Recent Advances in Fuel Additives and Their Spray Characteristics for Diesel-Based Blends

Abstract

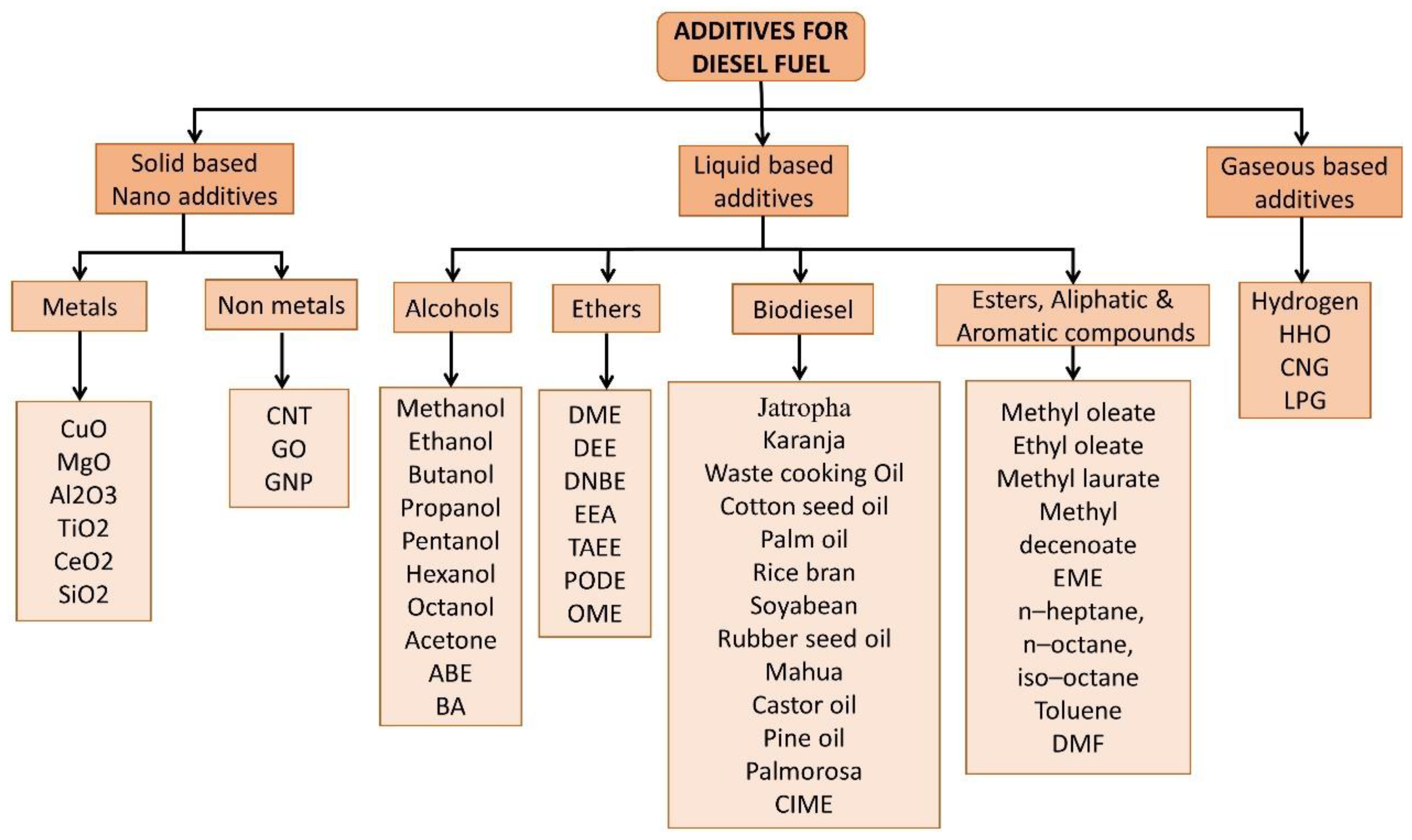

:1. Introduction

2. Alcohol Additives

2.1. Methanol

2.2. Ethanol

2.3. Propanol

2.4. Butanol

2.5. Pentanol

2.6. Octanol

2.7. Acetone-Butanol-Ethanol (ABE) Mixture

3. Ether Additives

3.1. DME and DEE

3.2. Dibutyl Ether (DBE)

3.3. PODE

4. Spray and Atomization of Biodiesel and Its Blends

| Sr. | Fuel name | Density kg/m3 | Viscosity at 40 °C (mm2/s) | Boiling Point °C | Lower Heating Value MJ/kg | Cetane Number | Flash Point °C |

|---|---|---|---|---|---|---|---|

| 1 | Diesel | 831 | 2.72 | 223 | 42.7 | 56 | 55 |

| 2 | Jatropha | 873 | 4.23 | 219 | 38.2–42.15 | 33.7–51 | 148 |

| 3 | Karanja | 880–890 | 4.37–9.6 | 316 | 34–38.8 | 45–67 | 170–205 |

| 4 | Mahua | 880–916 | 3.98–5.72 | - | 38.9 | 43.5 | 129–208 |

| 5 | Rubber seed oil | 910–930 | 34–76.4 | - | 37.5 | 37 | 37 |

| 6 | Cotton seed oil | 850–885 | 6–9.6 | 223 | 36.8 | 41.8 | 24 |

| 7 | Waste cooking Oil | 876 | 4.1 | 323 | 37.5 | 51 | 126 |

| 8 | Rapseed | 872–885 | 4.585–11 | 220 | 39.71 | 37.6 | 177–275 |

| 9 | Palm oil | 870–878.4 | 4.5–5.11 | 230 | 36.5 | 42 | 267 |

| 10 | Neem | 820 | 8.8 | - | 33.7–39.5 | 51 | 180 |

| 11 | Linseed | 920 | - | - | 37.7–39.8 | 28–35 | 241 |

| 12 | Pongamia | 866 | - | 316 | 36.5 | 51 | 172 |

| 13 | Calophylluminophyllum | 870 | - | N/A | 37.9 | 59.9 | 170 |

| 14 | Rice bran | 890 | - | 254 | 38.85 | - | 169 |

| 15 | Soyabean | 885–914 | - | 1.97 | 300 | 39.62 | 69–163 |

| 16 | Honne | 910 | - | 90.9 | 39.1 | 51 | 228 |

| 17 | COME | 872–885 | - | - | 70.1–40.8 | 45–60 | - |

| 18 | JOME | 862–886 | - | - | 37.2–43 | 43–59 | - |

| 19 | KOME | 865–898 | - | - | 36–42.1 | 36–61 | - |

| 20 | NOME | 820–942 | - | - | 39.6–40.2 | 51–53 | - |

| 21 | RSOME | 858–900 | - | - | 36.5–42.1 | 49–57 | - |

| 22 | ROME | 873 | - | - | 39.8 | 53 | - |

| 23 | LOME | 874–920 | - | - | 37.5–42.2 | 48–59 | - |

| 24 | MOME | 828–865 | - | - | 36.8–43 | 47–51 | - |

| Authors | Operating Conditions | Fuel Types | PL (mm) | SCA (°) | SMD (µm) | Area mm2/ Volume mm3 | Velocity (m/s) |

|---|---|---|---|---|---|---|---|

| Jatropha, Palm and waste cooking oil biodiesel blends [27] | Pinj = 70 MPa Pamb = 1.1 MPa Dinj = 200 Injection duration: 1 ms | JB5 JB10 JB20 JB50 JB100 PB5 PB10 PB20 PB50 PB100 WCB5 WCB10 WCB20 WCB50 WCB100 | 86.4 89.5 91.7 93.4 96.5 87 89.4 91.8 94.7 98.7 86.5 89.6 93 95 97.2 | 15 15.2 14.7 14.35 13.9 14.2 14 14.1 13.6 13.2 14.3 14.7 14.4 14.1 13.5 | - | - | 163 177 185 186.5 197 191 195 197 217 222 178 177 180 183 190 |

| Palm and cooked oil methyl esters [87] | Pinj = 70 MPa Pamb = 1.1 MPa Dinj = 160 μm Injection duration: 1.5 ms | BDFp BDFc | 87 83.5 | 11.9 14.1 | 16.8 15.08 | 465/5250 740/9200 | - |

| Biodiesel/diesel [102] | Pinj = 43 MPa Pamb = 0.1 MPa Dinj = 180 μm Injection duration: 1.6 ms | BD25 BD45 BD65 | 234 226 218 | 13.4 | - | - | - |

| Karanja biodiesel blends [88] | Pinj = 20MPa Pamb =0.9 MPa Dinj = 290 μm | KB5 KB20 KB100 | 140 132 127 | 17.3 18.12 18.8 | - | 3320 3300 2940 | - |

| Karanja biodiesel [98] | Pinj = 100 MPa Pamb = 2 MPa Dinj = 180 μm Injection duration: 1.6 ms | KB10 KB20 KB30 | 53.8 52.6 | - | - | 457 435 | - |

| Waste cooking oil biodiesel [99] | Pinj = 100 MPa Pamb = 3 MPa Dinj = 175 μm Tamb = 303 K | WCB20 WCB100 | 58.2 60 | 18.4 16.3 | - | 9000 8170 | 130,100 |

| Biodiesel/diesel [103] | Pinj = 80 MPa Pamb = 0.5 MPa Dinj = 300 μm Tamb = 293 K Injection duration: 1.6 ms | BD20 BD50 BD80 BD100 | 126 128 116 123 | 21.6 20.9 20.2 17.52 | - | 2350/4400 | - |

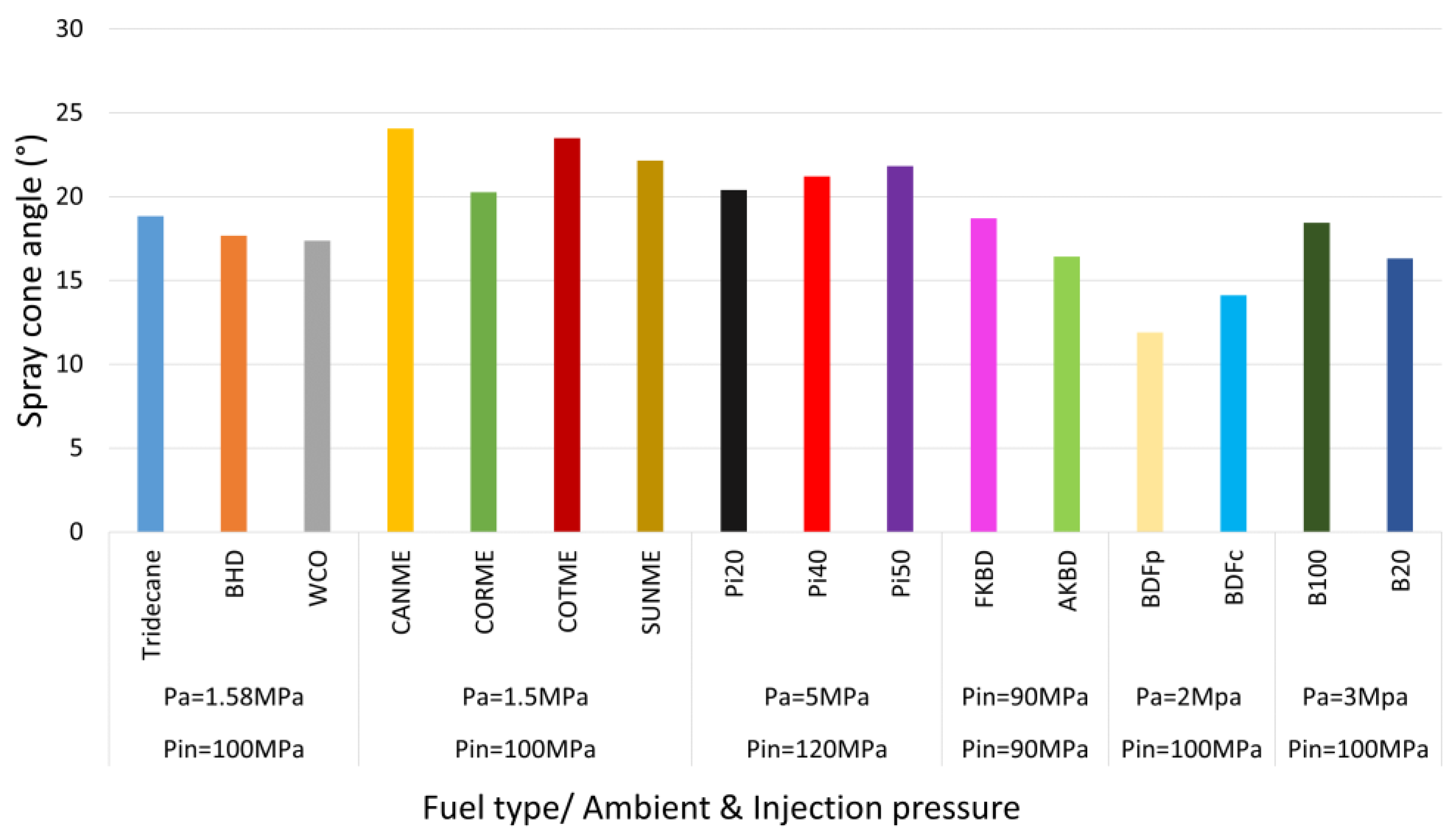

| Pine oil blend with diesel fuel [47] | Pinj = 120 MPa Pamb = 5 MPa Dinj = 170 μm Tamb = 373 K | Pi20 Pi40 Pi50 | 41 42.6 43 | 20.4 21.2 21.8 | - | - | - |

