Lateral Dynamic Response of Offshore Pipe Piles Considering Effect of Superstructure

Abstract

1. Introduction

2. Governing Equation and Boundary Conditions

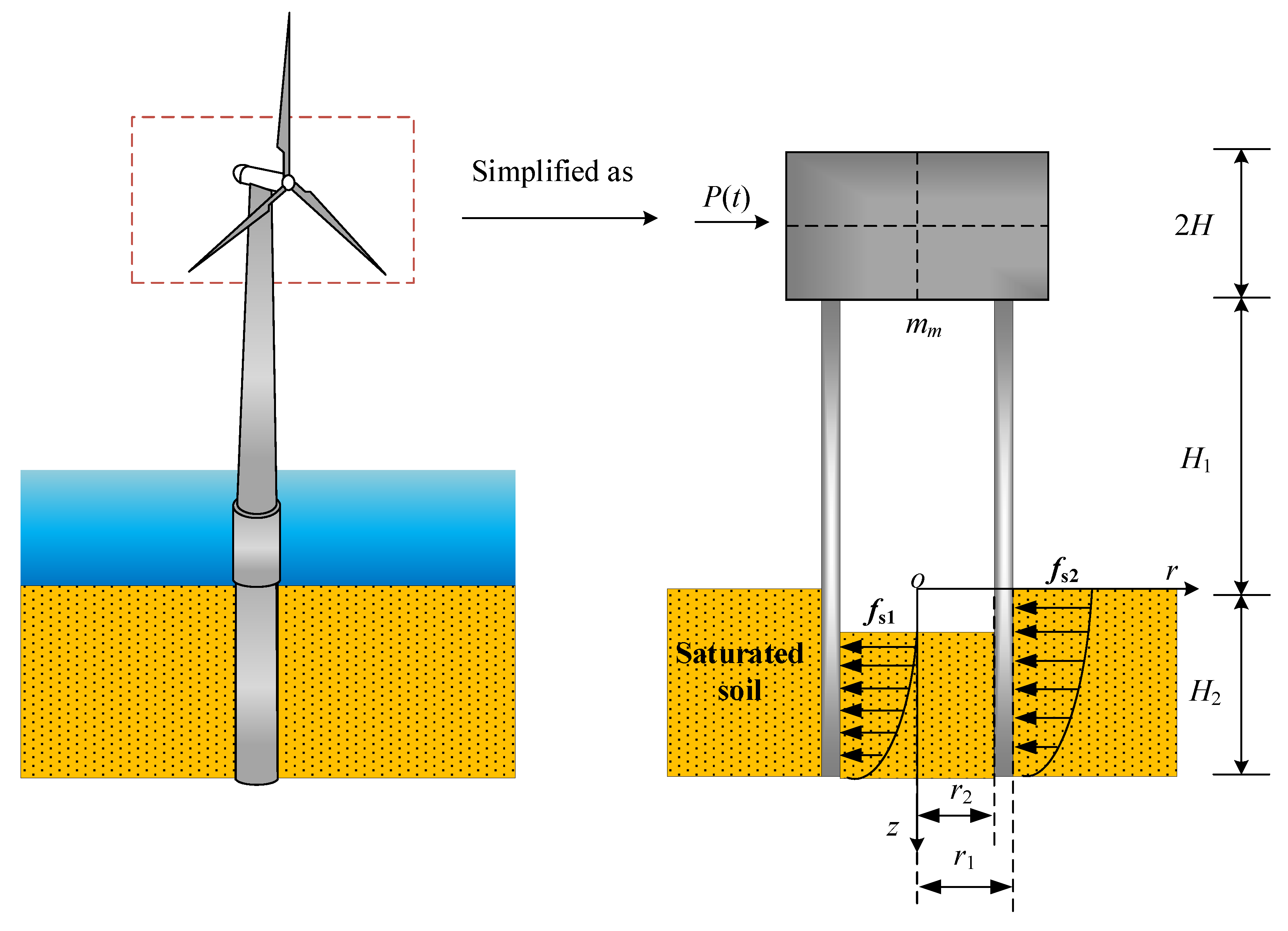

2.1. Models and Assumptions

- (1)

- (2)

- The soil is viscoelastic, isotropic and homogenous and regarded as a two-phase medium composed of pore fluid and solid skeleton;

- (3)

- The soil–pile system undergoes slight deformation throughout the vibration. The pile and soil are in perfect contact at the soil–pile interface;

- (4)

- The pile–soil interface is considered completely impervious to water, and the pile end is assumed to be a fixed boundary; and

- (5)

- The superstructure is simplified as a rigid platform with a concentrated mass block.

2.2. Governing Equation of the Soil

2.3. Governing Equation of Piles

2.4. Governing Equation of Rigid Platforms

2.5. Boundary and Continuity Conditions

- (1)

- The displacement and stress of the soil surrounding the pile approach zero at an infinite distance:

- (2)

- The displacement and stress at the center of the soil plug are finite values:

- (3)

- The pile–soil interface is considered to be completely impervious to water:

- (4)

- The continuity conditions at the pile–soil interface are:

- (5)

- Compared with the vertically loaded piles, the horizontally loaded piles have an efficient length beyond which further variation of pile length or boundary conditions gives rise to a negligible influence on the horizontal bearing capacity of the piles [28]. In reality, offshore piles generally exceed the efficient pile length, and varied pile-end assumptions almost have no influence on the horizontal dynamic impedance of piles. Therefore, from the viewpoint of engineering application, the pile end is assumed herein to be a fixed boundary condition for mathematical simplicity. Assuming the pile end to be a fixed support, the boundary conditions can be derived as:

- (6)

- The continuity conditions between different pile segments are expressed as:

