Extreme Learning Machine-Based Diagnostics for Component Degradation in a Microturbine

Abstract

:1. Introduction

2. Materials and Methods

2.1. Micro Turbojet

2.2. Prediction of Component Degradation

- The rig and flight data acquired from a real micro turbojet were used to validate the GSP model [45]. The validated model was subsequently used to simulate selected operating conditions to obtain the values of the virtual engine sensors, necessary to train and test the predictive techniques. The simulated parameters are listed in Table 2.

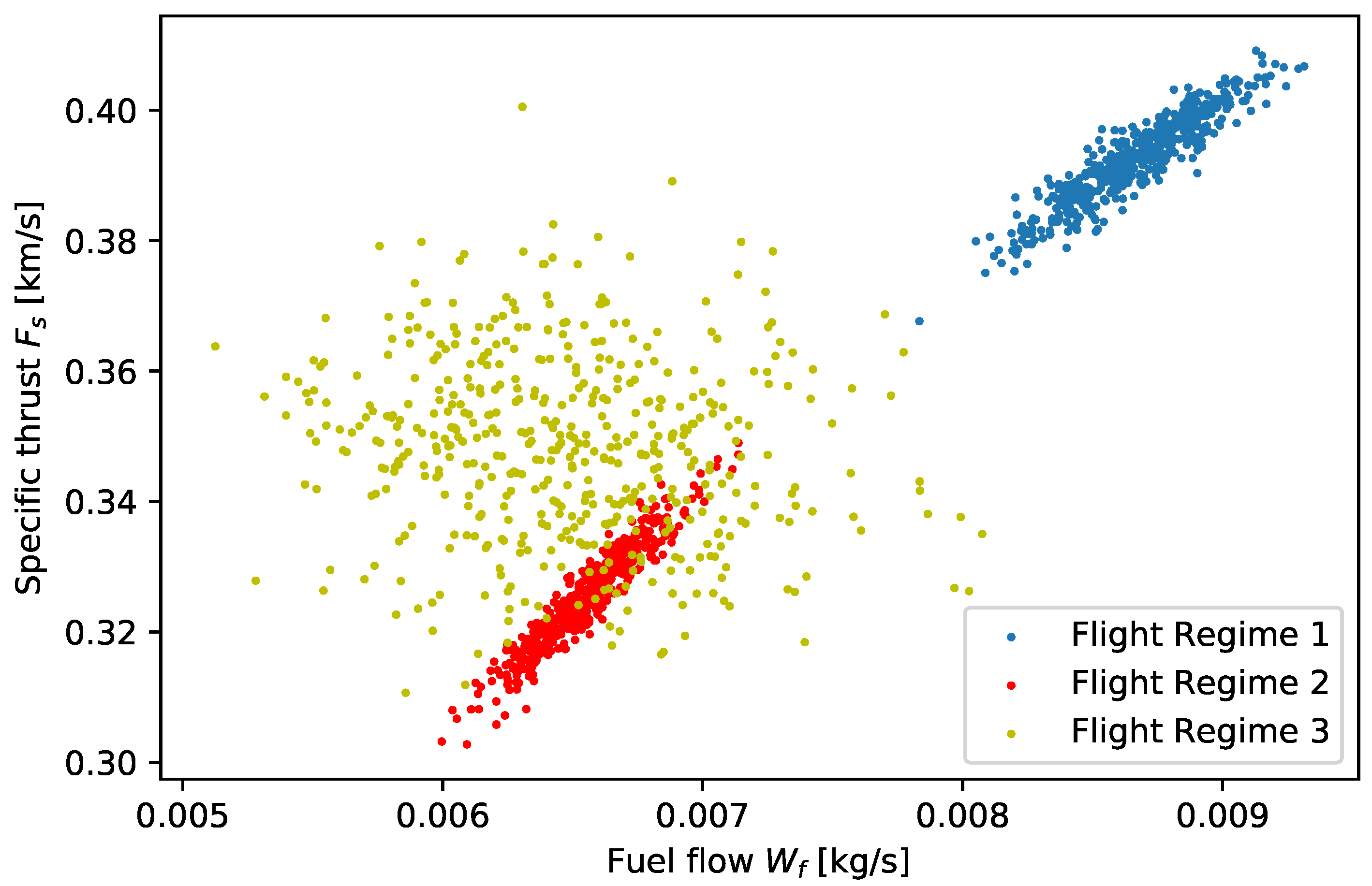

- Three simulated flight regimes, (1) takeoff, (2) cruise and (3) air mission, were defined by different Mach (M) and altitude () values (Table 3). Additionally, M and were randomly distributed in flight regime 3. For each operating regime, the data generated by GSP embrace 500 operating points: 400 for training, and 100 for testing. Training and testing data were randomly selected from the same dataset.

- Both clean and degraded conditions of the compressor and the turbine were simulated. Two degraded performance parameters, i.e., efficiency and mass flow, were altered for two components: the compressor and turbine. Each of the four performance parameters was assigned random values to simulate the different levels of degradation severity using the GSP Monte Carlo input controller by selecting the mean value () and standard deviation (2%). In further analysis, the absolute values of efficiency and corrected flow were used instead of degradation factors in percent to avoid ambiguity.

- From the virtual sensors, four input vectors for training AI models were selected, as reported in Table 4. Input vector 1 consists of nine virtual sensors used for flight regimes 1 and 2, excluding speed and ambient conditions, which are constant. Input vector 2, used for flight regime 3, has a complete set of 12 parameters. Input vector 3, used for flight regimes 1 and 2, has only two parameters that correspond to the real sensors installed on the microturbine: and EGT. Input vector 4 used for flight regime 3 includes M, TT, PT, and EGT.