| Hydrogenated vegetable oil, Palm, Soy and used cooking oil methyl ester [95] | Pinj = 180 MPa Pamb = 7 MPa Dinj = 160 μm Tamb = 373 K Injection duration: 0.6 ms | HVO PME SME UCOME | 52 53.8 55.3 54.1 | 22.7 21.2 20.7 21.8 | - | 910 865 902 880 | - |

| Cotton seed biodiesel [48] | Pinj = 50 MPa Pamb = 0.1 MPa Tamb = 295 K Dinj = 180 µm Injection duration = 1.5 ms | BD | 280 | 7.56 | - | 118,000 | - |

| Waste cooking oil biodiesel [104] | Pinj = 12 MPa Pamb = 2 MPa Tamb = 303 K | B10 B20 B30 B50 B100 | - | 5.7 5 5.24 4.45 4.32 | - | 8650 8520 8180 7190 7100 | - |

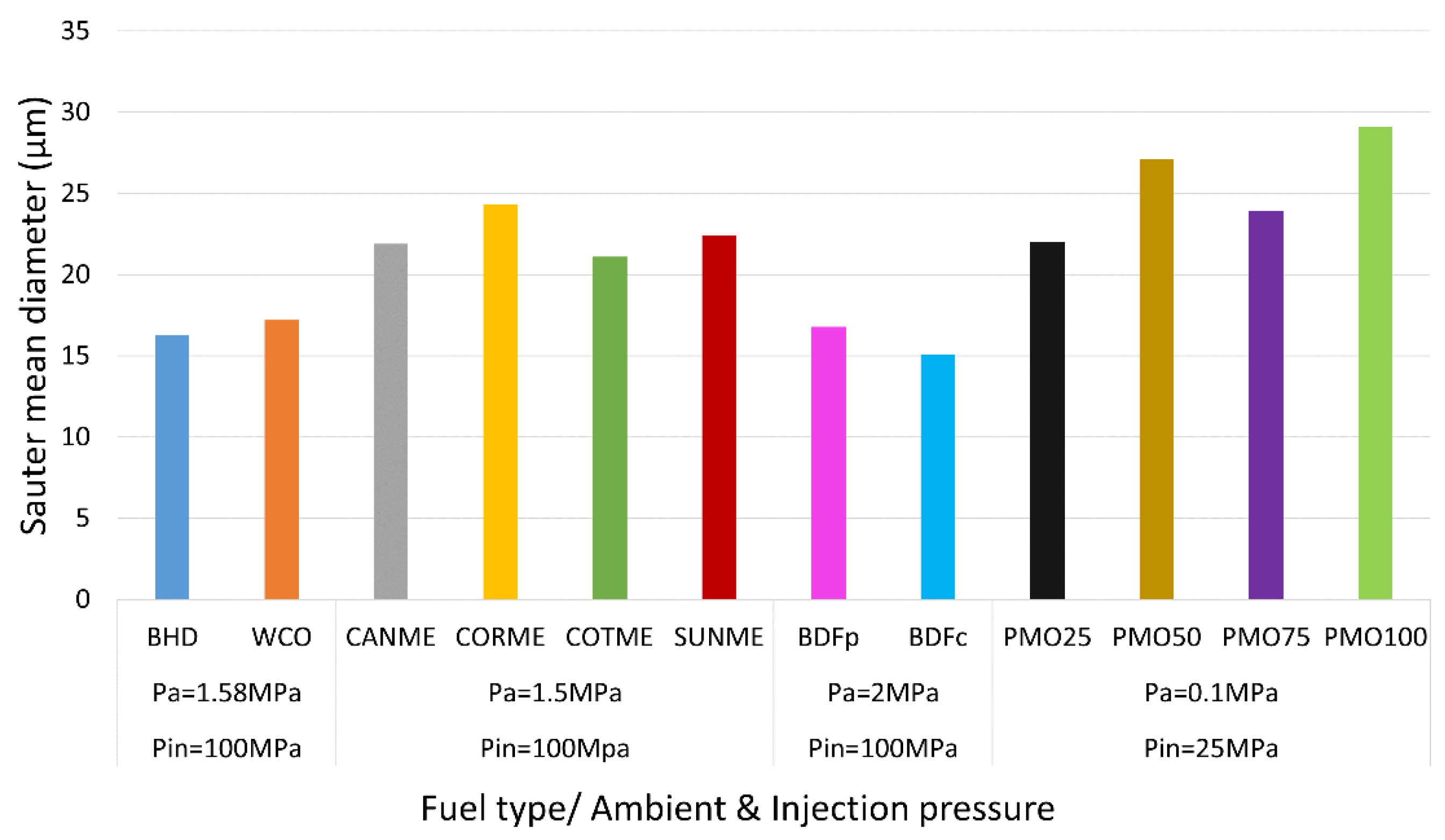

| Bio-hydro fined diesel/Waste cooking oil [99] | Pinj = 100 MPa Pamb = 1.58 MPa Tamb = 293 K Dinj = 123 μm FPS = 20,000 | BHD WCB | 53.8 57.4 | 17.7 17.38 | 16.3 17.2 | - | - |

| Karanja biodiesel/diesel blends [94] | Pinj = 90 MPa Pamb = 2 MPa Dinj = 149 FPS = 12,500 | FKBD AKBD | 60 57.5 | 18.7 16.4 | N/A | 465 442 | - |

| Palmorosa biodiesel/diesel blends [93] | Pinj = 25 MPa Pamb = 0.1 MPa Tamb = 300 K Dinj = 250 μm | PMO25 PMO50 PMO75 PMO100 | 55.7 56.5 60 66 | - | 22 27 24 29.1 | 22.3/2.9 20.9/3.6 19.8/3.8 18.2/3.9 | - |

| Canola, Corn, Cottonseed, and Sunflower methyl esters [92] | Pinj = 100 MPa Pamb = 1.5 MPa Tamb = 298 K Dinj = 200 μm | CANME CORME COTME SUNME | 70.2 70.8 68.7 69.5 | 24.07 20.26 23.48 22.154 | 21.9 24.3 21.1 22.4 | - | - |

5. Ester Fuels

6. Aliphatic Compound Additives

7. Aromatic Compound Additives

8. Nanoparticles

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Pin | Injection pressure | DNBE | Bi-n-butyl ether |

| Pa | Ambient pressure | EEA | Ethoxy ethyl acetate |

| PIV | Particle image velocimetry | PODE | Polyoxymethylene dimethyl ether |

| PDPA | Phase Doppler Particle Anemometry | OMEx | Oxyethylene Ethers |

| ID | Ignition delay | JB | Jatropha biodiesel |

| CN | Cetane number | KB | Karanja biodiesel |

| CI | Compression ignition | PB | Palm biodiesel |

| DI | Direct injection | Pi | Pine Biodiesel |

| CVV | Constant volume-vessel | WCB | Waste cooking oil biodiesel |

| PLIF | Planar laser induced fluorescence | EBD | Emulsified Castor oil biodiesel |

| PL | Penetration length | CBD | Castor oil biodiesel |

| SPA | Spray projected area | FKBD | Fresh Karanja biodiesel |

| SCA | Spray cone angle | AKBD | Aged Karanja biodiesel |

| SMD | Sauter mean diameter | PMO | Palmorosa biodiesel |

| FIP | Fuel injection pressure | ML | Methyl laurate |

| IBE | isopropanol-butanol-ethanol | MO | Methyl oleate |

| BA | Butanol acetone mixture | EO | Ethyl oleate |

| HVO /H | Hydrogenated vegetable oil | PME | Palm oil biodiesel |

| M | Methanol | SME | Soybean biodiesel |

| E | Ethanol | EME20 | Emulsified waste oil methyl ester |

| B | Butanol | DMF | 2-5 di methyl furan |

| P | Pentanol | UCOME | Used cooking oil biodiesel |

| BD | Biodiesel | BHD | Bio hydro diesel |

| D | Diesel | NH | n-heptane |

| OC | Octanol | WME | Waste oil methyl ester |

| D100 | Neat diesel | CORME | Corn biodiesel |

| BD100 | Neat biodiesel | COTME | Cottonseed biodiesel |

| DEE | Di ethyl ether | SUNME | Sunflower biodiesel |

| DME | Di methyl ether | CANME | Canola oil biodiesel |

| NF2 | GTL, 1 wt% of Al2O3 | OME1 | 100% methylal |

| CNT | Carbo nanotubes | RSO100 | Rapeseed biodiesel |

| G | Gasoline | GTL | Gas to liquid fuel |

| Ce | Cerium oxide nano particles | NF4 | GTL, 4 wt% of Al2O3 |

References

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, A.; Badruddin, I.; Banapurmath, N.; Akram, N. The effect of nano-additives in diesel-biodiesel fuel blends: A comprehensive review on stability, engine performance and emission characteristics. Energy Convers. Manag. 2018, 178, 146–177. [Google Scholar] [CrossRef]

- Kegl, T.; Kralj, A.K.; Kegl, B.; Kegl, M. Nanomaterials as fuel additives in diesel engines: A review of current state, opportunities, and challenges. Prog. Energy Combust. Sci. 2021, 83, 100897. [Google Scholar] [CrossRef]

- Lee, M.-Y.; Lee, G.-S.; Kim, C.-J.; Seo, J.-H.; Kim, K.-H. Macroscopic and Microscopic Spray Characteristics of Diesel and Gasoline in a Constant Volume Chamber. Energies 2018, 11, 2056. [Google Scholar] [CrossRef] [Green Version]

- Damanik, N.; Ong, H.C.; Tong, C.W.; Mahlia, T.M.I.; Silitonga, A.S. A review on the engine performance and exhaust emission characteristics of diesel engines fueled with biodiesel blends. Environ. Sci. Pollut. Res. 2018, 25, 15307–15325. [Google Scholar] [CrossRef] [PubMed]

- Kirubakaran, M.; Selvan, V.A.M. A comprehensive review of low cost biodiesel production from waste chicken fat. Renew. Sustain. Energy Rev. 2018, 82, 390–401. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, M. Long term storage stability of Jatropha curcas biodiesel. Energy 2011, 36, 5409–5415. [Google Scholar] [CrossRef]

- Obadiah, A.; Kannan, R.; Ramasubbu, A.; Kumar, S.V. Studies on the effect of antioxidants on the long-term storage and oxidation stability of Pongamia pinnata (L.) Pierre biodiesel. Fuel Process. Technol. 2012, 99, 56–63. [Google Scholar] [CrossRef]

