Abstract

Reusing waste cooking oil (WCO) as fuel in compression ignition (CI) engine offers a sustainable solution for energy scarcity and environmental protection. WCO and n-pentanol ternary blends deliver are attractive prospects in utilization as bio-components and recycled components to moderately substitute diesel fuel. The current study intends to investigate the performance and emission characteristics of a single cylinder CI engine, having constant load at a uniform speed of 1300 rpm, using diesel-waste cooking oil n-pentanol blends. Blends chosen and analogized with diesel oil as reference fuel and their contents were the following: (1) D95-WCO5 (95%vol. diesel, WCO5%vol. waste cooking oil, (2) D65-WCO20-Pe15 (65%vol. diesel, 20%vol. waste cooking oil, and 15%vol. n-pentanol) and (3) D60-WCO20-Pe20 (60%vol. diesel, 20%vol. waste cooking oil and 20%vol. n-pentanol). The experimental results revealed that with the DF95-WCO5 blend the BSFC improved by 0.32%. However, with the addition of n-pentanol as a ternary blend; DF65-WCO20-Pe15 and DF60-WCO20-Pe20 resulted in improvements of 0.49% and 0.68% respectively. The BTE for DF95-WCO5 increased by 38.7%, while the increase was 39.2% for DF65-WCO20-Pe15 and 39.6% for DF60-WCO20-Pe20, which was less, as compared with diesel fuel. The lowermost level of CO discharge was achieved when the engine was fueled with DF65-WCO20-Pe15 and DF60-WCO20-Pe20, due to the highest level of saturation. CO2, in the cases of DF65-WCO20-Pe15 and DF60-WCO20-Pe20, increased, as compared to diesel fuel under the same engine operating conditions. However, the binary blend DF95-WCO5 resulted in decreased CO2 as analogized to diesel, because of incomplete combustion of the fuel. During experimental work it could be observed that the DF95-WCO5 binary blend produced higher Particulate material (PM-1, PM-2.5, PM-7 and PM-10) emissions, compared to DF100. Moreover, with the addition of n-pentanol as a ternary blend in the ratio of 15 to 20%, emission was further reduced. This indicated that direct exertion of WCO in engines must be promoted, as it is an impressive choice for waste recapture.

1. Introduction

Rapid urbanization and continual growth of global population have increased energy requirements. This increase in energy requirements relates to human social, and economic, development, welfare, and health. Unlimited use of fossil fuels has led to global environmental degradation and health hazards [1]. The, and the demand and utilization of diesel, to be burnt in engines, has caused decrease in its reserves, the elevation of cost fluctuation, and a hike in environmental effluence and community health concerns [2,3]. The higher amount of consumption of energy has caused the utilization of higher quantities of fuels (mostly fossil fuels) and generation of higher risk factors to the environment. Changing to renewable energy sources would mitigate these problems by reducing the consumption of fossil fuels. Further, inexhaustible energy sources have the potential to meet future energy demands.

A study confirmed that waste cooking oil (WCO), from cooking or frying, is created in a considerable magnitude across the globe [4]. This study reported that almost 23 million tons of waste vegetable oil are produced from the food processing section in India (Food and Agricultural Organization of the United Nations) [5]. Moreover, dumping of waste cooking oil (WCO) has increased ecological concerns, which call for reprocessing or consumption allied with a financial inducement [6,7]. The findings confirmed that WCO transesterified to give biodiesel and was, consequently, analyzed for engine performance [8,9]. It was observed that there is inadequate literature related to the accessing of un-changed WCO as blend fuel with diesel for effluents classification and performance examination on its exploitation in a CI engine. The search for different cradlers of fuel for an IC engine was initiated first in the year 1893, when Rudolf Diesel assessed peanut oil as a fuel for engines [10]. The research work for alternating fuel oil has launched at several sites and the need to investigate this issue was acknowledged in 1930 and 1940, where vegetable oil from several edible sources was powered in engines [11]. On the basis of food-fuel certainty, second and third generation fuels replaced edible fuel sources in current eras [12,13]. The utilization of clean vegetable oil in engines resulted in its deposition on different engine parts, such as piston, and piston ring, and blocked the fuel injector because of extensive viscosity and the less volatile property of vegetable oil [14]. Despite diesel fuels releasing large fuel transformation productivity with unrivaled torque competency and stability, diesel engines were labeled as grubby, as they release the highest amounts of NOx and particulate emanations, considered hazardous for both the community and environment [15].

