Experimental Study on the Factors of the Oil Shale Thermal Breakdown in High-Voltage Power Frequency Electric Heating Technology

Abstract

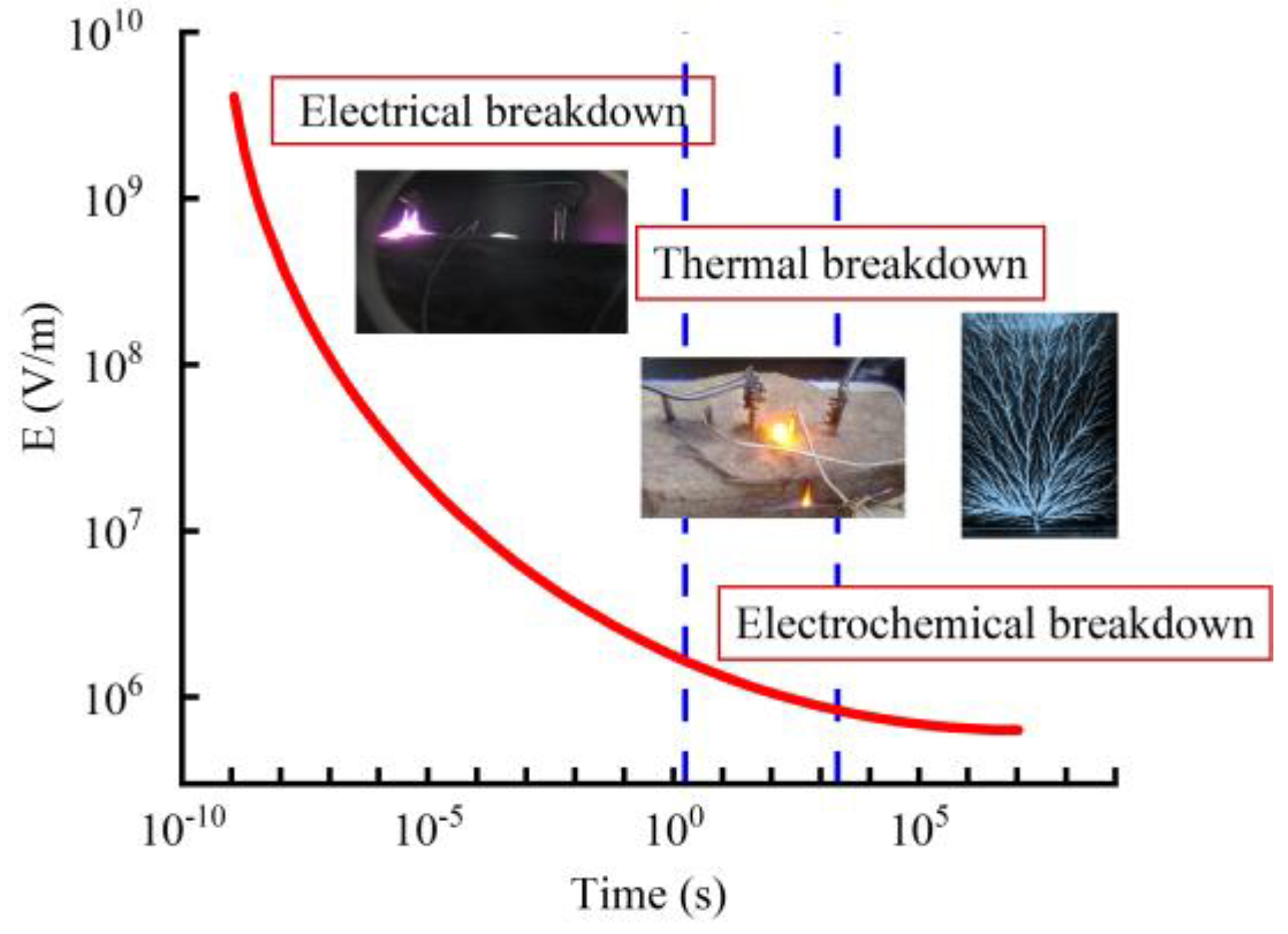

:1. Introduction

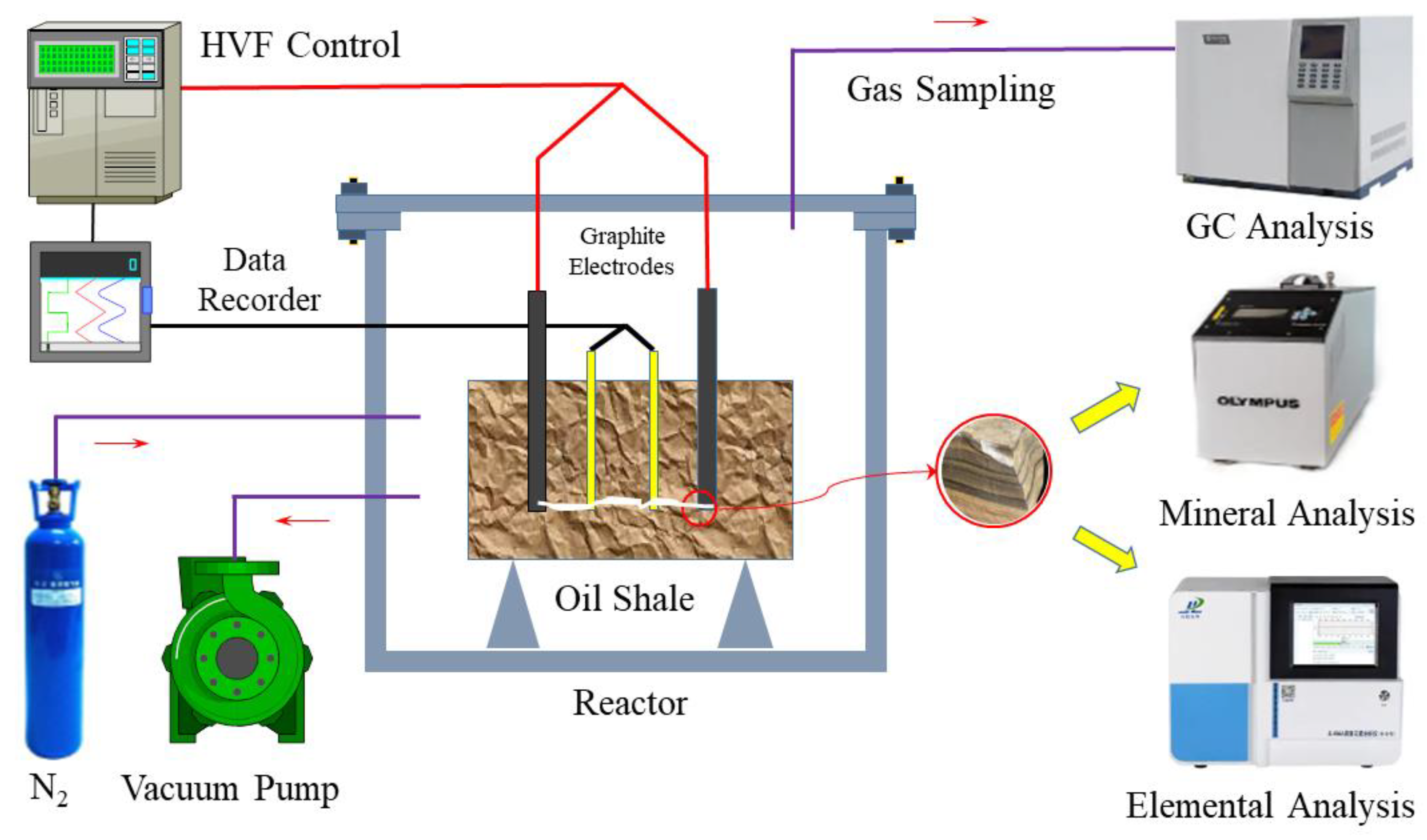

2. Materials and Methods

2.1. Apparatus and Materials

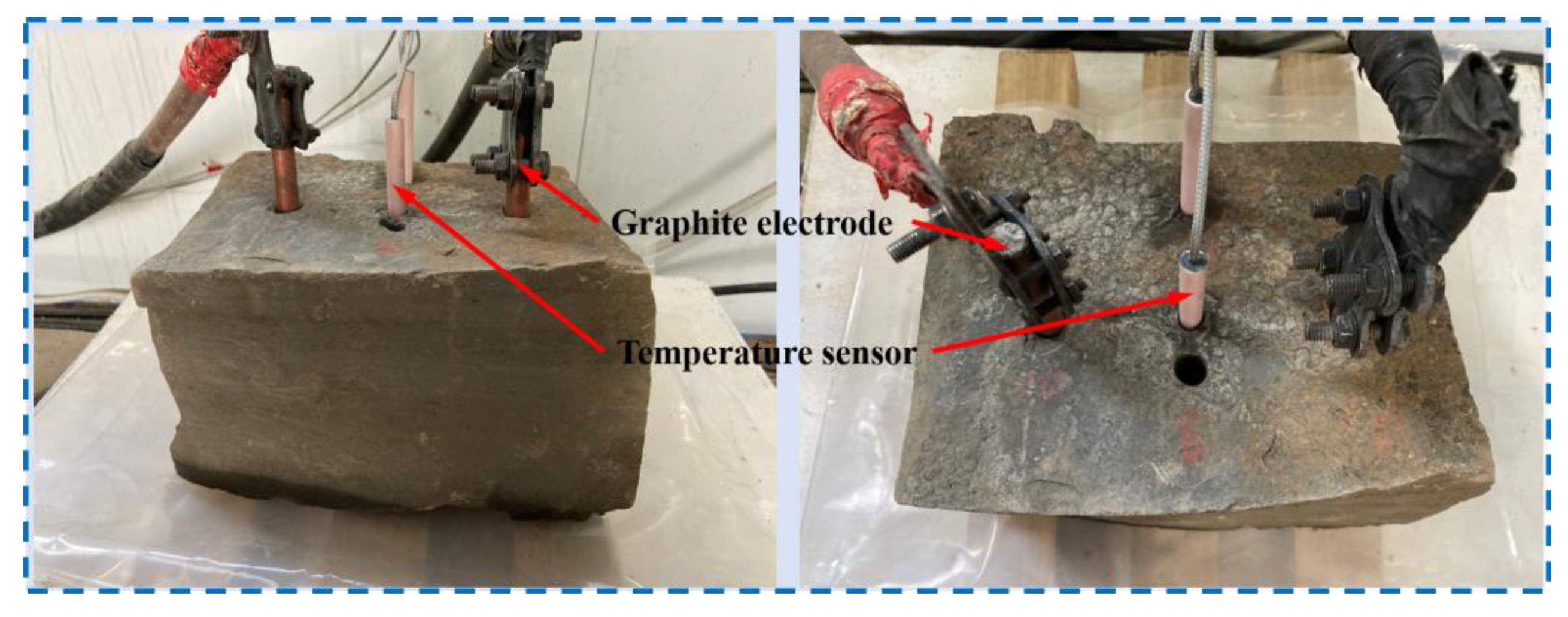

2.2. Experimental Methods

2.2.1. Experimental Procedure

- (1)

- Oil shale samples with different initial temperatures and moisture contents were prepared.

- (2)

- Electrodes and temperature sensors were arranged in the oil shale samples.

- (3)

- The sample was placed in the reactor, the electrodes were connected to the power supply, and the temperature sensors were connected to the data recorder.

- (4)

- The reactor was sealed and set to the designed gas environment.

- (5)

- The breakdown experiments were carried out. The HVF regulator was adjusted to the breakdown mode and the voltage was set to the initial value. If the current did not surge after applying the voltage for some time, and the temperature of the oil shale did not rise continuously, it was judged that the oil shale could not be broken down under this voltage; when the current increased sharply, the HVF regulator was switched to 220 V AC power frequency heating mode. If the oil shale could be heated continuously, it was judged that the oil shale was broken down; otherwise, it was not. At this time, the breakdown voltage was increased and the experiment was continued.

2.2.2. Experimental Parameters

- (1)

- Electric field intensity

- (2)

- Initial temperature

- (3)