3. Solutions of Governing Equations

3.1. Solutions of Soil Governing Equations

3.2. Solutions for Governing Equations of a Saturated Soil–Pipe Pile–Rigid Platform System

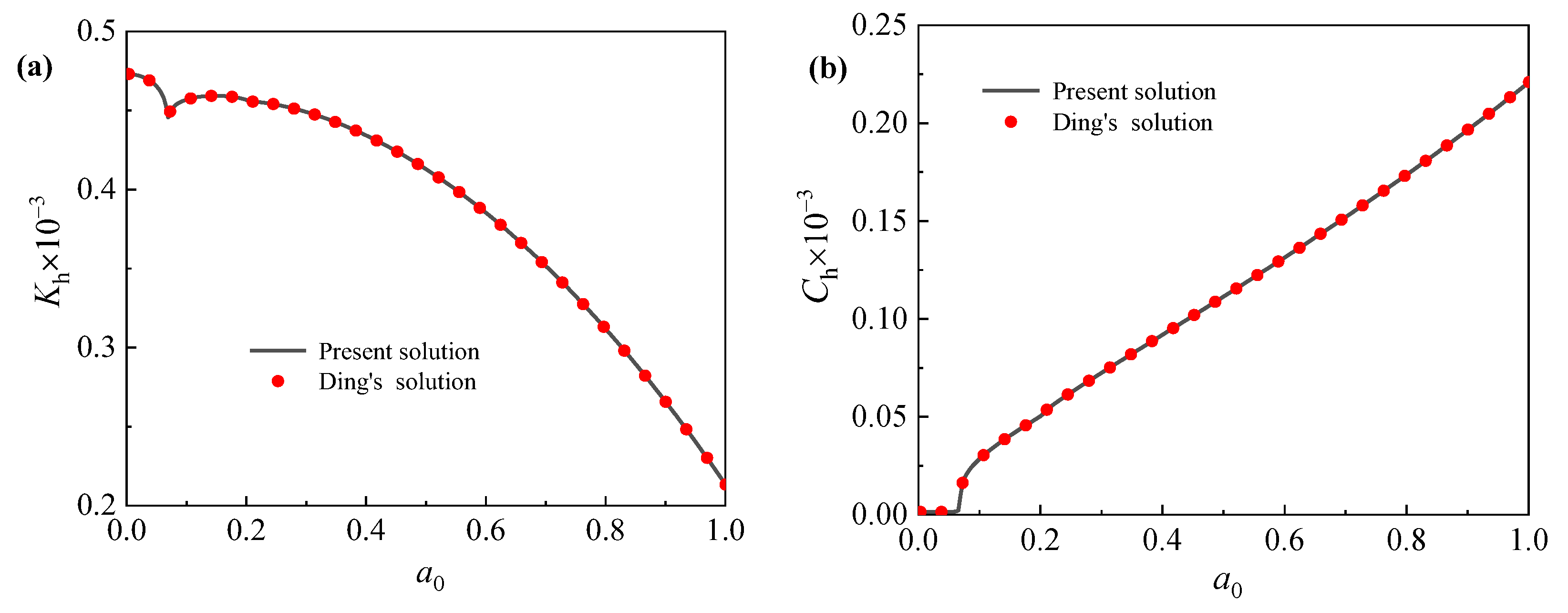

4. Validation

Comparison with Existing Theoretical Models

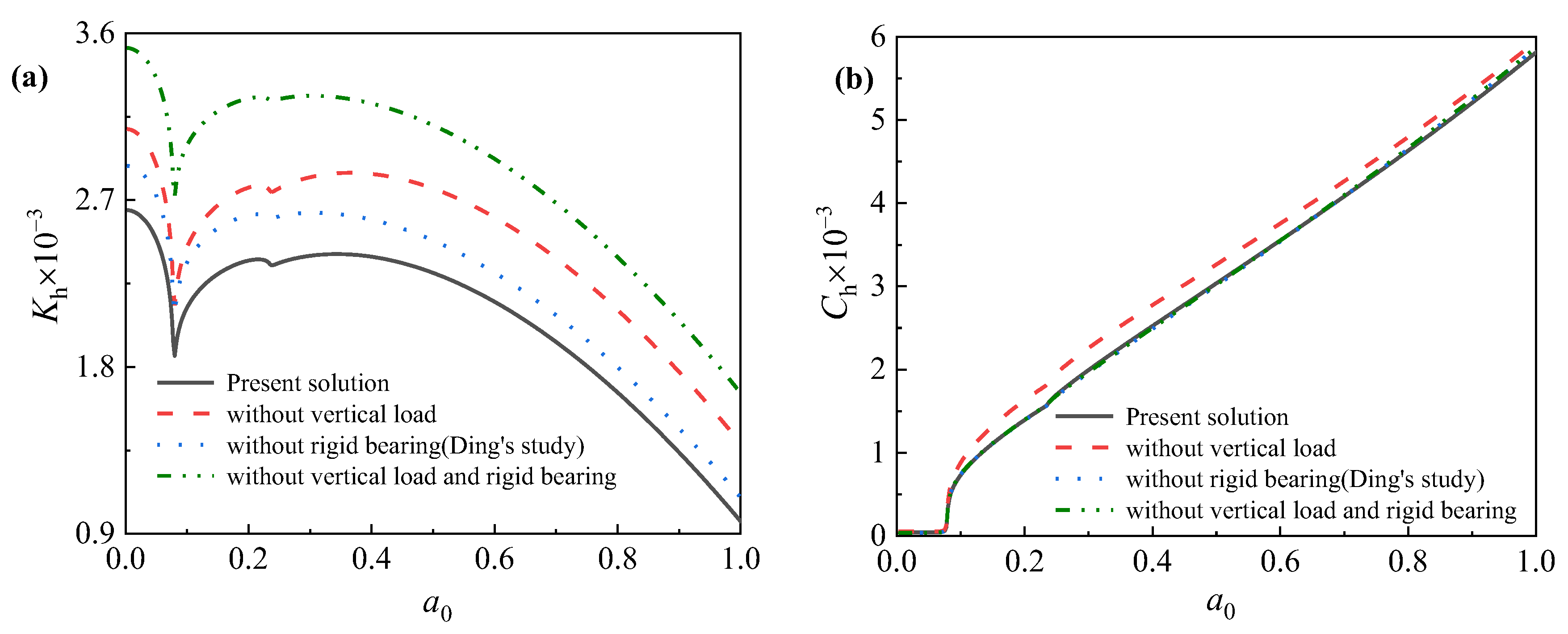

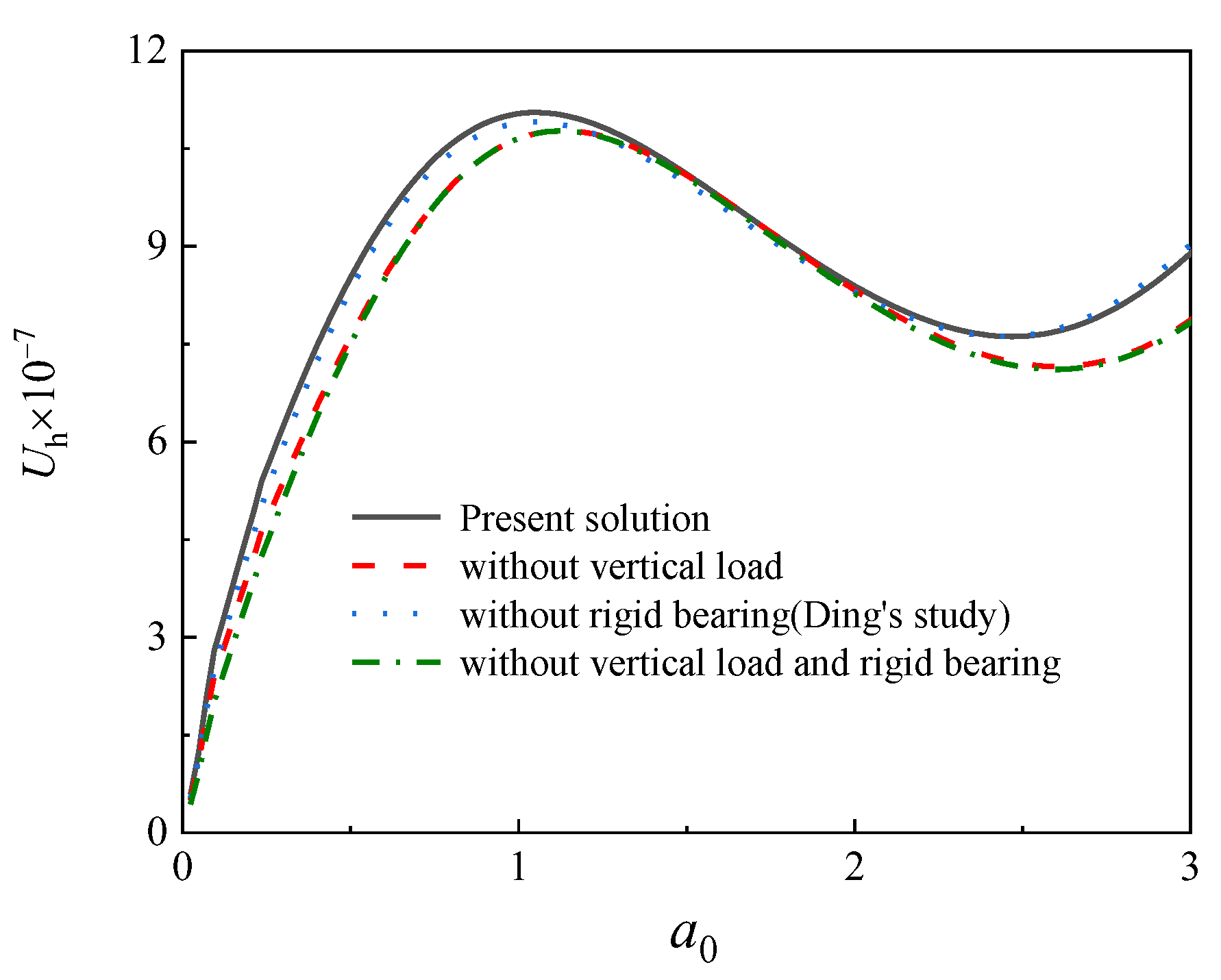

5. Parametric Analysis and Discussion

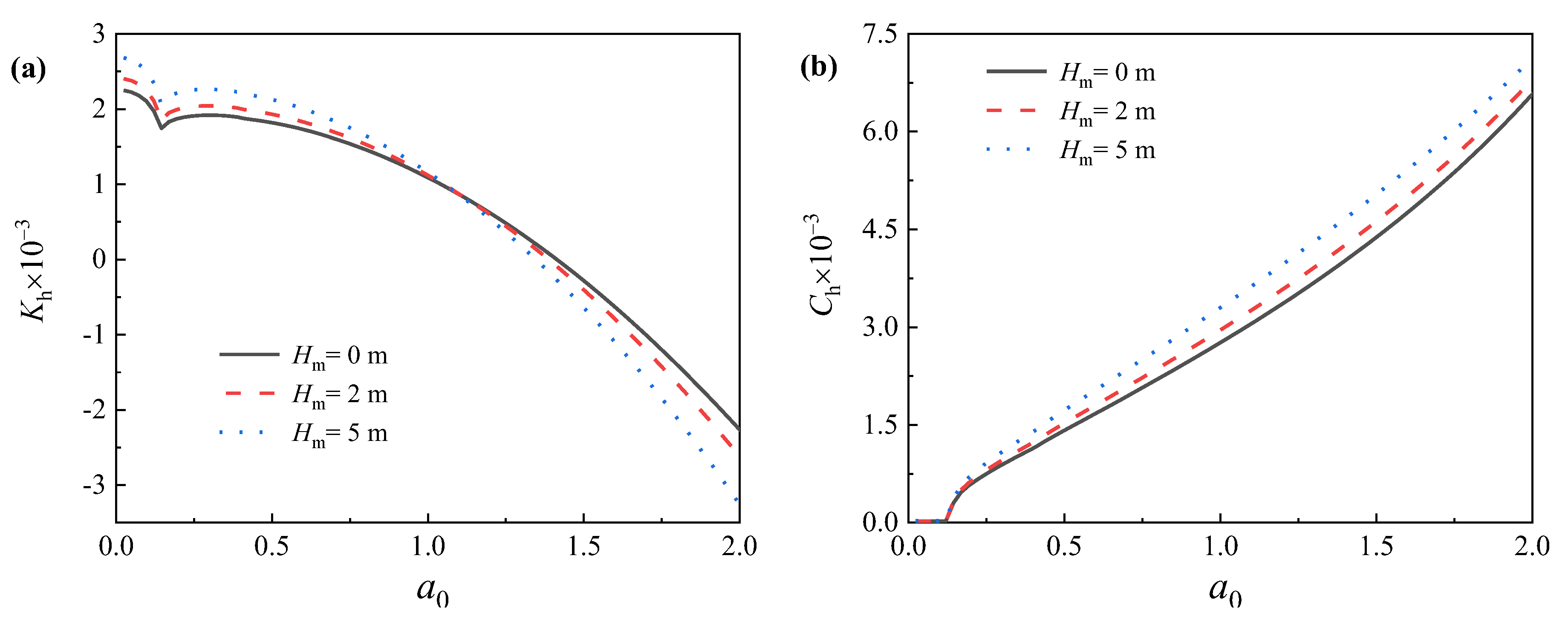

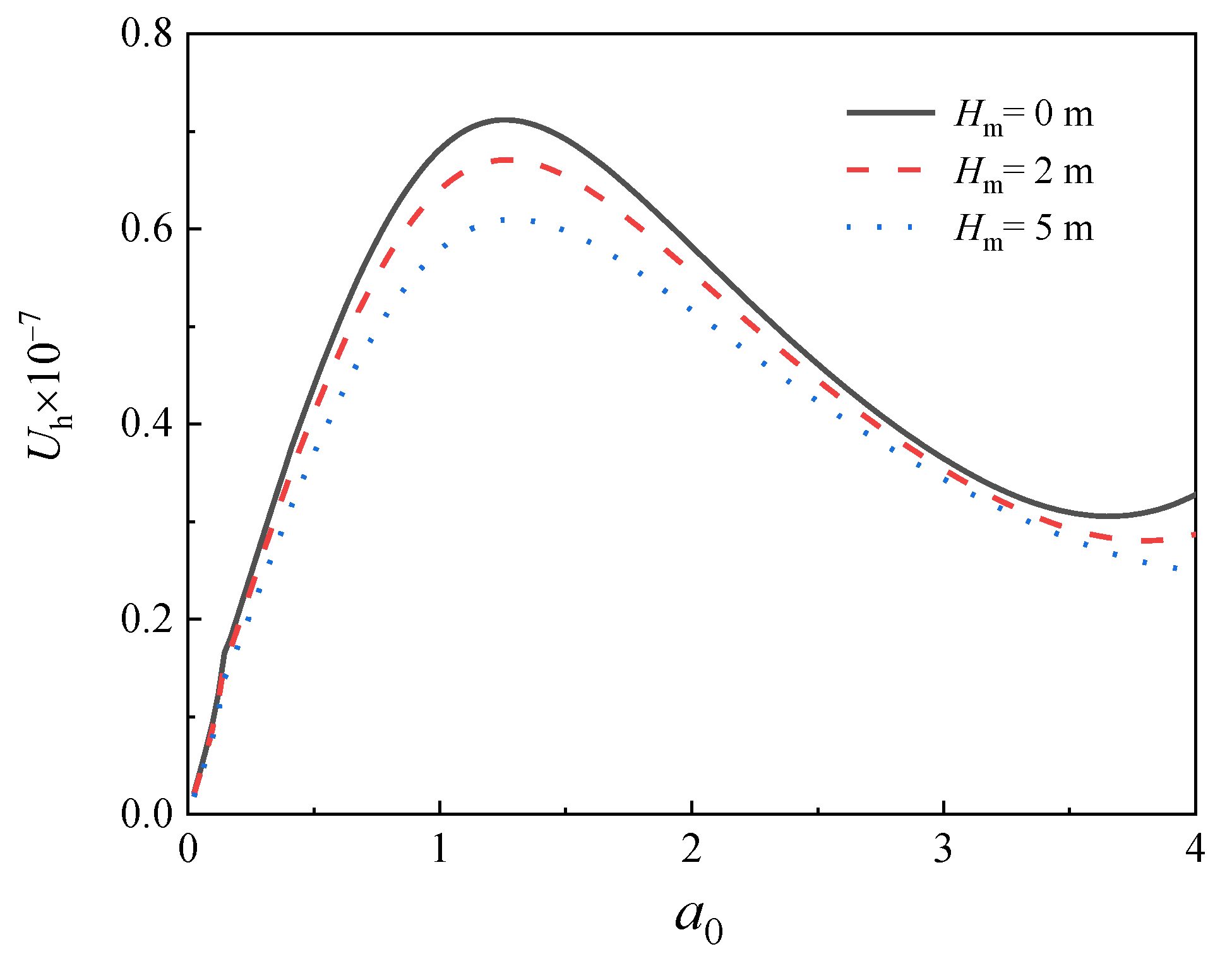

5.1. Influence of Rigid Platform Height on Lateral Dynamic Characteristics of Offshore Pipe Piles

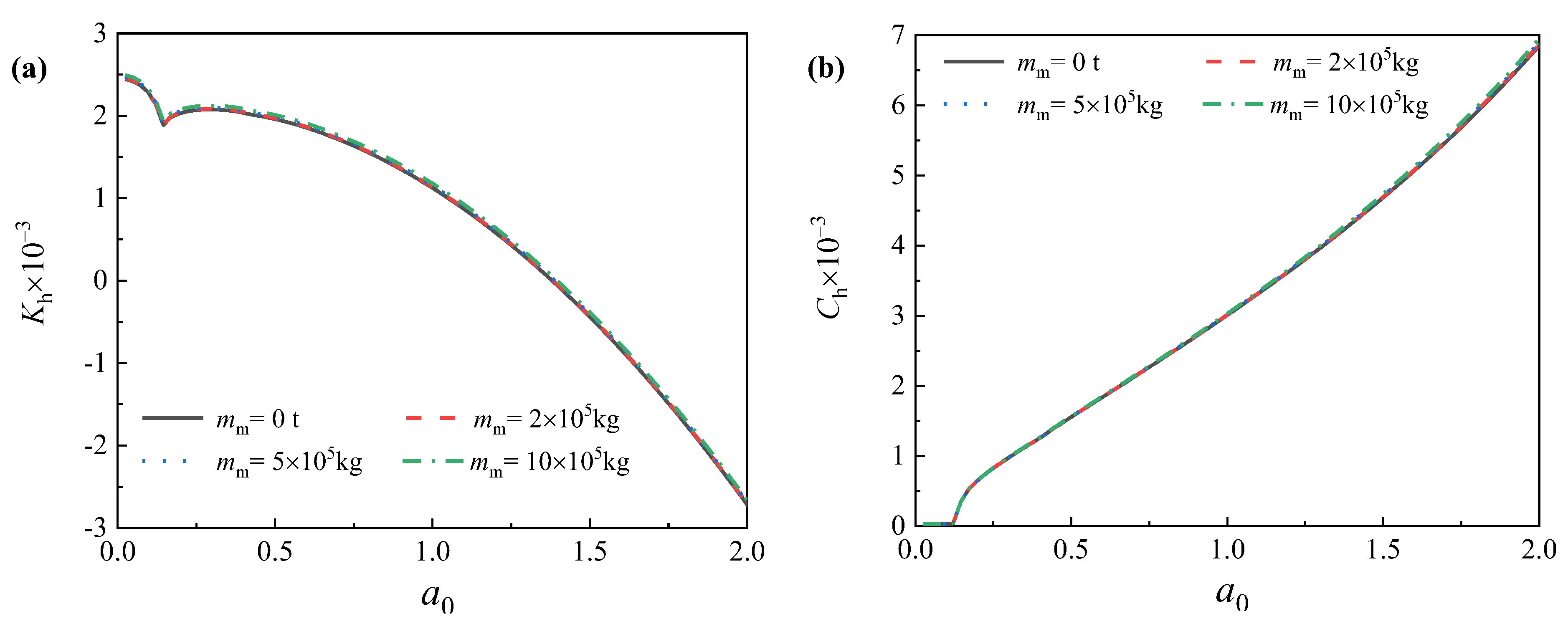

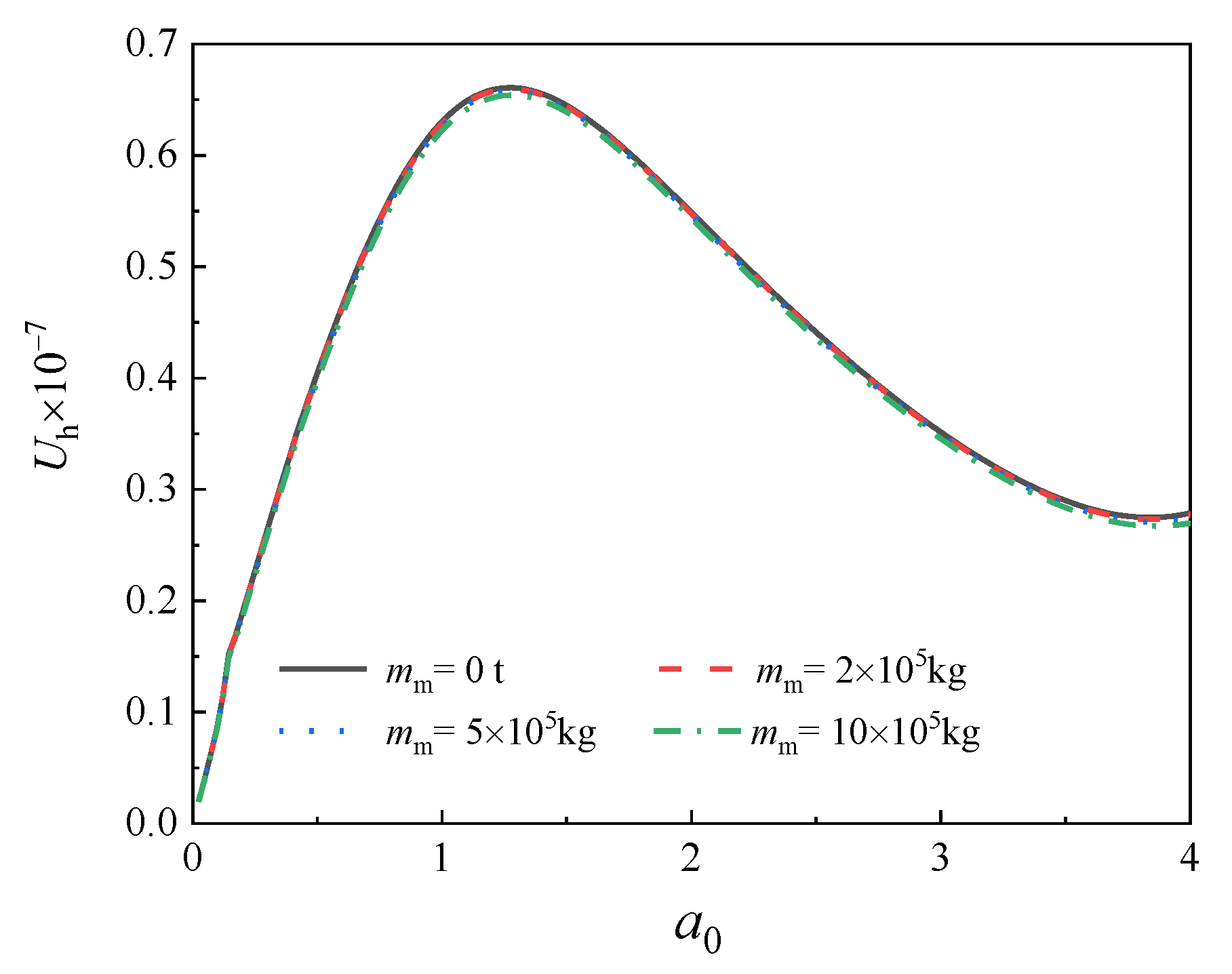

5.2. Influence of Superstruture Mass on Lateral Dynamic Characteristics of Offshore Pipe Piles

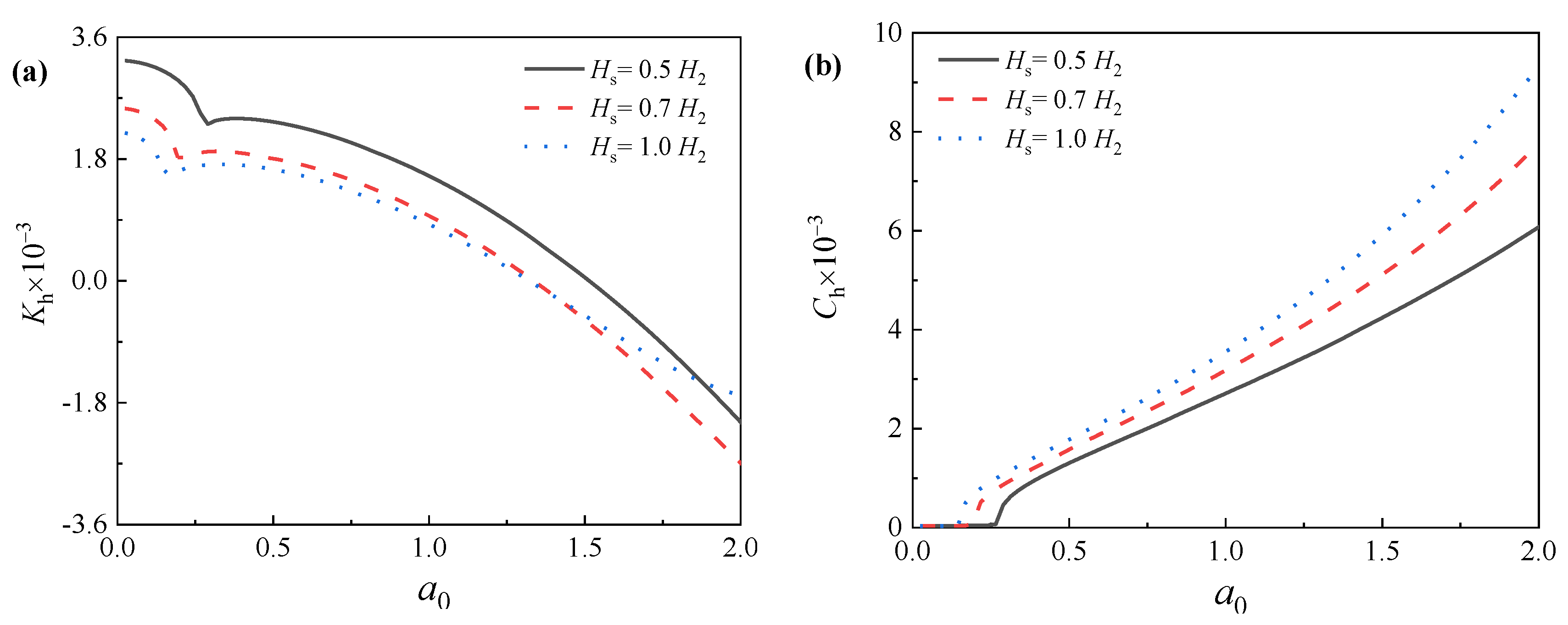

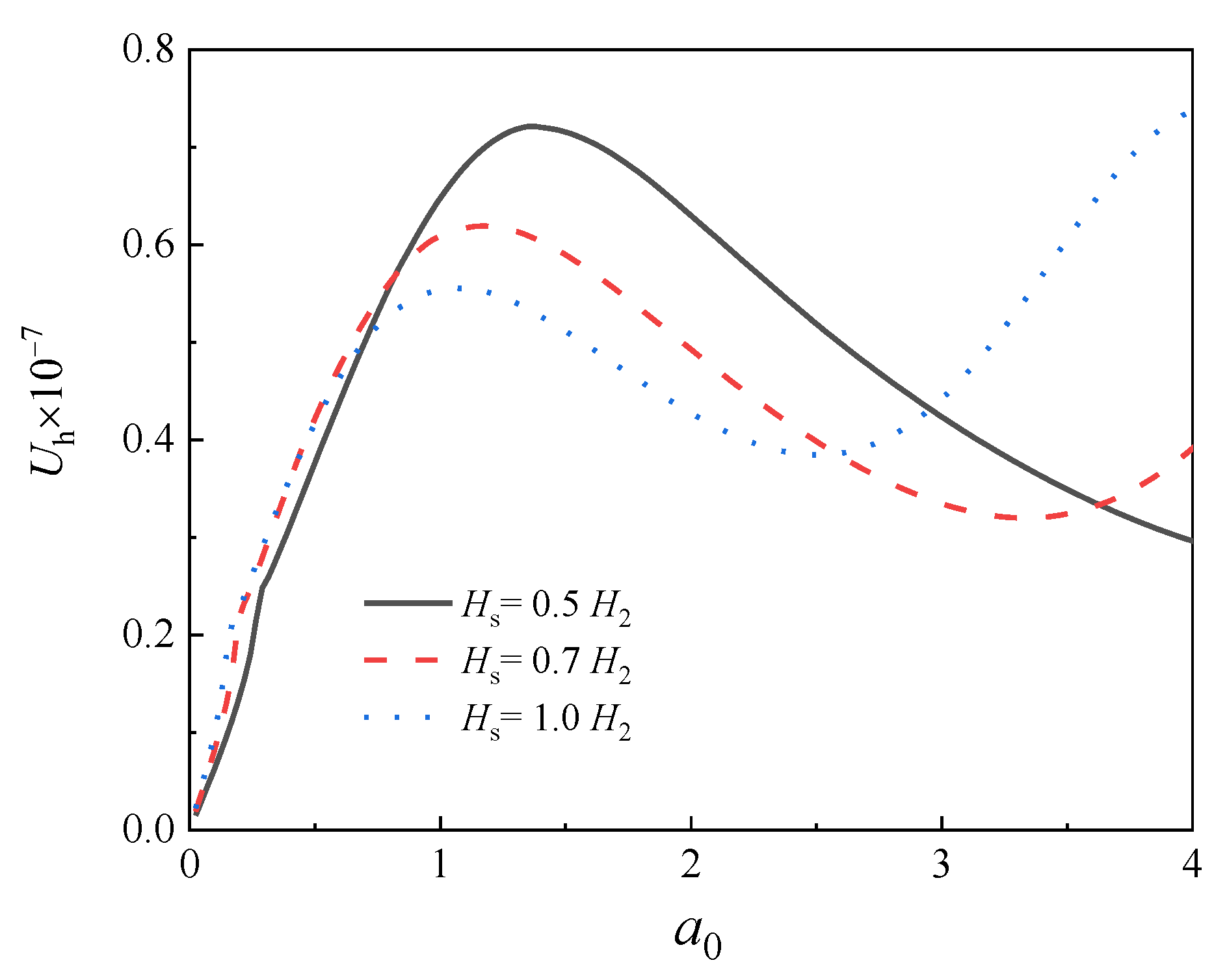

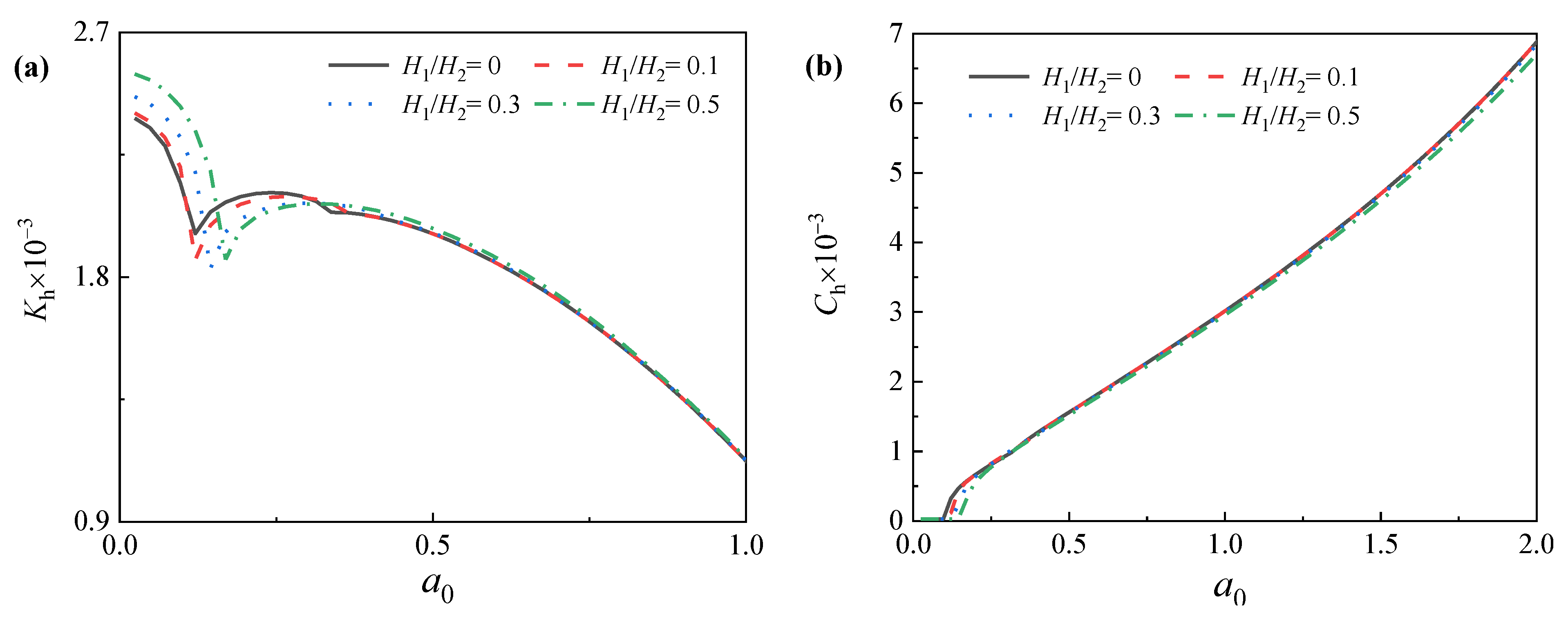

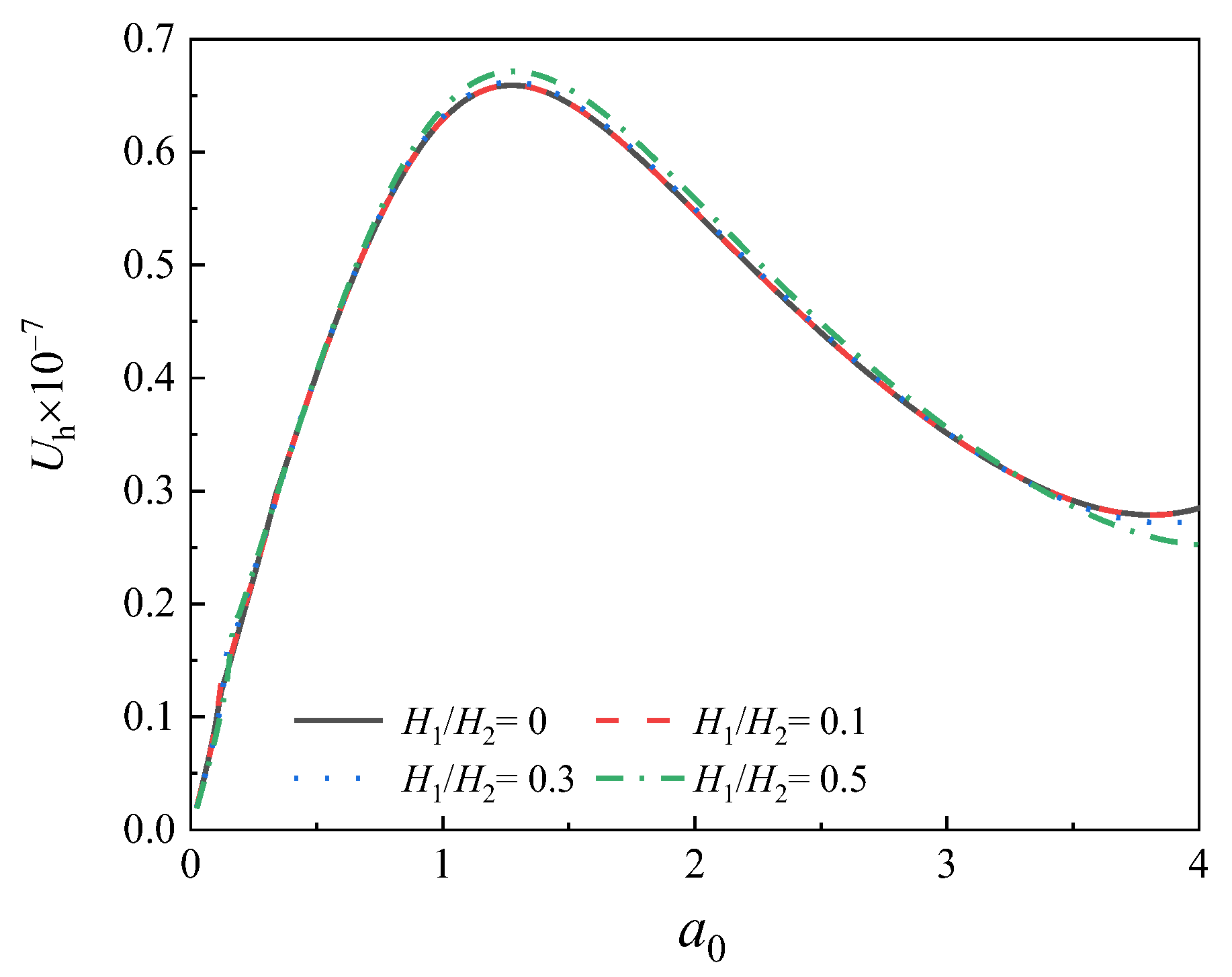

5.3. Influence of Soil Plug Height on Lateral Dynamic Characteristics of Offshore Pipe Piles

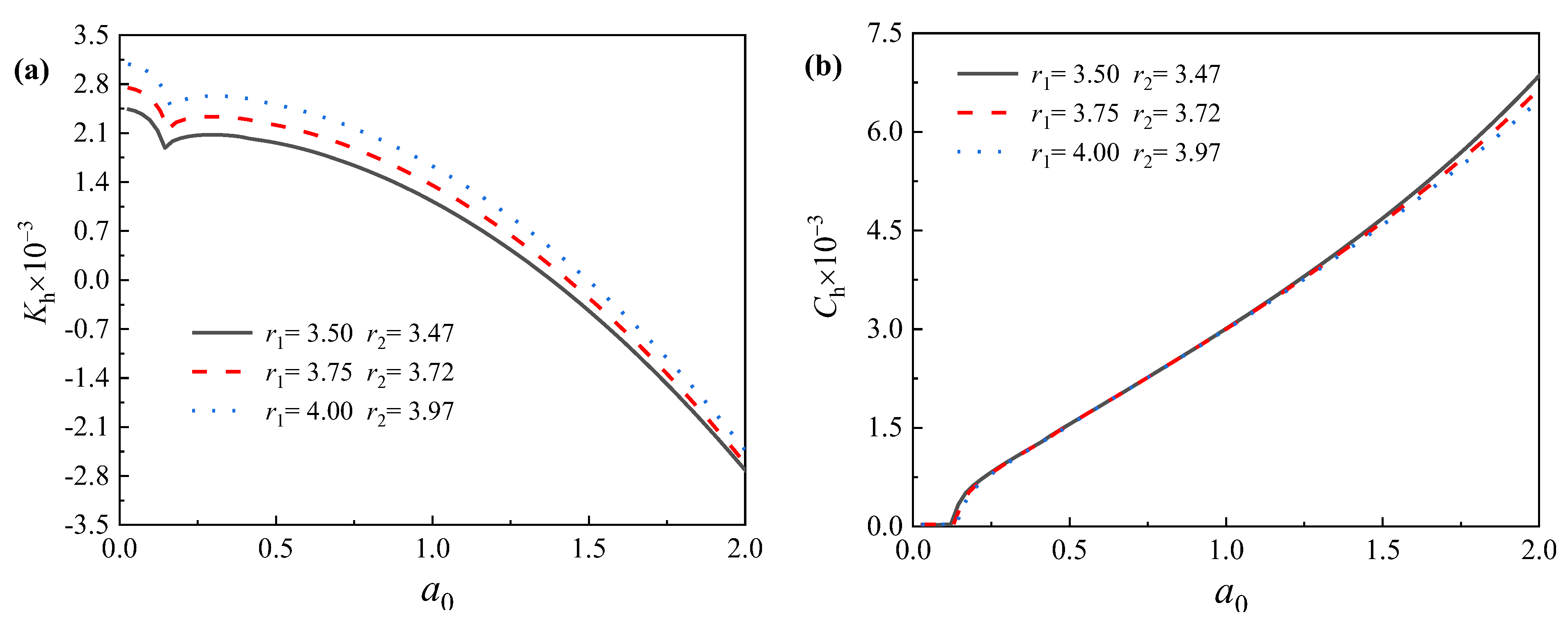

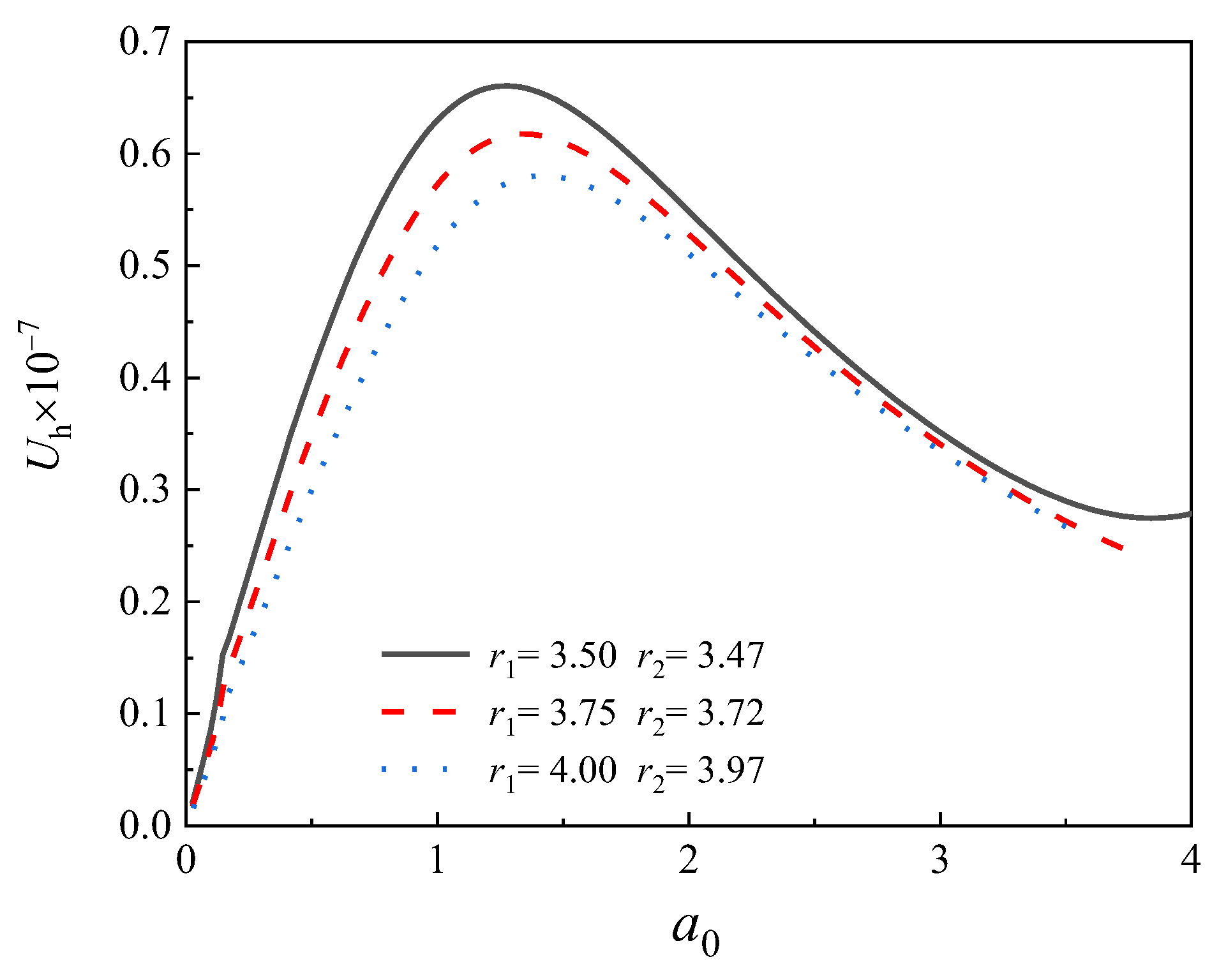

5.4. Influence of Pile Radius on Lateral Dynamic Characteristics of Offshore Pipe Piles

