Review on Innovative Piezoelectric Materials for Mechanical Energy Harvesting

Abstract

:1. Introduction

2. Lead-Free Materials

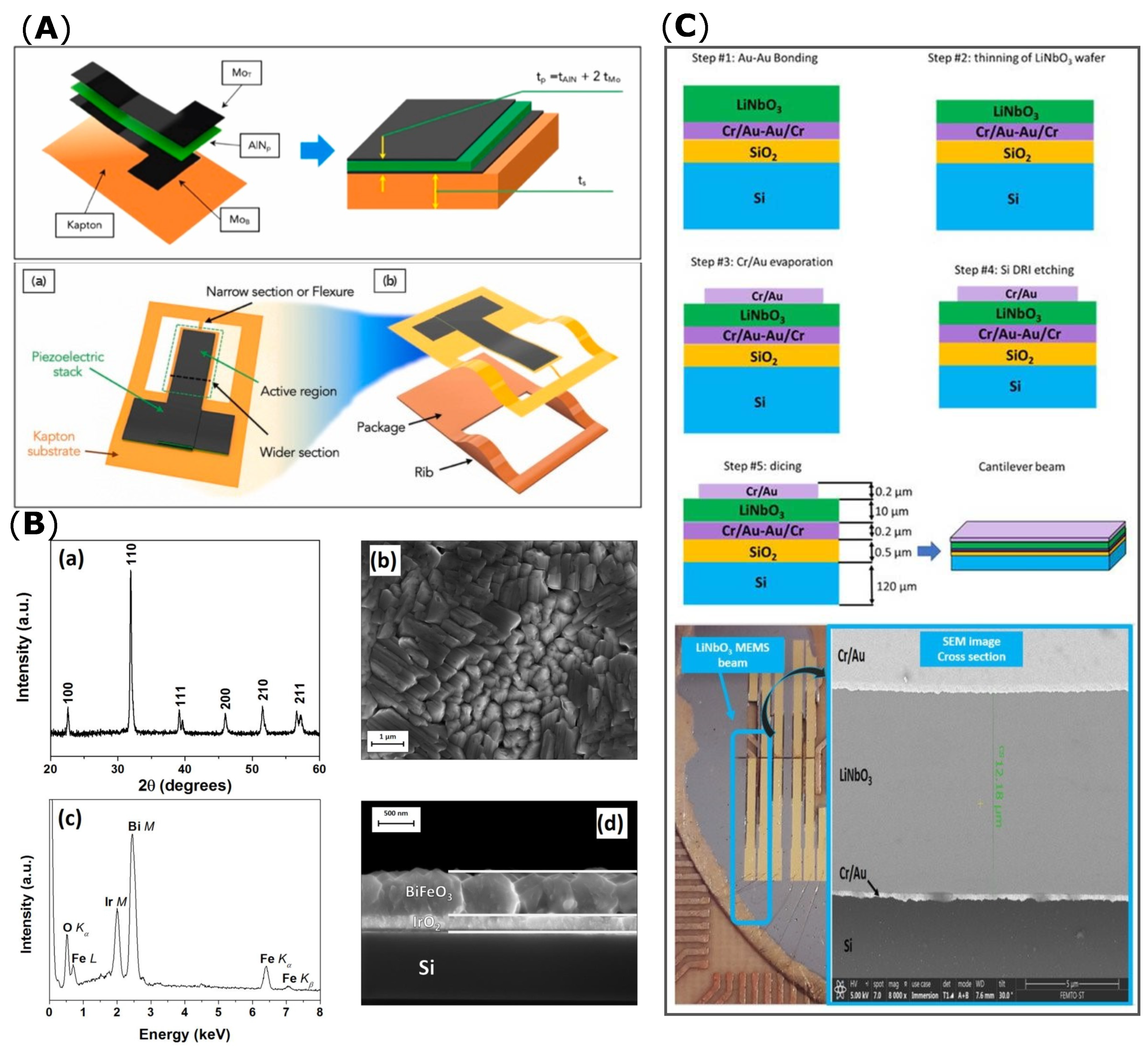

2.1. AlN

2.2. BiNaTiO and BaTiO

2.3. BiFeO

| Material | T | Ref. | ||||

|---|---|---|---|---|---|---|

| (pm/ N) | (pC/N) | (°C) | ||||

| PZT-5H | 15.9 | 3935 | 320 | 0.44 | 200 | [155] |

| AlN | 3.5 | 9.5 | 2 | 0.12 | - | [156] |

| BaTiO | 8.1 | 168 | 35 | 0.32 | 120 | [162] |

| BiFeO | - | 120 | - | 0.1 | 850 | [46] |

| KNN | 8.2 | 496 | 51 | 0.27 | 420 | [168] |

| LiNbO (YXlt)/128°/90° | 6.9 | 50.5 | 27 | 0.49 | 1150 | [169] |

| PVDF | 239 | 13 | 23.9 | 0.14 | 80 | [64] |

| ZnO | 7.9 | 11 | 5.2 | 0.19 | - | [170] |

2.4. KNN

2.5. LiNbO

2.6. PVDF

2.7. ZnO

3. Organic Materials

3.1. From Sustainable to Biodegradable Solutions

3.2. From Biodegradable to Biological Transducers

4. Electrets

Applications

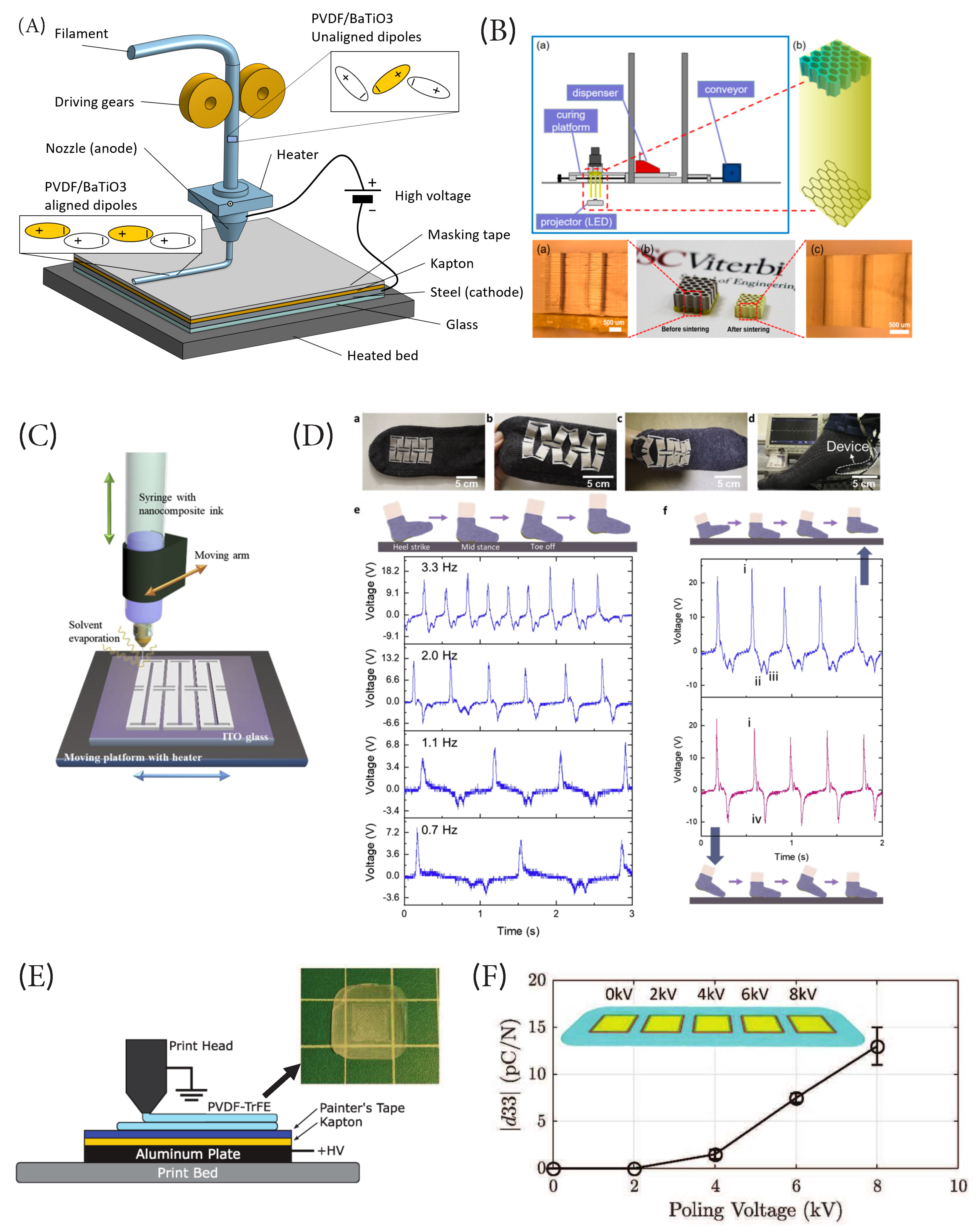

5. 3D Printed Materials

5.1. Piezoceramic Composites

5.2. Piezoelectric Polymers

6. Low Dimensional Materials

6.1. 2D Materials

6.2. 1D Materials

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Piezoelectric Materials Zoo

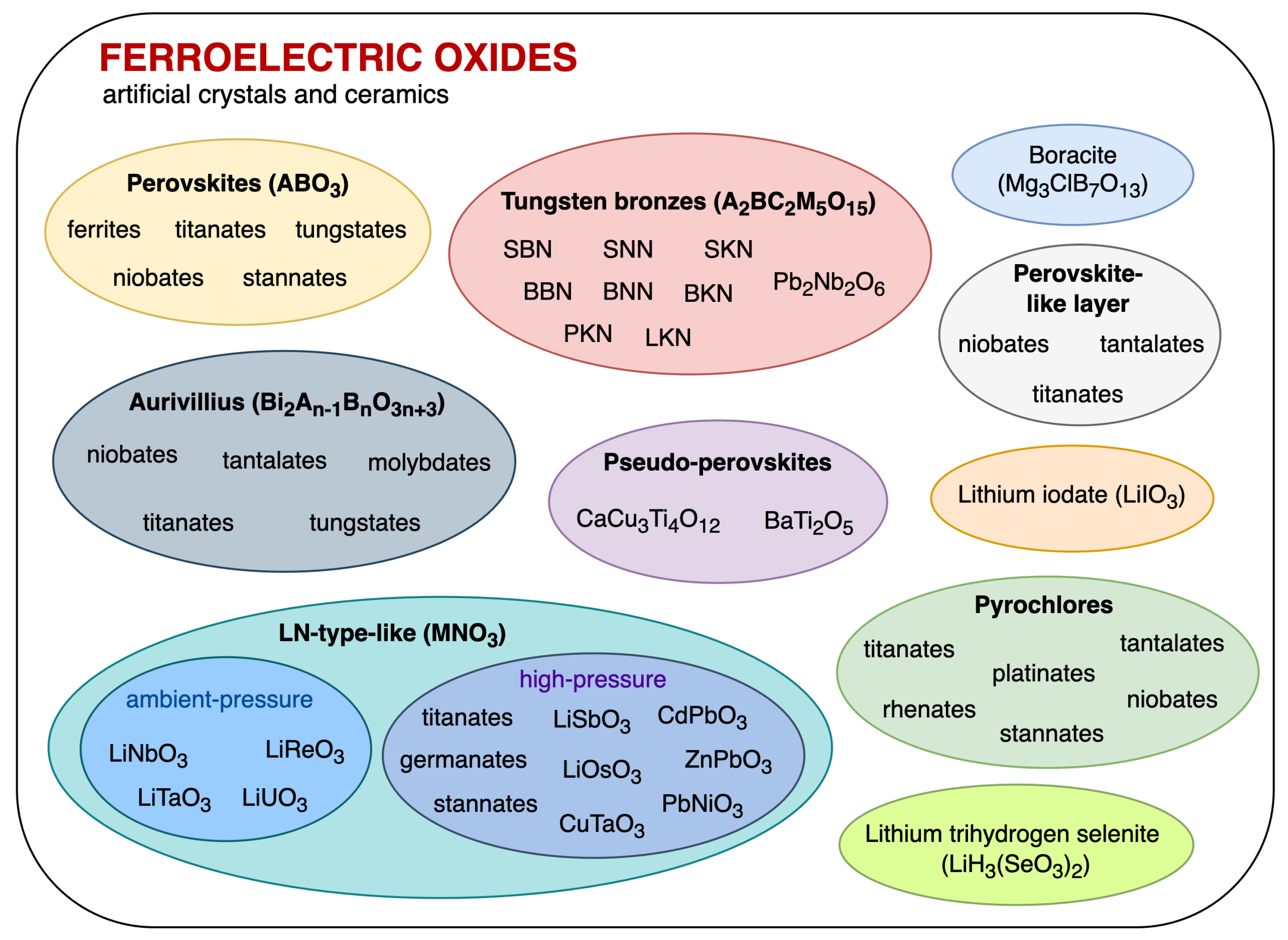

Appendix A.1. Ferroelectric Oxides

Appendix A.2. Quartz and Non-Ferroelectric Oxides

Appendix A.3. Salts

Appendix A.4. Semiconductors and Metals

Appendix A.5. Organic Materials

References

- Spillman, W.B.; Sirkis, J.S.; Gardiner, P.T. Smart materials and structures: What are they? Smart Mater. Struct. 1996, 5, 247–254. [Google Scholar] [CrossRef]

- Bogue, R. Smart materials: A review of capabilities and applications. Assem. Autom. 2014, 34, 16–22. [Google Scholar] [CrossRef]

- Orfei, F.; Neri, I.; Vocca, H.; Gammaitoni, L. Nonlinear bi-stable vibration energy harvester at work. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Buffalo, NY, USA, 17–20 August 2014; American Society of Mechanical Engineers: New York, NY, USA, 2014; Volume 46414, p. V008T11A091. [Google Scholar]

