242 | DGA (H2, CH4, C2H6, C2H4, C2H2) |

| T18 * | 12 | 2.48 | 0.00 | 2.48 | 0.00 | 71 | DGA (H2, CH4, C2H6, C2H4, C2H2, CO) |

| T19 * | 8 | 1.58 | 0.26 | 0.14 | 1.18 | 226 | DGA (H2, CH4, C2H6, C2H4, CO, CO2), WC and 2-FAL |

| T20 * | 23 | 3.20 | −0.01 | 3.76 | −0.55 | 521 | DGA (H2, CH4, C2H6, C2H4, C2H2) |

| T21 | 14 | 1.14 | −0.05 | 0.54 | 0.65 | 147 | DGA (H2, CH4, C2H6, C2H4, CO, CO2) |

| T22 | 6 | 0.69 | 0.11 | 0.58 | 0.00 | 174 | DGA (H2, CH4, C2H6, C2H4) |

| T23 | 4 | 0.91 | 0.63 | 0.28 | 0.00 | 174 | DGA (H2, CH4, C2H6) |

| T24 | 5 | 1.22 | 0.10 | 1.14 | −0.02 | 191 | DGA (H2, CH4, C2H6, CO) |

| T25 | 4 | 0.70 | 0.48 | 0.17 | 0.05 | 174 | DGA (H2, CH4, C2H6, CO2) |

| T26 | 5 | 0.81 | 0.05 | 0.65 | 0.11 | 191 | DGA (H2, CH4, C2H6, CO) |

| T27 | 5 | 0.57 | 0.00 | 0.27 | 0.30 | 118 | DGA (H2, CH4, C2H6, CO, CO2) |

| T28 | 6 | 0.53 | 0.00 | 0.32 | 0.21 | 485 | DGA (H2, CO, CO2) |

Appendix B

| Object | Age | HI Change | HIOIL Change | HIDGA Change | HIISO Change | Testing Interval in Days | Significant Changes |

|---|---|---|---|---|---|---|---|

| T1 | 24 | −0.52 | 0.00 | −0.58 | 0.06 | 375 | DGA (H2, CH4, C2H6, C2H4) |

| T2 | 35 | −1.04 | 0.00 | −1.04 | 0.00 | 104 | DGA (H2, CH4, C2H4, C2H2, CO) |

| T3 | 12 | −0.48 | 0.00 | −0.39 | −0.09 | 196 | DGA (H2, CH4, C2H4, C2H2, CO) |

| T4 | 35 | −0.61 | 0.00 | −0.59 | −0.02 | 402 | DGA (CH4, C2H6, C2H4) |

| T5 | 36 | −1.24 | 0.05 | −0.98 | −0.31 | 176 | DGA (H2, CH4, C2H6, C2H4, CO, CO2) |

| T6 | 37 | −1.01 | −0.05 | −0.92 | −0.04 | 98 | DGA (H2, CH4, C2H6, C2H4, C2H2, CO2) |

| T7 | 34 | −0.50 | −0.05 | −0.13 | −0.32 | 211 | DGA (C2H6, C2H4, C2H2, CO, CO2) |

| T8 | 35 | −0.56 | 0.00 | −0.46 | −0.10 | 283 | DGA (H2, C2H2, CO) |

| T9 | 50 | −0.81 | −0.82 | 0.00 | 0.01 | 291 | BDV and WC |

| T10 | 2 | −0.55 | 0.00 | −0.55 | 0.00 | 283 | DGA (CH4, C2H6) |

| T11 | 7 | −0.75 | −0.04 | −0.54 | −0.17 | 191 | DGA (CH4, C2H6, C2H4, C2H2, CO2) |

| T12 | 6 | −1.08 | 0.00 | −1.01 | −0.07 | 184 | DGA (H2, CH4, C2H6) |

| T13 | 6 | −0.68 | 0.00 | −0.50 | −0.18 | 184 | DGA (H2, CO, CO2) |

| T14 | 47 | −0.55 | −0.10 | −0.15 | −0.30 | 361 | DGA (CH4, C2H6, CO) |

| T15 | 47 | −0.54 | −0.09 | −0.41 | −0.04 | 427 | DGA (CH4, C2H6) |

| T16 | 15 | −1.34 | 0.10 | −0.56 | −0.88 | 357 | DGA (H2, CH4, C2H4, CO, CO2) |

| T17 | 16 | −0.75 | −0.76 | 0.00 | 0.01 | 233 | BDV and WC |

| T18 | 27 | −0.58 | 0.00 | −0.25 | −0.33 | 349 | DGA (C2H6, C2H4, CO, CO2) |

| T19 | 36 | −0.55 | 0.00 | −0.40 | −0.15 | 520 | DGA (CH4, C2H6) |

| T20 | 39 | −1.65 | 0.00 | −1.32 | −0.33 | 522 | DGA (H2, CH4, C2H6, CO) |

| T21 | 31 | −0.68 | −0.08 | −0.34 | −0.26 | 521 | DGA (CH4, C2H6) |

References

- Tenbohlen, S.; Coenen, S.; Djamali, M.; Müller, A.; Samimi, M.H.; Siegel, M. Diagnostic Measurements for Power Transformers. Energies 2016, 9, 347. [Google Scholar] [CrossRef]

