Artificial Intelligence Methodologies in Smart Grid-Integrated Doubly Fed Induction Generator Design Optimization and Reliability Assessment: A Review

Abstract

:1. Introduction

2. Smart Grid-Integrated Wind Energy Reliability Challenges Confined to IEC 61400-25-26/1/2/3 Standards

2.1. Fatigue Life Estimation

2.2. Availability

2.3. Failure Rate

2.4. Wind Farm Data Automation Architecture

3. Methodology and Review Structure

3.1. Functionalities and Methodologies of AI for DFIG and Power Converter Availability

- Optimization.

- Regression.

- Classification.

- Data structure exploration.

- Optimization: Research scholars have established that the optimization function provides an understanding of the most suitable solution by exploiting or diminishing the unbiased functions, including a selected set of available alternatives that are given limits, independence, or disproportions to satisfy the outcomes [56].

- Classification: Research scholars have established that abnormality finding and fault diagnostics in the maintenance of a specific arrangement task can select fault tags with condition monitoring data. However, the authentic database might consist of noise labeled in [57], comprising non-logical errors [58]. Researchers have also widely studied machine and deep learning methodologies and found that they specifically deal with conveying input data facts with a tag representing the k discrete modules [19].

- 4.

- Data structure exploration: The research scholars suggested that data structure comprises database gathering. It determines clusters of similar data within a dataset, density approximation that governs the supply of the dataset within the input planetary, and database density that plans a higher-dimension dataset down to a lower-dimension dataset for the futuristic decline.

3.1.1. Expert Systems

3.1.2. Fuzzy Logic

3.1.3. Metaheuristic Methods

3.1.4. Neural Network Learning

- 1.

- Supervised learning.

- 2.

- Unsupervised learning.

- 3.

- Reinforcement learning.

- 1.

- Supervised learning (SL)—This is explained by using tagged data (input and output pair) to train a set of rules to accurately set up the plotting and relevant connections between the inputs and outputs. This standpoint is exclusively correct for conditions in power electronic converters in which the formulation of structural shapes is encouraged. SL consists of classification and regression types of assignments. For example, the research scholars in [97] established a typical classification task of fault diagnostics for a multilevel inverter in which a different fault is discovered, given the input fault report. Another illustration of regression is the outstanding functional lifetime estimation of IGBTs [98], where the throughput, i.e., the good due time, is a permanent variable. The accomplished model is equipped to assess new database elements that vary from the training dataset. The model’s ability to trade with more unique database points, i.e., the ones in the analysis dataset, is called generalization.

- 2.

- Unsupervised learning (USL)—The unsupervised learning tasks are classified as database gathering and data compression. Unlike supervised learning, where the dataset is input and output sets, unsupervised learning does not have an output database for the learning objective during the learning procedure. For the dataset grouping, investigates the symmetries from the spread dataset and categorizes the dataset into many distinct clusters corresponding to their relationships. This way, the database features in one cluster differ from those in another group.

- 3.

- Reinforcement learning (RL)—In contrast to supervised and unsupervised learning, reinforcement learning does not need a training dataset. As an alternative, it finds an appropriate action that maximizes the incentive for a specific task, effectively an optimization task. Research scholars in [30,137] discovered that a trial run and error procedure prepares this objective-oriented approach from interfaces with simulation models. This way, it accrues a progressive experience and finds a particular system that extends the predefined objective. Ideally, RL is a Markov decision process [137]. The training of RL involves working out a Q-table. The Q-table is an instructive matrix that documents the optimum action for a given specific condition variable, which can increase the total estimated incentives over time.

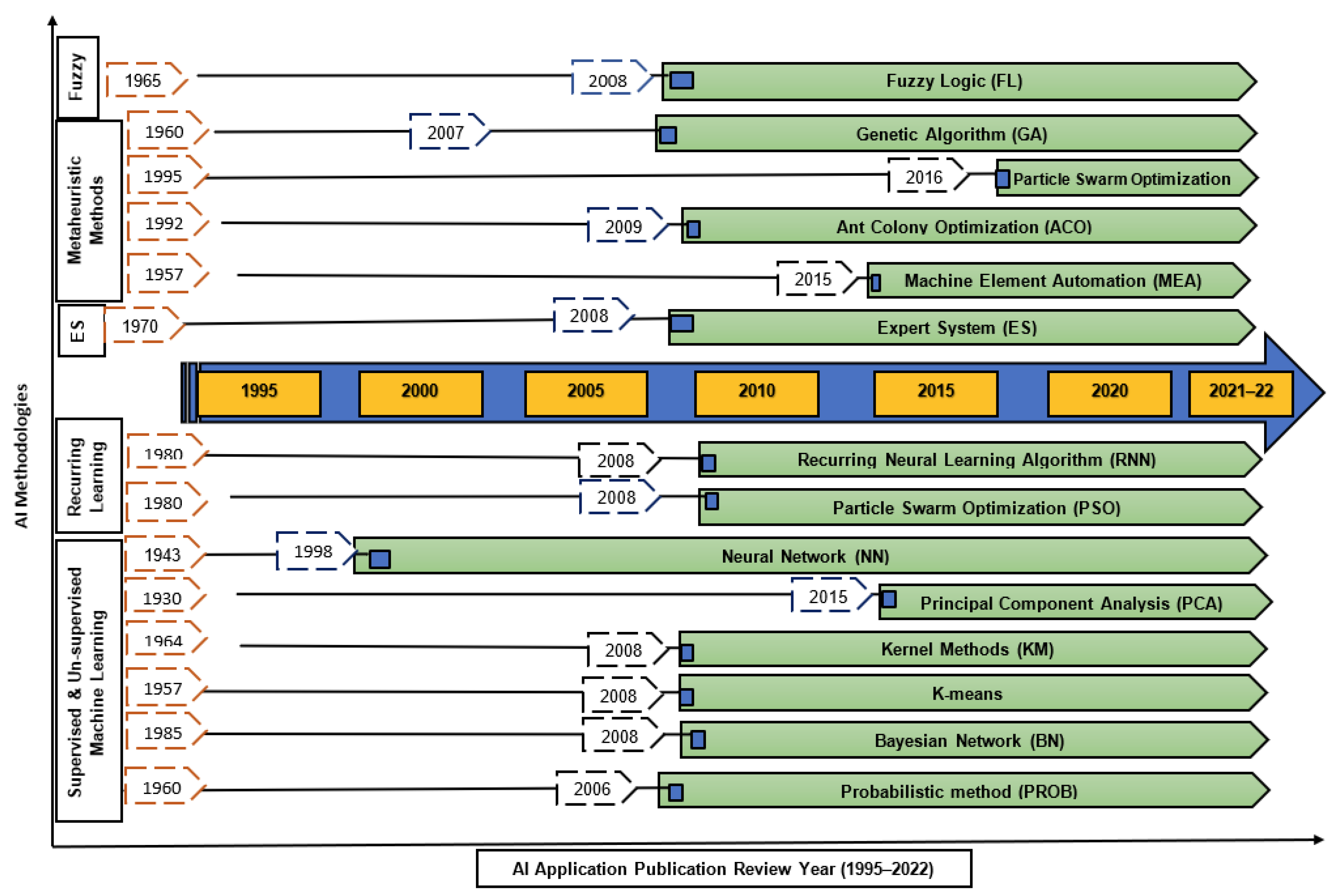

3.1.5. AI Events Timeline

- Currently, expert systems and fuzzy logic have become more acceptable, particularly expert systems [112]. Until 2005, their hands-on applications were established in the partial presentation of computing calculations and hardware [139], which have been meaningfully developed to date [140]. This fast improvement facilitates the acceleration of the application of several AI procedures for substituting the expert system and fuzzy logic [141].

- Metaheuristic methodologies are constantly developing and are practiced with power converters [77] and utilized for complex tasks with added ML methodologies.

- Neural network approaches are the most excellent hands-on sector for AI realization in power converter systems for the following reasons:

- The substantial growth of computational hardware advances the capabilities of neural network methodologies.

4. Design and Optimization System

- An empirical interpretation: Empirical tasks are appropriate for maximizing or minimizing objectives. Mostly, the design objectives in power electronic converters consist of element limitation [79,151] weight [152,153] volume [154,155,156] cost [152], heatsink pattern [95,157] area [158,159,160] and power loss [86]. The research scholars in [150] established that it is critical to articulate the anticipated design constraints to several obvious statistical expressions as a particular purpose, as specified in Equation (7), or numerous objectives, as presented in Equation (8) [77,150]:

- where g(x) and h(x) are inequities and similarities, Xl and Xu are the minor and the higher limits for ruling variable quantity x, respectively. Here, the maximization can be applied as the objective to the minimization case. Note that multiple goals in Equation (8) can be explained by either maximizing a scalar functionality WT f(x) by weighting numerous objectives altogether or by directly enhancing the objective vector function f(x). The researchers illustrated a common 2D Pareto optimization problem in [150] in a graphical manner about capitalizing efficiency while curtailing cost. Here, the researchers highlighted an enhanced point as a Pareto front of the optimum solution. The study explains the signs that give the Pareto-optimal facts, repeatedly termed as non-dominated and dominated points. It is up to the designer to first-rate one of these proposals by trading cost vs. efficiency. Space constraint: The research scholars in [152,153] outlined that the space constraint in the designing aspect is subject to the reasonable spacing, limits, association, and conditions that the design function meets the linear or nonlinear similarities and variations. The functional model constraints, shape, capacity, life expectancy attributes, costing, etc., are derived from the design space constraints.