- Peterson, J.; Lopes, V.; Cunha, A., Jr. On the nonlinear dynamics of a bi-stable piezoelectric energy harvesting device. In Proceedings of the 24th ABCM International Congress of Mechanical Engineering (COBEM 2017), Curitiba, Brazil, 3–8 December 2017. [Google Scholar]

- Vocca, H.; Cottone, F.; Neri, I.; Gammaitoni, L. A comparison between nonlinear cantilever and buckled beam for energy harvesting. Eur. Phys. J. Spec. Top. 2013, 222, 1699–1705. [Google Scholar] [CrossRef]

- Sharma, P.K.; Baredar, P.V. Analysis on piezoelectric energy harvesting small scale device—A review. J. King Saud-Univ. 2019, 31, 869–877. [Google Scholar] [CrossRef]

- Cottone, F.; Mattarelli, M.; Vocca, H.; Gammaitoni, L. Effect of boundary conditions on piezoelectric buckled beams for vibrational noise harvesting. Eur. Phys. J. Spec. Top. 2015, 224, 2855–2866. [Google Scholar] [CrossRef]

- Neri, I.; Travasso, F.; Mincigrucci, R.; Vocca, H.; Orfei, F.; Gammaitoni, L. A real vibration database for kinetic energy harvesting application. J. Intell. Mater. Syst. Struct. 2012, 23, 2095–2101. [Google Scholar] [CrossRef]

- Lu, Y.; Juillard, J.; Cottone, F.; Galayko, D.; Basset, P. An impact-coupled MEMS electrostatic kinetic energy harvester and its predictive model taking nonlinear air damping effect into account. J. Microelectromech. Syst. 2018, 27, 1041–1053. [Google Scholar] [CrossRef]

- Kurt, E.; Cottone, F.; Uzun, Y.; Orfei, F.; Mattarelli, M.; Özhan, D. Design and implementation of a new contactless triple piezoelectrics wind energy harvester. Int. J. Hydrog. Energy 2017, 42, 17813–17822. [Google Scholar] [CrossRef]

- Lu, Y.; Cottone, F.; Boisseau, S.; Marty, F.; Galayko, D.; Basset, P. A nonlinear MEMS electrostatic kinetic energy harvester for human-powered biomedical devices. Appl. Phys. Lett. 2015, 107, 253902. [Google Scholar] [CrossRef]

- Peterson, J.V.L.L.; Lopes, V.G.; Cunha Jr, A. Maximization of the electrical power generated by a piezo-magneto-elastic energy harvesting device. In Proceeding Series of the Brazilian Society of Computational and Applied Mathematics; Sociedade de Matemática Aplicada e Computacional: São Carlos, SP, USA, 2017; Volume 5. [Google Scholar]

- Cunha, A. Enhancing the performance of a bistable energy harvesting device via the cross-entropy method. Nonlinear Dyn. 2021, 103, 137–155. [Google Scholar] [CrossRef]

- Izadgoshasb, I.; Lim, Y.Y.; Lake, N.; Tang, L.; Padilla, R.V.; Kashiwao, T. Optimizing orientation of piezoelectric cantilever beam for harvesting energy from human walking. Energy Convers. Manag. 2018, 161, 66–73. [Google Scholar] [CrossRef]

- Vocca, H.; Neri, I.; Travasso, F.; Gammaitoni, L. Kinetic energy harvesting with bistable oscillators. Appl. Energy 2012, 97, 771–776. [Google Scholar] [CrossRef]

- Liu, H.; Zhong, J.; Lee, C.; Lee, S.W.; Lin, L. A comprehensive review on piezoelectric energy harvesting technology: Materials, mechanisms, and applications. Appl. Phys. Rev. 2018, 5, 041306. [Google Scholar] [CrossRef]

- Tian, W.; Ling, Z.; Yu, W.; Shi, J. A review of MEMS scale piezoelectric energy harvester. Appl. Sci. 2018, 8, 645. [Google Scholar] [CrossRef]

- Wei, H.; Wang, H.; Xia, Y.; Cui, D.; Shi, Y.; Dong, M.; Liu, C.; Ding, T.; Zhang, J.; Ma, Y.; et al. An overview of lead-free piezoelectric materials and devices. J. Mater. Chem. C 2018, 6, 12446–12467. [Google Scholar] [CrossRef]

- Elahi, H.; Eugeni, M.; Gaudenzi, P. A review on mechanisms for piezoelectric-based energy harvesters. Energies 2018, 11, 1850. [Google Scholar] [CrossRef]

- Li, X.; Sun, M.; Wei, X.; Shan, C.; Chen, Q. 1D piezoelectric material based nanogenerators: Methods, materials and property optimization. Nanomaterials 2018, 8, 188. [Google Scholar] [CrossRef]

- Safaei, M.; Sodano, H.A.; Anton, S.R. A review of energy harvesting using piezoelectric materials: State-of-the-art a decade later (2008–2018). Smart Mater. Struct. 2019, 28, 113001. [Google Scholar] [CrossRef]

- Covaci, C.; Gontean, A. Piezoelectric energy harvesting solutions: A review. Sensors 2020, 20, 3512. [Google Scholar] [CrossRef]

- Mahapatra, S.D.; Mohapatra, P.C.; Aria, A.I.; Christie, G.; Mishra, Y.K.; Hofmann, S.; Thakur, V.K. Piezoelectric materials for energy harvesting and sensing applications: Roadmap for future smart materials. Adv. Sci. 2021, 8, 2100864. [Google Scholar] [CrossRef]

- Aabid, A.; Raheman, M.A.; Ibrahim, Y.E.; Anjum, A.; Hrairi, M.; Parveez, B.; Parveen, N.; Mohammed Zayan, J. A systematic review of piezoelectric materials and energy harvesters for industrial applications. Sensors 2021, 21, 4145. [Google Scholar] [CrossRef]

- Sezer, N.; Koç, M. A comprehensive review on the state-of-the-art of piezoelectric energy harvesting. Nano Energy 2021, 80, 105567. [Google Scholar] [CrossRef]

- Heidrich, N.; Knobber, F.; Sah, R.E.; Pletschen, W.; Hampl, S.; Cimalla, V.; Lebedev, V. Biocompatible AlN-based piezo energy harvesters for implants. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011. [Google Scholar]

- Algieri, L.; Todaro, M.T.; Guido, F.; Mastronardi, V.; Desmaële, D.; Qualtieri, A.; Giannini, C.; Sibillano, T.; Vittorio, M.D. Flexible Piezoelectric Energy-Harvesting Exploiting Biocompatible AlN Thin Films Grown onto Spin-Coated Polyimide Layers. ACS Appl. Energy Mater. 2018, 1, 5203–5210. [Google Scholar] [CrossRef]

- Jackson, N.; Keeney, L.; Mathewson, A. Flexible-CMOS and biocompatible piezoelectric AlN material for MEMS applications. Smart Mater. Struct. 2013, 22, 115033. [Google Scholar] [CrossRef]

- Marzencki, M.; Ammar, Y.; Basrour, S. Integrated power harvesting system including a MEMS generator and a power management circuit. Sens. Actuators A Phys. 2008, 145–146, 363–370. [Google Scholar] [CrossRef]

- Elfrink, R.; Renaud, M.; Kamel, T.M.; Nooijer, C.D.; Jambunathan, M.; Goedbloed, M.; Hohlfeld, D.; Matova, S.; Pop, V.; Caballero, L.; et al. Vacuum-packaged piezoelectric vibration energy harvesters: Damping contributions and autonomy for a wireless sensor system. J. Micromech. Microeng. 2010, 20, 104001. [Google Scholar] [CrossRef]

- Elfrink, R.; Kamel, T.M.; Goedbloed, M.; Matova, S.; Hohlfeld, D.; Van Andel, Y.; Van Schaijk, R. Vibration energy harvesting with aluminum nitride-based piezoelectric devices. J. Micromech. Microeng. 2009, 19, 249–252. [Google Scholar] [CrossRef]

- Alamin Dow, A.B.; Bittner, A.; Schmid, U.; Kherani, N.P. Design, fabrication and testing of a piezoelectric energy microgenerator. Microsyst. Technol. 2014, 20, 1035–1040. [Google Scholar] [CrossRef]

- Mayrhofer, P.M.; Rehlendt, C.; Fischeneder, M.; Kucera, M.; Wistrela, E.; Bittner, A.; Schmid, U. ScAlN MEMS Cantilevers for Vibrational Energy Harvesting Purposes. J. Microelectromech. Syst. 2017, 26, 102–112. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, B.; Cai, Y.; Zhou, J.; Liu, W.; Tovstopyat, A.; Wu, G.; Sun, C. Design and Performance of ScAlN/AlN Trapezoidal Cantilever-Based MEMS Piezoelectric Energy Harvesters. IEEE Trans. Electron Devices 2021, 68, 2971–2976. [Google Scholar] [CrossRef]

- Minh, L.V.; Hara, M.; Yokoyama, T.; Nishihara, T.; Ueda, M.; Kuwano, H. Highly piezoelectric MgZr co-doped aluminum nitride-based vibrational energy harvesters [Correspondence]. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 62, 2005–2008. [Google Scholar] [CrossRef]

- Cao, Z.; He, J.; Wang, Q.; Hara, M.; Oguchi, H.; Kuwano, H. High output power AlN vibration-driven energy harvesters. J. Phys. Conf. Ser. 2013, 476, 012034. [Google Scholar] [CrossRef]

- Jackson, N.; Stam, F.; Olszewski, O.Z.; Doyle, H.; Quinn, A.; Mathewson, A. Widening the bandwidth of vibration energy harvesters using a liquid-based non-uniform load distribution. Sens. Actuators A Phys. 2016, 246, 170–179. [Google Scholar] [CrossRef]

- Mariello, M.; Blad, T.W.; Mastronardi, V.M.; Madaro, F.; Guido, F.; Staufer, U.; Tolou, N.; Vittorio, M.D. Flexible piezoelectric AlN transducers buckled through package-induced preloading for mechanical energy harvesting. Nano Energy 2021, 85, 105986. [Google Scholar] [CrossRef]

- Dubey, A.K.; Thrivikraman, G.; Basu, B. Absence of systemic toxicity in mouse model towards BaTiO3 nanoparticulate based eluate treatment. J. Mater. Sci. Mater. Med. 2015, 26, 103. [Google Scholar] [CrossRef] [PubMed]

- Koka, A.; Zhou, Z.; Sodano, H.A. Vertically aligned BaTiO3 nanowire arrays for energy harvesting. Energy Environ. Sci. 2014, 7, 288–296. [Google Scholar] [CrossRef]

- Park, K.I.; Xu, S.; Liu, Y.; Hwang, G.T.; Kang, S.J.L.; Wang, Z.L.; Lee, K.J. Piezoelectric BaTiO3 thin film nanogenerator on plastic substrates. Nano Lett. 2010, 10, 4939–4943. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Guo, X.; Li, D.; Cui, B.; Wu, K.; Yun, J.; Mao, J.; Xi, L.; Zuo, Y. Hybrid nanogenerator of BaTiO3 nanowires and CNTs for harvesting energy. J. Mater. Sci. 2018, 53, 13081–13089. [Google Scholar] [CrossRef]

- Luo, C.; Hu, S.; Xia, M.; Li, P.; Hu, J.; Li, G.; Jiang, H.; Zhang, W. A Flexible Lead-Free BaTiO3/PDMS/C Composite Nanogenerator as a Piezoelectric Energy Harvester. Energy Technol. 2018, 6, 922–927. [Google Scholar] [CrossRef]

- You, H.; Jia, Y.; Wu, Z.; Xu, X.; Qian, W.; Xia, Y.; Ismail, M. Strong piezo-electrochemical effect of multiferroic BiFeO3 square micro-sheets for mechanocatalysis. Electrochem. Commun. 2017, 79, 55–58. [Google Scholar] [CrossRef]

- Aramaki, M.; Yoshimura, T.; Murakami, S.; Satoh, K.; Fujimura, N. Demonstration of high-performance piezoelectric MEMS vibration energy harvester using BiFeO3 film with improved electromechanical coupling factor. Sens. Actuators A Phys. 2019, 291, 167–173. [Google Scholar] [CrossRef]

- Yoshimura, T.; Murakami, S.; Wakazono, K.; Kariya, K.; Fujimura, N. Piezoelectric vibrational energy harvester using lead-free ferroelectric BiFeO3 films. Appl. Phys. Express 2013, 6, 2–6. [Google Scholar] [CrossRef]

- Yan, J.; Zhu, H.; Ouyang, J.; Kanno, I.; Yan, P.; Wang, Y.; Onishi, K.; Nishikado, T. Highly (00l)-textured BiFeO3 thick films integrated on stainless steel foils with an optimized piezoelectric performance. J. Eur. Ceram. Soc. 2022, 42, 3454–3462. [Google Scholar] [CrossRef]

- Ren, X.; Fan, H.; Zhao, Y.; Liu, Z. Flexible Lead-Free BiFeO3/PDMS-Based Nanogenerator as Piezoelectric Energy Harvester. ACS Appl. Mater. Interfaces 2016, 8, 26190–26197. [Google Scholar] [CrossRef]

- Gaukås, N.H.; Huynh, Q.S.; Pratap, A.A.; Einarsrud, M.A.; Grande, T.; Holsinger, R.M.D.; Glaum, J. In vitro biocompatibility of piezoelectric K0.5Na0.5NbO3 thin films on platinized silicon substrates. ACS Appl. Bio Mater. 2020, 3, 8714–8721. [Google Scholar] [CrossRef]

- Kanno, I.; Ichida, T.; Adachi, K.; Kotera, H.; Shibata, K.; Mishima, T. Power-generation performance of lead-free (K,Na)NbO3 piezoelectric thin-film energy harvesters. Sens. Actuators A Phys. 2012, 179, 132–136. [Google Scholar] [CrossRef]

