Abstract

Of the various waste and side streams created in a kraft pulp mill, the biological sludges from the wastewater treatment plant are some of the most problematic to handle. Incineration is becoming a common solution as landfilling is no longer permitted by legislation in many countries, but this is also problematic due to the high moisture content, poor drying characteristics, and high ash content in the solids. This study evaluates the technical potential of mild hydrothermal carbonization (HTC) at 160 °C for 3 h to improve the energy efficiency of on-site incineration as a biosludge handling method. HTC treatment transforms wet organic substrates into a hydrophobic carbonaceous material (hydrochar). The heating value and elemental composition of both the sludge and the hydrochar product were analyzed. Based on this, a hydrothermal carbonization model developed earlier was adjusted for the feedstock, and process integration modelling performed to evaluate the performance impact on the power and heat generation at the mill. The results indicate that if the alternative is combustion in the power boiler, HTC pre-treatment could allow a significant increase in power generation. If the sludge is combusted in the recovery boiler, a practice often avoided in order to not introduce non-process elements to the chemical recovery cycle but sometimes necessary due to, e.g., absence of a power boiler, a much smaller increase is obtained. The increase is smallest if the freed evaporator plant capacity cannot be utilized for increasing the firing liquor dry solids content.

1. Introduction

Waste disposal is an important concern worldwide due to the potential environmental and health hazards caused by the waste, and the costs of treatment and/or disposal to minimize the risks. In order to fulfill the European Commission’s “reduce, reuse and recycle” principle of waste management hierarchy, increasingly strict waste handling legislations have been implemented in recent years, demanding new solutions from industries to handle their waste streams [1]. Pulp and paper production in kraft mills is one example of an industry that generates a variety of different by-products and waste streams. Some of these can be efficiently used by the industry itself or in recycling companies. For example, the tall oil produced in chemical pulping of softwood can be used as a raw material for producing traffic fuels. Solid residues, such as bark, can be easily used within the mill site for power and heat production. On the other hand, there are wastes whose disposal requires special procedures due to their nature; the sludge from the effluent treatment system is one such residue. Sludge disposal can account for over 50% of overall wastewater treatment (WWT) costs in some mills: it is therefore a significant issue especially in chemical pulp mills [2]. Direct combustion is currently the main handling option for sludge disposal, although the high moisture content often results in negligibly low or negative heating values, thereby increasing energy consumption. In order to maintain stable combustion, the sludges are mixed with other biofuels.

In a pulp mill, sludge is produced mainly in the primary (clarifier) and secondary (biological) WWT. The sludges contain fibers, mineral fillers such as carbonate, ink, calcium, clay, and adhesives from the converting processes [3]; some of these still have insufficient research regarding their environmental impact. Biosludge is produced after primary treatment, to reduce the dissolved organic compounds and colloidal particles still present in the effluent through biological oxidation. Environmental regulations, WWT costs, and rising freshwater cost factors are driving more conscious WWT management that also focuses on the reuse of treated wastewater. The latest technological developments in pulp mill WWT included tertiary treatment technology as an alternative to recover the treated effluent for reuse at the plant, but also to extract valuable compounds such as fibers. Physicochemical coagulation-flocculation is commonly used as a tertiary WWT stage in pulp and paper mills [4]. This treatment is energy-intensive, has residual toxic effects, is expensive, and the resulting chemical sludge has high treatment and disposal costs [5]. Due to these drawbacks, many mills have not implemented tertiary treatment.

In particular, the biosludge has proven resistant to attempts to reduce its moisture content through mechanical, thermal measures, as much of the water is not free but trapped inside the cell structures of the micro-organisms. Previous studies have suggested that a larger fraction of smaller particles, especially the colloidal sludge fraction, may be responsible for the difficulties in dewatering [6]. These types of particles can effectively block filter media and sludge cakes, thereby impeding water flow. In sewage sludge treatment the combination of sludge conditioning and mechanical dewatering is a widely used dewatering technology. Sludge conditioning involves adding doses of chemicals to reduce the colloidal content of the sludge and increase particle settling and the permeability of the sludge cake, thereby increasing the efficiency of downstream thickening and dewatering processes [7]. Chemical conditioning is performed by adding inorganic (mineral) coagulants and/or organic flocculants to the sludge, as in the pulp and paper mill tertiary WWT.

Potentially, improving biosludge dewatering, especially the use of inorganic chemicals, poses similar problems as tertiary treatment. Conditioning with organic polymer flocculants is used in some Nordic pulp mills, particularly those equipped with centrifugal dewatering [8,9]; these can achieve dry matter contents of slightly over 10% [10]. With the additional use of inorganic coagulants, typically aluminum or iron-based chlorides and sulphates, dry residue contents of almost 15% can be achieved. The drawbacks are not only the cost, but also corrosion and slagging issues in the boiler, or introducing NPEs to the chemical cycle if incinerated in the recovery boiler. Finally, even more complex chemical treatment options have been proposed, e.g., conditioning involving sulphuric acid and hydrogen peroxide to break the cellular structure, followed by inorganic coagulant treatment, neutralization with sodium hydroxide, and final dewatering. Although such treatment can produce easy-to-handle non-toxic solid residue with high solids content [11], the costly and complex system has found few implementations at operating mills [9].

Although theoretically mechanical dewatering can achieve dry residue contents as high as 15% or even more by mass [3], in practice, dewatering in a belt press in actual operating mills typically falls far short of these best-possible figures, usually at approximately 8% dry residue content [12], or 10–11% at best [2]. As much of the water is held inside the cell structure, already at over 10% dry matter content the sludge becomes difficult to pump through pipes [9], complicating the handling. While some limited uses have been found for the biosludge, such as amending disturbed soils, fostering revegetation, reducing erosion [13,14], artificial soil manufacture [15], as components of potting mixes in nurseries [16], and application in the establishment of turfgrasses [17], the main ways to dispose of the biosludge are currently landfilling, composting, or combustion in the recovery or biomass boiler. These all have drawbacks: the landfill option in the EU is not possible anymore; composting is costly and often faces public opposition due to odors; and the very high moisture and non-process element (NPE) content makes the biosludge a problematic fuel for disposal by combustion. Techno-economically feasible, environmentally friendly processes for biosludge treatment are thus clearly needed.

Although biosludge as such is a problematic fuel, with suitable treatment, there is still potential to use it as a way to increase the share of renewable energy while simultaneously reducing the costs of sludge handling [18]. This study focuses on investigating the feasibility of hydrothermal carbonization (HTC), a mild thermochemical conversion technology similar to torrefaction but taking place in water and sometimes referred to as “wet torrefaction”, for biosludge handling.

The main product of HTC is an energy-dense solid, hydrochar. Liquid and gaseous by-products are also produced. The mass yields of solid, liquid, and gaseous products are typically in the ranges of 50–90%, 5–20%, and <5%, respectively [19]. Due to the catalytic effect the water has on the process, the temperature levels are lower than in torrefaction; temperatures of 180–250 °C are common in HTC. The ratio of water to dry matter is high: often 6 to 10, but sometimes significantly higher, up to 30. The process typically takes place under autogenous pressure, with a residence time of some hours.

The hydrochar product is a hydrophobic coal-like material with increased carbon content and energy density compared to the raw feedstock; the contents of oxygen, hydrogen, and nitrogen are reduced [20]. The hydrochar typically retains 80 to 95% of its energy content. As a solid fuel, the hydrochar properties are similar to lignite [20].

