The Effect of Intake Valve Timing on Spark-Ignition Engine Performances Fueled by Natural Gas at Low Power

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Analysis

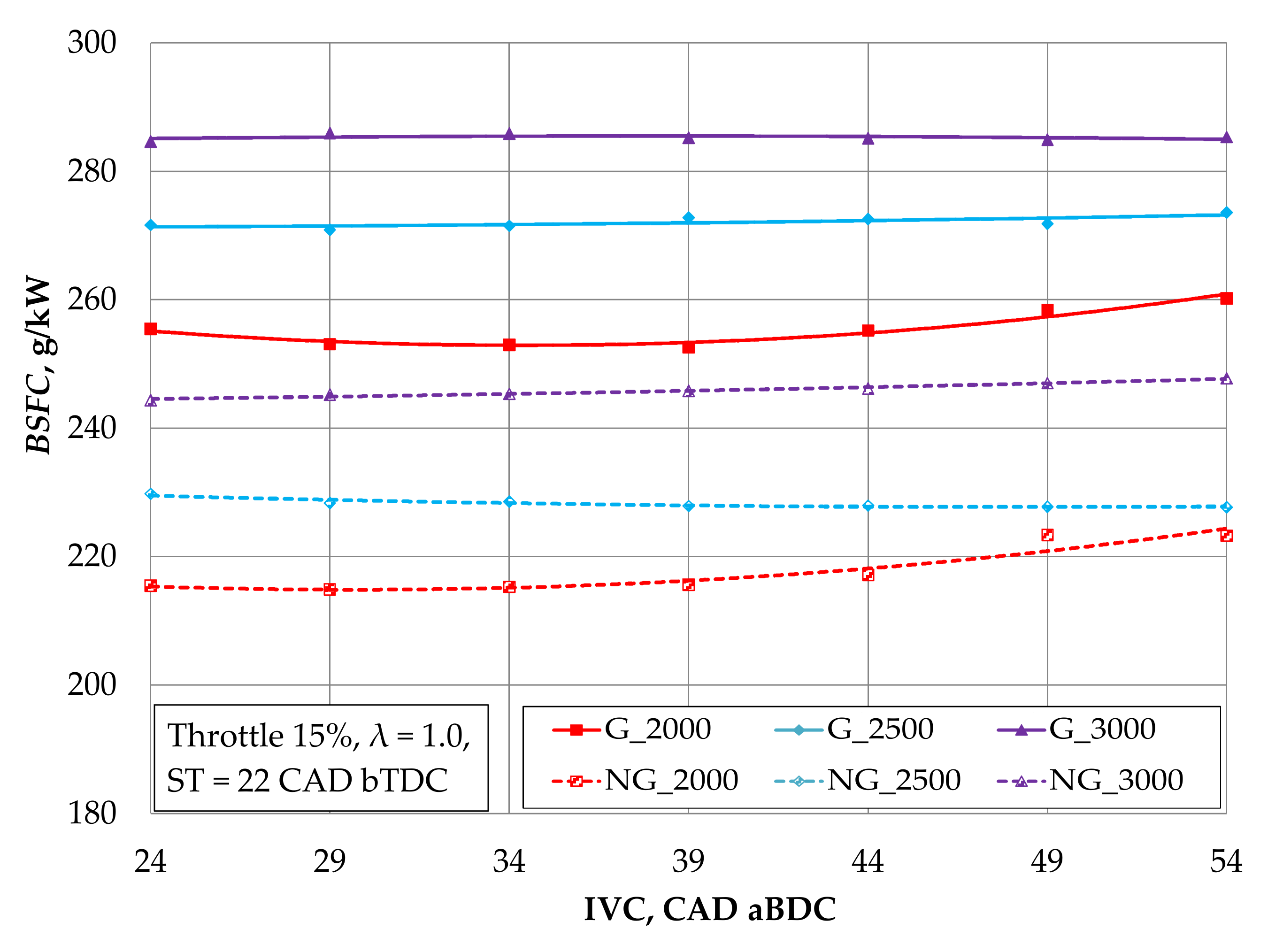

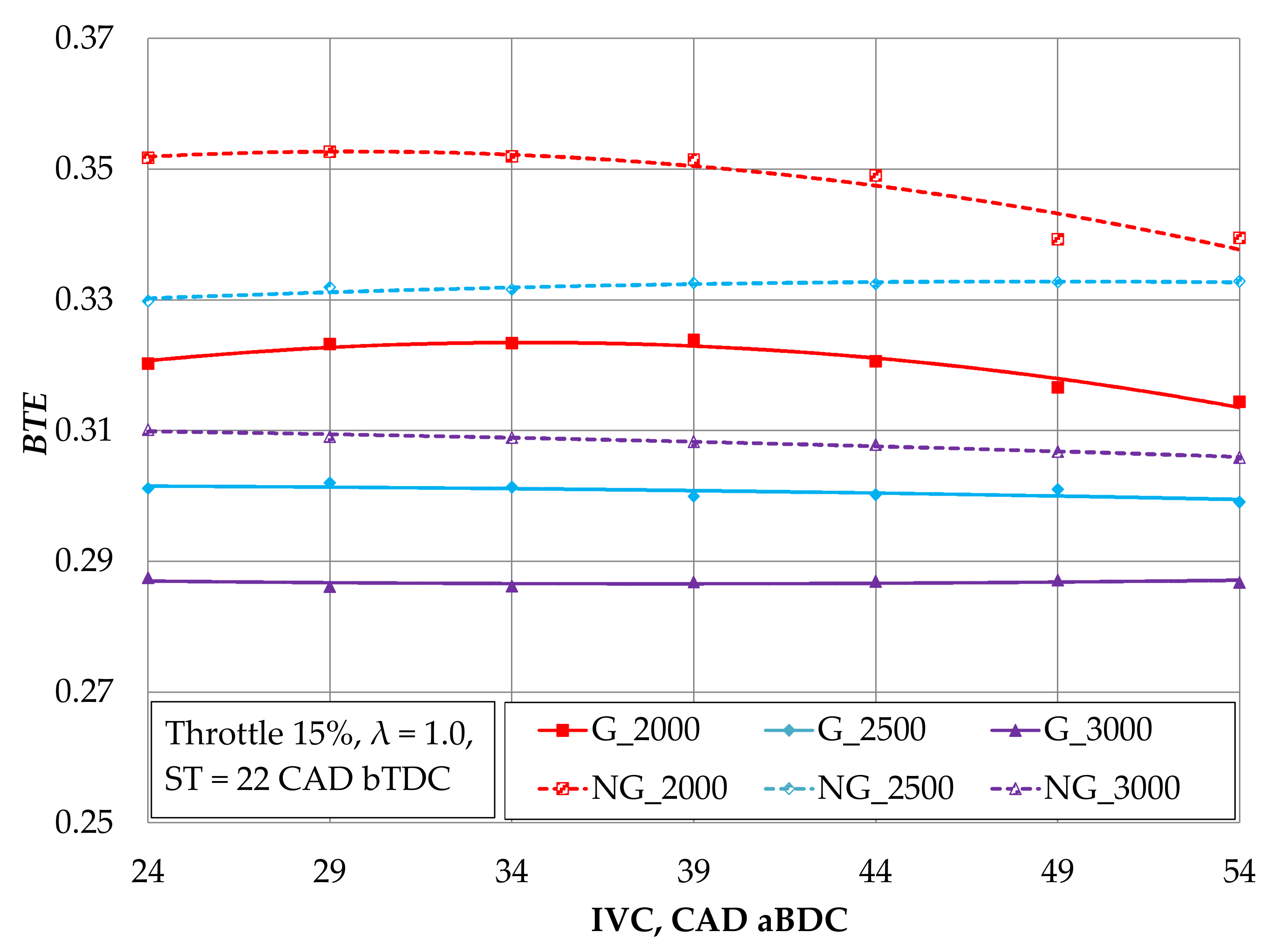

3.1. Analysis of the Energy Performance

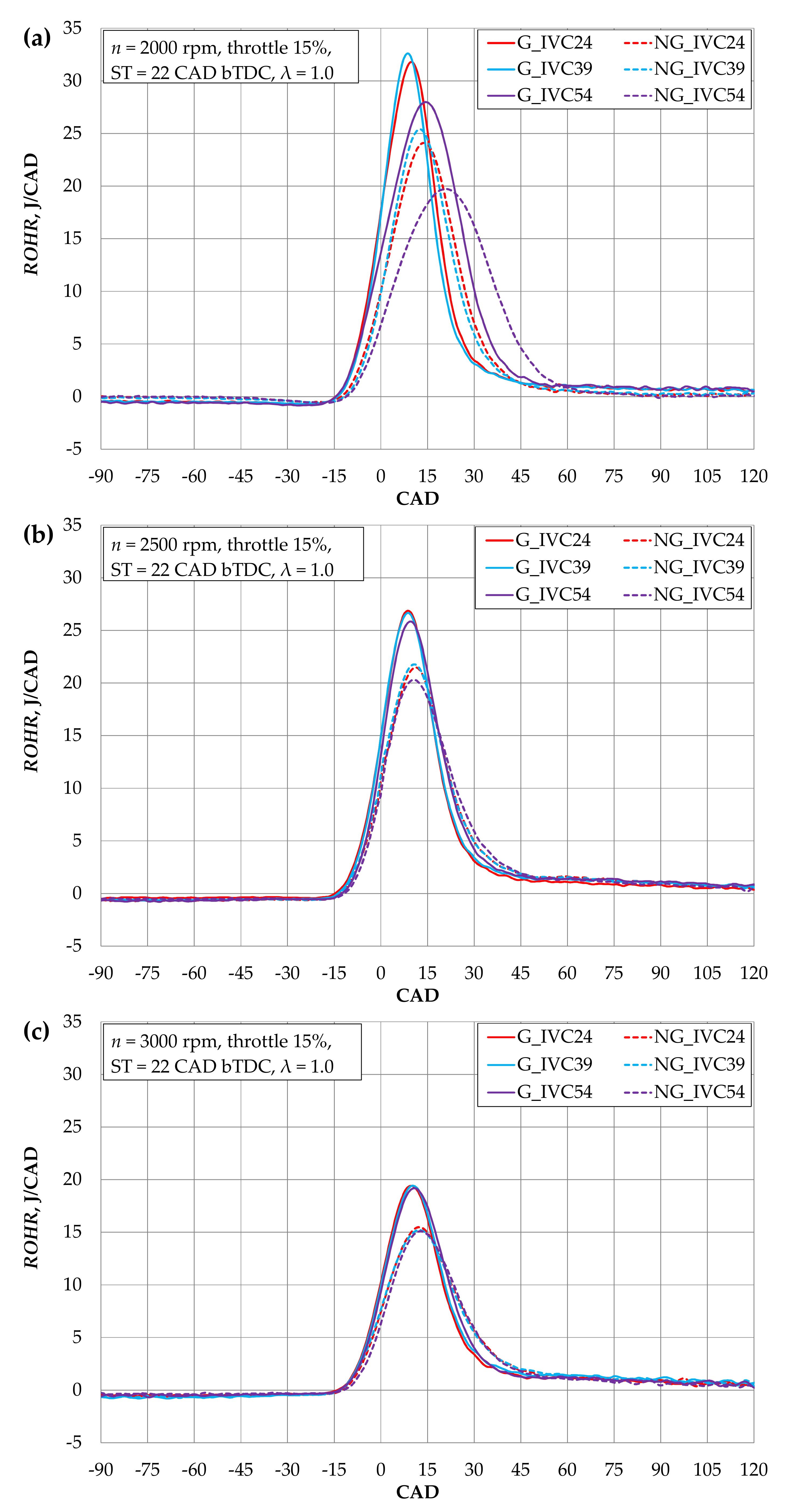

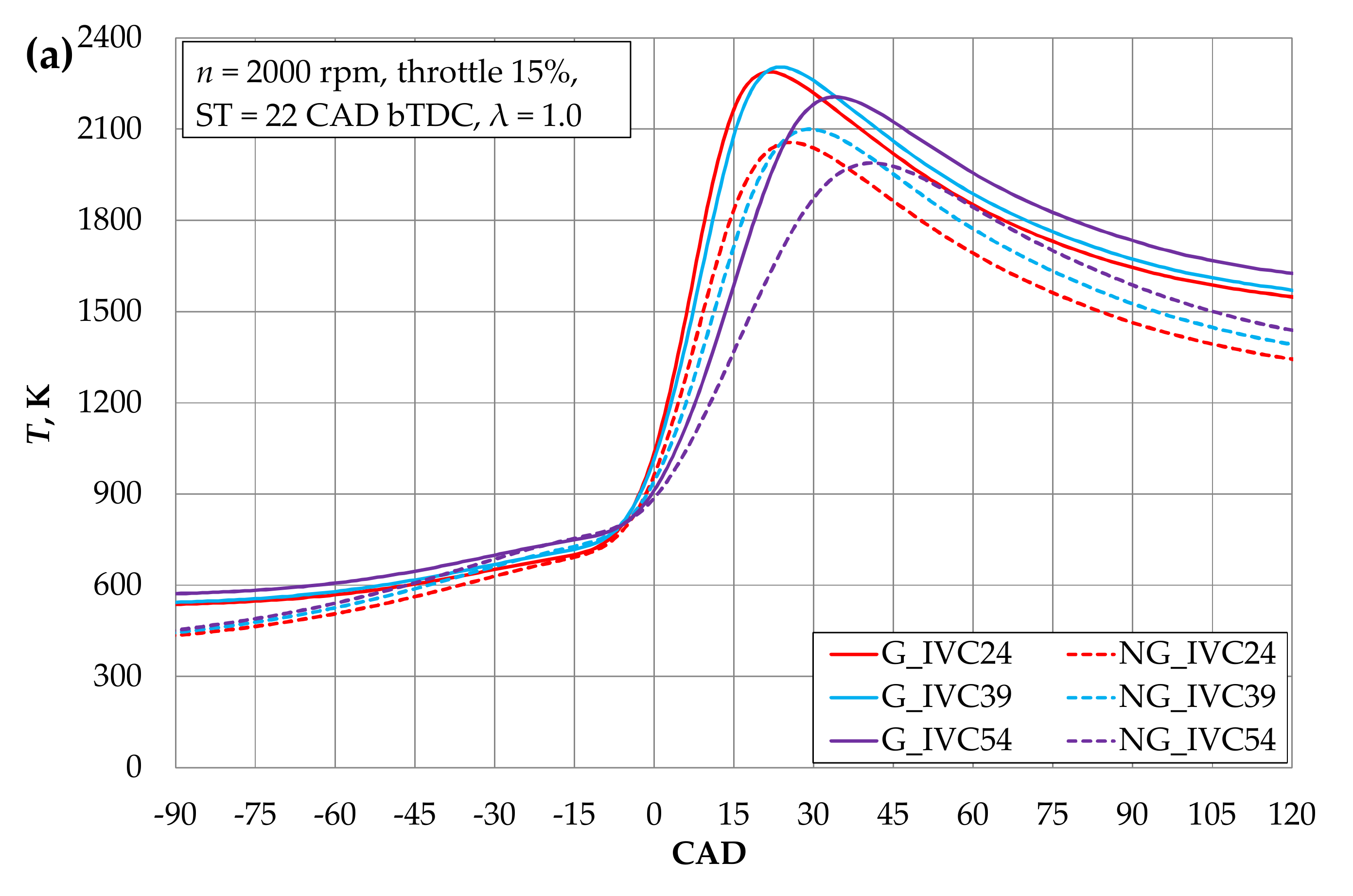

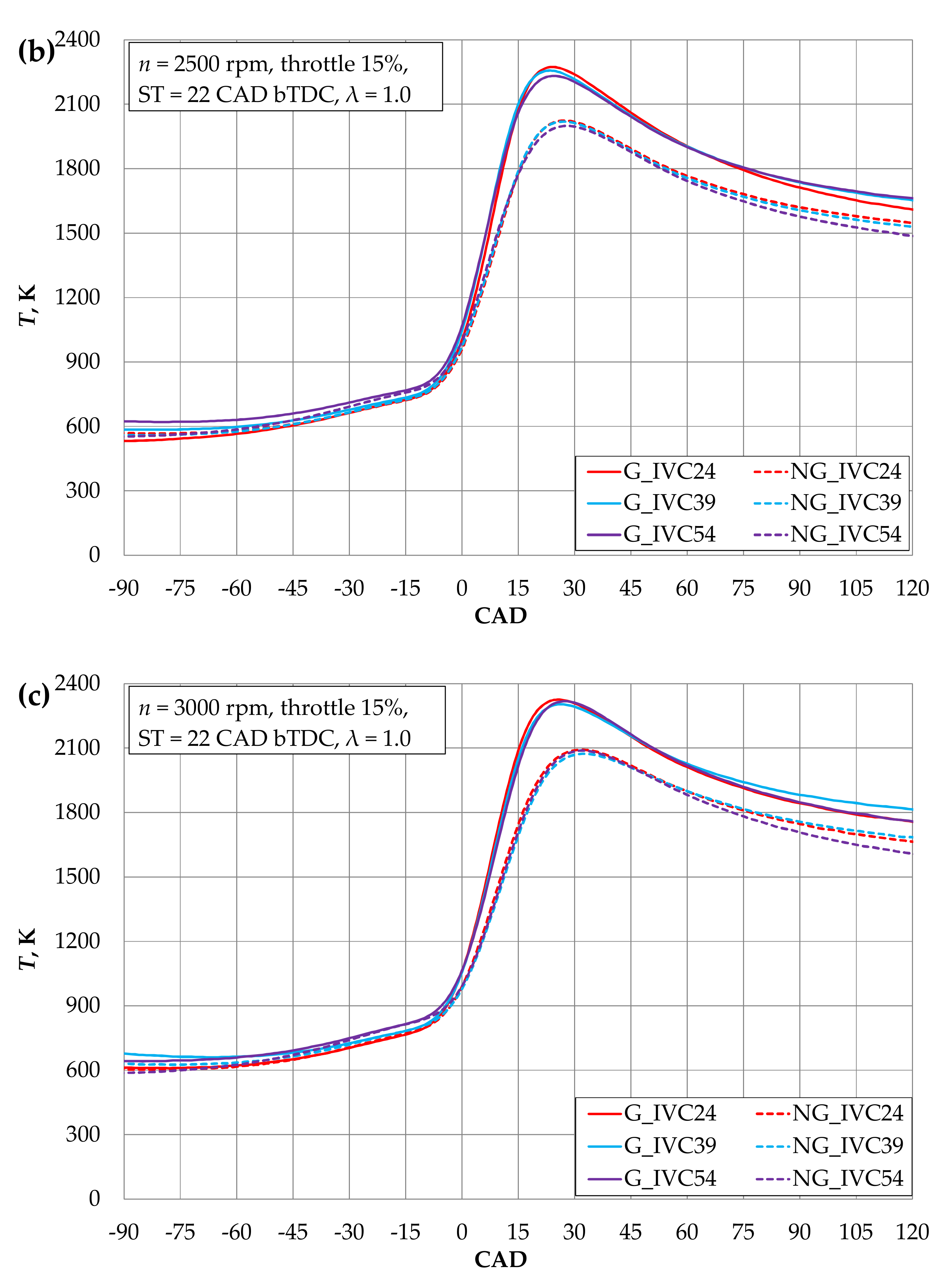

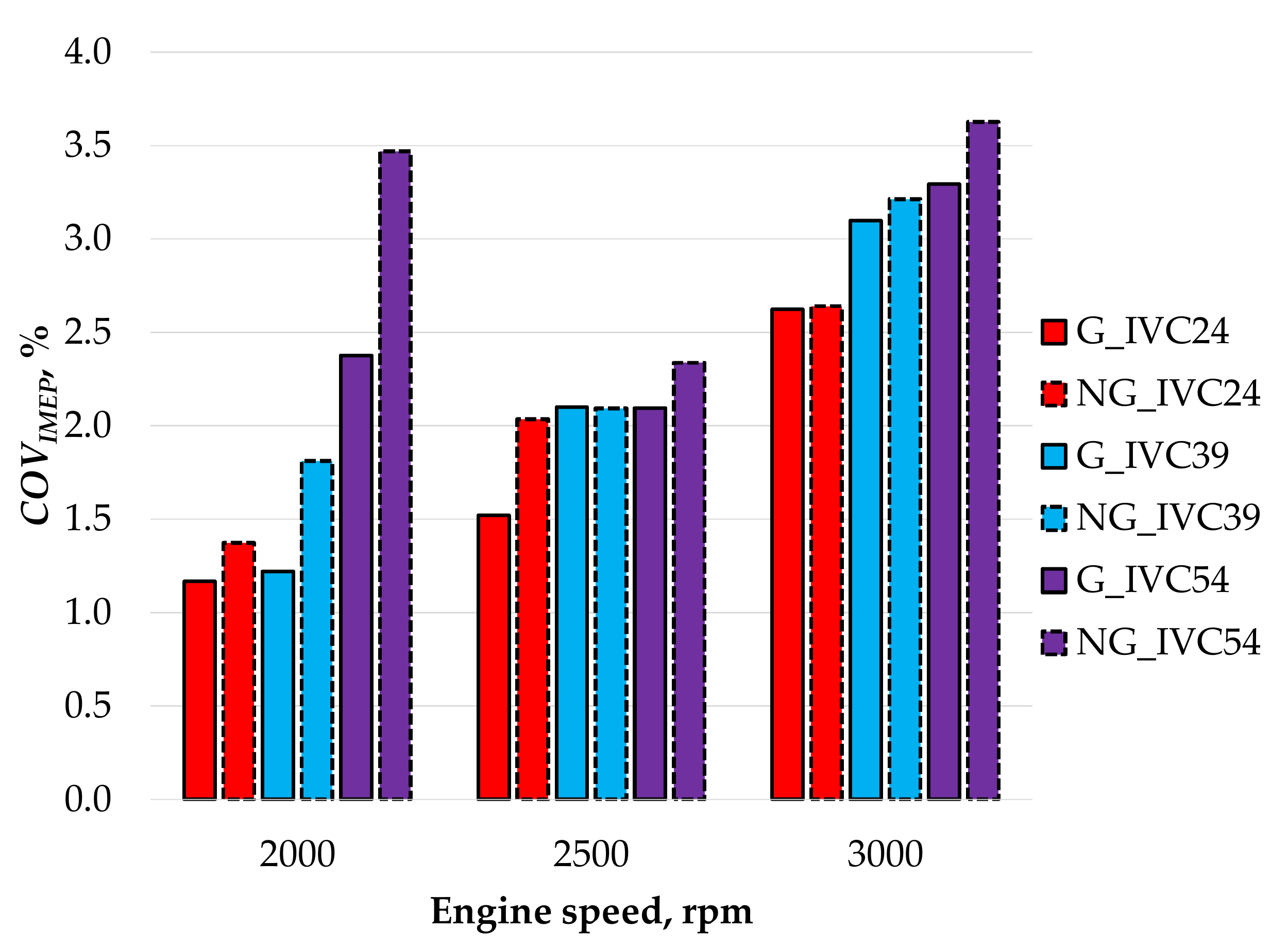

3.2. Numerical Analysis of the Combustion Process

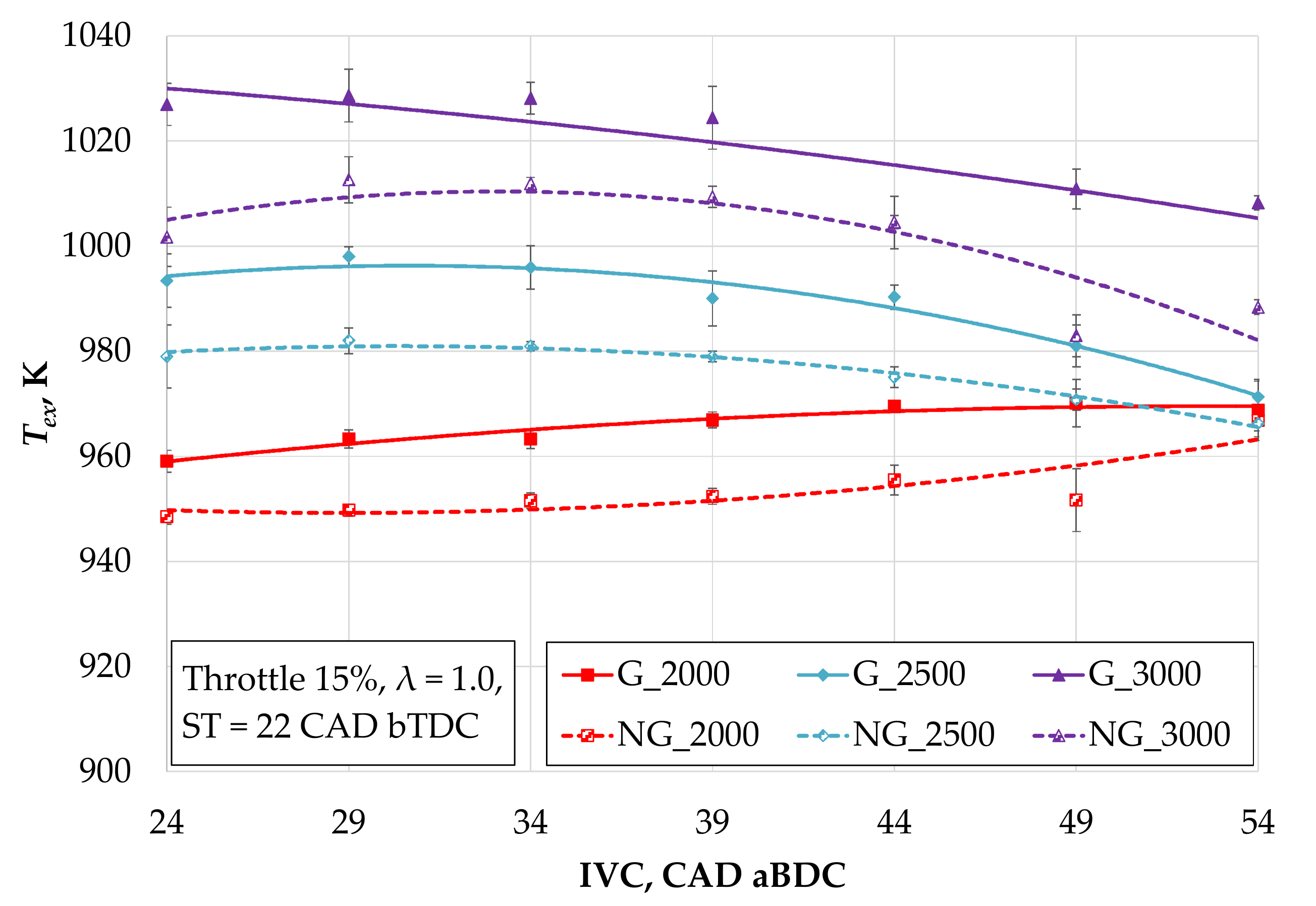

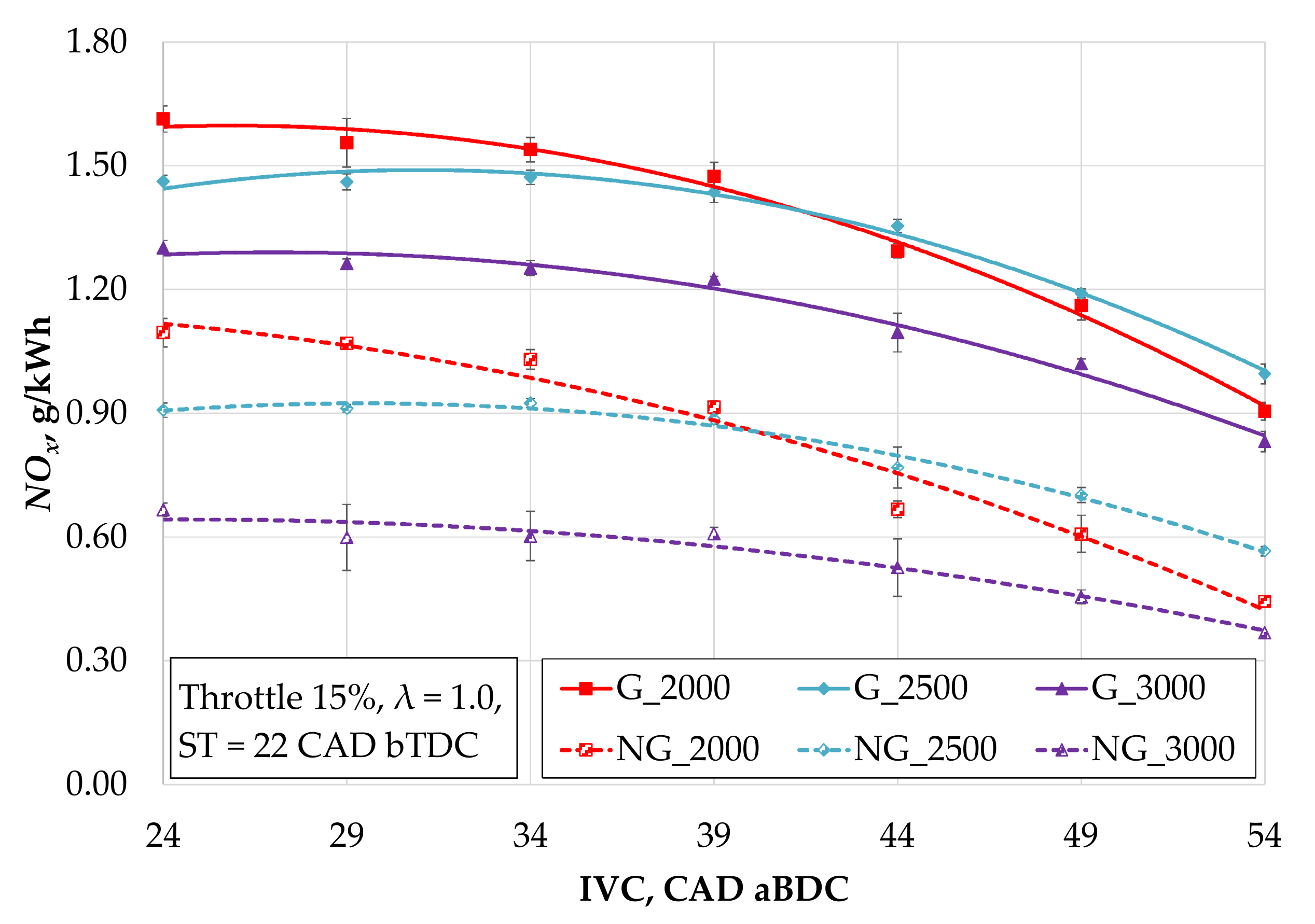

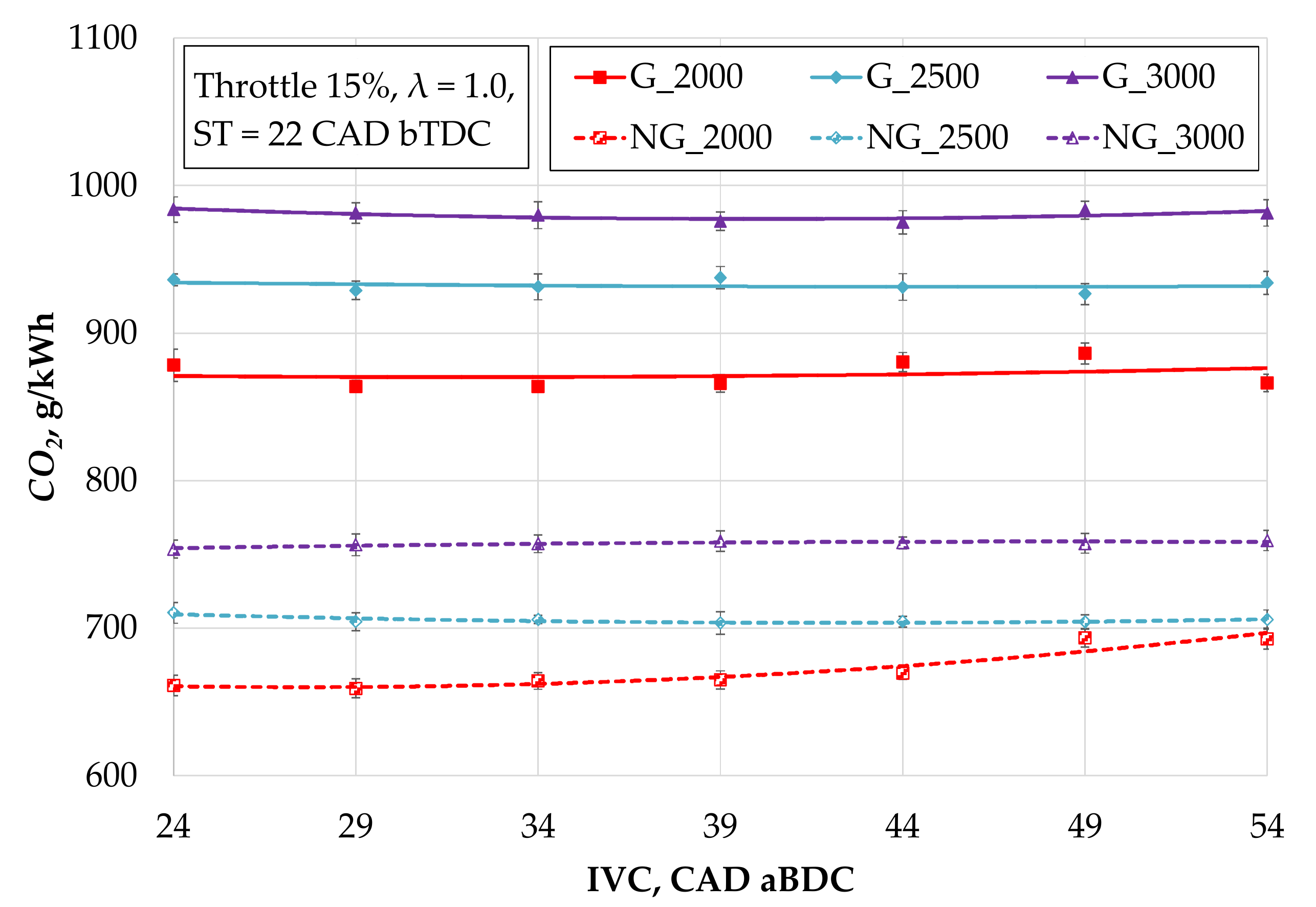

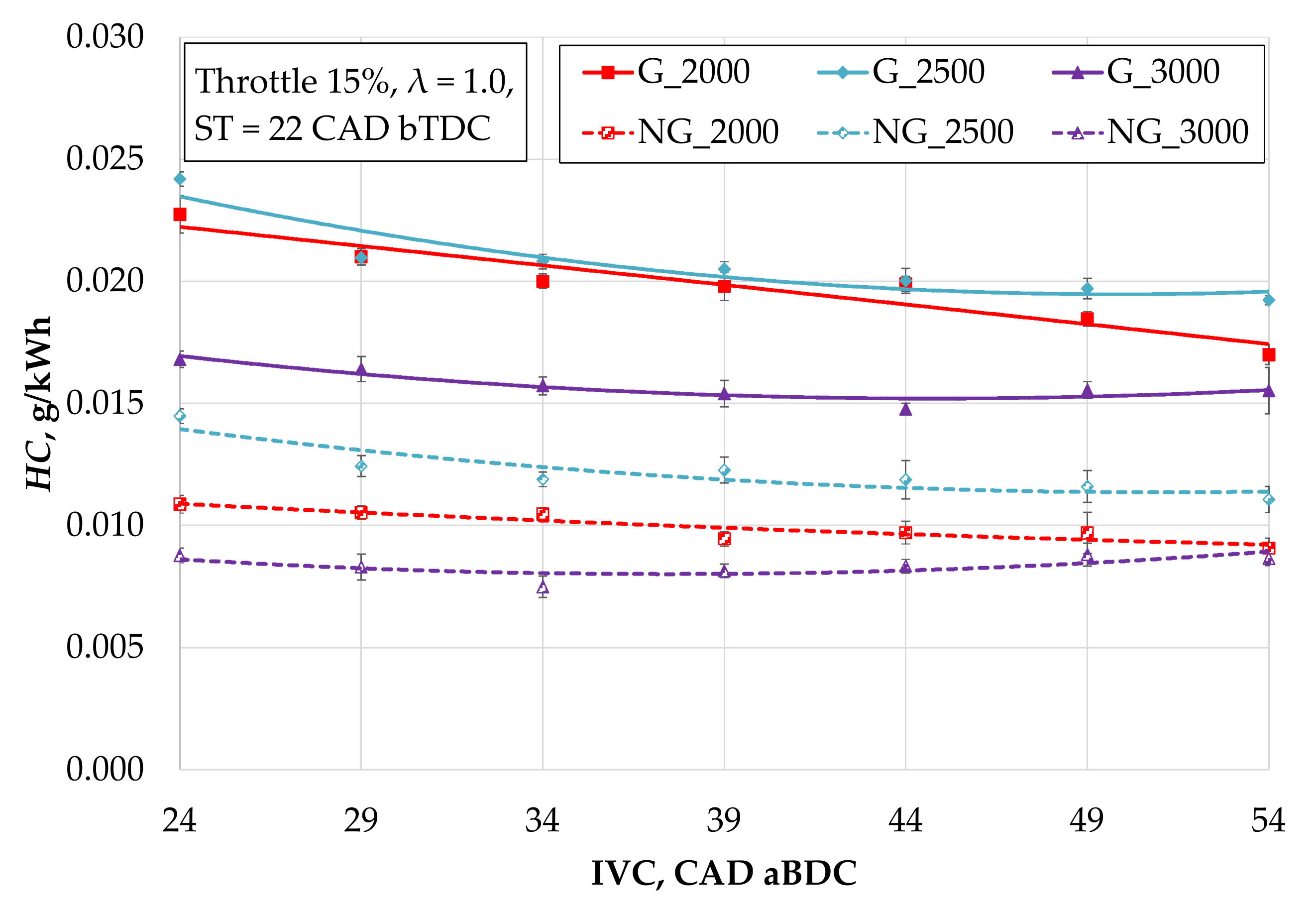

3.3. Ecological Indicators

4. Conclusions

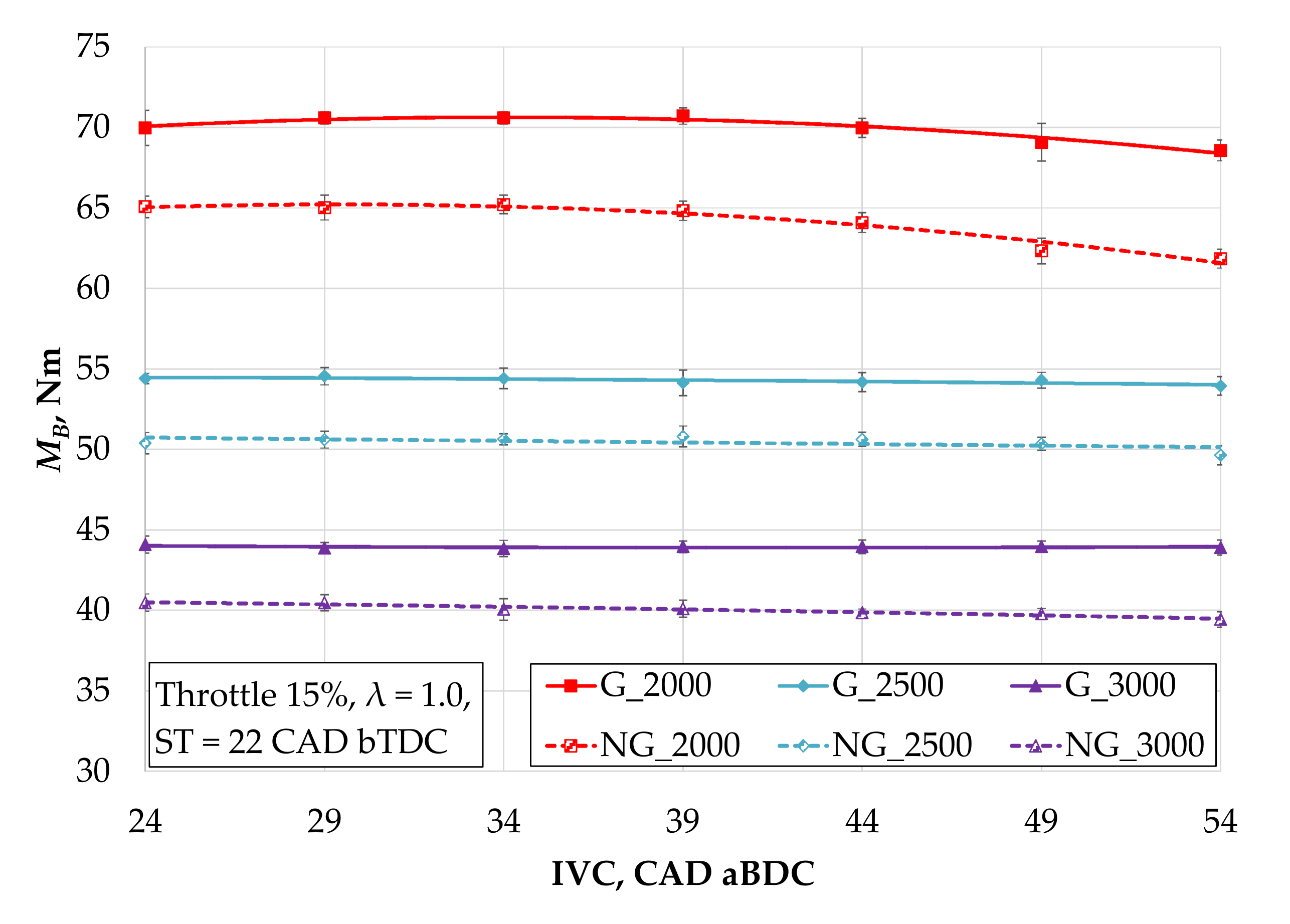