- Shiraishi, T.; Kaneko, N.; Kurosawa, M.; Uchida, H.; Suzuki, Y.; Kobayashi, T.; Funakubo, H. Vibration-energy-harvesting properties of hydrothermally synthesized (K,Na)NbO3 films deposited on flexible metal foil substrates. Jpn. J. Appl. Phys. 2015, 54, 10ND06. [Google Scholar] [CrossRef]

- Hara, M.; Van Minh, L.; Oguchi, H.; Kuwano, H. New output power estimation method for cantilever-based piezoelectric energy harvesters. Jpn. J. Appl. Phys. 2014, 53, 07KE04. [Google Scholar] [CrossRef]

- Van Minh, L.; Hara, M.; Kuwano, H. High Performance Nonlinear Micro Energy Harvester Integrated with (K,Na)NbO3/Si Composite Quad-Cantilever. In Proceedings of the 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014; pp. 397–400. [Google Scholar]

- Tsujiura, Y.; Suwa, E.; Kurokawa, F.; Hida, H.; Suenaga, K.; Shibata, K.; Kanno, I. Lead-free piezoelectric MEMS energy harvesters of (K,Na)NbO3 thin films on stainless steel cantilevers. Jpn. J. Appl. Phys. 2013, 52, 09KD13. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, X.Y.; Chen, Z.; Cai, B.; Ye, Z.Z.; Gao, C.Y.; Huang, J.Y. Synthesis of cubic LiNbO3 nanoparticles and their application in vitro bioimaging. Appl. Phys. A Mater. Sci. Process. 2014, 117, 2121–2126. [Google Scholar] [CrossRef]

- Funasaka, T.; Furuhata, M.; Hashimoto, Y.; Nakamura, K. Piezoelectric generator using a LiNbO3 plate with an inverted domain. In Proceedings of the 1998 IEEE Ultrasonics Symposium, Proceedings (Cat. No. 98CH36102), Sendai, Japan, 5–8 October 1998; Volume 1, pp. 959–962. [Google Scholar]

- Clementi, G.; Lombardi, G.; Margueron, S.; Suarez, M.A.; Lebrasseur, E.; Ballandras, S.; Imbaud, J.; Lardet-Vieudrin, F.; Gauthier-Manuel, L.; Dulmet, B.; et al. LiNbO3 films—A low-cost alternative lead-free piezoelectric material for vibrational energy harvesters. Mech. Syst. Signal Process. 2021, 149, 107171. [Google Scholar] [CrossRef]

- Vidal, J.V.; Turutin, A.V.; Kubasov, I.V.; Kislyuk, A.M.; Malinkovich, M.D.; Parkhomenko, Y.N.; Kobeleva, S.P.; Pakhomov, O.V.; Sobolev, N.A.; Kholkin, A.L. Low-Frequency Vibration Energy Harvesting with Bidomain LiNbO3 Single Crystals. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2019, 66, 1480–1487. [Google Scholar] [CrossRef]

- Clementi, G.; Ouhabaz, M.; Margueron, S.; Suarez, M.A.; Bassignot, F.; Gauthier-Manuel, L.; Belharet, D.; Dulmet, B.; Bartasyte, A. Highly coupled and low frequency vibrational energy harvester using lithium niobate on silicon. Appl. Phys. Lett. 2021, 119, 013904. [Google Scholar] [CrossRef]

- Barrientos, G.; Clementi, G.; Trigona, C.; Ouhabaz, M.; Gauthier-Manuel, L.; Belharet, D.; Margueron, S.; Bartasyte, A.; Malandrino, G.; Baglio, S. Lead-Free LiNbO3 Thick Film MEMS Kinetic Cantilever Beam Sensor/Energy Harvester. Sensors 2022, 22, 559. [Google Scholar] [CrossRef]

- Panayanthattaa, N.; Costanza, M.; Basrour, S.; Dehollain, C.; Clementi, G.; Margueron, S.; Bano, E.; Rosa, R.L.; Ouhabaz, M.; Bartasyte, A.; et al. A Self-Powered and Battery-Free Vibrational Energy to Time Converter for Wireless Vibration Monitoring. Sensors 2021, 22, 7503. [Google Scholar] [CrossRef]

- Yu, Y.; Sun, H.; Orbay, H.; Chen, F.; England, C.G.; Cai, W.; Wang, X. Biocompatibility and in vivo operation of implantable mesoporous PVDF-based nanogenerators. Nano Energy 2016, 27, 275–281. [Google Scholar] [CrossRef]

- Zhang, L.; Gui, J.; Wu, Z.; Li, R.; Wang, Y.; Gong, Z.; Zhao, X.; Sun, C.; Guo, S. Enhanced performance of piezoelectric nanogenerator based on aligned nanofibers and three-dimensional interdigital electrodes. Nano Energy 2019, 65, 103924. [Google Scholar] [CrossRef]

- Song, J.; Zhao, G.; Li, B.; Wang, J. Design optimization of PVDF-based piezoelectric energy harvesters. Heliyon 2017, 3, e00377. [Google Scholar] [CrossRef]

- Khadtare, S.; Ko, E.J.; Kim, Y.H.; Lee, H.S.; Moon, D.K. A flexible piezoelectric nanogenerator using conducting polymer and silver nanowire hybrid electrodes for its application in real-time muscular monitoring system. Sens. Actuators A Phys. 2019, 299, 111575. [Google Scholar] [CrossRef]

- Pi, Z.; Zhang, J.; Wen, C.; bin Zhang, Z.; Wu, D. Flexible piezoelectric nanogenerator made of poly(vinylidenefluoride-co-trifluoroethylene) (PVDF-TrFE) thin film. Nano Energy 2014, 7, 33–41. [Google Scholar] [CrossRef]

- Maity, K.; Garain, S.; Henkel, K.; Schmeißer, D.; Mandal, D. Self-Powered Human-Health Monitoring through Aligned PVDF Nanofibers Interfaced Skin-Interactive Piezoelectric Sensor. ACS Appl. Polym. Mater. 2020, 2, 862–878. [Google Scholar] [CrossRef]

- Gopikrishnan, R.; Zhang, K.; Ravichandran, P.; Baluchamy, S.; Ramesh, V.; Biradar, S.; Ramesh, P.; Pradhan, J.; Hall, J.C.; Pradhan, A.K.; et al. Synthesis, characterization and biocompatibility studies of zinc oxide (ZnO) nanorods for biomedical application. Nanomicro Lett. 2010, 2, 31–36. [Google Scholar] [CrossRef]

- Pan, C.T.; Liu, Z.H.; Chen, Y.C.; Liu, C.F. Design and fabrication of flexible piezo-microgenerator by depositing ZnO thin films on PET substrates. Sens. Actuators A Phys. 2010, 159, 96–104. [Google Scholar] [CrossRef]

- Chang, W.T.; Chen, Y.C.; Lin, R.C.; Cheng, C.C.; Kao, K.S.; Huang, Y.C. Wind-power generators based on ZnO piezoelectric thin films on stainless steel substrates. Curr. Appl. Phys. 2011, 11, S333–S338. [Google Scholar] [CrossRef]

- Wang, P.; Du, H. ZnO thin film piezoelectric MEMS vibration energy harvesters with two piezoelectric elements for higher output performance. Rev. Sci. Instrum. 2015, 86, 075002. [Google Scholar] [CrossRef]

- Bhatia, D.; Sharma, H.; Meena, R.S.; Palkar, V.R. A novel ZnO piezoelectric microcantilever energy scavenger: Fabrication and characterization. Sens. Bio-Sens. Res. 2016, 9, 45–52. [Google Scholar] [CrossRef]

- Tao, K.; Yi, H.; Tang, L.; Wu, J.; Wang, P.; Wang, N.; Hu, L.; Fu, Y.; Miao, J.; Chang, H. Piezoelectric ZnO thin films for 2DOF MEMS vibrational energy harvesting. Surf. Coat. Technol. 2019, 359, 289–295. [Google Scholar] [CrossRef]

- Rodrigues, S.; Dionísio, M.; López, C.R.; Grenha, A. Biocompatibility of chitosan carriers with application in drug delivery. J. Funct. Biomater. 2012, 3, 615–641. [Google Scholar] [CrossRef]

- Hänninen, A.; Sarlin, E.; Lyyra, I.; Salpavaara, T.; Kellomäki, M.; Tuukkanen, S. Nanocellulose and chitosan based films as low cost, green piezoelectric materials. Carbohydr. Polym. 2018, 202, 418–424. [Google Scholar] [CrossRef]

- Talebi, H.; Ghasemi, F.A.; Ashori, A. The effect of nanocellulose on mechanical and physical properties of chitosan-based biocomposites. J. Elastomers Plast. 2022, 54, 22–41. [Google Scholar] [CrossRef]

- Ogawa, Y.; Azuma, K.; Izawa, H.; Morimoto, M.; Ochi, K.; Osaki, T.; Ito, N.; Okamoto, Y.; Saimoto, H.; Ifuku, S. Preparation and biocompatibility of a chitin nanofiber/gelatin composite film. Int. J. Biol. Macromol. 2017, 104, 1882–1889. [Google Scholar] [CrossRef]

- Khan, A.; Khan, F.R.; Kim, H.S. Electro-active paper as a flexible mechanical sensor, actuator and energy harvesting transducer: A review. Sensors 2018, 18, 3474. [Google Scholar] [CrossRef]

- Venezuela, J.; Dargusch, M.S. The influence of alloying and fabrication techniques on the mechanical properties, biodegradability and biocompatibility of zinc: A comprehensive review. Acta Biomater. 2019, 87, 1–40. [Google Scholar] [CrossRef]

- Manikandan, M.; Rajagopalan, P.; Patra, N.; Jayachandran, S.; Muralidharan, M.; Prabu, S.M.; Palani, I.; Singh, V. Development of Sn-doped ZnO based ecofriendly piezoelectric nanogenerator for energy harvesting application. Nanotechnology 2020, 31, 185401. [Google Scholar] [CrossRef]

- Ba, Y.; Bao, J.; Song, R.; Zhu, C.; Zhang, X. Printing paper-like piezoelectric energy harvesters based on natural cellulose nanofibrils. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019. [Google Scholar]

- Mahadeva, S.K.; Walus, K.; Stoeber, B. Piezoelectric paper fabricated via nanostructured barium titanate functionalization of wood cellulose fibers. ACS Appl. Mater. Interfaces 2014, 6, 7547–7553. [Google Scholar] [CrossRef]

- Asadi, N.; Del Bakhshayesh, A.R.; Davaran, S.; Akbarzadeh, A. Common biocompatible polymeric materials for tissue engineering and regenerative medicine. Mater. Chem. Phys. 2020, 242, 122528. [Google Scholar] [CrossRef]

- Trigona, C.; Graziani, S.; Di Pasquale, G.; Pollicino, A.; Nisi, R.; Licciulli, A. Green energy harvester from vibrations based on bacterial cellulose. Sensors 2019, 20, 136. [Google Scholar] [CrossRef]

- van Essen, T.H.; van Zijl, L.; Possemiers, T.; Mulder, A.A.; Zwart, S.J.; Chou, C.H.; Lin, C.C.; Lai, H.J.; Luyten, G.P.M.; Tassignon, M.J.; et al. Biocompatibility of a fish scale-derived artificial cornea: Cytotoxicity, cellular adhesion and phenotype, and in vivo immunogenicity. Biomaterials 2016, 81, 36–45. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Mandal, D. High-performance bio-piezoelectric nanogenerator made with fish scale. Appl. Phys. Lett. 2016, 109, 103701. [Google Scholar] [CrossRef]

- Tsukada, S.; Nakashima, H.; Torimitsu, K. Conductive polymer combined silk fiber bundle for bioelectrical signal recording. PLoS ONE 2012, 7, e33689. [Google Scholar] [CrossRef] [Green Version]

- Fukada, E. On the piezoelectric effect of silk fibers. J. Phys. Soc. Jpn. 1956, 11, 1301A. [Google Scholar] [CrossRef]

- Rising, A.; Widhe, M.; Johansson, J.; Hedhammar, M. Spider silk proteins: Recent advances in recombinant production, structure-function relationships and biomedical applications. Cell. Mol. Life Sci. 2011, 68, 169–184. [Google Scholar] [CrossRef] [PubMed]

- Karan, S.K.; Maiti, S.; Kwon, O.; Paria, S.; Maitra, A.; Si, S.K.; Kim, Y.; Kim, J.K.; Khatua, B.B. Nature driven spider silk as high energy conversion efficient bio-piezoelectric nanogenerator. Nano Energy 2018, 49, 655–666. [Google Scholar] [CrossRef]

- Pan, C.T.; Yen, C.K.; Hsieh, M.C.; Wang, S.Y.; Chien, C.H.; Huang, J.C.C.; Lin, L.; Shiue, Y.L.; Kuo, S.W. Energy harvesters incorporating silk from the Taiwan-native spider nephila pilipes. ACS Appl. Energy Mater. 2018, 1, 5627–5635. [Google Scholar] [CrossRef]

- Trigona, C.; Cunsolo, C.; Cardillo, G.D.L.; Rizza, M.; Baglio, S. Exploitation of a Spider Silk based Sensing Element. In Proceedings of the 2022 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Ottawa, ON, Canada, 16–19 May 2022; pp. 1–5. [Google Scholar]

- Sarwar, M.N.; Ullah, A.; Haider, M.K.; Hussain, N.; Ullah, S.; Hashmi, M.; Khan, M.Q.; Kim, I.S. Evaluating antibacterial efficacy and biocompatibility of PAN nanofibers loaded with diclofenac sodium salt. Polymers 2021, 13, 510. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Zheng, Y.; Sun, Y.; Jin, X.; Niu, J.; Cheng, M.; Wang, H.; Shao, H.; Lin, T. High-temperature piezoelectric conversion using thermally stabilized electrospun polyacrylonitrile membranes. J. Mater. Chem. A 2021, 9, 20395–20404. [Google Scholar] [CrossRef]