- The datasets generated by the GSP were used for training and testing ANN and ELM models to validate their accuracy in predicting the efficiency and mass flow W of both components. There were thus four outputs in each network, and the prediction models were able to find which component is degraded and to what extent. On this basis, the operator can classify engine health to a certain damage class.

- The comparison between ANN and ELM was performed on the same datasets, with input vectors 1 and 2. After that, the reduced input vectors 3 and 4 were used to verify the ELM prediction accuracy for all the degraded flight regimes.

2.3. Machine Learning Techniques

2.3.1. ANN-Based Regression

2.3.2. ELM-Based Regression

- Randomly initialize the weights and thresholds of the ELM network and set the activation function.

- Calculate the hidden layer output matrix and its generalized inverse .

- Calculate the output vector.

3. Results

3.1. Engine Performance Simulations

3.2. ANN and ELM Predictions with Input Vectors 1 and 2

3.3. ELM Prediction with a Reduced Number of Virtual Sensors (Input Vectors 3 and 4)

3.4. Overall Accuracy Metrics

- Normalized root mean squared error (NRMSE);

- Coefficient of determination (CoD);

- Maximum relative absolute error (MaxRAE).

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alozie, O.; Li, Y.G.; Diakostefanis, M.; Wu, X.; Shong, X.; Ren, W. Assessment of degradation equivalent operating time for aircraft gas turbine engines. Aeronaut. J. 2020, 124, 549–580. [Google Scholar] [CrossRef]

- Cruz-Manzo, S.; Panov, V.; Zhang, Y. Gas path fault and degradation modelling in twin-shaft gas turbines. Machines 2018, 6, 43. [Google Scholar] [CrossRef] [Green Version]

- Dvirnyk, Y.; Pavlenko, D.; Przysowa, R. Determination of Serviceability Limits of a Turboshaft Engine by the Criterion of Blade Natural Frequency and Stall Margin. Aerospace 2019, 6, 132. [Google Scholar] [CrossRef] [Green Version]

- Przybyła, B.S.; Przysowa, R.; Zapałowicz, Z. Implementation of a new inlet protection system into HEMS fleet. Aircr. Eng. Aerosp. Technol. 2020, 92, 67–79. [Google Scholar] [CrossRef]

