Solar-Powered Plant Protection Equipment: Perspective and Prospects

Abstract

:1. Introduction

2. Eco-Friendly Strategies for Plant Protection

3. Applications of Solar Energy in Agriculture

4. Solar PV Technologies

5. Solar-Powered Equipment for Weed Management

Solar Power Weeders

6. Solar-Powered Equipment for Pest Management

6.1. Solar Insect Traps

6.2. Solar-Powered Sprayers

6.3. Solar PV Duster

Conventional and Solar-Based Plant Protection Equipment Methods

7. Solar-Powered Equipment for Non-Insect Pest Management

7.1. Solar Bird Scarer

7.2. Solar Fencing

8. Future Perspectives and Prospects

- The operating mechanism is an important deciding factor to finalize the size of the panel and the battery capacity to operate the machine. For instance, there are two common methods to eradicate weeds/insects, namely mechanical and chemical. Power requirements may be different for each of these methods.

- The improvement of solar panel efficiency results in a smaller panel size/area, and it indirectly results in an overall weight reduction of the system.

- The overall performance of the device ultimately depends on the performance of the battery. The battery capacity is directly linked to the size/weight of the battery. If the battery’s power density can be improved, the battery size will reduce while outputting the same power. Hence, it is suggested that battery life should be enhanced to reduce the maintenance cost. If all three requisites are fulfilled, an improvement in overall performance may be achieved.

- Sensors for image capturing of weeds/insects, sound detection, motion capturing of birds, and timers can be incorporated in the plant protection devices to improve their performance.

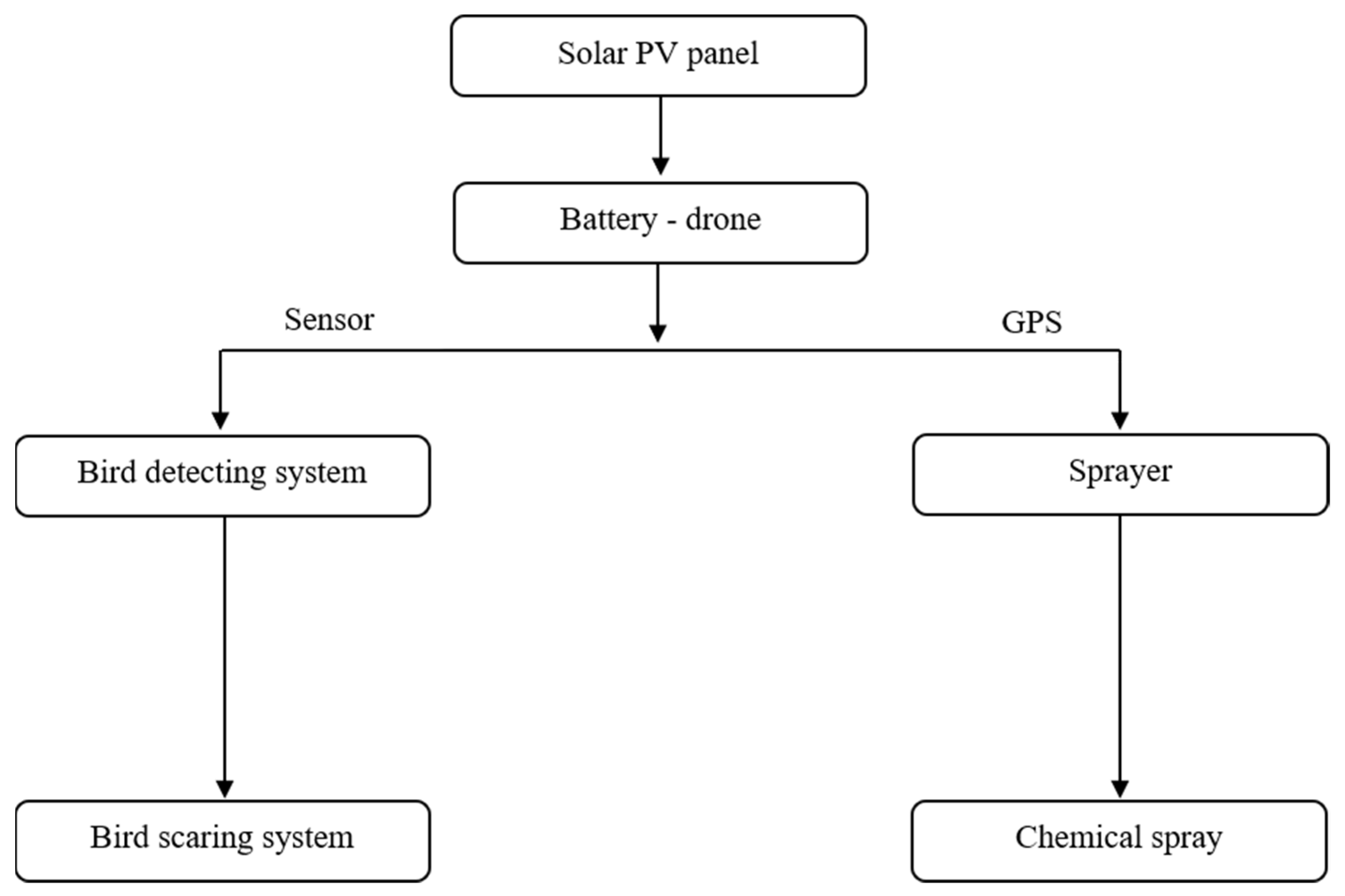

- The solar PV plant protection equipment with artificial intelligence (AI), remote sensing, and supporting software may minimize the required power and costs for their operations, resulting in better performance. For example, an integrated approach can be used for a drone-operated bird scarer cum sprayer (Figure 7). This would help in reducing the overall cost and can also be used for other purposes.

- The Internet of Things (IoT) has a potential purpose in agriculture, which would help in increasing the efficiency of agricultural production processes [139]. Applications of IoT technologies can modify existing agricultural practices [140]. Furthermore, IoT-supported automation of solar-powered plant protection equipment will reduce labor requirements with improved crop yield, which would lead to smart health monitoring in agriculture.

- Solar-powered plant protection equipment can be operational only for a few days or weeks in the entire crop duration (Table 7). The equipment will be idle when not used, and daily charging and discharging of the battery should be carried out for better utilization of the PV system. The battery in the PV system must be monitored regularly. Poor maintenance of the battery will lead to reduced battery life. In order to avoid this situation, the PV system and battery may be used for off-farming activities.

- Recently, farmers have started using drone sprayers due to the simplicity of operation and more coverage per day. There is not much research on solar-powered drone-operated sprayers. Since drone sprayers require fans for their operation and air mass, nearby areas also would be affected by their operation. Moreover, there will be more chances for the drift of chemicals in the air. Future research may focus on the effective utilization of solar-powered drones with proper calibrations.

- The economic and technical feasibility studies for such solar equipment may be carried out before launching them into the commercial market.