- Discovering a solution: A well-defined optimization problem is to extend (or reduce) objective functionalities by altering the outcome variable quantities in the constraint spaces. AI methodologies, particularly metaheuristic techniques, can be employed here.

- Performance evaluation: The research scholars in [148,149,150] established that using simulation hardwired loop testing and a practical prototype, the applied solution can be assessed contrary to the predefined objectives. They referenced the results of previous steps for further performance improvement and optimization.

4.1. Design Timeline Saving

4.2. Design Modeling and Optimization

5. Reliability-Centered Maintenance

- Offline training and knowledge sharing: It participates in numerous features of information comprising a historic observing dataset, model dataset, enhanced mature test experimentation, and fault mode and effect analysis (FMEA). Moreover, the authors in [172] used collaborative methodologies in the section on execution enhancement.

- Condition checking and healthiness valuation: This section connects the conditional checks of the component to the online and offline condition checking in-ground applications. The functions of parameter documentation do not involve introducing test instruments into the test body, dataset scrubbing, characteristic removal, abnormality observation, failure analysis, and RUL forecast. The authors customized the disconnected pattern with the provisional element between the model variable fine-tuning levels by regulating the ground-functioning capacity to ensure the removal of sensitive information on decision-making from the constant condition-check statistics.

- Administration and decision making: In this section, the authors deal with the compassionate understanding of a health review on ideal decision-making. This health review feedback can improve the governing strategies to improve system usage given the real-time asset health condition. Subsequently, the authors broadly debated the practical AI applications in maintenance.

5.1. Condition and Health Monitoring

5.2. System Parameter Identification

5.3. Anomaly Fault Discovery and Failure Analysis

5.3.1. Supervised Learning Methods

5.3.2. Unsupervised Learning Methods

5.3.3. Discussion

- In addition to singular element failure, the fault mode of several elements breaking down concurrently also has to be measured. The interdependency and linking effect amongst the failed elements should be integrated into the analytical procedures.

- In particular, the difficulties in the dataset acquirement of power electronic converter systems and the drilling database for practical use are usually restricted. This situation is much worse for a database when there are unstable failure labels, i.e., the sample dataset of the usual process and the insufficiency of the dataset with failure tags because of disastrous catastrophes. Therefore, the algorithm applies to a given partial dimension of the database, and an inferior database should be examined.

- The practicability, computational load, adjustable ability, sturdiness, the designing and correcting of the algorithm, and application budget must be extensively measured [119].

5.4. Remaining Useful Life Prediction

5.4.1. Ambiguity Presentation and Clarification

5.4.2. Ambiguity Quantification

5.4.3. Uncertainty Propagation

5.4.4. Adaptive Capability

6. Overview of AI for Power Electronic Reliability-Centered Maintenance Systems

6.1. Rationalizations of AI Applied to Power Converter Systems

6.2. AI Performances through Lifecycle Stages

6.3. Informative Association

6.4. Database Confidentiality

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Africa Case |

| ACO | Ant Colony Optimization algorithm |

| AE | Auto Encoder |

| AI | Artificial Intelligence |

| ANFIS | Adaptive Neuro-Fuzzy Inference System |

| ANN | Artificial Neural Network |

| APS | Announced Pledges Scenario |

| CC | Clean Compression |

| CLD | Constant Life Diagram |

| CNN | Convolution Neural Network |

| CSI | Current Source Inverter |

| C&HM | Condition and Health Management |

| DFIG | Doubly Fed Induction Generator |

| DfR | Design for Reliability |

| DL | Deep Learning |

| ENN | Elman Neural Network |

| ESN | Eco State Neural Network |

| ESR | Equivalent Series Resistance |

| FFNN | Feed-Forward Neural Network |

| FMEA | Fault Mode and Effective Analysis |

| FNN | Fuzzy Neural Network |

| FSMPC | Finite State Model Predictive Control |

| GA | Genetic Algorithm |

| GL | Germanischer Lloyd |

| IEC | International Electro-Technical Commission |

| IEDs | Intelligent Electrical Devices |

| IRENA | International Renewable Energy Agency |

| MDT | Mean Down Time |

| KLNN | Kohonen Learning Neural Network |

| LSTM | Long Short-Term Memory |

| ML | Machine Learning |

| MLPFF | Multi-Layer Perceptron Feed-Forward |

| MOTBF | Mean Operating Time Between Failure |

| MSE | Mean-Squared-Error |

| MTBF | Mean Time Between Failure |

| MTTF | Mean Time to Failure |

| MUT | Mean Up Time |

| NARX | Non-Linear Auto Regressive Network |

| NZE | Non-Zero Emission |

| PCA | Principal Component Analysis |

| PCC | Point of Common Coupling |

| PEC | Power Electronic Circuit |

| PFF | Probabilistic Feed-Forward |

| PHM | Prognostic Health Management |

| PSO | Particle Swarm Optimization |

| PWM | Pulse-Width Modulation |

| RCM | Reliability-Centered Maintenance |

| REs | Renewable Energies |

| RFNN | Recurrent Fuzzy Logic NNN Control |

| RL | Reinforcement Learning |

| RNN | Recurrent Neural Network |

| RT2FNN | Recurrent Type-2 Fuzzy Neural Network |

| RTF | Run to Failure |

| RTM | Real-Time Monitoring |

| RVM | Relevance Vector Machine |

| SE | Sum-Squared-Error |

| SL | Supervised Learning |

| SOA | System Operational Availability |

| SPQ | Small Power Quality |

| SPS’s | Stated Policy Scenarios |

| SSA | Stress–Strength Analysis |

| STEPs | Social, Technological, and Environmental Pathways |

| SVPWM | Space Vector PWM |

| SVM | Support Vector Machine |

| TD | Temporal Difference |

| TDNN | Time-Delayed Neural Network |

| TFs | Transfer Functions |

| USL | Unsupervised Learning |

| WP | Wind Power |

| WPFNN | Wavelet Packet and Formants Neural Networks |

References

- IEA. India Energy Outlook 2021—Analysis; IEA: Paris, France, 2021. [Google Scholar]

- International Renewable Energy Agency. Renewable Energy Statistics 2021; IRENA: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- De Klerk, M.L.; Saha, A.K. A review of the methods used to model traffic flow in a substation communication network. IEEE Access 2020, 8, 204545–204562. [Google Scholar] [CrossRef]

- Papathanassiou, M.T.S. A review of grid code technical requirements for wind farms. IET Renew. Power Gener. 2009, 3, 308–332. [Google Scholar]

- Duchesne, L.; Karangelos, E.; Wehenkel, L. Recent Developments in Machine Learning for Energy Systems Reliability Management. Proc. IEEE 2020, 108, 1656–1676. [Google Scholar] [CrossRef]

- Romeu, J.L. Practical Reliability Engineering. Technometrics 2003, 45, 173. [Google Scholar] [CrossRef]

- Wang, H.; Ma, K.; Blaabjerg, F. Design for reliability of power electronic systems. In Proceedings of the IECON 2012, 38th Annual Conference of the IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; pp. 33–44. [Google Scholar]

- Peyghami, S.; Blaabjerg, F.; Palensky, P. Incorporating Power Electronic Converters Reliability into Modern Power System Reliability Analysis. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 1668–1681. [Google Scholar] [CrossRef]

- Peyghami, S.; Davari, P.; Blaabjerg, F. System-Level Reliability-Oriented Power Sharing Strategy for DC Power Systems. IEEE Trans. Ind. Appl. 2019, 55, 4865–4875. [Google Scholar] [CrossRef]

- Akpolat, A.N.; Dursun, E.; Kuzucuoglu, A.E. AI-Aided Control of a Power Converter in Wind Energy Conversion System. In Proceedings of the 2020 Innovations in Intelligent Systems and Applications Conference (ASYU), Istanbul, Turkey, 15–17 October 2020; Volume 20, pp. 1–6. [Google Scholar]

- Sahri, Y.; Tamalouzt, S.; Hamoudi, F.; Belaid, S.L.; Bajaj, M.; Alharthi, M.M.; Alzaidi, M.S.; Ghoneim, S.S.M. New intelligent direct power control of DFIG-based wind conversion system by using machine learning under variations of all operating and compensation modes. Energy Rep. 2021, 7, 6394–6412. [Google Scholar] [CrossRef]

- Sahri, Y.; Tamalouzt, S.; Belaid, S.L.; Bacha, S.; Ullah, N.; Al Ahamdi, A.A.; Alzaed, A.N. Advanced fuzzy 12 dtc control of doubly fed induction generator for optimal power extraction in wind turbine system under random wind conditions. Sustainability 2021, 13, 11593. [Google Scholar] [CrossRef]

- Tavoosi, J.; Mohammadzadeh, A.; Pahlevanzadeh, B.; Kasmani, M.B.; Band, S.S.; Safdar, R.; Mosavi, A.H. A machine learning approach for active/reactive power control of grid-connected doubly-fed induction generators. Ain Shams Eng. J. 2022, 13, 101564. [Google Scholar] [CrossRef]

- Singh, C.; Kim, Y. An efficient technique for reliability analysis of power systems including time dependent sources. IEEE Trans. Power Syst. 1988, 3, 1090–1096. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, G.; Giannakis, G.B. Real-Time Power System State Estimation via Deep Learning Unrolled Neural Networks. IEEE Trans. Signal Process. 2019, 67, 2–6. [Google Scholar] [CrossRef] [Green Version]

- Omitaomu, O.A.; Niu, H. Artificial intelligence techniques in smart grid: A survey. Smart Cities 2021, 4, 548–568. [Google Scholar] [CrossRef]