- Karavalakis, G.; Hilari, D.; Givalou, L.; Karonis, D.; Stournas, S. Storage stability and ageing effect of biodiesel blends treated with different antioxidants. Energy 2011, 36, 369–374. [Google Scholar] [CrossRef]

- Fazal, M.; Haseeb, A.; Masjuki, H. Biodiesel feasibility study: An evaluation of material compatibility; performance; emission and engine durability. Renew. Sustain. Energy Rev. 2011, 15, 1314–1324. [Google Scholar] [CrossRef]

- Agarwal, A.; Das, L.M. Biodiesel Development and Characterization for Use as a Fuel in Compression Ignition Engines. J. Eng. Gas Turbines Power 2001, 123, 440–447. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Cho, H.M.; Masjuki, H.H.; Kalam, M.A.; Farooq, M.; Soudagar, M.E.M.; Gul, M.; Ahmed, W.; Afzal, A.; Bashir, S. Effect of alcoholic and nano-particles additives on tribological properties of diesel–palm–sesame–biodiesel blends. Energy Rep. 2021, 7, 1162–1171. [Google Scholar] [CrossRef]

- Gopinath, S.; Devan, P.; Sabarish, V.; Babu, B.S.; Sakthivel, S.; Vignesh, P. Effect of spray characteristics influences combustion in DI diesel engine—A review. Mater. Today Proc. 2020, 33, 52–65. [Google Scholar] [CrossRef]

- Martínez-Martínez, S.; Sánchez-Cruz, F.A.; Riesco-Ávila, J.M.; Gallegos-Muñoz, A.; Aceves, S.M. Liquid penetration length in direct diesel fuel injection. Appl. Therm. Eng. 2008, 28, 1756–1762. [Google Scholar] [CrossRef]

- Fang, T.; Lin, Y.-C.; Foong, T.M.; Lee, C.-F. Biodiesel combustion in an optical HSDI diesel engine under low load premixed combustion conditions. Fuel 2009, 88, 2154–2162. [Google Scholar] [CrossRef]

- Fang, T.; Lee, C.-F.F. Bio-diesel effects on combustion processes in an HSDI diesel engine using advanced injection strategies. Proc. Combust. Inst. 2009, 32, 2785–2792. [Google Scholar] [CrossRef]

- Soid, S.; Zainal, Z. Spray and combustion characterization for internal combustion engines using optical measuring techniques—A review. Energy 2011, 36, 724–741. [Google Scholar] [CrossRef]

- Bougie, B.; Tulej, M.; Dreier, T.; Dam, N.J.; Ter Meulen, J.J.; Gerber, T. Optical diagnostics of diesel spray injections and combustion in a high-pressure high-temperature cell. Appl. Phys. B 2005, 80, 1039–1045. [Google Scholar] [CrossRef] [Green Version]

- Merola, S.S.; Marchitto, L.; Corcione, F.; Valentino, G.; Tornatore, C. Optical Diagnostics of the Pollutant Formation in a CI Engine Operating with Diesel Fuel Blends. SAE Int. J. Engines 2011, 4, 2543–2558. [Google Scholar] [CrossRef]

- Li, F.; Fu, W.; Yi, B.; Song, L.; Liu, T.; Wang, X.; Wang, C.; Lei, Y.; Lin, Q. Comparison of macroscopic spray characteristics between biodiesel-pentanol blends and diesel. Exp. Therm. Fluid Sci. 2018, 98, 523–533. [Google Scholar] [CrossRef]

- Nishida, K.; Tian, J.; Sumoto, Y.; Long, W.; Sato, K.; Yamakawa, M. An experimental and numerical study on sprays injected from two-hole nozzles for DISI engines. Fuel 2009, 88, 1634–1642. [Google Scholar] [CrossRef]

- Xu, Z.; Duan, X.; Liu, Y.; Deng, B.; Liu, J. Spray combustion and soot formation characteristics of the acetone-butanol-ethanol/diesel blends under diesel engine-relevant conditions. Fuel 2020, 280, 118483. [Google Scholar] [CrossRef]

- Bang, S.H.; Lee, C.S. Fuel injection characteristics and spray behavior of DME blended with methyl ester derived from soybean oil. Fuel 2010, 89, 797–800. [Google Scholar] [CrossRef]

- Fansler, T.D.; Parrish, S.E. Spray measurement technology: A review. Meas. Sci. Technol. 2014, 26, 012002. [Google Scholar] [CrossRef]

- Kashdan, J.T.; Shrimpton, J.; Whybrew, A. A digital image analysis technique for quantitative characterisation of high-speed sprays. Opt. Lasers Eng. 2007, 45, 106–115. [Google Scholar] [CrossRef]

- Desantes, J.M.; Payri, R.; García, A.; Manin, J. Experimental Study of Biodiesel Blends’ Effects on Diesel Injection Processes. Energy Fuels 2009, 23, 3227–3235. [Google Scholar] [CrossRef]

- Chen, P.-C.; Wang, W.-C.; Roberts, W.L.; Fang, T. Spray and atomization of diesel fuel and its alternatives from a single-hole injector using a common rail fuel injection system. Fuel 2012, 103, 850–861. [Google Scholar] [CrossRef]

- Gao, Y.; Deng, J.; Li, C.; Dang, F.; Liao, Z.; Wu, Z.; Li, L. Experimental study of the spray characteristics of biodiesel based on inedible oil. Biotechnol. Adv. 2009, 27, 616–624. [Google Scholar] [CrossRef] [PubMed]

- Song, L.B.; Lin, Q.Z.; Xie, Y.Z.; Hu, H.W.; Pi, D.; Xu, S.M.; Hu, H.Q. Experimental Study of the Spray Characteristics of Diesohol Fuel using a High-Pressure Common-Rail Injection System in a Diesel Engine. Energy Technol. 2015, 3, 896–905. [Google Scholar] [CrossRef]

- Nilaphai, O.; Hespel, C.; Chanchaona, S.; Mounaïm-Rousselle, C. Spray and combustion characterizations of ABE/Dodecane blend in comparison to alcohol/Dodecane blends at high-pressure and high-temperature conditions. Fuel 2018, 225, 542–553. [Google Scholar] [CrossRef]

- Liu, J.; Feng, L.; Wang, H.; Zheng, Z.; Chen, B.; Zhang, D.; Yao, M. Spray characteristics of gasoline/PODE and diesel/PODE blends in a constant volume chamber. Appl. Therm. Eng. 2019, 159, 113850. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, H.; Jiang, C.; Wyszynski, M.L. Experimental study on microscopic and macroscopic characteristics of diesel spray with split injection. Fuel 2016, 174, 140–152. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Y.; Wang, C.; Xu, H.; Wyszynski, M.L. Experimental study on primary breakup of diesel spray under cold start conditions. Fuel 2016, 183, 617–626. [Google Scholar] [CrossRef]

- Bhatia, L.; Johri, S.; Ahmad, R. An economic and ecological perspective of ethanol production from renewable agro waste: A review. AMB Express 2012, 2, 65. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abou-Rachid, H.; El Marrouni, K.; Kaliaguine, S. DFT studies of the hydrogen abstraction from primary alcohols by O2 in relation with cetane number data. J. Mol. Struct. THEOCHEM 2003, 631, 241–250. [Google Scholar] [CrossRef]

- Hansen, A.C.; Zhang, Q.; Lyne, P.W.L. Ethanol–diesel fuel blends—A review. Bioresour. Technol. 2005, 96, 277–285. [Google Scholar] [CrossRef]

- Suh, H.K.; Lee, C.S. Experimental and analytical study on the spray characteristics of dimethyl ether (DME) and diesel fuels within a common-rail injection system in a diesel engine. Fuel 2008, 87, 925–932. [Google Scholar] [CrossRef]

- Walther, T.; François, J.M. Microbial production of propanol. Biotechnol. Adv. 2016, 34, 984–996. [Google Scholar] [CrossRef] [PubMed]

- Phillips, J.R.; Atiyeh, H.K.; Tanner, R.S.; Torres, J.R.; Saxena, J.; Wilkins, M.R.; Huhnke, R.L. Butanol and hexanol production in Clostridium carboxidivorans syngas fermentation: Medium development and culture techniques. Bioresour. Technol. 2015, 190, 114–121. [Google Scholar] [CrossRef]

- Imdadul, H.K.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Alabdulkarem, A.; Rashed, M.M.; Teoh, Y.H.; How, H.G. Higher alcohol–biodiesel–diesel blends: An approach for improving the performance, emission, and combustion of a light-duty diesel engine. Energy Convers. Manag. 2016, 111, 174–185. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, X.; Gu, G.; Hu, H.; Liu, T.; Huang, Z. Experimental study of the spray characteristics of USLD, methanol and DME on the swirl nozzle of a Stirling engine. Fuel Process. Technol. 2014, 119, 1–9. [Google Scholar] [CrossRef]

- Ghosh, A.; Ravikrishna, R. Evaporating spray characteristics of methanol-in-diesel emulsions. Fuel 2020, 290, 119730. [Google Scholar] [CrossRef]

- Zhan, C.; Feng, Z.; Ma, W.; Zhang, M.; Tang, C.; Huang, Z. Experimental investigation on effect of ethanol and di-ethyl ether addition on the spray characteristics of diesel/biodiesel blends under high injection pressure. Fuel 2018, 218, 1–11. [Google Scholar] [CrossRef]

- Bao, L.; Fu, W.; Li, F.; Liu, Y.; Bi, H.; Jiang, C.; Lin, Q. Experiments on macroscopic spray characteristics of diesel-ethanol with dispersed cerium nanoparticles. J. Energy Inst. 2020, 93, 2186–2196. [Google Scholar] [CrossRef]

- Geng, L.; Bi, L.; Li, Q.; Chen, H.; Xie, Y. Experimental study on spray characteristics, combustion stability, and emission performance of a CRDI diesel engine operated with biodiesel–ethanol blends. Energy Rep. 2021, 7, 904–915. [Google Scholar] [CrossRef]

- Yu, Y. Experimental study on effects of ethanol-diesel fuel blended on spray characteristics under ultra-high injection pressure up to 350 MPa. Energy 2019, 186, 115768. [Google Scholar] [CrossRef]

- Lee, T.H.; Hansen, A.C.; Li, G.; Lee, T. Effects of isopropanol-butanol-ethanol and diesel fuel blends on combustion characteristics in a constant volume chamber. Fuel 2019, 254, 115613. [Google Scholar] [CrossRef]

- Huang, H.; Liu, Q.; Shi, C.; Wang, Q.; Zhou, C. Experimental study on spray, combustion and emission characteristics of pine oil/diesel blends in a multi-cylinder diesel engine. Fuel Process. Technol. 2016, 153, 137–148. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P.; Yusaf, T.; Al-Lwayzy, S. Butanol–acetone mixture blended with cottonseed biodiesel: Spray characteristics evolution, combustion characteristics, engine performance and emission. Proc. Combust. Inst. 2019, 37, 4729–4739. [Google Scholar] [CrossRef]

- Mo, J.; Tang, C.; Li, J.; Guan, L.; Huang, Z. Experimental investigation on the effect of n-butanol blending on spray characteristics of soybean biodiesel in a common-rail fuel injection system. Fuel 2016, 182, 391–401. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P.; Yusaf, T. The Impact of Injector Hole Diameter on Spray Behaviour for Butanol-Diesel Blends. Energies 2018, 11, 1298. [Google Scholar] [CrossRef]

- Li, F.; Yi, B.; Fu, W.; Song, L.; Liu, T.; Hu, H.; Lin, Q. Experimental study on spray characteristics of long-chain alcohol-diesel fuels in a constant volume chamber. J. Energy Inst. 2019, 92, 94–107. [Google Scholar] [CrossRef]

- Zhang, T.; Andersson, M.; Munch, K.; Denbratt, I. Optical Diagnostics of Spray Characteristics and Soot Volume Fractions of n-butanol, n-octanol, Diesel, and Hydrotreated Vegetable Oil Blends in a Constant Volume Combustion Chamber; Technical Paper; SAE: Warrendale, PA, USA, 2019; 2019-01-0019. [Google Scholar]

