Complex Heat Exchange in Friction Steam of Brakes

Abstract

:1. Introduction

- (i)

- radiation-conductive heat exchange in a flat layer of a selective and anisotropically scattering medium with a heat source;

- (ii)

- radiation-convective heat exchange of the medium flow with the channel walls.

- (i)

- to take into account separately the peculiarities of each type of heat transfer, while highlighting the conductive type as a source of energy for certain types of heat transfer; therefore, it is necessary to consider in pairs conductive–convective, conductive–radiation and radiation–convection of heat exchanges;

- (ii)

- the relationship between the rough surface area forcedly cooled by air flows and polished heated surface and their emissivity has not been established;

- (iii)

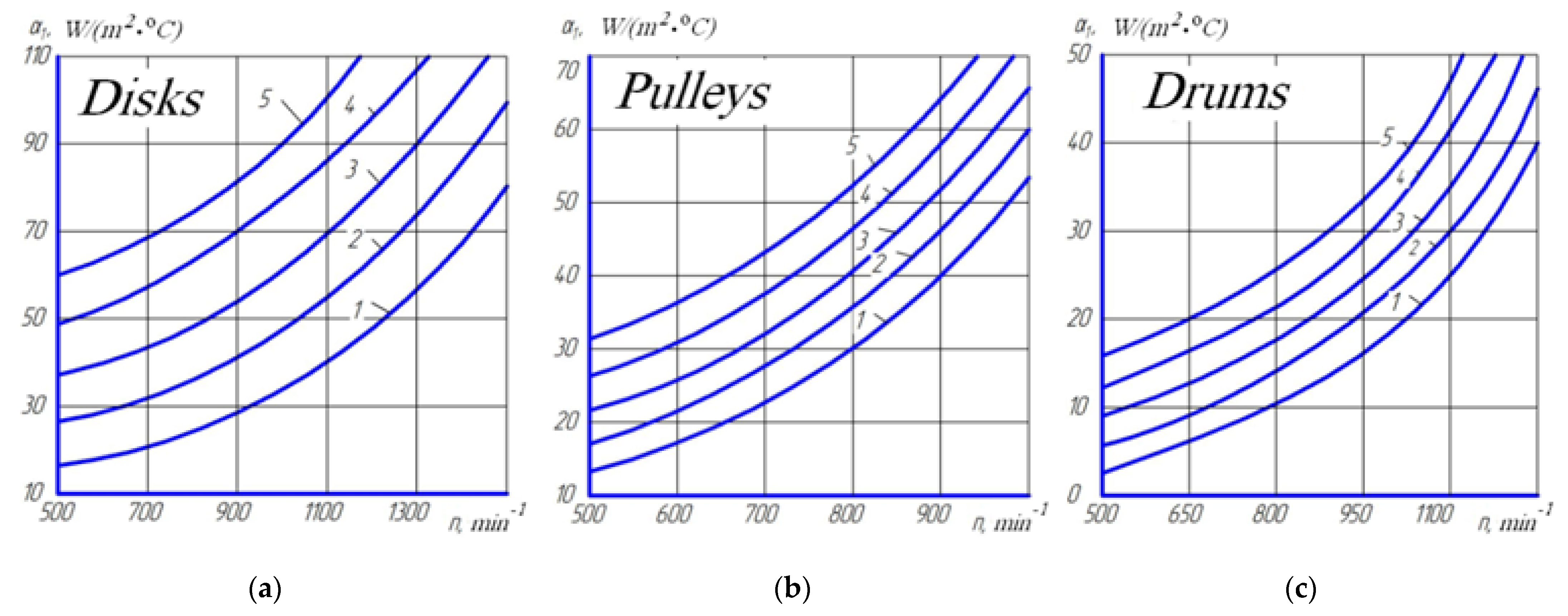

- there is no method for assessing heat transfer from the surfaces of rims of pulleys and drums, as well as solid and self-ventilated discs [23].

- (i)

- design and operation of frictional brake assemblies and their energy load;

- (ii)

- processes of heat exchange in friction pairs of brake devices;

- (iii)

- the combined action of convection fields from the washing air and thermal conductivity, and heat transfer from the metal friction elements of the brakes.

