1. Introduction

The UK has a legally binding commitment to net zero greenhouse gas emissions by 2050 [

1], with several interim carbon budgets between the present and 2050. Domestic heating is a significant contributor to UK emissions and is dominated by gas central heating—83% of homes in GB have gas central heating [

2]. In the near term, significant reductions in carbon emissions from domestic heating are needed to meet the interim carbon budgets, and complete decarbonisation is needed by 2050.

The popularity of gas heating has been driven by the relatively low cost of gas compared to electricity. The gas boiler market has moved steadily from system boilers with stored hot water tanks to more compact combination boilers, which now make up over 70% of gas boilers [

3]. Efforts have been made to reduce energy demand from gas boilers. In 2005, minimum efficiency product standards were raised, effectively mandating condensing boilers [

4], which resulted in a demonstrable reduction in gas demand [

5]. More recently, the Boiler Plus policy has sought to extract additional efficiency gains from boiler heating systems through the addition of measures such as smart controls and flue gas heat recovery [

6]. Further improvements have been identified which could increase boiler system efficiency, such as lowering emitter temperatures and introducing effective modulating controls [

7]. These changes would have the dual benefit of improving current boiler efficiency and preparing homes for low temperature heat pumps. The limitations on boiler performance and the cycling behaviour which result from a combination of the installation, system and control factors has been investigated previously both empirically [

7,

8] and through simulation [

9]. The deleterious effects of boiler oversizing and limited modulation have been known since the early days of domestic boilers [

10] and building physics modelling [

11] but the problem persists. Whilst any improvement in boiler efficiency is desirable, improving boiler efficiency alone will not be sufficient to meet decarbonisation targets.

Electrification of heat through Heat Pumps (HPs) presents the clearest way to decarbonise heating and is forefront in the Committee on Climate Change’s (CCC) recommendations [

12] and the UK Government’s 10 point plan and Heat and Buildings Strategy [

13]. The carbon intensity of electricity from the UK grid has fallen rapidly in the last ten years and will continue to fall in the coming years, thus reducing the emissions from electric heating. This is due to the closure of almost all coal power stations and a substantial increase in renewable electricity generation. Incentive schemes, such as domestic Renewable Heat Incentive (RHI), have sought to encourage the uptake of HPs, but have so far resulted in around 35,000 HP installations per year [

13] (over 1.5 million gas boilers are installed each year in the UK). The domestic RHI replacement will take the form of an upfront grant from 2022, but will in effect be limited to supporting 30,000 installations per year, due to a cap on funding. The UK Government aims to achieve price parity of HPs with gas boilers, through reduced installation costs, and through reduced running costs, enabled by market mechanisms to drive HP sales and up average new heating system efficiency [

13,

14].

Hydrogen is a low-carbon alternative to natural gas, but its role in combustion-based heating is not yet clear, with key decisions on the potential roll-out happening in 2026 [

13]. Consequently, the role of hybrid heating systems, which combine a HP with a boiler, is also currently unclear. At present, natural gas is burnt in boilers and hybrids, but in future this gas may be hydrogen. Hybrids play a key role in the CCC’s recommendations, alongside electrification of heat through heat pumps and a transition from natural gas to hydrogen. Nevertheless, uncertainty remains in the policy framework set out in the UK Government’s Heat and Buildings Strategy on the role of hybrids as a transition technology, and their continued use in 2050 in scenarios where hydrogen is available for combustion-based heating.

Significant challenges around the cost, disruption and supply chain for HP installations remain, especially the availability of skilled installers, which is partly due to the reluctance of incumbent boiler installers to switch to HPs [

15]. GasSafe boiler installers number around 130,000 with only a few thousand qualified HP installers [

13]. Low carbon heating appliances which can be installed by the existing workforce with minimal additional training can play an important role in domestic heat decarbonisation. Disruption during installation and additional space requirements of energy efficiency measures such as HPs has been cited as a key barrier to rapid deployment of heating emissions reduction measures [

12]. Retaining aspects of the current dominant combi boiler systems would address customer concerns and potentially accelerate market penetration. Compact form factor, ability to react quickly to heat demand, instantaneous hot water and modest cost are properties that could be retained in a low carbon heating system.