5.5. Influence of Embedment Ratio on the Lateral Dynamic Characteristics of Offshore Pipe Piles

6. Conclusions

- (1)

- If the inertia effect of the superstructure is not accounted for, the dynamic stiffness of piles will be remarkably underestimated, whereas the dynamic damping of piles remains basically unchanged;

- (2)

- The vertical load of the superstructure is the main factor affecting the natural frequency, whereas the inertia effect of the superstructure will result in increased resonance amplitude;

- (3)

- The first-order natural frequency of the pile increases significantly with the soil plug height, indicating that the overall lateral dynamic impedance of the pile also increases with the soil plug height;

- (4)

- Despite some fluctuations, the dynamic stiffness, as well as the dynamic damping of the pile, generally increases with the pile radius within the frequency range of most engineering applications.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Load frequency | |

| i | Imaginary unit |

| Mass of superstructure | |

| Cross-sectional area | |

| Vertical load () | |

| Outer radius | |

| Inner radius | |

| Bending rigidity | |

| Pile length above the soil | |

| Length of pile section embedded in the soil | |

| Height of rigid bearing | |

| Horizontal hamonic load | |

| Load magnitude | |

| Inertia of rotation around the center-of-mass axis | |

| Radial displacements of solid matrix | |

| Radial displacements of pore fluid | |

| Circumferential displacements of solid matrix | |

| Circumferential displacements of pore fluid | |

| Laplace operator | |

| Dilatational strain of the saturated soil | |

| Shear modulus | |

| Damping ratio | |

| Complex lamb constants | |

| Complex lamb constants () | |

| Biot compression coefficients | |

| Biot compression coefficients | |

| Solid skeleton | |

| Pore fluid | |

| Porosity of the soil | |

| Darcy permeability coefficient of the soil |

Appendix A

Appendix B

Appendix C

References

- Carter, J.M.F. North Hoyle offshore wind farm: Design and build. Energy 2007, 160, 21–29. [Google Scholar] [CrossRef]

- Gavin, K.; Igoe, D.; Doherty, P. Piles for offshore wind turbines: A state-of-art review. Proc. Inst. Civ. Eng. Geotech. Eng. 2011, 164, 245–256. [Google Scholar] [CrossRef]