- Pan, M.; Huang, R.; Liao, J.; Jia, C.; Zhou, X.; Huang, H.; Huang, X. Experimental study of the spray, combustion, and emission performance of a diesel engine with high n-pentanol blending ratios. Energy Convers. Manag. 2019, 194, 1–10. [Google Scholar] [CrossRef]

- Ma, Y.; Huang, S.; Huang, R.; Zhang, Y.; Xu, S. Spray and evaporation characteristics of n-pentanol–diesel blends in a constant volume chamber. Energy Convers. Manag. 2016, 130, 240–251. [Google Scholar] [CrossRef]

- Tian, J.; Liu, Y.; Li, F.; Han, K.; Zhou, W.; Lin, Q.; Meng, K. Experimental study on spray characteristics of octanol biodiesel and modification of spray tip penetration model. Phys. Fluids 2021, 33, 091902. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P.; Yusaf, T.; Hamawand, I. Production and application of ABE as a biofuel. Renew. Sustain. Energy Rev. 2018, 82, 1195–1214. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P.; Yusaf, T.; Hamawand, I. The impact of n-butanol and iso-butanol as components of butanol-acetone (BA) mixture-diesel blend on spray, combustion characteristics, engine performance and emission in direct injection diesel engine. Energy 2017, 140, 1074–1086. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P. Comparative Assessment of Spray Behavior, Combustion and Engine Performance of ABE-Biodiesel/Diesel as Fuel in DI Diesel Engine. Energies 2020, 13, 6521. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, F.; Han, K.; Yang, B.; Song, G. Evaporation characteristics of acetone–butanol–ethanol and diesel blends droplets at high ambient temperatures. Fuel 2015, 160, 43–49. [Google Scholar] [CrossRef]

- Wu, H.; Nithyanandan, K.; Lee, T.H.; Lee, C.-F.F.; Zhang, C. Spray and Combustion Characteristics of Neat Acetone-Butanol-Ethanol, n-Butanol, and Diesel in a Constant Volume Chamber. Energy Fuels 2014, 28, 6380–6391. [Google Scholar] [CrossRef]

- Huang, H.; Guo, X.; Huang, R.; Li, J.; Pan, M.; Chen, Y.; Pan, X. Assessment of n-pentanol additive and EGR rates effects on spray characteristics, energy distribution and engine performance. Energy Convers. Manag. 2019, 202, 112210. [Google Scholar] [CrossRef]

- Weber de Menezes, E.; da Silva, R.; Cataluña, R.; Ortega, R.J.C. Effect of ethers and ether/ethanol additives on the physicochemical properties of diesel fuel and on engine tests. Fuel 2006, 85, 815–822. [Google Scholar] [CrossRef]

- Tuan Hoang, A.; Nižetić, S.; Viet Pham, V.; Tuan Le, A.; Ga Bui, V.; Vang Le, V. Combustion and emission characteristics of spark and compression ignition engine fueled with 2,5-dimethylfuran (DMF): A comprehensive review. Fuel 2021, 288, 119757. [Google Scholar] [CrossRef]

- Sezer, I. Thermodynamic, performance and emission investigation of a diesel engine running on dimethyl ether and diethyl ether. Int. J. Therm. Sci. 2011, 50, 1594–1603. [Google Scholar] [CrossRef]

- Awad, O.I.; Ma, X.; Kamil, M.; Ali, O.M.; Ma, Y.; Shuai, S. Overview of polyoxymethylene dimethyl ether additive as an eco-friendly fuel for an internal combustion engine: Current application and environmental impacts. Sci. Total Environ. 2020, 715, 136849. [Google Scholar] [CrossRef]

- Kerschgens, B.; Cai, L.; Pitsch, H.; Heuser, B.; Pischinger, S. Di-n-buthylether, n-octanol, and n-octane as fuel candidates for diesel engine combustion. Combust. Flame 2016, 163, 66–78. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, C.S. Applicability of dimethyl ether (DME) in a compression ignition engine as an alternative fuel. Energy Convers. Manag. 2014, 86, 848–863. [Google Scholar] [CrossRef]

- Cipolat, D.; Valentim, D. Comparison of theoretical and experimental diesel and DME injection spray characteristics. Fuel Process. Technol. 2013, 107, 36–43. [Google Scholar] [CrossRef]

- Ying, W.; Genbao, L.; Wei, Z.; Longbao, Z. Study on the application of DME/diesel blends in a diesel engine. Fuel Process. Technol. 2008, 89, 1272–1280. [Google Scholar] [CrossRef]

- Kim, M.Y.; Bang, S.H.; Lee, C.S. Experimental Investigation of Spray and Combustion Characteristics of Dimethyl Ether in a Common-Rail Diesel Engine. Energy Fuels 2007, 21, 793–800. [Google Scholar] [CrossRef]

- Yang, J.; Lim, O. An investigation of the spray characteristics of diesel-DME blended fuel with variation of ambient pressure in a constant volume combustion chamber. J. Mech. Sci. Technol. 2014, 28, 2363–2368. [Google Scholar] [CrossRef]

- Suh, H.K.; Park, A.S.W.; Lee, C.S. Atomization Characteristics of Dimethyl Ether Fuel as an Alternative Fuel Injected through a Common-Rail Injection System. Energy Fuels 2006, 20, 1471–1481. [Google Scholar] [CrossRef]

- Youn, I.M.; Park, S.H.; Roh, H.G.; Lee, C.S. Investigation on the fuel spray and emission reduction characteristics for dimethyl ether (DME) fueled multi-cylinder diesel engine with common-rail injection system. Fuel Process. Technol. 2011, 92, 1280–1287. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, S.; Guo, X.; Jia, C.; Huang, X.; Wang, Y.; Huang, H. Experimental Research on the Macroscopic and Microscopic Spray Characteristics of Diesel-PODE3-4 Blends. Energies 2021, 14, 5559. [Google Scholar] [CrossRef]

- Guan, L.; Tang, C.; Yang, K.; Mo, J.; Huang, Z. Effect of di-n-butyl ether blending with soybean-biodiesel on spray and atomization characteristics in a common-rail fuel injection system. Fuel 2014, 140, 116–125. [Google Scholar] [CrossRef]

- Liu, Y.; Li, F.; Fu, W.; Jiang, X.; Song, Z.; Zhu, Z.; Lin, Q. Experimental Investigation of Effects of Di-N-Butyl Ether Addition on Spray Macroscopic Characteristics of Diesel-Biodiesel Blends. J. Energy Eng. 2019, 145, 04019028. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, J.; Li, F.; Han, K.; Bao, L.; Zhou, W.; Lin, Q. Spray characteristics of biodiesel-polyoxymethylene dimethyl ethers (PODE) blends in a constant volume chamber. Combust. Sci. Technol. 2022, 1–23. [Google Scholar] [CrossRef]

- Kim, W.I.; Lee, K.; Lee, C.S. Spray and atomization characteristics of isobutene blended DME fuels. J. Nat. Gas Sci. Eng. 2015, 22, 98–106. [Google Scholar] [CrossRef]

- Fu, W.; Li, F.; Meng, K.; Liu, Y.; Shi, W.; Lin, Q. Experiment and analysis of spray characteristics of biodiesel blending with di-n-butyl ether in a direct injection combustion chamber. Energy 2019, 185, 77–89. [Google Scholar] [CrossRef]

- Li, D.; Gao, Y.; Liu, S.; Ma, Z.; Wei, Y. Effect of polyoxymethylene dimethyl ethers addition on spray and atomization characteristics using a common rail diesel injection system. Fuel 2016, 186, 235–247. [Google Scholar] [CrossRef]

- Lin, Y.-S.; Lin, H.-P. Spray characteristics of emulsified castor biodiesel on engine emissions and deposit formation. Renew. Energy 2011, 36, 3507–3516. [Google Scholar] [CrossRef]

- Yu, J.; Bae, C. Dimethyl ether (DME) spray characteristics in a common-rail fuel injection system. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2003, 217, 1135–1144. [Google Scholar] [CrossRef]

- Kim, H.J.; Park, S.H.; Lee, C.S. A study on the macroscopic spray behavior and atomization characteristics of biodiesel and dimethyl ether sprays under increased ambient pressure. Fuel Process. Technol. 2010, 91, 354–363. [Google Scholar] [CrossRef]

- Pastor, J.V.; García-Oliver, J.M.; Micó, C.; García-Carrero, A.A.; Gómez, A. Experimental Study of the Effect of Hydrotreated Vegetable Oil and Oxymethylene Ethers on Main Spray and Combustion Characteristics under Engine Combustion Network Spray A Conditions. Appl. Sci. 2020, 10, 5460. [Google Scholar] [CrossRef]

- Das, M.; Sarkar, M.; Datta, A.; Santra, A.K. Study on viscosity and surface tension properties of biodiesel-diesel blends and their effects on spray parameters for CI engines. Fuel 2018, 220, 769–779. [Google Scholar] [CrossRef]

- Mohan, B.; Yang, W.; Tay, K.L.; Yu, W. Experimental study of spray characteristics of biodiesel derived from waste cooking oil. Energy Convers. Manag. 2014, 88, 622–632. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Z.; Kuti, O.A.; Zhang, W.; Nishida, K. Experimental and analytical study on biodiesel and diesel spray characteristics under ultra-high injection pressure. Int. J. Heat Fluid Flow 2010, 31, 659–666. [Google Scholar] [CrossRef]

- Agarwal, A.; Chaudhury, V.H. Spray characteristics of biodiesel/blends in a high pressure constant volume spray chamber. Exp. Therm. Fluid Sci. 2012, 42, 212–218. [Google Scholar] [CrossRef]

- Pachiannan, T.; Zhong, W.; Xuan, T.; Li, B.; He, Z.; Wang, Q.; Yu, X. Simultaneous study on spray liquid length, ignition and combustion characteristics of diesel and hydrogenated catalytic biodiesel in a constant volume combustion chamber. Renew. Energy 2019, 140, 761–771. [Google Scholar] [CrossRef]

- Liu, H.; Lee, C.; Huo, M.; Yao, M. Comparison of Ethanol and Butanol as Additives in Soybean Biodiesel Using a Constant Volume Combustion Chamber. Energy Fuels 2011, 25, 1837–1846. [Google Scholar] [CrossRef]

- Liu, H.; Ma, X.; Li, B.; Chen, L.; Wang, Z.; Wang, J. Combustion and emission characteristics of a direct injection diesel engine fueled with biodiesel and PODE/biodiesel fuel blends. Fuel 2017, 209, 62–68. [Google Scholar] [CrossRef]

- Ulu, A.; Yildiz, G.; Rodriguez, A.D.; Özkol, U. Spray Analysis of Biodiesels Derived from Various Biomass Resources in a Constant Volume Spray Chamber. ACS Omega 2022, 7, 19365–19379. [Google Scholar] [CrossRef]

- Sathiyamoorthi, R.; Sankaranarayanan, G.; Munuswamy, D.B.; Devarajan, Y. Experimental study of spray analysis for Palmarosa biodiesel-diesel blends in a constant volume chamber. Environ. Prog. Sustain. Energy 2021, 40, e13696. [Google Scholar] [CrossRef]

- Suraj, C.; Sudarshan, G.; Anand, K.; Sundararajan, T. Effects of autooxidation on the fuel spray characteristics of Karanja biodiesel. Biomass Bioenergy 2021, 149, 106084. [Google Scholar] [CrossRef]

- Bohl, T.; Tian, G.; Smallbone, A.; Roskilly, A.P. Macroscopic spray characteristics of next-generation bio-derived diesel fuels in comparison to mineral diesel. Appl. Energy 2017, 186, 562–573. [Google Scholar] [CrossRef]

- Hiroyasi, H.; Kadota, T.; Arai, M. Fuel spray characteristic in diesel engines. In Combustion Modeling in Repiprocating Engines; Plenum Press: New York, NY, USA; London, UK, 1980; p. 369. [Google Scholar]

- Hoang, A.T. Experimental study on spray and emission characteristics of a diesel engine fueled with preheated bio-oils and diesel fuel. Energy 2019, 171, 795–808. [Google Scholar] [CrossRef]