Unrefined oil backups are consistently decreasing at a level of 2.1% [16]. Consequently, the quest for an unconventional source to operate diesel engines that exhibits dynamic function in transference, energy production and heavy-duty gadgets began. Reprocessing is a specific feature for accomplishing ecological acceptability. Billions of gallons of waste cooking oil, generated from frequent frying of a broad range of foods in vegetable oil, are consistently junked [17]. Research in Japan indicated that 0.4 to 0.6 million tons of WCO are produced every year. However, just 0.25 to 0.26 million tons are collected for industrial use, and the rest is drained through kitchen sinks, which is not only damaging for the drainage system, but also puts a redundant burden on sewage systems. WCO has reached and affected aquatic ecology [18]. Mishandling and inappropriate dumping of this fluid waste (WCO) are allied with unfavorable ecological and health concerns [19,20]. Direct use of vegetable oil in compression ignition engines displays several difficulties, such as fuel strainer blockage, injector choking, carbon deposition in machine components, piston ring stabbing, lubrication oil clotting and extreme engine scratch [21,22,23]. WCO possesses high viscosity and causes trouble in compression ignition (CI) engines, such as in starting, low atomization at the time of injection, carbon settlings in the burning cylinder, bigger demand of energy to propel the fuel, filter plugging [24,25]. WCO has high viscosity and low volatility effects in deprived atomization.. Waste cooking oil is free from particulate matter and can be directly used as a fuel in internal combustion engines like diesel engines. Waste cooking oil as a fuel can provide better power output. Therefore, proper treatment of WCO is essential for using it as an unconventional fuel for CI engines. Techniques, such as pre-heating WCO or trans- -esterifying WCO to biodiesel, are commonly employed [26]. The proper treatment and reprocessing of WCO for use in diesel machines offer justifiable conclusions for environmental wellness and energy security [24]. The supplementary advantage of WCO is its low cost, costs being sustained in its accumulation and treatment only [22]. Preheating requires more energy expenses and depresses the gross efficacy of a unit. Trans-esterification of WCO to biodiesel is a time consuming, complicated and uneconomic method that generates glycerin as a derivative product which has to be constantly dumped wisely [27]. Presently, decompounding WCO with alcohols has received attention from various investigators as it is a modest, direct, and economical technique to lessen the viscidity of vegetable oils [28,29]. The application of WCO (without transesterification) in diesel mixtures has been rather less investigated. A few explorations described the preheating of WCO prior to blending with diesel [30]. Preheating decreases the viscosity and expands the spray property of the fuel. The amalgamation of alcohol to WCO-diesel blends lower its viscosity [31]. In order to achieve better miscibility and stability, the addition of higher alcohols as a co-solvent was proposed and showed promising potential regarding fuel properties in [32]. Studies have proven that ternary melds of WCO with diesel and alcohol have lower viscosity, fine cetane number and density closer to diesel. The importance of ternary compo-sites lies in the fact that they enhance atmosphere protection and energy security by partly swapping diesel with a reprocessed constituent, namely WCO and inexhaustible bio-derived elements like alcohol [33,34]. A ternary mixture comprising diesel (40%), biodiesel (30%) and pentanol (30%) produces sensible burning, performance and emanations. The obtained yield with 15–20% addition of n-pentanol with Calophyllum biodiesel/diesel blends in a DI diesel engine optimized emanations and performance in [35]. Krishnamoorthy et al., so as to find the optimum characteristics of engine oil used three bio-alcohols, namely, n-pentanol (Pe), n-butanol (Bu) and n-prponal (Pr), to form the following ternary blends: “D50-WCO30-Pr20”, “D50-WCO30-Bu20” and “D50-WCO30-Pe20”. They concluded that “D50-WCO30-Pe20” was the most suitable alcohol among all ternary blends [36].

The objective of this study was to investigate diesel engine performance and its exhaust emission characteristics fueled by diesel, waste cooking oil and n-pentanol. Waste cooking oil provides the advantages of its reduced raw material cost in contrast with fresh vegetable oil cost and eradicates the environmental impacts caused by its disposal. This work aims at investigating the impact of waste cooking oil percentage, in blends with diesel oil and n-pentanol, on the performance and emission characteristics of a single cylin der diesel engine. Diesel-WCO-Alcohol ternary blends deliver straightforward prospects as a substitute for diesel. Recently, reformulating waste cooking oil along with alcohols has caught the attention of researchers, as it is a straightforward and cheap method to decrease viscosity. Some studies showed that ternary blends of waste cooking oil with diesel and alcohol have low viscosity, improved cetane number and density closer to diesel. Only a minor share of these researchers has devoted themselves to the long-term endurance test, because this is more time-consuming.

Based on the above literature, an experimental study conducting a long-term durability test was carried out to investigate the performance and emissions behavior of blends in a single cylinder diesel engine.

2. Materials and Methods

WCO was collected from a nearby well-reputed restaurant to be used in our tests. In order to reduce the viscosity of the WCO, an additive named n-pentanol was found through a detailed literature survey. The blend samples were then sent to a university laboratory for characterization. The WCO had been principally utilized for frying activities in a temperature range of 130 and 180 °C. Prior to mixing, the oil was strained and warmed to eliminate any foodstuff and water dribbles. This was necessary to modify the strength of the mixtures, because diesel is water-abhorrent, and the occurrence of water may cause phase separation over a cycle of time. In order to filter WCO a 4 µm filter was used. Each test fuel blend (% vol) was prepared before the engine was fueled for operation. In this respect, all fuel components were mixed using the splash blending method, by employing a mechanical homogenizer machine for 30 min at 4000 rpm. Three mixtures were formed: (1) D95-WCO5 (95%vol. diesel, WCO5%vol. waste cooking oil, (2) D65-WCO20-Pe15 (65%vol. diesel, 20%vol. waste cooking oil, and 15%vol. n-pentanol) and (3) D60-WCO20-Pe20 (60%vol. diesel, 20%vol. waste cooking oil and 20%voil. n-pentanol). No surfactants, cetane refiners or cleaners were mixed in. Figure 1 represents the physical posture of the composites.

Figure 1.

Physical postures of test fuels (a) Diesel (b) DF95-WCO5 (c) D65-WCO2-0Pe15, and (d) D60-WCO20-Pe20.

Table 1 The characteristics of diesel, waste cooking oil and n-pentanol alcohol exploited in this experimental work.

Table 1.

Diesel, waste cooking oil and n-pentanol properties.

Different fuel samples were blended and prepared to investigate their effects on performance and emission characteristics. The qualities of diesel oil and their mixtures were weighed, as per ASTM guidelines. The calculated outcomes are expressed in Table 2.

Table 2.

Fuel Characterization.