A rapid transition to HPs presents challenges to the electricity grid at a national and local level, due to the high electrical demand of HPs in periods of cold weather [

16,

17]. At a local level, the electrical demand may outstrip the capacity at local substations and violate voltage and/or thermal limits of the local network. At a national level, additional electrical demand at times of existing peaks in demand could necessitate the construction and use of higher carbon peaking plant. At those times of high marginal carbon intensity of electricity generation, combustion of gas locally can be a lower carbon option than using electricity for heating.

Hybrid heating systems, where a gas boiler is combined with a HP, can potentially reduce the negative impact of rapid electrification, by switch to gas at times of peak demand. In addition, the two technologies can complement each other. Boilers can react quickly to heat demands, making them highly suitable for instantaneous hot water production. Boiler output and efficiency are largely independent of weather, whereas air-source HP output and efficiency decline during cold weather. Within the boiler’s modulation range, boiler efficiency is largely independent of modulation level [

9,

18], but when the heat required drops below the minimum modulation range of the boiler, cycling occurs, which is detrimental to efficiency. By combining a boiler with a small heat pump, this cycling can be eliminated, and the heat pump provides space heating when the weather is mild and heat demands are low. Under these conditions the heat pump will perform well. When the weather is colder and heat demands are higher, the boiler augments or replaces the heat pump. A BEIS study has found that hybrid heating systems can deliver significant decarbonisation in practice [

19] and field trials [

20] show that when coupled with optimisation controls can deliver grid flexibility and additional savings. The hybrid systems previously analysed can be characterised as hybrid bivalent systems, where either the boiler or HP has the capacity to fully heat the home and integration is minimal. Focus in these studies has been on the flexibility dimension of hybrids and how coordinated switching between boiler and HP can offer services to the grid and savings to the customer. Advanced control of hybrids can be disconcerting to customers, who are unclear as to the operation of the system and potentially doubtful about the heat and cost performance as a result. The predictability of gas boilers means that customer acceptance of new heating technologies is a challenge, made more so by the different operating characteristics of HPs and hybrids. Whilst flexible control may ease the challenges of high levels of HP penetration in the grid, it is also important to consider how a hybrid could decarbonise heating while providing a ‘boiler—like’ heating experience in an appliance form factor similar to that of the current boilers.

The combination of the need for rapid decarbonisation of heat, a boiler-focussed installer base and concerns on the electrical supply grid has placed the hybrid heating device as a potential near term solution. Emerging compact, combi hybrid systems (CoCo hybrids), which combine the low carbon potential of HPs with the accepted form factor and performance of combi boilers [

21,

22], can accelerate decarbonisation in a way compatible with today’s supply chain and grid constraints. In addition, if hydrogen is available in homes, they may continue to be used in 2050 and beyond. Due to the spatial constraint of CoCo hybrids being required to have a similar size to a combi boiler, it is likely that Domestic Hot Water (DHW) will be heated instantaneously by the boiler part of a CoCo hybrid, since there is insufficient space for a large DHW storage tank.

To address the question of how such compact hybrid systems could perform in reality, trials are being run [

23] which will deliver valuable insights. In this study we have looked at gaining general understanding of the potential of compact hybrids from the point of view of how they can provide a similar heating experience to an existing compact boiler. Using actual monitored boiler performance data (power output, temperatures, etc.) a wide parameter space of compact hybrid configurations and operation can be modelled.