- Darab, C.; Tarnovan, R.; Turcu, A.; Martineac, C. Artificial Intelligence Techniques for Fault Location and Detection in Distributed Generation Power Systems. In Proceedings of the 2019 8th International Conference on Modern Power Systems, Cluj-Napoca, Romania, 21–23 May 2019; Volume 9, pp. 1–4. [Google Scholar]

- Deng, Y.C.; Tang, X.H.; Zhou, Z.Y.; Yang, Y.; Niu, F. Application of machine learning algorithms in wind power: A review. Energy Sources Part A Recover. Util. Environ. Eff. 2021, 10, 1–22. [Google Scholar] [CrossRef]

- Yang, S.; Bryant, A.; Mawby, P.; Xiang, D.; Ran, L.; Tavner, P. An industry-based survey of reliability in power electronic converters. IEEE Trans. Ind. Appl. 2011, 47, 1441–1451. [Google Scholar] [CrossRef]

- Yang, S.; Xiang, D.; Bryant, A.; Mawby, P.; Ran, L.; Tavner, P. Condition monitoring for device reliability in power electronic converters: A review. IEEE Trans. Power Electron. 2010, 25, 2734–2752. [Google Scholar] [CrossRef]

- Zhao, S.; Blaabjerg, F.; Wang, H. An overview of artificial intelligence applications for power electronics. IEEE Trans. Power Electron. 2021, 36, 4633–4658. [Google Scholar] [CrossRef]

- Wang, H.; Liserre, M.; Blaabjerg, F. Toward Reliable Power Electronics. Ind. Electron. Mag. IEEE 2013, 7, 17–26. [Google Scholar] [CrossRef]

- Al-Shaalan, A.M. Reliability Evaluation of Power Systems. Intech 2016, 11, 13. [Google Scholar]

- Ullah, N.; Sami, I.; Chowdhury, M.S.; Techato, K.; Alkhammash, H.I. Artificial Intelligence Integrated Fractional Order Control of Doubly Fed Induction Generator-Based Wind Energy System. IEEE Access 2021, 9, 5734–5748. [Google Scholar] [CrossRef]

- Mehraj, A.; Singh, H.; Singh, O. Design and Analysis of Artificial Intelligence Based Approach for Control of Wind Turbine. Int. J. Trend Sci. Res. Dev. 2020, 5, 2456–6470. [Google Scholar]

- IEC 61400-1-202x; Wind Energy Generation Systems Part 1: Design Requirements. International Electrotechnical Commission: Geneva, Switzerland, 2021.

- IEC 61400-1; Wind Turbines—Part 1: Design Requirements. International Electrotechnical Commission: Geneva, Switzerland, 2005; p. 92.

- Karlson, B. Availability and Reliability Standards Standardizing Definitions for Wind Turbine Availability and Reliability for Operations & Maintenance Analyses; Sandia National Laboratories: Albuquerque, NM, USA, 2015. [Google Scholar]

- Bhavadharini, N.; Pavithra, B.R.; Lavanya, M.C.; Dhanesh, L. Electrical Simulation Model of IEC 61400-27-1 Doubly-Fed Induction Generator (Type 3A) Based Wind Turbine. Int. Res. J. Eng. Technol. 2019, 6, 3318–3322. [Google Scholar]

- Cao, D.; Hu, W.; Zhao, J.; Zhang, G.; Zhang, B.; Liu, Z.; Chen, Z.; Blaabjerg, F. Reinforcement Learning and Its Applications in Modern Power and Energy Systems: A Review. J. Mod. Power Syst. Clean Energy 2020, 8, 1029–1042. [Google Scholar] [CrossRef]

- Chai, E.; Zeng, P.P.; Ma, S.; Xing, H.; Zhao, B. Artificial intelligence approaches to fault diagnosis in power grids: A review. In Proceedings of the 2019 Chinese Control Conference (CCC), Guangzhou, China, 27–30 July 2019; pp. 7346–7353. [Google Scholar]

- Almohaimeed, S.A.; Abdel-Akher, M. Power quality issues and mitigation for electric grids with wind power penetration. Appl. Sci. 2020, 10, 8852. [Google Scholar] [CrossRef]

- Mohod, S.W.; Aware, M.V. Power quality issues it’s mitigation technique in wind energy generation. In Proceedings of the 2008 13th International Conference on Harmonics and Quality of Power, Wollongong, NSW, Australia, 28 September–1 October 2008; pp. 5–10. [Google Scholar]

- Emanuel, H.; Schellschmidt, M.; Wachtel, S.; Adloff, S. Power quality measurements of wind energy converters with full-scale converter according to IEC 61400-21. In Proceedings of the 2009 10th International Conference on Electrical Power Quality and Utilisation, Lodz, Poland, 15–17 September 2009; Volume 10, pp. 1–6. [Google Scholar]

- Goksu, O.; Altin, M.; Fortmann, J.; Sorensen, P.E. Field Validation of IEC 61400-27-1 Wind Generation Type 3 Model with Plant Power Factor Controller. IEEE Trans. Energy Convers. 2016, 31, 1170–1178. [Google Scholar] [CrossRef] [Green Version]

- Osborne, H.S. The international electrotechnical commission. Electr. Eng. 2013, 72, 101–104. [Google Scholar] [CrossRef]

- ISO 14224:2016; Petroleum, Petrochemical and Natural Gas Industries—Collection and Exchange of Reliability and Maintenance Data for Equipment. ISO: Geneva, Switzerland, 2016.

- Barouni, F. Intelligent wind farm data automation using IEC standards. In Proceedings of the 2016 Saudi Arabia Smart Grid (SASG), Jeddah, Saudi Arabia, 6–8 December 2016; pp. 1–4. [Google Scholar]

- Liu, Y.J.; Chen, P.A.; Su, H.J. Power Control Characteristic of Generic Type-3 Wind Turbine Model Based on IEC 61400-27-1 Standard. In Proceedings of the 2019 International Conference on Engineering, Science, and Industrial Applications (ICESI), Tokyo, Japan, 22–24 August 2019. [Google Scholar]

- Qiao, W.; Harley, R.G. Effect of Grid-Connected DFIG Wind Turbines on Power System Transient Stability. In Proceedings of the 2008 IEEE Power and Energy Society General Meeting-Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–24 July 2008; pp. 1–7. [Google Scholar]

- Mohod, S.W.; Aware, M.V. Power Quality and Grid Code Issues in Wind Energy Conversion System. In An Update on Power Quality; InTech: Houston, TX, USA, 2013. [Google Scholar]

- Buck, J. International electrotechnical commission. In Handbook of Transnational Economic Governance Regimes; Brill: Leiden, The Netherlands, 2009; pp. 573–584. ISBN 9789004163300. [Google Scholar]

- Presentation on IEC 61400 26 Richard Nichol IEC. Available online: https://cupdf.com/document/presentation-on-iec-61400-26-richard-nichol-iec-61400-26-committee-member.html?page=1 (accessed on 19 September 2022).

- Booma, J.; Priyanka, K.; Dhanarega, A.J.; Revency, J. A Review on Type Certification Schemes of Wind Turbine. Int. J. Eng. Res. Technol. 2014, 3, 1414–1417. [Google Scholar]

- Hayat, K.; Asif, M.; Ali, H.T.; Ijaz, H.; Mustafa, G. Fatigue life estimation of large-scale composite wind turbine blades. In Proceedings of the 2015 12th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 13–17 January 2015; pp. 60–66. [Google Scholar]

- Wind, G.L. GL Guidelines-2010; DNV: Bærum, Norway, 2010. [Google Scholar]

- DNV GL. Definitions of Availability Terms for the Wind Industry; DNV: Bærum, Norway, 2017; p. 17. [Google Scholar]

- Pfaffel, S.; Faulstich, S.; Rohrig, K. Performance and reliability of wind turbines: A review. Energies 2017, 10, 1904. [Google Scholar] [CrossRef]

- Leahy, K.; Gallagher, C.; O’Donovan, P.; O’Sullivan, D.T.J. Issues with data quality for wind turbine condition monitoring and reliability analyses. Energies 2019, 12, 201. [Google Scholar] [CrossRef]

- Operational Certainty Consulting. Wind Farms Operational Intelligence; Emerson: St. Louis, MO, USA, 2019. [Google Scholar]

- Riera-Guasp, M.; Antonino-Daviu, J.A.; Capolino, G.A. Advances in Electrical Machine, Power Electronic, and Drive Condition Monitoring and Fault Detection: State of the Art. IEEE Trans. Ind. Electron. 2015, 62, 1746–1759. [Google Scholar] [CrossRef]

- Soliman, H.; Wang, H.; Blaabjerg, F. A Review of the Condition Monitoring of Capacitors in Power Electronic Converters. IEEE Trans. Ind. Appl. 2016, 52, 4976–4989. [Google Scholar] [CrossRef]

- Pecht, M.; Jaai, R. Microelectronics Reliability A prognostics and health management roadmap for information and electronics-rich systems. Microelectron. Reliab. 2010, 50, 317–323. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, Z.; Outbib, R. A prognostic methodology for power MOSFETs under thermal stress using echo state network and particle filter. Microelectron. Reliab. 2018, 88–90, 350–354. [Google Scholar] [CrossRef]

- Yin, C.Y.; Lu, H.; Musallam, M.; Bailey, C.; Johnson, C.M. A prognostic assessment method for power electronics modules. In Proceedings of the 2008 2nd Electronics System-Integration Technology Conference, Greenwich, UK, 1–4 September 2008; pp. 1353–1358. [Google Scholar]

