Displacement Characteristics and Produced Oil Properties in Steam Flood Heavy Oil Process

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Materials

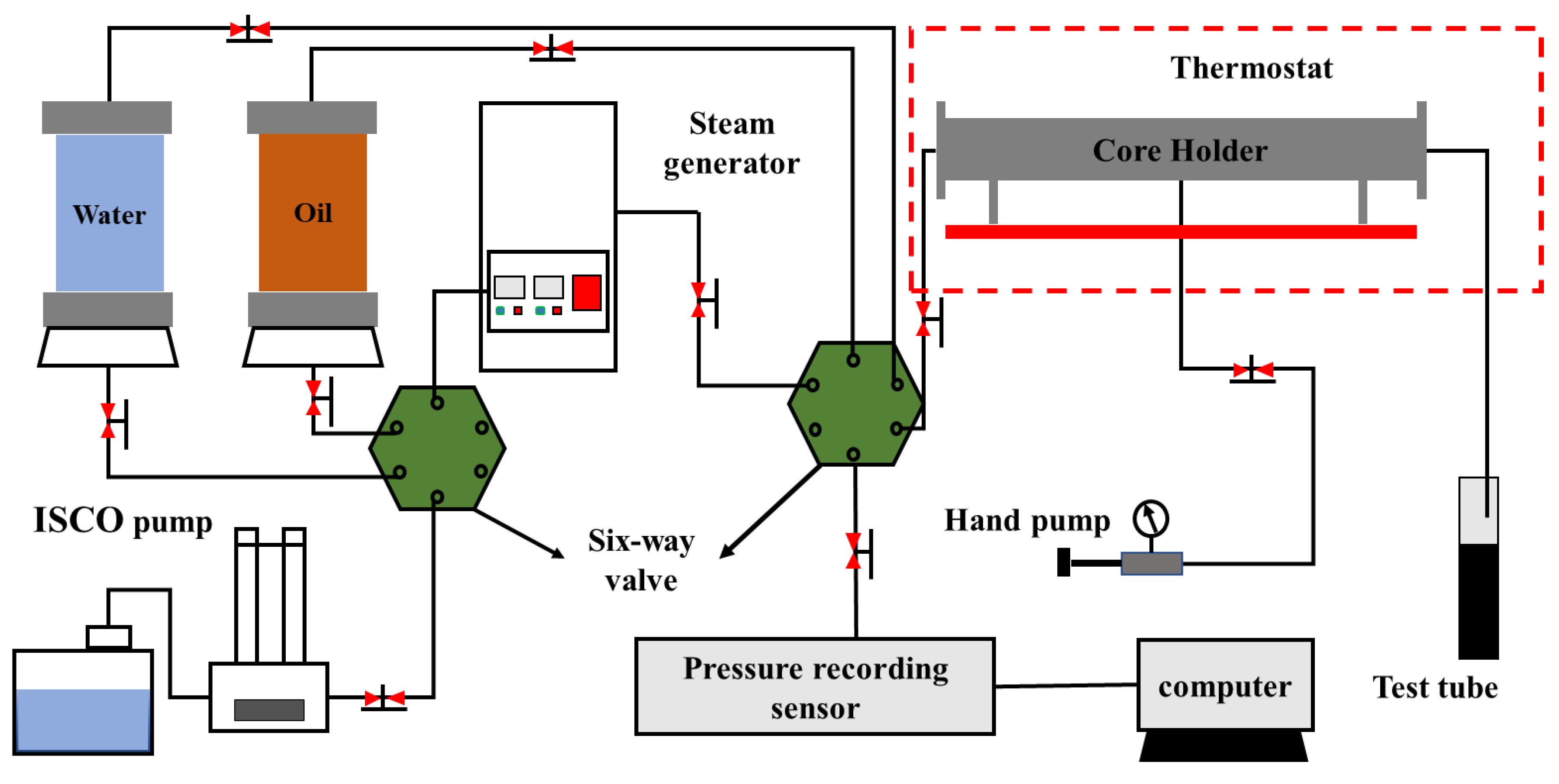

2.2. Core Steam Flooding Experiments

2.3. Rheological Property Test

2.4. SARA Fractionation

3. Results and Discussion

3.1. Steam Flooding Characteristics Analysis

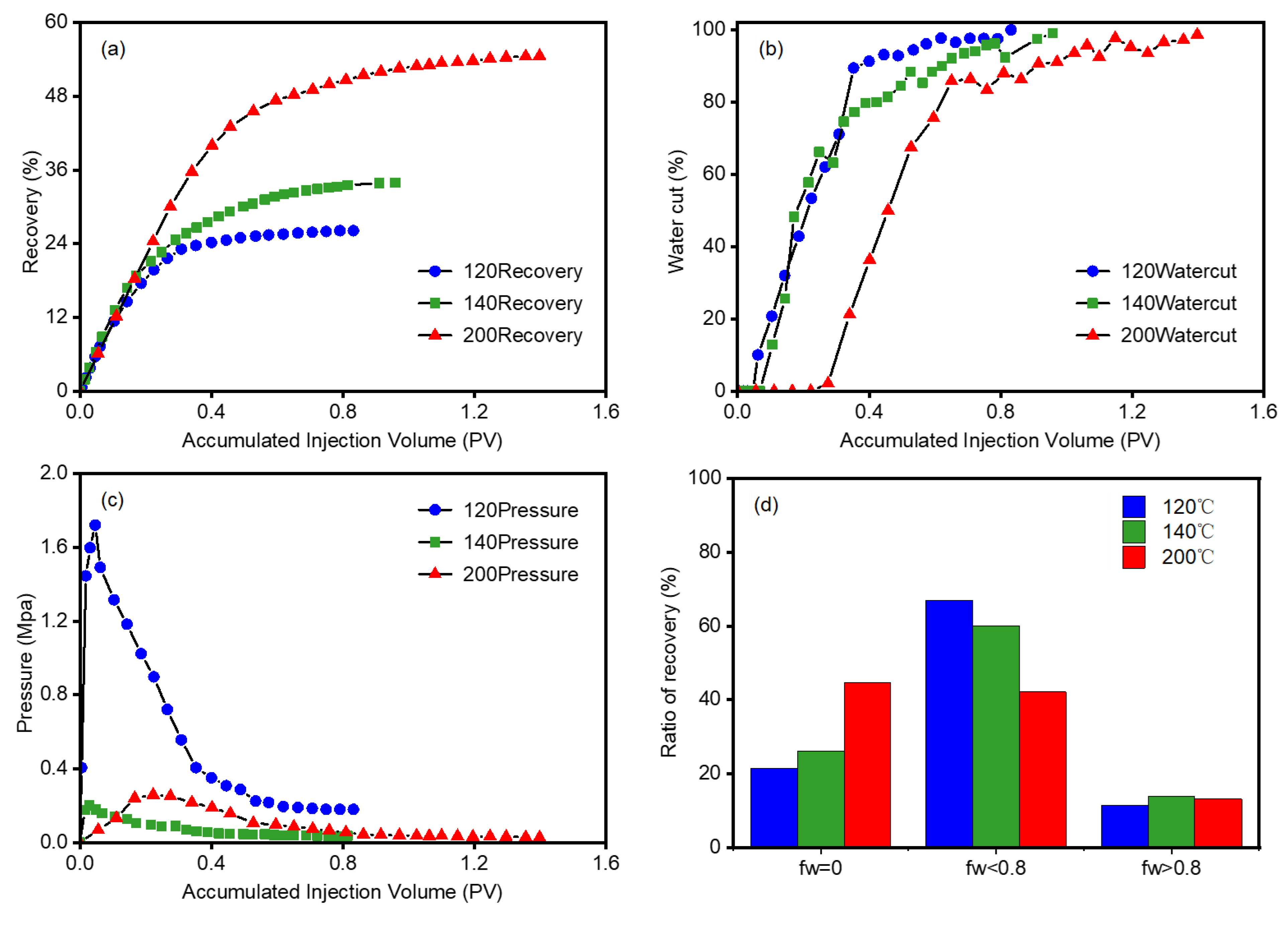

3.1.1. Temperature Effect of Injected Steam

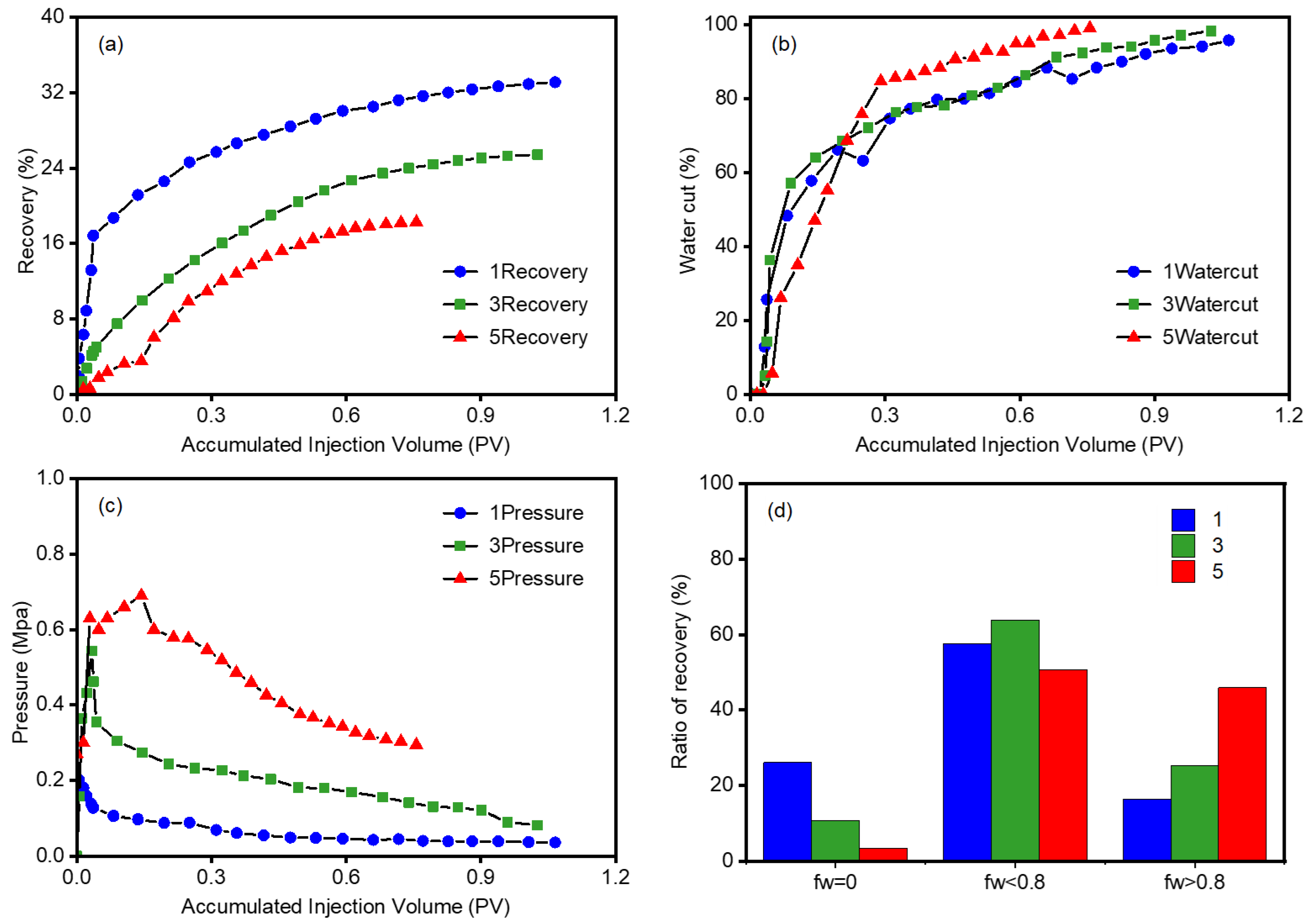

3.1.2. Velocity Effect of Injected Steam

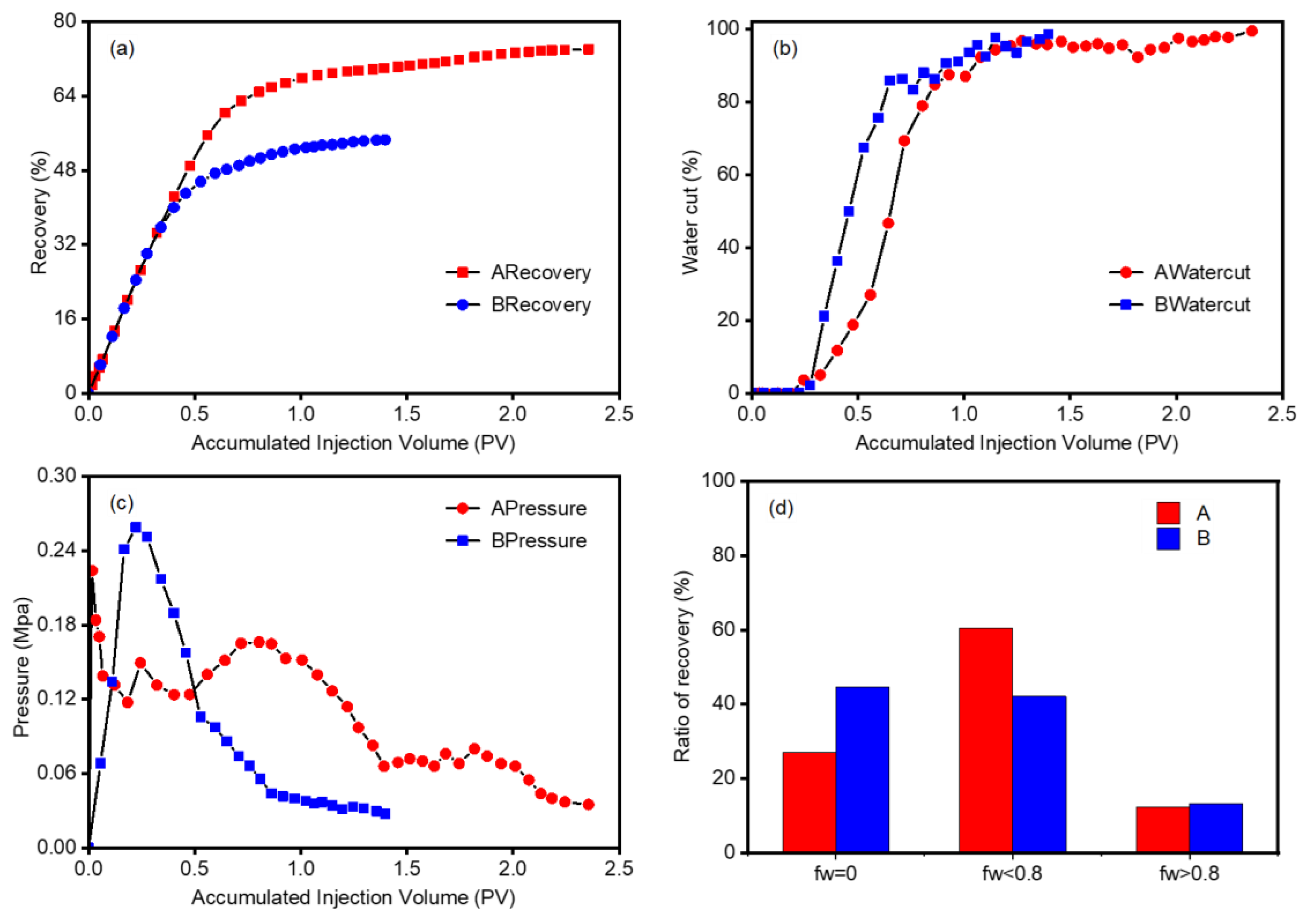

3.1.3. Comparison of Different Heavy Oil Viscosities

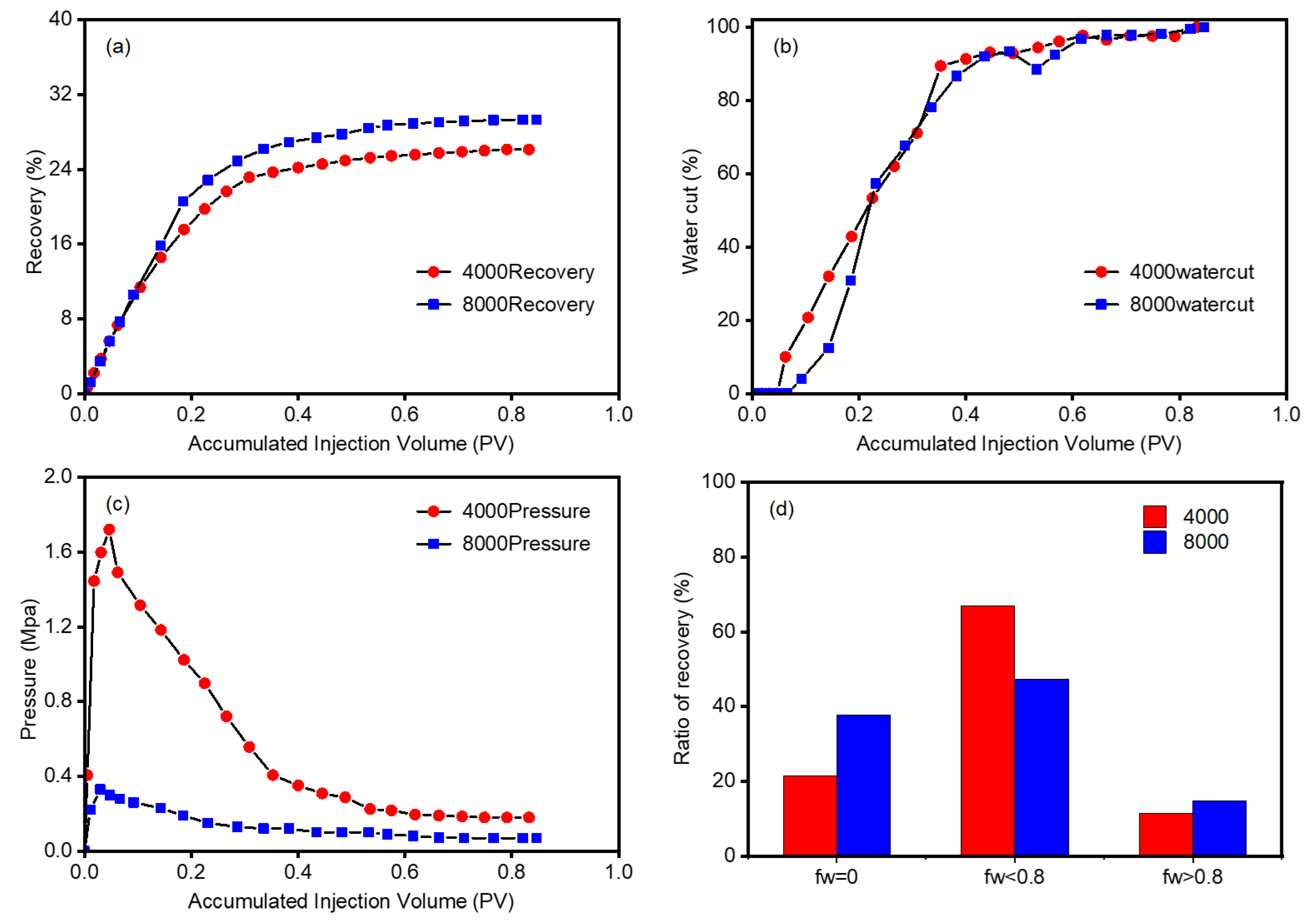

