Review of Energy Challenges and Horizons of Hydrogen City Buses

Abstract

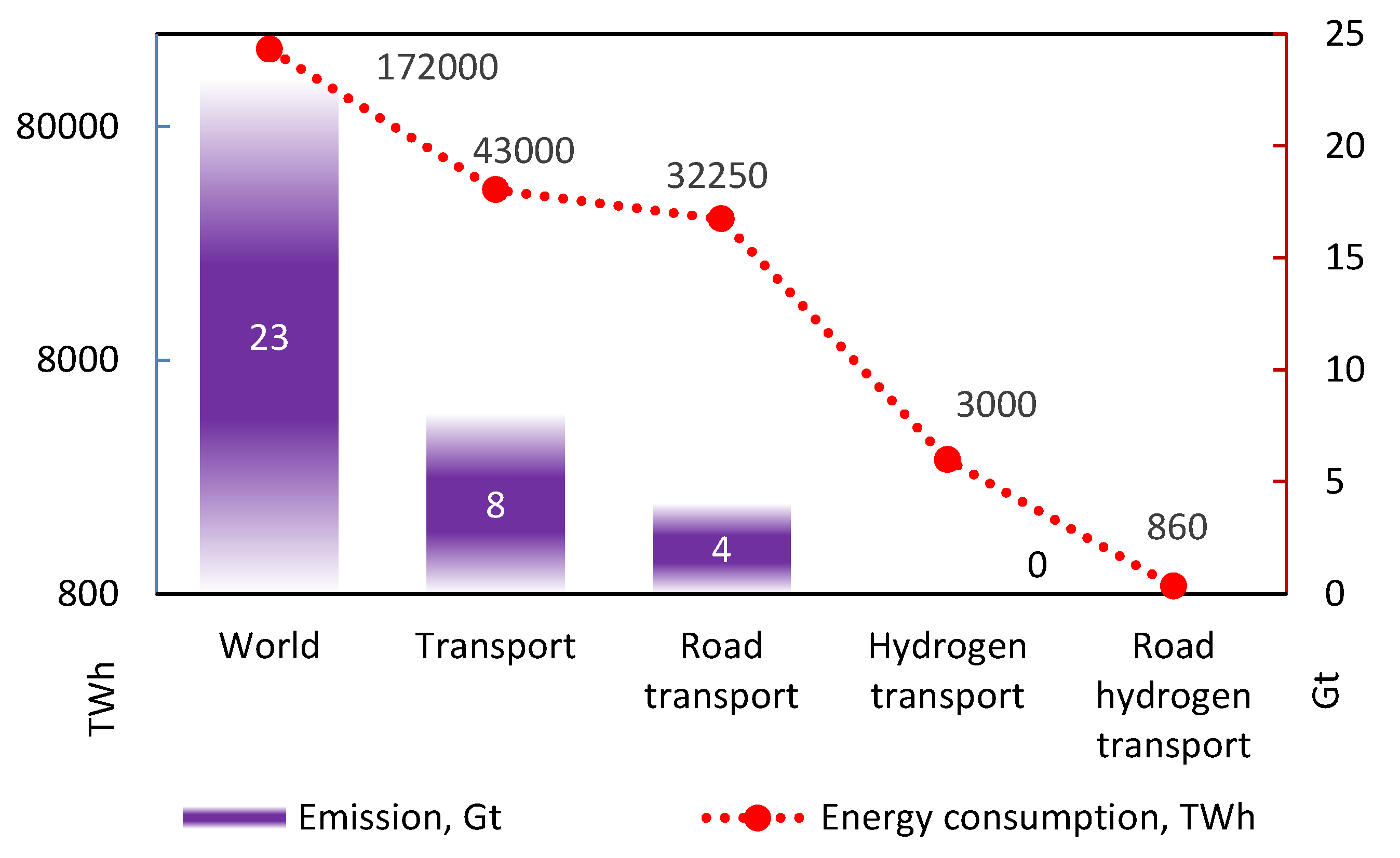

:1. Introduction

1.1. Work Scope, Aim, Features, and Restrictions

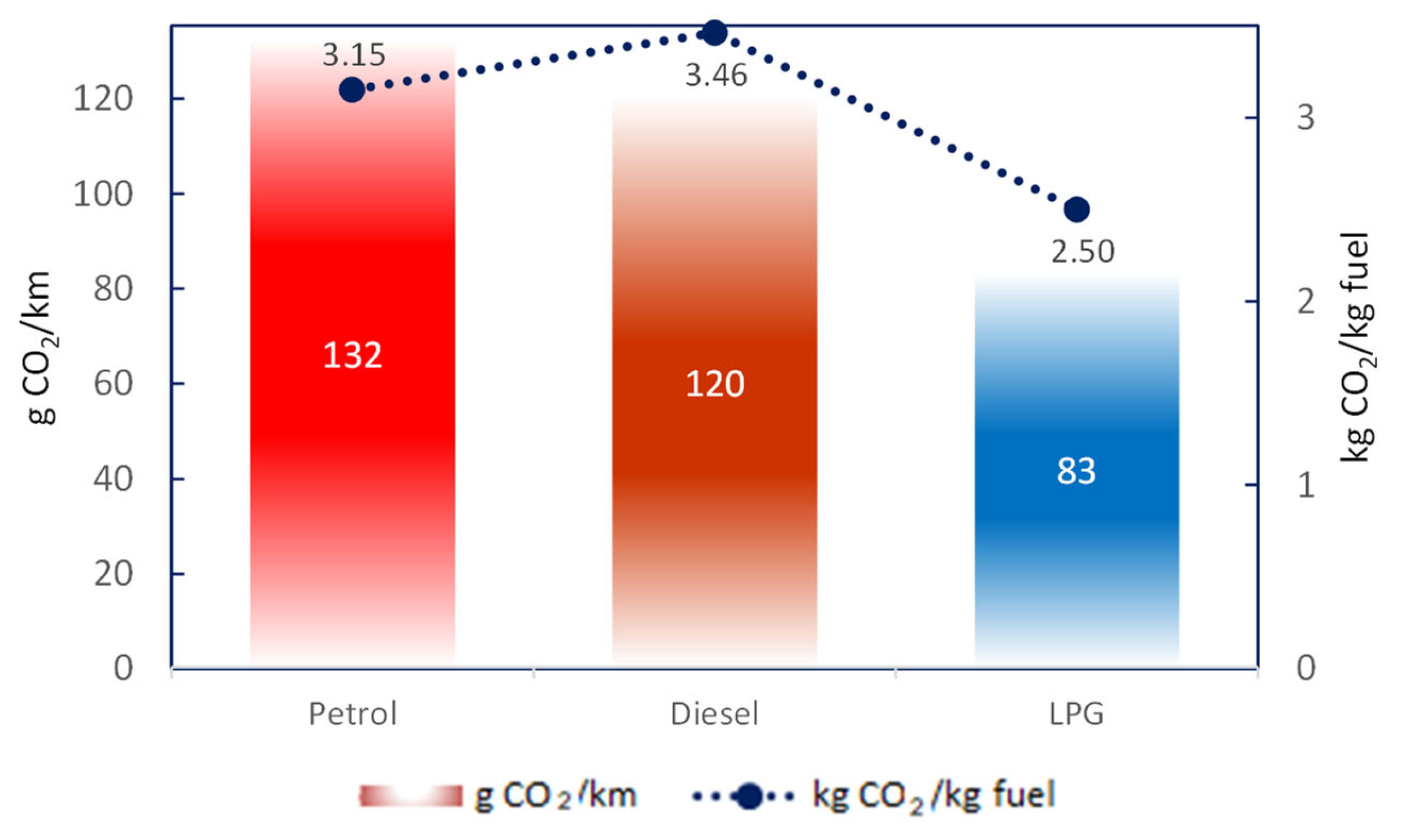

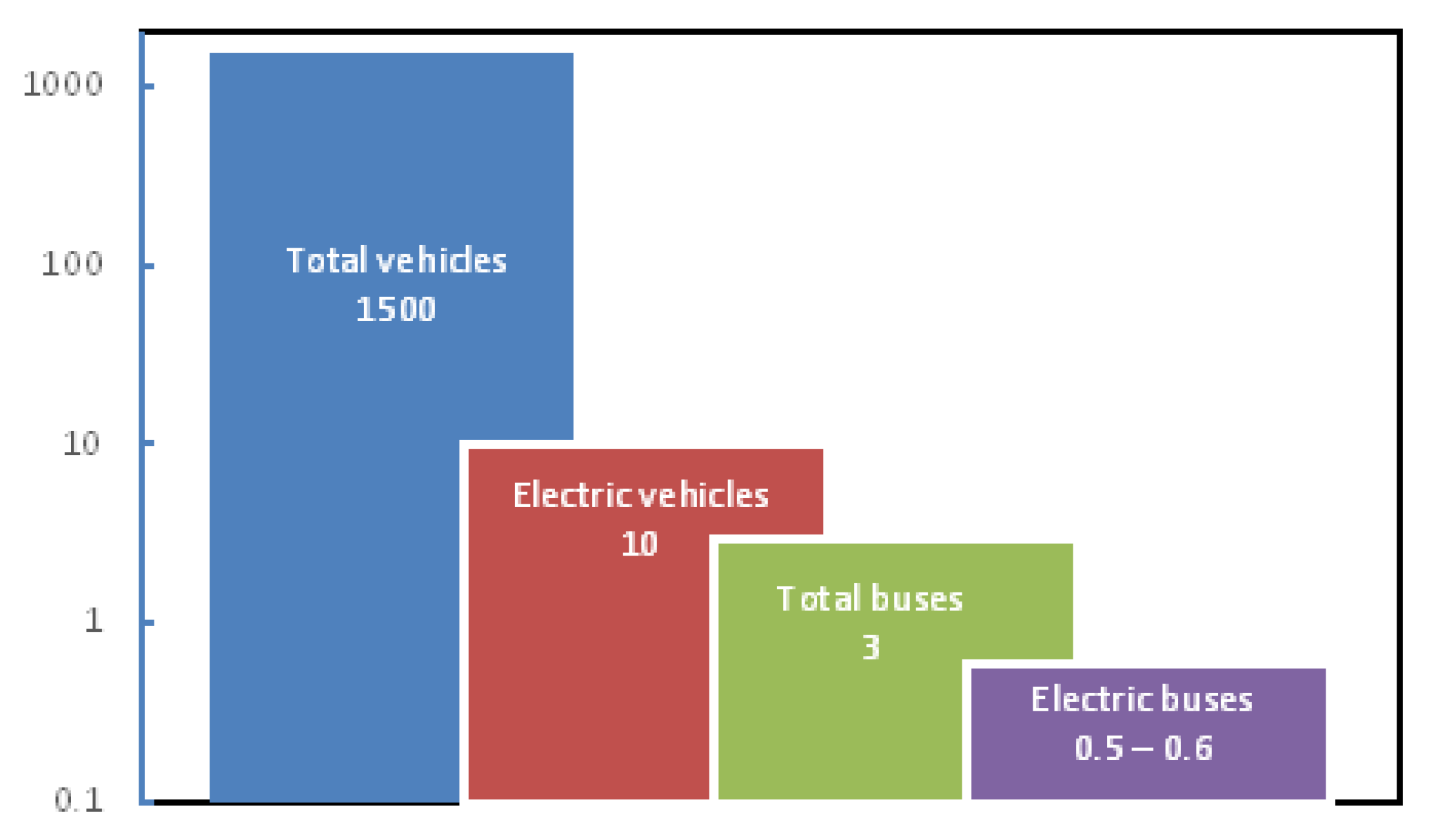

1.2. Towards Electric Transport

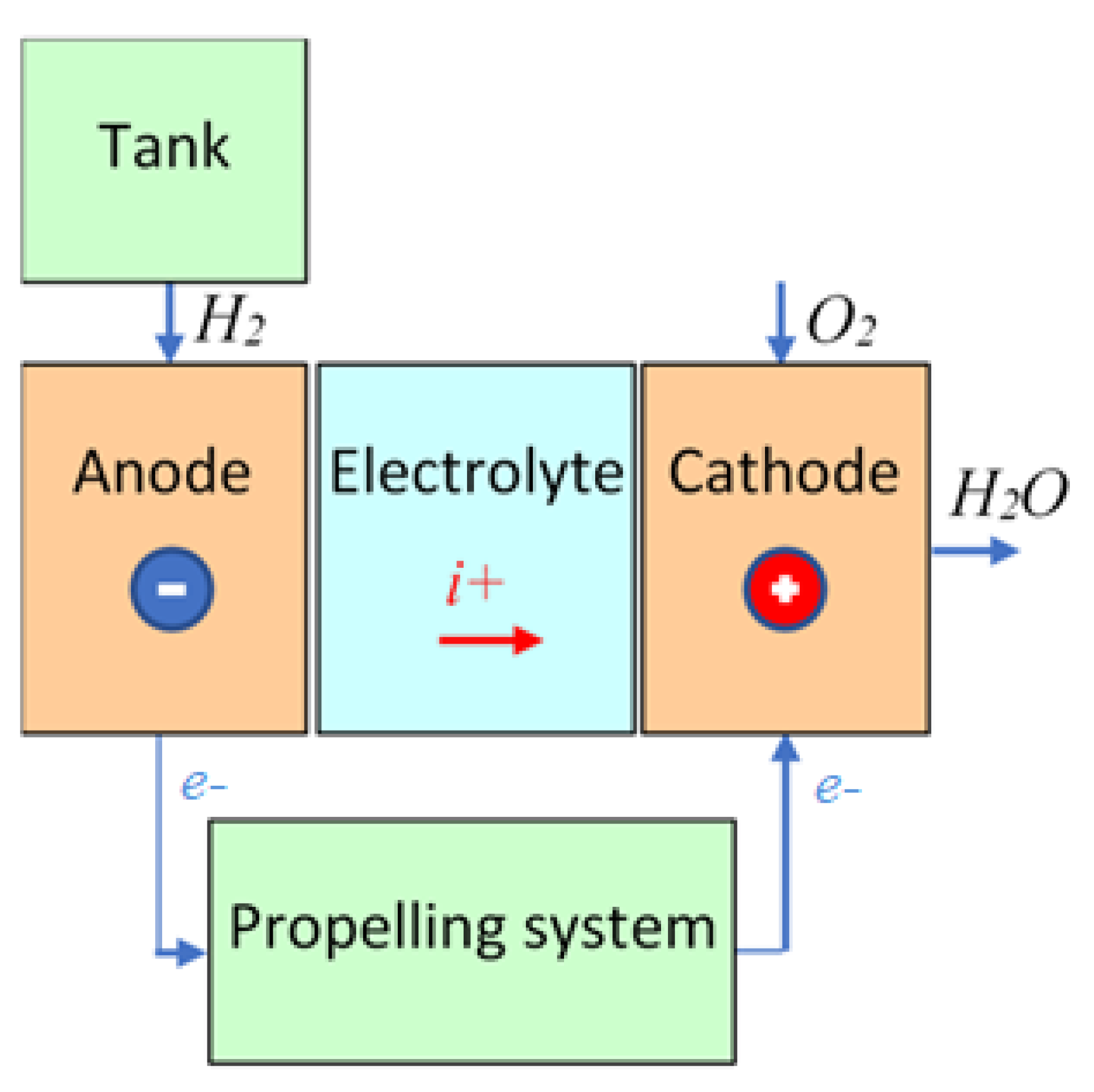

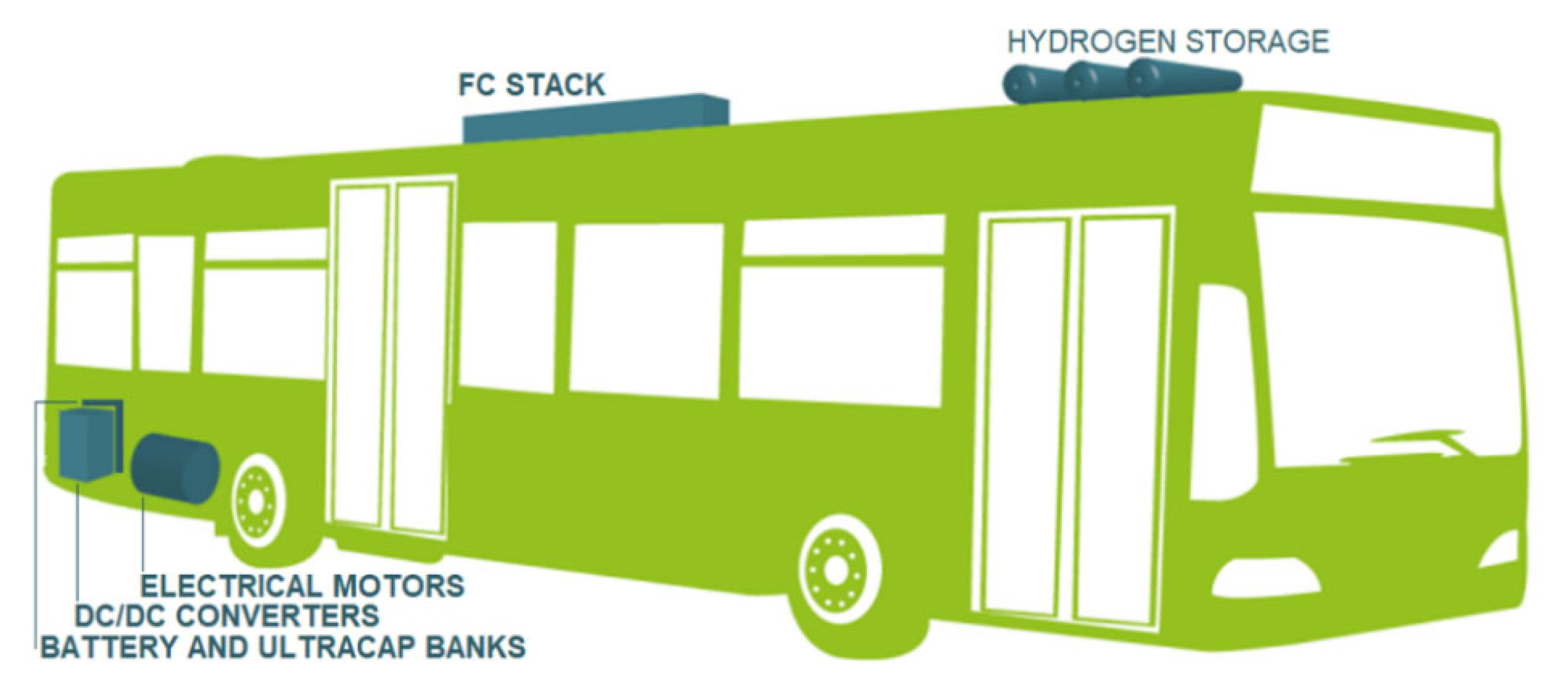

1.3. Fuel Cell Electric Vehicles

1.4. Hydrogen Buses–The Next Frontier in City Transport

2. Commitment to Excellence via Increase of Energy Efficiency

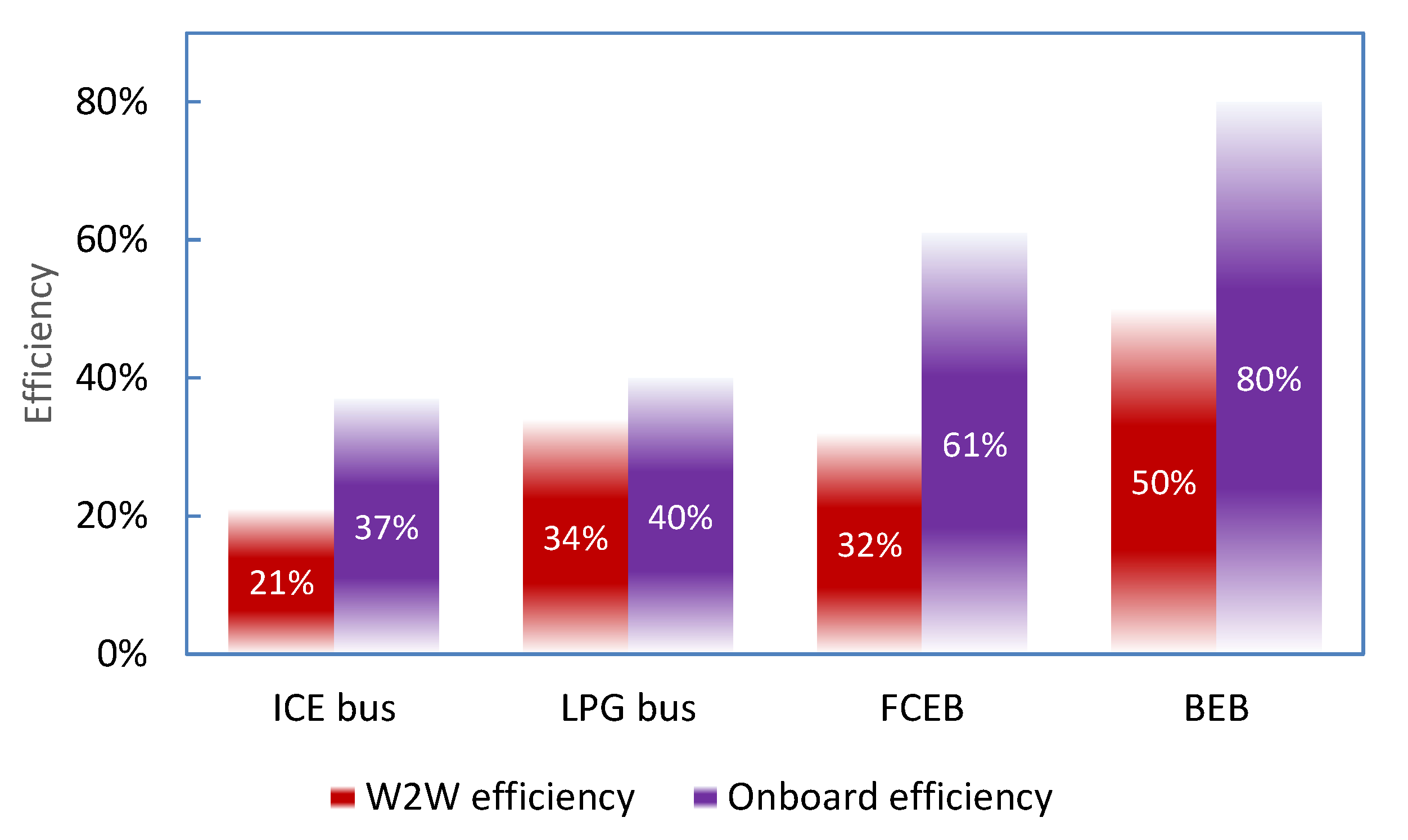

2.1. FCEB vs. BEB

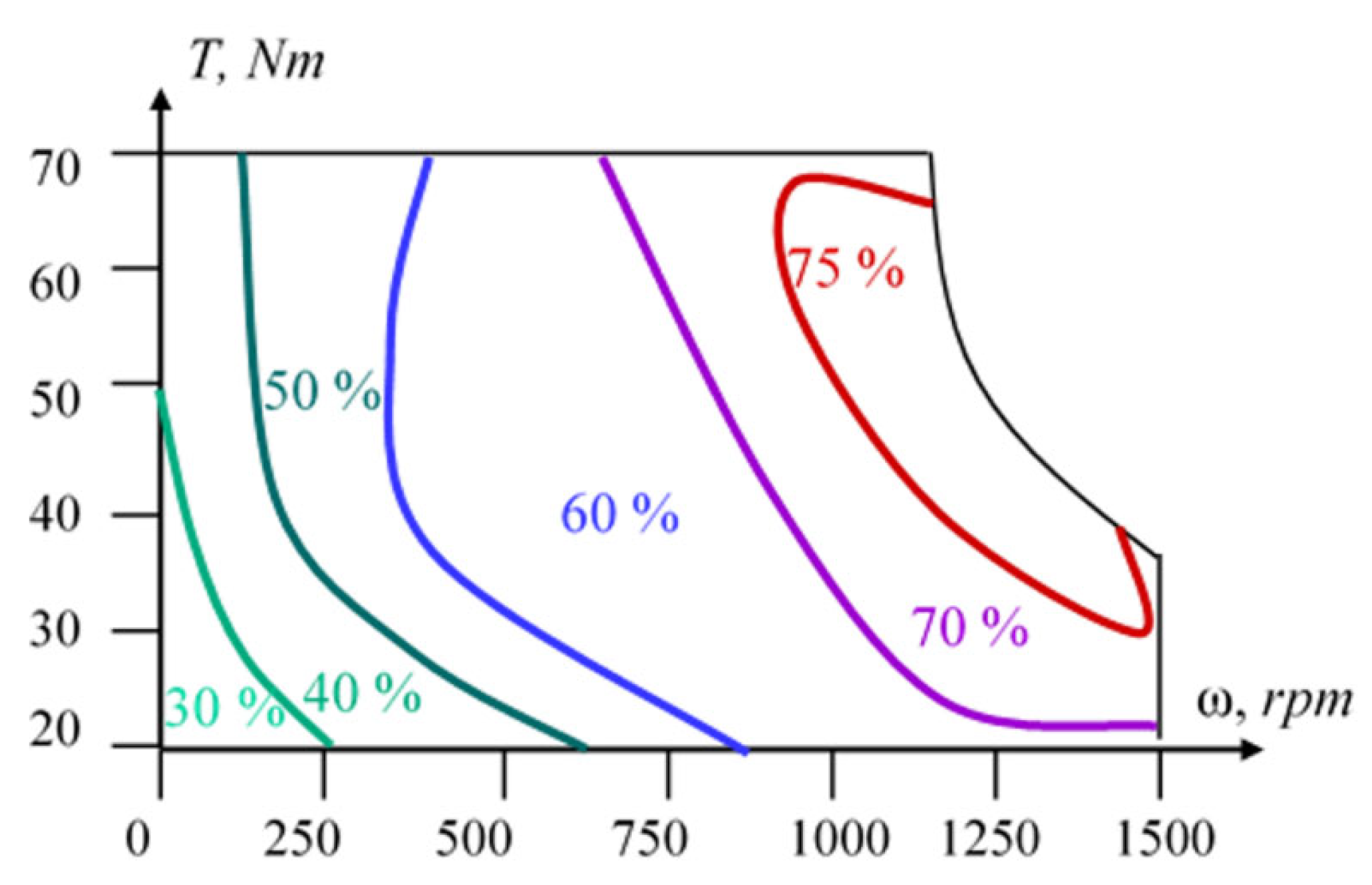

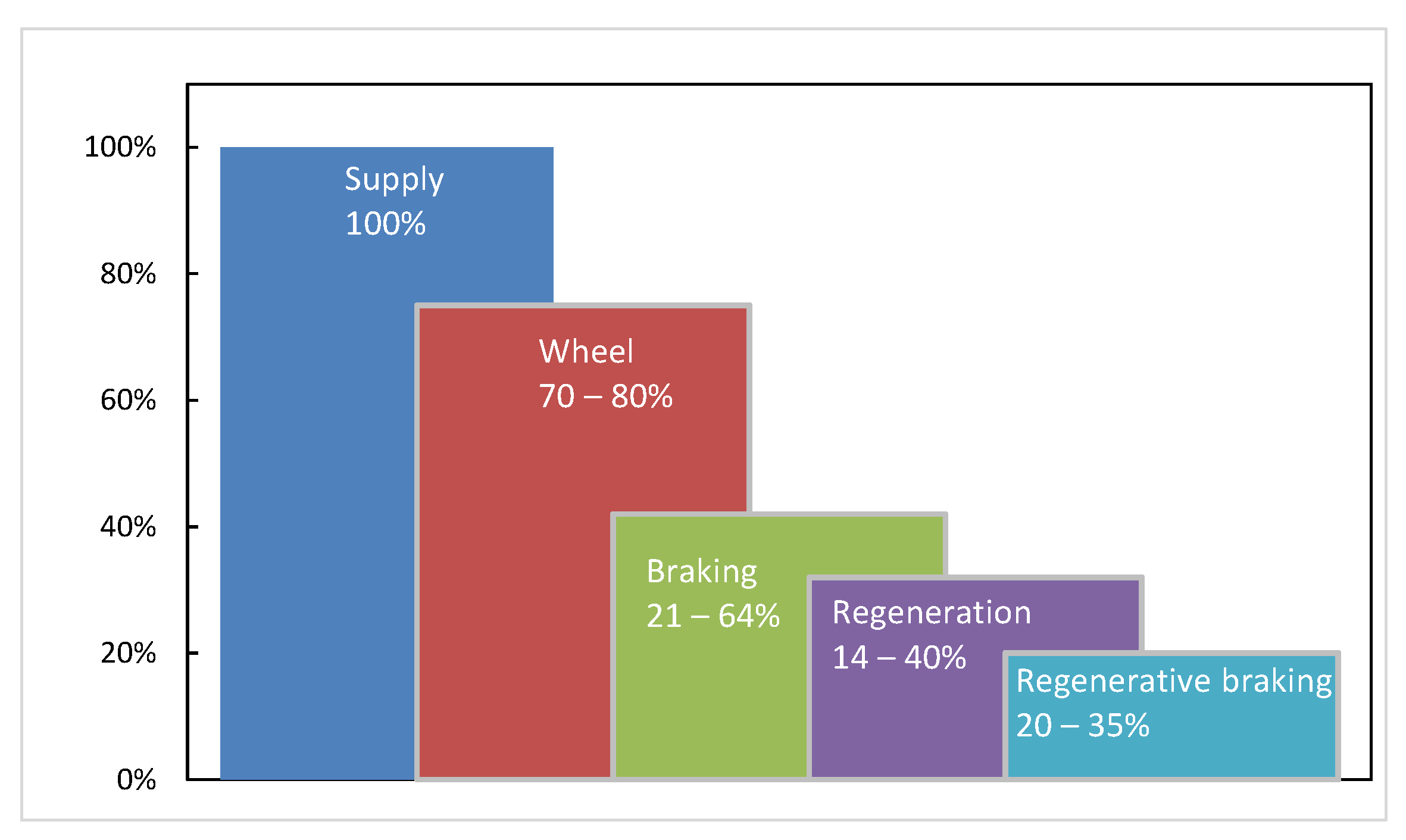

2.2. Efficiency Issues

2.3. Diversity of Efficiency

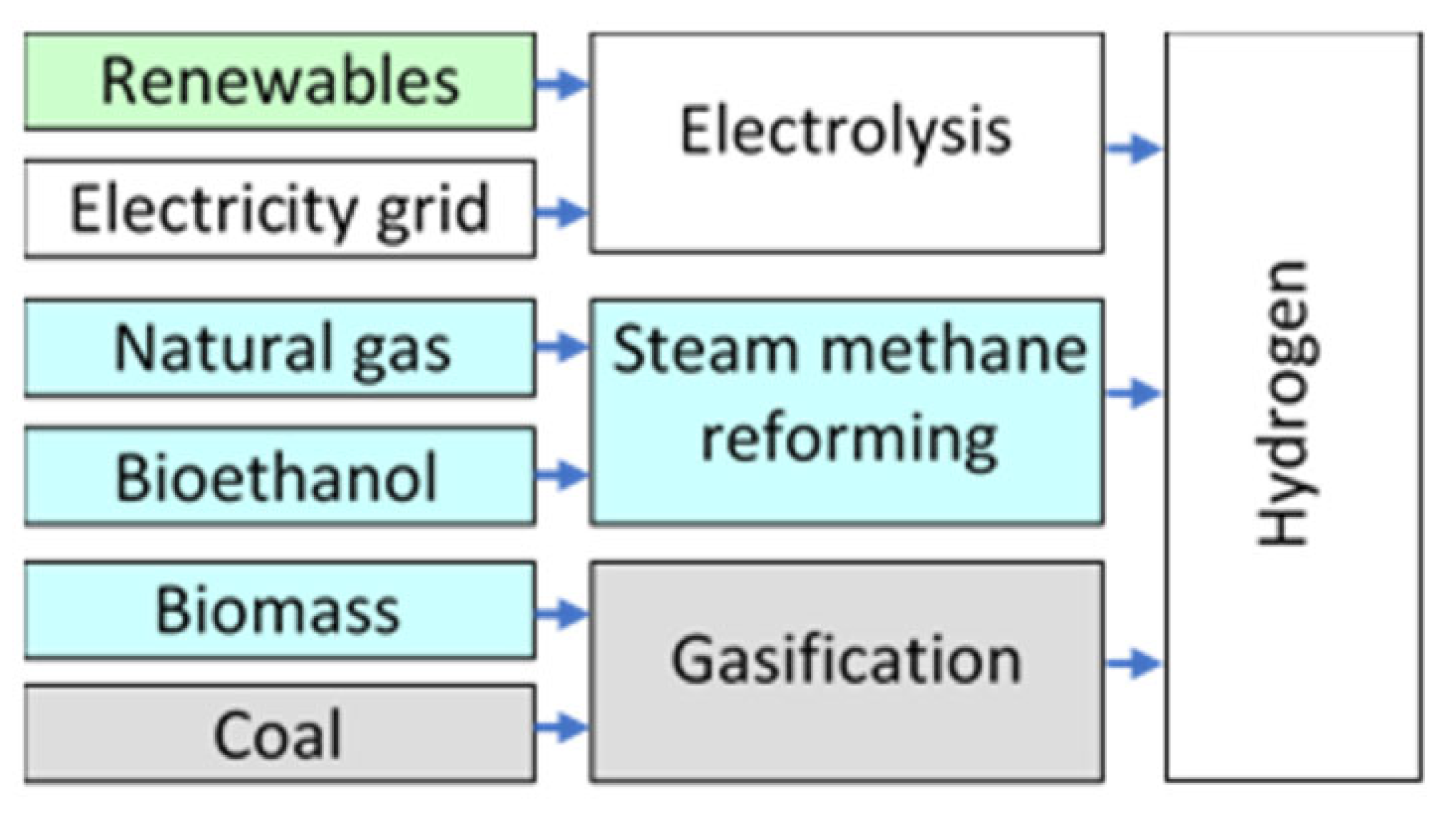

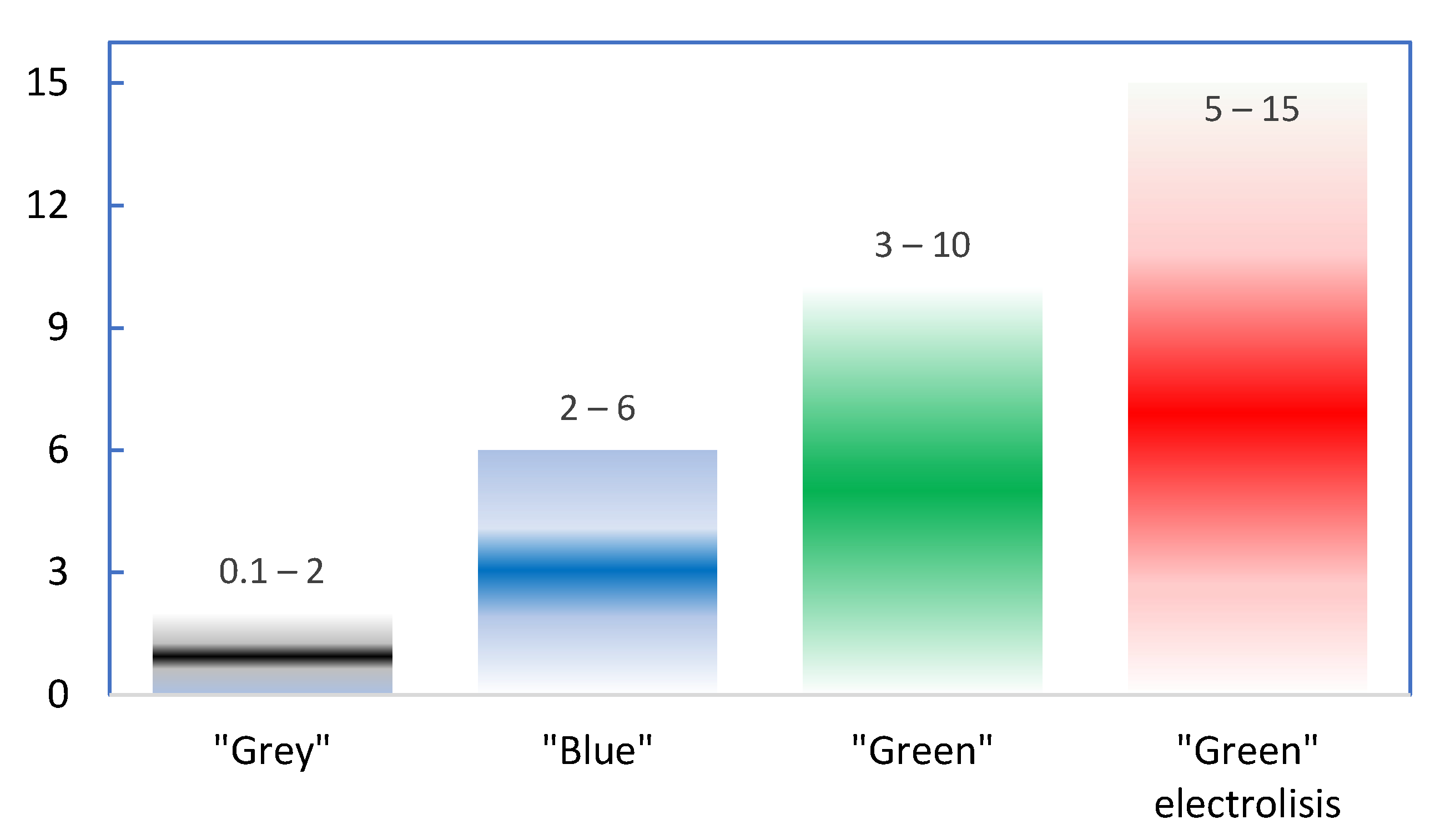

3. Advancing the Hydrogen Production Technologies

3.1. Engagement in Hydrogen

