Hybrid Performance Modeling of an Agrophotovoltaic System in South Korea

Abstract

:1. Introduction

2. Background

2.1. Photovoltaic and Agrophotovoltaic Systems

2.2. Estimation Models for Electricity Generation by a Photovoltaic Module

3. Physical-Based Performance Modeling for an Agrophotovoltaic System

3.1. Electricity Generation from a Photovoltaic Module

| Algorithm 1. Pseudocode for the polynomial regression algorithm with gradient descent |

| 1: LOAD dataset from the database 2: SPLIT dataset into ten equal-sized blocks 3: REPEAT 4: SET L which is a set of degrees of independent variables 5: REPEAT 6: COMPUTE parameter set under L 7: COMPUTE the LOOCV error () 8: COMPUTE gradients 9: UNTIL the LOOCV error () is less than threshold |

3.2. Crop Yield Estimation

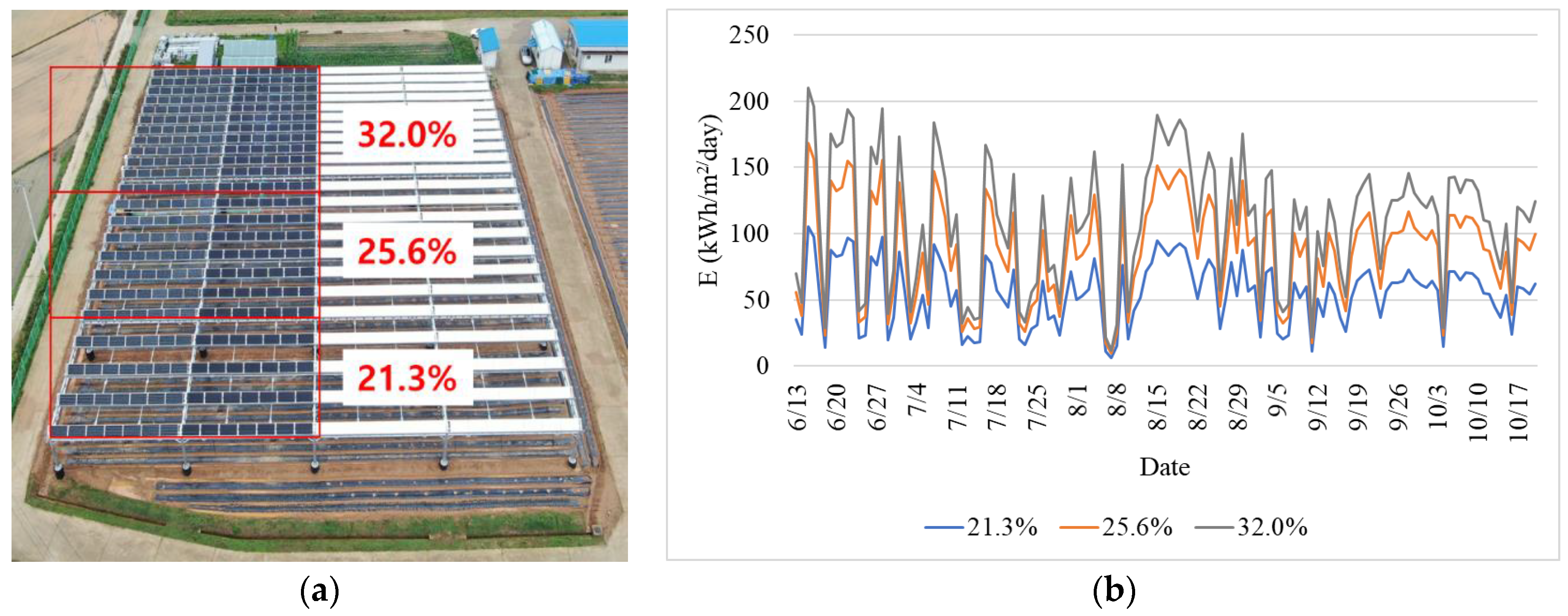

4. Experiments

4.1. Model Validation

4.2. Model Application

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nematollahi, O.; Kim, K.C. A feasibility study of solar energy in South Korea. Renew. Sustain. Energy Rev. 2017, 77, 566–579. [Google Scholar] [CrossRef]

