Model Predictive Phase Control for Single-Phase Electric Springs

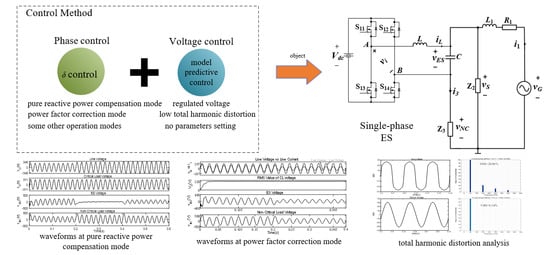

Abstract

:1. Introduction

- Enrich the control means of the ES;

- Enable the circuit to operate in different power modes;

- Model predictive control is used instead of the traditional controller to avoid the trouble of the controller parameter setting in the traditional system control;

- Compared with the existing methods, the CL voltage distortion degree during line voltage distortion is further reduced.

2. Operating Principles of Single-Phase ES

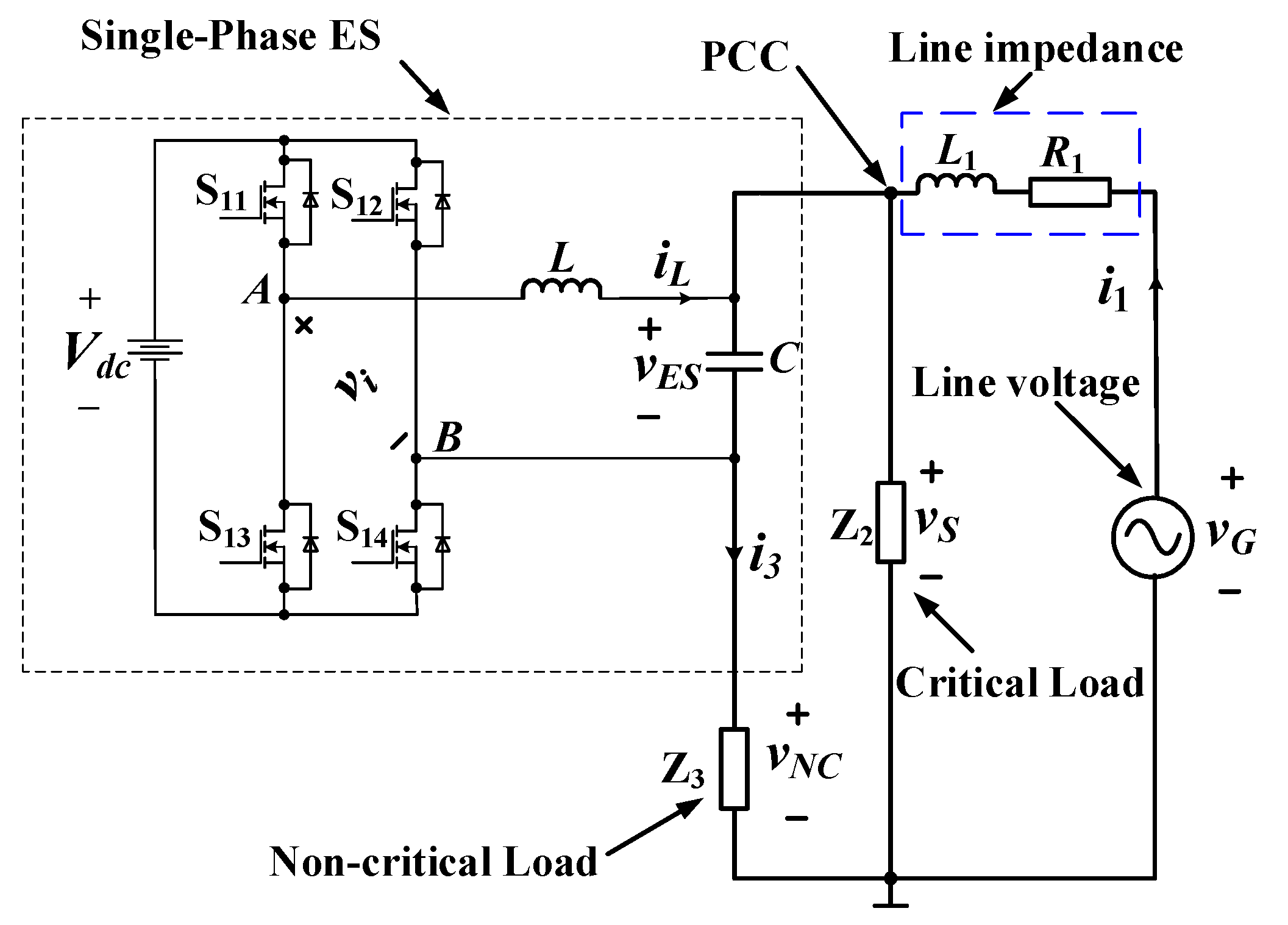

2.1. Topology of Existing Single-Phase ES