- Nogami, T. Soil-pile interaction model for earthquake response analysis of offshore pile foundations. In Proceedings of the International Conference on Recent Advances in Geotechnical Earthquake Engineering & Soil Dynamics, St. Louis, MO, USA, 11–15 March 1991; Volume 3, pp. 2133–2137. [Google Scholar]

- Nogami, T.; Novak, M. Resistance of soil to a horizontally vibrating pile. Earthq. Eng. Struct. Dyn. 1977, 5, 249–261. [Google Scholar] [CrossRef]

- Zheng, C.J.; Liu, H.L.; Ding, X.M.; Fu, Q. Horizontal vibration of a large-diameter pipe pile in viscoelastic soil. Math. Probl. Eng. 2013, 2013, 269493. [Google Scholar] [CrossRef]

- Luan, L.B.; Ding, X.M.; Zhou, W.; Zheng, C.; Qu, L. Horizontal dynamic response of a large-diameter pipe pile considering the second-order effect of axial force. Earthq. Eng. Eng. Vib. 2018, 17, 567–579. [Google Scholar] [CrossRef]

- Ding, X.M.; Zheng, C.J.; Liu, H.L.; Kouretzis, G. Resistance of inner soil to the horizontal vibration of pipe piles. J. Eng. Mech. 2017, 143, 6017015. [Google Scholar] [CrossRef]

- Biot, M.A. General theory of three-dimensional consolidation. J. Appl. Phys. 1941, 12, 155–164. [Google Scholar] [CrossRef]