- Alsharif, M.H.; Kim, J.; Kim, J.H. Opportunities and challenges of solar and wind energy in South Korea: A review. Sustainability 2018, 10, 1822. [Google Scholar] [CrossRef]

- Kim, S.; Lee, H.; Kim, H.; Jang, D.H.; Kim, H.J.; Hur, J.; Hur, K. Improvement in policy and proactive interconnection procedure for renewable energy expansion in South Korea. Renew. Sustain. Energy Rev. 2018, 98, 150–162. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S.; Yoon, C.Y. An efficient structure of an agrophotovoltaic system in a temperate climate region. Agronomy 2021, 11, 1584. [Google Scholar] [CrossRef]

- Yonhap News Agency. 70% of Lands in Seoul Are Needed for Solar Power Plants Construction. Available online: https://www.yna.co.kr/view/AKR20201006172900001 (accessed on 20 June 2022).

- Ministry of Agriculture, Food and Rural Affairs. Status of Self-Sufficiency Rates of Grains. Available online: https://www.mafra.go.kr/bbs/mafra/131/322523/artclView.do (accessed on 20 June 2022).

- Kim, S.; Kim, S. Performance Estimation Modeling via Machine Learning of an Agrophotovoltaic System in South Korea. Energies 2021, 14, 6724. [Google Scholar] [CrossRef]

- Congressional Budget Office. Impose a Tax on Emissions of Greenhous Gases. Available online: https://www.cbo.gov/budget-options/54821 (accessed on 20 June 2022).

- Korea Power Exchange. A Price of the Renewable Energy Certificate. Available online: https://onerec.kmos.kr/portal/index.do (accessed on 20 June 2022).

- Electric Power Statistics Information System. Status of Power Generating Unit in 2020. Available online: http://epsis.kpx.or.kr/epsisnew/selectEkifBoardList.do?menuId=080402&boardId=040200 (accessed on 20 June 2022).

- Goetzberger, A.; Zastrow, A. On the coexistence of solar-energy conversion and plant cultivation. Int. J. Sol. Energy 1982, 1, 55–69. [Google Scholar] [CrossRef]

- Kim, S.; Ofekeze, E.; Kiniry, J.R.; Kim, S. Simulation-Based Capacity Planning of a Biofuel Refinery. Agronomy 2020, 10, 1702. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S. Hybrid simulation framework for the production management of an ethanol biorefinery. Renew. Sustain. Energy Rev. 2021, 155, 111911. [Google Scholar] [CrossRef]

- Zafeiropoulou, M.; Mentis, I.; Sijakovic, N.; Terzic, A.; Fotis, G.; Maris, T.I.; Vita, V.; Zoulias, E.; Ristic, V.; Ekonomou, L. Forecasting Transmission and Distribution System Flexibility Needs for Severe Weather Condition Resilience and Outage Management. Appl. Sci. 2022, 12, 7334. [Google Scholar] [CrossRef]

- Sijakovic, N.; Terzic, A.; Fotis, G.; Mentis, I.; Zafeiropoulou, M.; Maris, T.I.; Zoulias, E.; Elias, C.; Ristic, V.; Vita, V. Active Sys-tem Management Approach for Flexibility Services to the Greek Transmission and Distribution System. Energies 2022, 15, 6134. [Google Scholar] [CrossRef]

- Moreda, G.P.; Muñoz-García, M.A.; Alonso-García, M.C.; Hernández-Callejo, L. Techno-Economic Viability of Agro-Photovoltaic Irrigated Arable Lands in the EU-Med Region: A Case-Study in Southwestern Spain. Agronomy 2021, 11, 593. [Google Scholar] [CrossRef]

- SISIFO. On-Line Simulator of PV Systems. Solar Energy Institute of the Universidad Politécnica de Madrid. Web Service Supported by the European Commission with the H2020 Project MASLOWATEN. Available online: https://www.sisifo.info/en/datainput (accessed on 1 September 2022).

