1. Introduction

Climate neutrality is one of the main objectives of the European Union’s (EU) environmental policies. The goals set out within the European Green Deal [

1] and the implemented legislative framework amended by the European Commission [

2] make the EU a frontrunner in climate mitigation. Climate action is foreseen within the purposes of European environmental policies, strongly based on the principles of precaution, prevention and rectifying pollution at source. Mitigation strategies are indeed intended to prevent or reduce the emissions of greenhouse gases (GHGs) to ease the impacts of climate change.

The strong commitment of the EU dates back to 2015, when 195 countries signed the Paris Agreement, agreeing “to keep the increase in global mean surface temperature to well below 2 °C, and to limit the increase to 1.5 °C” in order to lessen the negative outcomes of climate change [

3]. Signing the agreement, the EU set a binding target to cut emissions in the EU territory by 2030 to levels at least 40% below those in 1990 [

4]. Nonetheless, according to a report published by the European Environment Agency in 2021, the strategies implemented by the EU lead to a decrease in GHGs as high as 31% with respect to 1990 levels [

5], thus supporting the new targets adopted in 2021 under the European Climate Law increasing the reduction target to 55% [

2].

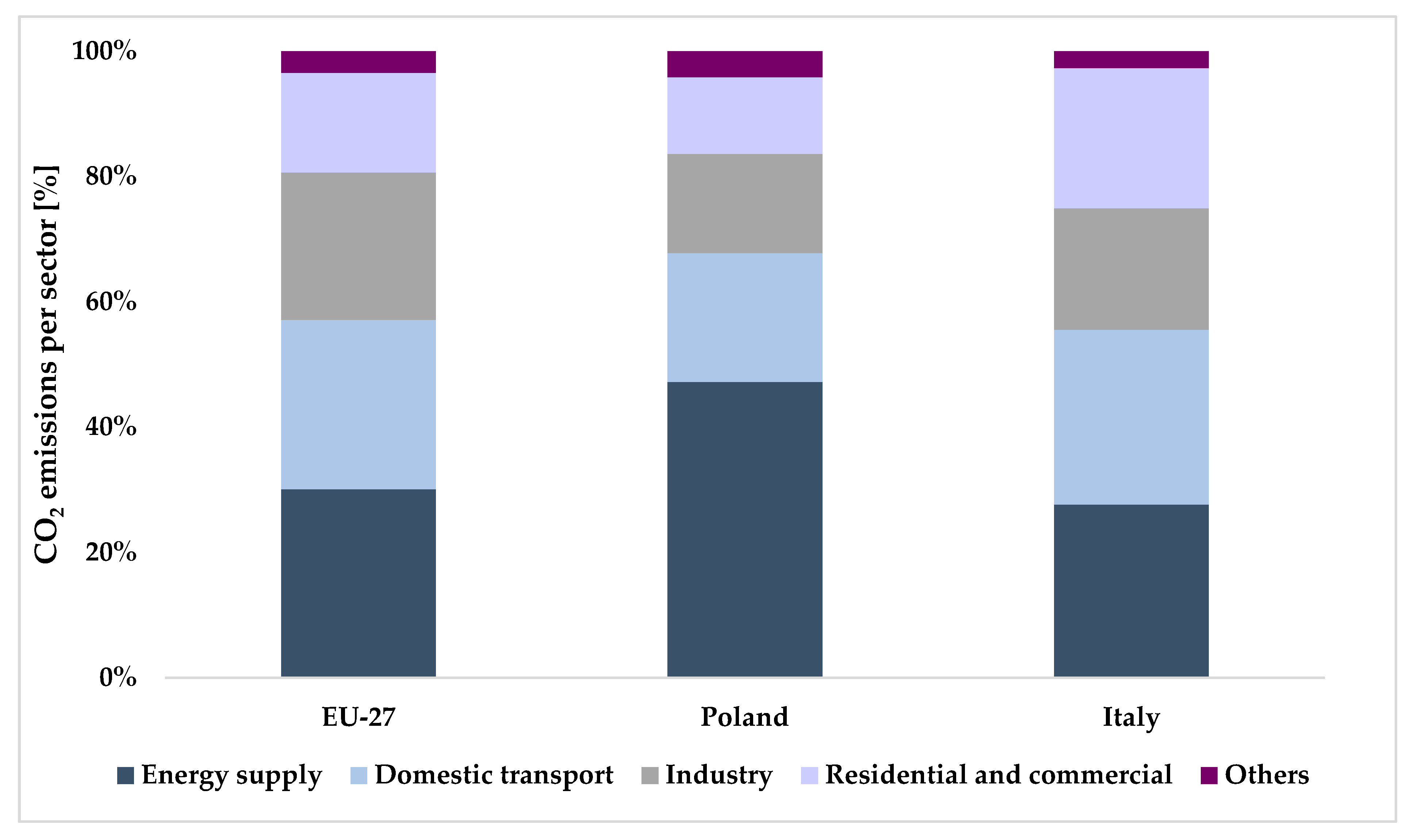

However, in 2020, CO

2 emissions in the 27 Member States of the EU exceeded 2.6 Gt (also considering the other GHGs, the value rose to around 3.3 Gt of CO

2), with the energy supply sector being the main source (~31%), followed by the transport sector (~28%), manufacturing industries (~24%), and residential and commercial activities (~16%) [

6]. It is therefore evident that the energy sector is the largest contributor to GHG emissions, and that the achievement of the aforementioned goals requires the combined action of a series of climate mitigation strategies.

Among them, the European Commission called for the improvement of energy efficiency, a deeper electrification of fossil fuel–supplied sectors, and a growing share of renewable energy production (in 2020, the share of energy consumed from renewable sources reached 22.1%, whereas the 2030 target was set at 40%) [

5]. According to Gelien et al. [