- Walsh, P.P.; Fletcher, P. Gas Turbine Performance, 2nd ed.; Blackwell Science Ltd.: Oxford, UK, 2004. [Google Scholar]

- Fentaye, A.D.; Baheta, A.T.; Gilani, S.I.; Kyprianidis, K.G. A Review on Gas Turbine Gas-Path Diagnostics: State-of-the-art Methods, Challenges and Opportunities. Aerospace 2019, 6, 83. [Google Scholar] [CrossRef] [Green Version]

- Tahan, M.; Tsoutsanis, E.; Muhammad, M.; Abdul Karim, Z.A. Performance-based health monitoring, diagnostics and prognostics for condition-based maintenance of gas turbines: A review. Appl. Energy 2017, 198, 122–144. [Google Scholar] [CrossRef] [Green Version]

- Igie, U.; Diez-Gonzalez, P.; Giraud, A.; Minervino, O. Evaluating Gas Turbine Performance Using Machine-Generated Data: Quantifying Degradation and Impacts of Compressor Washing. J. Eng. Gas Turbines Power 2016, 138, 122601. [Google Scholar] [CrossRef]

- Sun, X.; Jafari, S.; Miran Fashandi, S.A.; Nikolaidis, T. Compressor Degradation Management Strategies for Gas Turbine Aero-Engine Controller Design. Energies 2021, 14, 5711. [Google Scholar] [CrossRef]

- Gou, L.; Liu, Z.; Fan, D.; Zheng, H. Aeroengine Robust Gain-Scheduling Control Based on Performance Degradation. IEEE Access 2020, 8, 104857–104869. [Google Scholar] [CrossRef]

- Zaccaria, V.; Ferrari, M.L.; Kyprianidis, K. Adaptive Control of Micro Gas Turbine for Engine Degradation Compensation. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; Campilongo, S.; Ficarella, A. Predictions of operational degradation of the fan stage of an aircraft engine due to particulate ingestion. J. Eng. Gas Turbines Power 2015, 137, 052603. [Google Scholar] [CrossRef]

- Ellis, M.; Bojdo, N.; Filippone, A.; Clarkson, R. Monte carlo predictions of aero-engine performance degradation due to particle ingestion. Aerospace 2021, 8, 146. [Google Scholar] [CrossRef]

- Minijets. The Website for Fans of Light Jet Aircraft. Available online: https://minijets.org (accessed on 22 July 2022).

- Pavlenko, D.; Dvirnyk, Y.; Przysowa, R. Advanced Materials and Technologies for Compressor Blades of Small Turbofan Engines. Aerospace 2021, 8, 1. [Google Scholar] [CrossRef]

- Gaonkar, D.N.; Patel, R.N. Modeling and Simulation of Microturbine Based Distributed Generation System. In Proceedings of the 2006 IEEE Power India Conference, New Delhi, India, 10–12 April 2005; pp. 256–260. [Google Scholar]

- Badami, M.; Giovanni Ferrero, M.; Portoraro, A. Dynamic Parsimonious Model and Experimental Validation of a Gas Microturbine at Part-Load Conditions. Appl. Therm. Eng. 2015, 75, 14–23. [Google Scholar] [CrossRef]

- Alulema, V.; Valencia, E.; Cando, E.; Hidalgo, V.; Rodriguez, D. Propulsion Sizing Correlations for Electrical and Fuel Powered Unmanned Aerial Vehicles. Aerospace 2021, 8, 171. [Google Scholar] [CrossRef]

- Adamski, M. Analysis of Propulsion Systems of Unmanned Aerial Vehicles. J. Mar. Eng. Technol. 2018, 16, 291–297. [Google Scholar] [CrossRef]

- Oppong, F.; Spuy, S.J.V.D.; Diaby, A.L. An Overview on the Performance Investigation and Improvement of Micro Gas Turbine Engine. R&D J. S. Afr. Inst. Mech. Eng. 2015, 31, 35–41. [Google Scholar] [CrossRef]