- Kim, S.; Jeong, J.; Kahara, S.N.; Kim, S.; Kiniry, J.R. APEX simulation: Water quality of Sacramento Valley wetlands impacted by waterfowl droppings. J. Soil Water Conserv. 2020, 75, 713–726. [Google Scholar] [CrossRef]

- Raza, M.Q.; Khosravi, A. A review on artificial intelligence-based load demand forecasting techniques for smart grid and buildings. Renew. Sustain. Energy Rev. 2015, 50, 1352–1372. [Google Scholar] [CrossRef]

- Mandal, P.; Madhira, S.T.S.; Meng, J.; Pineda, R.L. Forecasting power output of solar photovoltaic system using wavelet transform and artificial intelligence techniques. Procedia Comput. Sci. 2012, 12, 332–337. [Google Scholar] [CrossRef]

- Bizzarri, F.; Bongiorno, M.; Brambilla, A.; Gruosso, G.; Gajani, G.S. Model of photovoltaic power plants for performance analysis and production forecast. IEEE Trans. Sustain. Energy 2012, 4, 278–285. [Google Scholar] [CrossRef]

- Santra, P.; Pande, P.C.; Kumar, S.; Mishra, D.; Singh, R.K. Agri-voltaics or solar farming: The concept of integrating solar PV based electricity generation and crop production in a single land use system. Int. J. Renew. Energy Res. 2017, 7, 694–699. [Google Scholar]

- Beck, M.; Bopp, G.; Goetzberger, A.; Obergfell, T.; Reise, C.; Schindele, S. Combining PV and food crops to Agrophotovoltaic–optimization of orientation and harvest. In Proceedings of the 27th European Photovoltaic Solar Energy Conference and Exhibition, EU PVSEC, Frankfurt, Germany, 24 September 2012. [Google Scholar]

- Elborg, M. Reducing land competition for agriculture and photovoltaic energy generation—A comparison of two agro-photovoltaic plants in japan. In Proceedings of the International Conference on Sustainable and Renewable Energy Development and Design (SREDD2017), Thimphu, Bhutan, 3 April 2017. [Google Scholar]

- Schindele, S.; Trommsdorff, M.; Schlaak, A.; Obergfell, T.; Bopp, G.; Reise, C.; Braun, C.; Weselek, A.; Bauerle, A.; Högy, P.; et al. Implementation of agrophotovoltaics: Techno-economic analysis of the price-performance ratio and its policy implications. Appl. Energy 2020, 265, 114737. [Google Scholar] [CrossRef]

- Hassanpour Adeh, E.; Selker, J.S.; Higgins, C.W. Remarkable agrivoltaic influence on soil moisture, micrometeorology and water-use efficiency. PLoS ONE 2018, 13, e0203256. [Google Scholar]

- Ayvazoğluyüksel, Ö.; Filik, Ü.B. Estimation methods of global solar radiation, cell temperature and solar power forecasting: A review and case study in Eskişehir. Renew. Sustain. Energy Rev. 2018, 91, 639–653. [Google Scholar] [CrossRef]

- Cha, W.C.; Park, J.H.; Cho, U.R.; Kim, J.C. A study on solar power generation efficiency empirical analysis according to temperature and wind speed. Trans. Korean Inst. Electr. Eng. 2015, 64, 1–6. [Google Scholar]

- Mellit, A.; Sağlam, S.; Kalogirou, S.A. Artificial neural network-based model for estimating the produced power of a photovoltaic module. Renew. Energy 2013, 60, 71–78. [Google Scholar] [CrossRef]