- Moisture content

3. Results and Discussion

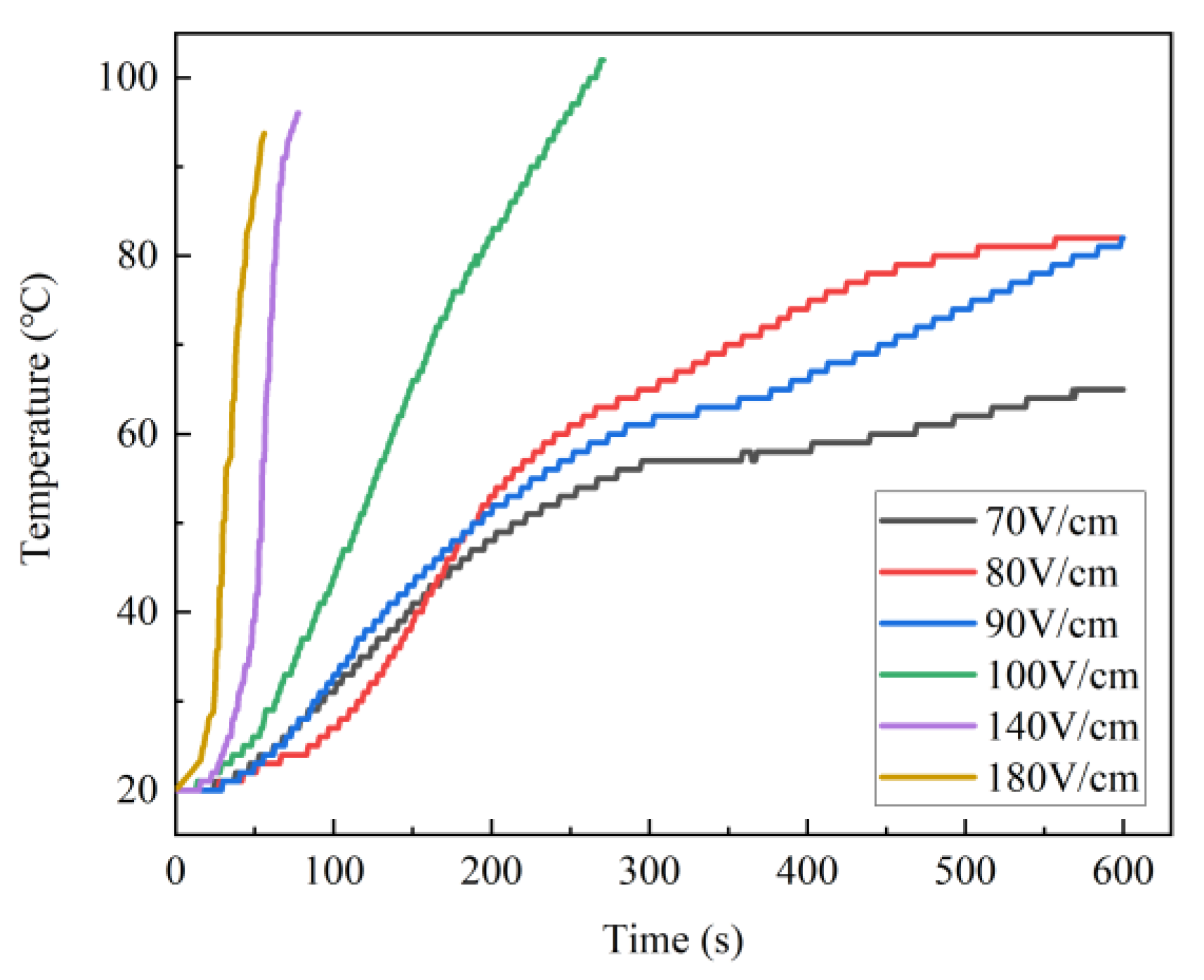

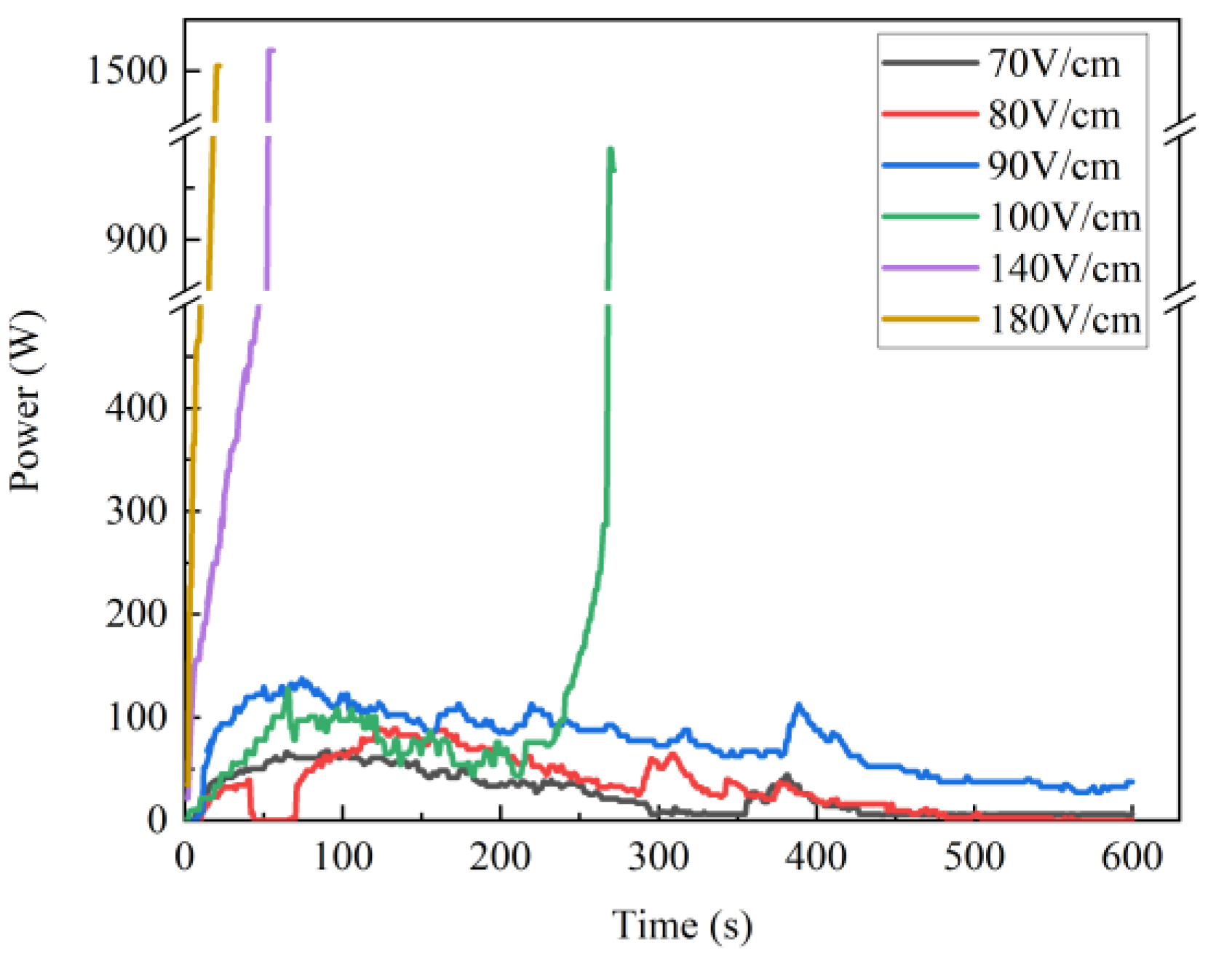

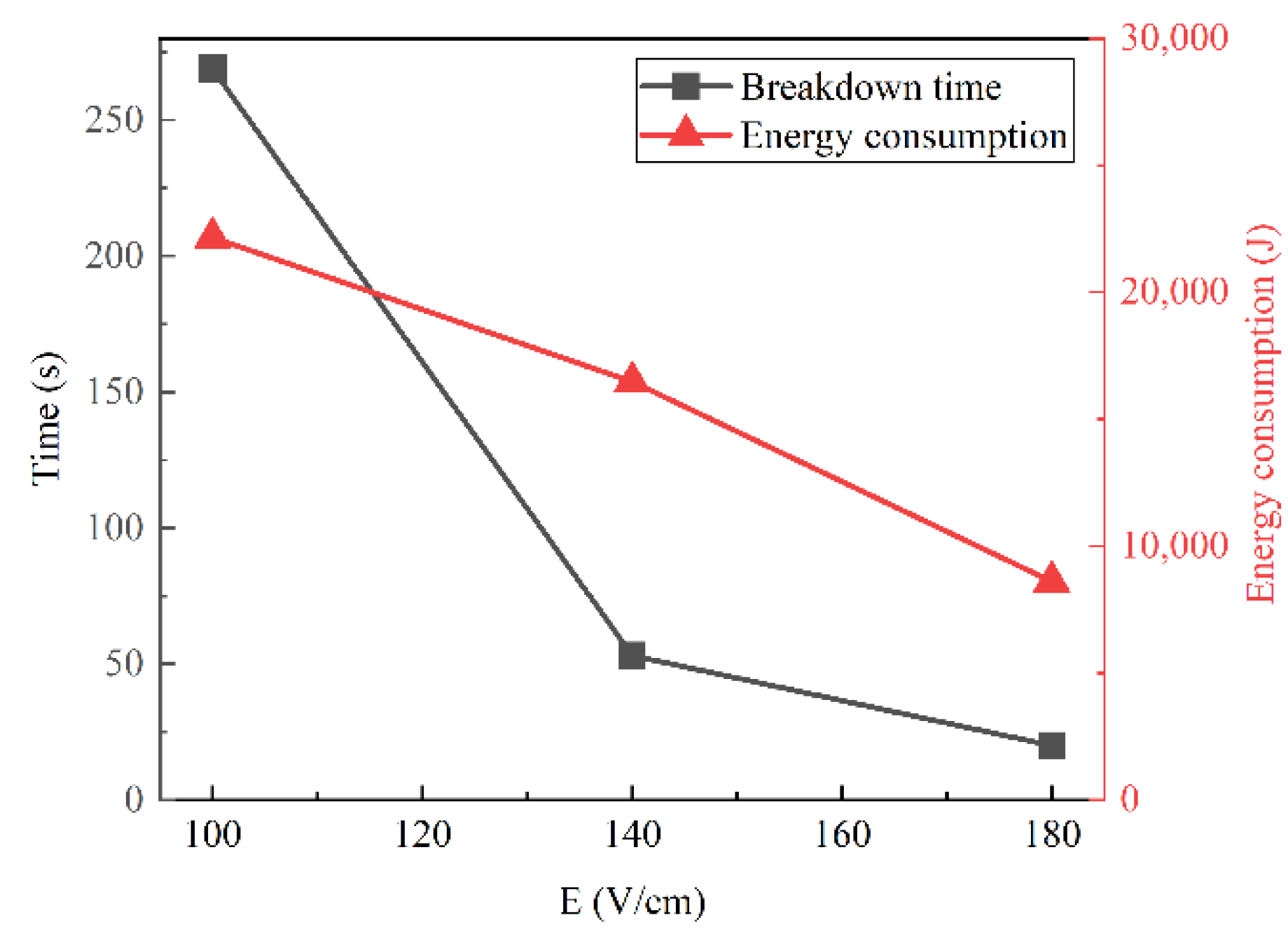

3.1. Effect of the Electric Field Intensity on the Oil Shale Breakdown

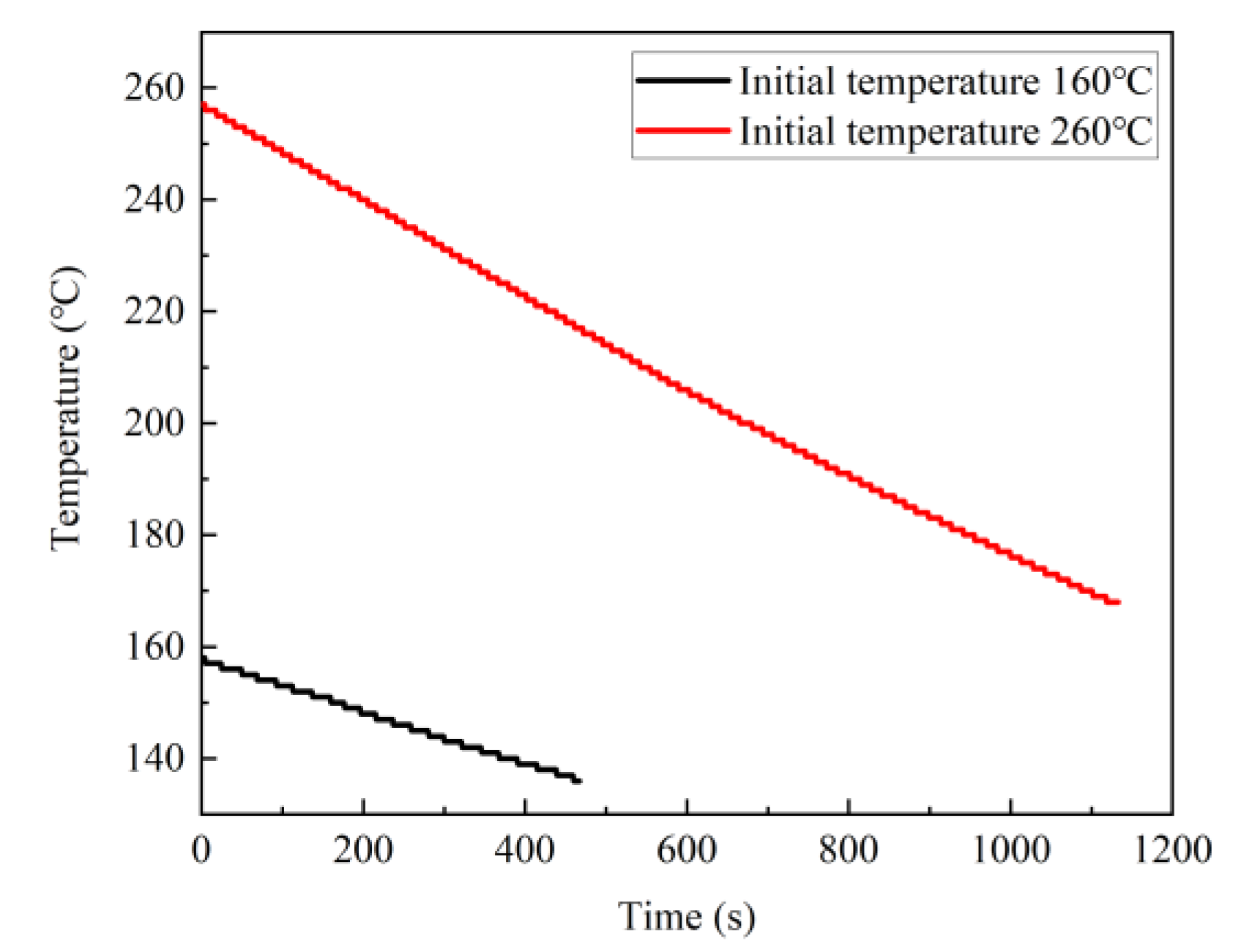

3.2. Effect of the Initial Temperature on the Oil Shale Breakdown

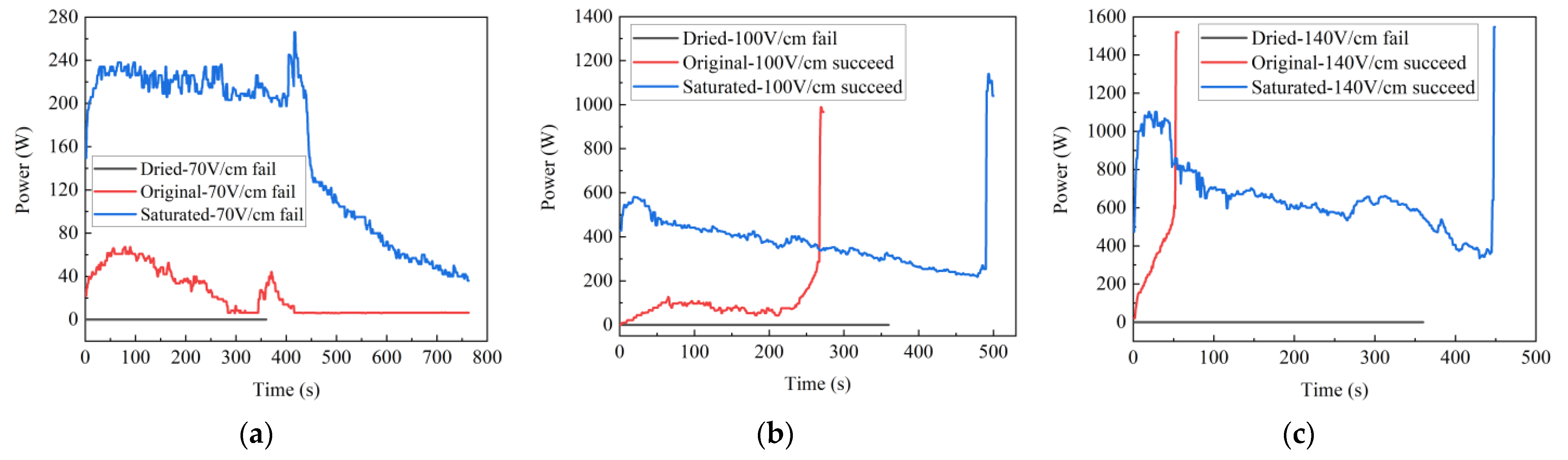

3.3. Effect of the Moisture Content on the Oil Shale Breakdown

4. Conclusions

- (1)

- Under the same experimental conditions, the thermal breakdown occurred when the electric field intensity was between 100 and 180 V/cm. The greater the electric field intensity, the easier the thermal breakdown and the lower the energy consumption. The critical thermal breakdown temperatures of the oil shale were between 93 and 102 °C.

- (2)

- A higher initial temperature increases the difficulty of breakdown, which is inconsistent with the classical theory of the solid thermal breakdown because increasing the initial temperature leads to a reduction in water in the oil shale, which significantly affects the electrophysical properties of the oil shale. When the temperature rises, the oil shale’s components change, affecting its macro and micro physical and chemical structures and altering its electrophysical and thermophysical properties.

- (3)

- The main factor that affects the electrical conductivity of the oil shale is the existence of water, which is also a necessary condition for the oil shale’s thermal breakdown. In addition, there should be an optimal moisture content to minimize both the breakdown time and the energy consumption.