The HTC process has some notable advantages for biosludge treatment in a pulp mill: taking place in water, it is well suited for high-moisture sludge, unlike torrefaction it can also remove some of the alkali metals and other inorganic substances from the feedstock, and the destruction of any organic pollutants results in a sterile end product [19,21]. For the sludge drying, not only does the HTC treatment generally convert biomass into easier-to-dry hydrophobic char, but the steam explosions from flashing the pressurized saturated water in the product slurry will burst the cells, releasing the intracellular water for effective drying. The hydrochar could be potentially applicable for various non-combustion applications as well [22]. However, within this study the investigation of such applications is ruled beyond the scope, with the focus on the energy efficiency potential of HTC treatment in conjunction with conventional combustion solutions instead.

The energy consumption of an HTC process with efficient heat recovery is clearly less than that of the latent heat of evaporation of the sludge moisture in combustion; the advantage of the process is that no preceding energy-intensive drying is needed [23]. While the hydrochar product dry matter heating value could be clearly increased over that of raw sludge solids through the use of high enough temperatures [24], improved energy densification was considered of little value for local energy use of the product without significant storage or transportation needs. Minimizing the amount and temperature level of heat supply and high solid-product energy yield while producing a solid product with improved drying and dewatering characteristics was considered of higher importance, leading to the selection of a relatively low temperature of 160 °C.

Two different types of mills are considered, where the biosludge is combusted either in the recovery boiler after introducing the sludge into black liquor in the evaporator, or in a power boiler after only mechanical dewatering of the sludge. In both mill cases, the hydrochar combustion takes place in the same boiler where the sludge would otherwise be combusted. Two different HTC plant configurations are considered. The HTC plant steam and electricity consumptions are evaluated using IPSEpro process simulation software.

2. Materials and Methods

The study was conducted in two main stages. First, the raw biosludge was characterized, and laboratory-scale experiments were performed to evaluate the characteristics of the hydrochar from the HTC process. In the second stage of the study, the results from experiments were used to simulate the HTC process and evaluate different plant configurations. The following chapters describe the methods of the different stages of the study.

2.1. Experimental Process

The investigated biosludge (BS) samples were obtained from a wastewater treatment plant of UPM Kaukas pulp and paper mill located in Lappeenranta, Finland. The sampling period of the sludges represented normal process operating conditions for the mill. After sampling, the samples were stored in polyethylene buckets in a freezer at a temperature of −10 °C prior to analysis, in order to minimize any biological, chemical, or physical changes that could occur between the time of collection and the experimental procedures.

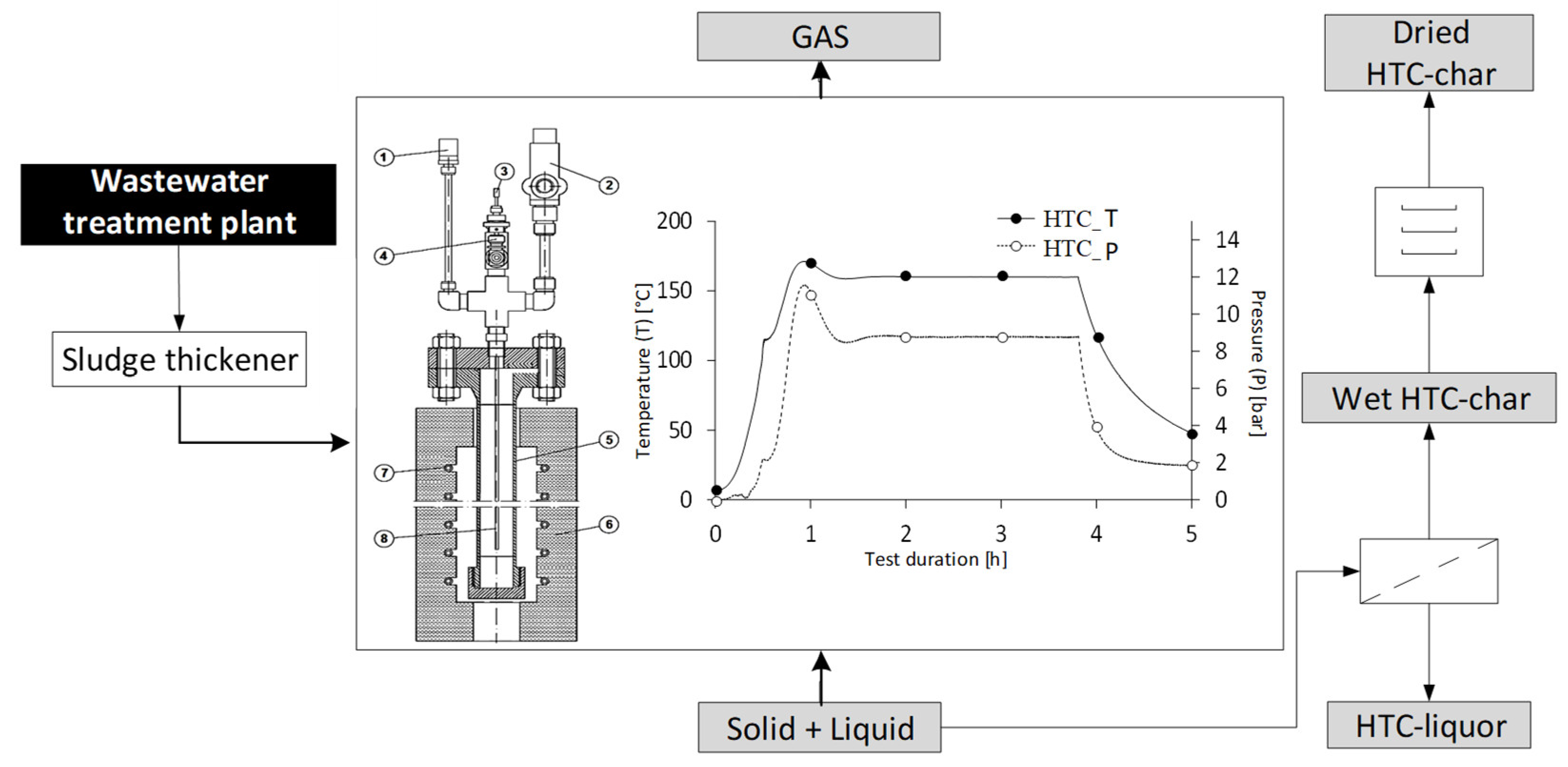

The hydrothermal carbonization of sludge samples was performed in the facilities of Lappeenranta-Lahti University of Technology LUT, Finland, in four main stages: feedstock preparation and characterization, HTC treatment, liquid–solid separation, and product characterization. The experimental procedure and process parameters behavior (pressure and temperature) are depicted in Figure 1. The reactor was loaded with a 1:8 dry:water ratio (constant mass of 50 g of sludge on dry basis). The individual experiments were performed at reaction temperature of 160 °C and a three-hour residence time. The comparatively low HTC temperature of 160 °C was chosen as it was considered the minimum temperature for carbonization to occur. The low temperature would minimize the amount and pressure level of steam needed for reactor heating, while being enough to burst the carbonized cells of the microbes during product slurry flashing to facilitate easy dewatering and drying. A higher reaction temperature would yield improved energy densification and hydrochar properties, but this would be of little advantage if the final use is on-site combustion for energy.

Figure 1.