- improving the efficiency of the hydrogen fuel chain and search for options to decrease losses;

- estimation of the potential for reducing greenhouse gas emission in the hydrogen production;

- solving the problem of transferring pipeline systems from natural gas to hydrogen;

- assessment of the possibilities for using the best available renewable resources outside the country;

- assessment of the socio-economic consequences of the hydrogen economy.

3.2. Leaving behind Fossil Fuels

3.3. Time for Renewable Hydrogen

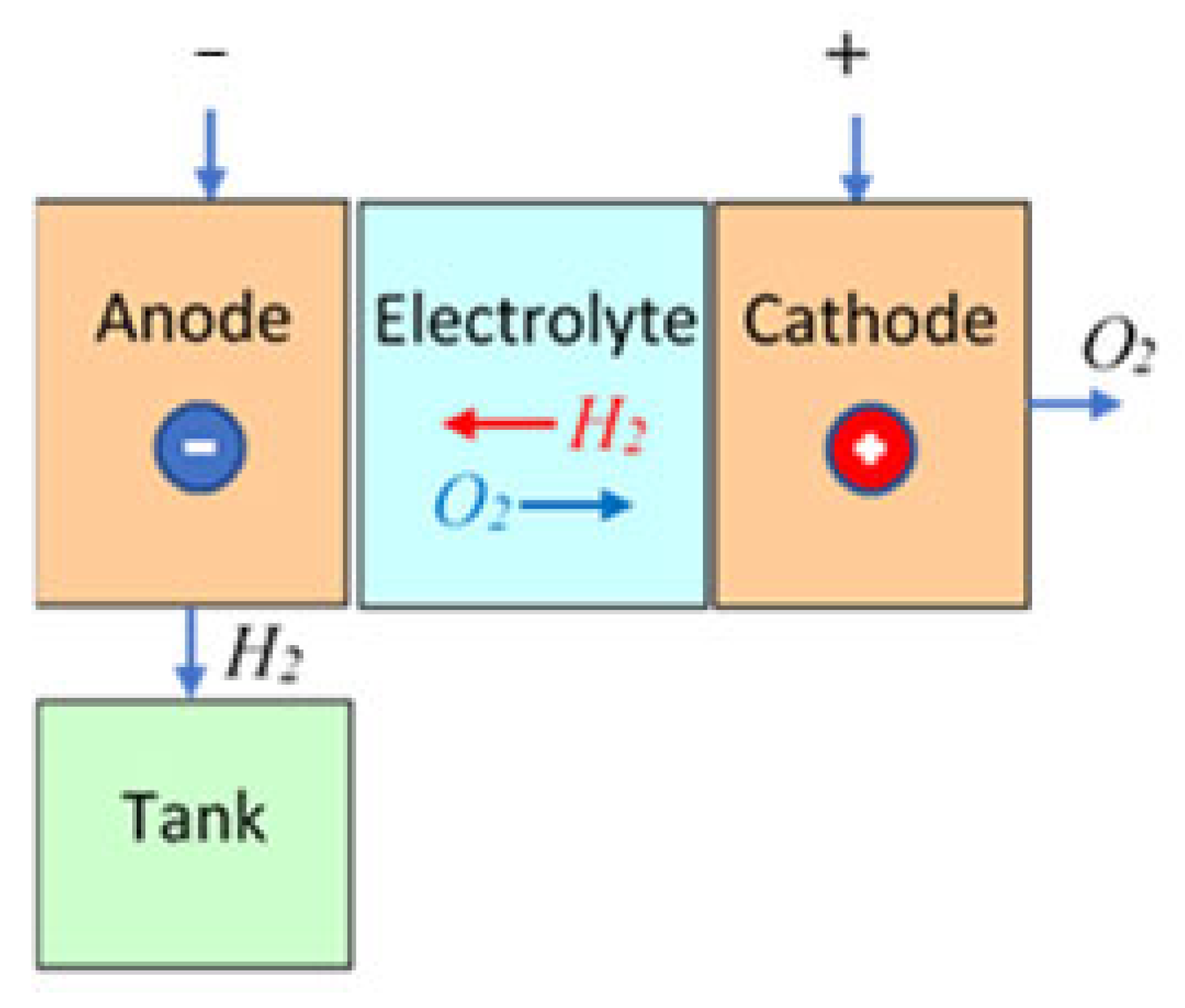

3.4. Challenges and Prospects of Electrolysis

- assessment of the economic efficiency of seasonal storage and flexibility on the electrolyzers’ demand side;

- assessment of the potential to reduce the electrolyzers’ cost and their ability to work with a partial load, given the availability of variable power;