- (4)

- The thermal breakdown of the oil shale results from the heat generation and dissipation, which are affected by many factors. The electric field intensity only affects the heat generation process, whereas the initial temperature and the moisture content impact both the heat generation and dissipation processes, and the impacts of the moisture content are more significant than that of the initial temperature.

Author Contributions

Funding

Conflicts of Interest

References

- Han, X.; Kulaots, I.; Jiang, X.; Suuberg, E.M. Review of oil shale semicoke and its combustion utilization. Fuel 2014, 126, 143–161. [Google Scholar] [CrossRef]

- Taheri-Shakib, J.; Kantzas, A. A comprehensive review of microwave application on the oil shale: Prospects for shale oil production. Fuel 2021, 305, 121519. [Google Scholar] [CrossRef]

- Liu, Z.; Meng, Q.; Dong, Q.; Zhu, J.; Guo, W.; Ye, S.; Liu, R.; Jia, J. Characteristics and Resource Potential of Oil Shale in China. Oil Shale 2017, 34, 15–41. [Google Scholar] [CrossRef]

- Kang, Z.; Zhao, Y.; Yang, D. Review of oil shale in-situ conversion technology. Appl. Energy 2020, 269, 115121. [Google Scholar] [CrossRef]

- Dyni, J.R. Geology and resources of some world oil-shale deposits. Oil Shale 2003, 20, 193–252. [Google Scholar]

- Liu, R.; Liu, Z. Oil shale resource situation and multi-purpose development potential in China and abroad. J. Jilin Univ. 2006, 36, 892–898. [Google Scholar]

- Huang, X.; Yang, D.; Kang, Z. Study on the Pore and Fracture Connectivity Characteristics of Oil Shale Pyrolyzed by Superheated Steam. Energies 2020, 13, 5716. [Google Scholar] [CrossRef]

- Al Asfar, J.J.; AlShwawra, A.; Sakhrieh, A.; Hamdan, M.A. Combustion characteristics of solid waste biomass, oil shale, and coal. Energy Sources Part A: Recovery Util. Environ. Eff. 2018, 40, 335–342. [Google Scholar] [CrossRef]

- Al Asfar, J.J.; Hammad, A.; Sakhrieh, A.; Hamdan, M.A. Two-dimensional numerical modeling of combustion of Jordanian oil shale. Energy Sources Part A: Recovery Util. Environ. Eff. 2016, 38, 1189–1196. [Google Scholar] [CrossRef]

- He, W.; Sun, Y.; Shan, X. Organic matter evolution in pyrolysis experiments of oil shale under high pressure: Guidance for in situ conversion of oil shale in the Songliao Basin. J. Anal. Appl. Pyrolysis 2021, 155, 105091. [Google Scholar] [CrossRef]

- Yang, Y. Theoretical and Experimental Research of Oil Shale In-Situ Pyrolysis by High Voltage-Power Frequency Electrical Heating Method. Ph.D. Thesis, Jilin University, Changchun, China, 2014. [Google Scholar]

- Yan, F.; Lin, B.; Zhu, C.; Zhou, Y.; Liu, X.; Guo, C.; Zou, Q. Experimental investigation on anthracite coal fragmentation by high-voltage electrical pulses in the air condition: Effect of breakdown voltage. Fuel 2016, 183, 583–592. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, F.; Li, J.; Ran, H.; Li, X.; Fu, Q. Breakdown Voltage and Its Influencing Factors of Thermally Aged Oil-Impregnated Paper at Pulsating DC Voltage. Energies 2017, 10, 1411. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.W.; Li, S.T. Research status and development of insulation breakdown in engineering solid dielectrics. Chin. Sci. Bull.-Chin. 2020, 65, 3461–3474. [Google Scholar] [CrossRef]

- Danikas, M.G.; Vardakis, G.E.; Sarathi, R. Some Factors Affecting the Breakdown Strength of Solid Dielectrics: A Short Review. Eng. Technol. Appl. Sci. Res. 2020, 10, 5505–5511. [Google Scholar] [CrossRef]

- Frohlich, H. Dielectric properties of dipolar solids. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1946, 185, 399–414. [Google Scholar]

- Michaels, J.A.; Wood, D.R.; Froeter, P.J.; Huang, W.; Sievers, D.J.; Li, X.L. Effect of Perforation on the Thermal and Electrical Breakdown of Self-Rolled-Up Nanomembrane Structures. Adv Mater Interfaces 2019, 6, 1901022. [Google Scholar] [CrossRef]

- O’dwyer, J. The theory of avalanche breakdown in solid dielectrics. J. Phys. Chem. Solids 1967, 28, 1137–1144. [Google Scholar] [CrossRef]

- Kao, K.C. New theory of electrical discharge and breakdown in low-mobility condensed insulators. J. Appl. Phys. 1984, 55, 752–755. [Google Scholar] [CrossRef]

- Hippel, A.v. Elektrische Festigkeit und Kristallbau. Z. Für Phys. 1932, 75, 145–170. [Google Scholar] [CrossRef]