- Khandelwal, G.; Minocha, T.; Yadav, S.K.; Chandrasekhar, A.; Maria Joseph Raj, N.P.; Gupta, S.C.; Kim, S.J. All edible materials derived biocompatible and biodegradable triboelectric nanogenerator. Nano Energy 2019, 65, 104016. [Google Scholar] [CrossRef]

- Zhang, M.; Xiang, X.; Zhang, X.; Dai, Y. Tape-like Vibrational Energy Harvesters Using Flexible Fluorinated Polyethylene Propylene (FEP) Piezoelectret as Transduction Material. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 768–776. [Google Scholar] [CrossRef]

- Saxena, S.; Ray, A.R.; Kapil, A.; Pavon-Djavid, G.; Letourneur, D.; Gupta, B.; Meddahi-Pellé, A. Development of a new polypropylene-based suture: Plasma grafting, surface treatment, characterization, and biocompatibility studies. Macromol. Biosci. 2011, 11, 373–382. [Google Scholar] [CrossRef]

- Hillenbrand, J.; Pondrom, P.; Sessler, G.M. Electret transducer for vibration-based energy harvesting. Appl. Phys. Lett. 2015, 106, 183902. [Google Scholar] [CrossRef]

- Wu, N.; Cheng, X.; Zhong, Q.; Zhong, J.; Li, W.; Wang, B.; Hu, B.; Zhou, J. Cellular Polypropylene Piezoelectret for Human Body Energy Harvesting and Health Monitoring. Adv. Funct. Mater. 2015, 25, 4788–4794. [Google Scholar] [CrossRef]

- Kim, K.; Zhu, W.; Qu, X.; Aaronson, C.; McCall, W.R.; Chen, S.; Sirbuly, D.J. 3D optical printing of piezoelectric nanoparticle-polymer composite materials. ACS Nano 2014, 8, 9799–9806. [Google Scholar] [CrossRef]

- Kim, H.; Renteria-Marquez, A.; Islam, M.D.; Chavez, L.A.; Garcia Rosales, C.A.; Ahsan, M.A.; Tseng, T.B.; Love, N.D.; Lin, Y. Fabrication of bulk piezoelectric and dielectric BaTiO3 ceramics using paste extrusion 3D printing technique. J. Am. Ceram. Soc. 2019, 102, 3685–3694. [Google Scholar] [CrossRef]

- Chen, Z.; Song, X.; Lei, L.; Chen, X.; Fei, C.; Chiu, C.T.; Qian, X.; Ma, T.; Yang, Y.; Shung, K.; et al. 3D printing of piezoelectric element for energy focusing and ultrasonic sensing. Nano Energy 2016, 27, 78–86. [Google Scholar] [CrossRef]

- Zeng, Y.; Jiang, L.; Sun, Y.; Yang, Y.; Quan, Y.; Wei, S.; Lu, G.; Li, R.; Rong, J.; Chen, Y.; et al. 3D-Printing Piezoelectric Composite with Honeycomb Structure for Ultrasonic Devices. Micromachines 2020, 11, 713. [Google Scholar] [CrossRef]

- Gaytan, S.M.; Cadena, M.A.; Karim, H.; Delfin, D.; Lin, Y.; Espalin, D.; MacDonald, E.; Wicker, R.B. Fabrication of barium titanate by binder jetting additive manufacturing technology. Ceram. Int. 2015, 41, 6610–6619. [Google Scholar] [CrossRef]

- Chen, X.; Li, X.; Shao, J.; An, N.; Tian, H.; Wang, C.; Han, T.; Wang, L.; Lu, B. High-performance piezoelectric nanogenerators with imprinted P(VDF-TrFE)/BaTiO3 nanocomposite micropillars for self-powered flexible sensors. Small 2017, 13, 1604245. [Google Scholar] [CrossRef]

- Zhou, X.; Parida, K.; Halevi, O.; Liu, Y.; Xiong, J.; Magdassi, S.; Lee, P.S. All 3D-printed stretchable piezoelectric nanogenerator with non-protruding kirigami structure. Nano Energy 2020, 72, 104676. [Google Scholar] [CrossRef]

- Yuan, X.; Gao, X.; Yang, J.; Shen, X.; Li, Z.; You, S.; Wang, Z.; Dong, S. The large piezoelectricity and high power density of a 3D-printed multilayer copolymer in a rugby ball-structured mechanical energy harvester. Energy Environ. Sci. 2020, 13, 152–161. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Castles, F.; Isakov, D.; Lui, A.; Lei, Q.; Dancer, C.E.; Wang, Y.; Janurudin, J.M.; Speller, S.C.; Grovenor, C.R.; Grant, P.S. Microwave dielectric characterisation of 3D-printed BaTiO3/ABS polymer composites. Sci. Rep. 2016, 6, 1–8. [Google Scholar] [CrossRef]

- Grinberg, D.; Siddique, S.; Le, M.Q.; Liang, R.; Capsal, J.F.; Cottinet, P.J. 4D Printing based piezoelectric composite for medical applications. J. Polym. Sci. B Polym. Phys. 2019, 57, 109–115. [Google Scholar] [CrossRef]

- Qi, F.; Chen, N.; Wang, Q. Dielectric and piezoelectric properties in selective laser sintered polyamide11/BaTiO3/CNT ternary nanocomposites. Mater. Des. 2018, 143, 72–80. [Google Scholar] [CrossRef]

- Gryshkov, O.; Al Halabi, F.; Kuhn, A.I.; Leal-Marin, S.; Freund, L.J.; Förthmann, M.; Meier, N.; Barker, S.A.; Haastert-Talini, K.; Glasmacher, B. PVDF and P(VDF-TrFE) electrospun scaffolds for nerve graft engineering: A comparative study on piezoelectric and structural properties, and in vitro biocompatibility. Int. J. Mol. Sci. 2021, 22, 11373. [Google Scholar] [CrossRef]

- Kim, H.; Torres, F.; Villagran, D.; Stewart, C.; Lin, Y.; Tseng, T.B. 3D Printing of BaTiO3/PVDF Composites with Electric In Situ Poling for Pressure Sensor Applications. Macromol. Mater. Eng. 2017, 302, 1700229. [Google Scholar] [CrossRef]

- Ikei, A.; Wissman, J.; Sampath, K.; Yesner, G.; Qadri, S.N. Tunable in situ 3d-printed pvdf-trfe piezoelectric arrays. Sensors 2021, 21, 5032. [Google Scholar] [CrossRef]

- Revati, R.; Abdul Majid, M.S.; Ridzuan, M.J.M.; Normahira, M.; Mohd Nasir, N.F.; Rahman Y, M.N.; Gibson, A.G. Mechanical, thermal and morphological characterisation of 3D porous Pennisetum purpureum/PLA biocomposites scaffold. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 75, 752–759. [Google Scholar] [CrossRef]

- Mirkowska, A.; Kacprzyk, R.; Rozmaryniewicz, K. Piezoelectric Structure with a 3D Printed Mesh Layer. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 823–828. [Google Scholar] [CrossRef]

- Zhang, P.; Zhou, X.; Qi, R.; Gai, P.; Liu, L.; Lv, F.; Wang, S. Conductive polymer–exoelectrogen hybrid bioelectrode with improved biofilm formation and extracellular electron transport. Adv. Electron. Mater. 2019, 5, 1900320. [Google Scholar] [CrossRef]

- Woodward, D.I.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A.; Leigh, S.J. Additively-manufactured piezoelectric devices. Phys. Status Solidi (A) Appl. Mater. Sci. 2015, 212, 2107–2113. [Google Scholar] [CrossRef] [Green Version]

- Chorsi, M.T.; Curry, E.J.; Chorsi, H.T.; Das, R.; Baroody, J.; Purohit, P.K.; Ilies, H.; Nguyen, T.D. Piezoelectric biomaterials for sensors and actuators. Adv. Mater. 2019, 31, e1802084. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Bao, X.; Wong, C.M.; Cheng, J.; Wu, H.; Song, H.; Ji, X.; Wu, S. PZT ceramics fabricated based on stereolithography for an ultrasound transducer array application. Ceram. Int. 2018, 44, 22725–22730. [Google Scholar] [CrossRef]

- Chen, W.; Wang, F.; Yan, K.; Zhang, Y.; Wu, D. Micro-stereolithography of KNN-based lead-free piezoceramics. Ceram. Int. 2019, 45, 4880–4885. [Google Scholar] [CrossRef]

- Fuh, Y.K.; Ho, H.C. Highly flexible self-powered sensors based on printed circuit board technology for human motion detection and gesture recognition. Nanotechnology 2016, 27, 095401. [Google Scholar] [CrossRef]

- Fuh, Y.K.; Wang, B.S.; Tsai, C.Y. Self-Powered Pressure Sensor with fully encapsulated 3D printed wavy substrate and highly-aligned piezoelectric fibers array. Sci. Rep. 2017, 7, 6759. [Google Scholar] [CrossRef]

- Shah, P.; Narayanan, T.N.; Li, C.Z.; Alwarappan, S. Probing the biocompatibility of MoS2 nanosheets by cytotoxicity assay and electrical impedance spectroscopy. Nanotechnology 2015, 26, 315102. [Google Scholar] [CrossRef]

- Nan, Y.; Tan, D.; Shao, J.; Willatzen, M.; Wang, Z.L. 2D materials as effective cantilever piezoelectric nano energy harvesters. ACS Energy Lett. 2021, 6, 2313–2319. [Google Scholar] [CrossRef]

- Wu, T.; Song, Y.; Shi, Z.; Liu, D.; Chen, S.; Xiong, C.; Yang, Q. High-performance nanogenerators based on flexible cellulose nanofibril/MoS2 nanosheet composite piezoelectric films for energy harvesting. Nano Energy 2021, 80, 105541. [Google Scholar] [CrossRef]

- Wu, W.; Wang, L.; Li, Y.; Zhang, F.; Lin, L.; Niu, S.; Chenet, D.; Zhang, X.; Hao, Y.; Heinz, T.F.; et al. Piezoelectricity of single-atomic-layer MoS2 for energy conversion and piezotronics. Nature 2014, 514, 470–474. [Google Scholar] [CrossRef]

- Yi, F.; Ren, H.; Shan, J.; Sun, X.; Wei, D.; Liu, Z. Wearable energy sources based on 2D materials. Chem. Soc. Rev. 2018, 47, 3152–3188. [Google Scholar] [CrossRef]

- Zhong, C.; Zhao, X.; Wang, L.; Li, Y.; Zhao, Y. Facile synthesis of biocompatible MoSe2 nanoparticles for efficient targeted photothermal therapy of human lung cancer. RSC Adv. 2017, 7, 7382–7391. [Google Scholar] [CrossRef]

- Ma, N.; Zhang, M.K.; Wang, X.S.; Zhang, L.; Feng, J.; Zhang, X.Z. NIR light-triggered degradable MoTe2 nanosheets for combined photothermal and chemotherapy of cancer. Adv. Funct. Mater. 2018, 28, 1801139. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Z. Self-powered 2D material-based pH sensor and photodetector driven by monolayer MoSe2 piezoelectric nanogenerator. ACS Appl. Mater. Interfaces 2020, 12, 58132–58139. [Google Scholar] [CrossRef]

- Appel, J.H.; Li, D.O.; Podlevsky, J.D.; Debnath, A.; Green, A.A.; Wang, Q.H.; Chae, J. Low cytotoxicity and genotoxicity of two-dimensional MoS2 and WS2. ACS Biomater. Sci. Eng. 2016, 2, 361–367. [Google Scholar] [CrossRef]

- Wang, Q.; Kim, K.B.; Woo, S.B.; Song, Y.S.; Sung, T.H. A Flexible Piezoelectric Energy Harvester-Based Single-Layer WS2 Nanometer 2D Material for Self-Powered Sensors. Energies 2021, 14, 2097. [Google Scholar] [CrossRef]

- Jia, X.; Bai, J.; Ma, Z.; Jiang, X. BSA-exfoliated WSe2 nanosheets as a photoregulated carrier for synergistic photodynamic/photothermal therapy. J. Mater. Chem. B Mater. Biol. Med. 2017, 5, 269–278. [Google Scholar] [CrossRef]

- Manjunatha, S.; Rajesh, S.; Vishnoi, P.; Rao, C.N.R. Reaction with organic halides as a general method for the covalent functionalization of nanosheets of 2D chalcogenides and related materials. J. Mater. Res. 2017, 32, 2984–2992. [Google Scholar] [CrossRef]

- Yang, A.; Qiu, Y.; Yang, D.; Lin, K.; Guo, S. Piezoelectric property comparison of two-dimensional ZnO nanostructures for energy harvesting devices. RSC Adv. 2021, 11, 3363–3370. [Google Scholar] [CrossRef]

- Manjula, Y.; Kumar, R.R.; Raju, P.M.S.; Kumar, G.A.; Rao, T.V.; Akshaykranth, A.; Supraja, P. Piezoelectric flexible nanogenerator based on ZnO nanosheet networks for mechanical energy harvesting. Chem. Phys. 2020, 533, 110699. [Google Scholar] [CrossRef]

- Saravanakumar, B.; Kim, S.J. Growth of 2D ZnO nanowall for energy harvesting application. J. Phys. Chem. C 2014, 118, 8831–8836. [Google Scholar] [CrossRef]

- Mateti, S.; Wong, C.S.; Liu, Z.; Yang, W.; Li, Y.; Li, L.H.; Chen, Y. Biocompatibility of boron nitride nanosheets. Nano Res. 2018, 11, 334–342. [Google Scholar] [CrossRef]

- López-Suárez, M.; Pruneda, M.; Abadal, G.; Rurali, R. Piezoelectric monolayers as nonlinear energy harvesters. Nanotechnology 2014, 25, 175401. [Google Scholar] [CrossRef] [PubMed]