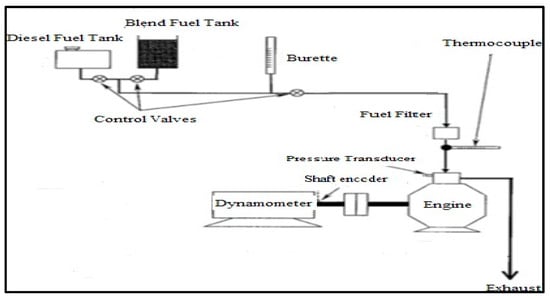

Engine Test Bed

Experiments were conducted on a single-cylinder, 4-stroke, water-cooled, direct-injection diesel engine (layout in Figure 2), which had been extensively exploited in the agronomic region to pull water toward irrigate grounds. Table 3 indicates the engine specifications. The measuring equipment was coupled with the testing setup to record various aspects of the experiments. The measuring equipment is concisely listed in Table 4. The experimental work was carried out at 1300 rpm and 1 Nm load at laboratory temperature to enhance the accuracy of measuring the performance and emission characteristics. Prior to measuring the characteristics, the engine was run for 10 min to ensure stability and then run for 8 h every day. However, each fuel sample was tested separately so as to measure stable and exact results. In order to determine emission characteristics, the details of the three instruments used are as follows. Testo 315-1 CO Measurement Means. Range, 0 to 2000 ppm, Accuracy, 10 ppm (0 to 100 ppm), Resolution, 1 ppm, Alarm limits, 50/100/500 ppm (factory setting). Testo 535 Sensor 2 channel infrared absorption principle, Measuring range, (0 to 9999 vol.% CO2), Accuracy, 0 to 5000 ppm, ± (75 ppm + 3% of m.v.) 5000 to 9999 ppm, ± (150 ppm + 5% of m.v.). AEROCET 531 Mass mode. Mass concentration Ranges, PM1, PM2.5, PM7 and PM10, Concentration Range, 0–1 mg/m3, Sample time-Mass Mode, 2 min. Particle Mode. Particle size Range, Two channals-0.5 and 5.0 µm, Concentration Range, 0–3,000,000 Particles per cubic foot (105,900 particles/L), Sample Time particle mode, 1 min, Accuracy, ±10%. Calibration aerosol. Sensitivity, 0.5 µm @ 2 to 1 peak to valley (JIS), 2 to 1 S/N Flow Rate: 0.1 cfm (2.83 lpm).

Figure 2.

Graphical illustration of experimental setup.

Table 3.

Engine specifications.

Table 4.

Engine instrument details.

The experiment was carried out at laboratory temperature to improve the reliability of the recordings. The engine always ran for 10 min to allow for stabilization before the readings were recorded. Each reading was repeated three times and the values were averaged to improve reliability.

3. Results and Discussion

3.1. Engine Performance

The engine performance was studied at steady state thermal stabilized conditions. As discussed earlier, research indicated the use of fossil fuels to biodiesel. Numerous biodiesel fuels were investigated as described previously, and their findings were also discussed. WCO was considered as an alternative fuel, and limited examination had been carried out to find the performance and emanation attributions. However, prior to use, a proper treatment of WCO was essential. The WCO in the make-up tank was preheated to approximately 40 °C to ensure that it was in liquid form. Simultaneously, the heating tank was heated to the intended test temperature. Therefore, a treated WCO was used, along with diesel fuel and n-pentanol, to investigate performance and emission attributions.

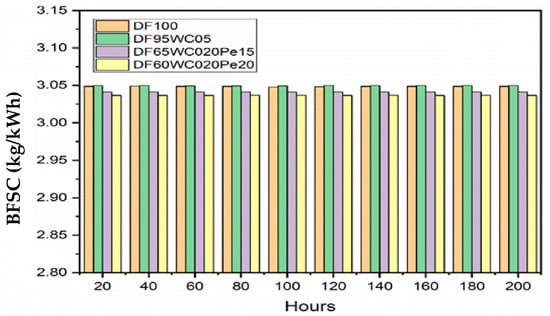

3.1.1. Brake Specific Fuel Consumption (BSFC)

Figure 3 shows the comparative analysis of all test blends with reference fuel. BSFC is influenced by three factors: (1) oxygen content of the additive. (2) Applicable yield power. (3) Engine speed. Once the oxygenated fuels were mixed with the diesel fuel, the BSFC rose because the amalgamation of such fuels with the diesel fuel indicated higher oxygen content that gave better perfect ignition [37]. While conducting experiments on the engine test bed with diesel fuel and WCO blends, the functioning acquired with diesel fuel was exploited as reference fuel. The outcomes agreed that the utilization of DF95-WCO5 as a fuel increased BSFC compared to diesel fuel under constant load and rpm. Moreover, the high viscosity of WCO and low volatility resulted in poor automation and vaporization. While blending WCO and n-pentanol with diesel oil, it was confirmed that BSFC decreased, as compared to diesel fuel. The BSFC parameter reflects how well the engine is working. After conducting endurance tests, the decreased fuel consumption for the ternary fuel blend was analyzed because an appropriate amount of oxygen in the fuel resulted in a lower heating value. The addition of n-Pentanol to DF95-WCO5 indicated improvement in the BSFC for both ternary mixtures. Investigation showed that the DF95-WCO5 blend had higher BSFC than diesel. However, with the addition of n-pentanol there was 15 to 20% improvement in BSFC results. The experimental results showed that the BSFC of the D95-WCO5 blend increased by 0.32%. However, with the addition of n-Pentanol as a ternary blend, DF65-WCO20-Pe15 and DF60-WCO20-Pe20 improved by 0.49% and 0.68%, respectively.

Figure 3.

Comparison of BSFC for all test fuels.