- Capata, R.; Saracchini, M. Experimental Campaign Tests on Ultra Micro Gas Turbines, Fuel Supply Comparison and Optimization. Energies 2018, 11, 799. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.J.; Kim, J.H.; Kim, T.S. The effects of internal leakage on the performance of a micro gas turbine. Appl. Energy 2018, 212, 175–184. [Google Scholar] [CrossRef]

- Talebi, S.; Tousi, A.; Madadi, A.; Kiaee, M. A methodology for identifying the most suitable measurements for engine level and component level gas path diagnostics of a micro gas turbine. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 2646–2661. [Google Scholar] [CrossRef]

- Grannan, N.D.; Hoke, J.; McClearn, M.J.; Litke, P.; Schauer, F. Trends in jetCAT Microturbojet-Compressor Efficiency. In Proceedings of the AIAA SciTech Forum—55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar] [CrossRef]

- Thomas Jayachandran, A.V.; Omar, H.; Tkachenko, A.; Krishnakumar, A. Machine learning predictor for micro gas turbine performance evaluation. Aeronaut. Aerosp. Open Access J. 2020, 4, 172–180. [Google Scholar] [CrossRef]

- Gomes, E.E.B.; McCaffrey, D.; Garces, M.J.M.; Polizakis, A.L.; Pilidis, P. Comparative Analysis of Microturbines Performance Deterioration and Diagnostics. In Proceedings of the ASME Turbo Expo 2006: Power for Land, Sea, and Air, Barcelona, Spain, 8–11 May 2006; pp. 269–276. [Google Scholar] [CrossRef]

- Rahman, M.; Zaccaria, V.; Zhao, X.; Kyprianidis, K. Diagnostics-Oriented Modelling of Micro Gas Turbines for Fleet Monitoring and Maintenance Optimization. Processes 2018, 6, 216. [Google Scholar] [CrossRef] [Green Version]

- Khustochka, O.; Chernysh, S.; Yepifanov, S.; Ugryumov, M.; Przysowa, R. Estimation of Performance Parameters of Turbine Engine Components Using Experimental Data in Parametric Uncertainty Conditions. Aerospace 2020, 7, 6. [Google Scholar] [CrossRef] [Green Version]

- Hanachi, H.; Mechefske, C.; Liu, J.; Banerjee, A.; Chen, Y. Performance-based gas turbine health monitoring, diagnostics, and prognostics: A survey. IEEE Trans. Reliab. 2018, 67, 1340–1363. [Google Scholar] [CrossRef]

- de Castro-Cros, M.; Velasco, M.; Angulo, C. Machine-Learning-Based Condition Assessment of Gas Turbines—A Review. Energies 2021, 14, 8468. [Google Scholar] [CrossRef]

- Akpudo, U.E.; Hur, J.W. Investigating the Efficiencies of Fusion Algorithms for Accurate Equipment Monitoring and Prognostics. Energies 2022, 15, 2204. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; Campilongo, S.; Ficarella, A. A Diagnostics Tool for Aero-Engines Health Monitoring Using Machine Learning Technique. Energy Procedia 2018, 148, 860–867. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; Campilongo, S.; Ficarella, A. Development of a Real Time Intelligent Health Monitoring Platform for Aero-Engine. MATEC Web Conf. 2018, 233, 00007. [Google Scholar] [CrossRef]

- Huang, G.B.; Zhu, Q.Y.; Siew, C.K. Extreme learning machine: Theory and applications. Neurocomputing 2006, 70, 489–501. [Google Scholar] [CrossRef]

- Albadr, M.A.A.; Tiun, S. Extreme Learning Machine: A Review. Int. J. Appl. Eng. Res. 2017, 12, 4610–4623. [Google Scholar]

- Zhao, Y.P.; Huang, G.; Hu, Q.K.; Tan, J.F.; Wang, J.J.; Yang, Z. Soft Extreme Learning Machine for Fault Detection of Aircraft Engine. Aerosp. Sci. Technol. 2019, 91, 70–81. [Google Scholar] [CrossRef]