2.2. Existing δ Control

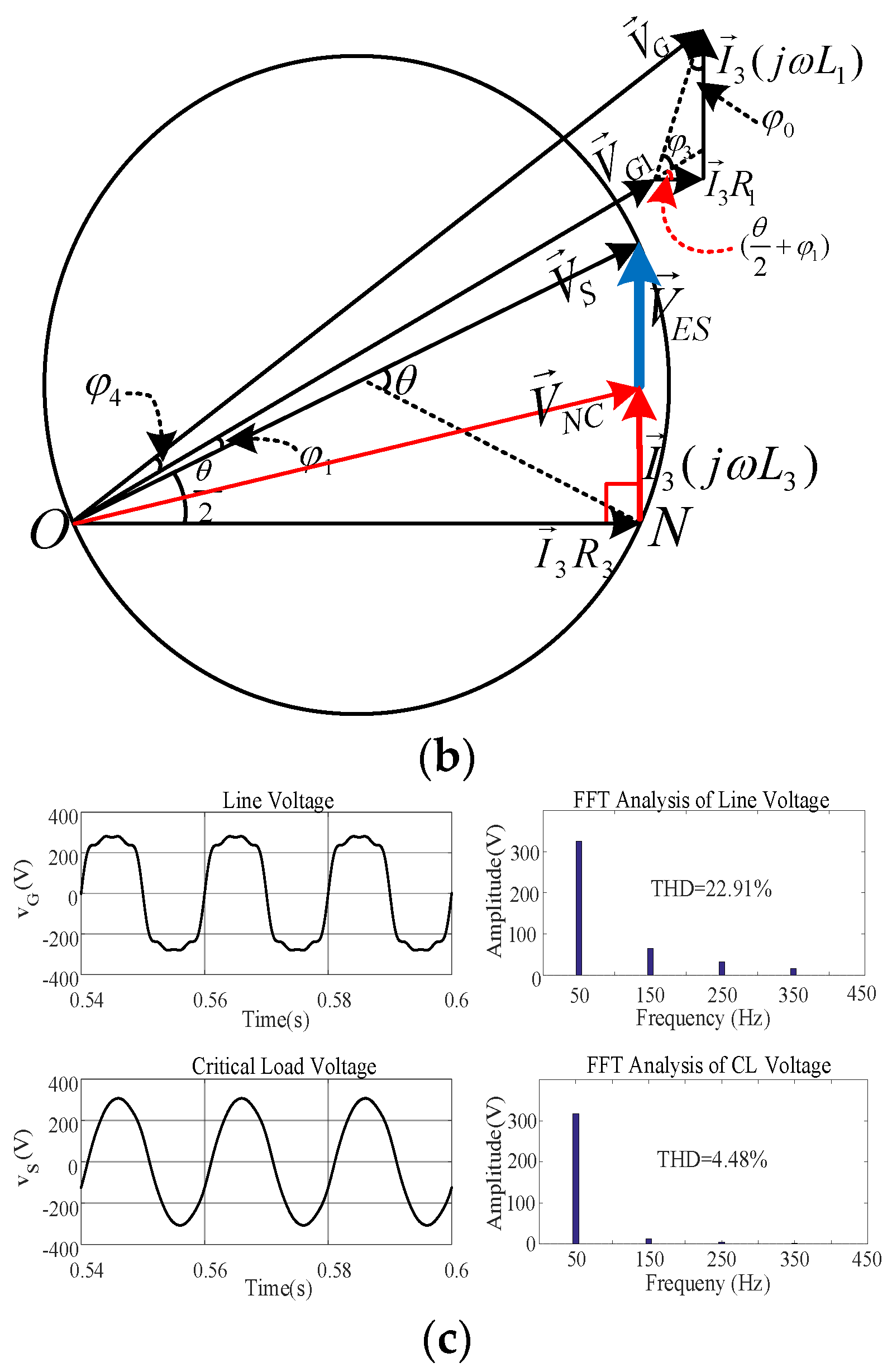

2.3. Disadvantages of Existing δ Control

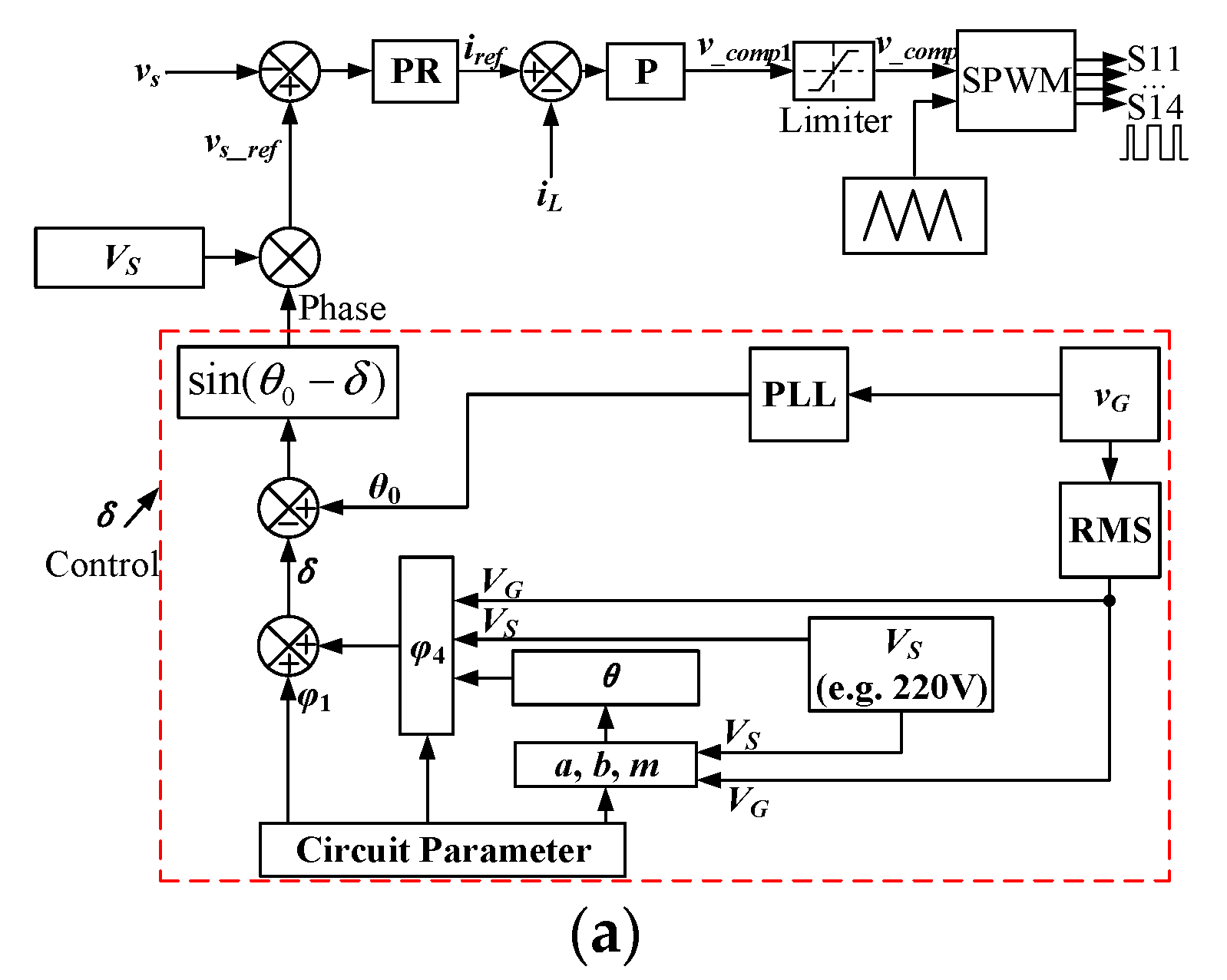

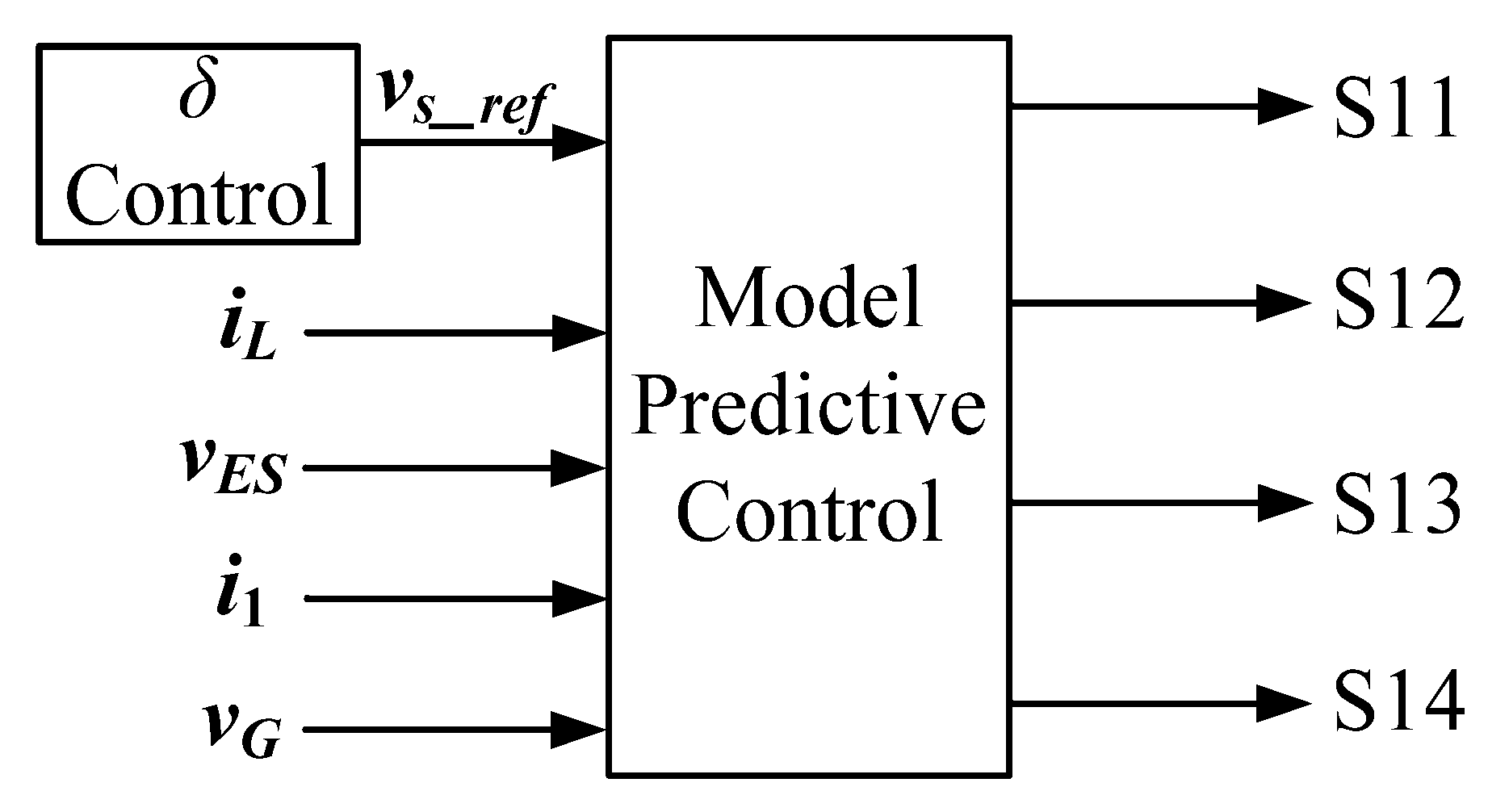

3. Model Predictive Control of Single-Phase ES

3.1. The Proposed MPC for Single-Phase ES

3.2. System Modeling of Single-Phase ES