7], energy efficiency and renewable energy technologies are the core elements of energy transition, having the potential to meet ~70% of the global energy demand. Nonetheless, without favorable policies at national and international levels, there is no possibility to fully exploit that potential. Though recognizing the high level of maturity and economic competitiveness of solar photovoltaic power generation, Jäger-Waldau et al. [

8] underlined that to reach a 55% emission reduction, the solar photovoltaic installed capacity should be brought to 455–605 GW, thus making mandatory a drastic growth of the photovoltaic market volume in the EU due to the increase of the average annual growth rate. Nonetheless, the intrinsic intermittency of these sources requires proper integration with other energy systems. For instance, Rashidi et al. [

9] proposed to utilize wind energy to supply power to desalination systems. This resulted in improvements of the overall reliability of the systems, lower GHG emissions, and a proper balance of power fluctuations.

In addition to wind and solar photovoltaics, natural gas can be considered as a bridge towards a cleaner energy system. Natural gas indeed represents a cleaner energy source option compared to other fossil fuels (such as coal, bitumen, and diesel) [

10], with the potential to take advantage of the well-developed dedicated infrastructure and having strong economic competitiveness. Within the EU, the inland demand for natural gas in 2020 exceeded 360 Mtoe [

11], representing 21.5% of the EU’s primary energy consumption, with the residential sector accounting for most EU gas demand (40%), followed by industry and gas use for power generation [

12]. Worldwide, natural gas–fired power plants supplied ~6300 TWh, accounting for about 24% of total global power generation, in 2020 [

13]; this technology is seemingly the only one among fossil resources that is capable of providing flexibility for the power system in the coming years [

14], enabling the integration of intermittent renewable energy sources [

10].

In order to continue using natural gas, the implementation of technologies to avoid CO2 emissions into the atmosphere is essential. Within this context, Carbon Capture Utilization and Storage (CCUS) can be seen as a viable tool to enable industrial decarbonization while curbing CO2 emissions. CCUS refers to a set of technologies aiming at capturing CO2 emitted from a wide variety of sources (i.e., power plants, cements plants, etc.) in order to store in different forms. The captured CO2 can be either stored underground or employed as a feedstock to other industrial processes for the production of fuels, chemicals, or building materials.