- Lu, F.; Jiang, C.; Huang, J.; Wang, Y.; You, C. A Novel Data Hierarchical Fusion Method for Gas Turbine Engine Performance Fault Diagnosis. Energies 2016, 9, 828. [Google Scholar] [CrossRef] [Green Version]

- Jiang, W.; Xu, Y.; Shan, Y.; Liu, H. Degradation Tendency Measurement of Aircraft Engines Based on FEEMD Permutation Entropy and Regularized Extreme Learning Machine Using Multi-Sensor Data. Energies 2018, 11, 3301. [Google Scholar] [CrossRef] [Green Version]

- Pérez-Ruiz, J.L.; Tang, Y.; Loboda, I. Aircraft Engine Gas-Path Monitoring and Diagnostics Framework Based on a Hybrid Fault Recognition Approach. Aerospace 2021, 8, 232. [Google Scholar] [CrossRef]

- Liu, X.; Liu, L.; Wang, L.; Guo, Q.; Peng, X. Performance Sensing Data Prediction for an Aircraft Auxiliary Power Unit Using the Optimized Extreme Learning Machine. Sensors 2019, 19, 3935. [Google Scholar] [CrossRef] [Green Version]

- Bai, M.; Liu, J.; Ma, Y.; Zhao, X.; Long, Z.; Yu, D. Long Short-Term Memory Network-Based Normal Pattern Group for Fault Detection of Three-Shaft Marine Gas Turbine. Energies 2020, 14, 13. [Google Scholar] [CrossRef]

- Berghout, T.; Mouss, L.H.; Kadri, O.; Saïdi, L.; Benbouzid, M. Aircraft Engines Remaining Useful Life Prediction with an Improved Online Sequential Extreme Learning Machine. Appl. Sci. 2020, 10, 1062. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Li, Q.; Pang, S.; Zhou, W. A State Space Modeling Method for Aero-Engine Based on AFOS-ELM. Energies 2022, 15, 3903. [Google Scholar] [CrossRef]

- Gu, Z.; Pang, S.; Zhou, W.; Li, Y.; Li, Q. An Online Data-Driven LPV Modeling Method for Turbo-Shaft Engines. Energies 2022, 15, 1255. [Google Scholar] [CrossRef]

- Erario, M.L.; De Giorgi, M.G.; Przysowa, R. Model-Based Dynamic Performance Simulation of a Microturbine Using Flight Test Data. Aerospace 2022, 9, 60. [Google Scholar] [CrossRef]

- Visser, W.P.J.; Broomhead, M.J. GSP, a Generic Object-Oriented Gas Turbine Simulation Environment. In Proceedings of the ASME Turbo Expo 2000: Power for Land, Sea, and Air, Munich, Germany, 8–11 May 2000. [Google Scholar] [CrossRef] [Green Version]

- GSP Development Team GSP 11 User Manual; NLR—Royal Netherlands Aerospace Centre: Amsterdam, The Netherlands, 2021.

- JetCatRX Turbines with V10 ECU; Ingenieur-Büro CAT, M. Zipperer GmbH: Staufen, Germany, 2010; pp. 1–54.

- Hajduk, J.; Rykaczewski, D. Possibilities of Developing Aerial Target System JET-2 (Możliwości Rozwoju Zestawu Odrzutowych Celów Powietrznych Zocp-Jet2). In Mechanika w Lotnictwie ML-XVIII Tom 2 (Mechanics in Aviation ML-XVIII Volume 2); Sibilski, K., Ed.; PTMTS: Warszawa, Poland, 2018; pp. 139–154. [Google Scholar]

- Visser, W.P.J.; Broomhead, M.J.; Kogenhop, O.; Rademaker, E.R. Technical Manual of Gas Turbine Simulation Program; Technical Report NLR-TR-2010-343-Issue-2; National Aerospace Laboratory NLR: Amsterdam, The Nederlands, 2010. [Google Scholar]