2. Materials and Methods

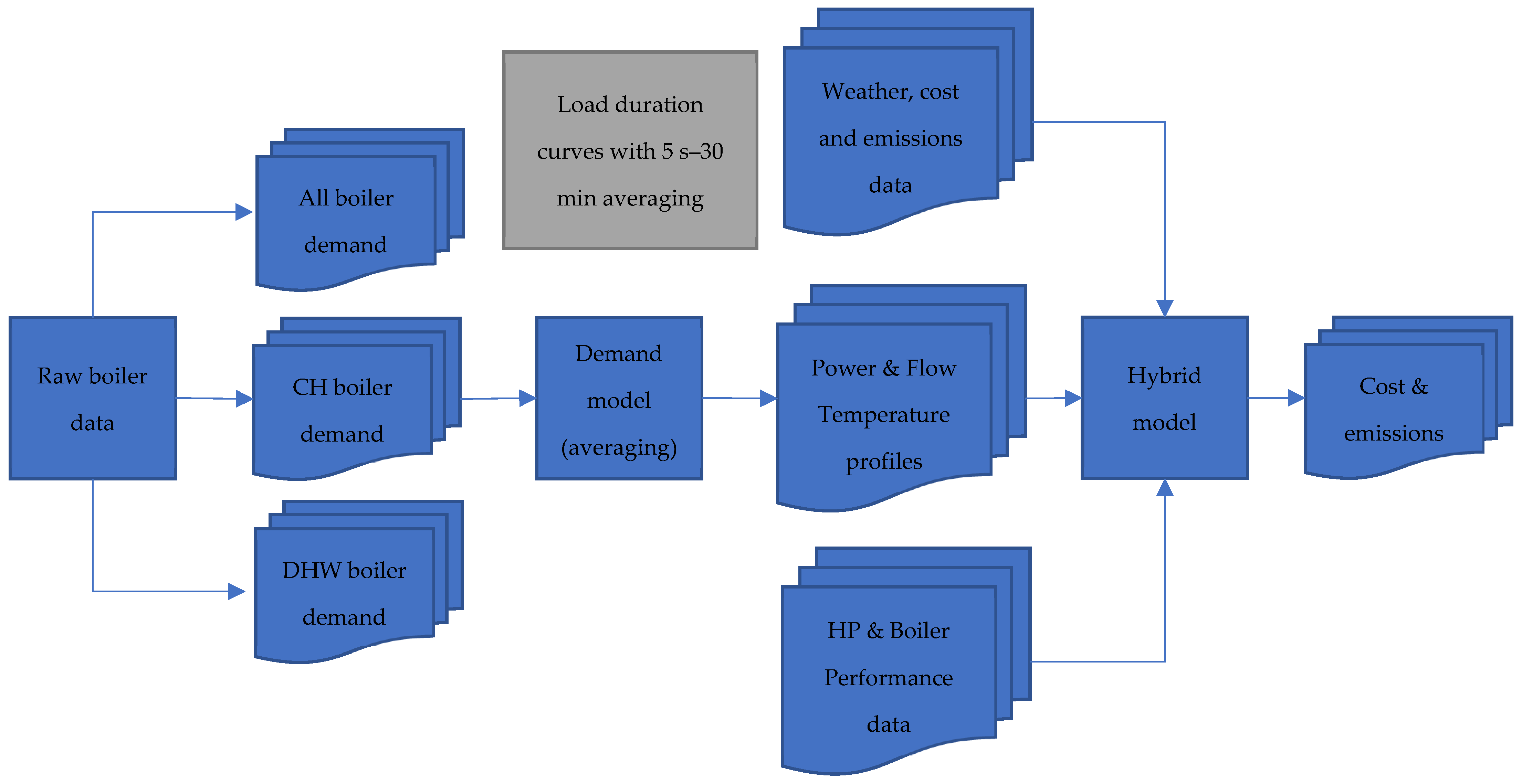

The development of low cost remote monitoring and internet-connected appliances has enabled high quality heating operational data to be collected which can support new insights into today’s heating demand and inform the decarbonisation pathways to follow. This study uses high frequency collected from internet-connected boilers utilising the existing sensors and electronics within the boiler to facilitate the measurement and monitoring. Two UK homes were monitored as part of this study, the details of which are shown in

Table 1. This dataset provides a relatively detailed case study, which is used to investigate the methodological framework needed to model compact hybrid operation in a home on the basis of measured boiler data.