As for the storage pathway, Carbon Capture and Storage (CCS) involves different operations, mainly consisting of three major processes: CO

2 capture, transportation, and injection underground [

15,

16]. The technical aspects of carbon sequestration depend on the specific industrial application; it can be performed by adopting different physico-chemical processes, with the main distinction being among pre-combustion, post-combustion, and oxy-fuel combustion [

17]. On the other hand, both transportation and storage phases are deeply site-dependent, thus requiring an extended investigation of the local and geological characteristics [

18]. The main hinderance to widespread CCS, in addition to the high costs, is the low social acceptance [

19]. Concerns of CO

2 being leaked from the storage sites are mainly related to both climate change issues and ecosystem damage at a local level. Therefore, in order for CCS to be considered as a safe technology, the storage site must be properly selected according to strict safety, geological, and technical standards [

18].

On the other hand, Carbon Capture and Utilization (CCU) uses the same process schemes of CCS for CO

2 capturing, with the main difference lying in CO

2 being used as a raw material for the production of synthetic fuels or chemical compounds. CO

2 is commonly perceived as an industrial waste, but its hydrogenation leads to the generation of several valuable products (such as methane, methanol, dimethyl ether, formic acid, etc.) [

20]. The required hydrogen could be produced by water electrolysis fueled by renewable energies, therefore creating a network connecting the renewable energy supply system and the industrial value chain according to a concept known as Power-to-Gas (PtG). PtG is described as a chemical energy storage technology aiming at transforming electric energy through water electrolysis into combustible gases with high energy density [

21]. Among CCU technologies, however, great attention has been paid to CO

2 conversion into fuels, with both methanol [

22] and dimethyl ether [

23] produced within this context being credited as potential alternative fuels in the future energy scenarios.

Nonetheless, the spread of these technologies is still limited. According to the latest estimates [

24], the current capacity of CCUS facilities allow the capturing of ~40 MtCO

2 each year. At first, these plants were constructed to supply CO

2 to local oil producers for enhanced oil recovery operation (this is still one of the main utilization pathways for CO

2, covering more than 30% of the overall demand), being connected to natural gas processing facilities. However, in the 1980s, CCUS facilities barely managed to handle 0.5 Mt of CO

2; a major expansion has taken place during the last decade, with the majority of plants still operating in the natural gas processing sector (~28.5 Mt of CO

2) and some related to the power generation sector (~2.4 Mt of CO

2). Though the largest deployment of CCUS has been seen in China, European countries are also committed to the implementation of these kinds of technologies. The North Sea is currently the center of CCUS deployment in Europe, with the first projects being implemented in 1996. Indeed, to date, the main large-scale CCUS projects operating in Europe (namely, Sleipner and Snøhvit), with a combined storage capacity of 1.7 Mt of CO

2 per year, are both located in Norway and both capture CO

2 from natural gas processing and reinject it into dedicated storage sites. Nonetheless, other small pilot and demonstration projects are currently operating in Europe, with a capacity of nearly 30 Mt of CO

2 per year, which is projected to rise to around 35 Mt in 2030. CCUS technologies should thus be coupled with existing facilities belonging to the three main CO

2 emission contributors (namely, power generation, transport, and manufacturing), considering that most of Europe’s energy sector emissions come from sources located in relatively close proximity to potential storage sites (for instance, ~68% of all the emissions from power plants and factories in Europe are located within 100 km of a potential storage site) [

16].

A deeper understanding of the environmental outcomes related to the implementation of this kind of system could be obtained by means of Life Cycle Assessment (LCA). Holistic LCA, dealing with performance improvement of industrial processes, is recognized as a valid tool for governments in aiding decision-making processes [

25]. This tool is crucial, since implementing CO

2 emission–mitigating technologies and shifting the energy supply towards more sustainable technologies could lead to significant environmental trade-offs, thus leading to further negative outcomes.

