Glare at Outdoor Workplaces—An Underestimated Factor of Occupational Risk

Abstract

:1. Introduction

1.1. Motivation

1.2. Accidents at Work—The Impact of Inadequate Lighting

1.3. Glare at Outdoor Workplaces—A Short Story

1.4. Aim of the Paper

2. Materials and Methods

2.1. How to Assess Objectively the Glare at Outdoor Workplaces—The Practice

2.2. The Research Methodology

3. Results

3.1. General Circulation Areas at Outdoor Workplaces

3.2. Airports

3.3. Building Sites

3.4. Canals, Locks, and Harbors

3.5. Fuel Filling Stations

3.6. Industrial Sites and Storage Areas

3.7. Parking Areas

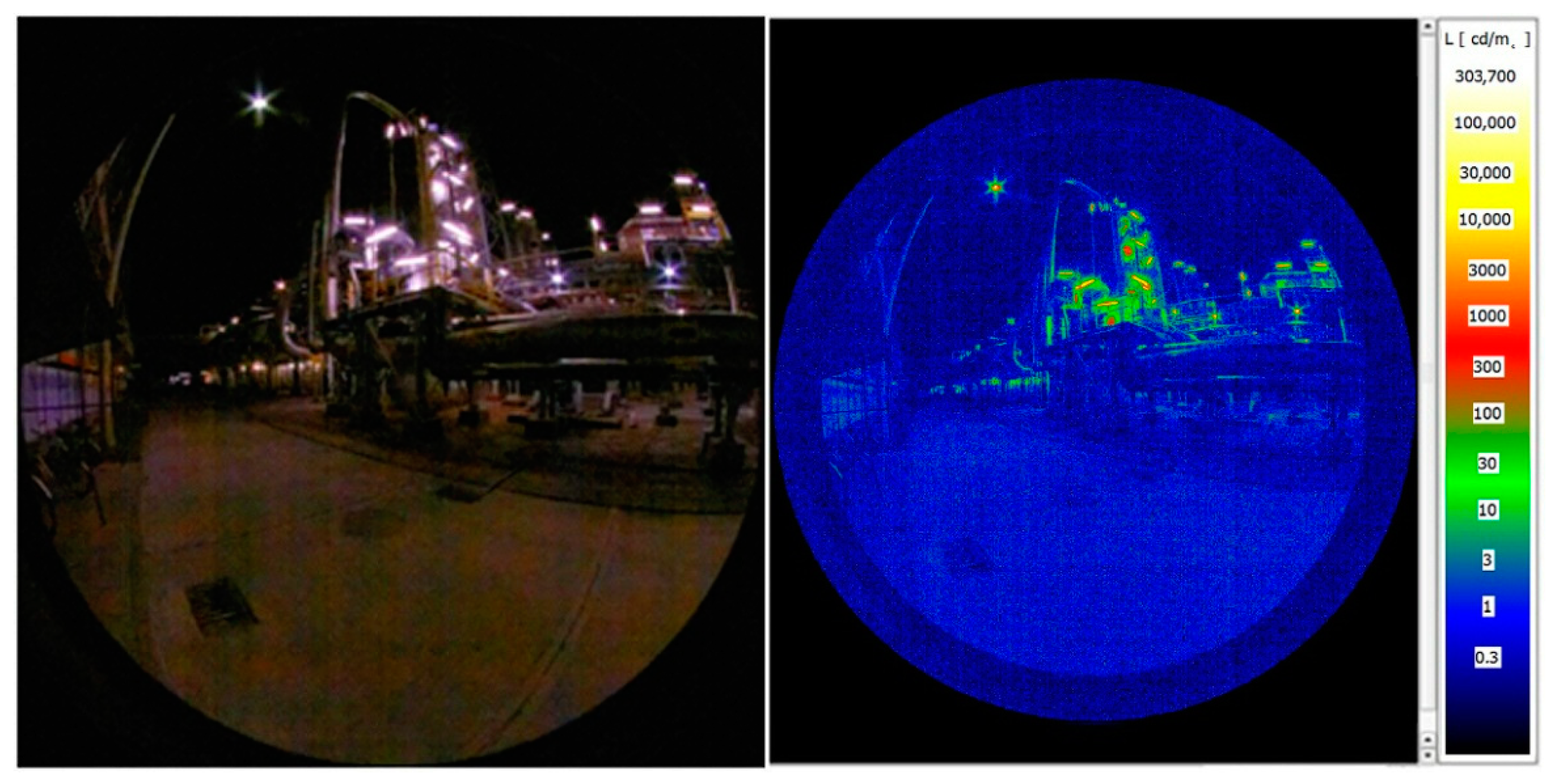

3.8. Oil and Other Chemical Industries

3.9. Railways and Tramways

3.10. Saw Mills

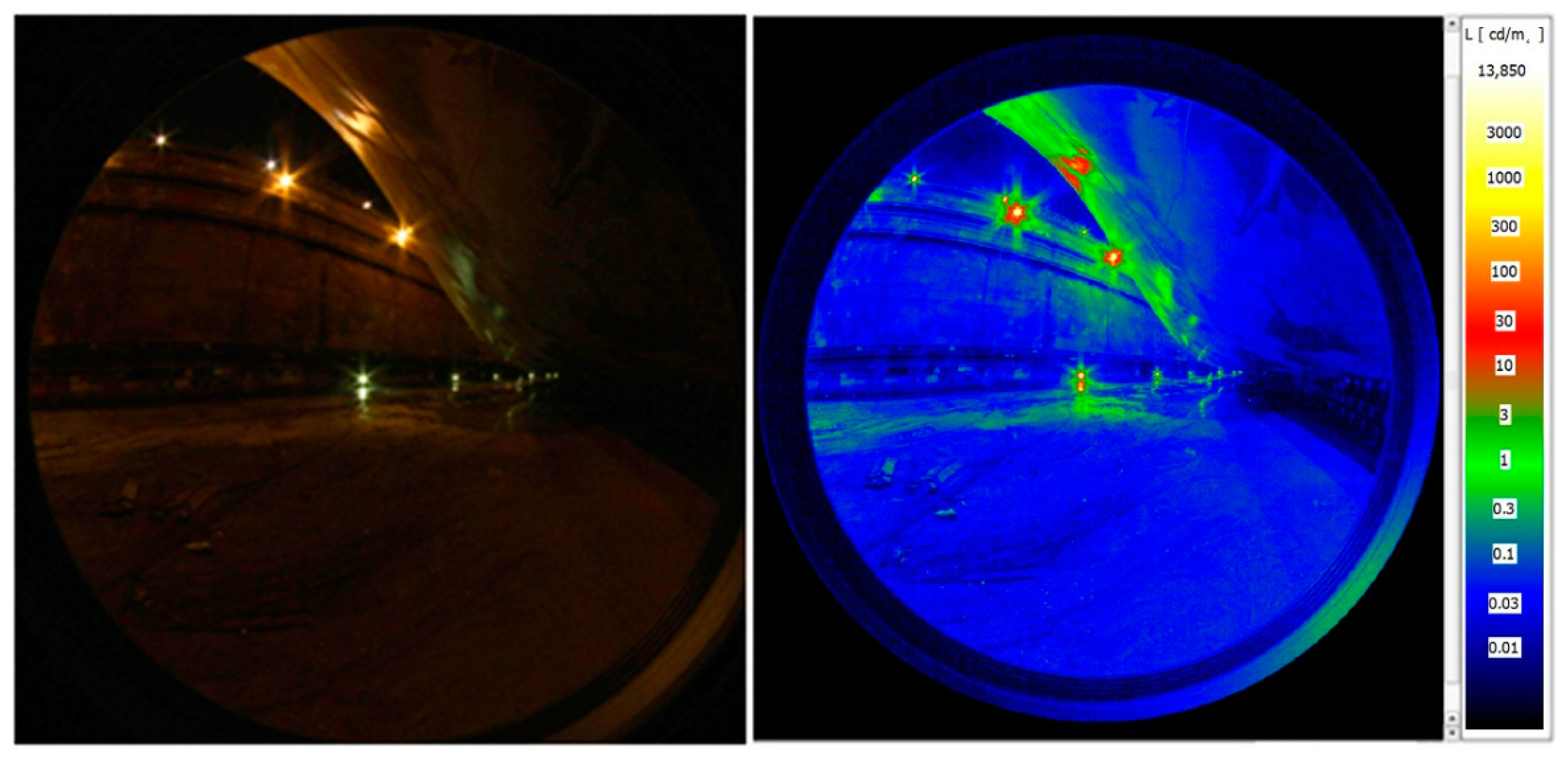

3.11. Shipyards and Docks

3.12. Water and Sewage Plants

4. Discussion

4.1. Analysis of the Collected Results

- At 20 task areas (out of 93 examined, meaning 21.5%) the determined degree of glare (measured GR values or subjective assessment) exceeded the limits specified in the standard—i.e., the requirements of the standard in terms of glare limitation were not met.