HTC experimental unit and pressure and temperature variation at 160 °C, 3 h HTC test. Modified from [24]. 1—pressure sensor; 2—safety valve; 3—thermocouples; 4—sampling valve; 5—reactor tube; 6—insulation; 7—heater; 8—thermocouple.

HTC experiments were performed in a stainless-steel batch reactor with an inner volume of approximately 1 L (705 mm height and 42 mm inner diameter) with a flange connection at the top and screw closing at the bottom. The inner reactor temperature was monitored with two thermocouples located at 245 mm and at 645 mm from the top of the reactor. An additional thermocouple measured the temperature of the outer surface of the reactor. The pressure measurement was collected by a pressure sensor, which had a pressure relief valve (set point pressure 40 bar, maximum temperature 300 °C) for safety purposes. The heat demand for the process was provided by a heating jacket, which consisted of electric resistance wire elements surrounded by a ceramic fiber insulation and an outer steel cover. The software utilized as a device control and measurement of the operating parameters was the National Instruments LabVIEW. The required temperature level inside the reactor during the period studied was maintained with a proportional-integral-derivative (PID) controller. After HTC, the solid–liquid product was released from the reactor tube. The solid product was separated by vacuum filtration using a Büchner funnel with a Whatman glass microfiber filter paper of grade GF/A (pore size: 1.6 m). Liquid product was collected in plastic vials and stored in a refrigerator (+4 °C) until analysis. All tests were carried out at least in duplicate and the average values for mass yields were used.

The solid samples were first dried overnight at 105 ± 5 °C until constant mass according to the EN 14774-2 (SFS, 2010) standard procedure. Both feedstock and hydrocarbonized biomass samples were characterized by proximate analysis in accordance with DIN EN 15148:2010-03 (2010) and DIN EN 14775:2010-04 (2010) standard procedures for volatile matter (VM) and ash content (AC), respectively. Fixed carbon (FC) was calculated by subtracting from 100% the sum of the VM and AC percentage in db. Additional ash content analysis at temperature of 815 ± 10 °C was performed according to ISO 1171:2010 standard procedure due to high content of inorganic solids in the samples. The silica content of the hydrochar was measured according to the Technical Association of the Pulp and Paper Industry (TAPPI) T245 cm-98 (1998).

Ultimate analysis was performed using a TruSpec Micro—LECO Instruments CHN628 Series Elemental Determinator coupled with a 628S Sulphur Add-On Module. Prior the analysis, the standard samples (ethylenediaminetetraacetic acid for CHN and coal for S measurements) were analyzed to verify the experimental error within ±1% for the elements. The oxygen content was calculated by subtracting from 100% the sum of the weight percentages of the major elements and ash in dry basis. The analyses were carried out in triplicate and a mean value corrected for moisture content is reported.

The higher heating values (HHV) of the solid samples were determined according to DIN EN 14918:2014-08 (2014) standard procedure, in duplicate, using an adiabatic oxygen-bomb calorimeter.

The variations of the mass yield (MY) of the solid product defined as the dry solid mass ratio of hydrochar (HC) to that of the biosludge (BS) and energy yield (EY) were calculated for the hydrochar samples according to Equations (1) and (2), respectively.

2.2. Considered Pulp and Paper Mills

The studied mills represent typical large, modern mills in Nordic countries, producing 1.6 million ADt/a of bleached pulp from softwood. “NorPulp” has only the pulp mill, producing steam in the recovery boiler; there is no power boiler. Steam is used in the mill processes and for electricity generation. The mill is self-sufficient in energy and able to sell excess electricity.

Mechanically dewatered biosludge is mixed with black liquor in the evaporator plant and incinerated in the kraft recovery boiler (KRB). A dry residue content xdr = 0.08 is assumed as both typical for the practical performance in operating mills [12] and sufficient to ensure the sludge still remains a fairly easily pumpable liquid [9].

When the biosludge is mixed with black liquor in the evaporator plant, the highly alkaline liquor breaks the cells, enabling effective removal of the moisture [25]; the evaporation is also efficient in a multiple-effect evaporator plant, i.e., a comparatively small amount of steam is saved, if the sludge is inserted as a high-solids-content hydrochar rather than 8% solids mechanically dewatered raw sludge. A much greater impact on energy efficiency can be achieved, however, if the evaporator plant capacity that is freed by the reduced moisture input can be utilized for reaching a higher firing liquor dry solids content. Whether this could be done would depend on the equipment of a particular evaporator and recovery boiler. Calculations are thus performed with the two values for the firing liquor dry solids content, unchanged at xds = 0.82, a typical value for modern recovery boilers, and increased to xds = 0.85, the highest dry solids content of any currently operating recovery boiler the authors are aware of. These are considered the two extremes, within which any actual implementation would be likely to fall.

The “NorInt” mill, described in [26], represents a large northern integrated pulp and paper mill with similar pulping process, recovery boiler, and related steam and power production and generation as the NorPulp. It differs from the NorPulp in having an integrated paper mill producing coated and uncoated paper. The paper mill is a notable additional consumer of both power and heat (steam), and, to supply these, there is an additional separate power boiler. The power boiler is a circulating fluidized bed (CFB) biomass boiler, where all solid residues from the wood handling process (mainly bark) are combusted. The mechanically dewatered biosludge is mixed with these residues for incineration. To permit higher steam values for the biomass boiler, both boilers have their own separate turbogenerators, but partially share the condensate system in having common production of demineralized makeup water and a common deaerator and feedwater tank. Table 1 shows the main parameters of the mills.

Table 1.

Operating data of the considered mills.

In the NorInt mill, the incineration of biosludge, which even after dewatering is still mainly water, consumes a considerable amount of energy. If most of the moisture in the dewatered sludge can be removed after HTC treatment, steam generation will be considerably increased—so much so that the swallowing capacity of an existing condensing turbine is unlikely to permit expanding all newly available additional steam to vacuum condenser pressure. Two different scenarios are thus considered here as well; the first is one of an existing plant considering the biosludge HTC treatment as a retrofit, with an existing, typically sized condensing turbine. In this case, much of the excess steam must be directed to a dump condenser. In the other case, the original condensing turbine is replaced with a new one, ideally sized for the higher steam generation. This represents a case of either a greenfield mill design with biosludge HTC plant, or a case where turbine replacement would in any case be needed.