- Agarwal, A.; Dhar, A.; Gupta, J.G.; Kim, W.I.; Lee, C.S.; Park, S. Effect of fuel injection pressure and injection timing on spray characteristics and particulate size–number distribution in a biodiesel fuelled common rail direct injection diesel engine. Appl. Energy 2014, 130, 212–221. [Google Scholar] [CrossRef]

- Bhikuning, A.; Sugawara, R.; Matsumura, E.; Senda, J. Investigation of spray characteristics from waste cooking oil, bio-hydro fined diesel oil (BHD)and n-tridecane in a constant volume chamber. Case Stud. Therm. Eng. 2020, 21, 100661. [Google Scholar] [CrossRef]

- Kumar, A.; Bhattacharya, T.; Hasnain, S.M.; Nayak, A.K.; Hasnain, M.S. Applications of biomass-derived materials for energy production, conversion, and storage. Mater. Sci. Energy Technol. 2020, 3, 905–920. [Google Scholar] [CrossRef]

- Shameer, P.M.; Ramesh, K.; Sakthivel, R.; Purnachandran, R. Effects of fuel injection parameters on emission characteristics of diesel engines operating on various biodiesel: A review. Renew. Sustain. Energy Rev. 2017, 67, 1267–1281. [Google Scholar] [CrossRef]

- Ghurri, A.; Kim, J.-D.; Kim, H.G.; Jung, J.-Y.; Song, K.-K. The effect of injection pressure and fuel viscosity on the spray characteristics of biodiesel blends injected into an atmospheric chamber. J. Mech. Sci. Technol. 2012, 26, 2941–2947. [Google Scholar] [CrossRef]

- Xie, H.; Song, L.; Xie, Y.; Pi, D.; Shao, C.; Lin, Q. An Experimental Study on the Macroscopic Spray Characteristics of Biodiesel and Diesel in a Constant Volume Chamber. Energies 2015, 8, 5952–5972. [Google Scholar] [CrossRef] [Green Version]

- Anis, S.; Budiandono, G.N. Investigation of the effects of preheating temperature of biodiesel-diesel fuel blends on spray characteristics and injection pump performances. Renew. Energy 2019, 140, 274–280. [Google Scholar] [CrossRef]

- Sukjit, E.; Herreros, J.; Dearn, K.D.; Contreras, M.R.G.; Tsolakis, A. The effect of the addition of individual methyl esters on the combustion and emissions of ethanol and butanol -diesel blends. Energy 2012, 42, 364–374. [Google Scholar] [CrossRef]

- Han, D.; Zhai, J.; Duan, Y.; Ju, D.; Lin, H.; Huang, Z. Macroscopic and microscopic spray characteristics of fatty acid esters on a common rail injection system. Fuel 2017, 203, 370–379. [Google Scholar] [CrossRef]

- Lin, Y.-S.; Lin, H.-P. Study on the spray characteristics of methyl esters from waste cooking oil at elevated temperature. Renew. Energy 2010, 35, 1900–1907. [Google Scholar] [CrossRef]

- Zhang, P.; Su, X.; Chen, H.; Geng, L.; Zhao, X. Assessing fuel properties effects of 2,5-dimethylfuran on microscopic and macroscopic characteristics of oxygenated fuel/diesel blends spray. Sci. Rep. 2020, 10, 1427. [Google Scholar] [CrossRef] [Green Version]

- Kumar, C.; Rana, K.B.; Tripathi, B.; Nayyar, A. Properties and effects of organic additives on performance and emission characteristics of diesel engine: A comprehensive review. Environ. Sci. Pollut. Res. 2018, 25, 22475–22498. [Google Scholar] [CrossRef] [PubMed]

- Andrae, J.; Johansson, D.; Björnbom, P.; Risberg, P.; Kalghatgi, G. Co-oxidation in the auto-ignition of primary reference fuels and n-heptane/toluene blends. Combust. Flame 2005, 140, 267–286. [Google Scholar] [CrossRef]

- Luo, J.; Yao, M.; Liu, H.; Yang, B. Experimental and numerical study on suitable diesel fuel surrogates in low temperature combustion conditions. Fuel 2012, 97, 621–629. [Google Scholar] [CrossRef]

- Lanjekar, R.D.; Deshmukh, D. Experimental and numerical investigations on spray characteristics of fatty acid methyl esters. R. Soc. Open Sci. 2018, 5, 171121. [Google Scholar] [CrossRef]

- Tian, G.; Li, H.; Xu, H.; Li, Y.; Raj, S.M. Spray Characteristics Study of DMF Using Phase Doppler Particle Analyzer. SAE Int. J. Passeng. Cars—Mech. Syst. 2010, 3, 948–958. [Google Scholar] [CrossRef]

- Ealias, A.M.; Saravanakumar, M.P. A review on the classification, characterisation, synthesis of nanoparticles and their application. IOP Conf. Ser. Mater. Sci. Eng. 2017, 263, 032019. [Google Scholar]

- Machado, S.; Pacheco, J.G.; Nouws, H.P.A.; Albergaria, J.T.; Delerue-Matos, C. Characterization of green zero-valent iron nanoparticles produced with tree leaf extracts. Sci. Total Environ. 2015, 533, 76–81. [Google Scholar] [CrossRef] [Green Version]

- Tiwari, D.K.; Behari, J.; Sen, P. Application of Nanoparticles in Waste Water Treatment. World Appl. Sci. J. 2008, 3, 417–433. [Google Scholar]

- Jeevanandam, J.; Barhoum, A.; Chan, Y.S.; Dufresne, A.; Danquah, M.K. Review on nanoparticles and nanostructured materials: History, sources, toxicity and regulations. Beilstein J. Nanotechnol. 2018, 9, 1050–1074. [Google Scholar] [CrossRef] [Green Version]

- Tai, C.Y.; Tai, C.-T.; Chang, M.-H.; Liu, H.-S. Synthesis of Magnesium Hydroxide and Oxide Nanoparticles Using a Spinning Disk Reactor. Ind. Eng. Chem. Res. 2007, 46, 5536–5541. [Google Scholar] [CrossRef]

- Shamun, S.; Belgiorno, G.; Di Blasio, G.; Beatrice, C.; Tunér, M.; Tunestål, P. Performance and emissions of diesel-biodiesel-ethanol blends in a light duty compression ignition engine. Appl. Therm. Eng. 2018, 145, 444–452. [Google Scholar] [CrossRef]

- Das, S.K.; Choi, S.U.S.; Patel, H.E. Heat Transfer in Nanofluids—A Review. Heat Transf. Eng. 2006, 27, 3–19. [Google Scholar] [CrossRef]

- Sundaram, D.S.; Yang, V.; Zarko, V.E. Combustion of nano aluminum particles (Review). Combust. Explos. Shock Waves 2015, 51, 173–196. [Google Scholar] [CrossRef]

- Zhang, Z.; Lu, Y.; Qian, Z.; Roskilly, A.P. Spray and engine performance of cerium oxide nanopowder and carbon nanotubes modified alternative fuel. Fuel 2022, 320, 123952. [Google Scholar] [CrossRef]

- Kannaiyan, K.; Sadr, R. The effects of alumina nanoparticles as fuel additives on the spray characteristics of gas-to-liquid jet fuels. Exp. Therm. Fluid Sci. 2017, 87, 93–103. [Google Scholar] [CrossRef]

- Kannaiyan, K.; AlDosari, A.; Sadr, R. Effects of nanoscale fuel additives on properties and non-reacting spray performance of alternative, conventional and blended jet fuels at elevated ambient conditions. Fuel Process. Technol. 2020, 208, 106436. [Google Scholar] [CrossRef]

- Ahmad, K.H.; Hossain, A.K. Impact of nanoparticles and butanol on properties and spray characteristics of waste cooking oil biodiesel and pure rapeseed oil. E3S Web Conf. 2017, 23, 10001. [Google Scholar] [CrossRef]

| Physio-Chemical Properties | Acetone | Butanol | Ethanol | Methanol | Pentanol | Propanol | Octanol | Butanol-Acetone | ABE |

|---|---|---|---|---|---|---|---|---|---|

| Molecular structure | C3H6O | C4H9OH | C2H5OH | CH3OH | C5H11OH | C3H7OH | C8H18O | C7H18O3 | C8.5H18.6O0.4 |

| Molecular weight g/mol | 58.08 | 74.12 | 46.07 | 32.04 | 88.15 | 60.10 | 130.22 | 150.22 | 127.27 |

| Density kg/m3 | 789 | 809.7 | 789.4 | 791.3 | 815 | 803.7 | 830 | 0.795 | 763.3 |

| Viscosity at 40 °C (mm2/s) | 0.149 | 2.22 | 1.08 | 0.58 | 2.89 | 1.74 | 5.5 | 1.03 | 2.124 |

| Boiling point °C | 489 | 117 | 79 | 65 | 138 | 97 | 195 | - | 464 |

| Flash point °C | −20 | 29 | 13 | 9 | 43 | 15 | 81 | - | - |

| Lower heating value MJ/kg | 44.1 | 32.01 | 26.83 | 20.08 | 29.82 | 32.16 | 37.5 | 31.43 | 41.5 |

| Self-ignition temperature °C | 465 | 345 | 363 | 385 | 300 | 350 | 270 | - | - |

| Cetane number | 74 | 17 | 11 | 2 | 20 | 12 | 37.5 | 14 | - |

| Latent heat of vaporization kJ/kg | 362 | 585.4 | 918.4 | 1162.6 | 308 | 727.8 | 562 | - | 411 |

| Oxygen content (wt.%) | 27.6 | 21.5 | 34.7 | 49.9 | 18.15 | 26.62 | 12.31 | - | 5.2 |

| Fuel Name | Operating Conditions | Blend | PL (mm) | SCA (°) | Area/ Volume (mm2/mm3) | Velocity (m/s) |

|---|---|---|---|---|---|---|

| Ethanol/Diesel [28] | Pinj = 90 MPa Pamb = 0.7 MPa Dinj = 300 μm Injection duration = 1.5 ms | E20 E40 E100 | 137 130 135 | 14.45 14.3 15.1 | - | 220 245 205 |

| Acetone/Ethanol/Butanol/ Diesel blends [29] | Pinj = 150 MPa Pamb = 6 MPa Tamb = 800 K Ρamb = 22.8 kg/m3 Dinj = 89.7 µm Injection duration = 1.5 ms | B20 B40 E20 ABE20 B20E20 | 70 69.3 68.7 66.9 69.5 | 26 21.5 22 22.7 24 | - | - |

| Pentanol/Diesel blends [53] | Pinj = 120 MPa Pamb = 5 MPa Tamb = 673 K Dinj = 120 µm Injection duration = 2 ms | D75Pe25 D50Pe50 | 31 26 | 16.9 17.12 | 85 mm2 58 mm2 | - |

| Pentanol, Biodiesel and diesel blends [61] | Pinj = 120 MPa Pamb = 5 MPa Tamb = 800 K Dinj = 120 µm Injection duration = 2 ms | DBPe20 | 44 | 14.5 | - | - |

| Pentanol/Diesel blends [54] | Pinj = 100 MPa Pamb = 5 MPa Tamb = 800 K Ρamb = 15 kg/m3 Dinj = 234 µm Injection duration = 1.5 ms | D80Pe20 D60Pe40 | 88 76 | 19.6 19.5 | 23,500 mm3 21,000 mm3 | - |

| Butanol/Diesel blends [49] | Pinj = 100 MPa Pamb = 2 MPa Tamb = 800 K Dinj = 250 µm Injection duration = 1.5 ms | BDB80 | 69 | 20.76 | 830 mm2/9.2 cm | - |

| Ethanol/Diesel blends [45] | Pinj = 200 MPa Pamb = 0.1 MPa Tamb = 295 K Dinj = 300 µm Injection duration = 1.5 ms | D100 D95E5 D90E10 D85E15 | 79 65.4 61.2 60 | - | - | 760 580 500 430 |

| Cotton seed biodiesel blended with Butanol-Acetone mixture [48] | Pinj = 50 MPa Pamb = 0.1 MPa Tamb = 295 K Dinj = 180 µm Injection duration = 1.5 ms | BA10BD90 BA20BD80 | 288 290 | 7.4 7.1 | 161,000 172,000 | - |

| Octanol/Butanol/diesel blends [52] | Pinj = 120 MPa Pamb = 4.59 MPa Tamb = 623 K Dinj = 180 µm Injection duration = 1.7 ms | B20D80 B20H40D40 B30H70 B30D70 Oc100 Bu100 | 68.3 71.8 70.7 67.6 66.4 67 | 16.42 16.71 16.94 16.26 16.31 16.18 | - | - |

| Soybean Biodiesel/Ethanolblends [44] | Pinj = 30 MPa Pamb = 0.1 MPa Tamb = 293 K Dinj = 366 µm | BD90E10 BD80E20 BD70E30 | 46.5 43 40.9 | 16.7 17.35 18.6 | - | - |