2. Materials and Methods

3. Results and Discussions

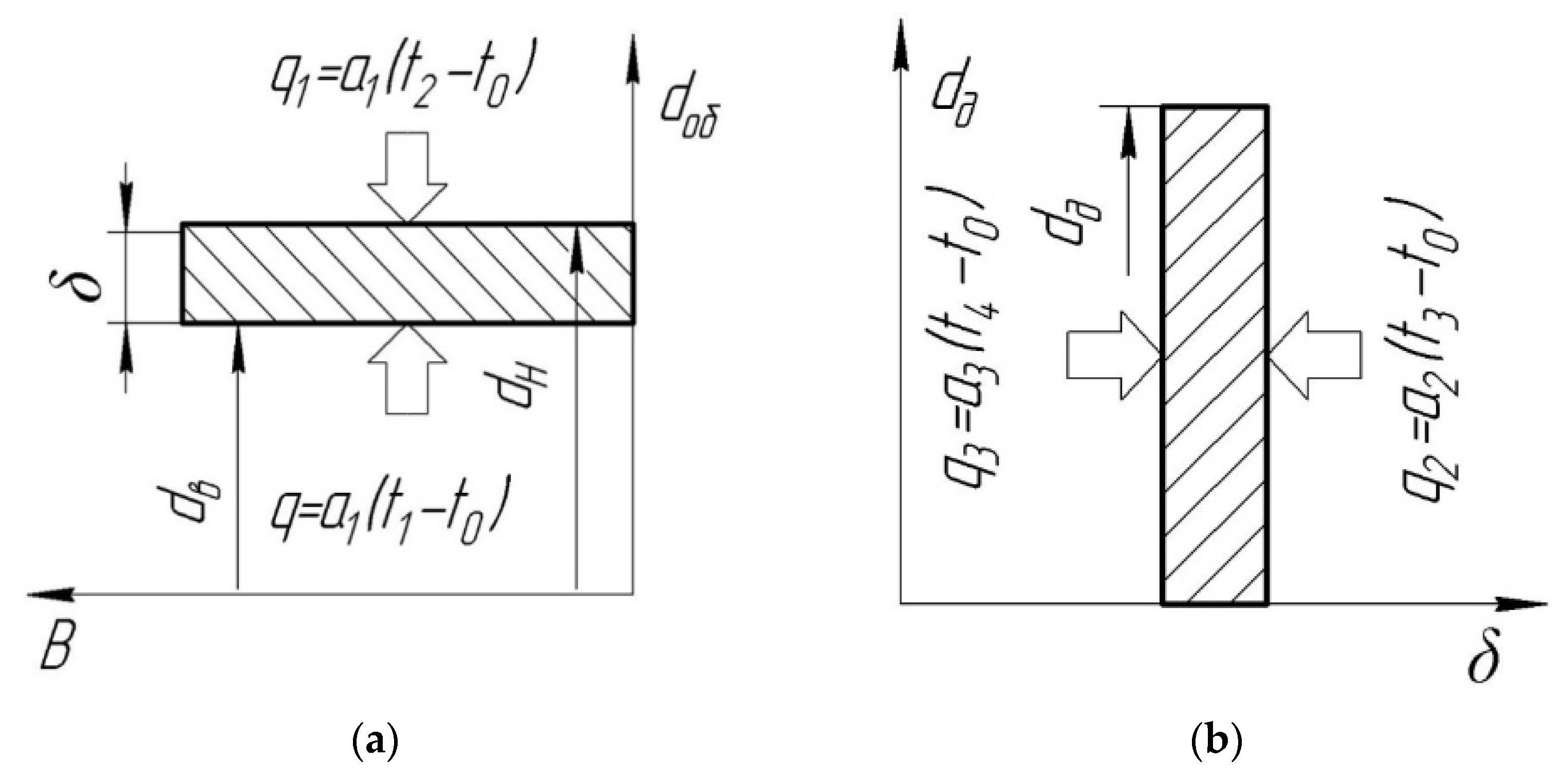

3.1. Heat Transfer Processes in Friction Pairs of Brake Devices