- At eight categories of industrial plants defined in the standard [5] (out of 12 examined, meaning 66.7%) there was at least one task area where the requirements of the standard in terms of glare limitation were not met.

- At 11 task areas (out of 93 examined, meaning 11.8%) we found a high degree of risk. Unfortunately, this was in industries from the category of hazardous industries where the consequences of accidents can be very serious.

- No glare was found at outdoor workplaces where high masts were used and bright sources illuminated the surface from a great height. This applies to storage areas, parking areas, and some areas of airports, water and sewage installations. It is worth paying attention to the fact that the reflections of light from large surfaces with specular reflectance properties (e.g., water surfaces) can create hazards if the lamps are not installed high enough.

- The problem existed at workplaces where it was difficult to light up the task areas. Occurrence of glare in these cases is related to the specificity of the workplace and activities performed there. This is mainly the case with docks and large chemical and petrochemical installations. The glare risks are very serious in these cases. Working in such places is always dangerous, and worsening conditions by glare can result in very serious accidents or even death.

- The most serious problem was noticed at workplaces where temporary lighting installations were built to carry out tasks at a given moment. This case is practically observed mostly for maintenance and repair tasks in railway and tramway enterprises. Similarly, this condition is seen on construction/building sites where lighting is changed and glare limitation is seldom taken into consideration.

4.2. How to Improve the Situation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Atzeria, A.M.; Cappellettib, F.; Tzempelikosc, A.; Gasparella, A. Comfort metrics for an integrated evaluation of buildings performance. Energy Build. 2016, 127, 411–424. [Google Scholar] [CrossRef]

- Ryckaert, W.R.; Lootens, C.; Geldof, J.; Hanselaer, P. Criteria for energy efficient lighting in buildings. Energy Build. 2010, 42, 341–347. [Google Scholar] [CrossRef]

- Linhart, F.; Scartezzini, J.L. Evening office lighting—visual comfort vs. energy efficiency vs. performance? Build. Environ. 2011, 46, 981–989. [Google Scholar] [CrossRef]

- European Standard. EN 12464-1:2011. Part 1: Indoor Work Places. Light and Lighting—Lighting of Work Places; European Committee for Standardization (CEN): Brussels, Belgium, 2011. [Google Scholar]

- European Standard. EN 12464-2:2014: Part 2: Outdoor Work Places. Light and Lighting—Lighting of Work Places; European Committee for Standardization (CEN): Brussels, Belgium, 2014. [Google Scholar]

- Lighting of Outdoor Work Places; CIE S 015/E: 2005; International Commission on Illumination (CIE): Vienna, Austria, 2005.

- Part 1: Indoor. Lighting of Work Places; ISO 8995-1:2002(E)/CIE S 008/E:2001; ISO: Geneva, Switzerland, 2002; International Commission on Illumination (CIE): Vienna, Austria, 2001.

- Part 3: Lighting Requirements for Safety and Security of Outdoor Work Places. Lighting of Work Places; ISO: Geneva, Switzerland, 2006; International Commission on Illumination (CIE): Vienna, Austria, 2005; ISO 8995-3:2006(E)/CIE S 016/E: 2005.

- Licht.wissen 13. Outdoor Workplaces. Licht.de. Fördergemeinschaft Gutes Licht. Frankfurt am Main, Germany, 2007. Available online: http://en.licht.de/fileadmin/Publications/licht-wissen/0712_lw13_E_Outdoor_Workplaces_web.pdf (accessed on 20 August 2021).

