Flowing Refractometer for Feed Water State Control in the Second Loop of Nuclear Reactor

Abstract

:1. Introduction

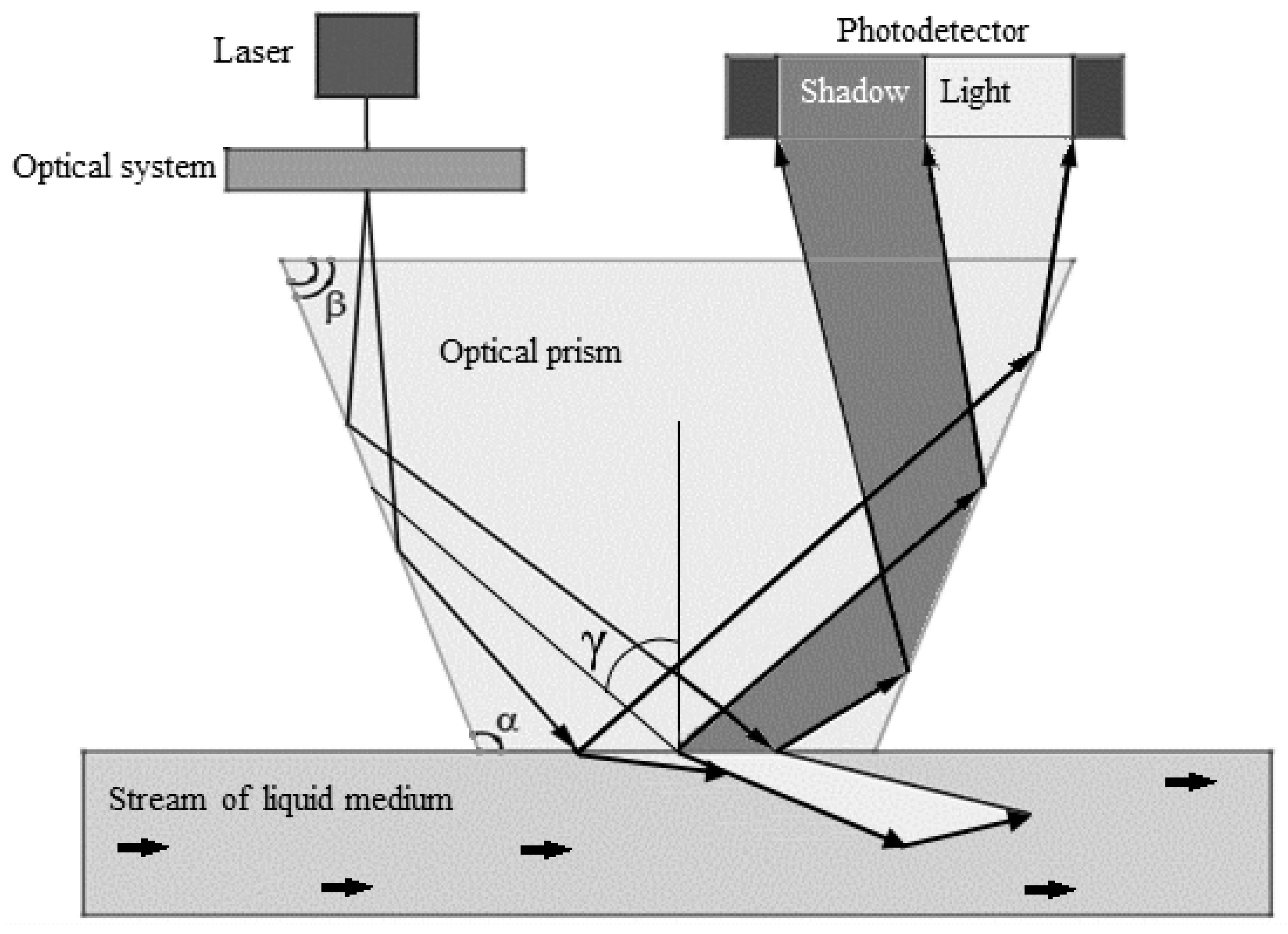

2. Methodology for Monitoring the State of Feed Water and Its Practical Implementation

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Agafonova, N.D.; Egorov, M.Y.; Sergeev, V.V.; Gotovskii, M.A.; Kruglikov, P.A.; Lebedev, M.E.; Sudakov, A.V.; Fedorovich, E.D.; Fokin, B.S. Heat-and-Mass Transfer Intensification in Saturated-Steam Generators in NPP with VVER as a Means for Increasing Efficiency and Reliability. At. Energy 2018, 123, 154–158. [Google Scholar] [CrossRef]