LCA methodology has been widely adopted to evaluate and compare the environmental profile of systems and products [

26]. During the last decades, many assessments were performed to investigate the outcomes deriving from changing the energy scenarios at national or regional levels [

27,

28,

29,

30]. Through a wider perspective, Carvalho et al. [

30] carried out an environmental assessment to gain insights into the environmental profile of the electricity system of seven European countries in 2030. The authors found out that the implementation of the policies promoted by the European Commission would eventually lead to an average reduction of 42% in the impacts of climate change, with the best result coming from the reduction of acidification (impact category closely linked to the first). In addition, assessments have been performed to evaluate the feasibility of implementing both CCUS units [

14,

31,

32]. Singh et al. [

31] proposed a hybrid life cycle assessment to evaluate the consequence of coupling a natural gas combined cycle (NGCC) power plant with CCS, showing that a CO

2 capture efficiency of 90% could result in the avoidance of 70% of CO

2 emissions per kWh, reducing global warming potential (GWP) by 64%. The authors also identified some relevant trade-offs related to acidification, eutrophication, and toxicity, whose increase is due to the use and degradation of monoethanolamine (MEA) and on some process wastes. Similarly, Barbera et al. [

14] investigated the effects of the introduction of the most promising CCS configurations in series to a gas-fired combined cycle power plant, employing either MEA or potassium carbonate as solvents. The authors also considered electricity generation from a photovoltaic plant and a wind turbine to identify the technology with the higher environmental performance, assuming Germany as a reference site. The environmental impacts of renewable energy sources were found to be very low when compared with those of fossil fuel–based technologies, but a burden shifting among environmental compartments was also found, with detrimental effects towards human health and freshwater. A more holistic perspective was instead proposed by Volkart et al. [

32], who performed an assessment to evaluate the environmental consequences of integrating a carbon capture and storage (CCS) unit in both power generation and the cement industry, assuming Europe as a reference geographical region. The authors assessed the impacts on power generation assuming 2050 as a reference year, considering the time required for large-scale implementation of the CCS technology and the future potential technology development. They found a significant reduction of the life cycle GHG emissions from power generation thanks to CCS unit implementation for all the investigated power generation technologies, while the benefits of integrating CCS in cement plants was found to be highly dependent on the source of heat and power for the capturing process. Studies related to CCU technologies, on the contrary, have been mostly focused on the potential environmental benefits of the process itself rather than their integration into the energy sector [

33,

34]. However, the evaluation of the environmental impacts of these technologies are also intimately related to territorial features and to production–consumption patterns [

35]; this relationship should be taken into account in order to understand which technology best suits the needs of a specific territory.

With this aim, a systematic analysis focused on the effect of storing or utilizing the CO

2 emitted from a power plant could be useful in order to address national environmental policies. Therefore, the present study aims at evaluating the potential environmental benefits of a NCGC power plant coupled with either a CCS or CCUS unit in two different European countries. The analyzed plant configurations are the same as those reported in a parallel work by De Falco et al. [

36], within which an energetic and exergetic comparison between CCS and CCUS was made. Two possible routes for the CO

2 captured from a NGCC power plants are considered: (1) feeding 25% of the captured CO

2 to a methanol and dimethyl ether production plant while storing the remaining 75% underground under supercritical conditions, and (2) storing 100% of the captured CO

2 underground. An LCA-based comparison, relying on an extensive evaluation of the country’s environmental profile, was thus performed to identify whether CCUS technologies could actually play a beneficial role within the climate-mitigating efforts of those countries, and which processes could potentially hinder their deployment.

The paper is organized as follows:

Section 2 describes the current environmental profile of the selected countries, with a brief insight into the potential for CCUS spread;

Section 3 outlines the methodology adopted to run the assessment, with an in-depth description of the process units;

Section 4 shows the results from the two analyzed routes in Italy and Poland, identifying the major drawbacks coming from their development; lastly, some final considerations are reported in

Section 5.

4. Results and Discussion

In the case of CCS and CCUS, the modified environmental profile was compared to the reference case of each scenario. In this section, the environmental consequences of implementing CCS and CCUS technologies will be therefore discussed for both Italy and Poland, with each process and sub-process modelled considering the country’s market for natural gas and the national market for electricity supply. Results are reported normalized to the highest computed value.