- López-Suárez, M.; Abadal, G.; Gammaitoni, L.; Rurali, R. Noise energy harvesting in buckled BN nanoribbons from molecular dynamics. Nano Energy 2015, 15, 329–334. [Google Scholar] [CrossRef]

- Ma, X.; Zhu, X.; Huang, C.; Li, Z.; Fan, J. Molecular mechanisms underlying the role of the puckered surface in the biocompatibility of black phosphorus. Nanoscale 2021, 13, 3790–3799. [Google Scholar] [CrossRef]

- Muralidharan, N.; Li, M.; Carter, R.E.; Galioto, N.; Pint, C.L. Ultralow frequency electrochemical–mechanical strain energy harvester using 2D black phosphorus nanosheets. ACS Energy Lett. 2017, 2, 1797–1803. [Google Scholar] [CrossRef]

- Fei, C.; Liu, X.; Zhu, B.; Li, D.; Yang, X.; Yang, Y.; Zhou, Q. AlN piezoelectric thin films for energy harvesting and acoustic devices. Nano Energy 2018, 51, 146–161. [Google Scholar] [CrossRef]

- Jeong, C.K.; Han, J.H.; Palneedi, H.; Park, H.; Hwang, G.T.; Joung, B.; Kim, S.G.; Shin, H.J.; Kang, I.S.; Ryu, J.; et al. Comprehensive biocompatibility of nontoxic and high-output flexible energy harvester using lead-free piezoceramic thin film. APL Mater. 2017, 5, 074102. [Google Scholar] [CrossRef]

- Xu, S.; Hansen, B.J.; Wang, Z.L. Piezoelectric-nanowire-enabled power source for driving wireless microelectronics. Nat. Commun. 2010, 1, 93. [Google Scholar] [CrossRef]

- Jeong, C.K. Toward bioimplantable and biocompatible flexible energy harvesters using piezoelectric ceramic materials. MRS Commun. 2020, 10, 365–378. [Google Scholar] [CrossRef]

- Gu, L.; Cui, N.; Cheng, L.; Xu, Q.; Bai, S.; Yuan, M.; Wu, W.; Liu, J.; Zhao, Y.; Ma, F.; et al. Flexible fiber nanogenerator with 209 V output voltage directly powers a light-emitting diode. Nano Lett. 2013, 13, 91–94. [Google Scholar] [CrossRef] [Green Version]

- Maeder, M.D.; Damjanovic, D.; Setter, N. Lead free piezoelectric materials. J. Electroceram. 2004, 13, 385–392. [Google Scholar] [CrossRef]

- Lee, Y.B.; Han, J.K.; Noothongkaew, S.; Kim, S.K.; Song, W.; Myung, S.; Lee, S.S.; Lim, J.; Bu, S.D.; An, K.S. Toward arbitrary-direction energy harvesting through flexible piezoelectric nanogenerators using perovskite PbTiO3 nanotube arrays. Adv. Mater. 2017, 29, 1604500. [Google Scholar] [CrossRef]

- Durai, L.; Badhulika, S. A wearable PVA film supported TiO2 nanoparticles decorated NaNbO3 nanoflakes-based SERS sensor for simultaneous detection of metabolites and biomolecules in human sweat samples. Adv. Mater. Interfaces 2022, 9, 2200146. [Google Scholar] [CrossRef]

- Jung, J.H.; Lee, M.; Hong, J.I.; Ding, Y.; Chen, C.Y.; Chou, L.J.; Wang, Z.L. Lead-free NaNbO3 nanowires for a high output piezoelectric nanogenerator. ACS Nano 2011, 5, 10041–10046. [Google Scholar] [CrossRef]

- Park, K.I.; Lee, M.; Liu, Y.; Moon, S.; Hwang, G.T.; Zhu, G.; Kim, J.E.; Kim, S.O.; Kim, D.K.; Wang, Z.L.; et al. Flexible nanocomposite generator made of BaTiO3 nanoparticles and graphitic carbons. Adv. Mater. 2012, 24, 2999–3004. [Google Scholar] [CrossRef]

- Uchino, K. Ferroelectric Devices; Taylor & Francis: Abingdon, UK, 2018. [Google Scholar] [CrossRef]

- Erturk, A.; Inman, D.J. Piezoelectric Energy Harvesters; Wiley: Hoboken, NJ, USA, 2011; pp. 1–24. [Google Scholar]

- Tsubouchi, K.; Mikoshiba, N. Zero-Temperature-Coefficient SAW Devices on AlN Epitaxial Films. IEEE Trans. Sonics Ultrason. 1985, 32, 634–644. [Google Scholar] [CrossRef]

- Matloub, R.; Hadad, M.; Mazzalai, A.; Chidambaram, N.; Moulard, G.; Sandu, C.S.; Metzger, T.; Muralt, P. Piezoelectric Al1−xScxN thin films: A semiconductor compatible solution for mechanical energy harvesting and sensors. Appl. Phys. Lett. 2013, 102, 152903. [Google Scholar] [CrossRef]

- Akiyama, M.; Umeda, K.; Honda, A.; Nagase, T. Influence of scandium concentration on power generation figure of merit of scandium aluminum nitride thin films. Appl. Phys. Lett. 2013, 102, 021915. [Google Scholar] [CrossRef]

- Neri, I.; López-Suárez, M. Efficient nonlinear energy harvesting with wrinkled piezoelectric membranes. Energy Harvest. Syst. 2016, 3, 133–137. [Google Scholar] [CrossRef]

- Trigona, C.; Giuffrida, S.; Andò, B.; Baglio, S. Micromachined “Random Mechanical Switching Harvester on Inductor” to recovery energy from very low-amplitude vibrations with zero-voltage threshold. In Proceedings of the 2016 IEEE SENSORS, Orlando, FL, USA, 30 October 2016–3 November 2016; pp. 1–3. [Google Scholar]

- Zhao, C.; Huang, Y.; Wu, J. Multifunctional barium titanate ceramics via chemical modification tuning phase structure. InfoMat 2020, 2, 1163–1190. [Google Scholar] [CrossRef]

- Jaffe, B.; Cook, W.R.; Jaffe, H.L. Piezoelectric Ceramics; Academic Press: Cambridge, MA, USA, 1971; Volume 3, p. 317. [Google Scholar]

- Tu, C.S.; Siny, I.G.; Schmidt, V.H. Sequence of dielectric anomalies and high-temperature relaxation behavior in Na1/2Bi1/2TiO3. Phys. Rev. B 1994, 49, 11550. [Google Scholar] [CrossRef]

- Zhou, X.; Xue, G.; Luo, H.; Bowen, C.R.; Zhang, D. Phase structure and properties of sodium bismuth titanate lead-free piezoelectric ceramics. Prog. Mater. Sci. 2021, 122, 100836. [Google Scholar] [CrossRef]

- Niu, M.; Zhu, H.; Wang, Y.; Yan, J.; Chen, N.; Yan, P.; Ouyang, J. Integration-Friendly, Chemically Stoichiometric BiFeO3 Films with a Piezoelectric Performance Challenging that of PZT. ACS Appl. Mater. Interfaces 2020, 12, 33899–33907. [Google Scholar] [CrossRef]

- Ujimoto, K.; Yoshimura, T.; Ashida, A.; Fujimura, N. Direct piezoelectric properties of (100) and (111) BiFeO3 epitaxial thin films. Appl. Phys. Lett. 2012, 100, 102901. [Google Scholar] [CrossRef]

- Micard, Q.; Condorelli, G.G.; Malandrino, G. Piezoelectric BiFeO3 thin films: Optimization of MOCVD process on Si. Nanomaterials 2020, 10, 630. [Google Scholar] [CrossRef]

- Jaeger, R.E.; Egerton, L. Hot Pressing of Potassium-Sodium. J. Am. Ceram. Soc. 1962, 45, 209. [Google Scholar] [CrossRef]

- Nakamura, K.; Shimizu, H. Hysteresis-free piezoelectric actuators using linbo3 plates with a ferroelectric inversion layer. Ferroelectrics 1989, 93, 211–216. [Google Scholar] [CrossRef]

- Jaffe, H.; Berlincourt, D.A. Piezoelectric Transducer Materials. Proc. IEEE 1965, 53, 1372–1386. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, R.; Shrout, T.R. Modified (K0.5Na0.5)NbO3 based lead-free piezoelectrics with broad temperature usage range. Appl. Phys. Lett. 2007, 91, 132913. [Google Scholar] [CrossRef]

- Shibata, K.; Oka, F.; Ohishi, A.; Mishima, T.; Kanno, I. Piezoelectric properties of (K, Na)NbO3 films deposited by RF magnetron sputtering. Appl. Phys. Express 2008, 1, 011501. [Google Scholar] [CrossRef]

- Bordui, P.F.; Norwood, R.G.; Bird, C.D.; Calvert, G.D. Compositional uniformity in growth and poling of large-diameter lithium niobate crystals. J. Cryst. Growth 1991, 113, 61–68. [Google Scholar] [CrossRef]

- Bartasyte, A.; Margueron, S.; Baron, T.; Oliveri, S.; Boulet, P. Toward High-Quality Epitaxial LiNbO3 and LiTaO3 Thin Films for Acoustic and Optical Applications. Adv. Mater. Interfaces 2017, 4, 1600998. [Google Scholar] [CrossRef]

- Nakamura, K.; Ando, H.; Shimizu, H. Bending vibrator consisting of a LINBO3 plate with a ferroelectric inversion layer. Jpn. J. Appl. Phys. 1987, 26, 198–200. [Google Scholar] [CrossRef]

- Yue, W.; Yi-Jian, J. Crystal orientation dependence of piezoelectric properties in LiNbO3 and LiTa3. Opt. Mater. 2003, 23, 403–408. [Google Scholar] [CrossRef]

- Pusty, M.; Shirage, P.M. Insights and perspectives on graphene-PVDF based nanocomposite materials for harvesting mechanical energy. J. Alloys Compd. 2022, 904, 164060. [Google Scholar] [CrossRef]

- Lu, L.; Ding, W.; Liu, J.; Yang, B. Flexible PVDF based piezoelectric nanogenerators. Nano Energy 2020, 78, 105251. [Google Scholar] [CrossRef]

- Sukumaran, S.; Chatbouri, S.; Rouxel, D.; Tisserand, E.; Thiebaud, F.; Zineb, T.B. Recent advances in flexible PVDF based piezoelectric polymer devices for energy harvesting applications. J. Intell. Mater. Syst. Struct. 2021, 32, 746–780. [Google Scholar] [CrossRef]

- Raja, A.N. Recent development in chitosan-based electrochemical sensors and its sensing application. Int. J. Biol. Macromol. 2020, 164, 4231–4244. [Google Scholar]

- Fukada, E.; Yasuda, I. On the piezoelectric effect of bone. J. Phys. Soc. Jpn. 1957, 12, 1158–1162. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Mandal, D. Efficient natural piezoelectric nanogenerator: Electricity generation from fish swim bladder. Nano Energy 2016, 28, 356–365. [Google Scholar] [CrossRef]

- Karan, S.K.; Maiti, S.; Paria, S.; Maitra, A.; Si, S.K.; Kim, J.K.; Khatua, B.B. A new insight towards eggshell membrane as high energy conversion efficient bio-piezoelectric energy harvester. Mater. Today Energy 2018, 9, 114–125. [Google Scholar] [CrossRef]

- Lee, B.Y.; Zhang, J.; Zueger, C.; Chung, W.J.; Yoo, S.Y.; Wang, E.; Meyer, J.; Ramesh, R.; Lee, S.W. Virus-based piezoelectric energy generation. Nat. Nanotechnol. 2012, 7, 351–356. [Google Scholar] [CrossRef]

- Yucel, T.; Cebe, P.; Kaplan, D.L. Structural origins of silk piezoelectricity. Adv. Funct. Mater. 2011, 21, 779–785. [Google Scholar] [CrossRef]

- Kao, K.C. Dielectric Phenomena in Solids: With Emphasis on Physical Concepts of Electronic Processes; Academic Press: Cambridge, MA, USA, 2004; p. 601. [Google Scholar]

- Li, X.; Wang, Y.; Xu, M.; Shi, Y.; Wang, H.; Yang, X.; Ying, H.; Zhang, Q. Polymer electrets and their applications. J. Appl. Polym. Sci. 2021, 138, 50406. [Google Scholar] [CrossRef]

- Boisseau, S.; Despesse, G.; Ricart, T.; Defay, E.; Sylvestre, A. Cantilever-based electret energy harvesters. Smart Mater. Struct. 2011, 20, 105013. [Google Scholar] [CrossRef]

- Sappati, K.K.; Bhadra, S. Piezoelectric Polymer and Paper Substrates: A Review. Sensors 2018, 18, 3605. [Google Scholar] [CrossRef]

- Sessler, G.M.; Hillenbrand, J. Electromechanical response of cellular electret films. Appl. Phys. Lett. 1999, 75, 3405–3407. [Google Scholar] [CrossRef]

- Bauer, S.; Gerhard-Multhaupt, R.; Sessler, G.M. Ferroelectrets: Soft Electroactive Foams for Transducers. Phys. Today 2004, 57, 37–43. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Y.; Liu, J.; Zou, X.; Zhang, J. PECVD SiO2/Si3N4 Double-layer Electrets for Application in Micro-devices. IOP Conf. Ser. Mater. Sci. Eng. 2019, 611, 012088. [Google Scholar] [CrossRef]

- Erhard, D.P.; Lovera, D.; Von Salis-Soglio, C.; Giesa, R.; Altstädt, V.; Schmidt, H.W. Recent advances in the improvement of polymer electret films. Adv. Polym. Sci. 2010, 228, 155–207. [Google Scholar] [CrossRef]

- Sakane, Y.; Suzuki, Y.; Kasagi, N. The development of a high-performance perfluorinated polymer electret and its application to micro power generation. J. Micromech. Microeng. 2008, 18, 104011. [Google Scholar] [CrossRef]