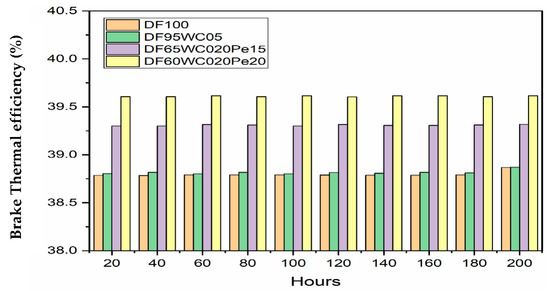

3.1.2. Brake Thermal Efficiency

In the investigation of n-pentanol/diesel mixtures of up to 25% in CI engines, the inclusion of pentanol to diesel could expand brake thermal efficiency (BTE), with a minor reduction in output power [38]. The consequences were attractive as the exploitation of this ternary blend heightened the BSFC and contracted BTE, in contrast with diesel fuel. Improved BSFC and enhanced BTE performance were also recorded in composites of WCO and petrol-diesel [39,40]. An experimental investigation carried out on a single cylinder diesel engine’s performance at uniform load and constant speed (rpm) for diesel oil and waste cooking oil mixtures was conducted at laboratory conditions. The experimental work showed that the insertion of waste cooking oil in diesel increased thermal efficiency as shown in Figure 4. However, with the addition of n-pentanol as a ternary blend, BTE further improved. Brake thermal efficiency of DF65-WCO20-Pe15 and DF60-WCO20-Pe20 blends was comparable to diesel fuel, due to improvement in atomization. It was observed that the binary blend of DF95-WCO5 had higher BTE, compared to Petroleum diesel, due to its high viscosity and density. Further investigation showed that the average brake thermal efficiency increased with the addition of n-Pentanol as a ternary blend. The experimental data indicated that BTE for DF95-WCO5 improved by 38.7%, while BTE for DF65-WCO20-Pe15 improved by 39.2% and for DF60-WCO20-Pe20 by 39.6%, respectively.

Figure 4.

Comparison of BTE for all test fuels.

3.2. Engine Emissions

Contamination is the induction of foreign particles in an ecosystem that brings un-certainty, disorder, affliction or disquiet to the environment i.e., physical systems or living creatures. Both SI and CI machines are equally responsible. The exhaust emissions cause problems like global warming, acid rain, smoke, respiratory and other health dangers. The foremost of these releases are due to non-stoichiometric burning. In the following section, emission characteristics from the experimental work are presented.

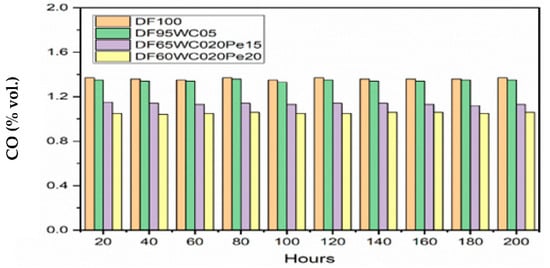

3.2.1. Carbon Monoxide (CO)

Carbon monoxide (CO) is a colorless and odorless gas. It is a toxic gas, as it confers itself to red blood cells, stopping the uptake of oxygen. It is formed when combustion reactions are incomplete, or the availability of oxygen is lower due to poor mixing [41]. Thermal combustion is the chief frequent source of carbon monoxide, yet there are several environmental and biological origins that produce and release an important quantity of carbon monoxide. It is poisonous and extremely dangerous in confined areas [28]. Factors that affect the air–fuel ratio, such as intake pressure temperature, engine operating conditions, and intake tube vacuum, all have an impact on the formation of CO. Figure 5 shows the test outcomes of CO emanation for diesel fuel and waste cooking oil blends with respect to engine running hours. From Figure 5, it can be clearly observed that CO emission for DF95-WCO5 increased, compared to diesel fuel, because of incomplete combustion of the fuel. Moreover, CO emission has been reported to be influenced by the saturation of the fatty acids and found to decrease as the saturation level increases. CO production developed due to burning in the absence of oxygen and reduced flame temperature. The high viscosity of WCO indicated poor spray characteristics, causing unburned fuel. Additionally, the usage of WCO in an engine involves lower air/fuel ratios than diesel fuel. The addition of WCO in diesel caused higher CO emissions while emulsifying it with n-pentanol as a ternary blend brought about lesser emissions of carbon monoxide. Therefore, from the results, the lowest level of CO emission was achieved when the engine was fueled with DF65-WCO20-Pe15 and DF60-WCO20-Pe20, due to the highest levels of saturation. Finally, the results showed that CO emissions of DF95-WCO5 (0.18%) decreased as compared to diesel fuel. However, DF65-WCO20-Pe15 (0.15%), andDF60-WCO20-Pe20 (0.14%) resulted in further decrease, compared to diesel fuel.

Figure 5.

Carbon monoxide emissions versus engine running hours.

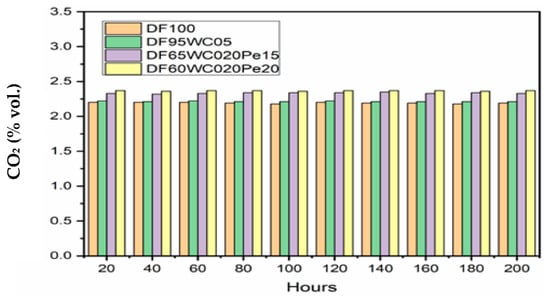

3.2.2. Carbon Dioxide (CO2)

This is one of the major pollutants in the atmosphere. Carbon dioxide is a colorless, odor-less nonflammable gas and is the most prominent greenhouse gas in Earth’s atmosphere [42]. Figure 6 shows CO2 with respect to engine running hours during the experimental work. It can be noted that the CO2 emissions increased with the addition of n-pentanol as additive. The carbon dioxide (CO2) emissions for using diesel and their blends as the engine test fuels were assessed at constant speed and the same throttle conditions. Experimental investigation showed that CO2 emissions with the addition of waste cooking oil as a binary blend were comparable to diesel fuel. This might have been due to higher kinematic viscosity, density and longer ignition delay of the WCO. Carbon dioxide is produced when complete combustion takes place. As WCO is highly viscous and dense n-pentanol alcohol was added as a ternary blend to reduce viscosity and density of blends to lead to complete combustion. Finally, the results showed that CO2 in the case of DF65-WCO20-Pe15 (0.511%) and DF60-WCO20-Pe20 (0.518%) increased compared to diesel fuel under the same operating conditions. However, the binary blend DF95-WCO5 showed an increase (0.48%) in comparison to diesel, due to inadequate combustion of fuel.