3.1.4. Comparison of Different Coal Permeability

3.2. Rheology and SARA of Produced Oils Analysis

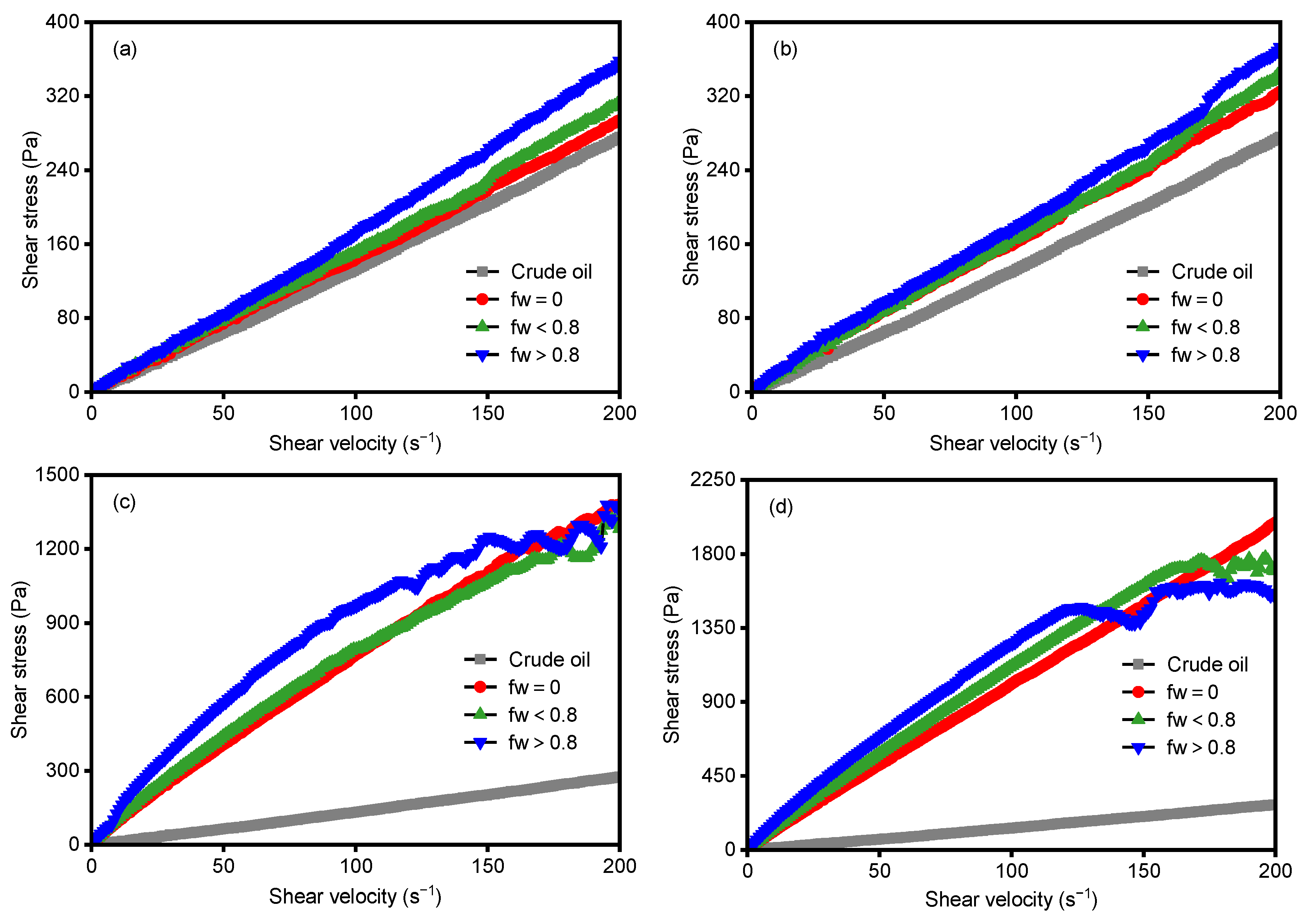

3.2.1. Rheology Analysis

3.2.2. SARA Composition Analysis

4. Conclusions

- (1)

- High temperature and low injection velocity of the injection steam contribute to a high oil recovery. The enhanced viscosity reduction contributes to the improved oil recovery with the increase in steam temperature. However, the increase in steam velocity easily forms the viscous fingering and cross flow phenomenon. This will decrease the recovery. Low viscosity of the heavy oil and high permeability of the core can also improve oil recovery in the steam flooding process.