- De Giorgi, M.G.; Quarta, M. Hybrid MultiGene Genetic Programming—Artificial Neural Networks Approach for Dynamic Performance Prediction of an Aeroengine. Aerosp. Sci. Technol. 2020, 103, 105902. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; Strafella, L.; Ficarella, A. Neural nonlinear autoregressive model with exogenous input (Narx) for turboshaft aeroengine fuel control unit model. Aerospace 2021, 8, 206. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; Strafella, L.; Menga, N.; Ficarella, A. Intelligent Combined Neural Network and Kernel Principal Component Analysis Tool for Engine Health Monitoring Purposes. Aerospace 2022, 9, 118. [Google Scholar] [CrossRef]

- Khumprom, P.; Grewell, D.; Yodo, N. Deep Neural Network Feature Selection Approaches for Data-Driven Prognostic Model of Aircraft Engines. Aerospace 2020, 7, 132. [Google Scholar] [CrossRef]

- Yoon, J.E.; Lee, J.J.; Kim, T.S.; Sohn, J.L. Analysis of performance deterioration of a micro gas turbine and the use of neural network for predicting deteriorated component characteristics. J. Mech. Sci. Technol. 2008, 22, 2516–2525. [Google Scholar] [CrossRef]

- Kurzke, J.; Halliwell, I. Monte Carlo Simulations. In Propulsion and Power: An Exploration of Gas Turbine Performance Modeling; Springer International Publishing: Cham, Switzerland, 2018; pp. 439–575. [Google Scholar] [CrossRef]

- Son, S.; Cho, S.K.; Lee, J.I. Experimental investigation on performance degradation of a supercritical CO2 radial compressor by foreign object damage. Appl. Therm. Eng. 2021, 183, 116229. [Google Scholar] [CrossRef]

- Safiyullah, F.; Sulaiman, S.; Naz, M.; Jasmani, M.; Ghazali, S. Prediction on performance degradation and maintenance of centrifugal gas compressors using genetic programming. Energy 2018, 158, 485–494. [Google Scholar] [CrossRef]

- Davison, C.R.; Birk, A.M. Automated Fault Diagnosis of a Micro Turbine With Comparison to a Neural Network Technique. In Proceedings of the ASME Turbo Expo 2006: Power for Land, Sea, and Air, Barcelona, Spain, 8–11 May 2006; pp. 795–804. [Google Scholar] [CrossRef]

- Liu, Y.; Banerjee, A.; Ravichandran, T.; Kumar, A.; Heppler, G. Data analytics for performance monitoring of gas turbine engine. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, Philadelphia, PA, USA, 24–27 September 2018; pp. 201–203. [Google Scholar] [CrossRef]

- Olsson, T.; Ramentol, E.; Rahman, M.; Oostveen, M.; Kyprianidis, K. A data-driven approach for predicting long-term degradation of a fleet of micro gas turbines. Energy AI 2021, 4, 100064. [Google Scholar] [CrossRef]

- Xu, M.; Wang, J.; Liu, J.; Li, M.; Geng, J.; Wu, Y.; Song, Z. An Improved Hybrid Modeling Method Based on Extreme Learning Machine for Gas Turbine Engine. Aerosp. Sci. Technol. 2020, 107, 106333. [Google Scholar] [CrossRef]

- Yang, X.; Pang, S.; Shen, W.; Lin, X.; Jiang, K.; Wang, Y. Aero Engine Fault Diagnosis Using an Optimized Extreme Learning Machine. Int. J. Aerosp. Eng. 2016, 2016, 7892875. [Google Scholar] [CrossRef]