- Bossoufi, B.; Aroussi, H.A.; Boderbala, M. Direct Power Control of Wind Power Systems based on DFIG-Generator (WECS). In Proceedings of the 2020 12th International Conference on Electronics, Computers and Artificial Intelligence (ECAI), Bucharest, Romania, 25–27 June 2020; Volume 2, pp. 1–5. [Google Scholar]

- Frénay, B.; Verleysen, M. Classification in the presence of label noise: A survey. IEEE Trans. Neural Netw. Learn. Syst. 2014, 25, 845–869. [Google Scholar] [CrossRef]

- Quinlan, J.R. Induction of decision trees. Mach. Learn. 1986, 1, 81–106. [Google Scholar] [CrossRef]

- Mahmud, K.; Ravishankar, J.; Hossain, M.J.; Dong, Z.Y. The Impact of Prediction Errors in the Domestic Peak Power Demand Management. IEEE Trans. Ind. Inform. 2020, 16, 4567–4579. [Google Scholar] [CrossRef]

- Ray, B.; Shah, R.; Islam, M.R.; Islam, S. A New Data Driven Long-Term Solar Yield Analysis Model of Photovoltaic Power Plants. IEEE Access 2020, 8, 136223–136233. [Google Scholar] [CrossRef]

- Ismail, A.; Saidi, L.; Sayadi, M.; Benbouzid, M. A new data-driven approach for power IGBT remaining useful life estimation based on feature reduction technique and neural network. Electronics 2020, 9, 1571. [Google Scholar] [CrossRef]

- Arce, J.M.M.; MacAbebe, E.Q.B. Real-time power consumption monitoring and forecasting using regression techniques and machine learning algorithms. In Proceedings of the 2019 IEEE International Conference on Internet of Things and Intelligence System (IoTaIS), Bali, Indonesia, 5–7 November 2019; pp. 135–140. [Google Scholar]

- Mahmud, K.; Azam, S.; Karim, A.; Zobaed, S.; Shanmugam, B.; Mathur, D. Machine Learning Based PV Power Generation Forecasting in Alice Springs. IEEE Access 2021, 9, 46117–46128. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G.; Puyana-Romero, V.; Trematerra, A. Machine learning-based tools for wind turbine acoustic monitoring. Appl. Sci. 2021, 11, 6488. [Google Scholar] [CrossRef]

- Bose, B.K. Artificial intelligence Techniques: How Can it Solve Problems. IEEE Power Electron. Mag. 2020, 7, 19–27. [Google Scholar] [CrossRef]

- Becker, F.G. Power Supply circuit development estimating aid: An expert system application. IEEE Appl. Power 1988, 7, 64–71. [Google Scholar]

- Li, W.; Ying, J. Design and analysis artificial intelligence (AI) research for power supply—Power electronics expert system (PEES). In Proceedings of the 2008 Twenty-Third Annual IEEE Applied Power Electronics Conference and Exposition, Austin, TX, USA, 24–28 February 2008; pp. 2009–2015. [Google Scholar]

- Chhaya, S.M.; Bose, B.K. Expert system aided automated design, simulation and controller tuning of AC drive system. In Proceedings of the IECON’95—21st Annual Conference on IEEE Industrial Electronics 1995, Orlando, FL, USA, 6–10 November 1995; Volume 1, pp. 712–718. [Google Scholar]

- Fezzani, D.; Piquet, H.; Foch, H. Expert system for the CAD in power electronics—Application to UPS. IEEE Trans. Power Electron. 1997, 12, 578–586. [Google Scholar] [CrossRef]

- Bassiliades, N.; Chalkiadakis, G. Artificial Intelligence Techniques for the Smart Grid. Adv. Build. Energy Res. 2018, 12, 1–2. [Google Scholar] [CrossRef]

- Bose, B.K. Artificial Intelligence Techniques in Smart Grid and Renewable Energy Systems—Some Example Applications. Proc. IEEE 2017, 105, 2262–2273. [Google Scholar] [CrossRef]

- Elsaadawi, A.M.; Kalas, A.E.; Fawzi, M. Development of an expert system to fault diagnosis of three phase induction motor drive system. In Proceedings of the 2008 12th International Middle-East Power System Conference, Aswan, Egypt, 12–15 March 2008; pp. 497–502. [Google Scholar]

- Simões, M.G.; Bose, B.K.; Spiegel, R.J. Design and performance evaluation of a fuzzy-logic-based variable-speed wind generation system. IEEE Trans. Ind. Appl. 1997, 33, 956–965. [Google Scholar] [CrossRef]

- Chen, W.; Bazzi, A.M. Logic-based methods for intelligent fault diagnosis and recovery in power electronics. IEEE Trans. Power Electron. 2017, 32, 5573–5589. [Google Scholar] [CrossRef]

- Zidani, F.; Diallo, D.; Benbouzid, M.E.H.; Naït-Saïd, R. A fuzzy-based approach for the diagnosis of fault modes in a voltage-fed PWM inverter induction motor drive. IEEE Trans. Ind. Electron. 2008, 55, 586–593. [Google Scholar] [CrossRef]

- Kacprzyk, R.F.J. Introduction to Neuro-Fuzzy Systems; Springer: Berlin/Heidelberg, Germany, 2013; Volume 2, ISBN 9783790812565. [Google Scholar]

- De Leon-Aldaco, S.E.; Calleja, H.; Alquicira, J.A. Metaheuristic Optimization Methods Applied to Power Converters: A Review. IEEE Trans. Power Electron. 2015, 30, 6791–6803. [Google Scholar] [CrossRef]

- Adetunji, K.E.; Hofsajer, I.W.; Abu-Mahfouz, A.M.; Cheng, L. A Review of Metaheuristic Techniques for Optimal Integration of Electrical Units in Distribution Networks. IEEE Access 2021, 9, 5046–5068. [Google Scholar] [CrossRef]

- Zhang, J.; Chung, H.S.H.; Lo, W.L.; Hui, S.Y.; Wu, A.K.M. Implementation of a decoupled optimization technique for design of switching regulators using genetic algorithms. IEEE Trans. Power Electron. 2001, 16, 752–763. [Google Scholar] [CrossRef]

- Lian, L.; Maskell, D.L.; Patra, J.C. A novel ant colony optimization-based maximum power point tracking for photovoltaic systems under partially shaded conditions. Energy Build. 2013, 58, 227–236. [Google Scholar]

- Wang, Q. Design, Modeling, and Control of a Novel Generator-Based Wind Power Generation System. IEEE Trans. Power Electron. 2018, 33, 3086–3096. [Google Scholar] [CrossRef]

- Liserre, M.; Dell’Aquila, A.; Blaabjerg, F. Genetic algorithm-based design of the active damping for an LCL-filter three-phase active rectifier. IEEE Trans. Power Electron. 2004, 19, 76–86. [Google Scholar] [CrossRef]

- Ni, Z.; Narimani, M.; Zargari, N.R. Optimal LCL Filter Design for a Regenerative Cascaded H-Bridge (CHB) Motor Drive. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 3038–3043. [Google Scholar]

- Ji, B.; Song, X.; Sciberras, E.; Cao, W.; Hu, Y.; Pickert, V. Multiobjective design optimization of IGBT power modules considering power cycling and thermal cycling. IEEE Trans. Power Electron. 2015, 30, 2493–2504. [Google Scholar] [CrossRef]

- Wang, F.; Chen, G.; Boroyevich, D.; Ragon, S.; Arpilliere, M.; Stefanovic, V.R. Analysis and design optimization of diode front-end rectifier passive components for voltage source inverters. IEEE Trans. Power Electron. 2008, 23, 2278–2289. [Google Scholar] [CrossRef]

- Antonio, M.D.; Shi, C.; Wu, B. Design and Optimization of a Solar Power Conversion System for Space Applications. IEEE Trans. Ind. Appl. 2018, 1, 1–8. [Google Scholar]

- Chen, B.; Liang, X.; Wan, N. Design Methodology for Inductor-Integrated Litz-Wired High-Power Medium-Frequency Transformer with the Nanocrystalline Core Material for Isolated DC-Link Stage of Solid-State Transformer. IEEE Trans. Power Electron. 2020, 35, 11557–11573. [Google Scholar] [CrossRef]

- Garaj, M.; Hong, K.Y.; Chung, H.S.-H.; Zhou, J.; Lo, A.W.L. Photovoltaic panel health diagnostic system for solar power plants. In Proceedings of the 2019 IEEE Applied Power Electronics Conference and Exposition (APEC), Anaheim, CA, USA, 17–21 March 2019; pp. 1078–1083. [Google Scholar]

- Singh, S.; Singh, B. Optimized passive filter design using modified particle swarm optimization algorithm for a 12-pulse converter-fed LCI-synchronous motor drive. IEEE Trans. Ind. Appl. 2014, 50, 2681–2689. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, Y.; Zhan, Z.H. Power electronic circuits design: A particle swarm optimization approach. In Proceedings of the Asia-Pacific Conference on Simulated Evolution and Learning, Melbourne, VIC, Australia, 7–10 December 2008; Volume 5361, pp. 605–614. [Google Scholar]

- Wang, W.; Liu, A.C.; Chung, H.S.; Lau, R.W.; Zhang, J.; Lo, A.W. Fault Diagnosis of Photovoltaic Panels Using Dynamic Current—Voltage Characteristics. IEEE Trans. Power Electron. 2016, 31, 1588–1599. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, X.; Huang, J. AI Algorithm-Based Two-Stage Optimal Design Methodology of High-Efficiency CLLC Resonant Converters for the Hybrid AC—DC Microgrid Applications. IEEE Trans. Ind. Electron. 2019, 66, 9756–9767. [Google Scholar] [CrossRef]