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Jha, G.K.; Pal, S.; Singh, A. Changing Energy-Use Pattern and the Demand Projection for Indian Agriculture. Agric. Econ. Res. Rev. 2012, 25, 61–68. [Google Scholar]

- Scherm, H.; Sutherst, R.W.; Harrington, R.; Ingram, J.S.I. Global Networking for Assessment of Impacts of Global Change on Plant Pests. Environ. Pollut. 2000, 108, 333–341. [Google Scholar] [CrossRef]

- Van Lenteren, J.C. Ecosystem Services to Biological Control of Pests: Why Are They Ignored? Proc. Sect. Exp. Appl. Entomol. Neth. Entomol. Soc. 2006, 17, 103. Available online: https://secties.nev.nl/pages/publicaties/proceedings/nummers/17/103-111.pdf (accessed on 4 October 2022).

- Bridges, D.C. Crop Losses Due to Weeds in the United States, 1992; Weed Science Society of America: Westminster, UK, 1992; ISBN 0911733159. [Google Scholar]

- Swinton, S.M.; Buhler, D.D.; Forcella, F.; Gunsolus, J.L.; King, R.P. Estimation of Crop Yield Loss Due to Interference by Multiple Weed Species. Weed Sci. 1994, 42, 103–109. [Google Scholar] [CrossRef]

- Boydston, R.A.; Mojtahedi, H.; Crosslin, J.M.; Brown, C.R.; Anderson, T. Effect of Hairy Nightshade (Solanum sarrachoides) Presence on Potato Nematodes, Diseases, and Insect Pests. Weed Sci. 2008, 56, 151–154. [Google Scholar] [CrossRef]

- Pimentel, D.; Peshin, R. Integrated Pest Management: Pesticide Problems; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2014; Volume 3, ISBN 9400777965. [Google Scholar]

- Dhaliwal, G.S.; Koul, O.; Arora, R.; Cuperus, G.W. Integrated Pest Management: Retrospect and Prospect. In Integrated Pest Management: Potential, Constraints and Challenges; CABI Publishing: Wallingford, UK, 2004. [Google Scholar]

- Kannan, N.; Vakeesan, D. Solar Energy for Future World—A Review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- Sermsri, N.; Torasa, C. Solar Energy-Based Insect Pest Trap. Procedia-Soc. Behav. Sci. 2015, 197, 2548–2553. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.-N.; Song, H.-S.; Li, C.-S.; Huang, Q.-Y.; Lei, C.-L. Effect of Several Factors on the Phototactic Response of the Oriental Armyworm, Mythimna separata (Lepidoptera: Noctuidae). J. Asia-Pac. Entomol. 2018, 21, 952–957. [Google Scholar] [CrossRef]

- Park, J.-H.; Lee, H.-S. Phototactic Behavioral Response of Agricultural Insects and Stored-Product Insects to Light-Emitting Diodes (LEDs). Appl. Biol. Chem. 2017, 60, 137–144. [Google Scholar] [CrossRef]

- Johansen, N.S.; Vänninen, I.; Pinto, D.M.; Nissinen, A.I.; Shipp, L. In the Light of New Greenhouse Technologies: 2. Direct Effects of Artificial Lighting on Arthropods and Integrated Pest Management in Greenhouse Crops. Ann. Appl. Biol. 2011, 159, 1–27. [Google Scholar] [CrossRef]

- Khan, J.; Arsalan, M.H. Solar Power Technologies for Sustainable Electricity Generation—A Review. Renew. Sustain. Energy Rev. 2016, 55, 414–425. [Google Scholar] [CrossRef]

- Mustayen, A.; Mekhilef, S.; Saidur, R. Performance Study of Different Solar Dryers: A Review. Renew. Sustain. Energy Rev. 2014, 34, 463–470. [Google Scholar] [CrossRef]

- El Chaar, L.; El Zein, N. Review of Photovoltaic Technologies. Renew. Sustain. Energy Rev. 2011, 15, 2165–2175. [Google Scholar] [CrossRef]

- Joshi, A.S.; Dincer, I.; Reddy, B. V Performance Analysis of Photovoltaic Systems: A Review. Renew. Sustain. Energy Rev. 2009, 13, 1884–1897. [Google Scholar] [CrossRef]

- Meral, M.E.; Dincer, F. A Review of the Factors Affecting Operation and Efficiency of Photovoltaic Based Electricity Generation Systems. Renew. Sustain. Energy Rev. 2011, 15, 2176–2184. [Google Scholar] [CrossRef]

- Parida, B.; Iniyan, S.; Goic, R. A Review of Solar Photovoltaic Technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Singh, G.K. Solar Power Generation by PV (Photovoltaic) Technology: A Review. Energy 2013, 53, 1–13. [Google Scholar] [CrossRef]

- Foster, R.; Cota, A. Solar Water Pumping Advances and Comparative Economics. Energy Procedia 2014, 57, 1431–1436. [Google Scholar] [CrossRef] [Green Version]

- Meah, K.; Ula, S.; Barrett, S. Solar Photovoltaic Water Pumping—Opportunities and Challenges. Renew. Sustain. Energy Rev. 2008, 12, 1162–1175. [Google Scholar] [CrossRef]

- Bal, L.M.; Satya, S.; Naik, S.N. Solar Dryer with Thermal Energy Storage Systems for Drying Agricultural Food Products: A Review. Renew. Sustain. Energy Rev. 2010, 14, 2298–2314. [Google Scholar] [CrossRef]

- Chaudhari, A.D.; Salve, S.P. A Review of Solar Dryer Technologies. Int. J. Res. Advent Technol. 2014, 2, 218–232. [Google Scholar]

- Chauhan, P.S.; Kumar, A.; Tekasakul, P. Applications of Software in Solar Drying Systems: A Review. Renew. Sustain. Energy Rev. 2015, 51, 1326–1337. [Google Scholar] [CrossRef]

- Chauhan, Y.B.; Rathod, P.P. A Comprehensive Review of the Solar Dryer. Int. J. Ambient Energy 2020, 41, 348–367. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Shalaby, S.M. Solar Drying of Agricultural Products: A Review. Renew. Sustain. Energy Rev. 2012, 16, 37–43. [Google Scholar] [CrossRef]

- Fudholi, A.; Sopian, K.; Ruslan, M.H.; Alghoul, M.A.; Sulaiman, M.Y. Review of Solar Dryers for Agricultural and Marine Products. Renew. Sustain. Energy Rev. 2010, 14, 1–30. [Google Scholar] [CrossRef]

- El Hage, H.; Herez, A.; Ramadan, M.; Bazzi, H.; Khaled, M. An Investigation on Solar Drying: A Review with Economic and Environmental Assessment. Energy 2018, 157, 815–829. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Sharma, A.; Kumar, A.; Jain, A. Thermal Energy Storage Based Solar Drying Systems: A Review. Innov. food Sci. Emerg. Technol. 2016, 34, 86–99. [Google Scholar] [CrossRef]

- Muhsen, D.H.; Khatib, T.; Nagi, F. A Review of Photovoltaic Water Pumping System Designing Methods, Control Strategies and Field Performance. Renew. Sustain. Energy Rev. 2017, 68, 70–86. [Google Scholar] [CrossRef]

- Murthy, M.V.R. A Review of New Technologies, Models and Experimental Investigations of Solar Driers. Renew. Sustain. Energy Rev. 2009, 13, 835–844. [Google Scholar] [CrossRef]