| Parameter | Specification | |

|---|---|---|

| Overall Pressure Ratio | 3.4 | |

| Air flow rate | 0.35 | kg/s |

| Maximum EGT | 749 | °C |

| Mass Flow | 0.34 | kg/s |

| Maximum Thrust | 142 | N |

| Design Speed | 125 | kRPM |

| Fuel consumption | 7.33 | g/s |

| Symbol | Parameter |

|---|---|

| TT | ambient total temperature |

| PT | ambient total pressure |

| M | Mach number |

| fuel flow | |

| PT | compressor outlet total pressure |

| TT | compressor outlet temperature |

| PT | turbine inlet total pressure |

| TT | turbine inlet temperature |

| PT | turbine outlet total pressure |

| TT | turbine outlet temperature |

| PT | nozzle outlet total pressure |

| TT | nozzle outlet total temperature |

| EGT | exhaust gas temperature |

| Flight Regime | Altitude | Air Speed | Compressor Efficiency | Compressor Mass Flow | Turbine Efficiency | Turbine Mass Flow | |

|---|---|---|---|---|---|---|---|

| [m] | M | [kg/s] | [kg/s] | ||||

| 1 | Takeoff | 0 | 0 | 0.740 | 0.350 | 0.750 | 0.359 |

| 2 | Cruise | 3000 | 0.3 | 0.738 | 0.277 | 0.748 | 0.284 |

| 3 | Air mission | 3000 ± 700 | 0.2 ± 0.05 | 0.735–0.740 | 0.209–0.350 | 0.747–0.750 | 0.212–0.359 |