- Gulevich, A.V.; Dekusar, V.M.; Chebeskov, A.N.; Kuchinov, V.P.; Voloshin, N.P. Possibility of Fast-Reactor Exportation Under an International Nuclear Non-Proliferation Regime. At. Energy 2020, 127, 192–195. [Google Scholar] [CrossRef]

- Ashurko, Y.M.; Gulevich, A.V.; Klinov, D.A.; Vasil’ev, B.A.; Vasyaev, A.V.; Marova, E.V.; Shepelev, S.F. Gen-IV Reactor Systems Criteria Implementation in BN-1200. At. Energy 2019, 125, 351–358. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, M.; Jiang, D.; Huang, X.; Zhang, Y.; Zhang, Z. Automatic Generation Control of Nuclear Heating Reactor Power Plants. Energies 2018, 11, 2782. [Google Scholar] [CrossRef] [Green Version]

- Lee, K.-H.; Kim, M.-G.; Lee, J.I.; Lee, P.-S. Recent Advances in Ocean Nuclear Power Plants. Energies 2015, 8, 11470–11492. [Google Scholar] [CrossRef] [Green Version]

- Wu, G.; Ju, P.; Song, X.; Xie, C.; Zhong, W. Interaction and Coordination among Nuclear Power Plants, Power Grids and Their Protection Systems. Energies 2016, 9, 306. [Google Scholar] [CrossRef] [Green Version]

- Davydov, V.V.; Myazin, N.S.; Kiryukhin, A.V. Nuclear-Magnetic Flowmeter-Relaxometers for Monitoring Coolant and Feed water Flow and Status in Npp. At. Energy 2020, 127, 274–279. [Google Scholar] [CrossRef]

- Davydov, R.; Antonov, V.; Makeev, S.; Batov, Y.; Dudkin, V.; Myazin, N. New high-speed system for controlling the parameters of a nuclear reactor in a nuclear power plant. E3S Web Conf. 2019, 140, 02001. [Google Scholar] [CrossRef] [Green Version]

- Krapivtsev, V.G.; Solonin, V.I. Model Studies of Interloop Coolant Mixing in VVER-1000 in-Reactor Pressure Channel. At. Energy 2019, 125, 307–313. [Google Scholar] [CrossRef]

- Elokhin, A.P. Unconventional Methods of Radiological Environmental Monitoring and Earthquake Prediction. At. Energy 2015, 117, 206–215. [Google Scholar] [CrossRef]

- Ksenofontov, A.I.; Elokhin, A.P.; Alalem, E.A. Application of simulation modelling approaches for analyzing γ-radiation characteristics of a plume induced by a Nuclear Accident at NPP. Loon 2019, 487, 012009. [Google Scholar] [CrossRef]

- Fadeenko, V.; Fadeenko, I.; Nikolaev, D. Remote environmental monitoring in the area of a nuclear power plant. IOP Conf. Ser. Earth Environ. Sci. 2019, 390, 012022. [Google Scholar] [CrossRef]

- Sorokin, A.P.; Kuzina, Y.A. Physical Modeling of Hydrodynamics and Heat Transfer in Liquid-Metal Cooled Fast Reactors. At. Energy 2020, 128, 277–286. [Google Scholar] [CrossRef]

- Filimonov, P.E.; Semchenkov, Y.M.; Malyshev, V.V.; Dolgopolov, N.Y.; Povarov, V.P.; Gusev, I.N. VVER-1200 Tests in No. 6 Unit of the Novovoronezh NPP During Operation in a Daily Load Schedule. At. Energy 2020, 129, 143–148. [Google Scholar] [CrossRef]

- Abramov, L.V.; Baklanov, A.V.; Bakmetiev, A.M.; Bylov, I.A.; Vasyuchenkov, A.A.; Gusev, D.O.; Kiselev, V.V. OKBM Afrikantov Experience in Developing Methods and Computer Codes for Reliability Analysis and Probabilistic Safety Analysis of Nuclear Installations. At. Energy 2020, 129, 103–108. [Google Scholar] [CrossRef]