- (2)

- The low water cut stage is the main production stage during the steam flooding process. Increasing the temperature is helpful in prolonging the water breakthrough time and improving the recovery of the no water cut stage. Higher velocity of the injection steam can increase the ratio of recovery in the high water cut stage.

- (3)

- Emulsification occurs during the steam flooding heavy oil process. The rheology properties of the produced oils are related to the content of the SARA composition. With the increase in the injection volume, the content of resins and asphaltenes increases, leading to an increase in viscosity of the produced oils.

- (4)

- With the increase in steam temperature, the relative content of resins in the produced oils decreases, and asphaltenes increase. The temperature increment can promote emulsification between the oil and the steam, which has more influence on the rheological properties of the produced oils. Moreover, the high injection velocity of steam leads to a strong shear effect between the steam and the heavy oil, which causes a higher viscosity of the produced oils.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, Z.; Mendiratta, S.; Chen, X.; Zhang, J.; Li, Y. Amphiphilic-polymer-assisted hot water flooding toward viscous oil mobilization. Ind. Eng. Chem. Res. 2019, 58, 16552–16564. [Google Scholar] [CrossRef]

- Sun, J.; Qiu, G.; Zhao, H. Research on the Prediction Method of Recoverable Reserves in Heavy Oil Reservoirs. Xinjiang Pet. Geol. 2003, 5, 441–443. [Google Scholar]

- Denney, D. Gas-/Steam-Slug Flooding Enhances Recovery from a Medium-Heavy-Oil Reservoir. J. Pet. Technol. 2000, 52, 65–66. [Google Scholar] [CrossRef]

- Yu, L. Distribution of heavy oil resources in the world and its status quo and prospect of extraction technology. Spec. Oil Gas Reserv. 2001, 2, 98–103. [Google Scholar]

- Liang, Z.; Tang, Q.; Chai, L. Development Technology of Steam Flooding in Heavy Oil Reservoirs. Spec. Oil Gas Reserv. 2000, 2, 46–47. [Google Scholar]

- Wang, X.; Zhang, H.; Liang, X.; Shi, L.; Chen, M.; Wang, X.; Liu, W.; Ye, Z. New Amphiphilic Macromolecule as Viscosity Reducer with Both Asphaltene Dispersion and Emulsifying Capacity for Offshore Heavy Oil. Energy Fuels 2021, 352, 1143–1151. [Google Scholar] [CrossRef]

- Yue, Q.; Li, P. Discussion on several problems of steam displacement. Spec. Oil Gas Reserv. 1997, 2, 10–13. [Google Scholar]

- Han, Y. Discussion on thermal recovery technology of heavy oil. Sci. Technol. Wind 2015, 1, 80. [Google Scholar]