- IEEE. IEEE C57.152-2013—Guide for the Diagnostic Field Testing of Fluid-Filled Power Transformers, Regulators, and Reactors; Institute of Electrical and Electronics Engineers: Piscataway, NJ, USA, 2013. [Google Scholar]

- CIGRE. Guide for Transformer Maintenance; WG A2.34, Technical Brochure No. 445; CIGRE: Paris, France, 2011. [Google Scholar]

- Subocz, J.; Banaszak, S.; Kornatowski, E.; Szrot, M.; Węgrzyn, B.; Zenker, M. Transformers Technical Condition Assessment and Population Management (in Polish—Ocena Stanu Technicznego i Zarządzanie Populacją Transformatorów); Joint Publication; OBRE: Piekary Śląskie, Poland, 2013; ISBN 978-83-938292-0-0. [Google Scholar]

- Soni, R.; Mehta, B. Review on asset management of power transformer by diagnosing incipient faults and faults identification using various testing methodologies. Eng. Fail. Anal. 2021, 128, 105634. [Google Scholar] [CrossRef]

- Davidenko, I.V.; Kuzina, T.S. Analysis of the modern methods of the power transformers health index calculation. In Proceedings of the 2017 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), St. Petersburg and Moscow, Russia, 1–3 February 2017. [Google Scholar] [CrossRef]

- Azmi, A.; Jasni, J.; Azis, N.; Kadir, M.Z.A.A. Evolution of transformer health index in the form of mathematical equation. Renew. Sustain. Energy Rev. 2017, 76, 687–700. [Google Scholar] [CrossRef]

- Jahromi, A.N.; Piercy, R.; Cress, S.; Service, J.R.R.; Fan, W. An Approach to Power Transformer Asset Management Using Health Index. IEEE Electr. Insul. Mag. 2009, 25, 20–34. [Google Scholar] [CrossRef]

- Aman, T.A.; Mokhtar, A.S.; AizamTalib, M. Assessment The Overall Health Condition of Transformer Using Health Index and Critical Index Approach: TNB GRID Case Study. In Proceedings of the 2020 IEEE International Conference on Power and Energy (PECon), Penang, Malaysia, 7–8 December 2020. [Google Scholar] [CrossRef]

- Scatiggio, F.; Pompili, M. Health index: The TERNA’s practical approach for transformer fleet management. In Proceedings of the 2013 IEEE Electrical Insulation Conference (EIC), Ottawa, ON, Canada, 2–5 June 2013. [Google Scholar] [CrossRef]

- Picher, P.; Boudreau, J.F.; Manga, A.; Rajotte, C.; Tardif, C.; Bizier, G.; Di Gaetano, N.; Garon, D.; Girard, B.; Hamel, J.F.; et al. Use of Health Index and Reliability Data for Transformer Condition Assessment and Fleet Ranking. In Proceedings of the Session CIGRE 2014, Paris, France, 24–29 August 2014; pp. 24–29. [Google Scholar]

- Singh, A.; Swanson, A.G. Analysis and improvement of the plant health index by ESKOM to assess the condition of the power transformers in its distribution fleet. In Proceedings of the 19th International Symposium on High Voltage Engineering, Pilsen, Czech Republic, 23–28 August 2015. [Google Scholar]

- Elsisi, M.; Tran, M.Q.; Mahmoud, K.; Mansour, D.E.A.; Lehtonen, M.; Darwish, M.M. Effective IoT-based deep learning platform for online fault diagnosis of power transformers against cyberattacks and data uncertainties. Measurement 2022, 190, 110686. [Google Scholar] [CrossRef]

- Badawi, M.; Ibrahim, S.A.; Mansour, D.E.A.; El-Faraskoury, A.A.; Ward, S.A.; Mahmoud, K.; Lehtonen, M.; Darwish, M.M. Reliable Estimation for Health Index of Transformer Oil Based on Novel Combined Predictive Maintenance Techniques. IEEE Access 2022, 10, 25954–25972. [Google Scholar] [CrossRef]

- Li, S.; Wu, G.; Dong, H.; Yang, L.; Zhen, X. Probabilistic Health Index-Based Apparent Age Estimation for Power Transformers. IEEE Access 2020, 8, 9692–9701. [Google Scholar] [CrossRef]