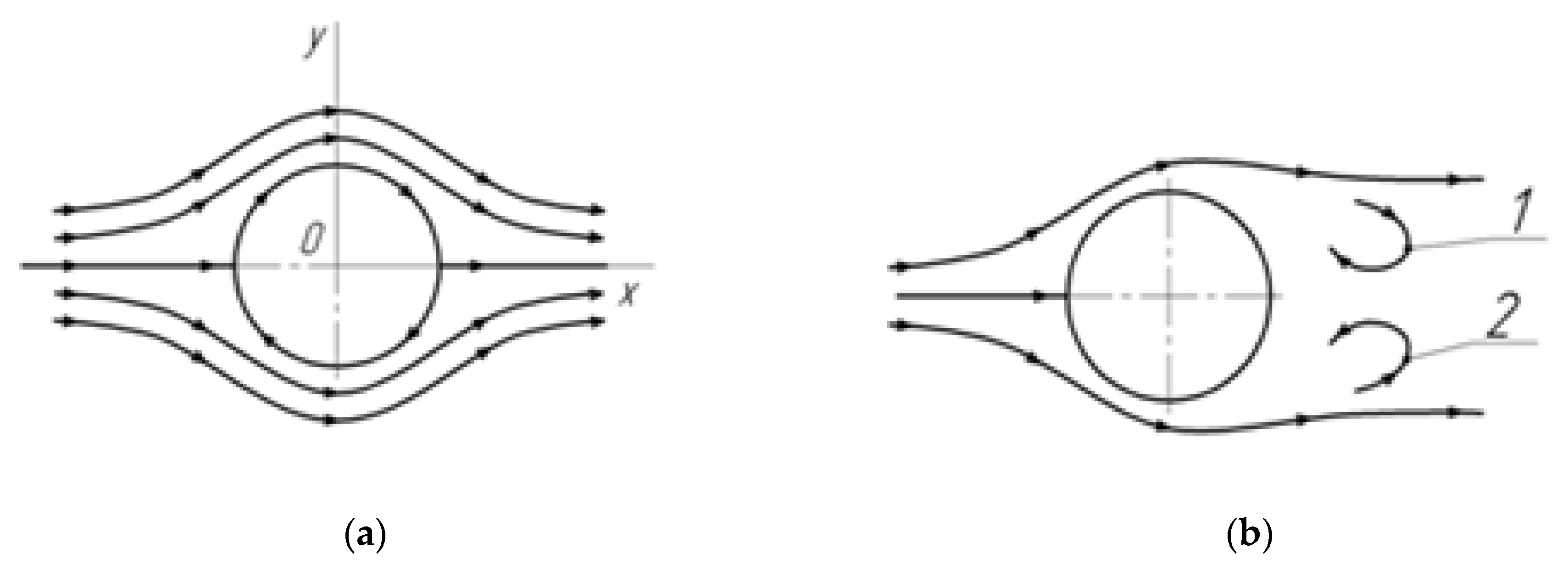

3.2. Combined Action of the Convection Fields from Washing Air and Thermal Conductivity of Metal Friction Elements of Brakes