- Hung, Y.C.; Lin, F.J.; Hwang, J.C.; Chang, J.K.; Ruan, K.C. Wavelet fuzzy neural network with asymmetric membership function controller for electric power steering system via improved differential evolution. IEEE Trans. Power Electron. 2015, 30, 2350–2362. [Google Scholar] [CrossRef]

- Liu, Z.; Wei, H.; Zhong, Q. Parameter Estimation for VSI-Fed PMSM Based on a Dynamic PSO with Learning Strategies. IEEE Trans. Power Electron. 2017, 32, 3154–3165. [Google Scholar] [CrossRef]

- Wu, T.; Wang, Z.; Ozpineci, B.; Chinthavali, M.; Campbell, S. Automated Heatsink Optimization for Air-Cooled Power Semiconductor Modules. IEEE Trans. Power Electron. 2019, 34, 5027–5031. [Google Scholar] [CrossRef]

- Zhang, J.; Chung, H.S.H.; Lo, A.W.L.; Huang, T. Extended ant colony optimization algorithm for power electronic circuit design. IEEE Trans. Power Electron. 2009, 24, 147–162. [Google Scholar] [CrossRef]

- Khomfoi, S.; Tolbert, L.M.; Member, S. Fault Diagnostic System for a Multilevel Inverter Using a Neural Network. IEEE Trans. Power Electron. 2007, 22, 1062–1069. [Google Scholar] [CrossRef]

- Modeling, T.I.F. Stochastic RUL calculation enhanced with TDNN-based IGBT failure modeling. IEEE Trans. Reliab. 2016, 65, 558–573. [Google Scholar]

- Grabowski, P.Z.; Kazmierkowski, M.P.; Böse, B.K.; Blaabjerg, F. A simple direct-torque neuro-fuzzy control of pwm-inverter-fed induction motor drive. IEEE Trans. Ind. Electron. 2000, 47, 863–870. [Google Scholar] [CrossRef]

- Abramson, N.; Braverman, D.; Sebestyen, G. Pattern recognition and machine learning. IEEE Trans. Inf. Theory 1963, 9, 257–261. [Google Scholar] [CrossRef]

- Inverters, T.; Drive, P.; Cai, B.; Zhao, Y.; Liu, H.; Xie, M. A Data-Driven Fault Diagnosis Methodology in three phase inverter for PMSM drive systems. IEEE Trans. Power Electron. 2017, 32, 5590–5600. [Google Scholar]

- Abo-Khalil, A.G.; Lee, D.C. DC-link capacitance estimation in AC/DC/AC PWM converters using voltage injection. IEEE Trans. Ind. Appl. 2008, 44, 1631–1637. [Google Scholar] [CrossRef]

- Ali, S.H.; Heydarzadeh, M.; Dusmez, S.; Li, X.; Kamath, A.S.; Akin, B. Lifetime Estimation of Discrete IGBT Devices Based on Gaussian Process. IEEE Trans. Ind. Appl. 2018, 54, 395–403. [Google Scholar] [CrossRef]

- Soliman, H.; Davari, P.; Wang, H.; Member, I.; Blaabjerg, F.; Fellow, I. Capacitance Estimation Algorithm based on DC-Link Voltage Harmonics Using Artificial Neural Network in Three-Phase Motor Drive Systems. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition, Cincinnati, OH, USA, 1–5 October 2017; pp. 5795–5802. [Google Scholar]

- Soliman, H.; Wang, H.; Gadalla, B.; Blaabjerg, F. Condition monitoring for DC-link capacitors based on artificial neural network algorithm. In Proceedings of the 2015 IEEE 5th International Conference on Power Engineering, Energy and Electrical Drives (POWERENG), Riga, Latvia, 11–13 May 2015; pp. 587–591. [Google Scholar]

- Soliman, H.; Abdelsalam, I.; Wang, H.; Blaabjerg, F. Artificial Neural Network based DC-link capacitance estimation in a diode-bridge front-end inverter system. In Proceedings of the 2017 IEEE 3rd International Future Energy Electronics Conference and ECCE Asia, Kaohsiung, Taiwan, 3–7 June 2017; pp. 196–201. [Google Scholar]

- Huang, Z.; Wang, Z.; Zhang, H. A Diagnosis Algorithm for Multiple Open-Circuited Faults of Microgrid Inverters Based on Main Fault Component Analysis. IEEE Trans. Energy Convers. 2018, 33, 925–937. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, Z.; Zhang, H. Multiple Open-Circuit Fault Diagnosis Based on Multistate Data Processing and Subsection Fluctuation Analysis for Photovoltaic Inverter. IEEE Trans. Instrum. Meas. 2018, 67, 516–526. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, Z.; Zhang, H. Multilevel feature moving average ratio method for fault diagnosis of the microgrid inverter switch. IEEE/CAA J. Autom. Sin. 2017, 4, 177–185. [Google Scholar] [CrossRef]

- Qiang, S.; Li, Y. Motor inverter fault diagnosis using wavelets neural networks. In Proceedings of the 2013 IEEE International Conference on Systems, Man, and Cybernetics, Manchester, UK, 13–16 October 2013; pp. 3168–3173. [Google Scholar]

- Mohagheghi, S.; Harley, R.G.; Habetler, T.G.; Divan, D. Condition monitoring of power electronic circuits using artificial neural networks. IEEE Trans. Power Electron. 2009, 24, 2363–2367. [Google Scholar] [CrossRef]

- Butt, C.; Rahman, M.A. Limitations of simplified fuzzy logic controller for IPM motor drive. In Proceedings of the 39th IAS Annual Meeting, Seattle, WA, USA, 3–7 October 2004; Volume 3, pp. 1891–1898. [Google Scholar]

- Morales, E.F.; Zaragoza, J.H. An introduction to reinforcement learning. In Decision Theory Models for Applications in Artificial Intelligence: Concepts and Solutions; IGI Global: Hershey, PA, USA, 2012; pp. 63–80. [Google Scholar]

- Chiozzi, D.; Bernardoni, M.; Delmonte, N.; Cova, P. A Neural Network Based Approach to Simulate Electrothermal Device Interaction in SPICE Environment. IEEE Trans. Power Electron. 2019, 34, 4703–4710. [Google Scholar] [CrossRef]

- Dragicevic, T.; Wheeler, P.; Blaabjerg, F. Artificial Intelligence Aided Automated Design for Reliability of Power Electronic Systems. IEEE Trans. Power Electron. 2019, 34, 7161–7171. [Google Scholar] [CrossRef]

- Kamel, T.; Biletskiy, Y.; Chang, L. Capacitor aging detection for the DC filters in the power electronic converters using ANFIS algorithm. In Proceedings of the 2015 IEEE 28th Canadian Conference on Electrical and Computer Engineering (CCECE), Halifax, NS, Canada, 3–6 May 2015; pp. 663–668. [Google Scholar]

- Soualhi, A.; Makdessi, M.; German, R.; Echeverria, F.R.; Razik, H.; Sari, A.; Venet, P.; Clerc, G. Heath Monitoring of Capacitors and Supercapacitors Using the Neo-Fuzzy Neural Approach. IEEE Trans. Ind. Inform. 2018, 14, 24–34. [Google Scholar] [CrossRef]

- Xiao, P.; Venayagamoorthy, G.K.; Corzine, K.A.; Huang, J. Recurrent neural networks based impedance measurement technique for Power Electronic Systems. IEEE Trans. Power Electron. 2010, 25, 382–390. [Google Scholar] [CrossRef]

- Da Silva, L.E.B.; Bose, B.K.; Pinto, J.O.P. Recurrent-neural-network-based implementation of a programmable cascaded low-pass filter used in stator flux synthesis of vector-controlled induction motor drive. IEEE Trans. Ind. Electron. 1999, 46, 662–665. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, Z.; Yao, X.; Zhang, H. Multi-switches fault diagnosis based on small low-frequency data for voltage-source inverters of PMSM drives. IEEE Trans. Power Electron. 2019, 34, 6845–6857. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Z.; Wang, H.; Blaabjerg, F. Artificial Intelligence-Aided Thermal Model Considering Cross-Coupling Effects. IEEE Trans. Power Electron. 2020, 35, 9998–10002. [Google Scholar] [CrossRef]

- Dehghani, M.; Ghiasi, M.; Niknam, T.; Kavousi-Fard, A.; Tajik, E.; Padmanaban, S.; Aliev, H. Cyber Attack Detection Based on Wavelet Singular Entropy in AC Smart Islands: False Data Injection Attack. IEEE Access 2021, 9, 16488–16507. [Google Scholar] [CrossRef]

- Xue, Z.Y.; Xiahou, K.S.; Li, M.S.; Ji, T.Y.; Wu, Q.H. Diagnosis of Multiple Open-Circuit Switch Faults Based on Long Short-Term Memory Network for DFIG-Based Wind Turbine Systems. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 2600–2610. [Google Scholar] [CrossRef]

- Bandyopadhyay, I.; Purkait, P.; Koley, C. Performance of a Classifier Based on Time-Domain Features for Incipient Fault Detection in Inverter Drives. IEEE Trans. Ind. Inform. 2019, 15, 3–14. [Google Scholar] [CrossRef]