- assessment of possible improvement of the characteristics of various electrolyser designs and their degradation under different operating conditions that affect the cost of hydrogen;

- assessment of the potential and the rate of reduction of investment costs for the electrolyzers.

3.5. Future-Oriented Initiatives

4. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| EV | electric vehicle |

| BEV | battery electric vehicle |

| BEB | battery electric bus |

| FC | fuel cell |

| FCEV | fuel cell electric vehicle |

| FCEB | fuel cell electric bus |

| EU | European Union |

| EC | European Commission |

| CO2 | carbon dioxide |

| H2 | hydrogen |

| DC | direct current |

| EM | electrical motor |

| ICE | internal combustion engine |

| HRS | hydrogen refueling station |

| CNG | compressed natural gas |

| LPG | liquid petroleum gas |

| W2W | well-to-wheel |

References

- A Hydrogen Strategy for a Climate-Neutral Europe; European Commission: Brussels, Belgium, 2020; 24p, Available online: https://ec.europa.eu/energy/sites/ener/files/hydrogen_strategy.pdf (accessed on 19 September 2022).

- Global Renewables Outlook: Energy Transformation 2050; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2020; 291p, Available online: https://www.irena.org/publications/2020/Apr/Global-Renewables-Outlook-2020 (accessed on 19 September 2022).

- Cardella, U.; Decker, L.; Klein, H. Roadmap to economically viable hydrogen liquefaction. Int. J. Hydrogen Energy 2017, 42, 13329–13338. [Google Scholar] [CrossRef]

- Sorlei, I.-S.; Bizon, N.; Thounthong, P.; Varlam, M.; Carcadea, E.; Culcer, M.; Iliescu, M.; Raceanu, M. Fuel cell electric vehicles—A brief review of current topologies and energy management strategies. Energies 2021, 14, 252. [Google Scholar] [CrossRef]

- How Fuel Cells Reduce Carbon Emissions as Effectively as Renewables. BloomEnergy White Paper. April 2019. 8p. Available online: https://www.bloomenergy.com/wp-content/uploads/bloom-energy-whitepaper-how-fuel-cells-reduce-carbon-emissions-as-effectively-as-renewables-new.pdf (accessed on 19 September 2022).

- World Energy Balances: Overview. Statistics Report; International Energy Agency (IEA): Paris, France, 2020; 59p, Available online: https://iea.blob.core.windows.net/assets/23f096ab-5872-4eb0-91c4-418625c2c9d7/World_Energy_Balances_Overview_2020_edition.pdf (accessed on 19 September 2022).

- Fossil Fuels; Environmental and Energy Study Institute (EESI): Washington, DC, USA, 2021; Available online: https://www.eesi.org/topics/fossil-fuels/description (accessed on 19 September 2022).

- REPowerEU Plan; European Commission: Brussels, Belgium, 2022; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2022%3A230%3AFIN&qid=1653033742483 (accessed on 19 September 2022).