| Degradation (mean ± std deviation) | 2% | 2% | 2% | 2% | |||

| Input Vector | Vector Length | Parameters | Flight Regime | ML Model |

|---|---|---|---|---|

| 1 | 9 | , PT, TT, PT, TT, PT, TT, PT, TT | 1 and 2 | ANN/ELM |

| 2 | 12 | M, TT,,, PT, TT, PT, TT, PT, TT, PT, TT | 3 | ANN/ELM |

| 3 | 2 | , EGT | 1 and 2 | ELM |

| 4 | 5 | M, TT, PT, , EGT | 3 | ELM |

| ANN | ELM | ||||||

|---|---|---|---|---|---|---|---|

| NMSE | CoD | MaxRAE | NMSE | CoD | MaxRAE | ||

| Degradation of Compressor—Flight Regime 1 | |||||||

| Train | 2.20 × | 0.999998 | 1.30 × | 1.13 × | 0.99999999 | 3.88 × | |

| Train | 8.29 × | 0.999992 | 3.21 × | 1.68 × | 0.99999832 | 1.05 × | |

| Test | 4.71 × | 0.999995 | 1.62 × | 1.91 × | 0.99999998 | 1.70 × | |

| Test | 9.33 × | 0.999991 | 3.28 × | 2.15 × | 0.99999783 | 8.29 × | |

| Degradation of Compressor—Flight Regime 2 | |||||||

| Train | 1.41 × | 0.999986 | 4.52 × | 6.44 × | 0.99264601 | 3.86 × | |

| Train | 4.39 × | 0.999956 | 8.18 × | 1.72 × | 0.99832588 | 5.33 × | |

| Test | 1.92 | 0.911250 | 9.45 × | 6.07 × | 0.99291352 | 3.41 × | |

| Test | 1.77 | 0.901034 | 1.03 × | 3.97 × | 0.99614528 | 4.91 × | |

| Degradation of Compressor—Flight Regime 3 | |||||||

| Train | 7.80 × | 0.999922 | 7.64 × | 2.65 × | 0.99997340 | 4.78 × | |

| Train | 1.17 × | 0.999988 | 9.39 × | 2.85 × | 0.99999714 | 6.13 × | |

| Test | 9.35 × | 0.999906 | 6.76 × | 2.70 × | 0.99997265 | 6.78 × | |

| Test | 1.27 × | 0.999987 | 2.20 × | 5.85 × | 0.99999409 | 3.13 × | |

| Degradation of Turbine—Flight Regime 1 | |||||||

| Train | 6.02 × | 0.999994 | 2.47 × | 2.36 × | 0.9999998 | 8.32 × | |

| Train | 5.46 × | 0.999945 | 1.10 × | 3.90 × | 0.9999609 | 7.57 × | |

| Test | 8.10 × | 0.999992 | 2.02 × | 2.69 × | 0.9999997 | 2.70 × | |

| Test | 7.47 × | 0.999924 | 7.45 × | 8.93 × | 0.9999096 | 9.10 × | |

| Train | 3.05 × | 0.999969 | 6.64 × | 7.12 × | 0.9151199 | 1.08 × | |

| Train | 2.78 × | 0.999721 | 1.36 × | 5.53 × | 0.9945780 | 4.43 × | |

| Test | 1.84 | 0.923113 | 8.12 × | 6.62 × | 0.9222553 | 1.14 × | |

| Test | 1.76 | 0.942045 | 9.89 × | 1.07 × | 0.9893549 | 3.75 × | |

| Degradation of turbine—Flight Regime 3 | |||||||

| Train | 1.57 × | 0.999843 | 1.39 × | 4.88 × | 0.9999509 | 4.01 × | |

| Train | 8.42 × | 0.999916 | 3.05 × | 6.44 × | 0.9999354 | 1.42 × | |

| Test | 2.10 × | 0.999787 | 8.40 × | 1.22 × | 0.9998769 | 8.81 × | |

| Test | 1.26 × | 0.999873 | 1.91 × | 1.33 × | 0.9998660 | 1.51 × | |

| Compressor | Turbine | ||||||

|---|---|---|---|---|---|---|---|

| NMSE | CoD | MaxRAE | NMSE | CoD | MaxRAE | ||

| Flight Regime 1 | |||||||

| Train | 0.5179 | 0.84124 | 0.0649 | 0.4583 | 0.8596 | 0.0642 | |

| W | Train | 2.2 | 0.99998 | 0.0001 | 0.0001 | 0.9999 | 0.0008 |

| Test | 0.6972 | 0.81431 | 0.0631 | 0.4569 | 0.8471 | 0.0416 | |

| W | Test | 2.5 | 0.99998 | 0.0001 | 0.0001 | 0.9999 | 0.0006 |

| Flight Regime 2 | |||||||

| Train | 0.9838 | 0.81124 | 0.0652 | 0.8632 | 0.8376 | 0.0623 | |

| W | Train | 0.0027 | 0.99741 | 0.0025 | 0.0036 | 0.9965 | 0.0025 |

| Test | 0.9074 | 0.80324 | 0.0733 | 0.9924 | 0.8271 | 0.0449 | |

| W | Test | 0.0043 | 0.99600 | 0.0018 | 0.0060 | 0.9944 | 0.0022 |

| Flight Regime 3 | |||||||

| Train | 1.5017 | 0.80201 | 0.0964 | 1.3536 | 0.8040 | 0.0739 | |

| W | Train | 0.0556 | 0.94047 | 0.0487 | 0.0535 | 0.9428 | 0.0477 |

| Test | 1.3805 | 0.79924 | 0.0770 | 2.0305 | 0.7893 | 0.0883 | |

| W | Test | 0.0640 | 0.92574 | 0.0466 | 0.0618 | 0.9285 | 0.0459 |

| Flight Regime | ANN | ELM |

|---|---|---|

| 1 | 3.9 | 1.65 |

| 2 | 4.7 | 1.20 |

| 3 | 2.79 | 0.43 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menga, N.; Mothakani, A.; De Giorgi, M.G.; Przysowa, R.; Ficarella, A. Extreme Learning Machine-Based Diagnostics for Component Degradation in a Microturbine. Energies 2022, 15, 7304. https://doi.org/10.3390/en15197304

Menga N, Mothakani A, De Giorgi MG, Przysowa R, Ficarella A. Extreme Learning Machine-Based Diagnostics for Component Degradation in a Microturbine. Energies. 2022; 15(19):7304. https://doi.org/10.3390/en15197304

Chicago/Turabian StyleMenga, Nicola, Akhila Mothakani, Maria Grazia De Giorgi, Radoslaw Przysowa, and Antonio Ficarella. 2022. "Extreme Learning Machine-Based Diagnostics for Component Degradation in a Microturbine" Energies 15, no. 19: 7304. https://doi.org/10.3390/en15197304