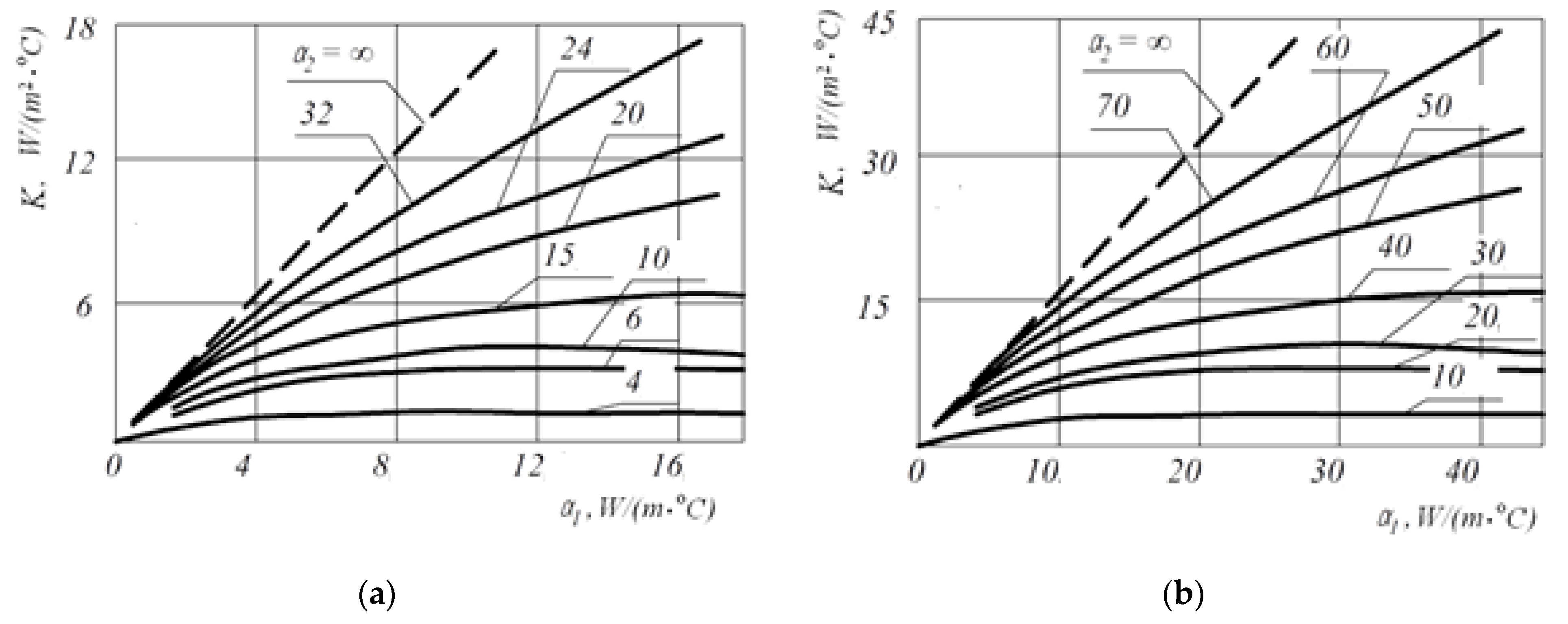

3.3. Combined Action of Convection Fields from Washing Air and Thermal Conductivity of Metal Friction Elements of Brakes

4. Conclusions

- (i)

- in the given relationship for determining the heat transfer coefficient (K), there are two terms related to the thermal coefficient of heat transfer resistance, which include the thermal coefficient of radiation resistance;

- (ii)

- a vacuum of 10−3 mm Hg is necessary to separate convection from radiation in air;

- (iii)

- contradictory data on the values of heat transfer coefficients used by various researchers suggest that they have a fictitious meaning;

- (iv)

- regulators of heat exchange processes in the air K2 and K always differ significantly from each other.

- metal friction elements of types of brakes in the design scheme are presented in the form of a plate;

- non-classical boundary conditions are given, but are modified;

- it has been established that the main type of heat transfer is conductive, and the rest depend on the energy load of the metal friction element;

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xiao, X.; Yin, Y.; Bao, J.; Lu, L.; Feng, X. Review on the Friction and Wear of Brake Materials. Adv. Mech. Eng. 2016, 8, 1687814016647300. [Google Scholar] [CrossRef] [Green Version]

- Wyczółkowski, R.; Bagdasaryan, V.; Gała, M.; Król, P.A. The Review of Chosen Methods Used to Investigate Heat Transfer in a Steel Porous Charge. Energies 2022, 15, 2266. [Google Scholar] [CrossRef]

- Lang, A.; Klüppel, M. Influences of Temperature and Load on the Dry Friction Behaviour of Tire Tread Compounds in Contact with Rough Granite. Wear 2017, 380–381, 15–25. [Google Scholar] [CrossRef]

- Ahmadijokani, F.; Shojaei, A.; Arjmand, M.; Alaei, Y.; Yan, N. Effect of Short Carbon Fiber on Thermal, Mechanical and Tribological Behavior of Phenolic-Based Brake Friction Materials. Compos. Part B Eng. 2019, 168, 98–105. [Google Scholar] [CrossRef]