Figure 6.

Carbon dioxide emissions versus engine running hours.

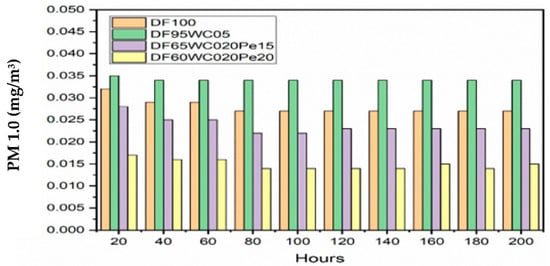

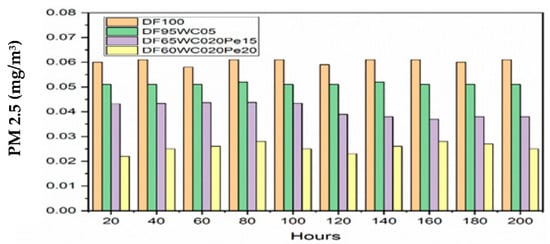

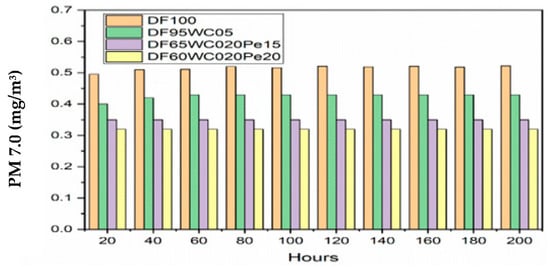

3.2.3. Particulate Matter (PM)

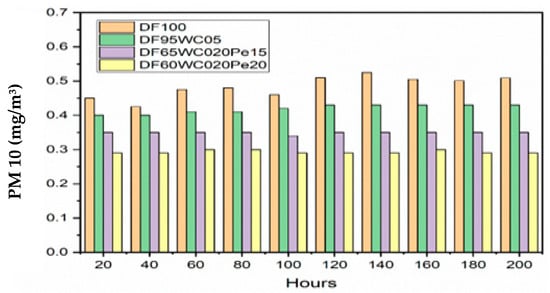

Particulate matter is a common term used to delineate a multifarious group of air toxins that differ in dimension and structure. Generally, there are two categories of particulate matter, one coarse particle (great than 2.5 mm) and the other are fine particles of less than 2.5 mm. Soot is a fine particulate. Figure 7 illustrates particulate matter emissions for diesel fuel and waste cooking oil blends with respect to engine running hours. PM at the exhaust decreased when using WCO, because of the presence of oxygen content in the oil, probably to let the soot form. PM effectively reduced the mass concentration of particulate matter [43]. The n-pentanol/diesel blend could more effectively inhibit the formation of elemental carbon and reduce the emission of particulate matter. When the blending ratio of the n-pentanol increased, the total particle amount reduced, due to a large decrease of 50 nm or more in the particle size. During experimental work, it could be observed that the DF95-WCO5 binary blend produced higher Particulate matter (PM-1, PM-2.5, PM-7 and PM-10) emissions compared to DF100.N-pentanol, which, containing oxygen, could provide more oxygen during the combustion process, reduce the local anoxic conditions in the cylinder, and suppress the formation of soot [44]. Furthermore, the C-O bond in the n-pentanol molecule has a higher bond energy, which reduces the formation of soot precursors and soot, and can reduce soot emissions. Moreover, with the addition of n-pentanol as a ternary blend in the ratio 15 to 20%, emission was further reduced. However, from Figure 7 and Figure 8 it can be observed that very minute variation occurred in the case of PM1.0 and PM2.5 emissions during 160 h to 200 h. This ess just because of the reduction in density and viscosity of the blends. The blend fuel droplets become comparatively smaller due to micro-explosions to consequently let complete burning occur. The micro-explosions cause the smaller fuel particles to interact easily with air for complete combustion and decreases the particulate matter generation without compromising combustion efficiency. The detailed results of particulate matter (PM-1, PM-2.5, PM-7 and PM-10) emissions of all test fuels can be observed in Figure 7, Figure 8, Figure 9 and Figure 10.

Figure 7.

Particulate emissions 1.0 (ppm) versus engine running hours.

Figure 8.

Particulate emission 2.5 (ppm) versus engine running hours.

Figure 9.

Particulate emission 7.0 (ppm) versus engine running hours.

Figure 10.

Particulate emission 10 (ppm) versus engine running hours.

3.3. Statistical Analysis

A statistical test is used to set the proper mechanism for quantitative decisions or to justify the results, as to whether results are as per hypothesis or generate an alternative hypothesis. The general linear regression model Equation (1) which accounts for the independent parameters with their interaction effects, was considered in this study:

where are the factors, where is the predicted response of the process (Production of blend fuel), n is the number of factors, is the intercept term, and are the linear and interactive coefficients, respectively.

where n is the number of points, where As are the predicted values, actual values, average values. RMSE is the value on the short-term performance of the correlations by comparing the deviations of the A’s. The R-square is a value determined by the As, where actual and predicted are discussed.

SM Method

The newly introduced numerical technique [45,46] is used in the mesh generation process for fast convergence. In this iterative method random step size is focused on the approximate solution and error analysis.