4.1. Carbon Capture and Storage

The addition of a CCS unit to the NGCC power plant mainly aims at reducing the emitted CO

2 during plant operation. Results from the impact assessment, as shown in

Figure 3 and

Figure 4, confirm a drastic reduction of CO

2-equivalent emissions both in Italy and Poland.

While current emissions are estimated to be 0.715 kg CO2-eq kWh−1 and 0.695 kg CO2-eq kWh−1 in Italy and Poland, in the CCS scenario the GWP is reduced to 0.076 kg CO2-eq kWh−1 and 0.021 kg CO2-eq kWh−1, respectively. Results for the reference case also reflect the choice of considering the heat coproduced from the plant (which is actually used in the carbon capture unit) as an avoided product for the sake of comparability between the case studies. Without this assumption, the gap would have been even higher. Moreover, it must be noted that the large decrease in GWP (~89% and ~97%, for Italy and Poland, respectively), is also attributable to the gate-to-gate approach. Indeed, if considering also the emissions associated with the carbon capture infrastructure development and the CO2 network (requiring further energy for the compressors and covering large distances), the total reduction of CO2 emissions would be limited.

However, since data on GHG emissions mainly refer to the operating phase, assuming as valid the obtained emission rates and considering the energetic scenario of the two countries, the implementation of CCS would lead to an overall CO2 emission reduction of 9.64% and 1.16% in Italy and Poland, respectively. As previously outlined, the main difference in the percentual decrease can be attributed to the different amount of electricity generated from NGCC power plants in the two countries.

On the other hand, in addition to CO

2 emissions, various other impact categories were analyzed, resulting in significant environmental trade-offs that must be properly treated, as also identified by similar earlier studies [

14,

31]. The significant increase of the other impact categories is mostly driven by natural gas utilization, in terms of extraction, processing, and transportation, especially as regards the increase in AP (+94% and +84% for Italy and Poland, respectively), EP (+93% and +101% for Italy and Poland, respectively), and ODP (+76% and +79% for Italy and Poland, respectively), with the difference between Italy and Poland mainly due to the amount of Russian natural gas imported. Moreover, neglecting the sulfur content within the natural gas feed and the amount of release of nitrogen oxides from the plant, the three impact categories are underestimated in the reference case, while the gap between the compared cases could have been also reduced from considering the beneficial effect of ammine scrubbing for nitrogen oxide and sulfur component removal.

The higher AD of fossil fuels (+72% for both Italy and Poland) can be attributed to the large energy consumption of both carbon capture and underground storage. Indeed, the energy required for the compression of the flow rate of flue gas resulting from the process simulation exceeds 60% of the net power produced from the plant, with severe consequences in terms of efficiency. This outcome is mainly due to the process not being optimized in terms of air excess and operating pressure of the absorber.

Even though impact categories related to toxicity have not been regarded as fitting the purpose of the present study, previous investigations have underlined the possible increase in toxicity-related issues due to the production and use of ammine-based solvents during the absorption process, most of which are toxic compounds whose emission during the process (to atmosphere, water, and soil) is unavoidable [

32,

66]. Therefore, further attention in process design must be paid both to efficiency losses and solvent selection if post-combustion processes are chosen for cleaning the flue gas stream.

4.2. Carbon Capture Utilization and Storage

Differently from the CCS scenario, CCUS processes represent multifunctional systems, and the reference case is provided with the equal amounts of renewable energy to substitute background processes, apart from being expanded to account for the conventional production of the equal amount of dimethyl ether.

Figure 5 and

Figure 6 provide the scores of each impact category for the Italian and Polish case study, respectively.