- Saikrishnan, G.; Jayakumari, L.S.; Vijay, R.; Lenin Singaravelu, D. Influence of Iron–Aluminum Alloy on the Tribological Performance of Non-Asbestos Brake Friction Materials—A Solution for Copper Replacement. Ind. Lubr. Tribol. 2020, 72, 66–78. [Google Scholar] [CrossRef]

- Afzal, A.; Abdul Mujeebu, M. Thermo-Mechanical and Structural Performances of Automobile Disc Brakes: A Review of Numerical and Experimental Studies. Arch. Comput. Methods Eng. 2019, 26, 1489–1513. [Google Scholar] [CrossRef]

- Wu, S.C.; Zhang, S.Q.; Xu, Z.W. Thermal Crack Growth-Based Fatigue Life Prediction Due to Braking for a High-Speed Railway Brake Disc. Int. J. Fatigue 2016, 87, 359–369. [Google Scholar] [CrossRef]

- Yevtushenko, A.A.; Grzes, P.; Adamowicz, A. Numerical Analysis of Thermal Stresses in Disk Brakes and Clutches (a Review). Numer. Heat Transf. Part A Appl. 2015, 67, 170–188. [Google Scholar] [CrossRef]

- Bashir, M.; Qayoum, A.; Saleem, S. Analysis of Frictional Heating and Thermal Expansion in a Disc Brake Using COMSOL. J. Phys. Conf. Ser. 2019, 1240, 012094. [Google Scholar] [CrossRef]

- Pinca-Bretotean, C.; Josan, A.; Preda, C. Numerical and Experimental Analysis of Dry Contact in Pad Disc Brake Assembly. J. Phys. Conf. Ser. 2020, 1426, 012002. [Google Scholar] [CrossRef]

- Pinca-Bretotean, C.; Bhandari, R.; Sharma, C.; Dhakad, S.K.; Cosmin, P.; Sharma, A.K. An Investigation of Thermal Behaviour of Brake Disk Pad Assembly with Ansys. Mater. Today Proc. 2021, 47, 2322–2328. [Google Scholar] [CrossRef]

- Jiregna, I.T.; Lemu, H.G. Thermal Stress Analysis of Disc Brake Using Analytical and Numerical Methods. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1201, 012033. [Google Scholar] [CrossRef]

- Yevtushenko, A.; Kuciej, M.; Topczewska, K. Some Theoretical Model for Determining the Temperature Field of a Multi-Disk Brake. Adv. Mech. Eng. 2020, 12, 1687814020902327. [Google Scholar] [CrossRef]

- Yevtushenko, A.; Kuciej, M.; Wasilewski, P. Experimental Study on the Temperature Evolution in the Railway Brake Disc. Theor. Appl. Mech. Lett. 2019, 9, 308–311. [Google Scholar] [CrossRef]

- Cravero, C.; Marsano, D. Flow and Thermal Analysis of a Racing Car Braking System. Energies 2022, 15, 2934. [Google Scholar] [CrossRef]

- Park, S.; Lee, K.; Kim, S.; Kim, J. Brake-Disc Holes and Slit Shape Design to Improve Heat Dissipation Performance and Structural Stability. Appl. Sci. 2022, 12, 1171. [Google Scholar] [CrossRef]

- Kalenik, M.; Chalecki, M. Experimental Study of o Air Lift Pump Delivery Rate. Rocz. Ochr. Sr. 2018, 20, 221–240. [Google Scholar]

- Muchnik, G.F.; Rubashov, I. Methods of Heat Transfer Theory. Part I. Thermal Conductivity; Vysshaya Shkola: Moscow, Russia, 1970. (In Russian) [Google Scholar]

- Ilskiy, A.A.; Mironov, Y.V.; Chernobylskiy, A. Calculation and Design of Drilling Equipment; Nedra: Moscow, Russia, 1985. (In Russian) [Google Scholar]

- Muchnik, G.F.; Rubashov, I. Methods of Heat Transfer Theory. Part II. Thermal Conductivity; Vysshaya Shkola: Moscow, Russia, 1974. (In Russian) [Google Scholar]