- Biot, M.A. General solutions of the equations of elasticity and consolidation for a porous material. J. Appl. Mech. 1956, 23, 91–96. [Google Scholar] [CrossRef]

- Biot, M.A. Theory of deformation of a porous viscoelastic anisotropic solid. J. Appl. Phys. 1956, 27, 459–467. [Google Scholar] [CrossRef]

- Ishihara, K. Approximate forms of wave equations for water-saturated porous materials and related dynamic modulus. Soils Found. 1970, 10, 10–38. [Google Scholar] [CrossRef]

- Ishihara, K. Propagation of compressional waves in a saturated soil. In Proceedings of the International Symposium of Wave Propagation and Dynamic Properties of Earth Materials, Albuquerque, NM, USA, 23–25 August 1967; University of New Mexico Press: Albuquerque, NM, USA, 1968; pp. 195–206. [Google Scholar]

- Zienkiewicz, O.C.; Shiomi, T. Dynamic behaviour of saturated porous media; the generalized Biot formulation and its numerical solution. Int. J. Numer. Anal. Methods Geomech. 1984, 8, 71–96. [Google Scholar] [CrossRef]

- Hu, A.F.; Fu, P.; Xia, C.Q.; Xie, K.H. Lateral dynamic response of a partially embedded pile subjected to combined loads in saturated soil. Mar. Georesources Geotechnol. 2017, 35, 788–798. [Google Scholar] [CrossRef]