- Patil, R.; Gawande, R. A Review on Solar Tunnel Greenhouse Drying System. Renew. Sustain. Energy Rev. 2016, 56, 196–214. [Google Scholar] [CrossRef]

- Phadke, P.C.; Walke, P.V.; Kriplani, V.M. Direct Type Natural Convection Solar Dryer: A Review. Int. J. Adv. Res. Sci. Eng. 2015, 4, 256–262. [Google Scholar]

- Pirasteh, G.; Saidur, R.; Rahman, S.M.A.; Rahim, N.A. A Review on Development of Solar Drying Applications. Renew. Sustain. Energy Rev. 2014, 31, 133–148. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Solar Greenhouse Drying: A Review. Renew. Sustain. Energy Rev. 2014, 29, 905–910. [Google Scholar] [CrossRef]

- Rawat, R.; Kaushik, S.C.; Lamba, R. A Review on Modeling, Design Methodology and Size Optimization of Photovoltaic Based Water Pumping, Standalone and Grid Connected System. Renew. Sustain. Energy Rev. 2016, 57, 1506–1519. [Google Scholar] [CrossRef]

- Shalaby, S.M.; Bek, M.A.; El-Sebaii, A.A. Solar Dryers with PCM as Energy Storage Medium: A Review. Renew. Sustain. Energy Rev. 2014, 33, 110–116. [Google Scholar] [CrossRef]

- Sharma, A.; Chen, C.R.; Lan, N.V. Solar-Energy Drying Systems: A Review. Renew. Sustain. Energy Rev. 2009, 13, 1185–1210. [Google Scholar] [CrossRef]

- Sontakke, M.S.; Salve, S.P. Solar Drying Technologies: A Review. Int. J. Eng. Sci. 2015, 4, 29–35. [Google Scholar]

- Thirugnanasambandam, M.; Iniyan, S.; Goic, R. A Review of Solar Thermal Technologies. Renew. Sustain. Energy Rev. 2010, 14, 312–322. [Google Scholar] [CrossRef]

- VijayaVenkataRaman, S.; Iniyan, S.; Goic, R. A Review of Solar Drying Technologies. Renew. Sustain. Energy Rev. 2012, 16, 2652–2670. [Google Scholar] [CrossRef]

- Ndukwu, M.C.; Bennamoun, L.; Simo-Tagne, M. Reviewing the Exergy Analysis of Solar Thermal Systems Integrated with Phase Change Materials. Energies 2021, 14, 724. [Google Scholar] [CrossRef]

- Chock, R.Y.; Clucas, B.; Peterson, E.K.; Blackwell, B.F.; Blumstein, D.T.; Church, K.; Fernández-Juricic, E.; Francescoli, G.; Greggor, A.L.; Kemp, P. Evaluating Potential Effects of Solar Power Facilities on Wildlife from an Animal Behavior Perspective. Conserv. Sci. Pract. 2021, 3, e319. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Solar Energy Engineering: Processes and Systems; Academic Press: Oxford, UK, 2013; ISBN 0123972566. [Google Scholar]

- Aliyu, M.; Hassan, G.; Said, S.A.; Siddiqui, M.U.; Alawami, A.T.; Elamin, I.M. A Review of Solar-Powered Water Pumping Systems. Renew. Sustain. Energy Rev. 2018, 87, 61–76. [Google Scholar] [CrossRef]

- Chandel, S.S.; Naik, M.N.; Chandel, R. Review of Performance Studies of Direct Coupled Photovoltaic Water Pumping Systems and Case Study. Renew. Sustain. Energy Rev. 2017, 76, 163–175. [Google Scholar] [CrossRef]

- Chandel, S.S.; Naik, M.N.; Chandel, R. Review of Solar Photovoltaic Water Pumping System Technology for Irrigation and Community Drinking Water Supplies. Renew. Sustain. Energy Rev. 2015, 49, 1084–1099. [Google Scholar] [CrossRef]

- Gopal, C.; Mohanraj, M.; Chandramohan, P.; Chandrasekar, P. Renewable Energy Source Water Pumping Systems—A Literature Review. Renew. Sustain. Energy Rev. 2013, 25, 351–370. [Google Scholar] [CrossRef]

- Koner, P.K. A Review on the Diversity of Photovoltaic Water Pumping Systems. Int. Energy J. 2017, 15, 89–110. [Google Scholar]

- Li, G.; Jin, Y.; Akram, M.W.; Chen, X. Research and Current Status of the Solar Photovoltaic Water Pumping System–A Review. Renew. Sustain. Energy Rev. 2017, 79, 440–458. [Google Scholar] [CrossRef]

- Periasamy, P.; Jain, N.K.; Singh, I.P. A Review on Development of Photovoltaic Water Pumping System. Renew. Sustain. Energy Rev. 2015, 43, 918–925. [Google Scholar] [CrossRef]

- Poompavai, T.; Kowsalya, M. Control and Energy Management Strategies Applied for Solar Photovoltaic and Wind Energy Fed Water Pumping System: A Review. Renew. Sustain. Energy Rev. 2019, 107, 108–122. [Google Scholar] [CrossRef]

- Shinde, V.B.; Wandre, S.S. Solar Photovoltaic Water Pumping System for Irrigation: A Review. Afr. J. Agric. Res. 2015, 10, 2267–2273. [Google Scholar]

- Sontake, V.C.; Kalamkar, V.R. Solar Photovoltaic Water Pumping System—A Comprehensive Review. Renew. Sustain. Energy Rev. 2016, 59, 1038–1067. [Google Scholar] [CrossRef]

- Wazed, S.M.; Hughes, B.R.; O’Connor, D.; Calautit, J.K. A Review of Sustainable Solar Irrigation Systems for Sub-Saharan Africa. Renew. Sustain. Energy Rev. 2018, 81, 1206–1225. [Google Scholar] [CrossRef]

- Duke, S.O. Why Have No New Herbicide Modes of Action Appeared in Recent Years? Pest Manag. Sci. 2012, 68, 505–512. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Machleb, J.; Peteinatos, G.G.; Kollenda, B.L.; Andújar, D.; Gerhards, R. Sensor-Based Mechanical Weed Control: Present State and Prospects. Comput. Electron. Agric. 2020, 176, 105638. [Google Scholar] [CrossRef]

- Khan, S.U.-D.; Almutairi, Z.A.; Al-Zaid, O.S.; Khan, S.U.-D. Development of Low Concentrated Solar Photovoltaic System with Lead Acid Battery as Storage Device. Curr. Appl. Phys. 2020, 20, 582–588. [Google Scholar] [CrossRef]

- Sujaritha, M.; Annadurai, S.; Satheeshkumar, J.; Sharan, S.K.; Mahesh, L. Weed Detecting Robot in Sugarcane Fields Using Fuzzy Real Time Classifier. Comput. Electron. Agric. 2017, 134, 160–171. [Google Scholar] [CrossRef]

- Sujaritha, M.; Lakshminarasimhan, M.; Fernandez, C.J.; Chandran, M. Greenbot: A Solar Autonomous Robot to Uproot Weeds in a Grape Field. Int. J. Comput. Sci. Eng. 2016, 4, 1351–1358. [Google Scholar]

- Patel, H.; Prajapati, A.; Maheshwari, R. Design & Implementation of Solar Weeding Robot for Cotton Field. Int. Res. J. Eng. Technol. 2018, 5, 3295–3298. [Google Scholar]

- Malani, H.; Nanda, M.; Yadav, J.; Purohit, P.; Didwania, K.L. Remote Controlled Solar Agro Sprayer Robot. In Proceedings of the International Conference on Information and Communication Technology for Intelligent Systems, Ahmedabad, India, 25–26 March 2017; Springer: Berlin/Heidelberg, Germany, 2017; pp. 513–518. [Google Scholar]

- Ecorobotix. Available online: https://www.Ecorobotix.Com/En/Avo-Autonomous-Robot-Weeder/ (accessed on 4 October 2022).