Regression Parameters

Coefficients (with 95% confidence bounds):

t1 = −4.533 × 10−22 (−1.326 × 10−61, 8.3651 × 10−22), t2 = 5.3532 × 10−18 (−1.19 × 10−17, 2.381 × 10−27)

t3 = −2.431 × 10−14 (−1.45 × 10−33, 7.15713 × 10−14), t4 = 6.667 × 10−11 (−2.12 × 10−10, 3.639 × 10−31)

t5 = −9.128 × 10−8 (−5.092 × 10−73, 4.0275 × 10−7), t6 = 7.242 × 10−5 (−0.000192, 0.000438)

t7 = −0.0014 × 10 (−0.2674, 0.225), t8 = 6.1112 × 10 (−54.21, 68.03), t9 = −386.002 × 10 (−5103, 4231)

Goodness of fit:

SSE = Sum of Square of Error: 2102

R-square (Square of Coefficient of Correlation): 0.9978

RMSE = Root Mean Square Error: 43.7918.

4. Conclusions

The conclusions were gathered from existing practical examinations to appraise performance and emission characteristics on a single cylinder water cooled horizontal type diesel engine operated with diesel, waste cooking oil and n-pentanol blends. The addition of n-pentanol improved diesel blending solubility and stability. The physical and chemical properties of D95-WCO5, DF65-WCO-20-Pe15 and DF60-WCO-20-Pe20 showed good potential to be used in CI engines, and the engine operated smoothly, without any defects, during the test.

- The experimental results showed that BSFC of the DF95-WCO5 blend improved 0.32%. However, with the addition of n-Pentanol as a ternary blend DF65-WCO20-Pe15 and DF60-WCO20-Pe20 increased by 0.49% and 0.68%, compared to diesel fuel, respectively.

- The experimental data showed that Brake thermal efficiency for DF95-WCO5 improved by 38.7%, while the BTEs for ternary blends were DF65-WCO20-Pe15 (39.2%) and DF60-WCO20-Pe20 (39.6%), respectively.

- CO measurements were DF65-WCO20-Pe15 (0.15%), and DF60-WCO20-Pe20 (0.14%), showing a decrease compared to diesel under the same engine operating conditions. However, the binary blend DF95WCO5 (0.18%) increased CO, compared to diesel, due to incomplete burning of fuel.

- Finally, the results showed that CO2 in the case of DF95-WCO5 (0.48%) improved, as compared to diesel fuel. However, the figures were DF65-WCO20-Pe15 (0.511%), and DF60-WCO20-Pe20 (0.518%), compared to diesel fuel.

- PM at the exhaust tended to decrease using WCO compared to petrol-diesel, due to the presence of oxygen content in the oil, probably to let the soot form. Sll test fuel blends produced Particulate matter due to improper combustion of fuel. However, with the addition of n-pentanol in the test fuels there was a decrease in concentration of particulate matter.

5. Future Scope

The ternary blends of diesel, waste cooking oil and n-pentanol offer better performance and emission characteristics than binary blends of diesel and waste cooking oil. In the addition of n-pentanol, less exhaust emissions occurred than for the binary blend and diesel fuel. Hence, more research on ternary blends of n-pentanol are required for different biofuels to use in future CI engines.

It was observed that renewable fuels provided good engine performance, and emissions. Furthermore, the utilization of waste cooking oil as a fuel requires its recapture and valorization in a smart mode. Finally, as it bypasses further physical-chemical treatments, direct use of WCO as a binary fuel with diesel and ternary blends with n-pentanol was preferable, since it showed minimum environmental impression. This indicated that direct consumption of WCO in engines ought to be encouraged as it signifies an efficacious choice for waste recovery to reduce dependency on fossil fuels in the future.

Author Contributions

Conceptualization, F.A.S., L.A.M. and M.R.L.; Data curation, A.A.B.; Formal analysis, F.A.S., Liaquat Ali, S.R.S., M.R.L. and A.A.B.; Investigation, F.A.S.; Methodology, Liaquat Ali, S.R.S. and M.R.L.; Project administration, S.R.S.; Software, A.M.A.; Supervision, A.A.B.; Writing—review & editing, A.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

We acknowledge and appreciate the Department of Mechanical Engineering, QUEST Nawabshah for permitting us to perform experimental work in Thermodynamics Laboratory.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| BSFC | Brake Specific Fuel Consumption |

| BTE | Brake Thermal Efficiency |

| CI | Compression ignition |

| DF | Diesel fuel |

| D95-WCO5 | 95%vol. diesel, WCO5%vol. waste cooking oil |

| D65-WCO20-Pe15 | 65%vol. diesel, 20%vol. waste cooking oil, and 15%vol. n-pentanol |

| D60-WCO20-Pe20 | 60%vol. diesel, 20%vol. waste cooking oil and 20%voil. n-pentanol |

| DI | Direct Injection |

| IC | Internal combustion |

| PM | Particulate Matter |

| RMSE | Root Mean Square Error |

| RMS | Root Mean Square |

| SI | Spark ignition |

| SM’s Method | Sanaullah Mastoi’s Method |

| WCO | Waste Cooking Oil |

References

- Debbarma, S.; Misra, R.D.; Das, B. Performance of graphene-added palm biodiesel in a diesel engine. Clean Technol. Environ. Policy 2020, 22, 523–534. [Google Scholar] [CrossRef]

- Dabi, M.; Saha, U.K. Application potential of vegetable oils as alternative to diesel fuels in compression ignition engines: A review. J. Energy Inst. 2019, 92, 1710–1726. [Google Scholar] [CrossRef]

- Capuano, D.; Costa, M.; Di Fraia, S.; Massarotti, N.; Vanoli, L. Direct use of waste vegetable oil in internal combustion engines. Renew. Sustain. Energy Rev. 2017, 69, 759–770. [Google Scholar] [CrossRef]

- Yesilyurt, M.K. The effects of the fuel injection pressure on the performance and emission characteristics of a diesel engine fuelled with waste cooking oil biodiesel-diesel blends. Renew. Energy 2018, 132, 649–666. [Google Scholar] [CrossRef]