- Path to Hydrogen Competitiveness. A Cost Perspective; Hydrogen Council: Brussels, Belgium, 2020; 88p, Available online: https://hydrogencouncil.com/wp-content/uploads/2020/01/Path-to-Hydrogen-Competitiveness_Full-Study-1.pdf (accessed on 19 September 2022).

- D’Ovidio, G.; Masciovecchio, C.; Rotondale, N. City bus powered by hydrogen fuel cell and flywheel energy storage system. In Proceedings of the IEEE International Electric Vehicle Conference (IEVC), Florence, Italy, 17–19 December 2014; pp. 1–5. [Google Scholar] [CrossRef]

- Ometto, A.; Masciovecchio, C.; Ciancetta, F.; D’Ovidio, G. A novel high efficiency hybrid power unit for hydrogen-fueled city transit bus. In Proceedings of the Electric Vehicles International Conference (EV), Bucharest, Romania, 3–4 October 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Renewables 2021 Global Status Report; REN21 Secretariat: Paris, France, 2021; 371p, Available online: https://www.ren21.net/wp-content/uploads/2019/05/GSR2021_Full_Report.pdf (accessed on 19 September 2022).

- Mulholland, E.; Rodríguez, F. Reducing Oil Dependence in the EU through Applied Measures for Trucks and Buses; The International Council on Clean Transportation (ICCT): San Francisco, CA, USA, 2022; 4p, Available online: https://theicct.org/wp-content/uploads/2022/05/fs-eu-hdv-oil-imports-may22.pdf (accessed on 19 September 2022).

- Jaworski, A.; Mądziel, M.; Kuszewski, H. Sustainable public transport strategies—Decomposition of the bus fleet and its influence on the decrease in greenhouse gas emissions. Energies 2022, 15, 2238. [Google Scholar] [CrossRef]

- CO2 Performance of New Passenger Cars in Europe; European Environmental Agency (EEA): Copenhagen, Denmark, 2021; Available online: https://www.eea.europa.eu/ims/co2-performance-of-new-passenger (accessed on 19 September 2022).

- Woodford, C. Fuel Cells. Explainthatstuff. 2021. Available online: https://www.explainthatstuff.com/fuelcells.html (accessed on 19 September 2022).

- How Many Cars Are There in the World in 2022? Hanges & Company: Singapore, 2022; Available online: https://hedgescompany.com/blog/2021/06/how-many-cars-are-there-in-the-world/ (accessed on 19 September 2022).

- The Future of Clean Transit is Electric; Ballard Power Systems: Burnaby, BC, Canada, 2022; Available online: https://www.ballard.com/markets/transit-bus (accessed on 19 September 2022).

- Shakhov, V.; Sokolova, O. Towards air pollution detection with Internet of vehicles. In Proceedings of the Transactions of 15th International Asian School-Seminar Optimization Problems of Complex Systems (OPCS), Novosibirsk, Russia, 26–30 August 2019; pp. 183–186. [Google Scholar] [CrossRef]

- Baxter, T. Hydrogen Cars Won’t Overtake Electric Vehicles Because They’re Hampered by the Laws of Science. The Conversation. 2020. Available online: https://theconversation.com/hydrogen-cars-wont-overtake-electric-vehicles-because-theyre-hampered-by-the-laws-of-science-139899 (accessed on 19 September 2022).

- How to Calculate the CO2 Emission from the Fuel Consumption? EcoScore: Brussels, Belgium, 2022; Available online: https://ecoscore.be/en/info/ecoscore/CO2 (accessed on 19 September 2022).

- Lawrence Livermore National Laboratory. 2021 Annual Report. Available online: https://flowcharts.llnl.gov (accessed on 19 September 2022).

- 500,000 e-Buses Today in Operation. Sustainable Bus. 2020. Available online: https://www.sustainable-bus.com/news/electric-vehicle-outlook-2020-bnef-electric-buses/#:~:text=By%20Editorial%20Staff-,Today%20there%20are%20500%2C000%20e%2Dbuses%20in%20operation%20globally.,New%20Energy%20Finance%20(BNEB) (accessed on 19 September 2022).

- Advancing Public Transport (UITP). Global Bus Survey. 2019; 4p, Available online: https://cms.uitp.org/wp/wp-content/uploads/2020/07/Statistics-Brief_Global-bus-survey-003.pdf (accessed on 19 September 2022).

- Fact Sheet: Buses. European Automobile Manufacturers’ Association (ACEA). 2021. Available online: https://www.acea.auto/fact/fact-sheet-buses/ (accessed on 19 September 2022).

- Ceccon, S.; Longo, M.; Mazzoncini, R.; Panarese, A. Analysis of the implementation of full electric and hydrogen hybrid buses in two lines of the city of Milan. In Proceedings of the 15th International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 10–12 September 2020; pp. 1–8. [Google Scholar] [CrossRef]

- Roadmap to a Single European Transport Area—Towards a Competitive and Resource Efficient Transport System; European Commission: Brussels, Belgium, 2011; 31p, Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=COM:2011:0144:FIN:en:PDF (accessed on 19 September 2022).

- Energy Technology Perspectives 2020; International Energy Agency (IEA): Paris, France, 2021; 400p, Available online: https://iea.blob.core.windows.net/assets/7f8aed40-89af-4348-be19-c8a67df0b9ea/Energy_Technology_Perspectives_2020_PDF.pdf (accessed on 19 September 2022).

- European Clean Hydrogen Alliance; European Commission: Brussels, Belgium, 2020; Available online: https://ec.europa.eu/growth/industry/strategy/industrial-alliances/european-clean-hydrogen-alliance_en (accessed on 19 September 2022).

- Green Hydrogen Investment and Support Report; Hydrogen Europe: Brussels, Belgium, 2020; 35p, Available online: https://profadvanwijk.com/wp-content/uploads/2020/05/Hydrogen-Europe_Green-Hydrogen-Recovery-Report_final.pdf (accessed on 19 September 2022).

- Khatibi, M. Investigating the impact of wind farms energy yields on reduction of power plants natural gas consumptions and CO2 emissions: A practical case study in Iran. In Proceedings of the 7th Iran Wind Energy Conference (IWEC), Shahrood, Iran, 17–18 May 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Zhou, Y.; Qin, C.; Chen, Z. Response and emissions performance of diffusion combustion fueled with DME and natural gas blends. In Proceedings of the IEEE International Conference on Power and Renewable Energy (ICPRE), Shanghai, China, 21–23 October 2016; pp. 694–698. [Google Scholar] [CrossRef]

- How Much CO2 is Produced When Burning 1GJ of Natural Gas? Stack Exchange Network: New York, NY, USA, 2021; Available online: https://chemistry.stackexchange.com/questions/155547/how-much-co2-is-produced-when-burning-1gj-of-natural-gas (accessed on 19 September 2022).

- Bliss, J. Carbon Dioxide Emissions per Barrel of Crude. The Quiet Road. 2008. Available online: http://numero57.net/2008/03/20/carbon-dioxide-emissions-per-barrel-of-crude/#:~:text=When%20fuel%20oil%20is%20burned,kilograms%20of%20carbon%20dioxide%20gas (accessed on 19 September 2022).

- Luft, S.; Skrzek, T. Effect of the exhaust gas recirculation ratio and the energy share of the gaseous fuel on basic operating parameters and exhaust emissions in a dual-fuel compression ignition engine operating on natural gas. In Proceedings of the XI International Science-Technical Conference Automotive Safety, Casta-Papiernicka, Slovakia, 18–20 April 2018; pp. 1–6. Available online: https://ieeexplore.ieee.org/document/8373351 (accessed on 19 September 2022).

- Iliev, S. A study of the influence of HHO gas on the performance and emissions of a diesel engine. In Proceedings of the 7th International Conference on Energy Efficiency and Agricultural Engineering (EE&AE), Ruse, Bulgaria, 12–14 November 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Takaish, T.; Numata, A.; Nakano, R.; Sakaguchi, K. Approach to high efficiency diesel and gas engines, Mitsubishi Heavy Industries, Ltd. Tech. Rev. 2008, 45, 21–24. Available online: http://www.mhi.co.jp/technology/review/pdf/e451/e451021.pdf (accessed on 19 September 2022).

- Roadmap Towards Zero Emissions: The Complementary Role of BEVs and FCEVs; Hydrogen Council: Brussels, Belgium, 2021; 26p, Available online: https://hydrogencouncil.com/wp-content/uploads/2021/10/Transport-Study-Full-Report-Hydrogen-Council-1.pdf (accessed on 19 September 2022).

- The European Green Deal; European Commission: Brussels, Belgium, 2019; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1576150542719&uri=COM%3A2019%3A640%3AFIN (accessed on 19 September 2022).

- Fuel Cell Electric Buses: Knowledge Base; Waterstofnet: Turnhout, Belgium, 2022; Available online: https://fuelcellbuses.eu/ (accessed on 19 September 2022).