- Reddy, M.R.N.; Ammika, S.G. Modelling and Optimazation of Solar Light Trap for Reducing and Controling the Pest Population. Int. J. Engeenering 2015, 3, 224–234. [Google Scholar]

- Augul, R.S.H.; Al-Saffar, H.H.; Mzhr, N.N. Survey of Some Hemipteran Species Attracted to Light Traps. Adv. Biores. 2015, 6, 122–127. [Google Scholar]

- Baker, R.R.; Cook, L.M. Moths: Population Estimates, Light-Traps and Migration. In Case Studies in Population Biology; Manchester University Press: Manchester, UK, 1985; pp. 188–211. [Google Scholar]

- Beck, J.; Linsenmair, K.E. Feasibility of Light-Trapping in Community Research on Moths: Attraction Radius of Light, Completeness of Samples, Nightly Flight Times and Seasonality of Southeast-Asian Hawkmoths (Lepidoptera: Sphingidae). J. Res. Lepid. 2006, 39, 18–37. [Google Scholar] [CrossRef]

- Hill, C.J.; Cermak, M. A New Design and Some Preliminary Results for a Flight Intercept Trap to Sample Forest Canopy Arthropods. Aust. J. Entomol. 1997, 36, 51–55. [Google Scholar] [CrossRef]

- Furlong, M.J.; Pell, J.K.; Choo, O.P.; Rahman, S.A. Field and Laboratory Evaluation of a Sex Pheromone Trap for the Autodissemination of the Fungal Entomopathogen Zoophthora radicans (Entomophthorales) by the Diamondback Moth, Plutella xylostella (Lepidoptera: Yponomeutidae). Bull. Entomol. Res. 1995, 85, 331–337. [Google Scholar] [CrossRef]

- Bacon, O.G.; Seiber, J.N.; Kennedy, G.G. Evaluation of Survey Trapping Techniques for Potato Tuberworm Moths with Chemical Baited Traps. J. Econ. Entomol. 1976, 69, 569–572. [Google Scholar] [CrossRef]

- Montgomery, G.A.; Belitz, M.W.; Guralnick, R.P.; Tingley, M.W. Standards and Best Practices for Monitoring and Benchmarking Insects. Front. Ecol. Evol. 2021, 8, 513. [Google Scholar] [CrossRef]

- Sheikh, A.H.; Bhandari, R.; Thomas, M.; Bunkar, K. Light Trap and Insect Sampling: An Overview. Int. J. Curr. Res. 2016, 8, 40868–40873. [Google Scholar]

- Bae, S.-D.; Park, J.-O.; Mainali, B.; Kim, H.; Yoon, Y.; Lee, Y.; Cho, Y. Evaluation of Different Light Colors in Solar Trap as Attractants to Cereal and Legume Insect Pests. Korean J. Int. Agric. 2015, 27, 516–521. [Google Scholar] [CrossRef]

- De Medeiros, B.A.S.; Barghini, A.; Vanin, S.A. Streetlights Attract a Broad Array of Beetle Species. Rev. Bras. Entomol. 2017, 61, 74–79. [Google Scholar] [CrossRef]

- Mwanga, E.P.; Ngowo, H.S.; Mapua, S.A.; Mmbando, A.S.; Kaindoa, E.W.; Kifungo, K.; Okumu, F.O. Evaluation of an Ultraviolet LED Trap for Catching Anopheles and Culex Mosquitoes in South-Eastern Tanzania. Parasit. Vectors 2019, 12, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Baehaki, S.E.; Iswanto, E.H.; Munawar, D. Relationship of Predators Flight and Rice Pests That Caught on the Light Trap of Mercury (ML-160 Watt) BSE-G3 Model and Light Trap of Solar Cell-CFL-20 Watt. Int. J. Entomol. Res. 2017, 2, 79–85. [Google Scholar]

- Kumar, N. Development and Evaluation of Eco-Friendly Solar Energy Based Light Trap. Int. J. Pure Appl. Biosci. 2019, 7, 356–360. [Google Scholar] [CrossRef]

- Thangalakshmi, S.; Ramanujan, R. Electronic Trapping and Monitoring of Insect Pests Troubling Agricultural Fields. Int. J. Emerg. Eng. Res. Technol. 2015, 3, 206–213. [Google Scholar]

- Calderon, R.A. Solar Powered Rice Black Bug Light Trap. In Proceedings of the 6th International Conference on Advances in Science, Engineering and Technology, Manila, Philippines, 17–18 December 2017; pp. 17–18. [Google Scholar]

- Brimapureeswaran, R.; Nivas, G.; Meenatchi, R.; Sujeetha, A.R.P.; Loganathan, M. Development of a New Solar Light Cum Glue Trap Model and Its Utilization in Agriculture. Int. J. Emerg. Technol. Innov. Eng. 2016, 2, 37–41. [Google Scholar]

- McQuate, G.T. Green Light Synergistally Enhances Male Sweetpotato Weevil Response to Sex Pheromone. Sci. Rep. 2014, 4, 4499. [Google Scholar] [CrossRef] [Green Version]

- Longing, S.D.; Discua, S.A.; Cokendolpher, J.C. A Solar-Powered UV Light Trap for Long-Term Monitoring of Insects in Remote Habitats. Coleopt. Bull. 2018, 72, 140–144. [Google Scholar] [CrossRef]

- Eccard, J.A.; Scheffler, I.; Franke, S.; Hoffmann, J. Off-grid: Solar Powered LED Illumination Impacts Epigeal Arthropods. Insect Conserv. Divers. 2018, 11, 600–607. [Google Scholar] [CrossRef]

- Hanson, S.M.; Johnson, A.L.; Hou, Y.; Hellwig, M.D. Recharging Centers for Disease Control Light Trap Batteries with Solar Panels. Int. J. Appl. 2012, 2, 76–80. [Google Scholar]

- Blahó, M.; Egri, Á.; Barta, A.; Antoni, G.; Kriska, G.; Horváth, G. How Can Horseflies Be Captured by Solar Panels? A New Concept of Tabanid Traps Using Light Polarization and Electricity Produced by Photovoltaics. Vet. Parasitol. 2012, 189, 353–365. [Google Scholar] [CrossRef] [PubMed]