- Prasojo, R.A.; Setiawan, A.; Suwarno; Maulidevi, N.U.; Soedjarno, B.A. Development of Power Transformer Remaining Life Model Using Multi-Parameters. In Proceedings of the 13th International Conference on the Properties and Applications of Dielectric Materials (ICPADM 2021), Johor Bahru, Malaysia, 12–14 July 2021. [Google Scholar] [CrossRef]

- Alvarez, D.L.; Rodriguez, D.F.; Cardenas, A.; Faria da Silva, F.; Leth Bak, C.; García, R.; Rivera, S. Optimal Decision Making in Electrical Systems Using an Asset Risk Management Framework. Energies 2021, 14, 4987. [Google Scholar] [CrossRef]

- Bohatyrewicz, P.; Mrozik, A. The Analysis of Power Transformer Population Working in Different Operating Conditions with the Use of Health Index. Energies 2021, 14, 5213. [Google Scholar] [CrossRef]

- IEC. IEC 60599:2015—Mineral Oil-Filled Electrical Equipment in Service—Guidance on the Interpretation of Dissolved and Free Gases Analysis; International Electrotechnical Commission: Geneva, Switzerland, 2015. [Google Scholar]

- IEEE. IEEE C57.104-2019—Guide for the Interpretation of Gases Generated in Oil-Immersed Transformers; Institute of Electrical and Electronics Engineers: Piscataway, NJ, USA, 2019. [Google Scholar]

- IEEE. IEEE C57.106-2015—Guide for the Acceptance and Maintenance of Insulating Mineral Oil in Electrical Equipment; Institute of Electrical and Electronics Engineers: Piscataway, NJ, USA, 2015. [Google Scholar]

- CIGRE. Recent Developments in DGA Interpretation; Joint Task Force D1.01/A2.11, Technical Brochure 296; CIGRE: Paris, France, 2006. [Google Scholar]

- CIGRE. Furanic Compounds for Diagnosis; WG D1.01 (TF13), Technical Brochure no. 494; CIGRE: Paris, France, 2012. [Google Scholar]

- Bohatyrewicz, P.; Płowucha, J.; Subocz, J. Condition Assessment of Power Transformers Based on Health Index value. Appl. Sci. 2019, 9, 4877. [Google Scholar] [CrossRef] [Green Version]

- Bagiński, A.; Domżalski, T.; Kaźmierski, M.; Łukaszewski, J.; Olech, W.; Olejniczak, H.; Owczarek, J.; Sieradzki, S.; Szymański, Z. Framework Instructions for Transformer Operation (in Polish—Ramowa Instrukcja Eksploatacji Transformatorów); Joint Publication; Zpbe Energopomiar-Elektryka: Gliwice, Poland, 2012; ISBN 978-83-916040-4-5. [Google Scholar]

- Walker, C.; Walker, D. Creation & Validation of Transformer Residual Life Models. In Proceedings of the 2022 IEEE 21st International Conference on Dielectric Liquids (ICDL), Sevilla, Spain, 29 May–2 June 2022. [Google Scholar] [CrossRef]

- Duval, M.; De Pablo, A.; Atanasova-Hoehlein, I.; Grisaru, M. Significance and detection of very low degree of polymerization of paper in transformers. IEEE Electr. Insul. Mag. 2017, 33, 31–38. [Google Scholar] [CrossRef]

- Bustamante, S.; Manana, M.; Arroyo, A.; Martinez, R.; González, A.; Rodriguez, J.I. Case Study—Calculation of DGA Limit Values and Sampling Interval in Power Transformers. In Proceedings of the 2019 6th International Advanced Research Workshop on Transformers (ARWtr), Cordoba, Spain, 7–9 October 2019. [Google Scholar] [CrossRef]

- Abu Bakar, N.; Abu-Siada, A.; Islam, S. A Review of Dissolved Gas Analysis Measurement and Interpretation Techniques. IEEE Electr. Insul. Mag. 2014, 30, 39–49. [Google Scholar] [CrossRef]