3.3. Discrete-Ttime State Space Model

3.4. VSI Modeling and Switching State Selection

4. Simulation and Discussion

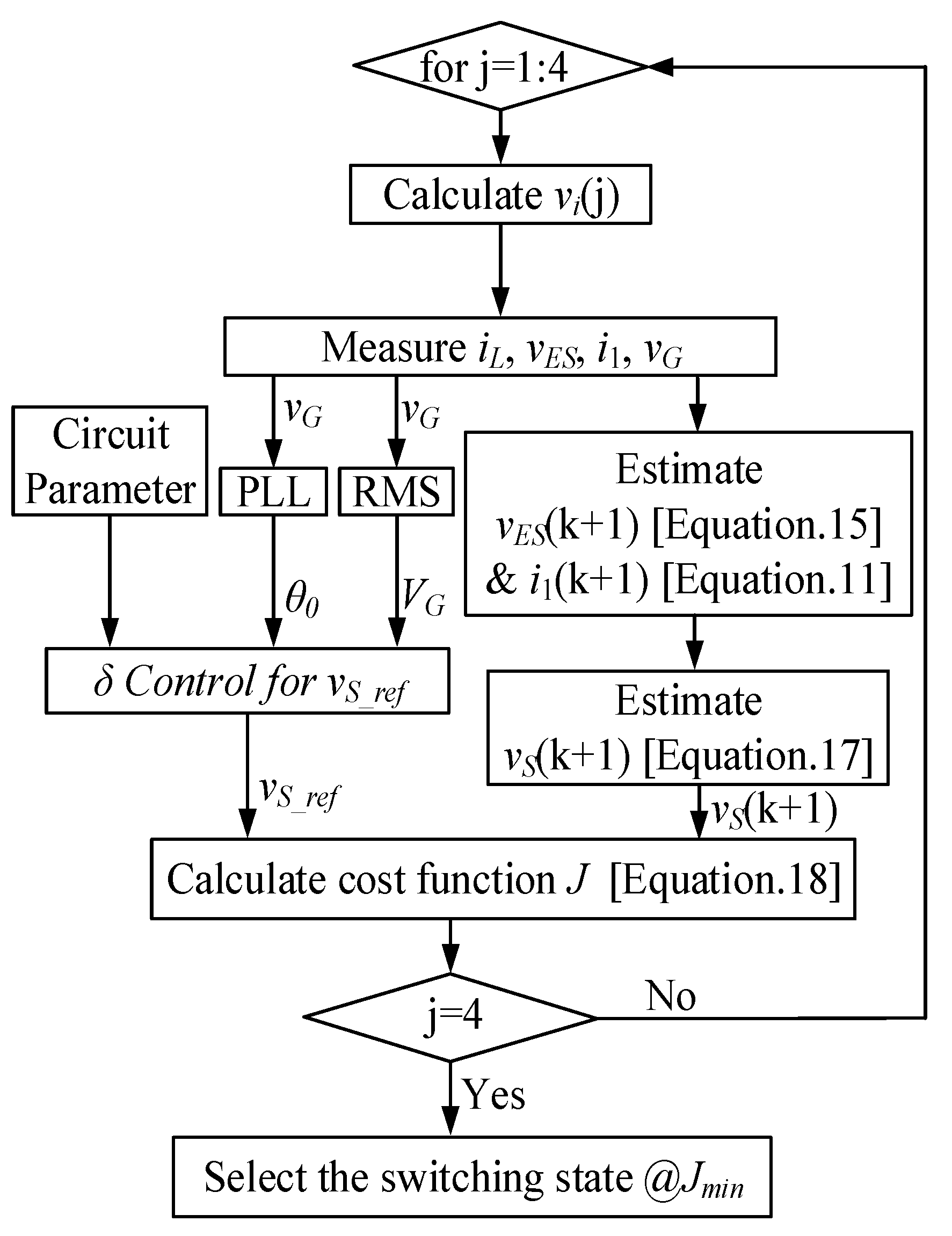

4.1. Flowchart of MPC and δ Control

- Measure grid voltage vG, grid current i1, inductor current iL, and ES voltage vES;

- Predict vS based on the predicted ES voltage and predicted grid current;

- Calculate the reference of vS based on the required circuit parameters and instantaneous phase and root-mean-square value of vG;

- Calculate the cost function J considering all the four switching states;

- Select the switching state that minimizes the cost function J and apply it to the inverter.