- Food and Agricultural Organization of the United Nations. Oilseeds and Oils and Meals—Monthly Price updates Report; Food and Agricultural Organization of the United Nations: Rome, Italy, 2018. [Google Scholar]

- Charpe, T.W.; Rathod, V.K. Biodiesel production using waste frying oil. Waste Manag. 2011, 31, 85–90. [Google Scholar] [CrossRef]

- Majhi, S.; Ray, S. A study on production of biodiesel using a novel solid oxide catalyst derived from waste. Environ. Sci. Pollut. Res. 2015, 23, 9251–9259. [Google Scholar] [CrossRef]

- Can, Ö. Combustion characteristics, performance and exhaust emissions of a diesel engine fueled with a waste cooking oil biodiesel mixture. Energy Convers. Manag. 2014, 87, 676–686. [Google Scholar] [CrossRef]

- Murugesan, A.; Umarani, C.; Subramanian, R.; Nedunchezhian, N. Bio-diesel as an alternative fuel for diesel engines—A review. Renew. Sustain. Energy Rev. 2009, 13, 653–662. [Google Scholar] [CrossRef]

- Prabu, S.S.; Asokan, M.A.; Roy, R.; Francis, S.; Sreelekh, M.K. Performance, combustion and emission character-istics of diesel engine fueled with waste cooking oil bio-diesel or diesel blends with additives. Energy 2017, 122, 638–648. [Google Scholar] [CrossRef]

- Dey, P.; Ray, S. Valorization of waste vegetable oil (WVO) for utilization as diesel blends in CI engine—Performance and emission studies. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 1–14. [Google Scholar] [CrossRef]

- Murugesan, A.; Umarani, C.; Chinnusamy, T.; Krishnan, M.; Subramanian, R.; Neduzchezhain, N. Production and analysis of bio-diesel from non-edible oils—A review. Renew. Sustain. Energy Rev. 2009, 13, 825–834. [Google Scholar] [CrossRef]

- Ramadhas, A.S.; Jayaraj, S.; Muraleedharan, C. Use of vegetable oils as IC engine fuels—A review. Renew. Energy 2004, 29, 727–742. [Google Scholar] [CrossRef]

- Nigam, P.S.; Singh, A. Production of liquid biofuels from renewable resources. Prog. Energy Combust. Sci. 2011, 37, 52–68. [Google Scholar] [CrossRef]

- Thiyagarajan, S.; Geo, V.E.; Leenus, J.M.; Nagalingam, B. Experimental investigation to reduce CO2 emission in a single cylinder CI engine using low carbon fuel blend with Karanja oil methyl ester and amine injection in the exhaust manifold. Int. J. Glob. Warm. 2017, 13, 278–295. [Google Scholar] [CrossRef]

- Martin, M.L.J.; Geo, V.E.; Nagalingam, B. Effect of fuel inlet temperature on cottonseed oil–diesel mixture composition and performance in a DI diesel engine. J. Energy Inst. 2017, 90, 563–573. [Google Scholar] [CrossRef]

- Vallinayagam, R.; Vedharaj, S.; Yang, W.; Lee, P.; Chua, K.J.; Chou, S. Combustion performance and emission characteristics study of pine oil in a diesel engine. Energy 2013, 57, 344–351. [Google Scholar] [CrossRef]

- Varuvel, E.G.; Mrad, N.; Tazerout, M.; Aloui, F. Experimental analysis of biofuel as an alternative fuel for diesel engines. Appl. Energy 2012, 94, 224–231. [Google Scholar] [CrossRef]

- Misra, R.; Murthy, M. Straight vegetable oils usage in a compression ignition engine—A review. Renew. Sustain. Energy Rev. 2010, 14, 3005–3013. [Google Scholar] [CrossRef]

- Özener, O.; Yüksek, L.; Ergenç, A.T.; Özkan, M. Effects of soybean biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2014, 115, 875–883. [Google Scholar] [CrossRef]

- Diaz-Felix, W.; Riley, M.R.; Zimmt, W.; Kazz, M. Pretreatment of yellow grease for efficient production of fatty acid methyl esters. Biomass Bioenergy 2009, 33, 558–563. [Google Scholar] [CrossRef]

- Hribernik, A.; Kegl, B. Performance and Exhaust Emissions of an Indirect-Injection (IDI) Diesel Engine When Using Waste Cooking Oil as Fuel. Energy Fuels 2009, 23, 1754–1758. [Google Scholar] [CrossRef]

- Murayama, T.; Fujiwara, Y.; Nato, T. Evaluating waste vegetable oils as a diesel fuel. Proc. Inst. Mech. Eng. Part D: J Automob. Eng. 2000, 214, 141–148. [Google Scholar] [CrossRef]

- Kalam, M.; Masjuki, H.; Jayed, M.; Liaquat, A. Emission and performance characteristics of an indirect ignition diesel engine fuelled with waste cooking oil. Energy 2011, 36, 397–402. [Google Scholar] [CrossRef]

- Pugazhvadivu, M.; Jeyachandran, K. Investigations on the performance and exhaust emissions of a diesel engine using preheated waste frying oil as fuel. Renew. Energy 2005, 30, 2189–2202. [Google Scholar] [CrossRef]

- Senthil Kumar, M.; Jaikumar, M. A comprehensive study on performance, emission and combustion behavior of a com-pression ignition engine fuelled with WCO (waste cooking oil) emulsion as fuel. J. Energy Inst. 2014, 87, 263–271. [Google Scholar] [CrossRef]

- Atmanlı, A.; Yüksel, B.; Ileri, E. Experimental investigation of the effect of diesel–cotton oil–n-butanol ternary blends on phase stability, engine performance and exhaust emission parameters in a diesel engine. Fuel 2013, 109, 503–511. [Google Scholar] [CrossRef]