2.2.1. Boiler and Steam Cycle Models

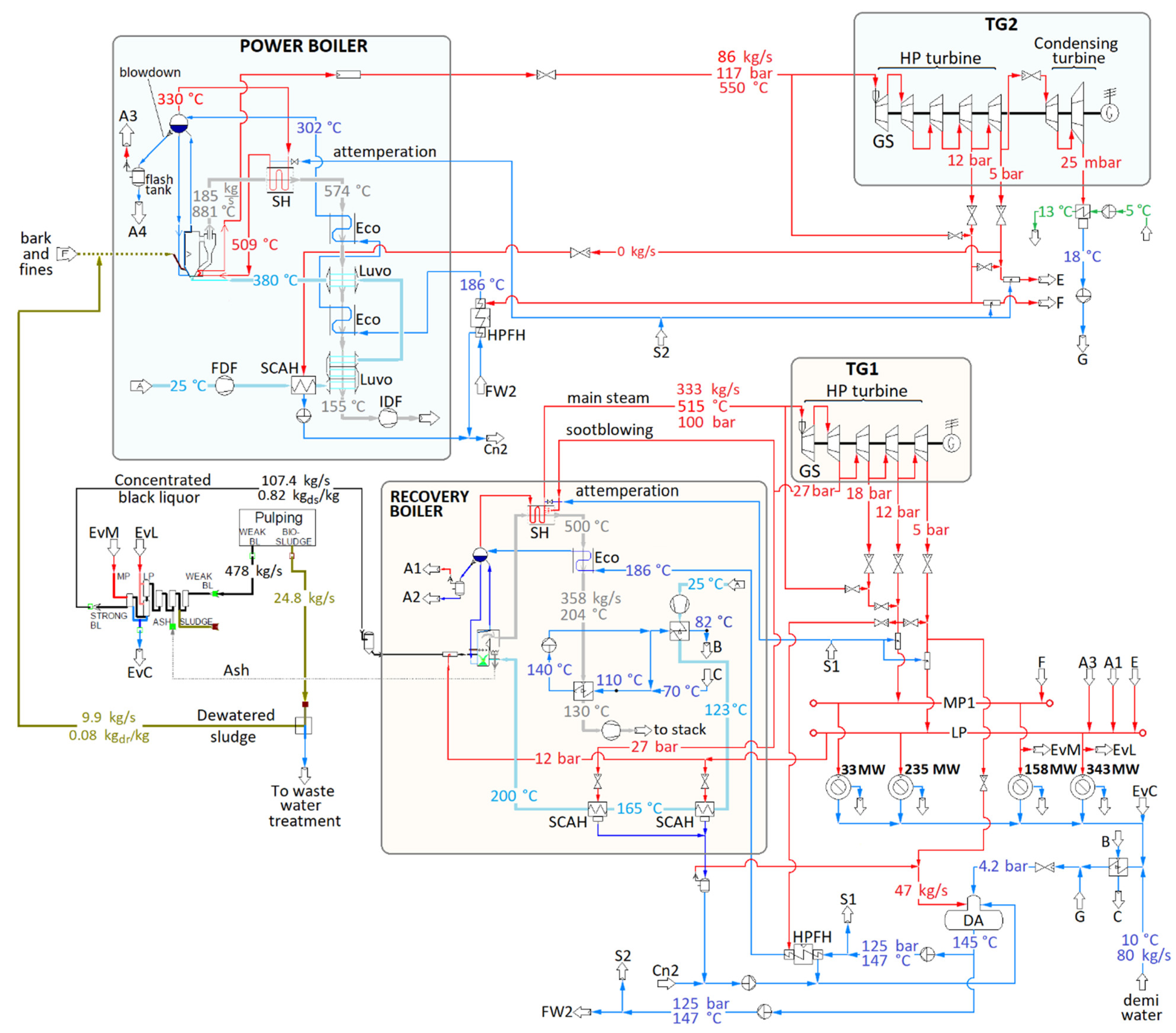

Figure 2 depicts the configuration of the boilers and steam cycles of the NorInt mill; Table 2 summarizes the main operating data and performance indicators. The NorPulp recovery boiler and turbogenerator are otherwise identical, except for the biosludge stream being sent to the evaporator plant, and the turbogenerator TG1 having the condensing tail, which in the integrated mill only the TG2 has.

Figure 2.

Boilers and steam cycles of the NorInt mill. The NorPulp recovery boiler and TG1 are otherwise similar, but, in the absence of power boiler, the dewatered sludge is mixed with black liquor in the evaporator plant, and the TG1 includes a condensing turbine. DA—deaerator; Eco—economizer; FDF—forced draft fan; GS—governing stage; HPFH—high pressure feed heater; IDF—induced draft fan; LP—low pressure; Luvo—air preheater; MP—medium pressure; SCAH—steam coil air heater; SH—superheater.

Table 2.

Operating data of the considered mills.

The NorPulp case has only the recovery boiler feeding steam to the sole turbogenerator. The turbine has a partial-admission governing stage with design-point isentropic expansion efficiency ηs of 0.70 from 100 bar inlet to 60 bar equalizing chamber, followed by a HP turbine, ηs = 0.909 and back pressure 5 bar(a), and finally a condensing LP turbine. At the base case, the inlet pressure of the LP turbine is 4.2 bar(a), the condenser pressure is 25 mbar, and ηs = 0.806. Dry efficiency variation due to flow rate change is determined according to Jüdes et al. [27] and corrected for possible moisture according to [28]. The variation of pressure ratios as a function of mass flow rate is modeled with the ellipse law by Traupel [29]. Determining the turbine efficiency and pressure level as a function of varying flows as well as the boiler and steam cycle heat exchanger calculation are described in more detail in [30]. The recovery boiler calculation is described in [31]; black liquor composition from the pulping process is identical to that of [32], with a slight change of final firing liquor composition due to biosludge being mixed with the black liquor in the evaporator plant.

In addition to the recovery boiler, identical to the one of NorPulp, the NorInt mill also has the CFB power boiler for combustion of bark and other solid wood residues. The biosludge is also combusted in the power boiler. Although less energy efficient than injecting the biosludge into the black liquor in the evaporator plant, this is usually the preferred option when available, as it avoids introducing the NPEs in the sludge to the chemical recovery cycle. The performance and operating parameters of the TG2 are largely similar to those of TG1, except for the slightly higher main steam parameters. A single high pressure feed heater operating with 12-bar(a) MP2 extraction steam is present for both boilers, for 186 °C final feedwater temperature.