4.2. Pure Reactive Power Compensation Mode

4.2.1. Ideal Grid Condition

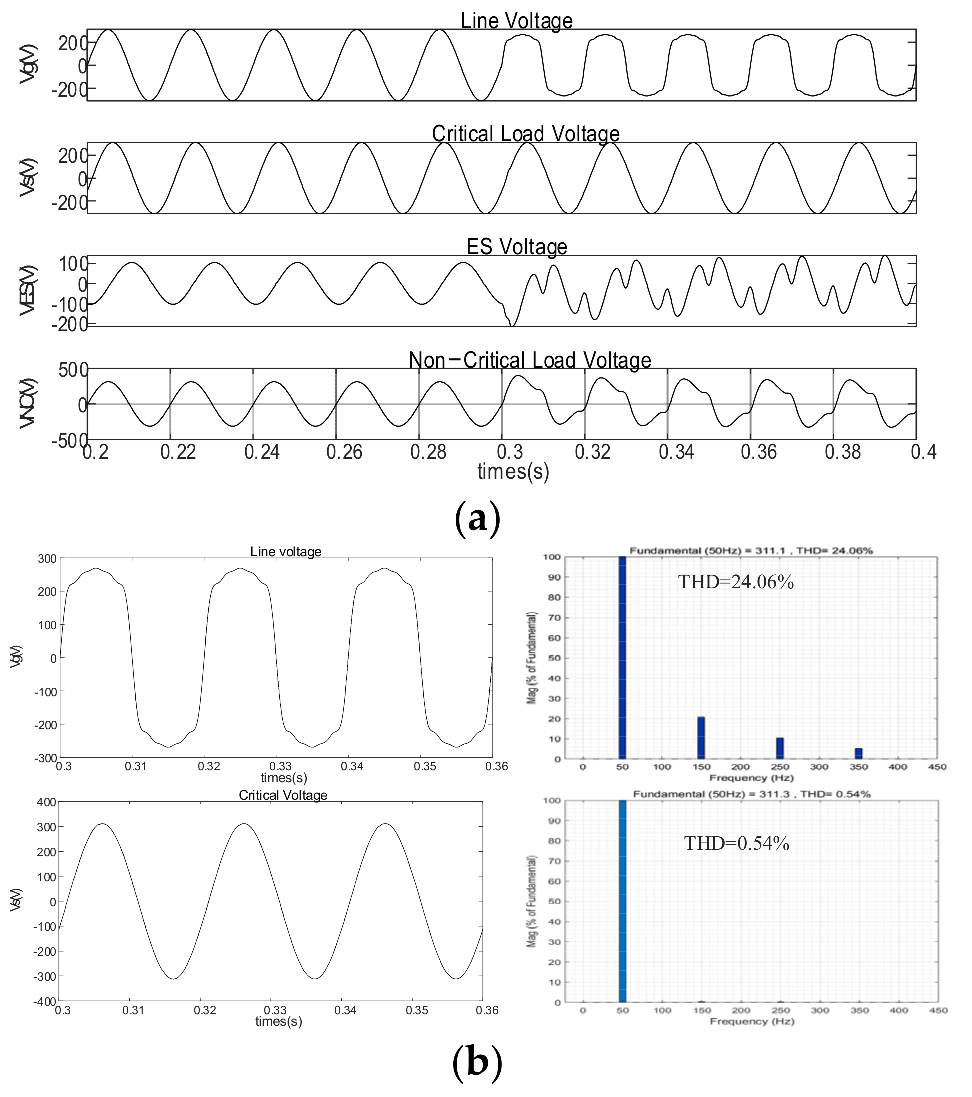

4.2.2. Grid Voltage Distorted

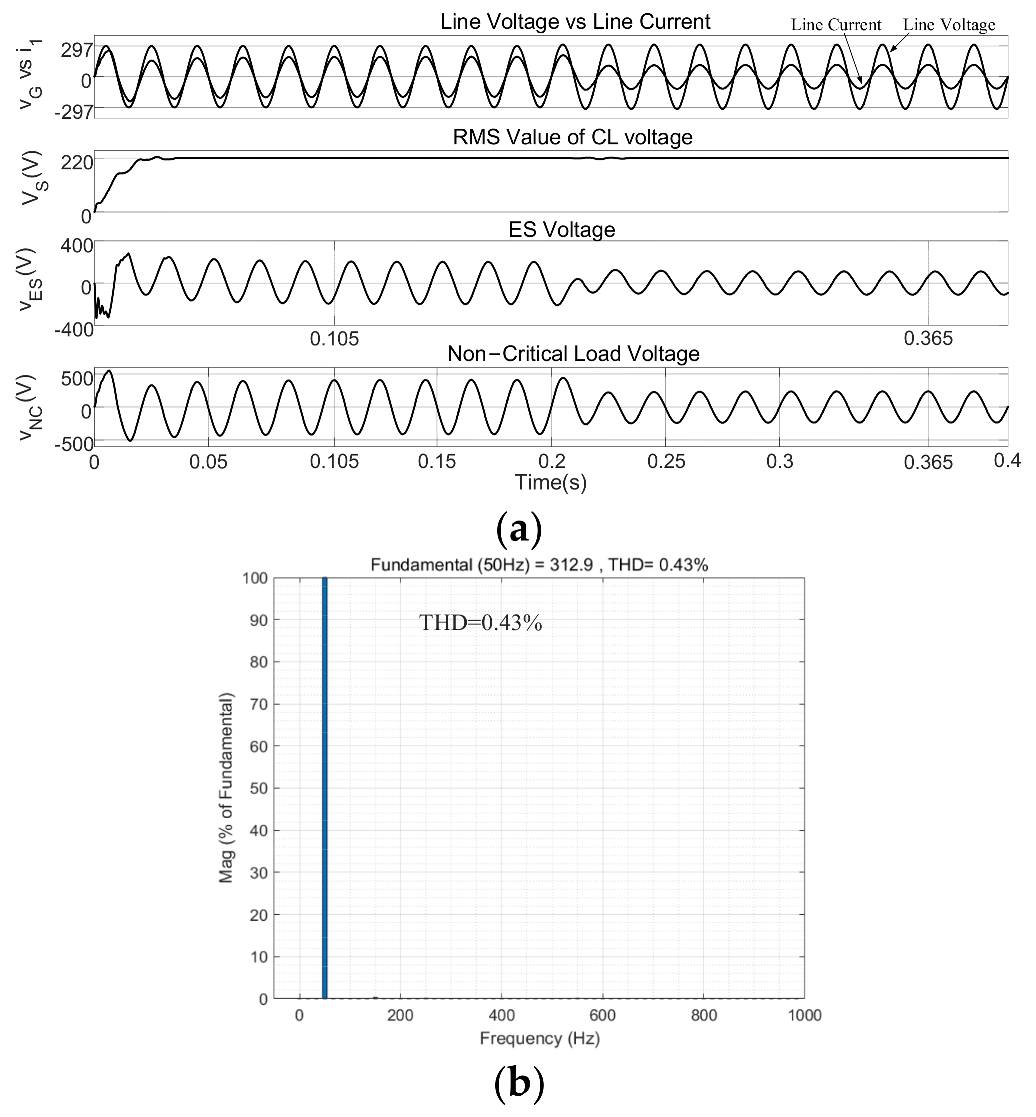

4.3. PFC Mode

4.4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Cheng, M.; Zhu, Y. The state of the art of wind energy conversion systems and technologies: A review. Energy Convers. Manag. 2014, 88, 332–347. [Google Scholar] [CrossRef]

- Hu, H.; Shao, Y.; Tang, L.; Ma, J.; He, Z.; Gao, S. Overview of harmonic and resonance in railway electrification systems. IEEE Trans. Ind. Appli. 2018, 54, 5227–5245. [Google Scholar] [CrossRef]

- Yang, T.; Mok, K.; Ho, S.; Tan, S.; Lee, C.; Hui, R. Use of integrated photovoltaic-electric spring system as a power balancer in power distribution networks. IEEE Trans. Power Electron. 2019, 34, 5312–5324. [Google Scholar] [CrossRef]

- Qiu, D.; Yuan, C.; Zhang, B.; Ke, M.; Chen, Y.; Xie, F. An improved electric spring topology based on LCL Filter. IEEE Trans. Power Electron. 2022, 37, 5984–5994. [Google Scholar] [CrossRef]

- Wang, Q.; Cheng, M.; Chen, Z.; Wang, Z. Steady-state analysis of electric springs with a novel δ control. IEEE Trans. Power Electron. 2015, 30, 7159–7169. [Google Scholar] [CrossRef]