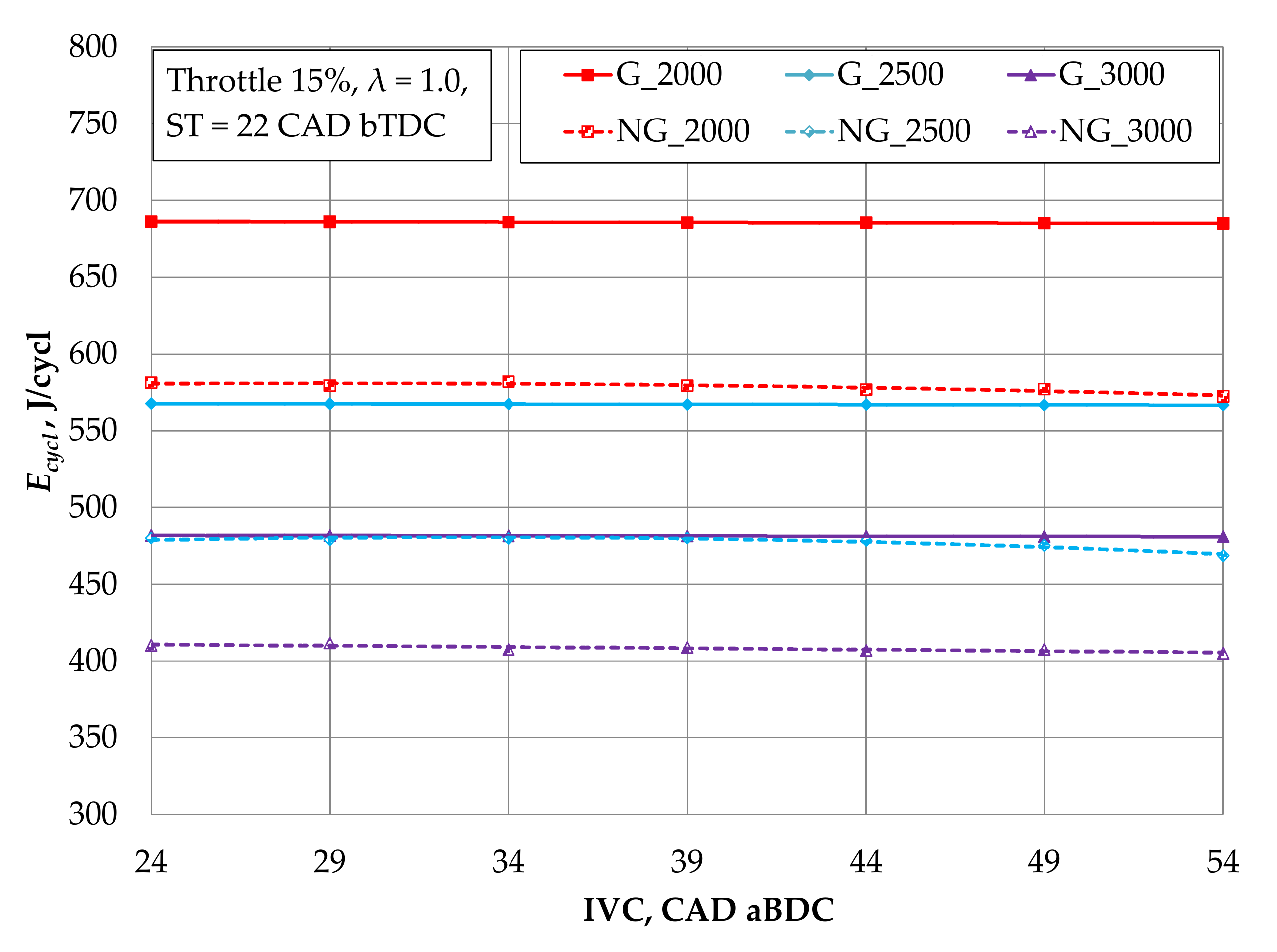

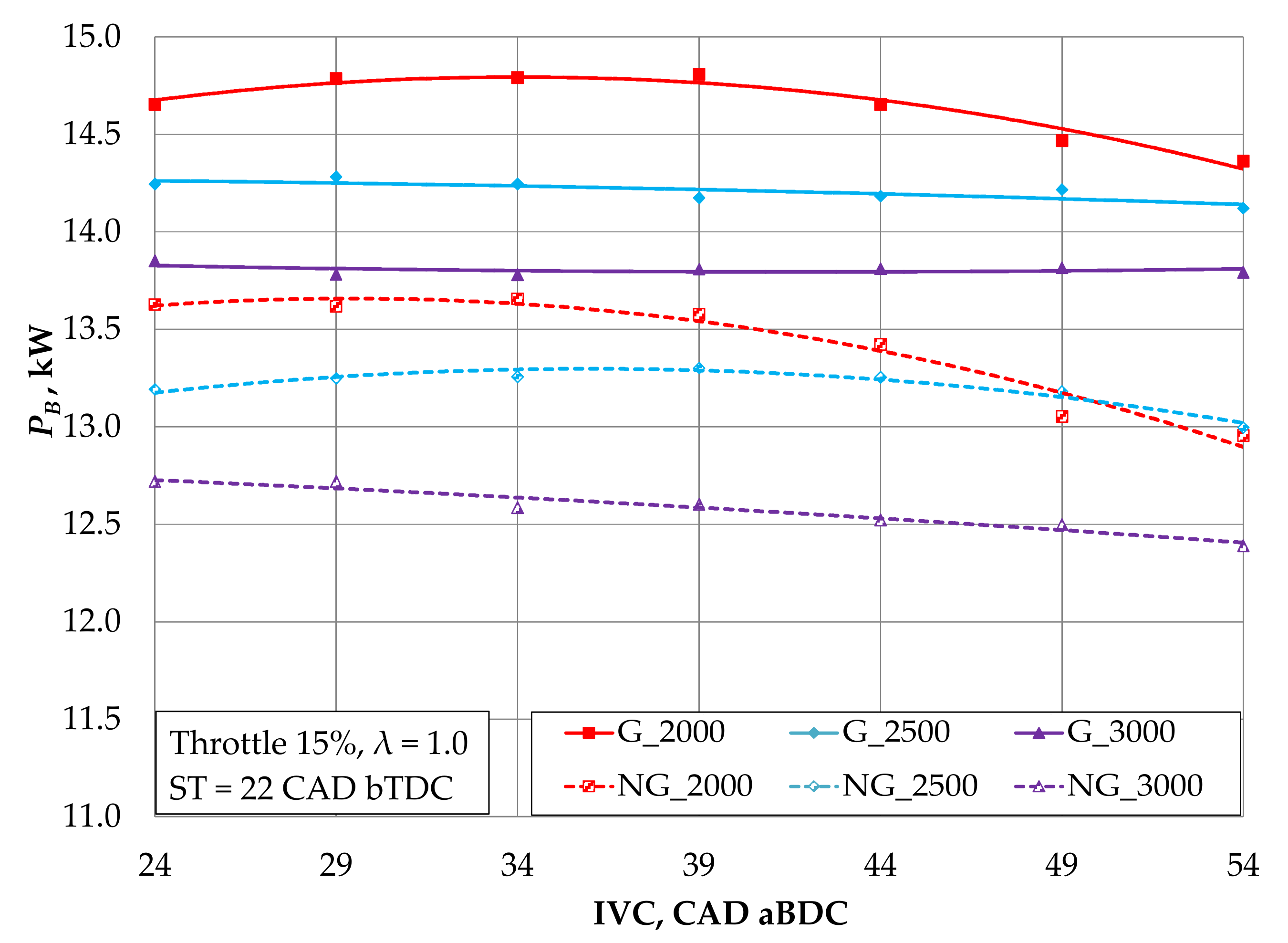

- When the engine was running on natural gas in the medium engine speed range, the MB was reduced by ~8% compared with gasoline. Although LHV of NG is ~8% higher compared with gasoline, the energy content in the cylinder was reduced by ~15.5%, because an NG reduces the amount of air in the cylinder (decreases volumetric efficiency), and stoichiometric mixture requires ~16% less fuel mass for the same amount of air. As a result, mcycl of NG was ~22% less. IVC timing adjustment had different effects on engine performance at different fuels and engine speeds.

- The closure timing control of the intake valve has a significant effect on the energy performance of the engine at a