- Kim, S.; Aydin, B.; Kim, S. Simulation Modeling of a Photovoltaic-Green Roof System for Energy Cost Reduction of a Building: Texas Case Study. Energies 2021, 14, 5443. [Google Scholar] [CrossRef]

- Weselek, A.; Ehmann, A.; Zikeli, S.; Lewandowski, I.; Schindele, S.; Högy, P. Agrophotovoltaic systems: Applications, challenges, and opportunities. A review. Agron. Sustain. Dev. 2019, 39, 35. [Google Scholar] [CrossRef]

- Zohdi, T.I. A digital-twin and machine-learning framework for the design of multiobjective agrophotovoltaic solar farms. Comput. Mech. 2021, 68, 357–370. [Google Scholar] [CrossRef]

- Chang, C.W.; Lee, H.W.; Liu, C.H. A review of artificial intelligence algorithms used for smart machine tools. Inventions 2018, 3, 41. [Google Scholar] [CrossRef]

- Barrera, J.M.; Reina, A.; Maté, A.; Trujillo, J.C. Solar Energy Prediction Model Based on Artificial Neural Networks and Open Data. Sustainability 2020, 12, 6915. [Google Scholar] [CrossRef]

- Deeplearning4j. Deeplearning4j Suite Overview. Available online: https://deeplearning4j.konduit.ai/ (accessed on 1 September 2022).

- Loyola-Gonzalez, O. Black-box vs. white-box: Understanding their advantages and weaknesses from a practical point of view. IEEE Access 2019, 7, 154096–154113. [Google Scholar] [CrossRef]

- Yu, G.J.; Lee, Y.H.; So, J.H.; Seong, S.J.; Yu, B.G. The study on optimum installation angle of photovoltaic arrays using the expert system. J. Korean Sol. Energy Soc. 2007, 27, 107–115. [Google Scholar]

- Park, Y.M.; Hong, S.K.; Choi, A.S. A study on the comparison of the PV Module Generation from Daylight Irradiation and Indoor Lighting Savings with Lighting Simulation. J. Korean Inst. Illum. Electr. Install. Eng. 2010, 24, 17–24. [Google Scholar]

- Teke, A.; Yıldırım, H.B.; Çelik, Ö. Evaluation and performance comparison of different models for the estimation of solar radiation. Renew. Sustain. Energy Rev. 2015, 50, 1097–1107. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; John Wiley & Sons: New York, NY, USA, 2013; pp. 3–42. [Google Scholar]

- Jang, S.T.; Chang, S.J. Exploration of a light shelf system for multi-layered vegetable cultivation. KIEAE J. 2013, 13, 61–66. [Google Scholar]

- Kim, S.; Meng, C.; Son, Y.J. Simulation-based machine shop operations scheduling system for energy cost reduction. Simul. Model. Pract. Theory 2017, 77, 68–83. [Google Scholar] [CrossRef]

- Prasad, K.M.; Bapat, R.B. The generalized moore-penrose inverse. Linear Algebra Its Appl. 1992, 165, 59–69. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S.; Cho, J.; Park, S.; Jarrín Perez, F.X.; Kiniry, J.R. Simulated biomass, climate change impacts, and nitrogen management to achieve switchgrass biofuel production at diverse sites in US. Agronomy 2020, 10, 503. [Google Scholar] [CrossRef]

- Kim, S.; Meki, M.N.; Kim, S.; Kiniry, J.R. Crop modeling application to improve irrigation efficiency in year-round vegetable production in the Texas winter garden region. Agronomy 2020, 10, 1525. [Google Scholar] [CrossRef]

- Mal-eum. Electricity Generation Data. Available online: https://www.mal-eum.com/sample (accessed on 29 June 2022).