- Valdez-Resendiz, J.E.; Rosas-Caro, J.C.; Mayo-Maldonado, J.C.; Claudio-Sanchez, A.; Ruiz-Martinez, O.; Sanchez, V.M. Improvement of ultracapacitors-energy usage in fuel cell based hybrid electric vehicle. Int. J. Hydrogen Energy 2020, 45, 13746–13756. [Google Scholar] [CrossRef]

- Escandón, A.M.A.C.; Escandón, B.E.A.B.; Zalamea-León, E.; Serrano-Guerrero, X. Hydrogen capacity for use in public transportation using the excess electricity generated by photovoltaics from rooftops in the urban area of Cuenca, Ecuador. In Proceedings of the 20th International Conference on Renewable Energies and Power Quality (ICREPQ), Vigo, Spain, 27–29 July 2022; pp. 1–6. Available online: https://www.icrepq.com/icrepq22/215-22-cevallos.pdf (accessed on 19 September 2022).

- Akadeemik Enn Lust: Eesti Mängib Ikka Veel Lolli ja Tahab Edasi Tossutada. Tuule Tehnoloogia Litt. 2019. Available online: http://www.tuuleliit.ee/akadeemik-enn-lust-eesti-mangib-ikka-veel-lolli-ja-tahab-edasi-tossutada/ (accessed on 19 September 2022).

- Gim, J.; Kim, M.; Ahn, C. Energy management control strategy for saving trip costs of fuel cell/battery electric vehicles. Energies 2022, 15, 2131. [Google Scholar] [CrossRef]

- Luciani, S.; Tonoli, A. Control strategy assessment for improving PEM fuel cell system efficiency in fuel cell hybrid vehicles. Energies 2022, 15, 2004. [Google Scholar] [CrossRef]

- Dobson, G. Exploding Hydrogen Station Leads to FCV Halt; EV Talk: Sydney, Australia, 2019; Available online: https://evtalk.com.au/exploding-hydrogen-station-leads-to-fcv-halt/ (accessed on 19 September 2022).

- Li, H.; Liu, J.; Tian, Y.; Li, J. Optimization design of the permanent seat structure of the hydrogen supply system of fuel cell bus. In Proceedings of the IEEE Asia-Pacific Conference on Image Processing, Electronics and Computers (IPEC), Dalian, China, 14–16 April 2021; pp. 689–692. [Google Scholar] [CrossRef]

- Global Hydrogen Review 2021; International Energy Agency (IEA): Paris, France, 2021; 223p, Available online: https://iea.blob.core.windows.net/assets/5bd46d7b-906a-4429-abda-e9c507a62341/GlobalHydrogenReview2021.pdf (accessed on 19 September 2022).

- Ônibus Brasileiro Movido a Hidrogênio Começa a Rodar em São Paulo; Inovação Tecnológica: Lille, France, 2009; Available online: www.inovacaotecnologica.com.br/noticias/noticia.php?artigo=onibus-brasileiro-movido-a-hidrogenio-comeca-a-rodar-em-sao-paulo (accessed on 19 September 2022).

- Yi, Y.; Jang, J.A.; Lee, I. Data design for driving monitoring of hydrogen electric bus. In Proceedings of the Transactions of International Conference on Information and Communication Technology Convergence (ICTC), Jeju Island, Korea, 20–22 October 2021; pp. 697–700. [Google Scholar] [CrossRef]

- Borbujo, I.C.; Pereirinha, P.G.; Vega, M.G.; del Valle, J.A.; Antón, J.C.Á. Heavy duty transport descarbonization: Legislation and standards for hydrogen and battery electric buses and heavy-duty trucks. In Proceedings of the Transactions of IEEE Vehicle Power and Propulsion Conference (VPPC), Gijon, Spain, 25–28 October 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Crawford, I. How Much CO2 is Emitted by Manufacturing Batteries? MIT Climate: Cambridge, MA, USA, 2022; Available online: https://meche.mit.edu/news-media/how-much-co2-emitted-manufacturing-batteries (accessed on 19 September 2022).

- Woollacott, E. Electric Cars: What Will Happen to All the Dead Batteries? BBC: London, UK, 2021; Available online: https://www.bbc.com/news/business-56574779 (accessed on 19 September 2022).

- Breuer, J.L.; Scholten, J.; Koj, J.C.; Schorn, F.; Fiebrandt, M.; Samsun, R.C.; Albus, R.; Görner, K.; Stolten, D.; Peters, R. An Overview of Promising Alternative Fuels for Road, Rail, Air, and Inland Waterway Transport in Germany. Energies 2022, 15, 1443. [Google Scholar] [CrossRef]

- Allen, J. Honda: Now Is The Right Time to Embrace Electric Cars. The Sunday Times. 4 November 2019. Available online: https://www.driving.co.uk/news/honda-embracing-electrified-cars-now-right-time (accessed on 19 September 2022).

- FCEV Sales, FCEB, & Hydrogen Station Data; California Fuel Cell Partnership: California, CA, USA, 2022; Available online: https://cafcp.org/by_the_numbers (accessed on 19 September 2022).

- Hanley, S. French City Cancels Hydrogen Bus Contract, Opts for Electric Buses; CleanTechnica: Long Beach, CA, USA, 2022; Available online: https://cleantechnica.com/2022/01/11/french-city-cancels-hydrogen-bus-contract-opts-for-electric-buses (accessed on 19 September 2022).

- Fernandes, R. Here’s Why Hydrogen Cars Were Doomed To Fail. 2022. Available online: https://www.slashgear.com/833231/heres-why-hydrogen-cars-were-doomed-to-fail (accessed on 19 September 2022).

- Williams, K. The Switch from Hydrogen to Electric Vehicles Continues Now Hyundai Makes Move; Seeking Alpha: New York, NY, USA, 2017; Available online: https://seekingalpha.com/article/4103682-switch-from-hydrogen-to-electric-vehicles-continues-now-hyundai-makes-move (accessed on 19 September 2022).

- Hydrogen from Renewable Power Technology Outlook for the Energy Transition; Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2018; 52p, Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2018/Sep/IRENA_Hydrogen_from_renewable_power_2018.pdf (accessed on 19 September 2022).

- He, C.; Ma, L.; Wang, R.; Zhang, X. Establishment of wind turbine energy efficiency index system based on f-neighborhood rough set. In Proceedings of the International Conference on Sensing, Diagnostics, Prognostics, and Control (SDPC), Beijing, China, 5–7 August 2020; pp. 17–21. [Google Scholar] [CrossRef]

- Weiss, M.; Cloos, K.C.; Helmers, E. Energy efficiency trade-offs in small to large electric vehicles. Environ. Sci. Eur. 2020, 32, 1–17. [Google Scholar] [CrossRef]

- Total Final Consumption; Energy Education: Burlington, VT, USA, 2021; Available online: https://energyeducation.ca/encyclopedia/Total_final_consumption (accessed on 19 September 2022).

- Well-to-Wheels Analyses; European Commission: Ispra, Italy, 2016; Available online: https://joint-research-centre.ec.europa.eu/welcome-jec-website/jec-activities/well-wheels-analyses_en (accessed on 19 September 2022).

- Wang, X.-Z.; Zhou, M.-H.; Dang, J.-M. A comparative efficiency evaluation of China’s logistics regions based on changing output indicators. In Proceedings of the International Conference on Information Management, Innovation Management and Industrial Engineering, Taipei, Taiwan, 19–21 December 2008; pp. 7–11. [Google Scholar] [CrossRef]

- Oziemski, M. Topping nuclear power plants steam cycles with gas turbines as the way of enhancing their efficiency. In Proceedings of the International Conference on Power Generation Systems and Renewable Energy Technologies (PGSRET), Istanbul, Turkey, 26–27 August 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Hydrogen: A Renewable Energy Perspective; Report of the 2nd Hydrogen Energy Ministerial Meeting in Tokyo, Japan; Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2019; 52p, Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Sep/IRENA_Hydrogen_2019.pdf (accessed on 19 September 2022).

- Electrolyzer Efficiency. HOMER Pro. 2022. Available online: https://www.homerenergy.com/products/pro/docs/latest/electrolyzer_efficiency.html (accessed on 19 September 2022).

- Skiba, E.D.; Shaposhnikov, V.V.; Kocharyan, E.V. Energy saving in the main gas pipeline transport. In Proceedings of the transactions of International Science and Technology Conference (EastConf), Vladivostok, Russia, 1–2 March 2019; pp. 1–3. [Google Scholar] [CrossRef]

- Klimash, V.S.; Tabarov, B.D. Improving the efficiency of transformer substations with unbalanced load schedule. In Proceedings of the Transactions of International Multi-Conference on Industrial Engineering and Modern Technologies (FarEastCon), Vladivostok, Russia, 6–9 October 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Moghbelli, H.; Niasar, A.H.; Langari, R. New generation of passenger vehicles: FCV or FCEV? In Proceedings of the Transactions of IEEE International Conference on Industrial Technology, Mumbai, India, 15–17 December 2006; pp. 1–8. [Google Scholar] [CrossRef]

- Lambert, F. Toyota Admits ‘Elon Musk is Right’ about Fuel Cell, but Moves Forward with Hydrogen Anyway. Electrek. 26 October 2017. Available online: https://electrek.co/2017/10/26/toyota-elon-musk-fuel-cell-hydrogen (accessed on 19 September 2022).

- Vodovozov, V. Electrical Drive: Performance, Design and Control; LAP Lambert Academic Publishing: Saarbrücken, Germany, 2014; 328p, Available online: https://www.amazon.co.uk/Electrical-Drive-Performance-Design-Control/dp/3659551910 (accessed on 19 September 2022).