moderate (2000 rpm) speed at partially opening throttle when using both gasoline and NG. Using gasoline (G_2000), maximum brake torque and power and minimum BSFC were achieved when the IVC timing was 39 CAD aBDC. Advancing the IVC time to 24 CAD aBDC, the brake torque was reduced by ~1%. Delaying the IVC time to 54 CAD aBDC resulted in MB being reduced by 3%. NG occupies a certain volume and reduces the density of the intake mixture that is allowed into the cylinder; the mixture has less inertia, and when the IVC is delayed for longer, part of the NG is pushed back into the intake manifold due to lower inertia, and it reduces the volumetric efficiency of the engine. The negative effect of the IVC timing delaying on energy performance is more pronounced in the case of NG_2500 and NG_3000, because partially opening the throttle (15%) reduces gas velocity and inertia.

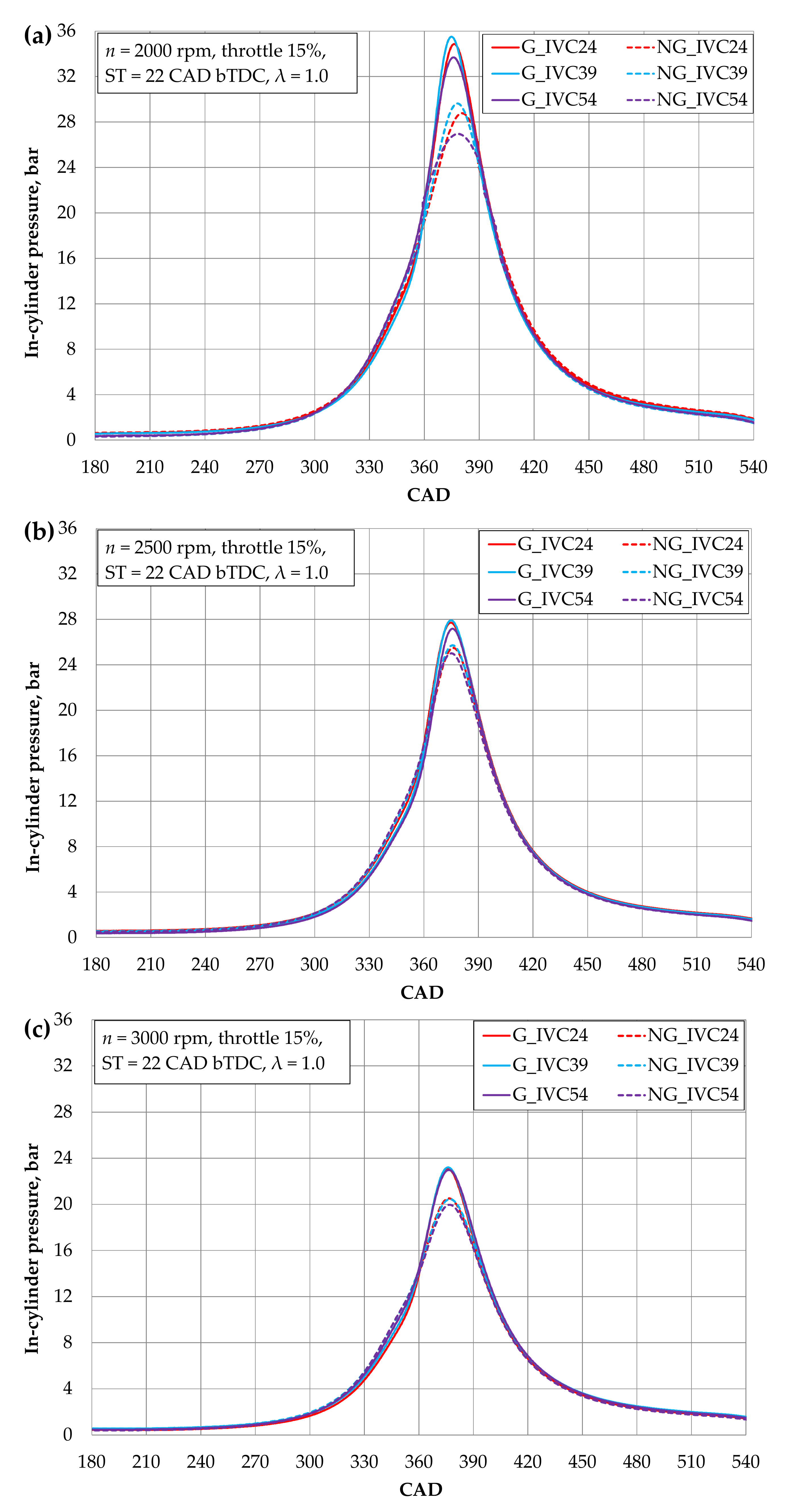

- When the engine was running at G_2000, the maximum ROHR, pressure, and temperature (2304 K) in the cylinder were reached when the IVC timing was 39 CAD aBDC. By further delaying the IVC timing to 54 CAD aBDC due to the reduced fuel energy per cycle in the cylinder, the maximum temperature of the ROHR and the pressure decreased by 4.3%. In the case of NG_2000, the maximum in-cylinder pressure was reached when the intake valve closed at same time—39 CAD aBDC. Due to a decrease in the burning rate of NG and slower ROHR reduced the maximum burning temperature by 8.8%, with the maximum value being 5 CAD later