- Bera, K.P. Development of a New Solar Light Trap Model and Its Utilisation as IPM Tool in Agriculture. JETIR 2015, 2, 549–554. [Google Scholar]

- Tu, H.; Tang, N.; Hu, X.; Yao, Z.; Wang, G.; Wei, H. LED Multispectral Circulation Solar Insecticidal Lamp Application in Rice Field. Trans. Chin. Soc. Agric. Eng. 2016, 32, 193–197. [Google Scholar]

- Ahalya, M.; Muktha, A.; Veena, M.; Vidyashree, G.; Rehna, V.J. Solar Powered Semi-Automatic Pesticide Sprayer for Use in Vineyards. SSRG Int. J. Electron. Commun. Eng. 2017, 4, 54–57. [Google Scholar]

- Kumar, R.; Gopalakrishnan, M.N.N. Fabrication of Solar Operated Agricultural Sprayer. Int. J. Sci. Res. Dev. 2017, 5, 658–661. [Google Scholar]

- Murthy, K.B.; Kanwar, R.; Yadav, I.; Das, V. Solar Pesticide Sprayer. Int. J. Latest Eng. Res. Appl. 2017, 2, 82–89. [Google Scholar]

- Yallappa, D.; Palled, V.; Veerangouda, M. Development and Evaluation of Solar Powered Sprayer with Multi-Purpose Applications. In Proceedings of the 2016 IEEE Global Humanitarian Technology Conference (GHTC), Seattle, WA, USA, 13–16 October 2016; pp. 1–6. [Google Scholar]

- Mishra, A.; Bhagat, N.; Singh, P. Development of Solar Operated Sprayer for Small Scale Farmers. Int. J. Curr. Microbiol. Appl. Sci. 2019, 8, 2019. [Google Scholar] [CrossRef]

- Sasaki, R.S.; Teixeira, M.M.; Oliveira Filho, D.; Cesconetti, C.J.; Silva, A.C.; Leite, D.M. Development of a Solar Photovoltaic Backpack Sprayer. Comun. Sci. 2014, 5, 395–401. [Google Scholar]

- Gokulavasan, B.; Alseena, C.S.; Kiruthika, P.R.; Lakshmi, S.M.; Pavithra, V. Design and Development of Solar Based Pesticide Sprayer. In Proceedings of the International Conference on Systems, Science, Control, Communication, Engineering and Technology, Coimbatore, India, 18–19 March 2016; pp. 751–754. [Google Scholar]

- Kumawat, M.M.; Wadavane, D.; Ankit, N.; Dipak, V.; Chandrakant, G. Solar Operated Pesticide Sprayer for Agriculture Purpose. Int. Res. J. Eng. Technol. 2018, 5, 3396. [Google Scholar]

- Mali, P.J.; Ahir, Y.G.; Bijagare, A.S.; Khadayate, R.S. Farmer Friendly Solar Operated Spray Pump. Int. Res. J. Eng. Technol. 2016, 3, 969–972. [Google Scholar]

- Patil, S.; Badarinarayan, K.S. Solar Agro Sprayer with Night Vision. Int. Res. J. Eng. Technol. 2016, 3, 1128–1130. [Google Scholar]

- Joshua, R.; Vasu, V.; Vincent, P. Solar Sprayer-An Agriculture Implement. Int. J. Sustain. Agric. 2010, 2, 16–19. [Google Scholar]

- Farrag, A.M. Design of Wearable Agricultural Solar-Powered Sprayer for Remote Areas. In Proceedings of the ASES National Solar Conference, San Francisco, CA, USA, 10–13 July 2016. [Google Scholar]

- Chavan, R.; Hussain, A.; Mahadeokar, S.; Nichat, S.; Devasagayam, D. Design and Construction of Solar Powered Agricultural Pesticide Sprayer. Int. J. Innov. Adv. Comput. Sci. 2015, 4, 145–150. [Google Scholar]

- Charvani, S.; Sowmya, K.; Malathi, M.; Rajani, P.; Saibaba, K. Design and Fabrication of a Solar Sprayer. In Proceedings of the 2nd International Conference on Emerging Trends in Engineering and Management Research, Pune, India, 28 May 2017; pp. 237–244. [Google Scholar]

- Aboegela, M.A.; Elmeadawy, M.I.; El-Sebaee, I.M.; Al Fakhrany, W.B. Development A Knapsack Sprayer Powered by Photovoltaic Panel. J. Soil Sci. Agric. Eng. 2019, 10, 907–912. [Google Scholar] [CrossRef]

- Swami, V.; Chauhan, D.K.; Santra, P.; Kothari, K. Design and Development of Solar PV Based Power Sprayer for Agricultural Use. Ann. Arid Zone 2016, 55, 51–57. [Google Scholar]

- Sinha, J.P.; Singh, J.K.; Kumar, A.; Agarwal, K.N. Development of Solar Powered Knapsack Sprayer. Indian J. Agric. Sci. 2018, 88, 590–595. [Google Scholar]

- Yadav, A.; Veerangouda, M.; Murali, M.; Prakash, K.V.; Nadagouda, S. Bio-Efficacy of Bullock Drawn Solar Powered High Clearance Sprayer. J. Pharmacogn. Phytochem. 2019, 8, 694–696. [Google Scholar]

- Karami Rad, M.; Omid, M.; Alimardani, R.; Mousazadeh, H. A Novel Application of Stand-Alone Photovoltaic System in Agriculture: Solar-Powered Microner Sprayer. Int. J. Ambient Energy 2017, 38, 69–76. [Google Scholar] [CrossRef]

- Rao, C.S.; Srinivas, I.; Adake, R.V.; Santra, P.; Reddy, B.S.; Kumar, M.; Rao, K.V.; Reddy, K.S.; Yadav, O.P.; Saxena, M.C. Utilization of Renewable Energy Sources in Dryland Systems. In Proceedings of the Twelfth International Dryland Development Conference, Sustainable Development of Drylands in the Post 2015 World, Alexandria, Egypt, 21–24 August 2016; International Dryland Development Commission (IDDC): Alexandria, Egypt, 2017; pp. 537–552. [Google Scholar]

- Poonia, S.; Jain, D.; Santra, P.; Singh, A.K. Use of Solar Energy in agricultural production and processing. Indian Farming 2018, 68, 104–107. [Google Scholar]

- Pande, P.C. Development of Photovoltaic Systems for Arid Zone of India. Energy Environ. 1990, 314–319. [Google Scholar] [CrossRef]

- Jivrag, A.; Chawre, V.; Bhagwat, A. Solar Operated Multiple Granulated Pesticide Duster. In Proceedings of the World Congress on Engineering, London, UK, 6–8 July 2011; Volume 3, pp. 52–56. [Google Scholar]

- Kar, A.; Garg, B.K.; Singh, M.P.; Kathju, S. Trends in Arid Zone Research in India; Central Arid Zone Research Institute: Jodhpur, India, 2009; pp. 221–222. [Google Scholar]

- Suryawanshi, V.R. Design, Manufacture and Test of a Solar Powered Audible Bird Scarer and Study of Sound Ranges Used in It. Int. J. Sci. Res. 2013, 4, SUB159173. [Google Scholar]

- Ruelle, P.; Bruggers, R.L. Traditional Approaches for Protecting Cereal Crops from Birds in Africa. In Proceedings of the Tenth Vertebrate Pest Conference, Monterey, CA, USA, 23–25 February 1982. [Google Scholar]

- Haque, A.K.M.F.; Broom, D.M. Experiments Comparing the Use of Kites and Gas Bangers to Protect Crops from Woodpigeon Damage. Agric. Ecosyst. Environ. 1985, 12, 219–228. [Google Scholar] [CrossRef]

- Marsh, R.E.; Erickson, W.A.; Salmon, T.P. Bird Hazing and Frightening Methods and Techniques (with Emphasis on Containment Ponds). 1991. Available online: https://digitalcommons.unl.edu/cgi/viewcontent.cgi?article=1051&context=icwdmother (accessed on 4 October 2022).