- Bonacci, F.; Di Michele, A.; Caponi, S.; Cottone, F.; Mattarelli, M. High charge density silica micro-electrets fabricated by electron beam. Smart Mater. Struct. 2018, 27, 75052. [Google Scholar] [CrossRef]

- Wang, C.; Cai, L.; Feng, Y.; Chen, L.; Yan, W.; Liu, Q.; Yao, T.; Hu, F.; Pan, Z.; Sun, Z.; et al. An electrostatic nanogenerator based on ZnO/ZnS core/shell electrets with stabilized quasi-permanent charge. Appl. Phys. Lett. 2014, 104, 1–5. [Google Scholar] [CrossRef]

- Fan, F.R.; Tian, Z.Q.; Lin Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Chen, B.D.; Tang, W.; Zhang, C.; Xu, L.; Zhu, L.P.; Yang, L.J.; He, C.; Chen, J.; Liu, L.; Zhou, T.; et al. Au nanocomposite enhanced electret film for triboelectric nanogenerator. Nano Res. 2018, 11, 3096–3105. [Google Scholar] [CrossRef]

- Li, Z.B.; Li, H.Y.; Fan, Y.J.; Liu, L.; Chen, Y.H.; Zhang, C.; Zhu, G. Small-Sized, Lightweight, and Flexible Triboelectric Nanogenerator Enhanced by PTFE/PDMS Nanocomposite Electret. ACS Appl. Mater. Interfaces 2019, 11, 20370–20377. [Google Scholar] [CrossRef] [PubMed]

- Ueda, H.; Carr, S.H. Piezoelectricity in polyacrylonitrile. Polym. J. 1984, 16, 661–667. [Google Scholar] [CrossRef]

- Hyeon, D.Y.; Lee, G.J.; Lee, S.H.; Park, J.J.; Kim, S.; Lee, M.K.; Park, K.I. High-temperature workable flexible piezoelectric energy harvester comprising thermally stable (K,Na)NbO3-based ceramic and polyimide composites. Compos. Part B Eng. 2022, 234, 109671. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, J.; Li, X.; Lu, Y.; Zhang, S.; Cheng, Z. Flexible piezoelectric energy harvester/sensor with high voltage output over wide temperature range. Nano Energy 2019, 61, 337–345. [Google Scholar] [CrossRef]

- Crosnier, J.J.; Micheron, F.; Dreyfus, G.; Lewiner, J. Pyroelectricity induced by space-charge injection in polymer electrets. J. Appl. Phys. 1976, 47, 4798–4799. [Google Scholar] [CrossRef]

- Zhang, X.; Hillenbrand, J.; Sessler, G.M. Piezoelectric d33 coefficient of cellular polypropylene subjected to expansion by pressure treatment. Appl. Phys. Lett. 2004, 85, 1226. [Google Scholar] [CrossRef]

- Mo, X.; Zhou, H.; Li, W.; Xu, Z.; Duan, J.; Huang, L.; Hu, B.; Zhou, J. Piezoelectrets for wearable energy harvesters and sensors. Nano Energy 2019, 65, 104033. [Google Scholar] [CrossRef]

- Kacprzyk, R.; Mirkowska, A. Bubble Electret-Elastomer Piezoelectric Transducer. Energies 2020, 13, 2884. [Google Scholar] [CrossRef]

- Kaczmarek, H.; Chylińska, M.; Klimiec, E.; Królikowski, B.; Sionkowski, G.; MacHnik, M. Piezo-electrets from polypropylene composites doped with mineral fillers. Pure Appl. Chem. 2019, 91, 967–982. [Google Scholar] [CrossRef]

- Zhang, X.; Pondrom, P.; Wu, L.; Sessler, G.M. Vibration-based energy harvesting with piezoelectrets having high d31 activity. Appl. Phys. Lett. 2016, 108, 1–5. [Google Scholar] [CrossRef]

- Zhong, J.; Zhong, Q.; Zang, X.; Wu, N.; Li, W.; Chu, Y.; Lin, L. Flexible PET/EVA-based piezoelectret generator for energy harvesting in harsh environments. Nano Energy 2017, 37, 268–274. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Vaezi, M.; Seitz, H.; Yang, S. A review on 3D micro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Chen, A.Y.; Pegg, E.; Chen, A.; Jin, Z.; Gu, G.X. 4D Printing of Electroactive Materials. Adv. Intell. Syst. 2021, 3, 2100019. [Google Scholar] [CrossRef]

- Engel, K.E.; Kilmartin, P.A.; Diegel, O. Recent advances in the 3D printing of ionic electroactive polymers and core ionomeric materials. Polym. Chem. 2022, 13, 456–473. [Google Scholar] [CrossRef]

- Chen, C.; Wang, X.; Wang, Y.; Yang, D.; Yao, F.; Zhang, W.; Wang, B.; Sewvandi, G.A.; Yang, D.; Hu, D. Additive Manufacturing of Piezoelectric Materials. Adv. Funct. Mater. 2020, 30, 2005141. [Google Scholar] [CrossRef]

- Bodkhe, S.; Ermanni, P. Challenges in 3D printing of piezoelectric materials. Multifunct. Mater. 2019, 2, 022001. [Google Scholar] [CrossRef]

- Karaki, T.; Yan, K.; Adachi, M. Barium Titanate Piezoelectric Ceramics Manufactured by Two-Step Sintering. Jpn. J. Appl. Phys. 2007, 46, 7035–7038. [Google Scholar] [CrossRef]

- Han, J.S.; Gal, C.W.; Park, J.M.; Kim, J.H.; Lee, S.H.; Yeo, B.W.; Lee, B.W.; Park, S.S.; Park, S.J. Powder injection molding process for fabrication of piezoelectric 2D array ultrasound transducer. Smart Mater. Struct. 2018, 27, 075058. [Google Scholar] [CrossRef]

- Liu, B.; Zeng, H.C. Hydrothermal synthesis of ZnO nanorods in the diameter regime of 50 nm. J. Am. Chem. Soc. 2003, 125, 4430–4431. [Google Scholar] [CrossRef] [PubMed]

- Corral-Flores, V.; Braza, S.; Christensen, T.M.; Glushchenko, A. Synthesis of zinc oxide microrod arrays and their performance as piezo-generators. Mater. Technol. 2018, 33, 575–581. [Google Scholar] [CrossRef]

- Wu, F.; Yao, N. PMN-PT nanostructures for energy scavenging. Semicond. Sci. Technol. 2017, 32, 063001. [Google Scholar] [CrossRef]

- Lee, C.; Tarbutton, J.A. Electric poling-assisted additive manufacturing process for PVDF polymer-based piezoelectric device applications. Smart Mater. Struct. 2014, 23, 095044. [Google Scholar] [CrossRef]

- Hoejin, K.; Torres, F.; Mingyue, L.; Yirong, L.; Tzu-Liang Bill, T. Fabrication and characterization of 3D printed BaTiO3/PVDF nanocomposites. J. Compos. Mater. 2018, 52, 197–206. [Google Scholar] [CrossRef]

- Bodkhe, S.; Rajesh, P.S.; Gosselin, F.P.; Therriault, D. Simultaneous 3D Printing and Poling of PVDF and Its Nanocomposites. ACS Appl. Energy Mater. 2018, 1, 2474–2482. [Google Scholar] [CrossRef]

- Cui, H.; Hensleigh, R.; Yao, D.; Maurya, D.; Kumar, P.; Kang, M.G.; Priya, S.; Zheng, X.R. Three-dimensional printing of piezoelectric materials with designed anisotropy and directional response. Nat. Mater. 2019, 18, 234–241. [Google Scholar] [CrossRef]

- Gao, S.; Gain, A.K.; Zhang, L. A metamaterial for wearable piezoelectric energy harvester. Smart Mater. Struct. 2021, 30, 015026. [Google Scholar] [CrossRef]

- Kim, H.; Torres, F.; Wu, Y.; Villagran, D.; Lin, Y.; Tseng, T.L.B. Integrated 3D printing and corona poling process of PVDF piezoelectric films for pressure sensor application. Smart Mater. Struct. 2017, 26, 085027. [Google Scholar] [CrossRef]

- Chakraborty, P.; Zhou, C.; Chung, D.D.L. Enhancing the inherent piezoelectric behavior of a three-dimensionally printed acrylate polymer by electrical poling. Smart Mater. Struct. 2018, 27, 115038. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, J.; Wang, Z.L.; Ren, K. A Poly (l-Lactic Acid) Polymer-Based Thermally Stable Cantilever for Vibration Energy Harvesting Applications. Adv. Sustain. Syst. 2017, 1, 1700068. [Google Scholar] [CrossRef]

- Duerloo, K.A.N.; Ong, M.T.; Reed, E.J. Intrinsic piezoelectricity in two-dimensional materials. J. Phys. Chem. Lett. 2012, 3, 2871–2876. [Google Scholar] [CrossRef]

- Gilbert, S.M.; Pham, T.; Dogan, M.; Oh, S.; Shevitski, B.; Schumm, G.; Liu, S.; Ercius, P.; Aloni, S.; Cohen, M.L.; et al. Alternative stacking sequences in hexagonal boron nitride. 2D Mater. 2019, 6, 021006. [Google Scholar] [CrossRef]

- Alem, N.; Erni, R.; Kisielowski, C.; Rossell, M.D.; Gannett, W.; Zettl, A. Atomically thin hexagonal boron nitride probed by ultrahigh-resolution transmission electron microscopy. Phys. Rev. B 2009, 80, 155425. [Google Scholar] [CrossRef]

- Pease, R. Crystal structure of boron nitride. Nature 1950, 165, 722–723. [Google Scholar] [CrossRef]

- Warner, J.H.; Rummeli, M.H.; Bachmatiuk, A.; Buchner, B. Atomic resolution imaging and topography of boron nitride sheets produced by chemical exfoliation. ACS Nano 2010, 4, 1299–1304. [Google Scholar] [CrossRef]

- Paine, R.T.; Narula, C.K. Synthetic routes to boron nitride. Chem. Rev. 1990, 90, 73–91. [Google Scholar] [CrossRef]

- Duerloo, K.A.N.; Reed, E.J. Flexural electromechanical coupling: A nanoscale emergent property of boron nitride bilayers. Nano Lett. 2013, 13, 1681–1686. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Zhang, X.; Liang, X.; Feng, Y.; Feng, W. Two-dimensional nanomaterials with engineered bandgap: Synthesis, properties, applications. Nano Today 2021, 37, 101059. [Google Scholar] [CrossRef]

- Susarla, S.; Kutana, A.; Hachtel, J.A.; Kochat, V.; Apte, A.; Vajtai, R.; Idrobo, J.C.; Yakobson, B.I.; Tiwary, C.S.; Ajayan, P.M. Quaternary 2D transition metal dichalcogenides (TMDs) with tunable bandgap. Adv. Mater. 2017, 29, 1702457. [Google Scholar] [CrossRef]

- Eftekhari, A. Molybdenum diselenide (MoSe2) for energy storage, catalysis, and optoelectronics. Appl. Mater. Today 2017, 8, 1–17. [Google Scholar] [CrossRef]

- Lin, D.Y.; Hsu, H.P.; Liu, G.H.; Dai, T.Z.; Shih, Y.T. Enhanced photoresponsivity of 2H-MoTe2 by inserting 1T-MoTe2 interlayer contact for photodetector applications. Crystals 2021, 11, 964. [Google Scholar] [CrossRef]

- Xu, Y.; Wu, L.; Ang, L.K. MoS2-Based Highly Sensitive Near-Infrared Surface Plasmon Resonance Refractive Index Sensor. IEEE J. Sel. Top. Quantum Electron. 2018, 25, 1–7. [Google Scholar]

- Zhu, H.; Wang, Y.; Xiao, J.; Liu, M.; Xiong, S.; Wong, Z.J.; Ye, Z.; Ye, Y.; Yin, X.; Zhang, X. Observation of piezoelectricity in free-standing monolayer MoS2. Nat. Nanotechnol. 2015, 10, 151–155. [Google Scholar] [CrossRef]

- Li, S.; Eastman, J.; Li, Z.; Foster, C.; Newnham, R.; Cross, L. Size effects in nanostructured ferroelectrics. Phys. Lett. A 1996, 212, 341–346. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Jiang, D.; Schedin, F.; Booth, T.; Khotkevich, V.; Morozov, S.; Geim, A.K. Two-dimensional atomic crystals. Proc. Natl. Acad. Sci. USA 2005, 102, 10451–10453. [Google Scholar] [CrossRef]

- Blonsky, M.N.; Zhuang, H.L.; Singh, A.K.; Hennig, R.G. Ab initio prediction of piezoelectricity in two-dimensional materials. ACS Nano 2015, 9, 9885–9891. [Google Scholar] [CrossRef] [PubMed]

- Sevik, C.; Çakır, D.; Gülseren, O.; Peeters, F.M. Peculiar piezoelectric properties of soft two-dimensional materials. J. Phys. Chem. C 2016, 120, 13948–13953. [Google Scholar] [CrossRef]

- Alyoruk, M.M.; Aierken, Y.; Çakır, D.; Peeters, F.M.; Sevik, C. Promising piezoelectric performance of single layer transition-metal dichalcogenides and dioxides. J. Phys. Chem. C 2015, 119, 23231–23237. [Google Scholar] [CrossRef]

- Alyörük, M.M. Piezoelectric properties of monolayer II–VI group oxides by first-principles calculations. Phys. Status Solidi (b) 2016, 253, 2534–2539. [Google Scholar] [CrossRef]

- Wan, C.; Tian, R.; Azizi, A.B.; Huang, Y.; Wei, Q.; Sasai, R.; Wasusate, S.; Ishida, T.; Koumoto, K. Flexible thermoelectric foil for wearable energy harvesting. Nano Energy 2016, 30, 840–845. [Google Scholar] [CrossRef]