The primary source of data was from the boiler diagnostic system, which captures the internal sensor data of the boiler (5-secondly) which it uses for operation and communication with external controls. The boiler data was supplemented with gas and electricity meter measurements (hourly) and internal temperature sensors in 9 locations in each home. Numerous variables were recorded by the boiler monitoring system, but in the context of this study the most important are boiler power, flow temperature and mode. The two modes are space heating, also called Central Heating (CH), and DHW. The power delivery profile recorded in the boiler data is considered in the analysis to be representative of the heating demand required to heat the building to the satisfaction of the occupants. It is indicative of what any replacement heating system which seeks to provide a ‘boiler-like’ heating experience to the occupant would need to provide. Alongside the heat power level delivered by the boiler, the temperature at which the space heating water is delivered (supply temperature, also known as flow temperature) is decisive in determining the rate at which heat is transferred to the rooms via the emitters, typically radiators. Heat output of radiators is dependent on the mean water temperature within them and the air temperature of the surrounding space. The temperature at which heat is delivered to a given building is therefore indicative of the installed radiator capacity. Without detailed room by room information on flow temperatures, return temperatures leaving the radiators and the surrounding air temperature, a full picture of the emitter system cannot be fully empirically derived from the data collected in this study. Nevertheless, it should be noted that the flow temperature from the boiler (which was monitored) plays an important role in determining the efficiency of both boilers and heat pumps.

An example subset of the data collected during the monitoring period is shown in

Figure 1; additional variables were recorded but are not shown here. The beginning of the scheduled heating period occurs at 06:00:40 and is marked in the ‘Boiler Power’ section. After a brief boiler start up sequence, the boiler power ramps up to a steady level. After this, power ramps down and then switches into a prolonged period of cycling on and off starting around 07:00. It is notable that the maximum boiler power shown on the chart is 74%. This corresponds to 31 kW, and is the maximum power available for space heating. When producing DHW, the boiler would reach 100%, giving a power output of 42 kW. (No DHW heating occurred during the period shown). The minimum modulation output of the boiler is visible at ~28%, corresponding to ~12 kW. When the required heat output is below 12 kW, the boiler is seen to cycle on and off.

The supply temperature ramps up during the period of boiler maximum output and is maintained at the setpoint as the boiler output is reduced to its minimum modulation. Once the minimum modulation of the boiler is reached, it cycles on and off to supply the required heat output. At this point the supply temperature also follows a cyclic pattern in time with the boiler power cycles. The detrimental effect of cycling on boiler system efficiency has been well documented [

9,

10]

Previous studies of boiler use were based on indirect measurement of boiler operation, through low resolution gas consumption or pipe temperatures [

18]. A crucial advantage of this data source over such studies is that the boiler records the mode in which it is operating (Central/space heating, CH or Domestic Hot Water, DHW). This allows researchers to confidently disaggregate the heating demand into space heating and DHW demand, which is of considerable interest. In

Figure 1 the CH Flag in the lower most trace indicates that all the output shown here is for space heating.

For this research, to assess the potential to replace a conventional condensing combination boiler with a compact hybrid which provides the same heat demand profile, it is necessary to separate the underlying heat demand from the boiler-specific performance signature. The underlying heat demand is the heat output needed to heat the home within the constraints of the heating schedule and emitter temperature requirements, whereas the boiler-specific performance signature consists of behaviour such as cycling which need not be carried over in the modelling. The raw boiler power data was converted to underlying heat demand by time interval averaging, a pragmatic and scalable method (see

Figure 2).