- Esipisu, I. Climate-Smart Kenyan Crop Hits a Setback–Hungry Birds. Thompson Reuters Foundation News, 2013–2015. Available online: https://news.trust.org/item/20130807112810-q5vw8 (accessed on 4 October 2022).

- Wang, Z.; Fahey, D.; Lucas, A.; Griffin, A.S.; Chamitoff, G.; Wong, K.C. Bird Damage Management in Vineyards: Comparing Efficacy of a Bird Psychology-Incorporated Unmanned Aerial Vehicle System with Netting and Visual Scaring. Crop Prot. 2020, 137, 105260. [Google Scholar] [CrossRef]

- Kiruba, S.; Mishra, B.P.; Stalin, S.I.; Jeeva, S.; Dhas, S. Traditional Pest Management Practices in Kanyakumari District, Southern Peninsular India. 2006. Available online: http://nopr.niscair.res.in/bitstream/123456789/6802/1/IJTK%205(1)%20(2006)%2071-74.pdf (accessed on 4 October 2022).

- Avery, M.L.; Werner, S.J.; Cummings, J.L.; Humphrey, J.S.; Milleson, M.P.; Carlson, J.C.; Primus, T.M.; Goodall, M.J. Caffeine for Reducing Bird Damage to Newly Seeded Rice. Crop Prot. 2005, 24, 651–657. [Google Scholar] [CrossRef] [Green Version]

- Cummings, J.L.; Pochop, P.A.; Engeman, R.M.; Davis Jr, J.E.; Primus, T.M. Evaluation of Flight ControlR to Reduce Blackbird Damage to Newly Planted Rice in Louisiana. Int. Biodeterior. Biodegrad. 2002, 49, 169–173. [Google Scholar] [CrossRef]

- Linz, G.M.; Homan, H.J.; Slowik, A.A.; Penry, L.B. Evaluation of Registered Pesticides as Repellents for Reducing Blackbird (Icteridae) Damage to Sunflower. Crop Prot. 2006, 25, 842–847. [Google Scholar] [CrossRef] [Green Version]

- Werner, S.J.; Linz, G.M.; Tupper, S.K.; Carlson, J.C. Laboratory Efficacy of Chemical Repellents for Reducing Blackbird Damage in Rice and Sunflower Crops. J. Wildl. Manag. 2010, 74, 1400–1404. [Google Scholar] [CrossRef] [Green Version]

- Stickley, A.R.; Andrews, K.J. Survey of Mississippi Catfish Farmers on Means, Effort, and Costs to Repel Fish-Eating Birds from Ponds. In Proceedings of the Fourth Eastern Wildlife Damage Control Conference, Madison, WI, USA, 25–28 September 1989; p. 39. [Google Scholar]

- De Mey, Y.; Demont, M.; Diagne, M. Estimating Bird Damage to Rice in Africa: Evidence from the Senegal River Valley. J. Agric. Econ. 2012, 63, 175–200. [Google Scholar] [CrossRef]

- Pande, P.C. A Novel Solar Device for Dusting Insecticide Powder. In Proceedings of the National Solar Energy Convention, Vienna, Austria, 6–10 July 1998; University of Roorkee: Roorkee, India, 1998; pp. 117–122. [Google Scholar]

- Muminov, A.; Jeon, Y.C.; Na, D.; Lee, C.; Jeon, H.S. Development of a Solar Powered Bird Repeller System with Effective Bird Scarer Sounds. In Proceedings of the 2017 International Conference on Information Science and Communications Technologies (ICISCT), Tashkent, Uzbekistan, 2–4 November 2017; pp. 1–4. [Google Scholar]

- Koyuncu, T.; Lule, F. Design, Manufacture and Test of a Solar Powered Audible Bird Scarer. Int. J. Agric. Biosyst. Eng. 2009, 3, 345–347. [Google Scholar]

- Siahaan, Y.; Wardijono, B.A.; Mukhlis, Y. Design of Birds Detector and Repellent Using Frequency Based Arduino Uno with Android System. In Proceedings of the 2017 2nd International conferences on Information Technology, Information Systems and Electrical Engineering (ICITISEE), Yogyakarta, Indonesia, 1–2 November 2017; 2017; pp. 239–243. [Google Scholar]

- Feuerbacher, A.; Lippert, C.; Kuenzang, J.; Subedi, K. Low-Cost Electric Fencing for Peaceful Coexistence: An Analysis of Human-Wildlife Conflict Mitigation Strategies in Smallholder Agriculture. Biol. Conserv. 2021, 255, 108919. [Google Scholar] [CrossRef]

- Peechi, T. Studies on Crop Damage by Wild Animals in Kerala and Evaluation of Control Measures. Available online: https://docs.kfri.res.in/KFRI-RR/KFRI-RR169.pdf (accessed on 4 October 2022).

- Amici, A.; Serrani, F.; Rossi, C.M.; Primi, R. Increase in Crop Damage Caused by Wild Boar (Sus scrofa L.): The “Refuge Effect”. Agron. Sustain. Dev. 2012, 32, 683–692. [Google Scholar] [CrossRef] [Green Version]

- Awasthi, B.; Singh, N.B. Status of Human-Wildlife Conflict and Assessment of Crop Damage by Wild Animals in Gaurishankar Conservation Area, Nepal. J. Inst. Sci. Technol. 2015, 20, 107–111. [Google Scholar] [CrossRef]

- Kadam, D.M.; Dange, A.R.; Khambalkar, V.P. Performance of Solar Power Fencing System for Agriculture. J. Agric. Technol. 2011, 7, 1199–1209. [Google Scholar]

- Evans, L.A.; Adams, W.M. Fencing Elephants: The Hidden Politics of Wildlife Fencing in Laikipia, Kenya. Land Use Policy 2016, 51, 215–228. [Google Scholar] [CrossRef] [Green Version]

- Hayward, M.W.; Kerley, G.I.H. Fencing for Conservation: Restriction of Evolutionary Potential or a Riposte to Threatening Processes? Biol. Conserv. 2009, 142, 1–13. [Google Scholar] [CrossRef]

- Schlageter, A.; Haag-Wackernagel, D. Effectiveness of Solar Blinkers as a Means of Crop Protection from Wild Boar Damage. Crop Prot. 2011, 30, 1216–1222. [Google Scholar] [CrossRef]