- Firth, J.; Ladouceur, F.; Brodzeli, Z.; Wyres, M.; Silvestri, L. A novel optical telemetry system applied to flowmeter networks. Flow Meas. Instrum. 2016, 48, 15–19. [Google Scholar] [CrossRef]

- Looney, R.; Priede, J. Concept of a next-generation electromagnetic phase-shift flowmeter for liquid metals. Flow Meas. Instrum. 2019, 65, 128–135. [Google Scholar] [CrossRef] [Green Version]

- Novikova, O.V.; Erastov, A.E.; Livshits, S.A. Features of evaluating the efficiency indicators of the electric power enterprise. E3S Web Conf. 2019, 124, 05057. [Google Scholar] [CrossRef] [Green Version]

- Medeiros, K.A.R.; Barbosa, C.R.H.; d’Almeida, J.R.M.; Ribeiro, A.S.; de Paula, I.B. Flowmeter based on a piezoelectric PVDF tube. Meas. J. Int. Meas. Confed. 2019, 138, 368–378. [Google Scholar] [CrossRef]

- Marusina, M.Y.; Bazarov, B.A.; Galaidin, P.A.; Marusin, M.P.; Silaev, A.A.; Zakemovskaya, E.Y.; Mustafaev, Y.N. Design of a Gradient System for a Multiphase Flowmeter. Meas. Tech. 2014, 57, 580–586. [Google Scholar] [CrossRef]

- Davydov, V.V.; Dudkin, V.I.; Karseev, A.Y.; Vologdin, V.A. Special Features in Application of Nuclear Magnetic Spectroscopy to Study Flows of Liquid Media. J. Appl. Spectrosc. 2016, 82, 1013–1019. [Google Scholar] [CrossRef]

- Karabegov, M.A. The dynamic characteristics of automatic analyzers. Meas. Tech. 2013, 55, 1301–1310. [Google Scholar] [CrossRef]

- Karabegov, M.A. Automatic differential prism refractometer for monitoring process liquids. Meas. Tech. 2007, 50, 619–628. [Google Scholar] [CrossRef]

- Mishchenko, Y.V. Method of refractometric control of liquids in processing plants. Meas. Tech. 2007, 50, 1274–1281. [Google Scholar] [CrossRef]

- Mishchenko, Y.V. Fiber-optic interferometric refractometer for deep-water studies of sea water. Meas. Tech. 2006, 49, 1210–1217. [Google Scholar] [CrossRef]

- Shur, V.L.; Naidenov, A.S.; Lukin, A.Y.; Leibengardt, G.I. A liquid autocollimation refractometer. Meas. Tech. 2006, 49, 815–819. [Google Scholar] [CrossRef]

- Davydov, V.V.; Grebenikova, N.M.; Smirnov, K.Y. An Optical Method of Monitoring the State of Flowing Media with Low Transparency That Contain Large Inclusions. Meas. Tech. 2019, 62, 519–526. [Google Scholar] [CrossRef]

- Meeten, G.H.; North, A.N. Refractive index measurement of absorbing and turbid fluids by reflection near the critical angle. Meas. Sci. Technol. 1995, 6, 214–221. [Google Scholar] [CrossRef]

- Contrerastello, H.; Márquezislas, R.; Vázquezestrada, O.; Sánchezpérez, C.; Garcíavalenzuela, A. Understanding the performance of Abbe-type refractometers with optically absorbing fluids. Meas. Sci. Technol. 2014, 25, 075201. [Google Scholar] [CrossRef]

- Leibengardt, G.I.; Naidenov, A.S.; Shur, V.L. A liquid laser interference refractometer for measuring the concentration of solutions. Meas. Tech. 2004, 47, 1211–1216. [Google Scholar] [CrossRef]

- Chen, J.; Guo, W.; Xia, M.; Li, W.; Yang, K. In situ measurement of seawater salinity with an optical refractometer based on total internal reflection method. Opt. Express 2018, 26, 25510–25523. [Google Scholar] [CrossRef] [PubMed]

- Morales-Luna, G.; Garcia-Valenzuela, A. Viability and fundamental limits of critical-angle refractometry of turbid colloids. Meas. Sci. Technol. 2017, 28, 125203. [Google Scholar] [CrossRef] [Green Version]

- Niskanen, I.; Räty, J.; Peiponen, K.-E. On the Immersion Liquid Evaporation Method Based on the Dynamic Sweep of Magnitude of the Refractive Index of a Binary Liquid Mixture: A Case Study on Determining Mineral Particle Light Dispersion. Appl. Spectrosc. 2017, 71, 1586–1592. [Google Scholar] [CrossRef]