Regarding GWP, the reduction in CO2 emissions is less marked. Indeed, the reduction of CO2 emissions has been estimated to account for ~58% and ~68% in Italy and Poland, respectively. In the reference scenario, the production of electricity and dimethyl ether accounts for 0.723 kg CO2-eq and 0.745 kg CO2-eq for the two countries, with the substitute electricity coming from renewables, contributing to a decrease of 0.053 kg CO2-eq in Italy and 0.024 kg CO2-eq in Poland. In both cases, the burden of conventional dimethyl ether production on GWP was less than 9%, mainly because of the small amount produced. The implementation of CCUS processes, however, lowers the emission to 0.303 kg CO2-eq and 0.236 kg CO2-eq in Italy and Poland, respectively. In the investigated case, the production of dimethyl ether from CO2 hydrogenation accounts for 26.95% in Italy and 28.32% in Poland, with differences related to the Polish country electricity mix used to satisfy the energy demand of the synthesis process being more CO2 intensive than the Italian one. However, adopting the same perspective as for the CCS scenario, CCUS technologies could lead to an overall emission reduction of 3.85% in Italy and 0.68% in Poland.

As in the CCS scenario, all the other investigated categories showed an increase. Considerations related to AD (fossil fuels)—whose increase was 67% for Italy and 66% for Poland—and ODP—whose increase was 74% for Italy and 75% for Poland—are the same as for the CCS scenario. On the other hand, little confidence is given to the results related to AP and EP; therefore, they are not shown within the graphs. Nonetheless, it must be underlined that both wind and solar power generation technologies are featured by a high impact in terms of AP and EP, and the implementation of CCUS processes fed with hydrogen produced by renewable electricity is therefore likely to be featured by a marked worsening of performance with respect to these categories [

66].

Lastly,

Figure 7 and

Figure 8 provide a wider comparison of the CCS scenario, properly modified to account for the production of dimethyl ether and the use of renewable electricity. As for the previous case, only impacts related to GWP, AD, and ODP are shown to avoid misinterpretation issues related to the substitution approach.

Considering the CCS comparable reference case, it is clear that, from a GWP perspective, it is the option to be implemented. Indeed, though entailing a conventional dimethyl ether production process, the CCS comparable scenario has a lower GWP (0.085 kg CO2-eq for Italy and 0.071 kg CO2-eq for Poland) than in the CCUS scenario (0.303 kg CO2-eq and 0.236 kg CO2-eq for Italy and Poland, respectively). This marked difference is mostly ascribable to renewable electricity replacing conventional fossil energy supply within the background processes. These results therefore suggest that, in terms of GWP, the considered amount of renewable electricity would perform better if employed within other processes rather than in CCUS.

As for the other categories, results from AD (45.16 MJ and 43.07 MJ for CCS and CCUS, respectively, in Italy, and 43.52 MJ and 40.98 MJ for CCS and CCUS, respectively, in Poland) are similar due to the small faction of the captured CO2 used as feedstock in the CCUS scenario. AD is mostly driven by the increased amount of natural gas required when multiple energy-demanding units are added to the NGCC power plant, though dimethyl ether production contributes 5.9% and 6.39% in Italy and Poland within the CCS scenario and 1.68% and 1.34%, respectively, in the CCUS scenario. Similarly, ODP levels do not significantly differ between the CCS (5.58 × 10−7 kg CFC-11-eq for the Italian case and 4.46 × 10−7 kg CFC-11-eq for the Polish case) and the CCUS (5.58 × 10−7 kg CFC-11-eq for the Italian case and 4.46 × 10−7 kg CFC-11-eq for the Polish case) scenarios, being majorly influenced by the modified power plant configurations. The higher ODP in the CCS reference scenario with respect to CCUS scenarios is partially attributable to conventional dimethyl ether production, contributing 3.02% and 3.70% in Italy and Poland, respectively, in the former case. However, in the CCUS scenario, the burden of green dimethyl ether production is decreased to 1.2% and 0.6% in Italy and Poland, respectively. Though not extremely significant in absolute terms, ODP caused by green dimethyl ether production in the Italian case (6.51 × 10−9 kg CFC-11-eq) is more than doubled with respect to its counterpart in Poland (2.57 × 10−9 kg CFC-11-eq), mainly due to the higher share of photovoltaics in the Italian renewable electricity market.