- Sharon, H.; Ram, P.J.S.; Fernando, K.J.; Murali, S.; Muthusamy, R. Fueling a stationary direct injection diesel engine with diesel-used palm oil–butanol blends—An experimental study. Energy Convers. Manag. 2013, 73, 95–105. [Google Scholar] [CrossRef]

- Lujaji, F.; Kristóf, L.; Bereczky, A.; Mbarawa, M. Experimental investigation of fuel properties, engine performance, combustion and emissions of blends containing croton oil, butanol, and diesel on a CI engine. Fuel 2011, 90, 505–510. [Google Scholar] [CrossRef]

- Atmanli, A.; İleri, E.; Yüksel, B. Experimental investigation of engine performance and exhaust emissions of a diesel engine fueled with diesel–n-butanol–vegetable oil blends. Energy Convers Manag. 2014, 81, 312–321. [Google Scholar] [CrossRef]

- Atmanli, A.; Ileri, E.; Yüksel, B. Effects of higher ratios of n-butanol addition to diesel–vegetable oil blends on performance and exhaust emissions of a diesel engine. J. Energy Inst. 2015, 88, 209–220. [Google Scholar] [CrossRef]

- Nour, M.; Attia, A.M.; Nada, S.A. Improvement of CI engine combustion and performance running on ternary blends of higher alcohol (Pentanol and Octanol)/hydrous ethanol/diesel. Fuel 2019, 251, 10–22. [Google Scholar] [CrossRef]

- Atmanli, A.; Ileri, E.; Yuksel, B.; Yilmaz, N. Extensive analyses of diesel–vegetable oil– n -butanol ternary blends in a diesel engine. Appl. Energy 2015, 145, 155–162. [Google Scholar] [CrossRef]

- Atmanli, A. Effects of a cetane improver on fuel properties and engine characteristics of a diesel engine fueled with the blends of diesel, hazelnut oil and higher carbon alcohol. Fuel 2016, 172, 209–217. [Google Scholar] [CrossRef]

- Atmanli, A. Comparative analyses of diesel–waste oil biodiesel and propanol, n-butanol or 1-pentanol blends in a diesel engine. Fuel 2016, 176, 209–215. [Google Scholar] [CrossRef]

- Krishnamoorthy, V.; Dhanasekaran, R.; Rana, D.; Saravanan, S.; Kumar, B.R. A comparative assessment of ternary blends of three bio-alcohols with waste cooking oil and diesel for optimum emissions and performance in a CI engine using response surface methodology. Energy Convers. Manag. 2018, 156, 337–357. [Google Scholar] [CrossRef]

- Imdadul, H.; Masjuki, H.; Kalam, M.; Zulkifli, N.; Alabdulkarem, A.; Rashed, M.; Teoh, Y.; How, H. Higher alcohol–biodiesel–diesel blends: An approach for improving the performance, emission, and combustion of a light-duty diesel engine. Energy Convers. Manag. 2016, 111, 174–185. [Google Scholar] [CrossRef]

- Atmanlı, A.; Yüksel, B.; Ileri, E.; Karaoglan, A.D. Response surface methodology based optimization of diesel–n-butanol –cotton oil ternary blend ratios to improve engine performance and exhaust emission characteristics. Energy Convers. Manag. 2015, 90, 383–394. [Google Scholar] [CrossRef]

- Rakopoulos, D.; Rakopoulos, C.; Giakoumis, E.; Dimaratos, A.; Kyritsis, D. Effects of butanol–diesel fuel blends on the performance and emissions of a high-speed DI diesel engine. Energy Convers. Manag. 2010, 51, 1989–1997. [Google Scholar] [CrossRef]

- Campos-Fernández, J.; Arnal, J.M.; Gómez, J.; Dorado, M.P. A comparison of performance of higher alcohols/diesel fuel blends in a diesel engine. Appl. Energy 2012, 95, 267–275. [Google Scholar] [CrossRef]

- Elumalai, P.V.; Parthasarathy, M.; Hariharan, V.; Jayakar, J.; Iqbal, S.M. Evaluation of water emulsion in biodiesel for engine performance and emission characteristics. J. Therm. Anal. 2021, 147, 4285–4301. [Google Scholar] [CrossRef]

- Lalvani, J.I.J.; Kirubhakaran, L.; Parthasarathy, M.; Sabarish, R.; Annamalai, K. Performance characteristics and emission analysis of a single cylinder diesel engine operated on blends of diesel and waste cooking oil. In Proceedings of the International Conference on IEEE Energy Efficient Technologies for Sustainability (ICEETS), Nagercoil, India, 10–12 April 2013. [Google Scholar]

- Wei, L.; Cheung, C.S.; Huang, Z. Effect of n-pentanol addition on the combustion, performance and emission characteristics of a direct-injection diesel engine. Energy 2021, 70 (Suppl. 01), 172–180. [Google Scholar] [CrossRef]

- Zhu, L.; Xiao, Y.; Cheung, C.; Guan, C.; Huang, Z. Combustion, gaseous and particulate emission of a diesel engine fueled with n-pentanol (C5 alcohol) blended with waste cooking oil biodiesel. Appl. Therm. Eng. 2016, 102, 73–79. [Google Scholar] [CrossRef]

- Mastoi, S.; Ganie, A.H.; Saeed, A.M.; Ali, U.; Rajput, U.A.; Othman, W.A.M. Numerical solution for two-dimensional partial differential equations using SM’s method. Open Phys. 2022, 20, 142–154. [Google Scholar] [CrossRef]

- Mastoi, S.; Kalhoro, N.B.; Mugheri, A.B.; Rajput, S.A.; Othman, W.A.M.; Nallasamy, K. A Simple Introduction to the SM’s Method. Sciencetech 2022, 3, 5–6. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).