- Wang, L.; Yue, J.; Su, Y.; Lu, F.; Sun, Q. A novel remaining useful life prediction approach for superbuck converter circuits based on modified greywolf optimizer-support vector regression. Energies 2017, 10, 459. [Google Scholar] [CrossRef]

- Tamilselvan, P.; Wang, P.; Pecht, M. A multi-attribute classification fusion system for insulated gate bipolar transistor diagnostics. Microelectron. Reliab. 2013, 53, 1117–1129. [Google Scholar] [CrossRef]

- Moosavi, S.S.; Kazemi, A.; Akbari, H. A comparison of various open-circuit fault detection methods in the IGBT-based DC/AC inverter used in electric vehicle. Eng. Fail. Anal. 2019, 96, 223–235. [Google Scholar] [CrossRef]

- Wang, T.; Xu, H.; Han, J.; Elbouchikhi, E.; Benbouzid, M.E.H. Cascaded H-Bridge Multilevel Inverter System Fault Diagnosis Using a PCA and Multiclass Relevance Vector Machine Approach. IEEE Trans. Power Electron. 2015, 30, 7006–7018. [Google Scholar] [CrossRef]

- Hsu, J.S.; Member, S. Monitoring of defects in Induction motor through Air-Gap Torque Observation. IEEE Trans. Ind. Appl. 1995, 31, 1016–1021. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.; Zhou, L.; Sun, P. Study on diagnostic method for defects in an IGBT module based on DTW deviations of time series. J. Chongqing Univ. 2013, 36, 89–95. [Google Scholar]

- Hanif, A.; Yu, Y.; Devoto, D.; Khan, F. A Comprehensive Review toward the State-of-the-Art in Failure and Lifetime Predictions of Power Electronic Devices. IEEE Trans. Power Electron. 2019, 34, 4729–4746. [Google Scholar] [CrossRef]

- Li, P.; Eickmeyer, J.; Niggemann, O. Data Driven Condition Monitoring of Wind Power Plants Using Cluster Analysis. In Proceedings of the 2015 International Conference on Cyber-Enabled Distributed Computing and Knowledge Discovery, Xi’an, China, 17–19 September 2015; pp. 131–136. [Google Scholar]

- Celaya, J.R.; Saxena, A.; Saha, S.; Goebel, K.F. Prognostics of power mosfets under thermal stress accelerated aging using data-driven and model-based methodologies. In Proceedings of the Annual Conference of the PHM Society, Montreal, QC, Canada, 25–29 September 2011; pp. 443–452. [Google Scholar]

- Zhao, S.; Makis, V.; Chen, S.; Li, Y. Health Assessment Method for Electronic Components Subject to Condition Monitoring and Hard Failure. IEEE Trans. Instrum. Meas. 2019, 68, 138–150. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, L.; Pattipati, K.; Bazzi, A.M.; Joshi, S.; Dede, E.M. Data-Driven Approach for Fault Prognosis of SiC MOSFETs. IEEE Trans. Power Electron. 2020, 35, 4048–4062. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, S.; Lu, H.; Zhang, H. Remaining Useful Life Model and Assessment of Mechanical Products: A Brief Review and a Note on the State Space Model Method. Chin. J. Mech. Eng. Engl. Ed. 2019, 32, 15. [Google Scholar] [CrossRef]

- Martins, J.F.; Pires, V.F.; Lima, C.; Pires, A.J. Fault detection and diagnosis of grid-connected power inverters using PCA and current mean value. In Proceedings of the IECON 2012-38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; pp. 5185–5190. [Google Scholar]

- Stock, S.; Babazadeh, D.; Becker, C. Applications of artificial intelligence in distribution power system operation. IEEE Access 2021, 9, 150098–150119. [Google Scholar] [CrossRef]

- Gordillo, F.; Aracil, J.; Alamo, T. Determining limit cycles in fuzzy control systems. In Proceedings of the 6th International Fuzzy Systems Conference, Barcelona, Spain, 5 July 1997; Volume 1, pp. 193–198. [Google Scholar]

- Khrulkov, V.; Vasilchenko, S.; Cherny, S. Method of Implementing a Fuzzy Logic Controller by Hardware. In Proceedings of the 2020 International Multi-Conference on Industrial Engineering and Modern Technologies, Vladivostok, Russia, 6–9 October 2020; pp. 4–8. [Google Scholar]

- Serchuk, P. The alleged limitations of fuzzy control. In Proceedings of the 35th International Symposium on Multiple-Valued Logic, Calgary, BC, Canada, 19–21 May 2005; pp. 154–159. [Google Scholar]

- Mi, J.X.; Li, A.D.; Zhou, L.F. Review study of interpretation methods for future interpretable machine learning. IEEE Access 2020, 8, 191969–191985. [Google Scholar] [CrossRef]

- Abdelmalek, S.; Rezazi, S.; Azar, A.T. Sensor Faults Detection and Estimation for a Dfig Equipped Wind Turbine. Energy Procedia 2017, 139, 3–9. [Google Scholar] [CrossRef]

- Gan, D.; Wang, Y.; Yang, S.; Kang, C. Embedding based quantile regression neural network for probabilistic load forecasting. J. Mod. Power Syst. Clean Energy 2018, 6, 244–254. [Google Scholar] [CrossRef]

- Alzubaidi, L.; Zhang, J.; Humaidi, A.J.; Al-Dujaili, A.; Duan, Y.; Al-Shamma, O.; Santamaría, J.; Fadhel, M.A.; Al-Amidie, M.; Farhan, L. Review of Deep Learning: Concepts, CNN Architectures, Challenges, Applications, Future Directions; Springer International Publishing: Berlin/Heidelberg, Germany, 2021; Volume 8, ISBN 4053702100444. [Google Scholar]

- Kosuru, R.; Chen, P.; Liu, S. A reinforcement learning based power system stabilizer for a grid connected wind energy conversion system. In Proceedings of the 2020 IEEE Electric Power and Energy Conference, Edmonton, AB, Canada, 9–10 November 2020; Volume 3. [Google Scholar]

- Wei, C.; Zhang, Z.; Qiao, W.; Qu, L. Reinforcement-Learning-Based Intelligent Maximum Power Point Tracking Control for Wind Energy Conversion Systems. IEEE Trans. Ind. Electron. 2015, 62, 6360–6370. [Google Scholar] [CrossRef]

- Lei, G.; Zhu, J.; Guo, Y.; Liu, C.; Ma, B. A review of design optimization methods for electrical machines. Energies 2017, 10, 1962. [Google Scholar] [CrossRef] [Green Version]

- Ismagilov, F.; Valiev, R.; Vavilov, V.; Urazbakhtin, R. The main aspects of the FMEA usage in the design of modern and advanced electrical machines. In Proceedings of the 2020 International Conference on Electrotechnical Complexes and Systems, Ufa, Russia, 27–30 October 2020; pp. 2020–2023. [Google Scholar]

- Practices, B.; Cavagnino, A.; Member, S. Modern Electrical Machine Design Optimization. IEEE Trans. Ind. Electron. 2018, 65, 7672–7684. [Google Scholar]

- Menon, S.; Stecki, C.; Song, J.; Pecht, M. Optimization of PHM System for Electronic Assemblies Using Maintenance Aware Design Environment Software. In Proceedings of the 14th Australian International Aerospace Congress 2011, Melbourne, VIC, Australia, 28 February–3 March 2011. [Google Scholar]

- Versèle, C.; Deblecker, O.; Lobry, J. Multiobjective optimal choice and design of isolated dc-dc power converters. In Proceedings of the 2011 14th European Conference on Power Electronics and Applications (EPE 2011), Birmingham, UK, 30 August–1 September 2011. [Google Scholar]

- Chimento, F.; Musumeci, S.; Raciti, A.; Tomarchio, S.; Scollo, R.; Doria, V.A. Optimized design of Power Semiconductor devices for DC-DC converters. In Proceedings of the 2006 12th International Power Electronics and Motion Control Conference, Portoroz, Slovenia, 30 August–1 September 2006; pp. 38–43. [Google Scholar]

- Walker, G.R.; Pierce, J.C. PhotoVoltaic DC-DC module integrated converter for novel cascaded and bypass grid connection topologies—Design and optimisation. In Proceedings of the 2006 37th IEEE Power Electronics Specialists Conference, Jeju, Korea, 18–22 June 2006. [Google Scholar]

- Jianqiang, W.; Jingxin, L. Design and experience of grid-connecting photovoltaic power system. In Proceedings of the 2008 IEEE International Conference on Sustainable Energy Technologies, Singapore, 24–27 November 2008; pp. 607–610. [Google Scholar]

- Vighetti, S.; Ferrieux, J.P.; Lembeye, Y. Optimization and design of a cascaded DC/DC converter devoted to grid-connected photovoltaic systems. IEEE Trans. Power Electron. 2012, 27, 2018–2027. [Google Scholar] [CrossRef]

- Luiten, W. Multi software thermal design optimization. In Proceedings of the 2020 26th International Workshop on Thermal Investigations of ICs and Systems, Berlin, Germany, 14 September–9 October 2020. [Google Scholar]

- Amaya, L.E.; Krein, P.T.; Najm, F.N. Design methodology for power electronics. IEEE Work. Comput. Power Electron. 1996, 52–57. [Google Scholar]

- Andreta, A.; Villa, L.F.L.; Lembeye, Y.; Crebier, J.C. A novel automated design methodology for power electronics converters. Electronics 2021, 10, 271. [Google Scholar] [CrossRef]

- Nardi, C.; Stein, C.M.O.; Carati, E.G.; Costa, J.P.; Cardoso, R. A methodology of LCL filter design for grid-tied power converters. In Proceedings of the 2015 IEEE 13th Brazilian Power Electronics Conference and 1st Southern Power Electronics Conference, Fortaleza, Brazil, 29 November–2 December 2015; Volume 2. [Google Scholar]

- Hoos, H.H.; Stützle, T. Local search algorithms for SAT: An empirical evaluation. J. Autom. Reason. 2000, 24, 421–481. [Google Scholar] [CrossRef]

- Alkasem, H.H.; El Bachir Menai, M. A stochastic local search algorithm for the partial max-sat problem based on adaptive tuning and variable depth neighborhood search. IEEE Access 2021, 9, 49806–49843. [Google Scholar] [CrossRef]

- Znati, T. A Novel Task Assignment Heuristic using Local Search in Distributed Computing Systems. In Proceedings of the 2017 International Conference on Energy, Communication, Data Analytics and Soft Computing (ICECDS), Chennai, India, 1–2 August 2017; pp. 2767–2771. [Google Scholar]

- Piechnicki, F.; Loures, E.; Santos, E. A Conceptual Framework of Knowledge Conciliation to Decision Making Support in RCM Deployment. Procedia Manuf. 2017, 11, 1135–1144. [Google Scholar] [CrossRef]

- IEC 60300-3-11:2009; Dependability Management—Part 3–11: Application Guide—Reliability Centred Maintenance. International Electrotechnical Commission: Geneva, Switzerland, 2009.