than it was at G_2000. The trend of slower natural gas combustion persists with increasing engine speeds to 3000 rpm. Changing gasoline to natural gas increased the cycle-to-cycle variation due to the fact that IVC was delayed, as delaying the IVC reduces the amount of air and fuel entering the cylinder, decreasing the maximum values of ROHR, combustion speed, and stability. The engine performance (fueled by NG) could be improved by opening the throttle wider and by creating a higher IMEP in the cylinder. Slower gas burning requires early spark timing.

- Using NG in the engine, specific emissions of NOx are ~30% lower than gasoline due to slower combustion ant lower combustion temperatures. Increasing the engine speed and maximum delay of IVC reduced the specific emissions of NOx, because the NOx concentration decreased more intensely, due to poorer volumetric efficiency, compared to the change in engine power. After switching from gasoline to NG emissions of CO2 decreased ~23%. The CO2 specific emissions for NG and gasoline at 2000 rpm are the lowest at IVC timing to 29–34 CAD aBDC as maximum BTE is achieved. Delaying the IVC to the maximum reduces BTE, and the combustion process is prolonged; therefore, the exhaust gas temperature increases. Increasing engine speed to 3000 rpm with throttle 15% due to poorer volumetric efficiency reduces BTE and increases CO2 emissions. At this engine speed, IVC timing adjustment has a negligible effect, because the throttle does not allow to improve volumetric efficiency.