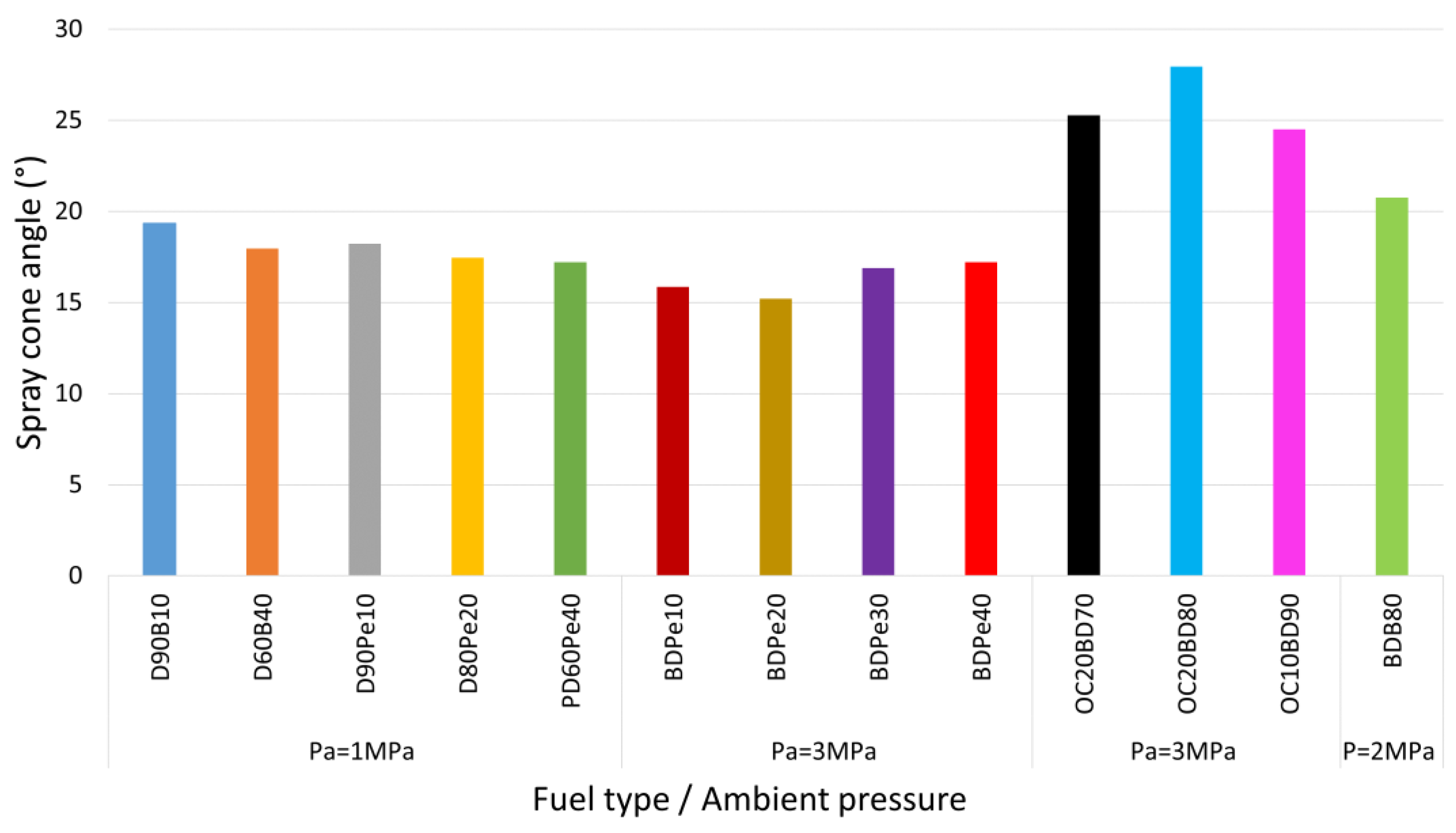

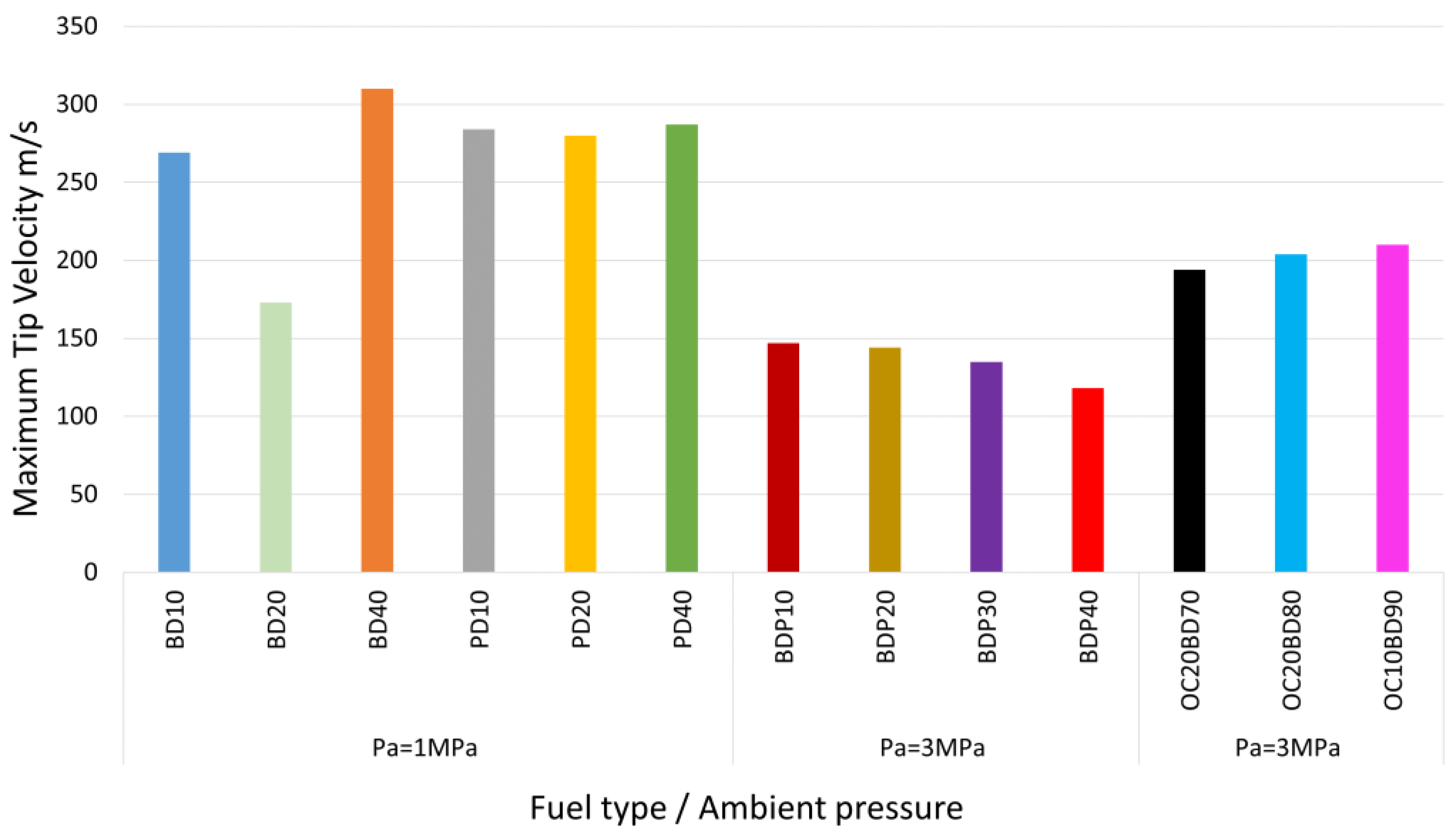

| Butanol/Pentanol/Dieselblends [51] | Pinj = 100 MPa Pamb = 1,2 MPa Tamb = 288 K Dinj = 300 µm Injection duration = 1.5 ms | D90B10 D80B20 D60B40 D90Pe10 D80Pe20 D60Pe40 | 82.3 81.5 80.1 80 79 78 | 19.5 18.9 17.9 18.7 16.45 16.3 | 1090 1079 1130 1095 1035 1100 | 269 273 310 284 280 287 |

| Ethanol/Diesel [43] | Pinj = 90 MPa Pamb = 1 MPa Tamb = 288 K Dinj = 180 µm Injection duration = 1.2 ms | DE20 | 74 | 18.2 | 775 | 180 |

| Methanol/Dieselblends [41] | Pinj = 100 MPa Pamb = 5 MPa Tamb = 900 K Dinj = 190 µm Injection duration = 1 ms | M5A M10A M25B M10B M5B | 35 33 33.9 32.2 31.4 | - | - | - |

| Pentanol/ Biodiesel blends [19] | Pinj = 100 MPa Pamb = 1,2,3 MPa Tamb = 298 K Ρamb = 23.2 kg/m3 Dinj = 300 µm Injection duration = 1.5 ms | BDPe10 BDPe20 BDPe30 BDPe40 | 85 83 81 80 | 15.86 15.21 16.88 17.22 | - | 147 144 135 118 |

| Octanol/Biodiesel blends [55] | Pinj = 100,140 MPa Pamb = 2, 3 MPa Tamb = 298 K Dinj = 300 µm Injection duration = 1.5 ms | OC10BD90 OC20BD80 OC30BD70 | 73.5 72 70.2 | 24.51 27.95 25.28 | 1090 1140 1170 | 210 204 194 |

| Physio-Chemical Properties | DEE | DME | DNBE | EEA | PODE |

|---|---|---|---|---|---|

| Molecular weight | C4H10O | CH3OCH3 | C8H18O | C6H12O3 | C2H6O(CH2O)n |

| Density kg/m3 | 710 | 667 | 770 | 975 | 860–1130 |

| Viscosity at 40 °C (mm2/s) | 1.21 | - | - | 1.32 | 0.36–2.36 |

| Boiling point °C | 34.6 | −25 | 144 | 156 | 42–280 |

| Lower heating value MJ/kg | 356 | - | 345 | - | 17.5–22.4 |

| Self-ignition temperature | 160 | 239 | - | 379 | - |

| Cetane number | 125 | 61 | 100 | 61 | 74–128 |

| Latent heat of vaporization kJ/kg | 33.9 | 27 | 32 | - | - |

| Oxygen content (wt.%) | 21 | 35 | - | 17 | 42–49 |

| Fuel Name | Operating Conditions | Blend | PL (mm) | SCA (°) | SMD (μm) | Area mm2/ Volume (mm3) | Velocity m/s |

|---|---|---|---|---|---|---|---|

| Dimethyl ether [82] | Pinj = 55 Mpa Pamb = 3 MPa Tamb = 293 K | DME | 29 | 17.5 | - | 12 | 12 |

| Biodiesel and Dimethyl ether [83] | Pinj = 50 MPa Pamb = 0.1, 1 MPa Tamb = 293 K Dinj = 300 µm Injection duration = 1.2 ms | B100 DME | 90 67 | 21 17 | 26.5 23 | 1250 880 | - |

| Dimethyl ether/ Isobutene blends [78] | Pinj = 50 MPa Pamb = 2 MPa Tamb = 293 K Dinj = 126 μm Injection duration = 1.2 ms | DME DME90L10 DME8020 DME70L30 | 48 47 46 45 | 16.8 17.2 17.6 16.5 | 3.2 7.8 7.5 7 | - | - |