- Andrianov, V. Foundations of Radiative and Complex Heat Transfer; Énergiya: Moscow, Russia, 1972. (In Russian) [Google Scholar]

- Sakhin, V.V. Convective Heat Transfer in a Homogeneous Medium (Heat Transfer): A Tutorial; D.F. Ustinov Baltic State Technical University "Voenmrkh": St. Petersburg, Russia, 2017. [Google Scholar]

- Janahmadov, A.K.; Volchenko, D.A.; Volchenko, N.A. Design and Verification Calculation of Frictional Units of Tape-Shoe Brakes of Drawworks; Azərbaycan Mühəndislik Akademiyası: Baku, Azerbaijan, 2016. (In Russian) [Google Scholar]

- Volchenko, N.; Volchenko, A.; Volchenko, D.; Polyakov, P.; Malyk, V.; Zhuravlev, D.; Vytvytskyi, V.; Krasin., P. Features of the Estimation Jf the Intensity of Heat Exchange in Self-Ventilated Disk-Shoe Brakes of Vehicles. East. Eur. J. Enterp. Technol. 2019, 1, 47–53. [Google Scholar]

- Skripnik, V.; Vudvud, O.; Zhuravlev, D.; Nikipchuk, S.; Danulyak, T. The Efficiency of Convective Heat Exchange at the Airflow of Metal Friction Elements of Brakes. In Advanced Manufacturing Processes IV. InterPartner 2022. Lecture Notes in Mechanical Engineering; Onkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Pavlenko, I., Eds.; Springer: Cham, Switzerland, 2022; pp. 574–583. [Google Scholar]

- Belyaev, I.M. Basics of Heat Transfer; Textbook, Vyscha Shkola: Kyiv, Ukraine, 1989. (In Russian) [Google Scholar]

- Avduevsky, V.S.; Galitseyskiy, B.M.; Globov, G.A.; Danilov, Y.I.; Dreitser, G.A.; Kalinin, E.K.; Koshkin, V.K.; Mikhailov, T.V.; Molchanov, A.M.; Ryzhov, I.A.; et al. Fundamentals of Heat Transfer in Aviation and Rocket-Space Technologies; Avduevsky, V.S., Koshkin, V.K., Eds.; Mashinostroyeniye: Moscow, Russia, 1992. (In Russian) [Google Scholar]

- Yudaev, B.N. Technical Thermodynamics: Heat Transfer; Viashaya Shkola: Moscow, Russia, 1988. (In Russian) [Google Scholar]

- Belyakov, N.S.; Nosko, A.P. Nonideal Thermal Contact of Bodies at Friction; LIBROKOM: Moscow, Russia, 2010. (In Russian) [Google Scholar]

- Belyakov, N.S.; Nosko, A.P. Heat Frictional Contact of Semi-Bounded Solids. Mot. Power Ind. Agric. 2008, 10, 83–91. [Google Scholar]

- Bogdanovich, P.N.; Tkachuk, D.V. Temperature Distribution over Contact Area and “Hot Spots” in Rubbing Solid Contact. Tribol. Int. 2006, 39, 1355–1360. [Google Scholar] [CrossRef]

- Ciavarella, M.; Johansson, L.; Afferrante, L.; Klarbring, A.; Barber, J.R. Interaction of Thermal Contact Resistance and Frictional Heating in Thermoelastic Instability. Int. J. Solids Struct. 2003, 40, 5583–5597. [Google Scholar] [CrossRef]

- Shevchuk, V.A. Calculation of Thermal State of Bodies with Multilayer Coatings. In Proceedings of the International Conference on Computational Science, Amsterdam, The Natherlands, 21–24 April 2002; Springer: Berlin/Heidelberg, Germany; pp. 500–509. [Google Scholar]

- Shillor, M.; Sofonea, M.; Telega, J.J. Models and Analysis of Quasistatic Contact: Variational Methods; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2004; Volume 655. [Google Scholar]