2.1. Time Averaging

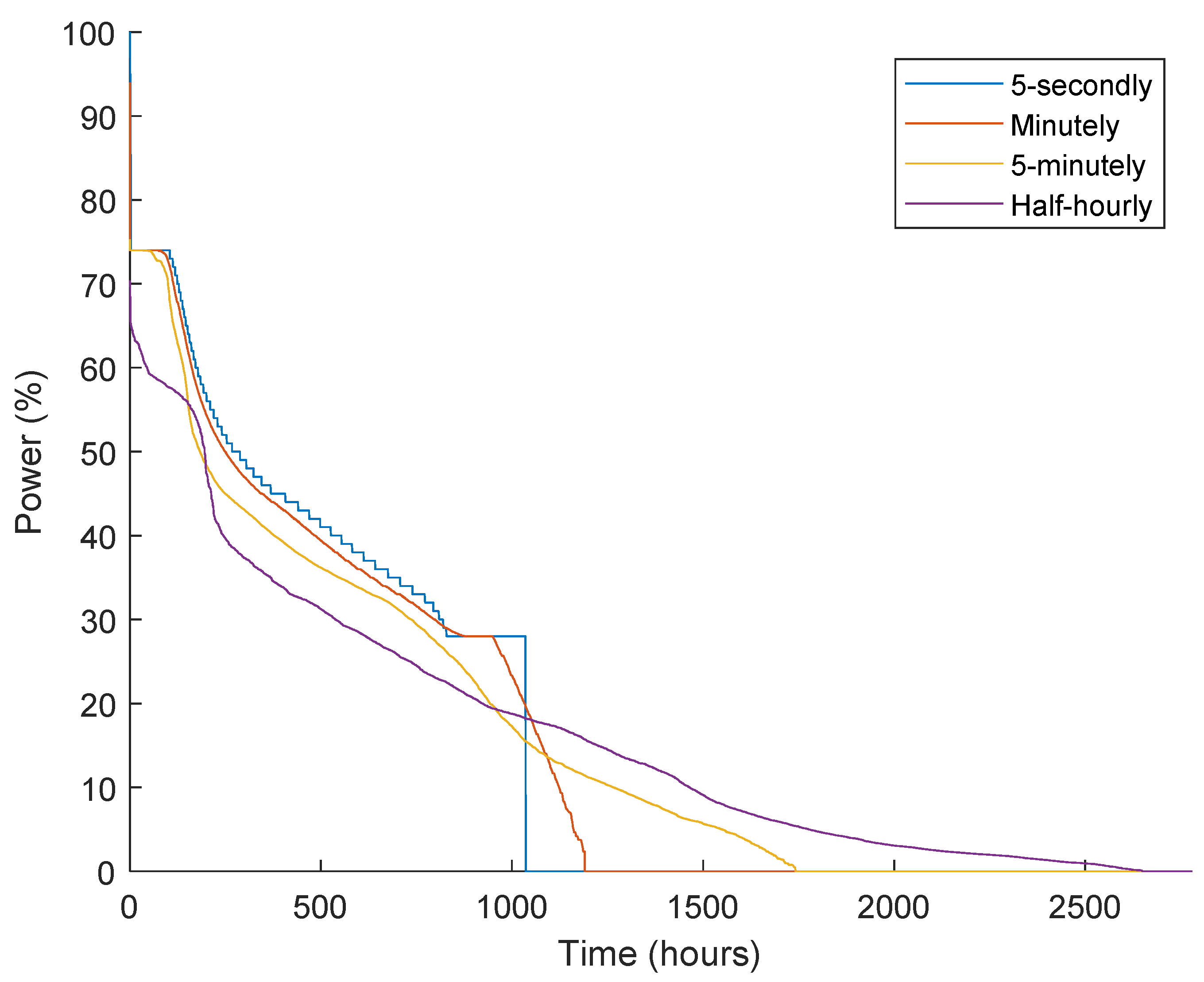

To determine the appropriate timestep over which to conduct the averaging, load duration curves were produced of boiler power (in %) at varying timescales, starting at the original 5-secondly and moving to minutely, 5-minutely, and half-hourly (

Figure 3). At the original 5-secondly resolution, the lowest power output is visible at about 28%, as this is the lowest output to which the boiler can modulate. When the building space heat demand required is lower than this, the boiler cycles on and off. When averaged over longer time periods, there are considerable periods of time where the power required is below 28%. The actual heat demand of the house is not constrained by the operational window of the boiler, so time averaging the boiler data to uncover the lower heat demand (below minimum boiler load) is needed to assess how that heat load could be provided by a HP.

It should be noted that the boiler in OXF1, although a combination boiler, was supplying mainly space heating, which has a maximum output of about 74%. This was due to hot water demand being provided by a cold feed washing machine and dishwasher and the use of an electric shower. A typical combination boiler installation, where the boiler supplies both Domestic Hot Water and space heating, there would be a greater proportion of readings of 74–100% than seen here in

Figure 3.