- Low engine speeds are sufficient to ensure high BTE and low emissions of the engine at low power. Adjusting IVC timing and spark timing can further improve engine performance, but engine torque using NG will be lower. The lower torque of engine powered by NG can be significantly increased by increasing the throttle, opening percentage, in conjunction with IVC timing and ST regulation and thus improving the volumetric efficiency and BTE of the engine.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kallas, S. White Paper on Transport: Roadmap to a Single European Transport Area: Towards a Competitive and Resource-Efficient Transport System; Publications Office of the European Union: Luxembourg, 2011; ISBN 978-92-79-18270-9. [Google Scholar]

- Mahdiloo, M.; Ngwenyama, O.; Scheepers, R.; Tamaddoni, A. Managing Emissions Allowances of Electricity Producers to Maximize CO2 Abatement: DEA Models for Analyzing Emissions and Allocating Emissions Allowances. Int. J. Prod. Econ. 2018, 205, 244–255. [Google Scholar] [CrossRef]

- Baz, K.; Cheng, J.; Xu, D.; Abbas, K.; Ali, I.; Ali, H.; Fang, C. Asymmetric Impact of Fossil Fuel and Renewable Energy Consumption on Economic Growth: A Nonlinear Technique. Energy 2021, 226, 120357. [Google Scholar] [CrossRef]

- CHWIST, M.; Al, E. Bio-Oil Blended Butanol as a Fuel to the Spark Ignition Internal Combustion Reciprocating Engine. Combust. Engines 2017, 56, 93–96. [Google Scholar] [CrossRef]

- Panoutsou, C.; Germer, S.; Karka, P.; Papadokostantakis, S.; Kroyan, Y.; Wojcieszyk, M.; Maniatis, K.; Marchand, P.; Landalv, I. Advanced Biofuels to Decarbonise European Transport by 2030: Markets, Challenges, and Policies That Impact Their Successful Market Uptake. Energy Strategy Rev. 2021, 34, 100633. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Talluri, G.; Scarlat, N.; Prussi, M. The Challenge of Forecasting the Role of Biofuel in EU Transport Decarbonisation at 2050: A Meta-Analysis Review of Published Scenarios. Renew. Sustain. Energy Rev. 2021, 139, 110715. [Google Scholar] [CrossRef]

- Hotta, S.K.; Sahoo, N.; Mohanty, K. Comparative Assessment of a Spark Ignition Engine Fueled with Gasoline and Raw Biogas. Renew. Energy 2019, 134, 1307–1319. [Google Scholar] [CrossRef]

- Lijewski, P.; Kozak, M.; Fuc, P.; Rymaniak, L.; Ziolkowski, A. Exhaust Emissions Generated under Actual Operating Conditions from a Hybrid Vehicle and an Electric One Fitted with a Range Extender. Transp. Res. Part D-Transp. Environ. 2020, 78, 102183. [Google Scholar] [CrossRef]

- Rottoli, M.; Dirnaichner, A.; Pietzcker, R.; Schreyer, F.; Luderer, G. Alternative Electrification Pathways for Light-Duty Vehicles in the European Transport Sector. Transp. Res. Part D Transp. Environ. 2021, 99, 103005. [Google Scholar] [CrossRef]

- Long, A.; Murphy, J.D. Can Green Gas Certificates Allow for the Accurate Quantification of the Energy Supply and Sustainability of Biomethane from a Range of Sources for Renewable Heat and or Transport? Renew. Sustain. Energy Rev. 2019, 115, 109347. [Google Scholar] [CrossRef]

- Zhao, J.; Patwary, A.K.; Qayyum, A.; Alharthi, M.; Bashir, F.; Mohsin, M.; Hanif, I.; Abbas, Q. The Determinants of Renewable Energy Sources for the Fueling of Green and Sustainable Economy. Energy 2022, 238, 122029. [Google Scholar] [CrossRef]

- Arias, M.B.; Kim, M.; Bae, S. Prediction of Electric Vehicle Charging-Power Demand in Realistic Urban Traffic Networks. Appl. Energy 2017, 195, 738–753. [Google Scholar] [CrossRef]

- Gkatzoflias, D.; Drossinos, Y.; Zubaryeva, A.; Zambelli, P.; Dilara, P.; Thiel, C. Optimal Allocation of Electric Vehicle Charging Infrastructure in Cities and Regions. Available online: https://publications.jrc.ec.europa.eu/repository/bitstream/JRC101040/allocatechargingpoints_sciencepolreport_eurreport_online.pdf (accessed on 1 January 2020).

- Schismenos, S.; Chalaris, M.; Stevens, G. Battery Hazards and Safety: A Scoping Review for Lead Acid and Silver-Zinc Batteries. Saf. Sci. 2021, 140, 105290. [Google Scholar] [CrossRef]

- Commission of The European Communities Green Paper—A European Strategy for Sustainable, Competitive and Secure Energy. Available online: https://europa.eu/documents/comm/green_papers/pdf/com2006_105_en.pdf (accessed on 16 November 2021).

- Abd Alla, S.; Bianco, V.; Tagliafico, L.A.; Scarpa, F. Pathways to Electric Mobility Integration in the Italian Automotive Sector. Energy 2021, 221, 119882. [Google Scholar] [CrossRef]

- Brown, M.A.; Soni, A. Expert Perceptions of Enhancing Grid Resilience with Electric Vehicles in the United States. Energy Res. Soc. Sci. 2019, 57, 101241. [Google Scholar] [CrossRef]

- Kukharonak, H.; Ivashko, V.; Pukalskas, S.; Rimkus, A.; Matijošius, J. Operation of a Spark-Ignition Engine on Mixtures of Petrol and N-Butanol. Procedia Eng. 2017, 187, 588–598. [Google Scholar] [CrossRef]

- Cho, H.M.; He, B.-Q. Spark Ignition Natural Gas Engines—A Review. Energy Convers. Manag. 2007, 48, 608–618. [Google Scholar] [CrossRef]

- Karagöz, M.; Sarıdemir, S.; Deniz, E.; Çiftçi, B. The Effect of the CO2 Ratio in Biogas on the Vibration and Performance of a Spark Ignited Engine. Fuel 2018, 214, 634–639. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.A.; Xu, L.; Ali, M.K.A.; Elagouz, A.; Mi, J.; Guo, S.; Liu, Y.; Zuo, L. Vibration Energy Harvesting in Automotive Suspension System: A Detailed Review. Appl. Energy 2018, 229, 672–699. [Google Scholar] [CrossRef]

- Kuramochi, T.; Nascimento, L.; Moisio, M.; den Elzen, M.; Forsell, N.; van Soest, H.; Tanguy, P.; Gonzales, S.; Hans, F.; Jeffery, M.L.; et al. Greenhouse Gas Emission Scenarios in Nine Key Non-G20 Countries: An Assessment of Progress toward 2030 Climate Targets. Environ. Sci. Policy 2021, 123, 67–81. [Google Scholar] [CrossRef]

- Fragkos, P.; Fragkiadakis, K.; Sovacool, B.; Paroussos, L.; Vrontisi, Z.; Charalampidis, I. Equity Implications of Climate Policy: Assessing the Social and Distributional Impacts of Emission Reduction Targets in the European Union. Energy 2021, 237, 121591. [Google Scholar] [CrossRef]

- Chandrasekar, K.; Sudhakar, S.; Rajappan, R.; Senthil, S.; Balu, P. Present Developments and the Reach of Alternative Fuel: A Review. Mater. Today Proc. 2021. Available online: https://doi.org/10.1016/j.matpr.2021.04.505 (accessed on 10 November 2021).

- Kalghatgi, G. Development of Fuel/Engine Systems—The Way Forward to Sustainable Transport. Engineering 2019, 5, 510–518. [Google Scholar] [CrossRef]

- Bari, S.; Sawant, P. Improvement of Performance by 2-Step Variations of Intake Runner Length and Intake Valve Timing in the Induction System of a SI Engine. Energy Procedia 2019, 160, 108–115. [Google Scholar] [CrossRef]

- Zhao, J.; Xi, Q.; Wang, S.; Wang, S. Improving the Partial-Load Fuel Economy of 4-Cylinder SI Engines by Combining Variable Valve Timing and Cylinder-Deactivation through Double Intake Manifolds. Appl. Therm. Eng. 2018, 141, 245–256. [Google Scholar] [CrossRef]

- Demir, U.; Coskun, G.; Soyhan, H.S.; Turkcan, A.; Alptekin, E.; Canakci, M. Effects of Variable Valve Timing on the Air Flow Parameters in an Electromechanical Valve Mechanism—A Cfd Study. Fuel 2022, 308, 121956. [Google Scholar] [CrossRef]

- Nagumo, S.; Hara, S. Study of Fuel Economy Improvement through Control of Intake Valve Closing Timing: Cause of Combustion Deterioration and Improvement. JSAE Rev. 1995, 16, 13–19. [Google Scholar] [CrossRef]

- Park, C.; Ebisu, M.; Bae, C. Improvement of Instantaneous Turbine Efficiency through Late Intake Valve Phase (LIVP) in a Turbocharged-Gasoline Direct Injection (T-GDI) Engine. Appl. Therm. Eng. 2020, 181, 115976. [Google Scholar] [CrossRef]