- Reinhold, K.; Tint, P. Lighting of workplaces and health risks. Electron. Electr. Eng. 2009, 2, 11–14. [Google Scholar]

- Hinze, J.W.; Teizer, J. Visibility-related fatalities related to construction equipment. Saf. Sci. 2011, 49, 709–718. [Google Scholar] [CrossRef]

- Badri, A.; Nadeau, S.; Gbodossou, A. Proposal of a risk–factor–based analytical approach for integrating occupational health and safety project risk evaluation. Accid. Anal. Prev. 2012, 48, 223–234. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Herrero, S.; Mariscal, M.A.; Garcia-Rodriguez, J.; Ritzel, D.O. Working conditions, psychological/physical symptoms and occupational accidents. Bayesian network models. Saf. Sci. 2012, 50, 1760–1774. [Google Scholar] [CrossRef]

- Babović, P. Occupational accidents as indicators of inadequate work conditions and work environment. Acta Med. Median. 2009, 48, 22–26. [Google Scholar]

- Wolska, A. Glare as specific factor in the working environment. Prz. Elektrotech. 2013, 89, 142–144. [Google Scholar]

- Hargroves, R.A.; Henry, I.C.; Trezzi, M. Glare evaluation of tennis court lighting. Light. Res. Technol. 1986, 18, 157–160. [Google Scholar] [CrossRef]

- Tekelenburg, J.; Fischer, D.; van Bommel, W.J. Sports Lighting. In Proceedings of the CIBS National Lighting Conference, Warwick, UK, 5–7 April 1982. [Google Scholar]

- Van Bommel, W.J.; Tekelenburg, J.; Fischer, D. Glare Evaluation System for Outdoor Sports Lighting and its Consequences for the Design Practice. In Proceedings of the 20th Session of the CIE Conference on Light and Lighting, Amsterdam, The Netherlands, 31 August–8 September 1983. [Google Scholar]

- Carlsson, L.; Knave, B.; Wibom, R. Exposure to and effects of glare from high mast lighting on workers at a timber terminal. Appl. Ergon. 1983, 14, 271–278. [Google Scholar] [CrossRef]

- Glare Evaluation System for Use within Outdoor Sports and Area Lighting; CIE Publication No 112; International Commission on Illumination (CIE): Vienna, Austria, 1994.

- Guide for Lighting Exterior Work Areas; CIE Publication No 129; International Commission on Illumination (CIE): Vienna, Austria, 1998.

- Environmental Impact Assessment Final Report (March 1995). Available online: https://www.epd.gov.hk/eia/register/report-bc/eia057/index.htm. (accessed on 19 September 2021).

- De Boer, J.B. Quality criteria for the passing beam of motocar headlights. In Proceedings of the GTB Meeting, Walldorf, Germany, September 1973. [Google Scholar]

- Sawicki, D.; Wolska, A. The unified semantic glare scale for GR and UGR indexes. In Proceedings of the 2016 IEEE Lighting Conference of the Visegrad Countries (Lumen V4), Karpacz, Poland, 13–16 September 2016. [Google Scholar] [CrossRef]

- EN 12193: 2007. Light and Lighting—Sports Lighting; European Committee for Standardization (CEN): Brussels, Belgium, 2007.

- UEFA Stadium Lighting Guide. 2016. Available online: https://www.uefa.com/MultimediaFiles/Download/uefaorg/General/02/36/26/72/2362672_DOWNLOAD.pdf. (accessed on 28 September 2021).

- FIFA Lighting Guide. Standards, Requirements and Guidance for Pitch Illuminance Systems at FIFA Tournament Stadiums and Training Sites. 2021. Available online: https://digitalhub.fifa.com/m/75486e34dc4aa39f/original/guide-the-artificial-lighting-for-football-pitches-552751.pdf. (accessed on 28 September 2021).

- EN 13201: 2014. Road Lighting; European Committee for Standardization (CEN): Brussels, Belgium, 2014.

- Bellia, L.; Cesarano, A.; Iuliano, G.; Spada, G. Daylight glare: A review of discomfort indexes. In Proceedings of the Visual Quality and Energy Efficiency in Indoor Lighting: Today for Tomorrow, Rome, Italy, 31 March–2 April 2008. [Google Scholar]

- EN 17037:2018. Daylight in Building; European Committee for Standardization (CEN): Brussels, Belgium, 2018.

- Guide on the Limitations of the Effects of Obtrusive Light from Outdoor Lighting Installations; CIE Publication No 150; International Commission on Illumination (CIE): Vienna, Austria, 2003.

- Maintenance of Outdoor Lighting Systems; CIE Publication No 154; International Commission on Illumination (CIE): Vienna, Austria, 2003.

- Lighting Guide 6: The Exterior Environment; Chartered Institution of Building Services Engineers (CIBSE): London, UK, 2016.

- DIN 5035 Beleuchtung Mit künstlichem Licht; German Institute for Standardization (DIN): Berlin, Germany, 2007.