- Zheng, C.; Liu, H.; Ding, X. Lateral dynamic response of a pipe pile in saturated soil layer. Int. J. Numer. Anal. Methods Geomech. 2016, 40, 159–184. [Google Scholar] [CrossRef]

- Cui, C.; Meng, K.; Xu, C.; Liang, Z.; Li, H.; Pei, H. Analytical solution for longitudinal vibration of a floating pile in saturated porous media based on a fictitious saturated soil pile model. Comput. Geotech. 2021, 131, 103942. [Google Scholar] [CrossRef]

- Wu, W.; Yang, Z.; Liu, X.; Zhang, Y.; Liu, H.; El Naggar, M.H.; Xu, M.; Mei, G. Horizontal dynamic response of pile in unsaturated soil considering its construction disturbance effect. Ocean Eng. 2022, 245, 110483. [Google Scholar] [CrossRef]

- Huo, S.; Chao, Y.; Dai, G.; Gong, W. Field Test Research of Inclined Large-Scale Steel Pipe Pile Foundation for Offshore Wind Farms. J. Coast. Res. 2015, 73, 132–138. [Google Scholar] [CrossRef]

- Feng, S.J.; Lu, S.F.; Shi, Z.M. Field Investigations of Two Super-long Steel Pipe Piles in Offshore Areas. Mar. Georesources Geotechnol. 2015, 34, 559–570. [Google Scholar] [CrossRef]