- Perceau, M.; Guibert, P.; Guilain, S. Zero-Dimensional Turbulence Modeling of a Spark Ignition Engine in a Miller Cycle «Dethrottling» Approach Using a Variable Valve Timing System. Appl. Therm. Eng. 2021, 199, 117535. [Google Scholar] [CrossRef]

- Li, Y.; Khajepour, A.; Devaud, C. Realization of Variable Otto-Atkinson Cycle Using Variable Timing Hydraulic Actuated Valve Train for Performance and Efficiency Improvements in Unthrottled Gasoline Engines. Appl. Energy 2018, 222, 199–215. [Google Scholar] [CrossRef]

- Komninos, N.P.; Rogdakis, E.D. Numerical Investigation into the Effect of Compressor and Expander Valve Timings on the Performance of an Ericsson Engine Equipped with a Gas-to-Gas Heat Exchanger. Energy 2018, 163, 1077–1092. [Google Scholar] [CrossRef]

- Takahashi, D.; Nakata, K.; Yoshihara, Y.; Ohta, Y.; Nishiura, H. Combustion Development to Achieve Engine Thermal Efficiency of 40% for Hybrid Vehicles; Society of Automotive Engineers: Warrendale, PA, USA, 2015; pp. 1–9. [Google Scholar]

- Kato, K.; Igarashi, K.; Masuda, M.; Otsubo, K.; Yasuda, A.; Takeda, K.; Sato, T. Development of Engine for Natural Gas Vehicle; SAE: Warrendale, PN, USA, 1999; pp. 1–11. [Google Scholar]

- Kim, S.; Park, C.; Jang, H.; Kim, C.; Kim, Y. Effect of Boosting on a Performance and Emissions in a Port Fuel Injection Natural Gas Engine with Variable Intake and Exhaust Valve Timing. Energy Rep. 2021, 7, 4941–4950. [Google Scholar] [CrossRef]

- Wang, J.; Duan, X.; Wang, W.; Guan, J.; Li, Y.; Liu, J. Effects of the Continuous Variable Valve Lift System and Miller Cycle Strategy on the Performance Behavior of the Lean-Burn Natural Gas Spark Ignition Engine. Fuel 2021, 297, 120762. [Google Scholar] [CrossRef]

- Dogru, B.; Lot, R.; Ranga Dinesh, K.K.J. Valve Timing Optimisation of a Spark Ignition Engine with Skip Cycle Strategy. Energy Convers. Manag. 2018, 173, 95–112. [Google Scholar] [CrossRef] [Green Version]

- Szwaja, S.; Ansari, E.; Rao, S.; Szwaja, M.; Grab-Rogalinski, K.; Naber, J.D.; Pyrc, M. Influence of Exhaust Residuals on Combustion Phases, Exhaust Toxic Emission and Fuel Consumption from a Natural Gas Fueled Spark-Ignition Engine. Energy Convers. Manag. 2018, 165, 440–446. [Google Scholar] [CrossRef]

- Melaika, M. Research of a Combustion Process in a Spark Ignition Engine, Fuelled With Gaseous Fuel Mixtures; Vilnius Gediminas Technical University: Vilnius, Lithuania, 2016; ISBN 978-609-457-996-7. [Google Scholar]

- Sendzikiene, E.; Rimkus, A.; Melaika, M.; Makareviciene, V.; Pukalskas, S. Impact of Biomethane Gas on Energy and Emission Characteristics of a Spark Ignition Engine Fuelled with a Stoichiometric Mixture at Various Ignition Advance Angles. Fuel 2015, 162, 194–201. [Google Scholar] [CrossRef]

- Lecuona, A.; Nogueira, J.I.; Famiglietti, A. Open Dual Cycle with Composition Change and Limited Pressure for Prediction of Miller Engines Performance and Its Turbine Temperature. Energies 2021, 14, 2870. [Google Scholar] [CrossRef]

- Melaika, M.; Herbillon, G.; Dahlander, P. Spark Ignition Engine Performance, Standard Emissions and Particulates Using GDI, PFI-CNG and DI-CNG Systems. Fuel 2021, 293, 120454. [Google Scholar] [CrossRef]

- Nguyen Duc, K.; Nguyen Duy, V.; Hoang-Dinh, L.; Nguyen Viet, T.; Le-Anh, T. Performance and Emission Characteristics of a Port Fuel Injected, Spark Ignition Engine Fueled by Compressed Natural Gas. Sustain. Energy Technol. Assess. 2019, 31, 383–389. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Duan, X.; Liu, S.; Liu, J.; Hu, S. Multi-Objective Energy Management for Atkinson Cycle Engine and Series Hybrid Electric Vehicle Based on Evolutionary NSGA-II Algorithm Using Digital Twins. Energy Convers. Manag. 2021, 230, 113788. [Google Scholar] [CrossRef]

| Parameter | The Units | Value |

|---|---|---|

| Engine type | Spark ignition | |

| Cylinder arrangement | In-line 4 | |

| Cooling | Water | |

| Displacement | dm3 | 1.598 |

| Cylinder bore and stroke | mm | 78.0 × 83.6 |

| Maximum power | kW (at rpm) | 84 (6000) |

| Maximum torque | Nm (at rpm) | 156 (4400) |

| Compression ratio | 10.7 | |

| Number of valves | 16 (DOHC) | |

| Intake valve open (IVO) | CAD bTDC 1 | 24 … −11 (VVT) |

| Intake valve close (IVC) | CAD aBDC 2 | 24 … 59 (VVT) |

| Intake valve duration (IVD) | CAD | 228 |

| Exhaust valve open (EVO) | CAD bBDC 3 | 24 |

| Exhaust valve close (EVC) | CAD aTDC 4 | 4 |

| Exhaust valve duration (EVD) | CAD | 208 |

| Equipment | Type | Specifications | Error |

|---|---|---|---|

| Engine load stand | Eddy current type | Maximum speed 6000 rpm, maximum brake torque 480 Nm | Torque: ±0.9 Nm |

| AMX200/100 | |||

| Coriolis mass flowmeter | RHEONIK RHM 015 | Measuring range | ±0.10% |

| 0.004… 0.6 kg/min | |||

| Intake air mass meter | BOSCH HFM 5 | Measuring range | ±2% |

| 8… 370 kg/h | |||

| Exhaust gas temperature sensor | K-type thermocouple | Measuring range | ±0.5% |

| 0… +1250 °C | |||

| Cylinder pressure sensor | AVL ZI31_Y7S | Measuring range | Sensitivity 11.62 pC/bar |

| 0… 200 bar | |||

| Crankshaft position sensor | Photoelectric encoder | Signal repeatability | - |

| A58M-F | 0.1758 CAD | ||

| Exhaust gas analyzer | AVL DiCom 4000 | Measuring range: | |

| CO2–0… 20% | ±0.1% | ||

| CO–0… 10% | ±0.01% | ||

| HC–0… 20,000 ppm | ±1 ppm | ||

| NOx–0… 5000 ppm | ±1 ppm | ||

| O2–0… 25% | ±0.01% |

| Parameter | The Units | Gasoline (G) | Natural Gas (NG) |

|---|---|---|---|

| Density | kg/m3 | 740 * | ~0.74 ** |

| Octane number | 95 | ~120 | |

| Lower heating value (LHV) | MJ/kg | ~44.0 | ~47.5 |

| Stoichiometric mixture (A/F) | kg/kg | ~14.7/1 | ~17.2/1 |

| Boiling temperature | °C | 25–215 *** | −162*,** |

| Specific heat of vaporization | kJ/kg | ~380 | ~550 |

| Freezing point | °C | −40 *** | −162 *** |

| Auto-ignition temperature | °C | ~400 | ~540 |

| Adiabatic flame temperature | °C | ~2150 | ~1890 |

| Flame spread rate | m/s | ~0.5 | ~0.41 |

| H/C ratio | ~0.163 | ~0.316 | |

| Chemical element/component | % (mass) | Carbon: ~0.836 | Methane: 91.97 |

| Hydrogen: ~0.139 | Ethane: 5.75 | ||

| Oxygen: ~0.025 | Propane: 1.30 | ||

| Butane: 0.281 | |||

| Nitrogen: 0.562 | |||

| Carbon dioxide: 0.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rimkus, A.; Vipartas, T.; Kriaučiūnas, D.; Matijošius, J.; Ragauskas, T. The Effect of Intake Valve Timing on Spark-Ignition Engine Performances Fueled by Natural Gas at Low Power. Energies 2022, 15, 398. https://doi.org/10.3390/en15020398

Rimkus A, Vipartas T, Kriaučiūnas D, Matijošius J, Ragauskas T. The Effect of Intake Valve Timing on Spark-Ignition Engine Performances Fueled by Natural Gas at Low Power. Energies. 2022; 15(2):398. https://doi.org/10.3390/en15020398

Chicago/Turabian StyleRimkus, Alfredas, Tadas Vipartas, Donatas Kriaučiūnas, Jonas Matijošius, and Tadas Ragauskas. 2022. "The Effect of Intake Valve Timing on Spark-Ignition Engine Performances Fueled by Natural Gas at Low Power" Energies 15, no. 2: 398. https://doi.org/10.3390/en15020398

APA StyleRimkus, A., Vipartas, T., Kriaučiūnas, D., Matijošius, J., & Ragauskas, T. (2022). The Effect of Intake Valve Timing on Spark-Ignition Engine Performances Fueled by Natural Gas at Low Power. Energies, 15(2), 398. https://doi.org/10.3390/en15020398