- Volchenko, D.; Skripnik, V.; Zhuravlev, D.; Yaroslav, S.; Savchyn, M. Non-Uniform Nanocapillary Fluid Cooling of the Drawworks’ Band-Shoe Brake Friction Couples. In Advanced Manufacturing Processes IV. InterPartner 2022. Lecture Notes in Mechanical Engineering; Onkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Pavlenko, I., Eds.; Springer: Cham, Switzerland, 2023; pp. 584–593. [Google Scholar]

| Dependencies | |||

|---|---|---|---|

| Type of boundary condition | I-st | The intensity of the heat flux from the outside into the body is given () | |

| (3) | |||

| II-nd | The body is in contact with another body that has different thermophysical characteristics | ||

| (4) | |||

| III-rd | The body’s surface temperature is known () | ||

| IV-th | The heat flux coming from the washing medium is directly proportional to the difference in temperature between the surface of the body and the medium, multiplied by the heat transfer coefficient | ||

| (5) | |||

| No. | Dependencies and Decoding of Their Parameters | |

|---|---|---|

| 1 | Heat transfer of conduits occurs according to the Fourier law: the heat flux density is directly proportional to the temperature gradient, i.e., | |

| (6) | ||

| where: is the coefficient of thermal conductivity of the material; is unit vector directed along the normal direction of increasing temperature; is the derivative of the temperature along the normal direction; = is the temperature gradient. | ||

| 2 | Convective heat transfer between the surface of a solid and the surrounding liquid or gaseous medium obeys the Newton-Richmann law: | |

| (7) | ||

| where: q is the heat flux from the surface of the solid to the medium; is heat exchange surface area; is the heat transfer coefficient between the body’s surface and the environment; and are the temperatures of the surface of the body and the environment. | ||

| 3 | Heat transfer by radiation is determined on the basis of the laws of thermal radiation and has the form: | |

| (8) | ||

| where: is the reduced emissivity of bodies i and j; is the coefficient of irradiation of the i-th body by the j-th; and are values of the absolute temperatures of bodies i and j; is the emissivity of an absolutely black body, equal to 5.67 W/(m2 ∙ K4). | ||

| (9) | ||

| where: is the emissivity of the polished surface in W/(m2 ∙ K4); and are heated and cooled body surface areas in m2. | ||

| 4 | The total thermal resistance R or the total thermal conductivity σ0 are equal to | |

| (10) | ||

| where , , are the thermal resistance of heat exchanges by thermal conductivity, convection and radiation. Note that the addition of three parallel-connected conductivities is justified by the law of the conservation of energy. If concerning thermal coefficients, then such an addition in the general case would be unreasonable. | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kernytskyy, I.; Volchenko, A.; Szlachetka, O.; Horbay, O.; Skrypnyk, V.; Zhuravlev, D.; Bolonnyi, V.; Yankiv, V.; Humenuyk, R.; Polyansky, P.; et al. Complex Heat Exchange in Friction Steam of Brakes. Energies 2022, 15, 7412. https://doi.org/10.3390/en15197412

Kernytskyy I, Volchenko A, Szlachetka O, Horbay O, Skrypnyk V, Zhuravlev D, Bolonnyi V, Yankiv V, Humenuyk R, Polyansky P, et al. Complex Heat Exchange in Friction Steam of Brakes. Energies. 2022; 15(19):7412. https://doi.org/10.3390/en15197412

Chicago/Turabian StyleKernytskyy, Ivan, Aleksandr Volchenko, Olga Szlachetka, Orest Horbay, Vasyl Skrypnyk, Dmytro Zhuravlev, Vasyl Bolonnyi, Volodymyr Yankiv, Ruslan Humenuyk, Pavlo Polyansky, and et al. 2022. "Complex Heat Exchange in Friction Steam of Brakes" Energies 15, no. 19: 7412. https://doi.org/10.3390/en15197412

APA StyleKernytskyy, I., Volchenko, A., Szlachetka, O., Horbay, O., Skrypnyk, V., Zhuravlev, D., Bolonnyi, V., Yankiv, V., Humenuyk, R., Polyansky, P., Leśniewska, A., Walasek, D., & Koda, E. (2022). Complex Heat Exchange in Friction Steam of Brakes. Energies, 15(19), 7412. https://doi.org/10.3390/en15197412