As noted earlier, a major advantage of the data acquired directly from the boiler is the ability to disaggregate space heating demand from hot water demand, allowing separate load duration curves to be plotted for these two uses. In the case of OXF1, where the boiler was providing no shower and bathing hot water, the resulting load duration curve for space heating only is similar to that for all boiler-reported heat demand (

Figure 4). There were two important differences between OXF1 and OXF2. Firstly, OXF2 was monitored from May to August 2016 and January to March 2017 only, due to technical and access issues. Therefore, results are not directly comparable to OXF1, since there is not a complete year of data. The months which are missing are “shoulder” heating months (April and September to December). These are months where the space heat demand is likely to be moderate, so the boiler will be spending a lot of time in cycling mode. Secondly, DHW in OXF2 was mainly supplied from the combi boiler under observation, in contrast to OXF1, where there was little use of the boiler for DHW. Load duration curves for OXF1 and OXF2 are given below at half hourly averaging, showing all heat demand and space heat only (

Figure 4).

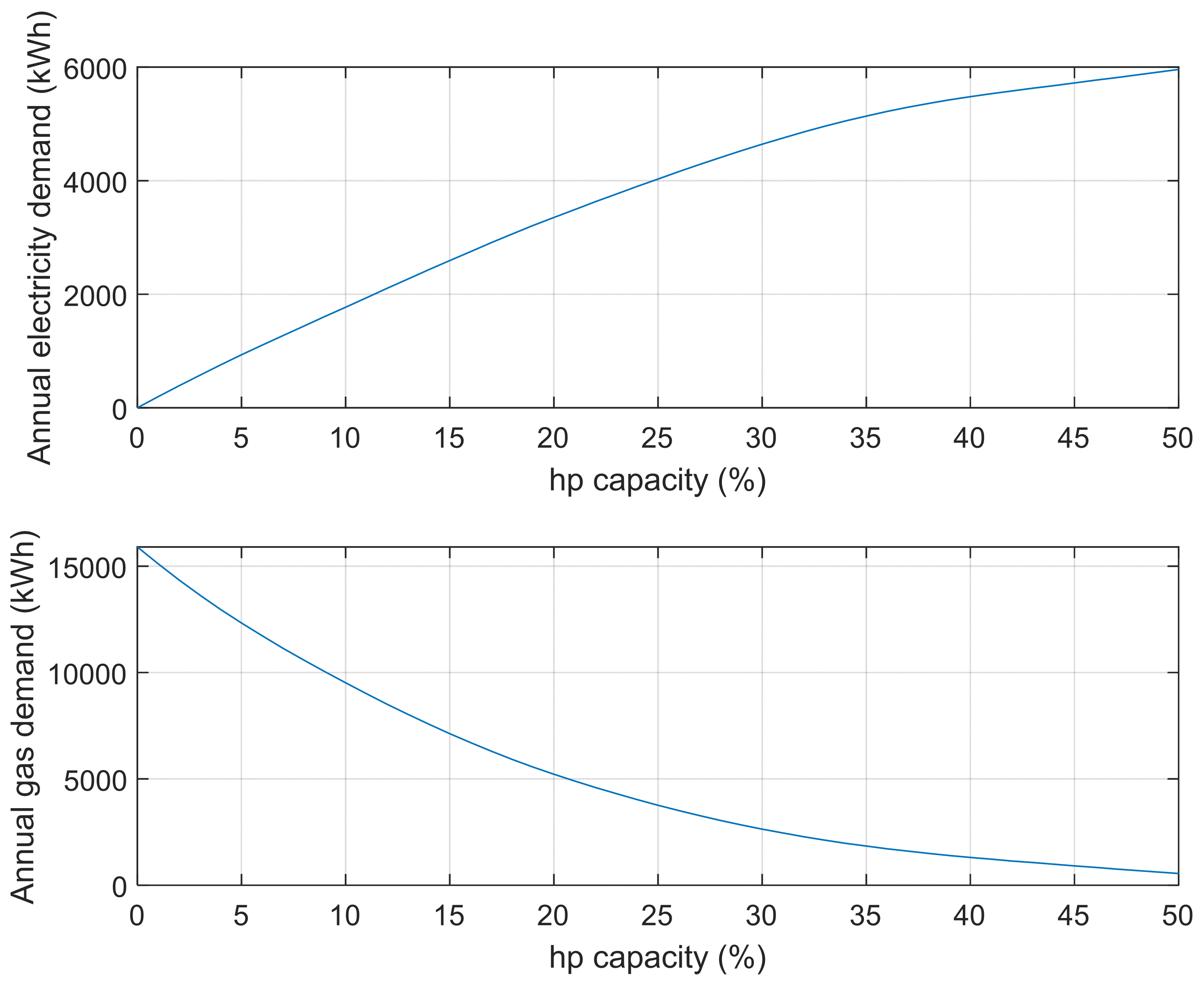

On the basis of the load duration curve analysis, the decision was made to take half hourly disaggregated space heating demand time series profiles into the next stage of analysis. The use of half-hourly averaged data means that, at most, the building could take half an hour longer to reach the desired temperature. In reality the difference will be much less than this. It was assumed that in a compact combination hybrid, all DHW demand would be met by the boiler component, so no further analysis of DHW demand was made.

2.2. Flow/Return Temperatures and Heat Pump COP

The effectiveness of a hybrid in decarbonising heat is dependent on the proportion of the heat delivered by the HP part of the hybrid and the Coefficient Of Performance (COP) of the HP part. The COP of the HP depends on both the source and the sink temperature. In theory the heat pump might be able to supply a given proportion of the heat load, but if that requires heating water from 60 °C to 70 °C (for example), this is less efficient for the heat pump than heating to lower temperatures.

2.2.1. Heat Pump Sink Temperature

The key parameters to determine heat pump sink temperature are the flow and return temperatures. Flow temperatures are monitored in the boiler but return temperatures are not in many boilers, including those observed in this study.