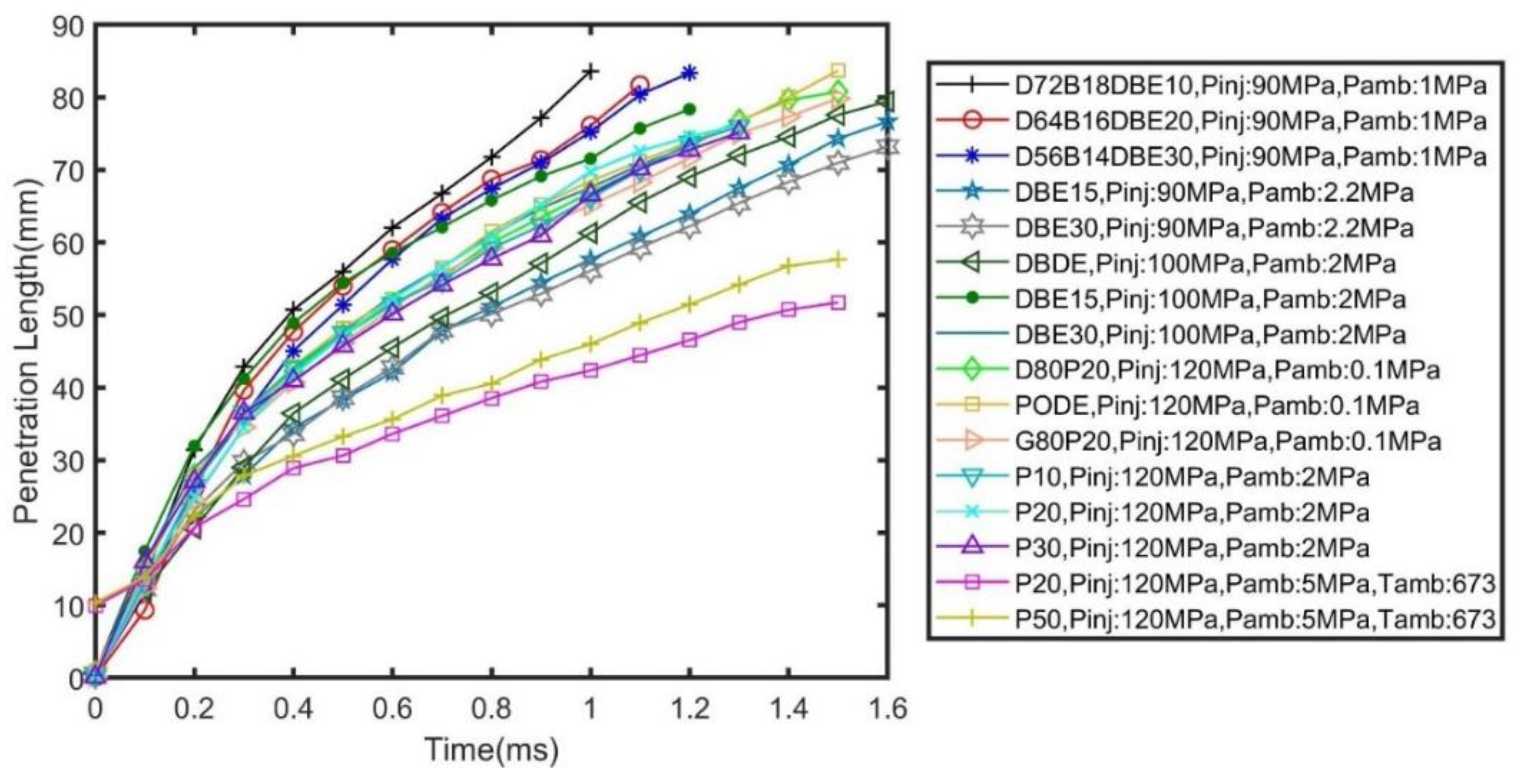

| Diesel, Soybean biodiesel/ di-n-butyl ether blends [75] | Pinj = 100 MPa Pamb = 2 MPa Tamb = 293 K Dinj = 250 μm Injection duration = 1.2 ms | B100 Diesel DBE15 DBE30 | 77 75 73.7 72 | 17.9 18.5 19.9 19.6 | 31 25.6 27 26 | 800 825 910 970 | - |

| Polyoxymethylene dimethyl ether/diesel blends [80] | Pinj = 90 Mpa Pamb = 4 MPa Tamb = 293 KDinj = 120 μmInjection duration = 1.5 ms | P0 P20 P50 P100 | 80.3 81 81.4 78 | 18.4 19.6 20.8 17 | 28.39 28 27.73 27.66 | N/A | 385 402 416 443 |

| Diethyl ether/diesel/biodiesel blend [42] | Pinj = 100 MPa Pamb = 2 MPa Tamb = 293 K Dinj = 200 μm Injection duration = 1.2 ms | D64B16DEE20 | 89.9 | 19.2 | 25.8 | 930 | - |

| PODE/diesel/gasoline blends [30] | Pinj = 120 MPa Pamb = 0.1 MPa Tamb = 300 K Dinj = 140 μm Injection duration = 1.5 ms | G80P20 D80P20 PODE | 80.7 79.8 83.6 | 14.4 21.6 13.2 | 6.5 12.9 12.5 | - | - |

| Diesel, biodiesel/ di-n-butyl ether blends [76] | Pinj = 80, 90, 100 MPa Pamb = 2 MPa Tamb = 298 K Dinj = 300 μm Injection duration = 1.2 ms | D72B18DBE10 D64B16DBE20 D56B14DBE30 | 81 76 74.5 | 18.5 18.4 22.0 | - | - | - |

| Soybean biodiesel/di n butyl ether blends [51] | Pinj = 90 MPa Pamb = 2.2 MPa Tamb = 300 K Dinj = 300 μm Injection duration = 1.2 ms | DBE15 DBE30 | 76.8 73.5 | 23.2 24.7 | - | - | 167 150 |

| Biodiesel/polyoxymethylene dimethyl ethers (PODE) blends [77] | Pinj = 120 MPa Pamb = 2,3 MPa Tamb = 300 K Dinj = 300 μm Injection duration = 1.5 ms | P0 P10 P20 P30 | 76.2 75.4 74.6 67.8 | 19.4 21.5 21.0 23.8 | - | 750 785 780 845 | - |

| Polyoxymethylene dimethyl ether (PODE) [74] | Pinj = 120 Mpa Pamb = 5 MPa Tamb = 573 K Dinj = 89.4 μm Injection duration = 2 ms | P20 P50 | 51.3 54.6 | 25.0 26.7 | - | 615 662 | - |

| Oxymethylene Ethers/Diesel blends [84] | Pinj = 100 MPa Pamb = 2 MPa Tamb = 900 K Injection duration = 2 ms | Diesel OMEX OME1 | 91 89 84 | - | - | - | - |

| Physio-Chemical Properties | n-Tridecane | DMF | n-Heptane | Methyl Laurate | Methyl Oleate | Ethyl Oleate | Iso-Octane |

|---|---|---|---|---|---|---|---|

| Molecular structure | C13H28 | C3H7NO | CH3(CH2)5CH3 | CH3(CH2)10COOCH3 | CH3(CH2)7CH=CH(CH2)7COOCH3 | CH3(CH2)7CH= CH(CH2)7COOCH2CH3 | CH3C(CH3)2CH2CH(CH3)2 |

| Molecular weight | 184.36 | 73.09 | 100.2 | 214.34 | 296.5 | 310.5 | 114.23 |

| Density kg/m3 | 752 | 944.5 | 679.5 | 860.5 | 864.0 | 858.5 | - |

| Viscosity at 40 C (mm2/s) | 2.148 | 0.802 | - | 2.38 | 4.20 | 4.76 | - |

| Surface tension (mN/m) | - | 0.003642 | - | 0.00293 | 0.00309 | 0.0031 | - |

| Vapor pressure (PA) | - | 515.9 | 4998.2 | 1.4 | 0.00547 | 0.000489 | - |

| Boiling point °C | - | 153 | −90.6 | - | - | - | - |

| Fuel Name | Operating Conditions | Blends | PL (mm) | SCA (°) | SMD (µm) | Area mm2/ Volume mm3 | Velocity (m/s) |