- Bapat, V.; Kale, P.; Shinde, V.; Deshpande, N.; Shaligram, A. WSN Application for Crop Protection to Divert Animal Intrusions in the Agricultural Land. Comput. Electron. Agric. 2017, 133, 88–96. [Google Scholar] [CrossRef]

- Nižetić, S.; Šolić, P.; González-de, D.L.-I.; Patrono, L. Internet of Things (IoT): Opportunities, Issues and Challenges towards a Smart and Sustainable Future. J. Clean. Prod. 2020, 274, 122877. [Google Scholar] [CrossRef]

- Shafi, U.; Mumtaz, R.; García-Nieto, J.; Hassan, S.A.; Zaidi, S.A.R.; Iqbal, N. Precision Agriculture Techniques and Practices: From Considerations to Applications. Sensors 2019, 19, 3796. [Google Scholar] [CrossRef] [Green Version]

- Kachhot, A.R.; Dulawat, M.S.; Vadher, A.L. Development of Solar Operated Walking Type Power Weeder. Agriculture Science and Green Energy 2021, 2, 30–41. [Google Scholar] [CrossRef]

- Sahu, G.; Raheman. H. Development of a Solar Energy Operated Weeder for Wetland Paddy Crop. J. Renew. Energy Environ. 2022, 9, 1–11. [Google Scholar]

- Kumari, S.; Mehta, A.K.; Menna, S.S. Development and Performance Evaluation of Solar Operated Power Weeder. Int. Res. J. Eng. Technol. 2019, 6, 1340–1343. [Google Scholar]

- Balamurugan, R.; Kandasamy, P. Effectiveness of portable solar powered light emitting diode insect trap: Experimental investigation in a groundnut field. J. Asia-Pac. Entomol. 2021, 24, 1024–1032. [Google Scholar] [CrossRef]

| S. No | Particulars | Transport | Solar Power | Battery Specification | PV Panel Attachment | Power Used to | Reference |

|---|---|---|---|---|---|---|---|

| 1. | Solar energy-based vehicle weed detecting robotic model | Wheels | 20–40 W | Rechargeable battery, 12 V, 7 Ah | Inbuilt | DC motors (7 nos.) | [60] |

| 2. | Greenbot—weeding | Wheels | 100 W | Rechargeable battery | Inbuilt | DC motors and other parts (3 nos.) | [61] |

| 3. | Prototype of solar weeding robot | Wheel | NA | --- | -- | DC motor and IR sensor | [62] |

| 4. | Remote-Controlled Solar Agro Sprayer Robot (prototype) | Wheels | NA | 12 V battery (2 nos.) | -- | DC motor and pumps | [63] |

| S. No. | Cropping System | Target Insects | Light Source | Battery Specification | Trapping System | Solar Panel Power | Reference |

|---|---|---|---|---|---|---|---|

| 1. | Vegetable and coconut | Leaf beetle, elephus beetle, aphids, leafhopper, leaf minor | UV LED bulb | 12 V, 14 Ah, lead acid calcium battery | High-voltage circuit of mosquito wire net | 20 W | [10] |

| 2. | Veterinary—animal farms | Tabanid fly | LED | 12 V, 45 Ah Lead acid battery | - | - | [86] |

| 3. | General vegetation | Ground beetles, Calathus melanocephalus, Pseudoophonus rifipes | White LED bulb | 1.2 V, 600 m Ah | Not mentioned | - | [84] |

| 4. | Vegetation and cropped fields | General insects | 12 W LED bulb | 12 V, 7.5 Ah | Not mentioned | 10 W | [87] |

| 5. | Mango garden | Hemipteran and Dipteran insects | 3 W UV LED bulb | 12 V, 7 Ah sealed lead battery | Wire mesh panel | 10 W | [78] |

| 6. | Rice and Brinjal field | General insects | UV lamp | 12 V battery | Wire mesh panel | 10 W | [79] |

| 7. | Plantation and Orchard crops | General insects | 3 W DC | 12 V, 4.5 Ah rechargeable | Mosquito net | 25 W | [65] |

| 8. | Annual crops | Spodoptera exigua, Heliothis assulta, Hemipteran bugs, green leafhopper, beetles, weevils, planthopper | 5 W DC lamp | 12 V battery | - | - | [74] |

| 9. | Rice | Black bug | LED bulb | 12 V polycrystalline solar cells | Circuit of mosquito trap | 20 W | [80] |

| 10. | Sweet potato | Sweet potato weevil | LED—Green light | Battery-powered solar cell | Pheromone funnel trap | - | [82] |

| 11. | Rice | Brown planthopper, yellow stem borer, pink stem borer, leaf folder, black bug | 20 W CFL | - | Container box for collecting pests with a solution of soap water | - | [77] |

| 12. | General cropping area | Herbivores | 12 W UV fluorescent bulb | 12 V, 35 Ah rechargeable battery | Aluminum funnel trap | 15 W | [83] |

| 13. | Gardens with vegetation | General insects | LED garden lamps | 1.2 V, 600 mAh rechargeable battery | Plastic cup as traps | - | [84] |

| 14. | Hayfield | Mosquito species | CDC light | 6 V, 12 Ah UB6120 battery | - | 6 W | [85] |

| 15. | - | - | UV LED | 12 V lead acid battery | Cum/glue trap | 10 W | [81] |

| 16. | Rice | Rice leaffolder, Tryporyza incertulas, Chilo suppressalis, Oxya chinensis, gall midge, brown plant hopper | Different wavelength bulbs | - | - | - | [88] |

| S. No. | Name of Sprayer | Device Movement | Solar Power | Battery | Solar Panel | PV Power Used | Reference |

|---|---|---|---|---|---|---|---|

| 1. | Solar-powered semi-automatic pesticide sprayer | Transport wheels | - | Lead acid battery, 12 V, 7.5 Ah | Inbuilt | DC motor—pump | [89] |

| 2. | Solar-powered sprayer | Backpack | 5 W | 12 V, 7 Ah | Stand alone | DC water pump | [90] |

| 3. | Solar pesticide sprayer | Transportable trolley type | 5 W | 12 V, 7 Ah | Inbuilt | DC motor | [91] |

| 4. | Solar PV backpack sprayer | Backpack | 5 W | 12 V, 9 Ah | Inbuilt | DC motor—diaphragm pump | [92] |

| 5. | Solar-powered sprayer | Backpack | 5 W | Lead acid battery 6 V, 4.5 Ah | Inbuilt | 6 V DC motor spinning disc | [93] |

| 6. | Solar-powered knapsack sprayer | Backpack | 10 W | 12 V | Inbuilt | Solarized agro sprayer | [94] |

| 7. | Solar-based pesticide Sprayer | Backpack | 10 W | 12 V | Inbuilt | DC motor pump | [95] |

| 8. | Solar-powered pesticide sprayer | Backpack | 20 W | Lead acid battery 12 V, 8 Ah | Stand alone | DC motor cum centrifuged pump | [96] |

| 9. | Solar-powered sprayer | Backpack | 10 W | 12 V, 7 Ah | Inbuilt | DC motor | [97] |

| 10. | Solar agro sprayer with night vision | Backpack | 10 W | 12 V, 7 Ah | Inbuilt | DC motor | [98] |