When examined at a half-hourly level, there is a relationship between flow temperature and heat output for OXF1 (

Figure 5). It can be seen that at higher powers, around 35% or more, flow temperature remains approximately constant or even slightly declines. However, at power outputs below 35% a linear relationship between flow temperature and output power appears. It is possible to fit a broken-stick regression to this (

Figure 5). The same method was repeated using data from OXF2.

Methods to determine the return temperature based on flow rate, flow temperature and power were explored. However, no direct flow rate was measured or monitored by the boilers and examining the Central Heating (CH) pump modulation showed that it is only used at two settings: 95% and 86%. This means that it is not useful in determining flow rate as it varies depending on hydraulic resistance of the emitter circuit, which changes with the position of the Thermostatic Radiator Valves (TRVs). Therefore, the flow rate was treated as unknown.

Since the return temperature has not been monitored, and we cannot calculate it from flow rate, flow temperature and power, the following assumptions were made to aid the analysis. When the heat output is zero, the temperature difference between flow and return can be considered to be zero. When the boiler is operating at full power, a typical difference between flow and return is 20 °C. Therefore, we could assume that the return temperature is constantly 20 °C below flow temperature in the region where flow temperature is constant (above 35% power), and that the difference between flow and return temperatures tapers to zero at temperatures below this.

The sink temperature is determined by the flow and return temperatures, and the proportion of heat demand which is met by the heat pump. If the heat pump is providing 50% of the heat output (for example), it must heat the water 50% of the way from the return temperature to the flow temperature (Equation (1)).

As a key determinant of heating system efficiency, both with boilers and HPs, the influencing factors of flow temperature are worth noting. The flow temperature is normally set by the user and should be chosen to suit the emitter sizing and heat loss of the building. Weather compensation controls automate the matching of flow temp to building heat loss through monitoring of outdoor temperature. Neither home in this study had a weather compensation control. There has been shown to be potential to lower flow temperatures in UK homes due to widespread emitter oversizing which could improve system efficiency [

24].