|---|---|---|---|---|---|---|---|

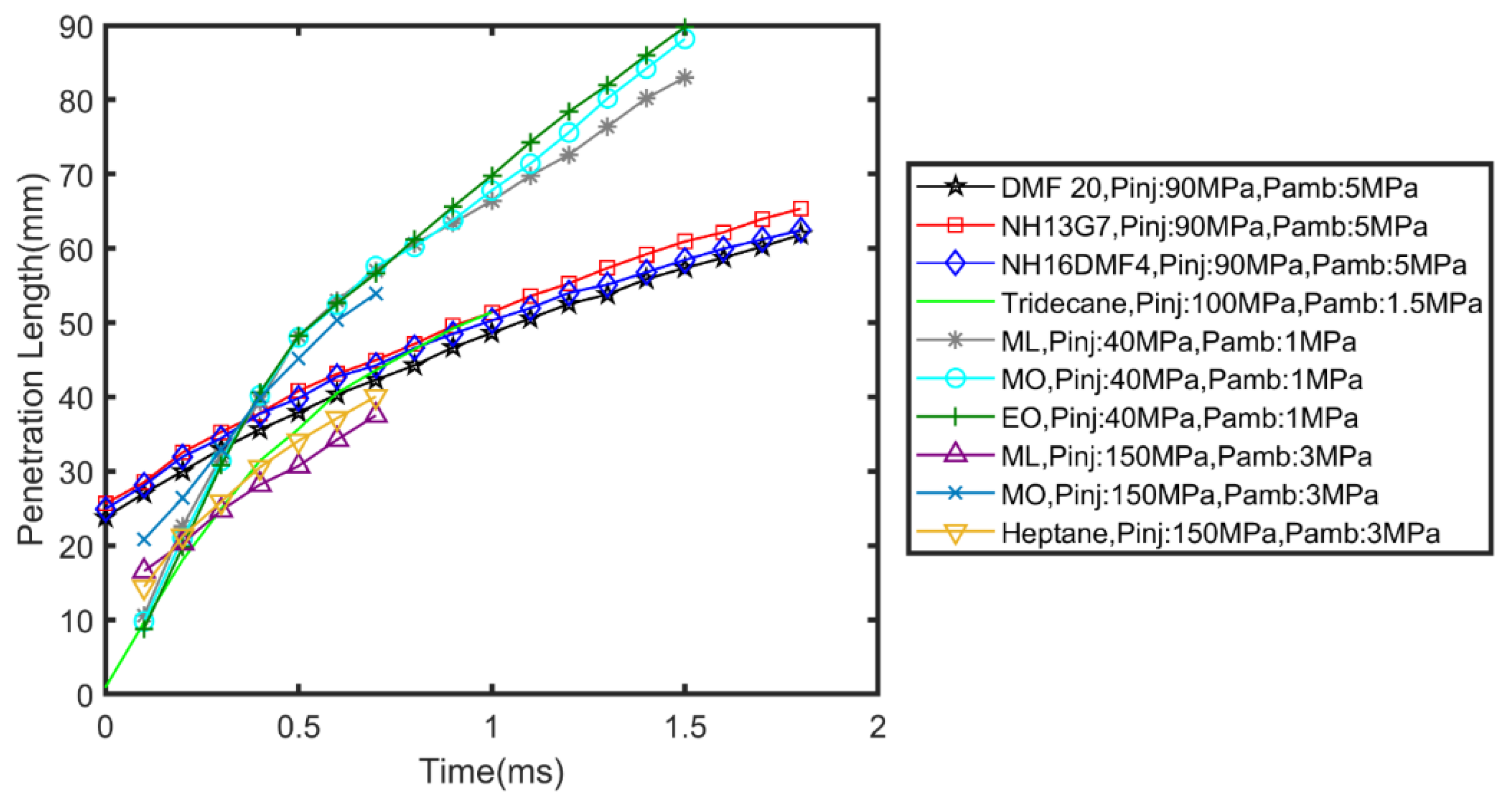

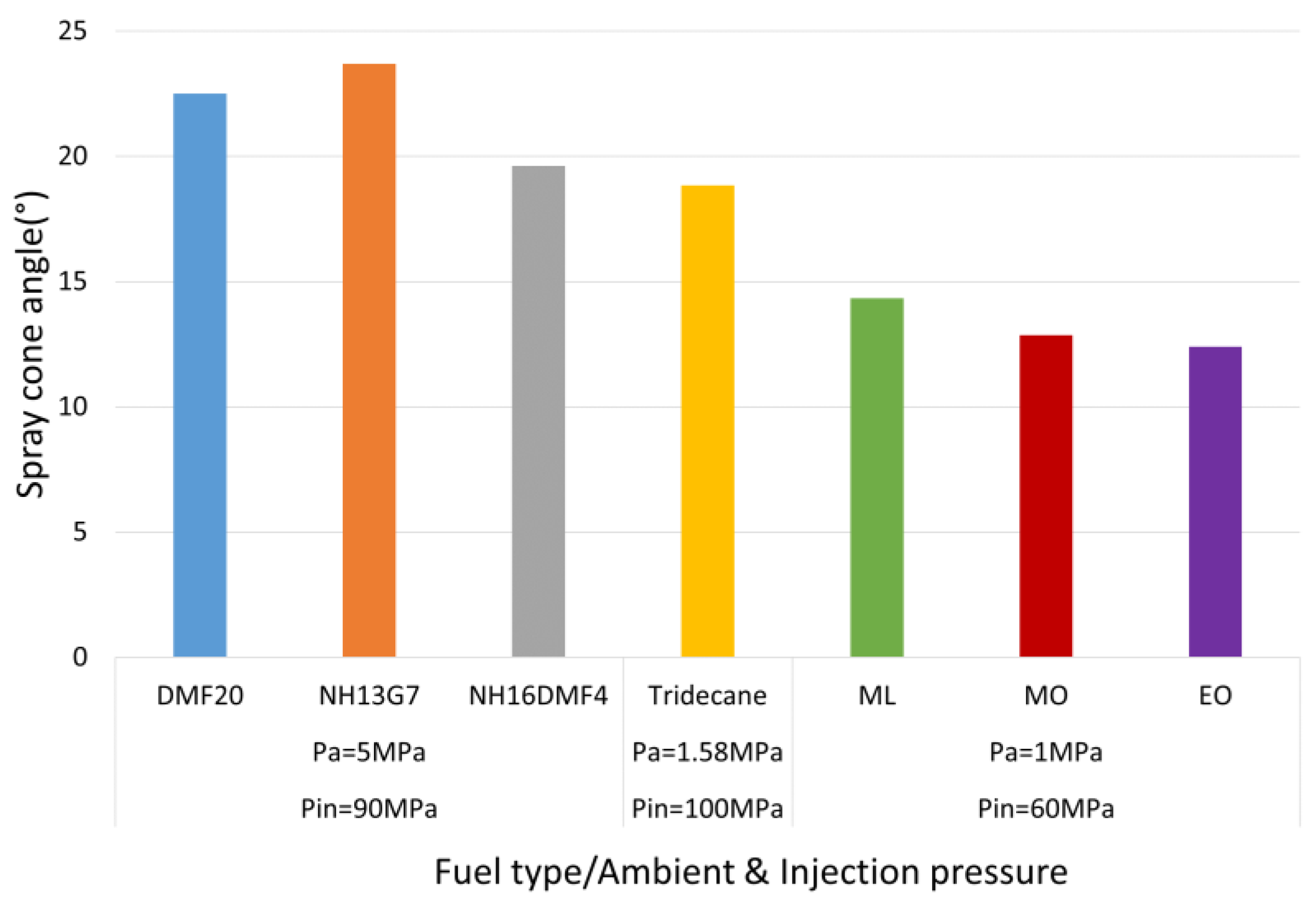

| Dimethyl furan/n-heptane/diesel [108] | Pinj = 70 Mpa Pamb = 1.1 MPa Dinj = 200 Injection duration: 1 ms | DMF20 NH13G7 NH16DMF4 | 61.83 65.33 62.44 | 22.5 23.7 19.61 | - | 645 600 640 | - |

| Tridecane [99] | Pinj = 70 MPa Pamb = 1.1 MPa Dinj = 200 Injection duration: 1 ms | Tridecane | 51.4 | 18.84 | - | - | - |

| Water/ waste cooking oil methyl ester blends and diesel [107] | Pinj = 140 MPa Tamb = 653 K Ρamb = 2 kg/m3 Injection duration: 1.5 ms | EME20 WCB D100 | 47.5 42 41 | 16.5 17 17.7 | - | - | - |

| Diesel, methyl laurate, methyl oleate and ethyl oleate [106] | Pinj = 60 MPa Pamb = 1 MPa Dinj = 280 Tamb = 293 Injection duration: 1 ms | ML MO EO | 83 88.4 89.8 | 14.33 12.86 12.40 | 20.78 24.53 26.31 | 10.3 11.7 11.6 | 135 152 156 |

| Methyl laurate, methyl oleate, heptane [112] | Pinj = 150 MPa Pamb = 3 MPa | ML MO n-heptane | 37.5 53.8 40.05 | - | - | - | - |

| Authors | Operating Conditions | Blends | PL (mm) | SCA (°) | Area mm2/ Volume mm3 | Velocity m/s |

|---|---|---|---|---|---|---|

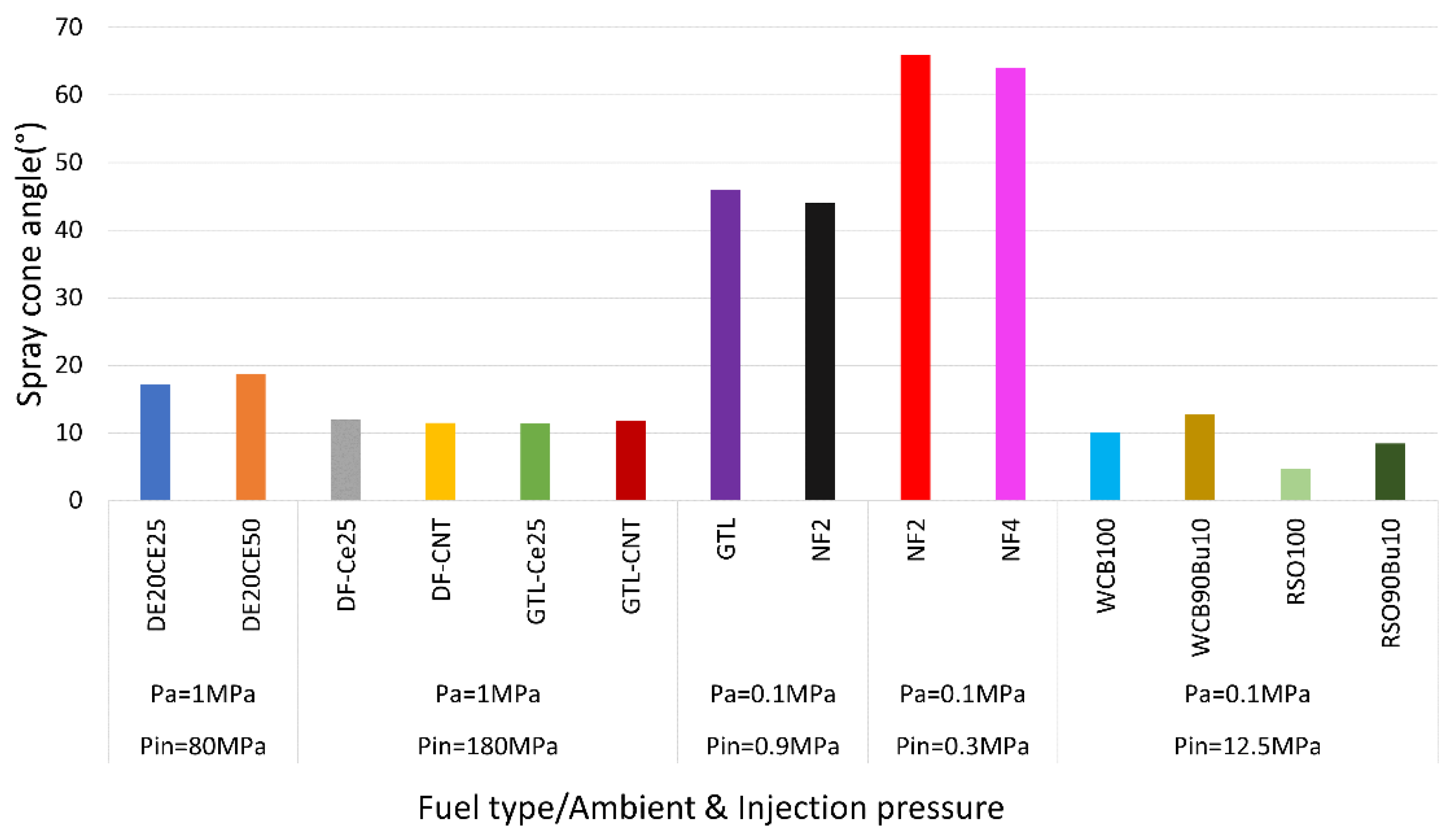

| GTL/Alumina [123] | Pinj = 0.9 Mpa Dinj = 800 µm | GTL NF1 NF2 | - | 46 44 | - | 18.72 18.5 18.37 |

| Cerium oxide/diesel/ethanol blends [43] | Pinj = 90 MPa Pamb = 1 MPa Tamb= 288 K Dinj= 180 µm Injection duration = 1.2 ms | DE2Ce25 DE20Ce50 DE20Ce100 | 73.8 73 | 17.14 18.74 19.6 | 748 770 875 | 130 118 107 |

| GTL/CNT /Diesel/CeO2 blends [122] | Pinj = 90 MPa Pamb = 1 MPa Tamb = 600 K Injection duration = 0.6 ms | DF-Ce25 DF-CNT GTL GTL-Ce25 GTL-CNT | 74.5 76 72.3 71.5 74.1 | 11.92 11.5 11.75 11.43 11.80 | - | - |

| GTL/Al2O3 [124] | Pinj = 0.3 MPa Tamb = 400 K Dinj = 800 µm | NF2 NF4 | - | 66 64 | - | - |

| Waste cooking biodiesel/Rapeseed biodiesel/butanol/Al2O3 [125] | Pinj = 12.5 MPa | WCB100 WCB90Bu10 RSO100 RSO90Bu10 | - | 10 12.68 4.73 8.44 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haq, M.U.; Jafry, A.T.; Ahmad, S.; Cheema, T.A.; Ansari, M.Q.; Abbas, N. Recent Advances in Fuel Additives and Their Spray Characteristics for Diesel-Based Blends. Energies 2022, 15, 7281. https://doi.org/10.3390/en15197281

Haq MU, Jafry AT, Ahmad S, Cheema TA, Ansari MQ, Abbas N. Recent Advances in Fuel Additives and Their Spray Characteristics for Diesel-Based Blends. Energies. 2022; 15(19):7281. https://doi.org/10.3390/en15197281

Chicago/Turabian StyleHaq, Muteeb Ul, Ali Turab Jafry, Saad Ahmad, Taqi Ahmad Cheema, Munib Qasim Ansari, and Naseem Abbas. 2022. "Recent Advances in Fuel Additives and Their Spray Characteristics for Diesel-Based Blends" Energies 15, no. 19: 7281. https://doi.org/10.3390/en15197281

APA StyleHaq, M. U., Jafry, A. T., Ahmad, S., Cheema, T. A., Ansari, M. Q., & Abbas, N. (2022). Recent Advances in Fuel Additives and Their Spray Characteristics for Diesel-Based Blends. Energies, 15(19), 7281. https://doi.org/10.3390/en15197281