- Gupta, G.; Mishra, R.P.; Mundra, N. Development of a framework for reliability centered maintenance. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bandung, Indonesia, 6–8 March 2018; pp. 2383–2391. [Google Scholar]

- SAE. Surface Vehicle/Aerospace Recommended Practice Evaluation Criteria for Reliability-Centered Maintenance (RCM) Processes. Eng. Soc. Adv. Mobil. Land Sea Air Space 2009, 4970, 1–12. [Google Scholar]

- Hunegnaw, Z.T. Deciphering Maintenance Challenges through Computerized Maintenance Management System in Ethiopian Manufacturing Industries Ukucacisa Imingeni Yolondolozo Ngokusebenzisa Iinkqubo Zolawulo Lokulondoloza Ngekhompyutha Kwimizimveliso Yase-Ethiopia; University of South Africa: Pretoria, South Africa, 2020. [Google Scholar]

- Chung, H.S.H.; Wang, H.; Blaabjerg, F.; Pecht, M. Reliability of Power Electronic Converter Systems; Institution of Engineering and Technology: Stevenage, UK, 2016; pp. 1–490. [Google Scholar]

- Zhao, S.; Makis, V.; Chen, S.; Li, Y. Evaluation of Reliability Function and Mean Residual Life for Degrading Systems Subject to Condition Monitoring and Random Failure. IEEE Trans. Reliab. 2018, 67, 13–25. [Google Scholar] [CrossRef]

- Zhao, S.; Makis, V.; Chen, S.; Li, Y. Health evaluation method for degrading systems subject to dependent competing risks. J. Syst. Eng. Electron. 2018, 29, 436–444. [Google Scholar] [CrossRef]

- Reliability Committee. IEEE Standard Framework for Prognostics and Health Management of Electronic Systems; IEEE Standards Association: Piscataway, NJ, USA, 2017; ISBN 9781504443197. [Google Scholar]

- Meng, L.; Pecht, M.; Liu, J.; Wang, Y.; Cheng, K. Health Monitoring of IGBTs with a Rule-Based Sub-safety Recognition Model Using Neural Networks. J. Progn. Health Manag. 2020, 1, 64–85. [Google Scholar] [CrossRef]

- Manohar, S.S.; Sahoo, A.; Subramaniam, A.; Panda, S.K. Condition monitoring of power electronic converters in power plants—A review. In Proceedings of the IEEE 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, Australia, 11–14 August 2017. [Google Scholar]

- Oh, H.; Han, B.; McCluskey, P.; Han, C.; Youn, B.D. Physics-of-failure, condition monitoring, and prognostics of insulated gate bipolar transistor modules: A review. IEEE Trans. Power Electron. 2015, 30, 2413–2426. [Google Scholar] [CrossRef]

- European Technology and Innovation Platform in Power Electronics. ECPE European Center for Power Electronics. 2015. Available online: https://silo.tips/download/ecpe-european-center-for-power-electronics-ev-the-ecpe-network (accessed on 19 September 2022).

- Mollov, S.; Blaabjerg, F. Condition and health monitoring in power electronics. In Proceedings of the 10th International Conference on Integrated Power Electronics Systems (CIPS 2018), Stuttgart, Germany, 20–22 March 2018; pp. 61–68. [Google Scholar]

- Al-Greer, M.; Armstrong, M.; Ahmeid, M.; Giaouris, D. Advances on system identification techniques for DC-DC switch mode power converter applications. IEEE Trans. Power Electron. 2019, 34, 6973–6990. [Google Scholar] [CrossRef] [Green Version]

- Wai, R.J.; Shih, L.C. Adaptive fuzzy-neural-network design for voltage tracking control of a DC-DC boost converter. IEEE Trans. Power Electron. 2012, 27, 2104–2115. [Google Scholar] [CrossRef]

- Clarke, D.W. Adaptive Control. In Industrial Digital Control Systems; IET: London, UK, 1986; pp. 190–220. [Google Scholar]

- Han, J.; Liu, Z.; Liang, N. Nonlinear Adaptive Robust Control Strategy of Doubly Fed Induction Generator Based on Virtual Synchronous Generator. IEEE Access 2020, 8, 159887–159896. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, A.; Shankar, G. Crow search algorithm based optimal dynamic performance control of SVC assisted SMIB system. In Proceedings of the 2018 20th National Power Systems Conference (NPSC), Tiruchirappalli, India, 14–16 December 2018. [Google Scholar]

- Martin, D.W. Fault Detection in Manufacturing Equipment Using Unsupervised Deep Learning; Massachusetts Institute of Technology: Cambridge, MA, USA, 2021. [Google Scholar]

- Brito, L.C.; Susto, G.A.; Brito, J.N.; Duarte, M.A.V. An explainable artificial intelligence approach for unsupervised fault detection and diagnosis in rotating machinery. Mech. Syst. Signal Process. 2022, 163, 108105. [Google Scholar] [CrossRef]

- Zhao, Q.; Bao, K.; Wei, Z.; Han, Y.; Wang, J. An Abnormal Data Processing Method Based on An Ensemble Algorithm for Early Warning of Wind Turbine Failure. IEEE Access 2021, 9, 69044–69060. [Google Scholar] [CrossRef]

- Zheng, X.X.; Peng, P. Fault diagnosis of wind power converters based on compressed sensing theory and weight constrained AdaBoost-SVM. J. Power Electron. 2019, 19, 443–453. [Google Scholar]

- Kiranyaz, S.; Gastli, A.; Ben-Brahim, L.; Al-Emadi, N.; Gabbouj, M. Real-Time Fault Detection and Identification for MMC Using 1-D Convolutional Neural Networks. IEEE Trans. Ind. Electron. 2019, 66, 8760–8771. [Google Scholar] [CrossRef]

- Wang, Z.; Yuan, G.; Pei, H.; Zhang, Y.; Liu, X. Unsupervised learning trajectory anomaly detection algorithm based on deep representation. Int. J. Distrib. Sens. Netw. 2020, 16, 1–21. [Google Scholar] [CrossRef]

- MATLAB. Introduction to Predictive Maintenance with MATLAB; MathWorks: Natick, MA, USA, 2019; pp. vii–viii. [Google Scholar]

- Colak, M. Fuzzy Logic and Artificial Neural Network Based Grid-Interactive Systems For Renewable Energy Sources: A Review. In Proceedings of the 2021 9th International Conference on Smart Grid (icSmartGrid), Setubal, Portugal, 29 June–1 July 2021. [Google Scholar]

- Abdalla, O.H.; Han, M.; Liu, C. Multi-level converter based variable speed pump storage for wind power compensation. In Proceedings of the 2014 International Conference on Information Science, Electronics and Electrical Engineering, Sapporo, Japan, 26–28 April 2014; Volume 3, pp. 1497–1501. [Google Scholar]

- Wang, H.; Blaabjerg, F. Power Electronics Reliability: State of the Art and Outlook. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 6476–6493. [Google Scholar] [CrossRef]

- Jo, S.; Jung, S.; Roh, T. Battery State-of-Health Estimation Using Machine Learning and Preprocessing with Relative State-of-Charge. Energies 2021, 14, 7206. [Google Scholar] [CrossRef]

- Tran Anh, D.; Dabrowski, K.; Skrzypek, K. The Predictive Maintenance Concept in the Maintenance Department of the “industry 4.0” Production Enterprise. Found. Manag. 2018, 10, 283–292. [Google Scholar] [CrossRef]

- Zhao, S.; Chen, S.; Yang, F.; Ugur, E.; Akin, B.; Wang, H. A Composite Failure Precursor for Condition Monitoring and Remaining Useful Life Prediction of Discrete Power Devices. IEEE Trans. Ind. Inform. 2021, 17, 688–698. [Google Scholar] [CrossRef]

- Cui, Y.; Shi, J.; Wang, Z. Quantum Assimilation-Based State-of-Health Assessment and Remaining Useful Life Estimation for Electronic Systems. IEEE Trans. Ind. Electron. 2016, 63, 2379–2390. [Google Scholar] [CrossRef]

- Power Semiconductor Reliability Handbook; Alpha & Omega Semiconductor: Sunnyvale, CA, USA, 2010; pp. 1–23.