2.2.2. Heat Pump Source Temperature

In the worst case, the source temperature is given by the outdoor air temperature. However, if the heat pump is being used in parallel with the gas boilers, it may be possible to recover heat which would otherwise be wasted in flue gasses, thus boosting the source temperature and improving COP. This system is implemented in one appliance known to the researchers but needs further investigation as to its effectiveness [

21]. For this study, the outdoor air temperature will be taken as the source temperature.

2.2.3. COP Model

Based on the preceding two sections, source and a sink temperature can be determined, giving a temperature difference (ΔT) across which the heat pump must operate. We know from the theory of heat pumps (Carnot efficiency) that heat pump COP is related to this difference. In this work, COP is given by Equation (2) derived from published performance data of a compact hybrid appliance, accounting for the improved performance expected from an HP where the heat source air is partially warmed by the boiler [

21].

4. Discussion

With an expected lifetime of 15 years, boilers and HPs can be expected to go through two or more replacements on the way to 2050. Moving away from natural gas is paramount, and the modest hybridisation possible in a single appliance while still delivering significant carbon reduction shows potential. It was found that all hybrids considered made significant emission reductions compared to gas boilers (although less than a full HP) while continuing to provide a boiler-like heating experience. When a simple price cut-off was used in combination with a dynamic Time of Use tariff, there were small cost savings compared to a gas boiler.

Although the model here aims to assess the ability of a hybrid to provide a boiler-like heating experience in terms of flow temperature and schedule, further savings could be made. CoCo hybrids would offer more savings if coupled with lower flow temperature radiators, a prerequisite for most full HP systems but with a CoCo hybrid could be implemented over a longer period, reducing upfront capital expenditure. Longer operating periods would also enable further use of the HP lowering carbon emissions and potentially costs.

This study is limited to two homes with the requisite high frequency boiler data monitored over an extended period. A larger cohort of monitored buildings would give further insight into the potential savings in relation to current heating and boiler usage profiles. The researchers are exploring how to gain access to a larger boiler population to expand on this exploratory case study.

The representativeness of the Octopus Agile tariff is not yet clear due to the innovative nature of the tariff in the UK consumer energy market. As more Time of Use tariffs emerge they can be added to the model.

The sensitivity of the model to the COP of the heat pump is based on the declared HP efficiency of a CoCo hybrid appliance. In situ efficiency is likely to be less due to performance gap issues, as real-world performance data emerges more realistic HP performance can be integrated into the model.

The modelled hybrid in this study is based on parallel operation of the boiler and HP, this was chosen to enable maximum contribution of the HP, practical limitations on the operation of a real appliance may limit this operation mode and separate running may be more suitable. As further field data emerges from hybrid appliances further modelling could be done.

Domestic Hot Water has not been modelled and are assumed to be fully boiler heater. Further benefits could be gained by using a small amount of DHW storage within the hybrid which can be partially heated by the HP component. This can be implemented in future iterations of the model.

5. Conclusions

A model has been developed to simulate the potential of hybrid appliances to recreate the current heating profiles of two homes. This is a scalable model with the potential to be applied to a larger population. From the modelling and results presented in this study, where hybrid appliances were modelled to provide similar ‘boiler like’ heating profiles, it has been shown that a modestly sized HP (between 1 and 4 kW) allows a significant proportion (up to 50%) of the heating load to be electrified, with associated carbon savings. This shows that in these limited cases a single compact hybrid appliance could provide a viable alternative to a combi boiler while decarbonising heat.

The emissions savings over a gas boiler are achievable across all hybrid scenarios modelled at 2019 grid emissions, but fall short of those achievable by a full HP system. Judged on standard tariffs, running costs would be higher than existing gas combi boilers, but by using Time of Use tariffs, such as Octopus Agile, with simple price cut-offs, a hybrid could be cheaper than both today’s gas boiler technology and a full HP system, while still delivering a boiler-like heating profile.

Compact Combination Hybrids could be a low-disruption, cost-effective, low-carbon alternative to gas boilers, thus providing a pathway to rapid decarbonisation and bypassing the barriers holding up full HP electrification of heat in the UK. The widespread uptake of Compact Combination hybrids is achievable within the constraints of the current housing stock and installer base, due to the compact nature of the appliance (enabled by small HP sizing) and similarity to gas boiler operation.