- Shuster, J. Addressing Glare in Solid-State Lighting. White Paper. Ephesus Lighting Inc., January 2014. Available online: https://www.cooperlighting.com/s/ephesus/assets/31-Bright-Paper-Adressing-Glare.pdf (accessed on 28 September 2021).

- Obtrusive Lighting. Presentation by Gruppe Lighting Solution Sdn. Bhd. from www.gruppelighting.com. Available online: https://www.slideserve.com/vinson/obtrusive-lighting (accessed on 28 September 2021).

- Sawicki, D.; Wolska, A. UGR for exterior working environment? Why not. In Proceedings of the 28th Session of the CIE, Manchester, UK, 28 June–4 July 2015; Volume 1, pp. 1617–1622. [Google Scholar]

- Mangkuto, R.A.; Rachman, A.P.; Aulia, A.G.; Asri, A.D.; Rohmah, M. Assessment of pitch floodlighting and glare condition in the Main Stadium of Gelora Bung Karno, Indonesia. Measurement 2018, 117, 186–199. [Google Scholar] [CrossRef]

- Bullough, D.J.; Brons, J.S.; Qi, R.; Rea, M.S. Predicting discomfort glare from outdoor lighting installations. Light. Res. Technol. 2008, 40, 225–242. [Google Scholar] [CrossRef]

- Sawicki, D.; Wolska, A. Objective assessment of glare at outdoor workplaces. Build. Environ. 2019, 149, 537–545. [Google Scholar] [CrossRef]

- LMK Mobile Advanced. Documentation and Instruction Manual of the TechnoTeam’s LMK Photometer System. Available online: http://www.technoteam.de/ (accessed on 15 September 2017).

- Wolska, A.; Sawicki, D. Practical application of HDRI for discomfort glare assessment at indoor workplaces. Measurement 2020, 151, 107179. [Google Scholar] [CrossRef]

- Wolska, A. Optical Radiation in the Working Anvironment (In Polish: Promieniowanie Optyczne W Środowisku pracy); Central Institute for Labour Protection—National Research Institute: Warsaw, Poland, 2013. [Google Scholar]

- Evalglare.pdf. RADSITE Radiance-Online.org. Available online: https://www.radiance-online.org/learning/documentation/manual-pages/pdfs/evalglare.pdf/view (accessed on 28 September 2021).

| Degree of Risk | GR Limit |

|---|---|

| Small | GR ≤ GRMAX 1 |

| Medium | GRMAX 1 < GR < 70 |

| High | 70 ≤ GR |

| Question | Answer | |

|---|---|---|

| 1. | Does the existing outdoor lighting ensure good visibility of circulation area to recognize the obstacles after dark (openings, manholes, thresholds, steps, etc.)? | Yes/No |

| 2. | Does the existing outdoor lighting provide good visibility at the task area after dark? | Yes/No |

| 3. | Do you see very bright light sources when you are working after dark? | Yes/No |

| 4. | The existing lighting at outdoor workplaces—is it satisfactory and does not require changes? | Yes/No |

| 5. | Degree of perceived glare on a five-step scale: | Select one answer |

| Unbearable Work—completely impossible Sensation of glare—the luminaires cause “blinding” | — | |

| Disturbing Work—hard to perform; recognizing of details is difficult during some time after looking toward the luminaire Sensation of glare—significant discomfort | — | |

| Just admissible Work—possible, difficulties in perception for a short period of time Sensation of glare—noticeable discomfort | — | |

| Noticeable Work—possible for quite a long time Sensation of glare—slight discomfort | — | |

| Imperceptible Work—possible for a long time Sensation of glare—imperceptible, no discomfort | — |

| Sensation of Glare | Assigned Value of GR |

|---|---|

| Unbearable | 90 ≤ GR |

| Disturbing | 70 ≤ GR < 90 |

| Just admissible | 50 ≤ GR < 70 |

| Noticeable | 30 ≤ GR < 50 |

| Imperceptible | GR < 30 |

| Category of Lighting Requirements (According to Standard [5]) | Number of Examined Task Activities (According to Standard [5]) | Task Area Where a High Degree of Risk Occurred: GRMAX—Limit of Glare Defined in Standard [5] Assessment of Glare Comments | |||