- Mok, K.; Tan, S.; Hui, S. Decoupled power angle and voltage control of electric springs. IEEE Trans. Power Electron. 2016, 31, 1216–1229. [Google Scholar] [CrossRef]

- Tan, S.; Lee, C.; Hui, S. General steady-state analysis and control principle of electric springs with active and reactive power compensations. IEEE Trans. Power Electron. 2013, 28, 3958–3969. [Google Scholar] [CrossRef]

- Chen, T.; Liu, H.; Lee, C.; Hui, S. A generalized controller for electric-spring-based smart load with both active and reactive power compensation. IEEE Trans. Emerg. Sel. Topics Power Electron. 2020, 8, 1454–1465. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, J.; Zheng, Y.; Qiu, J.; Wen, F. A hybrid method for electric spring control based on data and knowledge integration. IEEE Trans. Smart Grid 2020, 11, 2303–2312. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, Z.; Cheng, M.; Deng, F.; Buja, G. Direct power control of three-phase electric springs. IEEE Trans. Ind. Electron. 2022, 69, 13033–13044. [Google Scholar] [CrossRef]

- Wang, M.; Yan, S.; Tan, S.; Hui, S. Hybrid-DC electric springs for DC voltage regulation and harmonic cancellation in DC Microgrids. IEEE Trans. Power Electron. 2018, 33, 1167–1177. [Google Scholar] [CrossRef]