- Szymczak, P.D. Caspian Oil and Gas Leverages Strengths to Survive in a Low-Carbon World. Pet. Technol. 2021, 73, 23–27. [Google Scholar] [CrossRef]

- Carpenter, C. Subsea-Systems Innovations Improve Heavy-Oil Production in Ultradeep Water. Pet. Technol. 2021, 73, 53–54. [Google Scholar] [CrossRef]

- Chang, H.; Zhang, Y.; Dandekar, A.; Ning, S.; Barnes, J.; Edwards, R.; Schulpen, W.; Cercone, D.P.; Ciferno, J. Experimental Investigation on Separation Behavior of Heavy-Oil Emulsion for Polymer Flooding on Alaska North Slope. SPE Prod. Oper. 2020, 35, 579–591. [Google Scholar]

- Ge, M. Development Technology of SAGD in Medium and Deep Ultra-Heavy Oil in Liao he Oilfield. Spec. Oil Gas Reserv. 2021, 28, 175. [Google Scholar]

- Zhang, J.; Wang, W.; Shen, L.; Wang, J.; Jiang, D.; Ma, X.; Feng, Y. Experimental study on rheological characteristics of ultra-heavy oil in Liao he Oilfield. Surf. Eng. Oil Gas Fields 2006, 7, 11–15. [Google Scholar]

- Manchuk, J.G.; Garner, D.L.; Deutsch, C.V. Estimation of Permeability in the McMurray Formation Using High-Resolution Data Sources. Petrophysics 2015, 56, 125–139. [Google Scholar]

- Zhang, D.; Du, X.; Song, X.; Wang, H.; Li, X.; Jiang, Y.; Wang, M. Application of the Marangoni Effect in Nanoemulsion on Improving Waterflooding Technology for Heavy-Oil Reservoirs. SPE J. 2018, 23, 831–840. [Google Scholar] [CrossRef]

- Wilson, A. New Methods Analyze Asphaltene Deposition and Fouling in Reservoirs. Pet. Technol. 2017, 69, 98–100. [Google Scholar] [CrossRef]

- Li, Y.; Gao, W.; Liu, Z.; Pan, D.; Chen, X. Artificial Sandstone and/or Conglomerate Core Based on Lithology and Pore Structure Control and Preparation Method and Application. U.S. Patent 11192824, 7 December 2021. [Google Scholar]

- Li, Y.; Gao, W.; Liu, Z.; Pan, D.; Li, Y. Artificial Sandstone and/or Conglomerate Core Based on Lithology and Permeability Control and Preparation Method and Application. U.S. Patent 11136265, 5 October 2021. [Google Scholar]

- Liu, Z.; Cheng, H.; Li, Y.; Li, Y.; Chen, X.; Zhuang, Y. Experimental Investigation of Synergy of Components in Surfactant/Polymer Flooding Using Three-Dimensional Core Model. Transp. Porous Media 2019, 126, 317–335. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, J.; Li, X.; Xu, C.; Chen, X.; Zhang, B.; Zhao, G.; Zhang, H.; Li, Y. Conformance control by a microgel in a multi-layered heterogeneous reservoir during CO2 enhanced oil recovery process. Chin. J. Chem. Eng. 2022, 43, 324–334. [Google Scholar] [CrossRef]

- Ghalamizade Elyaderani, S.M.; Jafari, A.; Razavinezhad, J. Experimental Investigation of Mechanisms in Functionalized Multiwalled Carbon Nanotube Flooding for Enhancing the Recovery from Heavy-Oil Reservoirs. SPE J. 2019, 24, 2681–2694. [Google Scholar] [CrossRef]

- Laurierl, S.; Song, Y. Progress in thermal recovery technology of heavy oil. Foreign Oilfield Eng. 1997, 10, 12–32. [Google Scholar]

- Bybee, K. Investigation of Drainage-Height Effect on Production Rate in the Vapor-Extraction Process. Pet. Technol. 2007, 59, 90–92. [Google Scholar] [CrossRef]

- Bagherzadeh, H.; Golghanddashti, H.; Shahrabadi, A. A Proposed Systematic Approach for Experimental Asphaltene Investigation: An Oil-Reservoir Case Study. SPE Prod. Oper. 2018, 33, 102–112. [Google Scholar] [CrossRef]

- Wylde, J.J.; Coscio, S.E.; Barbu, V. A Case History of Heavy-Oil Separation in Northern Alberta: A Singular Challenge of Demulsifier Optimization and Application. SPE Prod. Oper. 2010, 25, 19–24. [Google Scholar] [CrossRef]