- Zhao, R.; Yan, R.; Chen, Z.; Mao, K.; Wang, P.; Gao, R.X. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Wang, Q.; Michau, G.; Fink, O. Domain Adaptive Transfer Learning for Fault Diagnosis. In Proceedings of the 2019 Prognostics and System Health Management Conference: PHM-Paris 2019, Paris, France, 2–5 May 2019; pp. 279–285. [Google Scholar]

- Liao, L. Discovering prognostic features using genetic programming in remaining useful life prediction. IEEE Trans. Ind. Electron. 2014, 61, 2464–2472. [Google Scholar] [CrossRef]

- Bieresborn, D. The Impact of the General Data Protection Regulation on Social Security; Springer: Berlin/Heidelberg, Germany, 2019; Volume 20, ISBN 9789284667710. [Google Scholar]

| Type | Description | Reference |

|---|---|---|

| IEC-61400 | WTG design requirements | [42] |

| IEC-61400-12 | Power curves | |

| IEC-61400-25 | Communication protocol | [43] |

| IEC-61400-26 | Accessibility of wind-driven turbines and wind turbine plants | [38] |

| IEC-61400-26-1 | Time-based WTG accessibility | |

| IEC-61400-26-2 | Production line-based WTG accessibility | |

| IEC-61400-26-3 | Wind power plant availability (time and production) | |

| IEC-61131-3 | WTG Automation language | [38] |

| IEC-61400-22 | WTG Project certification | [44] |

| Type | Conventional Algorithms | Applications | Variant | Advantage | Challenges | |

|---|---|---|---|---|---|---|

| Design | Reliability | |||||

| Population-based methods | Particle swarm optimization (PSO) | [89,90,92] | [91,94] | Velocity clamping | Velocity clamping lessens the step velocity dimension to regulate the element’s development | If all velocity turns into equivalent, the particle will remain to perform searches in a hypercube and possibly stay in the targets. It will still not meet in the regional area |

| Inertia weight | A considerable inertia weight at the end of the hunt will raise the merging capability | Attain optimality union intensely inclined by the inertia weight | ||||

| Limitation coefficient | Similar to inertia weight | When the process joins, the stable values of the constraints might lead to the needless variation of elements | ||||

| Synchronous and asynchronous information | Better merging rate | Advanced output: more refined finite section designs with advanced accuracy (web concentrations) | ||||

| Genetic algorithm (GA) | [79,82,84,85,87,95] | [88] | Parallel abilities | It has better parallel abilities | Not effective in resolving modest problems | |

| Merging | It can enhance numerous glitches such as distinct functions, multi-objective glitches, and constant functions | A lack of suitable application may make the algorithm obtain a result that is not best | ||||

| It offers answers that advance over the period | The feature of the final result is not certain | |||||

| Implementation ease | GA does not need derivative information | Computational challenges due to repetitive calculation of fitness values | ||||

| Ant colony optimization (ACO) | [96] | Capability | Capable of clustering and constructing routes | It is laborious to lay pheromone on trails used by ants as a communication standard | ||

| Implementation ease | Easy to apply | Glitches in parameter selection due to its poor assessment | ||||

| Parallel abilities | Inherent parallelism | Experimental rather than theoretical | ||||

| Applications | It can be used in dynamic applications | Probability distribution changes by duplications | ||||

| Solution with AI implementation: 1. Achieves pre-training with an attractive smaller learning rate to achieve rapid integration | ||||||

| Trajectory-based methods | Tabu search method (TSM) | [81] | Capability | Can outflow local targets by selecting non-improving results | The number of iterations can be very high BEST | |

| Ease of implementation | The tabu list can be utilized to evade cycles and return to old results | A lot of tunable parameters | ||||

| Applications | It can be helpful for both distinct and constant solutions | The actual application depends on the difficulty level | ||||

| Solution using AI implementation: 1. Works on indefinite junction location. 2. Less prone to a spontaneous mergers. 3. Minimum potential to become stuck in the local area. | ||||||

| Methods | Type | Conventional Algorithms | Applications | Advantages | Drawbacks |

|---|---|---|---|---|---|

| Machine/deep learning neural network (NN) methods | Clustering | Feed-forward neural network (FFNN) Radial basis function network (RBFN) | Reliability [104,105,106,107,108,109,110,111,112] Design [113,114] | Compared to feed-forward NN | |

| 1. Simple network shape 2. Greater training speed | 1. Longer training time 2. Less sensitive 3. Low ability to manage ambiguity | ||||

| Association | Adaptive Fuzzy neural interface system (ANFIS) | Reliability [115,116] | Compared to conventional FNN | ||

| 1. Automatic fuzzy logic rule production | |||||

| NN with recurrent unit | Recurrent neural network (RNN) or Elman NN (ENN) | Reliability [117,118] | Compared to conventional NN | ||

| 1. Improved transient ability 2. Enhanced responsiveness | 1. Lower long-term dependence dealing 2. Slower training speediness | ||||

| Echo state network (ESN) | Reliability [54,119] | Compared to RNN or ENN | |||

| 1. Only hidden output weights need to be established | 1. Less issue of gradient explodes | ||||

| Non-linear autoregressive network with exogenous inputs (NARX) | Reliability [120,121] | Compared to RNN or ENN | |||

| 1. Improved training speed 2. Improved simplification 3. Greater long-term dependence on trading | 1. Less sensitive | ||||

| NN with convolutional structure | Time-delayed neural network (TDNN) or1D convolutional NN (CNN), FSMPC | Reliability [98,122] | Compared to conventional RNN | ||

| 1. Softer time series model | |||||

| 1. Better liability | 1. Composite calculation 2. Theoretical output with arbitrary factors | ||||

| Kernel-based approach | Sparse kernel method | Support vector machine (SVM) | Reliability [102,123,124,125,126] | Compared to the conventional kernel method | |

| 1. Improved estimation 2. Improved computing effectiveness | 1. Probabilistic output 2. Longer training period | ||||

| Relevance vector machine (RVM) | Reliability [127,128,129] | Compared to the conventional kernel method | |||

| 1. Better sparser than SVM | 1. Longer training period | ||||

| Conventional kernel method | Gaussian processes | Reliability [103,130,131] | Compared to NN methods | ||

| 1. Probabilistic output 2. Uncertain quantification | |||||

| Way out with AI implementation: 1. Probabilistic findings are overcome with certainty 2. Using a database to estimate the frequency of past achievements and unsuccessful activities 3. Resolve training ranges locally | |||||

| Probabilistic graphical methods | Bayesian networks | Reliability-centered maintenance [55,61,101,125,126,132] | Compared to NN methods | ||

| 1. Better interpretability 2. Intensive computational | 1. Probabilistic output 2. Uncertain quantification | ||||

| Methods | References | Fault Diagnosis | Accuracy | Applications | Benefits | Drawbacks |

|---|---|---|---|---|---|---|

| Support vector machines (SVM) | [123] | Yes | 98.1%, | Reliability-centered maintenance (RCM) and health management | 1. Simple implementation 2. Better interpretability 3. Improved diagnostic accuracy 4. Discovers more fault patterns 5. Better optimization | 1. Sensitive to outliers 2. Enhanced training required |

| Fuzzy logic (FL) | [74,190] | Yes | 100% | 1. High cost | ||

| Eco-state Network (ESN) | [119] | Yes | 2. Enhanced training required | |||

| Solution with AI implementation: 1. Replace outliers with a suitable value using the quantile method | ||||||

| Relevance vector machine (RVM) | [83,127,191] | Yes | 97.30% | RCM and health management | 1. Can only be cast off with clustering and for smart moves | 1. Enhanced training required |

| Solution with AI implementation: 1. Substitute database minimization methods with filtering and normalization attempts | ||||||

| Abnormalities in the Smart Grid-Integrated Power Converter-Based DFIG | Configuration | AI-Based Solutions | Sensitivity | Speed |

|---|---|---|---|---|

| Uncertainties prediction | Patterning and simulating structures | Probability theory, classic set theory, fuzzy logic, rough set theory | Moderately sensitive | Sensible speed |

| Uncertainties quantification | Regression associated assignments | NN, Monte Carlo methods, Bayesian approaches, RVM, stochastic-based methods | Less sensitive | High speed |

| Uncertainties propagation | Forecast | Boolean threshold | Moderately sensitive | Sensible speed |

| Conditions of AI in Power Electronic Converter in Model Applications | Dataset Requirement | Accuracy | Sensitivity | Speed | Interpretation | Computing Effect |

|---|---|---|---|---|---|---|

| RCM and health management | High requirement | High accuracy | Moderately sensitive | Sensible speed | High | Moderate effect |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behara, R.K.; Saha, A.K. Artificial Intelligence Methodologies in Smart Grid-Integrated Doubly Fed Induction Generator Design Optimization and Reliability Assessment: A Review. Energies 2022, 15, 7164. https://doi.org/10.3390/en15197164

Behara RK, Saha AK. Artificial Intelligence Methodologies in Smart Grid-Integrated Doubly Fed Induction Generator Design Optimization and Reliability Assessment: A Review. Energies. 2022; 15(19):7164. https://doi.org/10.3390/en15197164

Chicago/Turabian StyleBehara, Ramesh Kumar, and Akshay Kumar Saha. 2022. "Artificial Intelligence Methodologies in Smart Grid-Integrated Doubly Fed Induction Generator Design Optimization and Reliability Assessment: A Review" Energies 15, no. 19: 7164. https://doi.org/10.3390/en15197164