- Chia, H.L.; Latiff, N.M.; Sofer, Z.; Pumera, M. Cytotoxicity of group 5 transition metal ditellurides (MTe2; M = V, Nb, Ta). Chem.- Eur. J. 2018, 24, 206–211. [Google Scholar] [CrossRef] [PubMed]

- Tan, E.; Li, B.L.; Ariga, K.; Lim, C.T.; Garaj, S.; Leong, D.T. Toxicity of two-dimensional layered materials and their heterostructures. Bioconjug. Chem. 2019, 30, 2287–2299. [Google Scholar] [CrossRef]

- Li, J.; Guiney, L.M.; Downing, J.R.; Wang, X.; Chang, C.H.; Jiang, J.; Liu, Q.; Liu, X.; Mei, K.C.; Liao, Y.P.; et al. Dissolution of 2D Molybdenum Disulfide Generates Differential Toxicity among Liver Cell Types Compared to Non-Toxic 2D Boron Nitride Effects. Small 2021, 17, 2101084. [Google Scholar] [CrossRef]

- Kim, S.G.; Priya, S.; Kanno, I. Piezoelectric MEMS for energy harvesting. MRS Bull. 2012, 37, 1039–1050. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Zheng, B.; Zang, J.; Lv, C.; Zhang, T.; Wang, H.; Zhao, G. Protein interface redesign facilitates the transformation of nanocage building blocks to 1D and 2D nanomaterials. Nat. Commun. 2021, 12, 4849. [Google Scholar] [CrossRef]

- Chen, Z.; Molina-Jirón, C.; Klyatskaya, S.; Klappenberger, F.; Ruben, M. 1D and 2D graphdiynes: Recent advances on the synthesis at interfaces and potential nanotechnological applications. Ann. Phys. 2017, 529, 1700056. [Google Scholar] [CrossRef] [Green Version]

- Zhong, Y.; Peng, C.; He, Z.; Chen, D.; Jia, H.; Zhang, J.; Ding, H.; Wu, X. Interface engineering of heterojunction photocatalysts based on 1D nanomaterials. Catal. Sci. Technol. 2021, 11, 27–42. [Google Scholar] [CrossRef]

- Zhao, X.; Li, Q.; Xu, L.; Zhang, Z.; Kang, Z.; Liao, Q.; Zhang, Y. Interface engineering in 1D ZnO-based heterostructures for photoelectrical devices. Adv. Funct. Mater. 2022, 32, 2106887. [Google Scholar] [CrossRef]

- Tonda, S.; Kumar, S.; Gawli, Y.; Bhardwaj, M.; Ogale, S. g-C3N4 (2D)/CdS (1D)/rGO (2D) dual-interface nano-composite for excellent and stable visible light photocatalytic hydrogen generation. Int. J. Hydrog. Energy 2017, 42, 5971–5984. [Google Scholar] [CrossRef]

- Machín, A.; Fontánez, K.; Arango, J.C.; Ortiz, D.; De León, J.; Pinilla, S.; Nicolosi, V.; Petrescu, F.I.; Morant, C.; Márquez, F. One-Dimensional (1D) Nanostructured Materials for Energy Applications. Materials 2021, 14, 2609. [Google Scholar] [CrossRef]

- Johar, M.A.; Hassan, M.A.; Waseem, A.; Ha, J.S.; Lee, J.K.; Ryu, S.W. Stable and high piezoelectric output of GaN nanowire-based lead-free piezoelectric nanogenerator by suppression of internal screening. Nanomaterials 2018, 8, 437. [Google Scholar] [CrossRef]

- Minary-Jolandan, M.; Bernal, R.A.; Kuljanishvili, I.; Parpoil, V.; Espinosa, H.D. Individual GaN nanowires exhibit strong piezoelectricity in 3D. Nano Lett. 2012, 12, 970–976. [Google Scholar] [CrossRef]

- Huang, C.T.; Song, J.; Tsai, C.M.; Lee, W.F.; Lien, D.H.; Gao, Z.; Hao, Y.; Chen, L.J.; Wang, Z.L. Single-InN-nanowire nanogenerator with upto 1 V output voltage. Adv. Mater. 2010, 22, 4008–4013. [Google Scholar] [CrossRef]

- Li, X.; Wei, X.; Xu, T.; Pan, D.; Zhao, J.; Chen, Q. Remarkable and crystal-structure-dependent piezoelectric and piezoresistive effects of InAs nanowires. Adv. Mater. 2015, 27, 2852–2858. [Google Scholar] [CrossRef]

- Lin, Y.F.; Song, J.; Ding, Y.; Lu, S.Y.; Wang, Z.L. Piezoelectric nanogenerator using CdS nanowires. Appl. Phys. Lett. 2008, 92, 022105. [Google Scholar] [CrossRef]

- Wang, X.; Dai, G.; Chen, Y.; Mo, X.; Li, X.; Huang, W.; Sun, J.; Yang, J. Piezo-phototronic enhanced photoresponsivity based on single CdTe nanowire photodetector. J. Appl. Phys. 2019, 125, 094505. [Google Scholar] [CrossRef]

- Zaraska, L.; Mika, K.; Syrek, K.; Sulka, G.D. Formation of ZnO nanowires during anodic oxidation of zinc in bicarbonate electrolytes. J. Electroanal. Chem. 2017, 801, 511–520. [Google Scholar] [CrossRef]

- Wang, Z.L.; Song, J. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef] [PubMed]

- Wang, X. Piezoelectric nanogenerators—Harvesting ambient mechanical energy at the nanometer scale. Nano Energy 2012, 1, 13–24. [Google Scholar] [CrossRef]

- Zhang, G.; Zhao, P.; Zhang, X.; Han, K.; Zhao, T.; Zhang, Y.; Jeong, C.K.; Jiang, S.; Zhang, S.; Wang, Q. Flexible three-dimensional interconnected piezoelectric ceramic foam based composites for highly efficient concurrent mechanical and thermal energy harvesting. Energy Environ. Sci. 2018, 11, 2046–2056. [Google Scholar] [CrossRef]

- Spanier, J.E.; Kolpak, A.M.; Urban, J.J.; Grinberg, I.; Ouyang, L.; Yun, W.S.; Rappe, A.M.; Park, H. Ferroelectric phase transition in individual single-crystalline BaTiO3 nanowires. Nano Lett. 2006, 6, 735–739. [Google Scholar] [CrossRef]

- Yang, C.; Chen, M.; Li, S.; Zhang, X.; Hua, C.; Bai, H.; Xiao, C.; Yang, S.A.; He, P.; Xu, Z.a.; et al. Coexistence of Ferroelectricity and Ferromagnetism in One-Dimensional SbN and BiN Nanowires. ACS Appl. Mater. Interfaces 2021, 13, 13517–13523. [Google Scholar] [CrossRef]

- Lin, Z.H.; Yang, Y.; Wu, J.M.; Liu, Y.; Zhang, F.; Wang, Z.L. BaTiO3 nanotubes-based flexible and transparent nanogenerators. J. Phys. Chem. Lett. 2012, 3, 3599–3604. [Google Scholar] [CrossRef]

- Cross, E. Lead-free at last. Nature 2004, 432, 24–25. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T.; Nonoyama, T.; Takatori, K.; Homma, T.; Nagaya, T.; Nakamura, M. Lead-free piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef]

- Chen, X.; Xu, S.; Yao, N.; Xu, W.; Shi, Y. Potential measurement from a single lead ziroconate titanate nanofiber using a nanomanipulator. Appl. Phys. Lett. 2009, 94, 253113. [Google Scholar] [CrossRef]

- Chen, X.; Xu, S.; Yao, N.; Shi, Y. 1.6 V nanogenerator for mechanical energy harvesting using PZT nanofibers. Nano Lett. 2010, 10, 2133–2137. [Google Scholar] [CrossRef]

- Yudin, P.; Tagantsev, A. Fundamentals of flexoelectricity in solids. Nanotechnology 2013, 24, 432001. [Google Scholar] [CrossRef]

- Wang, B.; Gu, Y.; Zhang, S.; Chen, L.Q. Flexoelectricity in solids: Progress, challenges, and perspectives. Prog. Mater. Sci. 2019, 106, 100570. [Google Scholar] [CrossRef]

- Han, J.K.; Jeon, D.H.; Cho, S.Y.; Kang, S.W.; Yang, S.A.; Bu, S.D.; Myung, S.; Lim, J.; Choi, M.; Lee, M.; et al. Nanogenerators consisting of direct-grown piezoelectrics on multi-walled carbon nanotubes using flexoelectric effects. Sci. Rep. 2016, 6, 29562. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, F. Piezoelectric materials for high temperature sensors. J. Am. Ceram. Soc. 2011, 94, 3153–3170. [Google Scholar] [CrossRef]

- Akishige, Y.; Fukano, K.; Shigematsu, H. New ferroelectric BaTi2O5. Jpn. J. Appl. Phys. 2003, 42, L946. [Google Scholar] [CrossRef]

- Gao, Z. Perovskite-Like Layered Structure A2B2O7 Ferroelectrics and Solid Solutions. Ph.D. Thesis, Queen Mary University of London, London, UK, 2012. [Google Scholar]

- Fuierer, P.A.; Newnham, R.E. La2Ti207 ceramics. J. Am. Ceram. Soc. 1991, 74, 74–85. [Google Scholar] [CrossRef]

- Talanov, M.V.; Talanov, V.M. Structural Diversity of Ordered Pyrochlores. Chem. Mater. 2021, 33, 2706–2725. [Google Scholar] [CrossRef]

- Moure, A. Review and perspectives of Aurivillius structures as a lead-free Piezoelectric system. Appl. Sci. 2018, 8, 62. [Google Scholar] [CrossRef]

- Simon, A.; Ravez, J. Solid-state chemistry and non-linear properties of tetragonal tungsten bronzes materials. C. R. Chim. 2006, 9, 1268–1276. [Google Scholar] [CrossRef]

- Shur, V.Y. Lithium niobate and lithium tantalate-based piezoelectric materials. In Advanced Piezoelectric Materials: Science and Technology; Woodhead Publishing: Cambridge, UK, 2010; pp. 204–238. [Google Scholar] [CrossRef]

- Cava, R.J.; Santoro, A.; Murphy, D.W.; Zahurak, S.; Roth, R.S. The Structures of Lithium-Inserted Metal Oxides: LiReO3 and Li2ReO3. J. Solid State Chem. 1982, 42, 251–262. [Google Scholar] [CrossRef]

- Inaguma, Y.; Aimi, A.; Mori, D.; Katsumata, T.; Ohtake, M.; Nakayama, M.; Yonemura, M. High-Pressure Synthesis, Crystal Structure, Chemical Bonding, and Ferroelectricity of LiNbO3-Type LiSbO3. Inorg. Chem. 2018, 57, 15462–15473. [Google Scholar] [CrossRef] [PubMed]

- Inaguma, Y.; Yoshida, M.; Katsumata, T. A polar oxide ZnSnO3 with a LiNbO3-type structure. J. Am. Chem. Soc. 2008, 130, 6704–6705. [Google Scholar] [CrossRef] [PubMed]

- Inaguma, Y.; Yoshida, M.; Tsuchiya, T.; Aimi, A.; Tanaka, K.; Katsumata, T.; Mori, D. High-pressure synthesis of novel lithium niobate-type oxides. J. Phys. Conf. Ser. 2010, 215, 012131. [Google Scholar] [CrossRef]

- Philippot, E.; Palmier, D.; Pintard, M.; Goiffon, A. A General Survey of Quartz and Quartz-like Materials: Packing Distortions, Temperature, and Pressure Effects. J. Solid State Chem. 1996, 123, 1–13. [Google Scholar] [CrossRef]

- Pisarevsky, Y.V.; Silvestrova, O.Y.; Phillippot, E.; Balitsky, D.V.; Pisharovsky, D.Y.; Balitsky, V.S. Piezoelectric, dielectric and elastic properties of germanium dioxide single crystals. In Proceedings of the 2000 IEEE/EIA International Frequency Control Symposium and Exhibition (Cat. No. 00CH37052), Kansas City, MO, USA, 9 June 2000; pp. 177–179. [Google Scholar] [CrossRef]

- Krispel, F.; Schleinzer, G.; Krempl, P.W.; Wallnöfer, W. Measurement of the piezoelectric and electrooptic constants of GaPO4 with a michelson interferometer. Ferroelectrics 1997, 202, 307–311. [Google Scholar] [CrossRef]

- Bohm, J.; Chilla, E.; Flannery, C.; Frok, H.J.; Hauke, T.; Heimann, R.B.; Hengst, M.; Straube, U.; Benz, K.W. Czochralski growth and characterization of piezoelectric single crystals with langasite structure: LaGaSiO (LGS), LaGaNbO (LGN) and LaGaTaO (LGT) II. Piezoelectric and elastic properties. J. Cryst. Growth 2000, 216, 293–298. [Google Scholar] [CrossRef]

- Xin, J.; Zheng, Y.; Kong, H.; Chen, H.; Tu, X.; Shi, E. Growth of a New Ordered Langasite Structure Crystal Ca3TaAl3Si2O14. Cryst. Growth Des. 2008, 8, 2617–2619. [Google Scholar] [CrossRef]

- Wu, A.; Xu, J.; Zhou, J.; Shen, H. Piezoelectric properties of Sr3Ga2Ge4O14 single crystals. Bull. Mater. Sci 2007, 30, 101–104. [Google Scholar] [CrossRef]

- Shen, C.; Zhang, H.; Zhang, Y.; Xu, H.; Yu, H.; Wang, J.; Zhang, S. Orientation and temperature dependence of piezoelectric properties for sillenite-type Bi12TiO20 and Bi12SiO20 single crystals. Crystals 2014, 4, 141–151. [Google Scholar] [CrossRef]