- Liu, H.; Wu, W.; Jiang, G.; El Naggar, M.H.; Mei, G.; Liang, R. Influence of soil plug effect on the vertical dynamic response of large diameter pipe piles. Ocean Eng. 2018, 157, 13–25. [Google Scholar] [CrossRef]

- Zheng, C.; Luan, L.; Qin, H.; Zhou, H. Horizontal Dynamic Response of a Combined Loaded Large-Diameter Pipe Pile Simulated by the Timoshenko Beam Theory. Int. J. Struct. Stab. Dyn. 2019, 20, 2071003. [Google Scholar] [CrossRef]

- Ding, X.; Luan, L.; Zheng, C.; Zhou, W. Influence of the second-order effect of axial load on lateral dynamic response of a pipe pile in saturated soil layer. Soil Dyn. Earthq. Eng. 2017, 103, 86–94. [Google Scholar] [CrossRef]

- Chen, L.; Yang, X.; Li, L.; Wu, W.; El Naggar, M.H.; Wang, K.; Chen, J. Numerical Analysis of the Deformation Performance of Monopile under Wave and Current Load. Energies 2020, 13, 6431. [Google Scholar] [CrossRef]

- Novak, M.; Nogami, T.; Aboul-Ella, F. Dynamic soil reactions for plane strain case. J. Eng. Mech. Div. 1978, 104, 953–959. [Google Scholar]

- Militano, G.; Rajapakse, R.K.N.D. Dynamic response of a pile in a multi-layered soil to transient torsional and axial loading. Geotechnique 1999, 49, 91–109. [Google Scholar] [CrossRef]

- Gupta, B.K.; Dipanjan, B. Timoshenko Beam Theory-Based Dynamic Analysis of Laterally Loaded Piles in Multilayered Viscoelastic Soil. J. Eng. Mech. 2018, 144, 04018091. [Google Scholar] [CrossRef]

- Zhang, Y.; El Naggar, M.H.; Wu, W.; Wang, Z.; Yang, X.; Jiang, G. Dynamic torsional impedance of large-diameter pipe pile for offshore engineering: 3D analytical solution. Appl. Math. Model. 2022, 111, 664–680. [Google Scholar] [CrossRef]

- Zhang, M.; Shang, W.; Wang, X.H.; Chen, F.Y. Lateral dynamic analysis of single pile in partially saturated soil. Eur. J. Environ. Civ. Eng. 2019, 23, 1156–1177. [Google Scholar] [CrossRef]

- Vázquez, K.; Rodríguez, R.R.; Esteban, M.D. Inventory proposal for monopiles in offshore wind farms. Ocean Eng. 2022, 247, 110741. [Google Scholar] [CrossRef]

- Paikowsky, S.G. A Static Evaluation of Soil Plug Behavior with Application to the Pile Plugging Problem. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1989. [Google Scholar]

- Randolph, M.F.; Leong, E.C.; Houlsby, G.T. One-dimensional analysis of soil plugs in pipe piles. Geotechnique 1991, 41, 587–598. [Google Scholar] [CrossRef]

- Feng, Y.; Yang, J. Base capacity of open-ended steel pipe piles in sand. J. Geotech. Geoenviron. Eng. 2012, 138, 1116–1128. [Google Scholar]

- Lehane, B.M.; Schneider, J.A.; Xu, X. The UWA-05 method for prediction of axial capacity of driven piles in sand. In Proceedings of the International Symposium on Frontiers in Offshore Geotechnics (ISFOG), Perth, Australia, 19–21 September 2005; Taylor & Francis: London, UK, 2005; pp. 683–689. [Google Scholar]

- Liu, H.; Jiang, G.; El Naggar, M.H.; Wu, W.; Mei, G.; Liang, R. Influence of soil plug effect on the torsional dynamic response of a pipe pile. J. Sound Vib. 2017, 410, 231–248. [Google Scholar] [CrossRef]

- Wu, W.; El Naggar, M.H.; Abdlrahem, M.; Mei, G.; Wang, K. A new interaction model for the vertical dynamic response of pipe piles considering soil plug effect. Can. Geotech. J. 2017, 54, 987–1001. [Google Scholar] [CrossRef]

- Liu, H.; Wu, W.; Jiang, G.; El Naggar, M.H.; Mei, G.; Liang, R. Benefits from using two receivers for the interpretation of low-strain integrity tests on pipe piles. Can. Geotech. J. 2019, 56, 1433–1447. [Google Scholar] [CrossRef]

- Liu, H.; Wu, W.; Ni, X.; Yang, X.; Jiang, G.; El Naggar, M.H.; Liang, R. Influence of soil mass on the vertical dynamic characteristics of pipe piles. Comput. Geotech. 2020, 126, 103730. [Google Scholar] [CrossRef]

- Li, L.; Zheng, M.; Liu, X.; Wu, W.; Liu, H.; El Naggar, M.H.; Jiang, G. Numerical analysis of the cyclic loading behavior of monopile and hybrid pile foundation. Comput. Geotech. 2022, 144, 104635. [Google Scholar] [CrossRef]

- Li, L.; Liu, X.; Liu, H.; Wu, W.; Lehane, B.M.; Jiang, G.; Xu, M. Experimental and numerical study on the static lateral performance of monopile and hybrid pile foundation. Ocean Eng. 2022, 255, 111461. [Google Scholar] [CrossRef]

- Henke, S.; Grabe, J. Field measurements regarding the influence of the installation method on soil plugging in tubular piles. Acta Geotech. 2012, 8, 335–352. [Google Scholar] [CrossRef]

- Henke, S.; Bienen, B. Investigation of the influence of the installation method on the soil plugging behaviour of a tubular pile. In Proceedings of the 8th International Conference on Physical Modelling in Geotechnics, Perth, Australia, 14–17 January 2014. [Google Scholar]

- Lehane, B.M.; Gavin, K.G. Base Resistance of Jacked Pipe Piles in Sand. J. Geotech. Geoenviron. Eng. 2001, 127, 473–480. [Google Scholar] [CrossRef]

- Chow, Y.K.; Phoon, K.K.; Chow, W.F.; Wong, K.Y. Low strain integrity testing of piles: Three-dimensional effects. J. Geotech. Geoenviron. Eng. 2003, 129, 1057–1062. [Google Scholar] [CrossRef]

| H2 (m) | r1 (m) | r2 (m) | Ep (GPa) | Es (MPa) | kd (m/s) | rp (kg/m3) | rf (kg/m3) | M (GPa) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 0.5 | 0.38 | 25 | 2.0 | 10−6 | 2500 | 1000 | 1.0 | 0.3 | 0.99 | 0.05 |

(m) | (m) | (m) | (m) | (GPa) | (MPa) | (m/s) | (kg/m3) | (kg/m3) | (GPa) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 40 | 3.5 | 3.47 | 220 | 1.0 | 10−6 | 7780 | 2000 | 4.9 | 0.4 | 0.99 | 0.01 | 0.05 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Li, J.; Yang, X.; Chen, L.; Wu, W.; Wen, M.; Jiang, M.; Guo, C. Lateral Dynamic Response of Offshore Pipe Piles Considering Effect of Superstructure. Energies 2022, 15, 6759. https://doi.org/10.3390/en15186759

Liu H, Li J, Yang X, Chen L, Wu W, Wen M, Jiang M, Guo C. Lateral Dynamic Response of Offshore Pipe Piles Considering Effect of Superstructure. Energies. 2022; 15(18):6759. https://doi.org/10.3390/en15186759

Chicago/Turabian StyleLiu, Hao, Jiaxuan Li, Xiaoyan Yang, Libo Chen, Wenbing Wu, Minjie Wen, Mingjie Jiang, and Changjiang Guo. 2022. "Lateral Dynamic Response of Offshore Pipe Piles Considering Effect of Superstructure" Energies 15, no. 18: 6759. https://doi.org/10.3390/en15186759

APA StyleLiu, H., Li, J., Yang, X., Chen, L., Wu, W., Wen, M., Jiang, M., & Guo, C. (2022). Lateral Dynamic Response of Offshore Pipe Piles Considering Effect of Superstructure. Energies, 15(18), 6759. https://doi.org/10.3390/en15186759