- Saffian, H.A.; Talib, M.A.; Lee, S.H.; Tahir, P.M.; Lee, C.H.; Ariffin, H.; Asa’ari, A.Z.M. Mechanical Strength, Thermal Conductivity and Electrical Breakdown of Kenaf Core Fiber/Lignin/Polypropylene Biocomposite. Polymers 2020, 12, 1833. [Google Scholar]

- Dissado, L.A.; Fothergill, J.C. Electrical Degradation and Breakdown in Polymers; IET: London, UK, 1992; Volume 9. [Google Scholar]

- Christensen, L.R.; Hassager, O.; Skov, A.L. Electro-Thermal model of thermal breakdown in multilayered dielectric elastomers. Aiche J. 2019, 65, 859–864. [Google Scholar]

- Zhang, C.B.; Yan, T.; Yang, Z.Q.; Ren, W.T.; Zhu, Z.P. A 3-D Theoretical Model of Thermal Breakdown in Semiconductor Devices Under Multiple Pulses. IEEE T Plasma Sci. 2019, 47, 5180–5185. [Google Scholar] [CrossRef]

- Christensen, L.R.; Hassager, O.; Skov, A.L. Electro-thermal and -mechanical model of thermal breakdown in multilayered dielectric elastomers. Aiche J. 2020, 66, 859–864. [Google Scholar] [CrossRef]

- Wagner, K.W. The physical nature of the electrical breakdown of solid dielectrics. J. Am. Inst. Electr. Eng. 1922, 41, 1034–1044. [Google Scholar] [CrossRef]

- Mon, G.R.; Orehotsky, J.; Ross, R.; Whitla, G. Predicting Electrochemical Breakdown in Terrestrial Photovoltaic Modules. In Proceedings of the 17th IEEE Photovoltaic Specialists Conference, Kissimmee, FL, USA, 1–4 May 1984; pp. 682–692. [Google Scholar]

- Chung, N.X.; Gatty, H.K.; Lu, X.; Zhang, M.; Linnros, J. Optimized electrochemical breakdown etching using temporal voltage variation for formation of nanopores in a silicon membrane. Sens. Actuators B Chem. 2021, 331, 129323. [Google Scholar] [CrossRef]

- Liu, L.; Chen, H.L.; Li, B.; Wang, Y.J.; Li, D.C. Thermal and strain-stiffening effects on the electromechanical breakdown strength of dielectric elastomers. Appl. Phys. Lett. 2015, 107, 5. [Google Scholar] [CrossRef]

- Jiasheng, L. Experimental Study on Resistance and Electrode Materials with Oil Shale In-situ Pyrolysis by High Voltage-Power Frequency Electric Heating. Master’s Thesis, Jilin University, Changchun, China, 2014. [Google Scholar]

- Ran, H.H.; Li, J.; Zhang, J.; Li, X.D.; Chen, J.S. Influence of Temperature and Thermal Aging on Breakdown Voltage of Oil-paper Insulation. In Proceedings of the IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016. [Google Scholar]

| Elements % | H/C | O/C | |||||

|---|---|---|---|---|---|---|---|

| N | C | O | H | S | HF | ||

| 2.36 | 59.60 | 7.82 | 7.16 | 0.57 | 14.65 | 1.44 | 0.10 |

| Shale Oil | Gas | Water | Residue |

|---|---|---|---|

| 18.32 | 5.27 | 5.99 | 70.42 |

| SiO2 (%) | Al2O3 (%) | TFe2O3 (%) | CaO (%) | MgO (%) | K2O (%) | Na2O (%) | TiO2 (%) | P2O5 (%) | MnO (%) | LOI (%) | Sum (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 52.73 | 15.75 | 5.77 | 1.74 | 2.11 | 3.38 | 2.15 | 0.58 | 0.33 | 0.06 | 15.16 | 99.76 |

| Q (%) | Fs (%) | Pl (%) | Cc (%) | Do (%) | Sid (%) | Fy (%) | Ana (%) | I/S (%) | I (%) | K (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| 29.0 | 6.0 | 10.0 | 12.0 | 3.0 | 4.0 | 2.0 | 2.0 | 10.0 | 20.0 | 6.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Liu, S.; Li, Q.; Lü, X. Experimental Study on the Factors of the Oil Shale Thermal Breakdown in High-Voltage Power Frequency Electric Heating Technology. Energies 2022, 15, 7181. https://doi.org/10.3390/en15197181

Sun Y, Liu S, Li Q, Lü X. Experimental Study on the Factors of the Oil Shale Thermal Breakdown in High-Voltage Power Frequency Electric Heating Technology. Energies. 2022; 15(19):7181. https://doi.org/10.3390/en15197181

Chicago/Turabian StyleSun, Youhong, Shichang Liu, Qiang Li, and Xiaoshu Lü. 2022. "Experimental Study on the Factors of the Oil Shale Thermal Breakdown in High-Voltage Power Frequency Electric Heating Technology" Energies 15, no. 19: 7181. https://doi.org/10.3390/en15197181

APA StyleSun, Y., Liu, S., Li, Q., & Lü, X. (2022). Experimental Study on the Factors of the Oil Shale Thermal Breakdown in High-Voltage Power Frequency Electric Heating Technology. Energies, 15(19), 7181. https://doi.org/10.3390/en15197181