|---|---|---|---|---|---|

| Total | With Varying Degrees of Risk | ||||

| Small | Medium | High | |||

| General circulation areas at outdoor workplaces (Table 5.1 in [5]) | 9 | 8 | 0 | 1 | Pedestrian passages, vehicle turning GRMAX from [5] = 50, Measured GR = 60, Subjective assessment = Disturbing (70 ≤ GR < 90) |

| Airports (Table 5.2 in [5]) | 10 | 8 | 2 | 0 | (1. Task) Aircraft maintenance stands GRMAX from [5] = 45, Measured GR = 51, Subjective assessment = just admissible (50 ≤ GR < 70) (2. Task) Fuel depot GRMAX from [5] = 50, Measured GR = 41, Subjective assessment = just admissible (50 ≤ GR < 70) The task activity corresponded to high risk (working with dangerous substances) |

| Building sites (Table 5.3 in [5]) | 2 | 0 | 0 | 2 | Construction areas, drain pipes mounting, transport, auxiliary and storage tasks GRMAX from [5] = 50, (1. Task) Subjective assessment = Disturbing (70 ≤ GR < 90) (2. Task) Subjective assessment = Unbearable (90 ≤ GR) |

| Canals, locks, and harbors (Table 5.4 in [5]) | 3 | 3 | 0 | 0 | |

| Fuel filling stations (Table 5.6 in [5]) | 13 | 12 | 1 | 0 | Meter reading area GRMAX from [5] = 45, Measured GR = 29, Subjective assessment = just admissible (50 ≤ GR < 70) The task activity corresponded to small risk, however may cause difficulties in reading indications. |

| Industrial sites and storage areas (Table 5.7 in [5]) | 14 | 14 | 0 | 0 | |

| Parking areas (Table 5.9 in [5]) | 4 | 4 | 0 | 0 | |

| Oil and other chemical industries (Table 5.10 in [5]) | 18 | 16 | 2 | 0 | (1. Task) Filling and emptying of container trucks and wagons with dangerous substances, replacements of pump packing, general service work, reading of instruments GRMAX from [5] = 45, Measured GR = 53, Subjective assessment = just admissible (50 ≤ GR < 70) (2. Task) Filling and emptying of container trucks and wagons with dangerous substances, replacements of pump packing, general service work, reading of instruments GRMAX from [5] = 45, Measured GR = 47, Subjective assessment = noticeable (30 ≤ GR < 50) Both task activities corresponded to high risk (working with dangerous substances) |

| Railways and tramways (Table 5.12 in [5]) | 5 | 0 | 0 | 5 | (1. Task) Freight track, short duration operations GRMAX from [5] = 45, Measured GR = 50, Subjective assessment = disturbing (70 ≤ GR < 90) (4. Tasks) Freight track, continuous operations GRMAX from [5] = 50, Measured GR = 60–79, Subjective assessment = disturbing (70 ≤ GR < 90) and unbearable (90 ≤ GR) In all cases a temporary lighting installation has been used. In all cases the consequences of accidents can be very serious. |

| Saw mills (Table 5.13 in [5]) | 4 | 4 | 0 | 0 | |

| Shipyards and docks l (Table 5.14 in [5]) | 5 | 0 | 3 | 2 | (2. Tasks with highest level) Cleaning of ship hull GRMAX from [5] = 50, Measured GR = 52–66, Subjective assessment = disturbing (70 ≤ GR < 90) |

| Water and sewage plants (Table 5.15 in [5]) | 6 | 4 | 1 | 1 | (1. Task with highest level) Handling of chemicals, inspection of leakage, changing of pumps, general servicing work, reading of instruments GRMAX from [5] = 45, Measured GR = 62, Subjective assessment = disturbing (70 ≤ GR < 90) |

| Sum of tasks: | 93 | 73 | 9 | 11 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sawicki, D.; Wolska, A. Glare at Outdoor Workplaces—An Underestimated Factor of Occupational Risk. Energies 2022, 15, 472. https://doi.org/10.3390/en15020472

Sawicki D, Wolska A. Glare at Outdoor Workplaces—An Underestimated Factor of Occupational Risk. Energies. 2022; 15(2):472. https://doi.org/10.3390/en15020472

Chicago/Turabian StyleSawicki, Dariusz, and Agnieszka Wolska. 2022. "Glare at Outdoor Workplaces—An Underestimated Factor of Occupational Risk" Energies 15, no. 2: 472. https://doi.org/10.3390/en15020472