- Hydrogen Electricity Value Chain. Group Technology & Research Position Paper. 2019. Available online: https://issuu.com/dnvgl/docs/190225193348-9479976654484e1884e8add3fe2c5095 (accessed on 19 September 2022).

- Battery Electric Cars Are a Better Choice for Emissions Reduction; PVBuzz Media: Scarborough, ON, Canada, 2016; Available online: https://pvbuzz.com/electric-cars-better (accessed on 19 September 2022).

- Liquid Hydrogen Online; IdealHy: Oldenburg, Germany, 2013; Available online: https://www.idealhy.eu/index.php?page=lh2_outline (accessed on 19 September 2022).

- Stolzenburga, K.; Berstadb, D.; Deckerc, L.; Elliottd, A.; Haberstrohe, C.; Hattof, C.; Klause, M.; Mortimerf, N.D.; Mubbalaa, R.; Mwabonjef, O.; et al. Efficient liquefaction of hydrogen: Results of the IDEALHY project. In Proceedings of the XXth Energie—Symposium, Stralsund, Germany, 7–9 November 2013; pp. 1–8. Available online: https://www.idealhy.eu/uploads/documents/IDEALHY_XX_Energie-Symposium_2013_web.pdf (accessed on 19 September 2022).

- Voelcker, J. Energy use for hydrogen fuel-cell vehicles: Higher than electrics, even hybrids (analysis). Green Car Reports. 4 May 2017. Available online: https://www.greencarreports.com/news/1110239_energy-use-for-hydrogen-fuel-cell-vehicles-higher-than-electrics-even-hybrids-analysis (accessed on 19 September 2022).

- Nekkers, R.; Ex, F.; van Beckhoven, J. Hydrogen buses on the Veluwe. Status Report 2BP. March 2020. Available online: https://www.h2nodes.eu/images/docs/20200416_status_verslag_2BP_Hydrogen_buses_on_the_Veluwe_Eng_.pdf (accessed on 19 September 2022).

- Ivkovic, I.; Kaplanović, S.; Milovanović, B. Influence of road and traffic conditions on fuel consumption and fuel cost for different bus technologies. Therm. Sci. 2017, 21, 693–706. [Google Scholar] [CrossRef]

- Al-Mahadin, A.; Mustafa, M.Y. Utilizing fuel cell technology for Dubai Roads and Transport Authority (RTA). In Proceedings of the Advances in Science and Engineering Technology International Conferences (ASET), Dhabi, United Arab Emirates, 6 February–5 April 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Vodovozov, V.; Raud, Z.; Lehtla, T. Design of an experimental setup to study the drives of battery electric vehicles. World Acad. Sci. Eng. Technol. 2013, 76, 704–710. [Google Scholar] [CrossRef]

- Raud, Z.; Vodovozov, V.; Lillo, N.; Rassolkin, A. Reserves for regenerative braking of battery electric vehicles. In Proceedings of the Electric Power Quality and Supply Reliability Conference (PQ), Rakvere, Estonia, 11–13 June 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Halderman, D.J. Advanced Automotive Electricity and Electronics; Pearson Education: New Jersey, NJ, USA, 2013; 455p. [Google Scholar]

- [20A] The Future of Hydrogen; International Energy Agency (IEA): Paris, France, 2019; 203p, Available online: https://iea.blob.core.windows.net/assets/9e3a3493-b9a6-4b7d-b499-7ca48e357561/The_Future_of_Hydrogen.pdf (accessed on 19 September 2022).

- Hydrogen; International Energy Agency (IEA): Paris, France, November 2021; Available online: https://www.iea.org/reports/hydrogen (accessed on 19 September 2022).

- Hydrogen Generation Market Size, Share & Trends Analysis Report; Grand View Research: San Francisco, CA, USA, 2022; 132p, Available online: https://www.grandviewresearch.com/industry-analysis/hydrogen-generation-market (accessed on 19 September 2022).

- Future European Fuel Cell Technology: Fit for Automatic Manufacturing and Assembly; Fuel Cells and Hydrogen Joint Undertaking: Brussels, Belgium, 2020; Available online: https://www.fch.europa.eu/project/future-european-fuel-cell-technology-fit-automatic-manufacturing-and-assembly (accessed on 19 September 2022).

- Vancouver Ends Hydrogen Bus Program Amid High Costs. 2015. Available online: https://enrg.io/vancouver-ends-hydrogen-bus-program-amid-high-costs (accessed on 19 September 2022).

- Swalec, C. Steel Plants are Responsible for Global CO2 Emissions. CarbonBrief. 2021. Available online: https://www.carbonbrief.org/guest-post-these-553-steel-plants-are-responsible-for-9-of-global-co2-emissions (accessed on 19 September 2022).

- Gibbs, M.J.; Soyka, P.; Conneely, D. CO2 emissions from cement production. In Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories; IPCC: Hayama, Japan, 2000; pp. 175–182. [Google Scholar]

- Mohseni, S.; Brent, A.C. Economic viability assessment of sustainable hydrogen production, storage, and utilization technologies integrated into on- and off-grid micro-grids: A performance comparison of different meta-heuristics. Int. J. Hydrogen Energy 2020, 45, 34412–34436. [Google Scholar] [CrossRef]

- Mobility and Transport; European Commission: Brussels, Belgium, 2022; Available online: https://transport.ec.europa.eu/index_en (accessed on 19 September 2022).

- Baroutaji, A.; Wilberforce, T.; Ramadan, M.; Olabi, A.C. Comprehensive investigation on hydrogen and fuel cell technology in the aviation and aerospace sectors. Renew. Sustain. Energy Rev. 2019, 106, 31–40. [Google Scholar] [CrossRef] [Green Version]

- 2017 Renewable Energy Data Book; National Renewable Energy Laboratory (NREL), U.S. Department of Energy: Portland, OR, USA, 2019; 142p. Available online: https://www.nrel.gov/docs/fy19osti/72170.pdf (accessed on 19 September 2022).

- Zhang, D.; Duan, R.; Li, H.; Yang, Q.; Zhou, H. Optimal design, thermodynamic, cost and CO2 emission analyses of coal-to-methanol process integrated with chemical looping air separation and hydrogen technology. Energy 2020, 203, 117876. [Google Scholar] [CrossRef]

- Cost, Logistics Offer ‘Blue Hydrogen’ Market; C&P Global: Crown Point, IN, USA, 2022; Available online: https://www.spglobal.com/marketintelligence/en (accessed on 19 September 2022).

- Statistical Review of World Energy; BP p.l.c.: London, UK, 2021; 72p, Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2021-full-report.pdf#page13 (accessed on 19 September 2022).

- United States Energy Information; EnerData: Grenoble, France, 2022; Available online: https://www.enerdata.net/estore/energy-market/united-states (accessed on 19 September 2022).

- Electricity Production, Consumption and Market Overview; Eurostat: Brussels, Belgium, 2022; Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_production,_consumption_and_market_overview (accessed on 19 September 2022).

- State of the Energy Union 2021—Contributing to the European Green Deal and the Union’s Recovery; European Commission: Brussels, Belgium, 2021; Available online: https://energy.ec.europa.eu/system/files/2021-10/state_of_the_energy_union_report_2021.pdf (accessed on 19 September 2022).

- Woodrow, M. Bay Area Experiences Hydrogen Shortage after Explosion. ABC News. 4 June 2019. Available online: https://abc7news.com/hydrogen-explosion-chemicals-chemical-plant/5328775 (accessed on 19 September 2022).

- International Renewable Energy Agency (IRENA). Available online: https://www.irena.org/ (accessed on 19 September 2022).

- Paris Agreement; United Nations: San Francisco, CA, USA, 2015; 27p, Available online: https://unfccc.int/sites/default/files/english_paris_agreement.pdf (accessed on 19 September 2022).

- Renewable Energy Directive; European Commission: Brussels, Belgium, 2018; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG&toc=OJ:L:2018:328:TOC (accessed on 19 September 2022).

- CO2 Emission Performance Standards for Cars and Vans; European Commission: Brussels, Belgium, 2019; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32020R0022 (accessed on 19 September 2022).

- European Regional Development Fund; European Commission: Brussels, Belgium, 2021; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32021R1058 (accessed on 19 September 2022).

- Public Transport in Estonia. Bus; Estonian Transport Administration: Tallinn, Estonia, 2021; Available online: https://www.transpordiamet.ee/en/mobility-and-transportation/public-transport-estonia/bus (accessed on 19 September 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vodovozov, V.; Raud, Z.; Petlenkov, E. Review of Energy Challenges and Horizons of Hydrogen City Buses. Energies 2022, 15, 6945. https://doi.org/10.3390/en15196945

Vodovozov V, Raud Z, Petlenkov E. Review of Energy Challenges and Horizons of Hydrogen City Buses. Energies. 2022; 15(19):6945. https://doi.org/10.3390/en15196945

Chicago/Turabian StyleVodovozov, Valery, Zoja Raud, and Eduard Petlenkov. 2022. "Review of Energy Challenges and Horizons of Hydrogen City Buses" Energies 15, no. 19: 6945. https://doi.org/10.3390/en15196945