- Adewunmi, A.A.; Kamal, M.S. Performance Evaluation of Fly Ash as a Potential Demulsifier for Water-in-Crude-Oil Emulsion Stabilized by Asphaltenes. SPE Prod. Oper. 2019, 34, 820–829. [Google Scholar] [CrossRef]

- Lv, X.; Liu, H.; Pang, Z.; Xie, M.; Zhang, F.; Wang, L.; Zhang, W. Visualization experiment of emulsifying viscosity reducer to improve the development effect of heavy oil reservoir. J. Xi’an Shiyou Univ. 2017, 32, 83–88. [Google Scholar]

- Yi, S.; Babadagli, T.; Li, H.A. Use of Nickel Nanoparticles for Promoting Aquathermolysis Reaction during Cyclic Steam Stimulation. SPE J. 2018, 23, 145–156. [Google Scholar] [CrossRef]

| Ion | Na+, K+ | Ca2+ | Mg2+ | Cl− | HCO3− | TDS |

|---|---|---|---|---|---|---|

| Concentration, mg·L−1 | 3636 | 220 | 89 | 5860 | 681 | 10,486 |

| Oil Sample | Injection Steam Temperature °C | Porosity % | Permeability mD | Original Oil Saturation % | Injection Velocity mL/min |

|---|---|---|---|---|---|

| A | 120 | 29.98 | 3954 | 85.87 | 1 |

| A | 140 | 34.72 | 4064 | 80.59 | 1 |

| A | 200 | 29.00 | 3891 | 82.59 | 1 |

| A | 140 | 33.93 | 4012 | 76.65 | 3 |

| A | 140 | 34.54 | 3920 | 85.61 | 5 |

| A | 200 | 29.57 | 4088 | 91.30 | 5 |

| A | 120 | 29.68 | 7840 | 80.99 | 1 |

| B | 200 | 29.13 | 3862 | 79.11 | 1 |

| Sample | Saturates, wt% | Aromatics, wt% | Resins, wt% | Asphaltenes, wt% | |

|---|---|---|---|---|---|

| Crude oil | 20.74 | 25.59 | 40.06 | 14.39 | |

| 140 °C 1 mL/min | fw = 0 | 16.25 | 24.69 | 40.34 | 15.47 |

| fw < 0.8 | 17.17 | 26.5 | 40.62 | 15.53 | |

| fw > 0.8 | 18.22 | 24.45 | 41.45 | 15.61 | |

| 140 °C 5 mL/min | fw = 0 | 19.65 | 26.46 | 39.16 | 15.42 |

| fw < 0.8 | 19.63 | 25.1 | 39.45 | 15.7 | |

| fw > 0.8 | 16.72 | 26.5 | 40.32 | 15.58 | |

| 200 °C 1 mL/min | fw = 0 | 20.35 | 29.8 | 34.06 | 15.51 |

| fw < 0.8 | 19.67 | 26.02 | 39.01 | 15.92 | |

| fw > 0.8 | 15.22 | 27.87 | 40.09 | 16.43 | |

| 200 °C 5 mL/min | fw = 0 | 19.2 | 25.93 | 37.37 | 16.25 |

| fw < 0.8 | 16.09 | 28.45 | 36.71 | 17.47 | |

| fw > 0.8 | 15.05 | 26.26 | 39.84 | 18.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Zhao, H.; Zhang, B.; Zhao, Q.; Cheng, Y.; Zhang, Y.; Li, Y. Displacement Characteristics and Produced Oil Properties in Steam Flood Heavy Oil Process. Energies 2022, 15, 6246. https://doi.org/10.3390/en15176246

Yang X, Zhao H, Zhang B, Zhao Q, Cheng Y, Zhang Y, Li Y. Displacement Characteristics and Produced Oil Properties in Steam Flood Heavy Oil Process. Energies. 2022; 15(17):6246. https://doi.org/10.3390/en15176246

Chicago/Turabian StyleYang, Xingchao, Hongyan Zhao, Bo Zhang, Qinghui Zhao, Yulin Cheng, Yong Zhang, and Yiqiang Li. 2022. "Displacement Characteristics and Produced Oil Properties in Steam Flood Heavy Oil Process" Energies 15, no. 17: 6246. https://doi.org/10.3390/en15176246

APA StyleYang, X., Zhao, H., Zhang, B., Zhao, Q., Cheng, Y., Zhang, Y., & Li, Y. (2022). Displacement Characteristics and Produced Oil Properties in Steam Flood Heavy Oil Process. Energies, 15(17), 6246. https://doi.org/10.3390/en15176246