- Morales-Luna, G.; Herrera-Domínguez, M.; Pisano, E.; Balderas-Elizalde, A.; Hernandez-Aranda, R.I.; Ornelas-Soto, N. Plasmonic biosensor based on an effective medium theory as a simple tool to predict and analyze refractive index changes. Opt. Laser Technol. 2020, 131, 106332. [Google Scholar] [CrossRef]

- Morales-Luna, G.; García-Valenzuela, A.; Barrera, R.G. Optical Coherent Reflection from a Confined Colloidal Film: Modeling and Experiment. J. Phys. Chem. B 2018, 122, 8570–8581. [Google Scholar] [CrossRef]

- Bhardwaj, V.K.; Maini, S. Compact and self-aligned fluid refractometer based on the Doppler-induced self-mixing effect. Appl. Opt. 2020, 59, 3064–3072. [Google Scholar] [CrossRef]

- Luo, Y.; Guo, W.; Yu, L.; Xia, M.; Li, W.; Yang, K. High-precision algorithms for critical angle refractive index measurement. Appl. Opt. 2019, 58, 6057–6062. [Google Scholar] [CrossRef]

- Guo, W.; Li, R.; Yu, L.; Chen, J.; Xia, M.; Li, W.; Yang, K. Self-referenced technology for refractive index measurement under mechanical vibration and temperature fluctuation. Appl. Opt. 2019, 58, 1862–1867. [Google Scholar] [CrossRef] [PubMed]

| Nº | Refractometer Type | |

|---|---|---|

| The Developed Flowing Refractometer | Abbe Refractometer (NAR-2T UH) | |

| 1 | 1.3317 ± 0.0003 | 1.3316 ± 0.0002 |

| 2 | 1.3318 ± 0.0003 | 1.3315 ± 0.0002 |

| 3 | 1.3317 ± 0.0003 | 1.3315 ± 0.0002 |

| 4 | 1.3316 ± 0.0003 | 1.3315 ± 0.0002 |

| 5 | 1.3318 ± 0.0003 | 1.3316 ± 0.0002 |

| 6 | 1.3317 ± 0.0003 | 1.3317 ± 0.0002 |

| 7 | 1.3317 ± 0.0003 | 1.3317 ± 0.0002 |

| 8 | 1.3316 ± 0.0003 | 1.3317 ± 0.0002 |

| 9 | 1.3316 ± 0.0003 | 1.3315 ± 0.0002 |

| 10 | 1.3318 ± 0.0003 | 1.3316 ± 0.0002 |

| 11 | 1.3318 ± 0.0003 | 1.3316 ± 0.0002 |

| 12 | 1.3316 ± 0.0003 | 1.3315 ± 0.0002 |

| 13 | 1.3317 ± 0.0003 | 1.3315 ± 0.0002 |

| 14 | 1.3317 ± 0.0003 | 1.3317 ± 0.0002 |

| 15 | 1.3317 ± 0.0003 | 1.3317 ± 0.0002 |

| 16 | 1.3316 ± 0.0003 | 1.3316 ± 0.0002 |

| 17 | 1.3316 ± 0.0003 | 1.3316 ± 0.0002 |

| 18 | 1.3318 ± 0.0003 | 1.3317 ± 0.0002 |

| 19 | 1.3317 ± 0.0003 | 1.3315 ± 0.0002 |

| 20 | 1.3318 ± 0.0003 | 1.3315 ± 0.0002 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Davydov, V.; Gureeva, I.; Davydov, R.; Dudkin, V. Flowing Refractometer for Feed Water State Control in the Second Loop of Nuclear Reactor. Energies 2022, 15, 457. https://doi.org/10.3390/en15020457

Davydov V, Gureeva I, Davydov R, Dudkin V. Flowing Refractometer for Feed Water State Control in the Second Loop of Nuclear Reactor. Energies. 2022; 15(2):457. https://doi.org/10.3390/en15020457

Chicago/Turabian StyleDavydov, Vadim, Irena Gureeva, Roman Davydov, and Valentin Dudkin. 2022. "Flowing Refractometer for Feed Water State Control in the Second Loop of Nuclear Reactor" Energies 15, no. 2: 457. https://doi.org/10.3390/en15020457