2.2.2. HTC Process Models

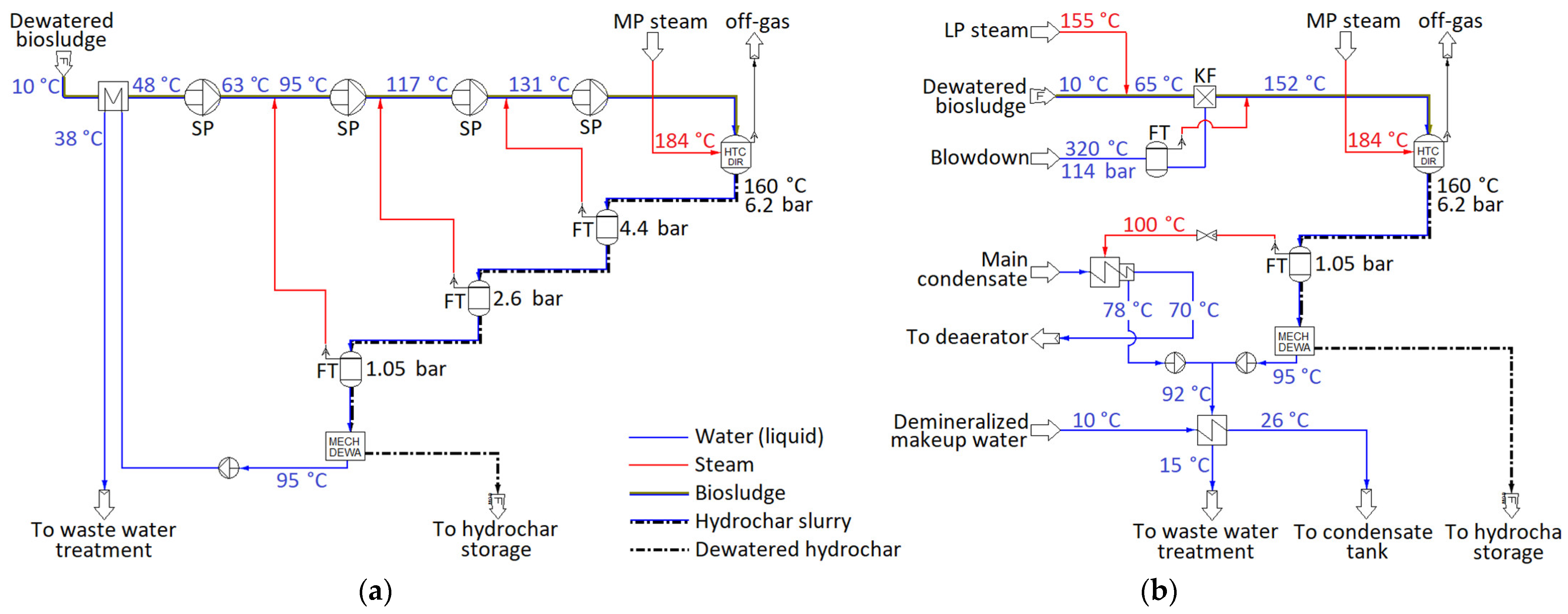

The HTC plant model is largely based on those presented originally in [20,30]. Two types of HTC plant design are considered. Case A represents a largely stand-alone plant, where heat recovery takes place entirely within the HTC plant recuperatively. The hydrochar slurry is depressurized through a series of flash tanks, and the flash vapor is injected to the feed slurry for pre-heating prior to entering the reactor. This necessitates pressurization in stages as well, in order to maintain a pressure gradient towards the feed while preventing boiling. A 5 °C safety margin to feed boiling point is maintained. The final heating to the 160 °C operating temperature is achieved with direct injection of 12 bar(a) MP steam to the reactor; otherwise the HTC plant performs as a stand-alone plant. The relatively low temperature of only 160 °C allows operating the system with small amounts of extraction steam at modest pressure levels.

Case A plant design is depicted in Figure 3a; the temperature levels represent typical magnitudes, but do not necessarily precisely match the precise results of any one calculated case: small variations of a few °C magnitude take place between the cases.

Figure 3.

Biosludge HTC treatment plants. Case A (a) represents a stand-alone plant with recuperative heat recovery connected to the mill only through the MP steam usage. Case B (b) represents a simplified HTC plant with waste heat recovery to the steam cycle.

Figure 3b depicts the Case B, the result of an attempt to both simplify the HTC process and improve its efficiency through heat integration with the steam cycle. The main difference from Case A is that instead of multiple stages of pressurization, depressurization, and recuperative heating, in Case B there are no slurry pumps, and only one flash tank for full depressurization of the hydrochar slurry.

Instead of using slurry pumps, the pressurization and initial feed slurry heating are achieved by using the drum blowdown water to simultaneously pressurize the sludge in a Kamyr feeder, add water, and bring the temperature to near the final carbonization temperature. As in Case A, 12 bar MP steam is again used for the final reactor heating, but a smaller amount is needed. The one-stage depressurization of the HTC takes advantage of the significant low-temperature heat sinks available in the steam cycle of the plant: the flash steam is used to heat the main condensate stream, while the hot water from the hydrochar slurry dewatering is used for heating the demineralized makeup water stream for the plant.

In both cases, the hydrochar is mechanically dewatered in a belt press. There are no data yet available on the dewatering characteristics of biosludge hydrochar in industrial-scale equipment. Although raw biosludge is difficult to dewater, the HTC treatment is known to transform untreated agro-industrial feedstocks into more easily dried hydrophobic char [33], and, equally importantly, the depressurization in the flash tanks produces a steam explosion to burst the cells, releasing the water trapped within. Primary sludges with little or no biosludge mixed in (<5%) can typically be dewatered to 30 ≤ xdr ≤ 50% dry solids contents in a belt press [34]. Based on the assumption that the hydrochar slurry would be unlikely to have worse drying characteristics, a final moisture content of 60% (xdr = 40%) is considered for the hydrochar after dewatering. The specific power consumption of the belt press is estimated at 20 kWhel/tdr [35].

3. Results and Discussion

3.1. Characterization and Yields of Feedstock and Products

Proximate and ultimate analyses along with the heating values of raw biosludge and hydrochar are shown in Table 3. The ultimate analyses, heating values, and yields of both are used in the simulation part of the work, while the proximate analysis gives an indication of the carbonization taking place during the HTC treatment.

Table 3.

Characterization analysis of feedstock and hydrochar (3 h at 160 °C) samples. All data are dry-basis, except for MC, which is mass fraction of wet sludge. The HHV was determined experimentally as described in Section 2.1.

The results indicate carbonization already taking place at the comparatively low temperature of 160 °C, with an approximately 7% reduction of volatiles over the raw sludge, and a broadly similar increase in fixed carbon. Raw biosludge is inherently difficult to dewater due to its gel-like structure consisting largely of intra-cellular water, as well as extra-cellular polymeric substances and interstitial water stored within the sludge flocs by capillary forces [24,36]. The hydrochar from HTC treatment of biosludge has increased hydrophobicity, an indicator of the reduction in the hydroxyl groups responsible for moisture adsorption [24].

The ash and elemental compositions of the sludge were confirmed to be typical for pulp mill biosludge: somewhat higher than reported for bleached kraft mill using eucalyptus [37], but below the values reported for the sludge of a Nordic mill [33]. HTC treatment failed to reduce the ash content. The elemental composition of the raw sludge, consisting largely of micro-organisms as well as some unsettled fibers and undigested organics, is fairly typical for a biomass, except for the high sulfur fraction. The Na2S used in the kraft pulping process results in a high 2.3% sulfur content in the sludge; typically waste from wood, e.g., fines and bark, would have <0.02% sulfur. Elemental composition change from HTC at only 160 °C is slight, with the small increase in carbon and decrease in oxygen being both expected, and in line with the increased HHV.