| 11. | Multipurpose solar-powered sprayer | Backpack | 20 W | 12 V,7 Ah | Inbuilt | DC motor—pump | [99] |

| 12. | Wearable agricultural solar-powered sprayer | Backpack | 20 W | Lead acid battery 12 V, 10 Ah | Inbuilt | DC motor—pump | [100] |

| 13. | Solar-powered agricultural pesticide sprayer lab model | Backpack | 20 W | Lead acid battery 12 V, 9 Ah | Inbuilt | Brushless DC motor—pump | [101] |

| 14. | Solar pesticide sprayer | Backpack | 20 W polycrystalline | 12 V, 8 Ah | Inbuilt | DC motor—pump | [102] |

| 15. | Solar knapsack sprayer | Backpack | 25 W | Lead acid battery 12 V–9 Ah | Inbuilt | DC pump | [103] |

| 16. | Solar-powered PV sprayer | Transport wheels | 60 Wp (2 nos.) | 12 V, 7 Ah (2 nos.) | Inbuilt | DC pump— diaphragm pump | [104] |

| 17. | Solar-powered knapsack sprayer | Backpack | 60 Wp | Lead acid battery 7 Ah | Stand alone | DC motor—pump set | [105] |

| 18. | Solar-powered sprayer | Backpack | 60 W | Lead acid battery | Stand alone | DC motor—pump | [104] |

| 19. | Solar sprayer | Backpack | 75 W | Lead acid 12 V, 7 Ah | Inbuilt | DC motor—blower | [105] |

| 20. | Solar PV power sprayer | Trolley type | 100 Wp polycrystalline (2 nos. × 50 W) | 12 V, 32 Ah | Inbuilt | DC motor—pump of 60 W | [104] |

| 21. | Solar-powered high-clearance sprayer | Bullock drawn | - | - | - | - | [106] |

| 22. | Solar-powered microner sprayer | Lab model | Polycrystalline silicone | Lead acid battery 12 V | Stand alone | DC motor | [107] |

| 23. | Bullock-drawn solar-powered hi-tech sprayer | Trolley type | 500 W | Dry lead acid 12 V, 100 Ah | Inbuilt | DC motor | [92] |

| 24. | Solar agro-remote controlled sprayer | Wheel type | - | 12 V battery (2 nos.) | Stand alone | DC motor—pump | [94] |

| 25. | Solar PV sprayer developed by NIPHM, Hyderabad | Trolley | - | - | Inbuilt/Standalone | DC motor—pump (60 W) | [108] |

| 26. | Remote-controlled solar agro sprayer robot (prototype) | Wheels | NA | 12 V battery (2 nos.) | -- | DC motor and pumps | [63] |

| S. No | Name of the Equipment | Model | Solar Power | Battery Specification | PV Panel Attachment | Power Used to | Reference |

|---|---|---|---|---|---|---|---|

| 1. | Solar-powered multiple granulated pesticide duster | Lab model | (Crystalline) 3 W | 6 V (3 nos.) | Inbuilt | DC motors for blower and feeding mechanism units | [111] |

| 2. | Solar-powered multiple granulated pesticide duster | Backpack | 3 W | Lead acid battery 6 V (3 nos.) | Inbuilt | DC motor | [111] |

| 3. | Solar PV sprayer/dusters | Backpack | 6.5 W | 12 V, 7 Ah | Inbuilt | DC motor—rotating pump | [112] |

| 4. | Solar PV duster | Backpack | - | - | Inbuilt | Dusting unit | [104] |

| Particulars | Plant Protection Equipment (Sprayers) | |

|---|---|---|

| Conventional | Solar | |

| Power source | Manual, battery, compression ignition (CI) engine (petrol or diesel) | Solar energy |

| Operational cost | Higher due to fuel price | Nil |

| Overall weight | Higher than solar PV sprayer | Slightly less than CI engines |

| Training for operating machine | Required | Required in case of drone sprayers |

| Cost | Less | Higher |

| Power supply | Immediate after engine running | Immediate after full charging of a battery |

| CO2 emissions | Possible | No |

| Mode of operation | The operator should carry the equipment into an entire field | The operator should carry the solar PV sprayer into the entire field, whereas solar drone sprayers alone enter the field |

| Drift | Less | More in a drone sprayer due to its fan |

| Technology | Most of the machinery is commercialized | It is still under development and testing, not yet fully commercialized except for solar insect trap and solar fencing |

| Maintenance | Periodical cleaning of equipment required and it may vary for different power sources | Periodic cleaning of the solar panel and checking the distilled water level in the battery |

| Improvement point | Almost nil | Overall efficiency |

| Possible failure | Engine failure due to poor maintenance | Battery failure due to poor maintenance |

| Unit | Specification | Crop | Field Efficiency (%) | References |

|---|---|---|---|---|

| Solar-powered knapsack sprayer | Capacity: 20 L Solar panel wattage: 25 W Flow rate: 600 mL min−1 | Egg plant | 77.00 | [103] |

| Solar-operated walking-type power weeder | Dimensions: 1260 × 960 mm Panel wattage: 150 W (2 Nos.) Operational width: 35 cm Weeding depth: 2–3 cm | Groundnut | 90.24 | [141] |

| Solar energy-operated paddy weeder | Dimensions: 1450 × 950 × 700 mm Panel wattage: 160 W Type: Cage wheel Depth of operation: 30–70 mm | Paddy | 83.30 | [142] |

| Solar-operated power weeder | Panel wattage: 160 W Cutting width of blade: 70 mm No. of blades: 4 | Maize | 88.03 | [143] |

| Solar-powered light-emitting diode insect trap | Dimension: 185 × 160 mm Panel wattage: 3 W Battery capacity: 10 Ah | Groundnut | 37.31 | [144] |

| Name of PV Device | Different Stages of Crop Cultivation in Agriculture * | ||||

|---|---|---|---|---|---|

| Sowing | Vegetative | Flowering | Maturity | Harvesting | |

| Solar bird scarer | |||||

| Solar weeder | |||||

| Solar insect trap | |||||

| Solar sprayer | |||||

| Solar duster | |||||

| Solar fencing | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramesh, D.; Chandrasekaran, M.; Soundararajan, R.P.; Subramanian, P.P.; Palled, V.; Kumar, D.P. Solar-Powered Plant Protection Equipment: Perspective and Prospects. Energies 2022, 15, 7379. https://doi.org/10.3390/en15197379

Ramesh D, Chandrasekaran M, Soundararajan RP, Subramanian PP, Palled V, Kumar DP. Solar-Powered Plant Protection Equipment: Perspective and Prospects. Energies. 2022; 15(19):7379. https://doi.org/10.3390/en15197379

Chicago/Turabian StyleRamesh, Desikan, Mohanrangan Chandrasekaran, Raga Palanisamy Soundararajan, Paravaikkarasu Pillai Subramanian, Vijayakumar Palled, and Deivasigamani Praveen Kumar. 2022. "Solar-Powered Plant Protection Equipment: Perspective and Prospects" Energies 15, no. 19: 7379. https://doi.org/10.3390/en15197379