- Wang, M.; Mok, K.; Tan, S.; Hui, S. Multifunctional DC electric springs for improving voltage quality of DC grids. IEEE Trans. Smart Grid 2018, 9, 1552–1561. [Google Scholar] [CrossRef]

- Liang, L.; Yi, H.; Hou, Y.; Hill, D. An optimal placement model for electric springs in distribution networks. IEEE Trans. Smart Grid 2021, 12, 491–501. [Google Scholar] [CrossRef]

- Chen, J.; Yan, S.; Yang, T.; Tan, S.; Hui, S. Practical evaluation of droop and consensus control of distributed electric springs for both voltage and frequency regulation in microgrid. IEEE Trans. Power Electron. 2019, 34, 6947–6959. [Google Scholar] [CrossRef]

- Mohammadali, N.; Jamshid, A.; Sasan, P. Hybrid stochastic/robust flexible and reliable scheduling of secure networked microgrids with electric springs and electric vehicles. Appl. Energy 2021, 300, 117395. [Google Scholar]

- Mohammadali, N.; Jamshid, A.; Sasan, P. Flexible operation of grid-connected microgrids using electric springs. IET Gener. Transm. Dis. 2019, 14, 254–264. [Google Scholar]

- Mohammadali, N.; Jamshid, A.; Taher, N.; Sasan, P.; Matti, L. Bi-level fuzzy stochastic-robust model for flexibility valorizing of renewable networked microgrids. Sustain. Energy Grids 2022, 31, 100684. [Google Scholar]

- Mohammadali, N.; Jamshid, A.; Sasan, P. Flexibility pricing of integrated unit of electric spring and EVs parking in microgrids. Energy 2022, 239, 122080. [Google Scholar]

- Wang, W.; Yan, L.; Zeng, X.; Fan, B.; Guerrero, J. Principle and design of a single-phase inverter based grounding system for neutral-to-ground voltage compensation in distribution networks. IEEE Trans. Ind. Electron. 2017, 64, 1204–1213. [Google Scholar] [CrossRef]

- Hu, Y.; Deng, Y.; Liu, Q.; He, X. Asymmetry three-level grid-connected current hysteresis control with varying bus voltage and virtual oversample method. IEEE Trans. Power Electron. 2014, 29, 3214–3222. [Google Scholar] [CrossRef]

- Pavlou, K.; Vasiladiotis, M.; Manias, S. Constrained model predictive control strategy for single-phase switch-mode rectifiers. IET Power Electron. 2012, 5, 31–40. [Google Scholar] [CrossRef]

- Gong, Z.; Wu, X.; Dai, P.; Zhu, R. Modulated model predictive control for MMC-based active front-end rectifiers under unbalanced grid conditions. IEEE Trans. Ind. Electron. 2019, 66, 2398–2409. [Google Scholar] [CrossRef]

- Xie, C.; Zhao, X.; Li, K.; Zou, J.; Guerrero, J. Multirate resonant controllers for grid-connected inverters with harmonic compensation function. IEEE Trans. Ind. Electron. 2019, 66, 8981–8991. [Google Scholar] [CrossRef] [Green Version]

| Parameters | Values |

|---|---|

| Regulated mains voltage (VS) | 220 V |

| DC bus voltage (Vdc) | 400 V |

| Line resistance (R1) | 0.1 Ω |

| Line inductance (L1) | 2.4 mH |

| Critical load (R2) | 43.5 Ω |

| Non-critical load (R3) | 2.2 Ω |

| Inductance of low-pass filter (L) | 3 mH |

| Capacitance of low-pass filter (C) | 50 µF |

| Switching frequency (fs) | 20 kHz |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Ding, H.; Yan, S.; Buja, G. Model Predictive Phase Control for Single-Phase Electric Springs. Energies 2022, 15, 6654. https://doi.org/10.3390/en15186654

Wang Q, Ding H, Yan S, Buja G. Model Predictive Phase Control for Single-Phase Electric Springs. Energies. 2022; 15(18):6654. https://doi.org/10.3390/en15186654

Chicago/Turabian StyleWang, Qingsong, Hao Ding, Shuo Yan, and Giuseppe Buja. 2022. "Model Predictive Phase Control for Single-Phase Electric Springs" Energies 15, no. 18: 6654. https://doi.org/10.3390/en15186654

APA StyleWang, Q., Ding, H., Yan, S., & Buja, G. (2022). Model Predictive Phase Control for Single-Phase Electric Springs. Energies, 15(18), 6654. https://doi.org/10.3390/en15186654