3.2. Plant Performance

3.2.1. Case NorPulp

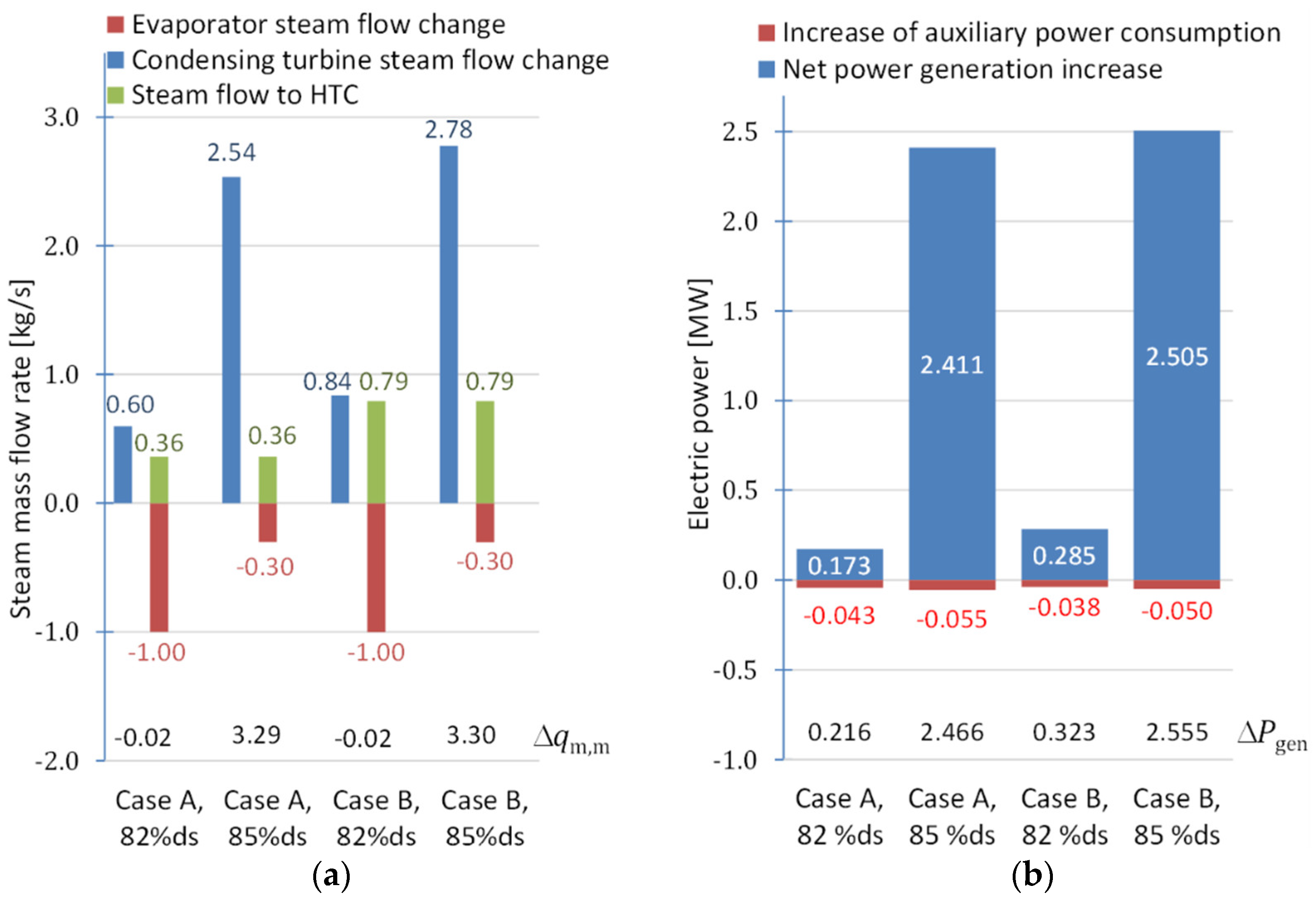

The central results of implementing biosludge HTC treatment in a pulp mill where the sludge or hydrochar are incinerated in the recovery boiler are visualized in Figure 4 in terms of changes in steam flow, Figure 4a, and power generation, Figure 4b. The main production and input data for the NorPulp case are listed in Table 4.

Figure 4.

Change of NorPulp plant steam production and use (a), and power generation (b) with HTC treatment of biosludge.

Table 4.

Plant performances with different NorPulp cases considered.

It is evident that while the results of HTC plant configurations A and B are relatively similar, there is a considerable difference between the assumptions of constant firing liquor dry solids and using the evaporator plant capacity released by biosludge water removal to increase the dry solids content to 85%.

Main steam production changes, shown at the bottom of Figure 4a, are negligible when the firing liquor dry solids content remains constant at 82%. The total steam consumption of the evaporator plant is reduced by approximately 1 kg/s with both HTC process configurations; this is partially offset by the additional (but smaller in magnitude) steam consumption of the HTC system. Although the configuration B consumes more than twice as much steam as the configuration A, there still remains slightly more additional steam flow for the condensing turbine with case B. This is due to the use of the makeup water and main condensate as heat sinks in heat recovery system of the configuration B, resulting in reduced steam need for the deaerator, translating to increased steam flow to the condensing turbine, and a 65% greater increase in power generation. The additional auxiliary power consumption of both schemes are very small, but still, at only 0.3 MW, it appears highly unlikely that even the configuration B could be a cost-effective way of increasing the energy efficiency of the plant, if the firing liquor dry solids content cannot be increased.

The situation becomes very different when an increase of firing liquor dry solids from 82% to 85% is assumed: with xds = 85%, approximately 3.3 kg/s of main steam flow increase is obtained as less energy is lost with evaporating the firing liquor moisture. This results in a more significant increase in power generation of well over 2 MW. Again, the configuration B provides slightly better figures by a very small margin of approximately 0.1 MW. The auxiliary power consumption increases at xds = 85% are slightly smaller than with the constant xds. Although the power consumptions of the HTC plants remain unchanged, with the drier firing liquor, the boiler and steam cycle auxiliary consumptions change somewhat: the reduction in induced draft fan power consumption due to the slightly reduced flue gas flow rate is approximately equal and opposite to the increase in feedwater pump power consumption due to the increased flow rate. Overall, the change can be considered negligible.