- Ministry of the Interior and Safety. Yeongam KIC Solar Power Plant Data. Available online: https://www.data.go.kr/data/15089810/fileData.do (accessed on 29 June 2022).

- Korea Meteorological Administration. Automated Synoptic Observing System (ASOS) Data. Available online: https://data.kma.go.kr/data/grnd/selectAsosRltmList.do?pgmNo=36 (accessed on 29 June 2022).

- Ministry of the Interior and Safety. Status of Solar Power Plants in Yeongam-gun. Available online: https://www.data.go.kr/data/15059660/fileData.do (accessed on 29 June 2022).

| Data Type | 21.3% | 25.6% | 32% |

|---|---|---|---|

| Total construction cost (USD) | 17,370.72 | 27,793.14 | 34,741.43 |

| Solar module cost (USD) | 4961.25 | 7938.00 | 9922.50 |

| Structure cost (USD) | 8211.81 | 13,138.90 | 16,423.63 |

| Electric distribution system cost (USD) | 3911.23 | 6257.97 | 7822.46 |

| Other costs (USD) 1 | 286.42 | 458.27 | 572.84 |

| Number of PV modules per unit area (units/m2) | 0.062 | 0.066 | 0.089 |

| Unit construction cost (USD/m2) | 15.32 | 16.34 | 22.06 |

| Month | Solar Radiation (MJ/m2) | Surface Temperature High (°C) 1 | Surface Temperature Low (°C) 2 | Precipitation (mm) | Humidity (%) | Wind Speed (m/s) |

|---|---|---|---|---|---|---|

| June | 3.70 | 29.40 | 19.43 | 12.72 | 76.93 | 2.01 |

| July | 2.77 | 27.71 | 20.92 | 14.80 | 84.67 | 1.94 |

| August | 3.62 | 34.05 | 24.25 | 17.83 | 73.36 | 2.45 |

| September | 3.03 | 27.74 | 16.74 | 7.17 | 74.11 | 1.67 |

| October | 3.27 | 24.68 | 8.73 | 0.30 | 56.94 | 1.67 |

| Crop Type | Shading Ratios (%) | |||

|---|---|---|---|---|

| 0 | 21.3 | 25.6 | 32 | |

| Sesame (Sesamum indicum) | 0.96 | 0.89 (−7%) 1 | 0.83 (−14%) 1 | 0.45 (−53%) 1 |

| Mung bean (Vigna radiata) | 1.95 | 1.54 (−21%) 1 | 1.1 (−44%) 1 | 1.09 (−44%) 1 |

| Red bean (Vigna angularis) | 2.35 | 1.75 (−26%) 1 | 1.52 (−35%) 1 | 1.47 (−37%) 1 |

| Corn (Zea mays) | 8.09 | 8.56 (+6%) 1 | 6.4 (−21%) 1 | 5.63 (−30%) 1 |

| Soybean (Glycine max) | 3.64 | 3.15 (−13%) 1 | 2.88 (−21%) 1 | 2.54 (−30%) 1 |

| Month | Observed Values | Estimated Values | ||

|---|---|---|---|---|

| June | 23.10 | 3.70 | 23.35 | 3.71 |

| July | 21.20 | 2.77 | 20.93 | 3.66 |

| August | 13.50 | 3.62 | 12.97 | 3.44 |

| September | 2.20 | 3.03 | 1.59 | 3.02 |

| October | −9.60 | 3.27 | −8.25 | 2.57 |

| Category | Shading Ratio | Month | ||||

|---|---|---|---|---|---|---|

| June | July | August | September | October | ||

| Measured Electricity (E, kWh/m2/day) | 21.3 1 | 0.06 | 0.04 | 0.05 | 0.05 | 0.05 |

| 25.6 2 | 0.06 | 0.04 | 0.06 | 0.05 | 0.05 | |

| 32.0 3 | 0.08 | 0.06 | 0.08 | 0.07 | 0.07 | |

| Estimated Electricity (E, kWh/m2/day) | 21.3 1 | 0.05 | 0.04 | 0.06 | 0.05 | 0.05 |