- Yu, F.; Duan, X.; Zhang, S.; Lu, Q.; Zhao, X. Rare-earth calcium oxyborate piezoelectric crystals ReCa4O(BO3)3: Growth and piezoelectric characterizations. Crystals 2014, 4, 241–261. [Google Scholar] [CrossRef]

- Lee, F.Y.; Jo, H.R.; Lynch, C.S. Pyroelectric and Piezoelectric Properties of Lithium Tetraborate Single Crystal. Jpn. J. Appl. Phys. 1985, 24, 727. [Google Scholar]

- Newnham, R.E. Properties of materials: Anisotropy, Symmetry, Structure; Oxford University Press: Oxford, UK, 2005. [Google Scholar]

- Zheludev, I.S. Physics of Crystalline Dielectrics, Electrical Properties; Springer Science Business Media: Berlin/Heidelberg, Germany, 1971; Volume 2. [Google Scholar]

- Hopwood, J.S.; Nicol, A.W. Crystal data for cadmium tartrate pentahydrate, CdC4H406.5H20. J. Appl. Cryst 1972, 5, 437. [Google Scholar] [CrossRef]

- Jin, Y.; Ren, J.; Chen, J.; Pinto, M.R.; Pereira, G.B.; Kitagaki, B.T.; Poizot, P.; Hung, C.J. Determination of the Elastic and Piezoelectric Coefficients of Monoclinic Crystals, with particular Reference to Ethylene Diamine Tartrate (EDT). Proc. Phys. Soc. Sect. B 1950, 63, 577. [Google Scholar]

- Prywer, J.; Kruszyński, R.; Świątkowski, M.; Soszyński, A.; Kajewski, D.; Roleder, K. First experimental evidence of the piezoelectric nature of struvite. Sci. Rep. 2021, 11, 14860. [Google Scholar] [CrossRef]

- Newnham, R.E. Crystal Chemistry of Non-Metallic Materials: Structure and Property Relations; Springer: Berlin/Heidelberg, Germany, 1975. [Google Scholar]

- Bishara, H.; Berezinsky, M.; Inbar, A.; Berger, S. A piezoelectric current response to small applied mechanical pressure changes of lithium sulfate monohydrate nano-crystals. Sens. Actuators A Phys. 2019, 288, 165–170. [Google Scholar] [CrossRef]

- Mason, W.P. Elastic, Piezoelectric, and Dielectric Properties of Sodium Chlorate and Sodium Bromate. Phys. Rev. 1946, 70, 529. [Google Scholar] [CrossRef]

- Wells, A.F. Structural Inorganic Chemistry, 5th ed.; Clarendon Press: Oxford, UK, 1984. [Google Scholar]

- Hübner, K. Piezoelectricity in Zincblende- and Wurtzite-Type Crystals. Phys. Status Solidi B 1973, 57, 627–634. [Google Scholar] [CrossRef]

- Srikanth, K.; Wazeer, A.; Mathiyalagan, P.; Vidya, S.; Rajput, K.; Kushwaha, H.S. Piezoelectric properties of ZnO. In Nanostructured Zinc Oxide: Synthesis, Properties and Applications; Elsevier: Amsterdam, Netherlands, 2021; pp. 717–736. [Google Scholar] [CrossRef]

- Joffe, H.; Berlincourt, D.; Krueger, H.; Shiozawa, L. Piezoelectric properties of cadmium sulfide crystals. In Proceedings of the 14th Annual Symposium on Frequency Control, Atlantic City, NJ, USA, 31 May 1960–2 June 1960; pp. 19–23. [Google Scholar] [CrossRef]

- Muensit, S.; Guy, I.L. The piezoelectric coefficient of gallium nitride GaN thin films. Appl. Phys. Lett. 1998, 72, 1896–1898. [Google Scholar] [CrossRef]

- Ferahtia, S.; Saib, S.; Bouarissa, N.; Benyettou, S. Structural parameters, elastic properties and piezoelectric constants of wurtzite ZnS and ZnSe under pressure. Superlattices Microstruct. 2014, 67, 88–96. [Google Scholar] [CrossRef]

- Strauss, A.J. The physical properties of cadmium telluride. Rev. Phys. Appliquée Société Française Phys. 1977, 12, 167–184. [Google Scholar] [CrossRef]

- Fricke, K. Piezoelectric properties of GaAs for application in stress transducers. J. Appl. Phys. 1991, 70, 914–918. [Google Scholar] [CrossRef]

- Wasilik, J.H.; Flippen, R.B. Piezoelectric Effect in Indium Antimonide. Phys. Rev. Lett. 1958, 1, 233–234. [Google Scholar] [CrossRef]

- Nanamatsu, S.; Doi, K.; Takahashi, M. Piezoelectric, elstic and dielectric properties of LiGaO2. Jpn. J. Appl. Phys. 1972, 11, 816–822. [Google Scholar] [CrossRef]

- Abrahams, S.C.; Bernstein, J.L. Piezoelectric nonlinear optic CuGaSe2 and CdGeAs2: Crystal structure, chalcopyrite microhardness, and sublattice distortion. J. Chem. Phys. 1974, 61, 1140–1146. [Google Scholar] [CrossRef]

- Queisser, J.L.; Wernick, J.H.; Fripp, A.L. Ternary Chalcopyrite Semiconductors: Growth, Electronic Properties, and Applications. J. Electrochem. Soc. 1976, 123, 170C–171C. [Google Scholar] [CrossRef]

- Helman, D.S. Symmetry-based electricity in minerals and rocks: A review with examples of centrosymmetric minerals that exhibit pyro- and piezoelectricity. Period. Mineral. 2016, 85, 201–248. [Google Scholar] [CrossRef]

- Kimura, M.; Fujino, Y.; Kawamura, T. New piezoelectric crystal: Synthetic fresnoite Ba2Si2TiO8. Appl. Phys. Lett. 1976, 29, 227–228. [Google Scholar] [CrossRef]

- Starczewska, A. New approach to well-known compounds: Fabrication and characterization of AVBVICVII nanomaterials. Acta Phys. Pol. A. 2021, 139, 394–400. [Google Scholar] [CrossRef]

- Szperlich, P.; Toroń, B.; Nowak, M.; Jesionek, M.; Kępińska, M.; Bogdanowicz, W. Growth of large SbSI crystals. Mater. Sci.-Pol. 2014, 32, 669–675. [Google Scholar] [CrossRef]

- Sarkar, A.S.; Stratakis, E. Recent Advances in 2D Metal Monochalcogenides. Adv. Sci. 2020, 7, 2001655. [Google Scholar] [CrossRef]

- Gomes, L.C.; Carvalho, A. Phosphorene analogues: Isoelectronic two-dimensional group-IV monochalcogenides with orthorhombic structure. Phys. Rev. B Condens. Matter Mater. Phys. 2015, 92, 085406. [Google Scholar] [CrossRef]

- Li, W.; Li, J. Piezoelectricity in two-dimensional group-III monochalcogenides. Nano Res. 2015, 8, 3796–3802. [Google Scholar] [CrossRef]

- Fei, R.; Li, W.; Li, J.; Yang, L. Giant piezoelectricity of monolayer group IV monochalcogenides: SnSe, SnS, GeSe, and GeS. Appl. Phys. Lett. 2015, 107, 173104. [Google Scholar] [CrossRef]

- Zhang, J.; Jia, S.; Kholmanov, I.; Dong, L.; Er, D.; Chen, W.; Guo, H.; Jin, Z.; Shenoy, V.B.; Shi, L.; et al. Janus Monolayer Transition-Metal Dichalcogenides. ACS Nano 2017, 11, 8192–8198. [Google Scholar] [CrossRef]

- Dong, L.; Lou, J.; Shenoy, V.B. Large In-Plane and Vertical Piezoelectricity in Janus Transition Metal Dichalchogenides. ACS Nano 2017, 11, 8242–8248. [Google Scholar] [CrossRef]

- Pérez, S. The structure of sucrose in the crystal and in solution. In Sucrose; Springer: Boston, MA, USA, 1995; pp. 11–32. [Google Scholar] [CrossRef]

- Guerin, S.; Syed, T.A.; Thompson, D. Deconstructing collagen piezoelectricity using alanine-hydroxyproline-glycine building blocks. Nanoscale 2018, 10, 9653–9663. [Google Scholar] [CrossRef]

- Shin, D.M.; Hong, S.W.; Hwang, Y.H. Recent advances in organic piezoelectric biomaterials for energy and biomedical applications. Nanomaterials 2020, 10, 123. [Google Scholar] [CrossRef]

- Guerin, S.; Tofail, S.A.; Thompson, D. Organic piezoelectric materials: Milestones and potential. NPG Asia Mater. 2019, 11, 10. [Google Scholar] [CrossRef]

- Kawai, H. The Piezoelectricity of Poly (Vinylidene Fluoride). Jpn. J. Appl. Phys. 1969, 8, 975–976. [Google Scholar] [CrossRef]

- Kalimuldina, G.; Turdakyn, N.; Abay, I.; Medeubayev, A.; Nurpeissova, A.; Adair, D.; Bakenov, Z. A review of piezoelectric PVDF film by electrospinning and its applications. Sensors 2020, 20, 5214. [Google Scholar] [CrossRef]

- Costa, P.; Nunes-Pereira, J.; Pereira, N.; Castro, N.; Gonçalves, S.; Lanceros-Mendez, S. Recent Progress on Piezoelectric, Pyroelectric, and Magnetoelectric Polymer-Based Energy-Harvesting Devices. Energy Technol. 2019, 7, 1800852. [Google Scholar] [CrossRef]

- Harrison, J.S.; Ounaies, Z. Piezoelectric Polymers; NASA Langley Research Center: Hampton, VA, USA, 2001.

- Smith, M.; Kar-Narayan, S. Piezoelectric polymers: Theory, challenges and opportunities. Int. Mater. Rev. 2022, 67, 65–88. [Google Scholar] [CrossRef]

- Wang, J.J.; Hsieh, J.M.; Tsai, R.W.; Su, Y.C. Piezoelectric PDMS films for power MEMS. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Transducers ’11, Beijing, China, 5–9 June 2011; pp. 2622–2625. [Google Scholar] [CrossRef]

- Pukada, E. History and recent progress in piezoelectric polymers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2000, 47, 1277–1290. [Google Scholar] [CrossRef]

- Ando, Y.; Fukada, E. Piezoelectric properties and molecular motion of poly-β-hydroxybutyrate. J. Polym. Sci. Polym. Phys. 1984, 22, 1821–1834. [Google Scholar] [CrossRef]

- Bharti, V.; Nath, R. Piezo-, pyro-and ferroelectric properties of simultaneously stretched and corona poled extruded poly(vinyl chloride) PVC films. J. Phys. D Appl. Phys 2001, 34, 667–672. [Google Scholar] [CrossRef]

- Miyata, S.; Yoshikawa, M.; Tasaka, S.; Ko, M. Piezoelectricity Revealed in the Copolymer of Vinylidene Cyanide and Vinyl Acetate. Polym. J. 1980, 12, 857–860. [Google Scholar] [CrossRef]

- Tasaka, S.; Toyama, T.; Inagaki, N. Ferro-and Pyroelectricity in Amorphous Polyphenylethernitrile PPEN. Jpn. J. Appl. Phys. 1994, 33, 5838. [Google Scholar] [CrossRef]

- Simpson, J.; Ounaies, Z.; Fay, C. Polarization and piezoelectric properties of a nitrile substituted polyimide. MRS Proc. 1996, 459, 59. [Google Scholar] [CrossRef]

- Zelisko, M.; Hanlumyuang, Y.; Yang, S.; Liu, Y.; Lei, C.; Li, J.; Ajayan, P.M.; Sharma, P. Anomalous piezoelectricity in two-dimensional graphene nitride nanosheets. Nat. Commun. 2014, 5, 4284. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.C.; Lin, Y.C.; Chen, H.C.; Lin, W.Y. Energy harvesting from g-C3N4 piezoelectric nanogenerators. Nano Energy 2021, 83, 105743. [Google Scholar] [CrossRef]

| Material | Features | Biocompatibility | Energy Harvesting Applications |

|---|---|---|---|

| Lead-free | |||

| AlN | CMOS compatible, high temperature resistance, micro-scale, scalable, reliable | yes [26,27,28] | vibration [27,29,30,31,32,33,34,35,36,37,38] |

| BaTiO | CMOS compatible, micro-scale, nano-scale, reliable | yes [39] | vibration [40], direct force [41,42,43] |

| BiFeO | CMOS compatible, high temperature resistance, fatigue resistance, micro-scale | yes [44] | vibration [45,46,47], direct force [48] |

| KNN | CMOS compatible, micro-scale, scalable, reliable | yes [49] | vibration [50,51,52,53,54] |

| LiNbO | commercially available, CMOS compatible compatible, high temperature resistance, micro-scale, mesoscale | yes [55] | impact [56], vibration [57,58,59,60,61] |

| PVDF | commercially available, flexible, mesoscale, excellent mechanical fatigue resistance | yes [62] | direct force [63], vibration [64,65,66], wearable [67] |

| ZnO | CMOS compatible, high temperature resistance, micro-scale, nano-scale, scalable, fragile, surface crack development | yes [68] | direct force/vibration [69,70,71,72,73] |

| Organic | |||

| Chitosan | flexible, sustainable, biodegradable | yes [74] | vibration [75] |

| Chitosan-CNF/CNC | flexible, sustainable, biodegradable | yes [76] | vibration [75] |

| CNF Film | flexible, sustainable, biodegradable | yes [77] | vibration [75] |

| EAPap | flexible, sustainable, biodegradable | yes [78] | vibration/strain [78] |

| ZONCE | ZnO doped, flexible, high conversion performance | yes [79] | vibration/strain [78] |

| Sn/ZnO/PVA PENG | Sn/ZnO doped, flexible, sustainable, high conversion performance | yes [80] | vibration [80] |