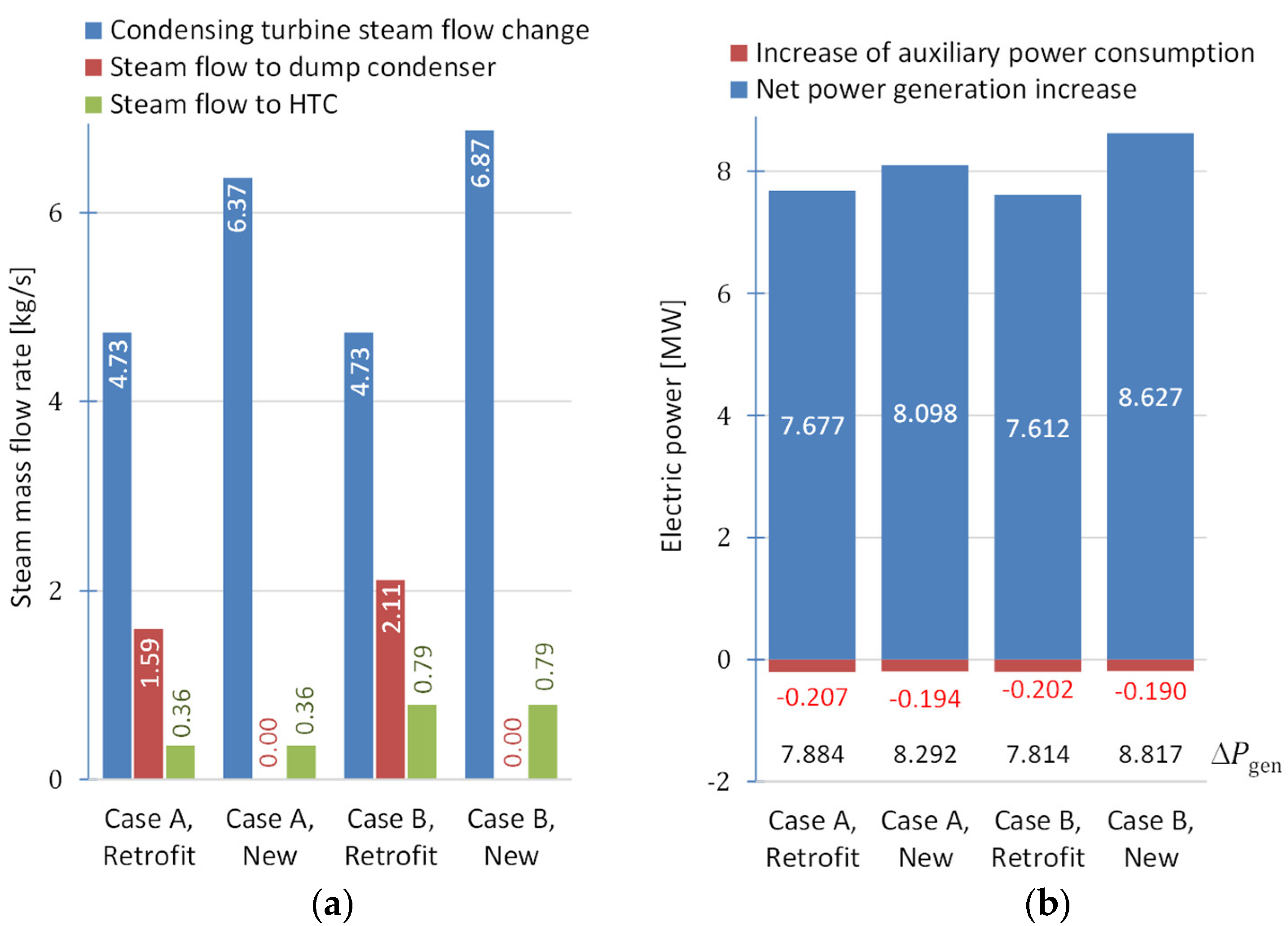

3.2.2. Case NorInt

The central results of implementing biosludge HTC treatment are visualized in Figure 5 in terms of changes in steam flow, Figure 5a, and power generation, Figure 5b. The main production and input data for the NorInt case are listed in Table 5.

Figure 5.

Change of NorInt plant steam production and use (a), and power generation (b) with biosludge HTC treatment. In all cases, CFB boiler main steam production for TG2 increases by 9.24 kg/s. KRB and TG1 remain unchanged.

Table 5.

Plant performances with different NorInt cases considered.

The main difference from the pure pulp mill of NorPulp is that here the considerable amount of water in the sludge is not reduced efficiently in a multiple-effect evaporator plant, but is introduced in its entirety to the CFB boiler furnace, resulting in a significant loss of lower heating value, and thus steam generation. When the hydrochar is dewatered to 60% moisture, the result is an over 9 kg/s (33 t/h) increase in boiler main steam production. The increase in steam flow is enough that the swallowing capacity of the condensing turbine becomes insufficient for the increased steam flow, and approximately 2 kg/s must be dumped to the auxiliary condenser with the retrofit-HTC cases; nevertheless, with the much-increased flow through the HP turbine, a 7.8 MW net power generation increase is still achieved; at most a further 0.4 MW (HTC plant A) or 1.0 MW (plant B) could be achieved, if a new turbine were to be ideally sized for a mill with HTC treatment of the sludge. As with the case of NorPulp, the steam and power consumptions of the HTC plants are small.

4. Conclusions

Pulp and paper mill biosludge is in many ways a problematic residue to dispose of. As landfilling is increasingly prohibited by legislation, incineration in a boiler has become the usual method of disposal, although the combination of very high moisture and resistance to dewatering/drying makes it a problematic fuel. Injection to black liquor in the evaporator plant for combustion in the recovery boiler is typically avoided when possible, in order to not introduce non-process elements to the chemical recovery cycle; this is none the less possible, however, and not an uncommon practice in the absence of a biomass-fired power boiler. If a biomass-fired power boiler is present, this is usually the preferred method of disposal, but here the very high moisture is a particularly significant drawback, resulting in negative lower heating value and loss of steam and power generation.

Hydrothermal carbonization (HTC) technology improves the characteristics of biosludge by converting the difficult-to-dry sludge into a hydrophobic char, while also slightly increasing the energy density of the dry solids. Low-temperature HTC treatment has the potential for considerable energy efficiency and power generation improvement in those kraft pulp mills where the biosludge is being incinerated in the power boiler.

If the biosludge is incinerated in the recovery boiler, the efficient drying in the evaporator means that power generation and efficiency would improve only very little through evaporator steam consumption reduction. Although an economic analysis was ruled beyond the scope of the work, these improvements are clearly too small to be cost-efficient. However, if the freed evaporator plant capacity can be utilized to increase the firing liquor dry solids content, a more significant and potentially cost-effective power generation increase can be achieved, albeit still only approximately one quarter of the considerable increase achieved if the biosludge is combusted in the power boiler.

Both with the combustion in the recovery or the power boiler, a slightly better overall energy efficiency was achieved by a simplified HTC plant configuration without recuperative feed slurry heating, using greater quantities of steam to heat the sludge to reactor temperature, and utilizing the steam cycle and boiler as heat sinks for the heat recovery instead.

While some uncertainty remains over the translation of laboratory-scale experimental results to industrial-scale equipment performance, this shortcoming of the obtained results is considered both practically inevitable and of comparatively small practical significance as there is no reason to expect large differences of performance due to scale. In order to evaluate the practical feasibility of the proposed low-temperature HTC treatment solution, the authors are currently working on techno-economic and life-cycle analyses on the basis of the experimental and simulation results obtained here.

Finally, it should also be noted that even if the HTC treatment fails to achieve cost-effectiveness on grounds of energy efficiency, if the result is that the hydrochar, unlike the raw sludge, could be disposed of by means other than incineration, the HTC treatment could still be an overall cost-effective solution for the mill. Such alternatives for on-site incineration could be, e.g., selling the char for use as a solid biofuel, adsorbent, or soil improvement use [24]. More research on potential applications, their requirements for the hydrochar quality, and process demands for achieving such qualities in the hydrochar are needed in the future.

Author Contributions

Conceptualization, J.S. and C.M.-M.; methodology, J.S., C.M.-M., and E.S.; investigation, J.S. and E.S.; data curation, J.S.; writing—original draft preparation, J.S.; writing—review and editing, K.K., S.L., E.S., J.K., M.H., and C.M.-M.; visualization, J.S. and C.M.-M.; supervision, C.M.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors gratefully acknowledge the role of Jordan Banks in the HTC experiments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Meyer, T.; Amin, P.; Allen, D.G.; Tran, H. Dewatering of pulp and paper mill biosludge and primary sludge. J. Environ. Chem. Eng. 2018, 6, 6317–6321. [Google Scholar] [CrossRef]

- Tarnawski, W. Emission factors for combustion of biomass fuels in the pulp and paper mills. Fibres Text. East. Eur. 2004, 12, 91–95. [Google Scholar]

- Mainardis, M.; Goi, D. Pilot-UASB reactor tests for anaerobic valorisation of high-loaded liquid substrates in friulian mountain area. J. Environ. Chem. Eng. 2019, 7, 103348. [Google Scholar] [CrossRef]

- Patel, K.; Patel, N.; Vaghamshi, N.; Shah, K.; Duggirala, S.M.; Dudhagara, P. Trends and strategies in the effluent treatment of pulp and paper industries: A review highlighting reactor options. Curr. Res. Microb. Sci. 2021, 2, 100077. [Google Scholar] [CrossRef]

- Karr, P.; Keinath, T.M. Influence of particle size on sludge dewaterability. J. Water Pollut. Control Fed. 1978, 50, 1911–1930. [Google Scholar]

- Judd, S. Chemical Sludge Conditioning—Sludge Processing. Available online: https://www.sludgeprocessing.com/sludge-conditioning/chemical-sludge-conditioning/ (accessed on 17 August 2022).

- Pöyry Environment Oy State of Sludgehandling in Finland and Competitiveness of Handling Methods; Sitra: Helsinki, Finland, 2007.