| 25.6 2 | 0.05 | 0.04 | 0.06 | 0.05 | 0.06 | |

| 32.0 3 | 0.07 | 0.05 | 0.08 | 0.07 | 0.08 | |

| Crop Type | Shading Ratios (%) | |||

|---|---|---|---|---|

| 0 | 21.3 | 25.6 | 32 | |

| Sesame (Sesamum indicum) | 0.96 | 0.89 (−14%) 1 | 0.80 (−17%) 1 | 0.76 (−21%) 1 |

| Mung bean (Vigna radiata) | 1.85 | 1.52 (−18%) 1 | 1.45 (−21%) 1 | 1.36 (−27%) 1 |

| Red bean (Vigna angularis) | 2.06 | 1.69 (−18%) 1 | 1.61 (−22%) 1 | 1.50 (−27%) 1 |

| Corn (Zea mays) | 8.09 | 6.33 (−22%) 1 | 5.98 (−26%) 1 | 5.47 (−32%) 1 |

| Soybean (Glycine max) | 3.81 | 3.05 (−20%) 1 | 2.90 (−24%) 1 | 2.67 (−30%) 1 |

| Year | Solar Radiation (MJ/m2) | Surface Temperature High (°C) 1 | Surface Temperature Low (°C) 2 | Precipitation (mm) | Humidity (%) | Wind Speed (m/s) |

|---|---|---|---|---|---|---|

| 2017 | 10.05 | 27.66 | 18.40 | 4.27 | 79.50 | 2.02 |

| 2018 | 9.59 | 27.80 | 18.46 | 7.23 | 76.00 | 2.34 |

| 2019 | 12.21 | 27.16 | 18.50 | 7.12 | 77.80 | 1.92 |

| 2020 | 14.95 | 26.72 | 18.24 | 8.05 | 78.80 | 1.96 |

| 2021 | 16.70 | 28.14 | 19.06 | 6.69 | 79.80 | 1.50 |

| Category | Year | ||

|---|---|---|---|

| 2018 | 2019 | 2020 | |

| Measured Electricity (E, kWh/day) 1 | 12,167.91 | 12,034.93 | 11,519.06 |

| Estimated Electricity (E, kWh/day) 1 | 10,323.13 | 9733.22 | 11,518.84 |

| Plant Type | Crop Type | ||||

|---|---|---|---|---|---|

| Sesame (Sesamum indicum) | Mung Bean (Vigna radiata) | Red Bean (Vigna angularis) | Corn (Zea mays) | Soybean (Glycine max) | |

| 98.8 kW PV Power Plant | 0.69 (−28%) 1 | 1.20 (−35%) 1 | 1.32 (−36%) 1 | 4.65 (−42%) 1 | 2.31 (−39%) 1 |

| 3 MW PV Power Plant | 0.58 (−39%) 1 | 0.94 (−49%) 1 | 1.02 (−50%) 1 | 3.30 (−59%) 1 | 1.70 (−55%) 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Kim, Y.; On, Y.; So, J.; Yoon, C.-Y.; Kim, S. Hybrid Performance Modeling of an Agrophotovoltaic System in South Korea. Energies 2022, 15, 6512. https://doi.org/10.3390/en15186512

Kim S, Kim Y, On Y, So J, Yoon C-Y, Kim S. Hybrid Performance Modeling of an Agrophotovoltaic System in South Korea. Energies. 2022; 15(18):6512. https://doi.org/10.3390/en15186512

Chicago/Turabian StyleKim, Sojung, Youngjin Kim, Youngjae On, Junyong So, Chang-Yong Yoon, and Sumin Kim. 2022. "Hybrid Performance Modeling of an Agrophotovoltaic System in South Korea" Energies 15, no. 18: 6512. https://doi.org/10.3390/en15186512