- Duval, M. Calculation of DGA Limit Values and Sampling Intervals in Transformers in Service. IEEE Electr. Insul. Mag. 2008, 24, 7–13. [Google Scholar] [CrossRef]

| Physicochemical Properties HIOIL | Dissolved Gas Analysis HIDGA | Solid insulation Evaluation HIISO |

|---|---|---|

| Breakdown voltage (BDV) | Hydrogen (H2) | Furfural (2-FAL) |

| Water content (WC) | Methane (CH4) | Carbon monoxide (CO) |

| Acidity | Ethane (C2H6) | Carbon dioxide (CO2) |

| Dissipation factor | Ethylene (C2H4) | |

| Acetylene (C2H2) |

| Level “0” | Level “1” | Level “2” | Level “3” |

|---|---|---|---|

| Group I as per [25] | Group I as per [25] | Group II as per [25] | Groups III and IV as per [25] |

| Crucial importance | Significant importance | Standard importance | Minor importance |

| Condition | Level “0” | Level “1” | Level “2” | Level “3” |

|---|---|---|---|---|

| Good | 0–5% | 0–10% | 0–15% | 0–15% |

| Fair | 5–15% | 10–20% | 15–25% | 15–30% |

| Poor | 15–30% | 20–40% | 25–50% | 30–55% |

| Risky | 30–100% | 40–100% | 50–100% | 55–100% |

| Criteria | H2 | CH4 | C2H6 | C2H4 | C2H2 | CO | CO2 |

|---|---|---|---|---|---|---|---|

| IEC 60599 low | 35 | 10 | 5 | 32 | 21 | 260 | 1700 |

| IEC 60599 high | 132 | 120 | 90 | 145 | 37 | 1060 | 10,000 |

| Bustamante et al. [28] | 97 | 15 | 8 | 20 | 37 | 223 | 1477 |

| Study group | 25 | 23 | 53 | 15 | 8 | 145 | 1510 |

| Criteria | H2 | CH4 | C2H6 | C2H4 | C2H2 | CO | CO2 |

|---|---|---|---|---|---|---|---|

| IEC 60599 low | 0.14 | 0.05 | 0.00 | 0.11 | 0.41 | 0.20 | 0.14 |

| IEC 60599 high | 0.52 | 0.59 | 0.05 | 0.49 | 0.72 | 0.57 | 0.57 |

| Bustamante et al. [28] | 0.38 | 0.07 | 0.00 | 0.07 | 0.72 | 0.17 | 0.12 |

| Study group | 0.10 | 0.11 | 0.03 | 0.05 | 0.16 | 0.11 | 0.14 |

| Criteria | Overheated Oil | Overheated Cellulose | PD in Oil | Arcing in Oil |

|---|---|---|---|---|

| IEC 60599 low | 0.08 | 0.19 | 0.13 | 0.21 |

| IEC 60599 high | 0.42 | 0.57 | 0.52 | 0.57 |

| Bustamante et al. [28] | 0.06 | 0.18 | 0.33 | 0.45 |

| Study group | 0.06 | 0.11 | 0.10 | 0.12 |

| Criteria | D1 | D2 | DT | PD | T1 | T2 | T3 |

|---|---|---|---|---|---|---|---|

| IEC 60599 low | 0.41 | 0.43 | 0.36 | 0.05 | 0.07 | 0.10 | 0.22 |

| IEC 60599 high | 0.72 | 1.23 | 1.03 | 0.64 | 0.82 | 1.24 | 1.00 |

| Bustamante et al. [28] | 0.72 | 0.72 | 0.23 | 0.08 | 0.10 | 0.15 | 0.14 |

| Study group | 0.16 | 0.24 | 0.18 | 0.12 | 0.16 | 0.15 | 0.13 |

| Criteria | H2 | CH4 | C2H6 | C2H4 | C2H2 | CO | CO2 |

|---|---|---|---|---|---|---|---|

| CIGRE | 3 | 5 | 11 | 5 | 0.5 | N/R * | N/R * |

| Criteria | Overheated oil | Overheated Cellulose | PD in Oil | Arcing in Oil |

|---|---|---|---|---|

| CIGRE | 0.46 | - * | 0.39 | 0.35 |

| Criteria | D1 | D2 | DT | PD | T1 | T2 | T3 |

|---|---|---|---|---|---|---|---|

| CIGRE | 0.29 | 0.74 | 0.79 | 0.65 | 0.88 | 1.33 | 1.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bohatyrewicz, P.; Banaszak, S. Assessment Criteria of Changes in Health Index Values over Time—A Transformer Population Study. Energies 2022, 15, 6078. https://doi.org/10.3390/en15166078

Bohatyrewicz P, Banaszak S. Assessment Criteria of Changes in Health Index Values over Time—A Transformer Population Study. Energies. 2022; 15(16):6078. https://doi.org/10.3390/en15166078

Chicago/Turabian StyleBohatyrewicz, Patryk, and Szymon Banaszak. 2022. "Assessment Criteria of Changes in Health Index Values over Time—A Transformer Population Study" Energies 15, no. 16: 6078. https://doi.org/10.3390/en15166078

APA StyleBohatyrewicz, P., & Banaszak, S. (2022). Assessment Criteria of Changes in Health Index Values over Time—A Transformer Population Study. Energies, 15(16), 6078. https://doi.org/10.3390/en15166078