- Liimatainen, P. Alternative handling methods of the wastewater sludges in forest industry. Technical Report, LTKK-EN-B136, 2000.

- Räty, H. Techno-Economic Analysis of Sludge Dewatering. Master’s Thesis, LUT University, Lappeenranta, Finland, 2019. [Google Scholar]

- Thunberg, A. Optimizing Sludge Dewatering by Using the KemiCond® Process with the Bucher Hydraulic Filter Press—Full Scale Experiences at Käppala WWTP. Proc. Water Environ. Fed. 2010, 11, 225–235. [Google Scholar]

- Stoica, A.; Sandberg, M.; Holby, O. Energy use and recovery strategies within wastewater treatment and sludge handling at pulp and paper mills. Bioresour. Technol. 2009, 100, 3497–3505. [Google Scholar] [CrossRef]

- Feagley, S.E.; Valdez, M.S.; Hudnall, W.H. Papermill Sludge, Phosphorus, Potassium, and Lime Effect on Clover Grown on a Mine Soil. J. Environ. Qual. 1994, 23, 759–765. [Google Scholar] [CrossRef]

- Kost, D.A.; Boutelle, D.A.; Larson, M.M.; Smith, W.D.; Vimmerstedt, J.P. Papermill Sludge Amendments, Tree Protection, and Tree Establishment on an Abandoned Coal Minesoil. J. Environ. Qual. 1997, 26, 1409–1416. [Google Scholar] [CrossRef]

- Carpenter, A.F.; Fernandez, I.J. Pulp.p Sludge as a Component in Manufactured Topsoil. J. Environ. Qual. 2000, 29, 387–397. [Google Scholar] [CrossRef]

- Chong, C.; Cline, R.A. Response of Four Ornamental Shrubs to Container Substrate Amended with Two Sources of Raw Paper Mill Sludge. HortScience 1993, 28, 807–809. [Google Scholar] [CrossRef]

- Norrie, J.; Gosselin, A. Paper sludge amendments for turfgrass. HortScience 1996, 31, 957–960. [Google Scholar] [CrossRef] [Green Version]

- Mäkelä, M.; Benavente, V.; Fullana, A. Hydrothermal carbonization of lignocellulosic biomass: Effect of process conditions on hydrochar properties. Appl. Energy 2015, 155, 576–584. [Google Scholar] [CrossRef]

- Libra, J.A.; Ro, K.S.; Kammann, C.; Funke, A.; Berge, N.D.; Neubauer, Y.; Titirici, M.M.; Fühner, C.; Bens, O.; Kern, J.; et al. Hydrothermal carbonization of biomass residuals: A comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2011, 2, 71–106. [Google Scholar] [CrossRef]

- Mendoza Martinez, C.L.; Sermyagina, E.; Saari, J.; Silva de Jesus, M.; Cardoso, M.; Matheus de Almeida, G.; Vakkilainen, E. Hydrothermal carbonization of lignocellulosic agro-forest based biomass residues. Biomass Bioenergy 2021, 147, 106004. [Google Scholar] [CrossRef]

- Funke, A.; Ziegler, F. Hydrothermal carbonization of biomass: A summary and discussion of chemical mechanisms for process engineering. Biofuels Bioprod. Biorefining 2010, 4, 160–177. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Broch, A.; Robbins, C. Hydrothermal carbonization (HTC) of lignocellulosic biomass. Energy Fuels 2011, 25, 1802–1810. [Google Scholar] [CrossRef]

- Alatalo, S.M.; Repo, E.; Mäkilä, E.; Salonen, J.; Vakkilainen, E.; Sillanpää, M. Adsorption behavior of hydrothermally treated municipal sludge & pulp and paper industry sludge. Bioresour. Technol. 2013, 147, 71–76. [Google Scholar] [CrossRef]

- Martinez, C.L.M.; Sermyagina, E.; Vakkilainen, E. Hydrothermal Carbonization of Chemical and Biological Pulp Mill Sludges. Energies 2021, 14, 5693. [Google Scholar] [CrossRef]

- Harila, P.; Kivilinna, V.A. Biosludge incineration in a recovery boiler. Water Sci. Technol. 1999, 40, 195–200. [Google Scholar] [CrossRef]

- Kuparinen, K.; Vakkilainen, E.; Tynjälä, T. Biomass-based carbon capture and utilization in kraft pulp mills. Mitig. Adapt. Strateg. Glob. Chang. 2019, 24, 1213–1230. [Google Scholar] [CrossRef]

- Jüdes, M.; Vigerske, S.; Tsatsaronis, G. Optimization of the Design and Partial-Load Operation of Power Plants Using Mixed-Integer Nonlinear Programming. In Optimization in the Energy Industry; Springer: Berlin/Heidelberg, Germany, 2009; pp. 193–220. [Google Scholar] [CrossRef] [Green Version]

- Sanders, W.P. Turbine Steam Path Vol. 3a-Mechanical Design and Manufacture; PennWell: Tulsa, OK, USA, 2004. [Google Scholar]

- Traupel, W. Thermische Turbomaschinen: 1. Thermodynamisch-Strömungstechnische Berechnung; Springer: Berlin, Germany, 1966. [Google Scholar]

- Saari, J.; Kuparinen, K.; Sermyagina, E.; Vakkilainen, E.; Kaikko, J.; Sergeev, V. Effect of integration method and carbonization temperature on the performance of an integrated hydrothermal carbonization and CHP plant. BioResources 2018, 13, 5080–5110. [Google Scholar] [CrossRef]

- Axegård, P. C-Green‘s HTC-solution for conversion of biosludge to hydrochar. In Proceedings of the 2nd International Symposium on Hydrothermal Carbonization, Berlin, Germany, 14–16 May 2017. [Google Scholar]

- Saari, J.; Sermyagina, E.; Kaikko, J.; Haider, M.; Hamaguchi, M.; Vakkilainen, E. Evaluation of the Energy Efficiency Improvement Potential through Back-End Heat Recovery in the Kraft Recovery Boiler. Energies 2021, 14, 1550. [Google Scholar] [CrossRef]

- Kuokkanen, T.; Nurmesniemi, H.; Pöykiö, R.; Kujala, K.; Kaakinen, J.; Kuokkanen, M. Chemical and leaching properties of paper mill sludge. Chem. Speciat. Bioavailab. 2015, 20, 111–122. [Google Scholar] [CrossRef]

- Bajpai, P. Basic Overview of Pulp and Paper Manufacturing Process. In Green Chemistry and Sustainability in Pulp and Paper Industry; Springer: Cham, Switzerland, 2015; pp. 11–39. [Google Scholar] [CrossRef]

- Ding, L.; Ter Harmsel, M.; Yee, T.W. A geotextile tube contribution to carbon footprint savings at Tianjin Eco-City, China. In Proceedings of the 10th International International Conference on Geosynthetics (10ICG), Berlin, Germany, 21–25 September 2014; pp. 2133–2141. [Google Scholar]

- Mowla, D.; Tran, H.N.; Allen, D.G. A review of the properties of biosludge and its relevance to enhanced dewatering processes. Biomass Bioenergy 2013, 58, 365–378. [Google Scholar] [CrossRef]

- do Carmo Precci Lopes, A.; Mudadu Silva, C.; Pereira Rosa, A.; de Ávila Rodrigues, F. Biogas production from thermophilic anaerobic digestion of kraft pulp mill sludge. Renew. Energy 2018, 124, 40–49. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).