Adaptation of Fire-Fighting Systems to Localization of Fires in the Premises: Review

Abstract

:1. Introduction

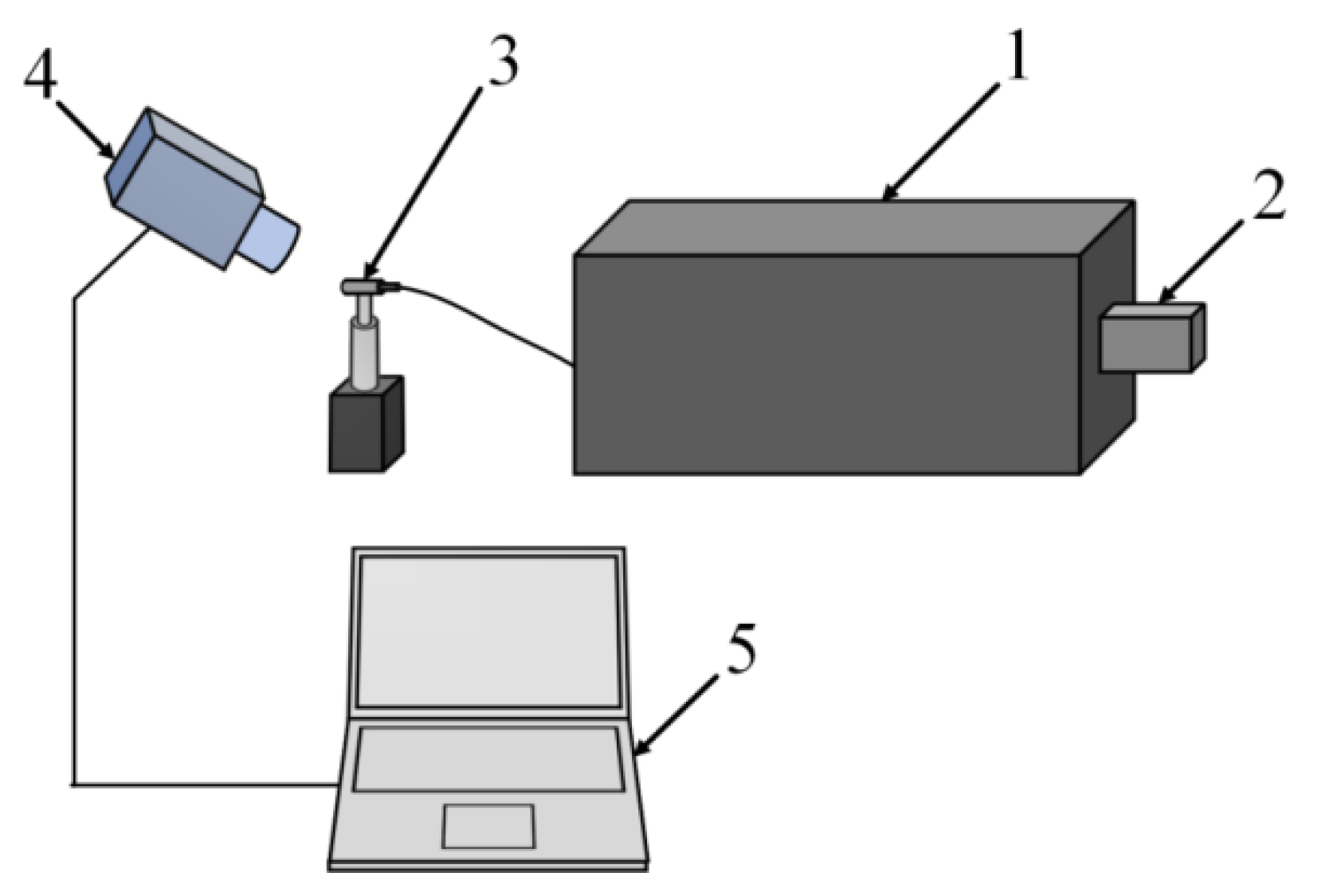

2. Fire Identification Systems

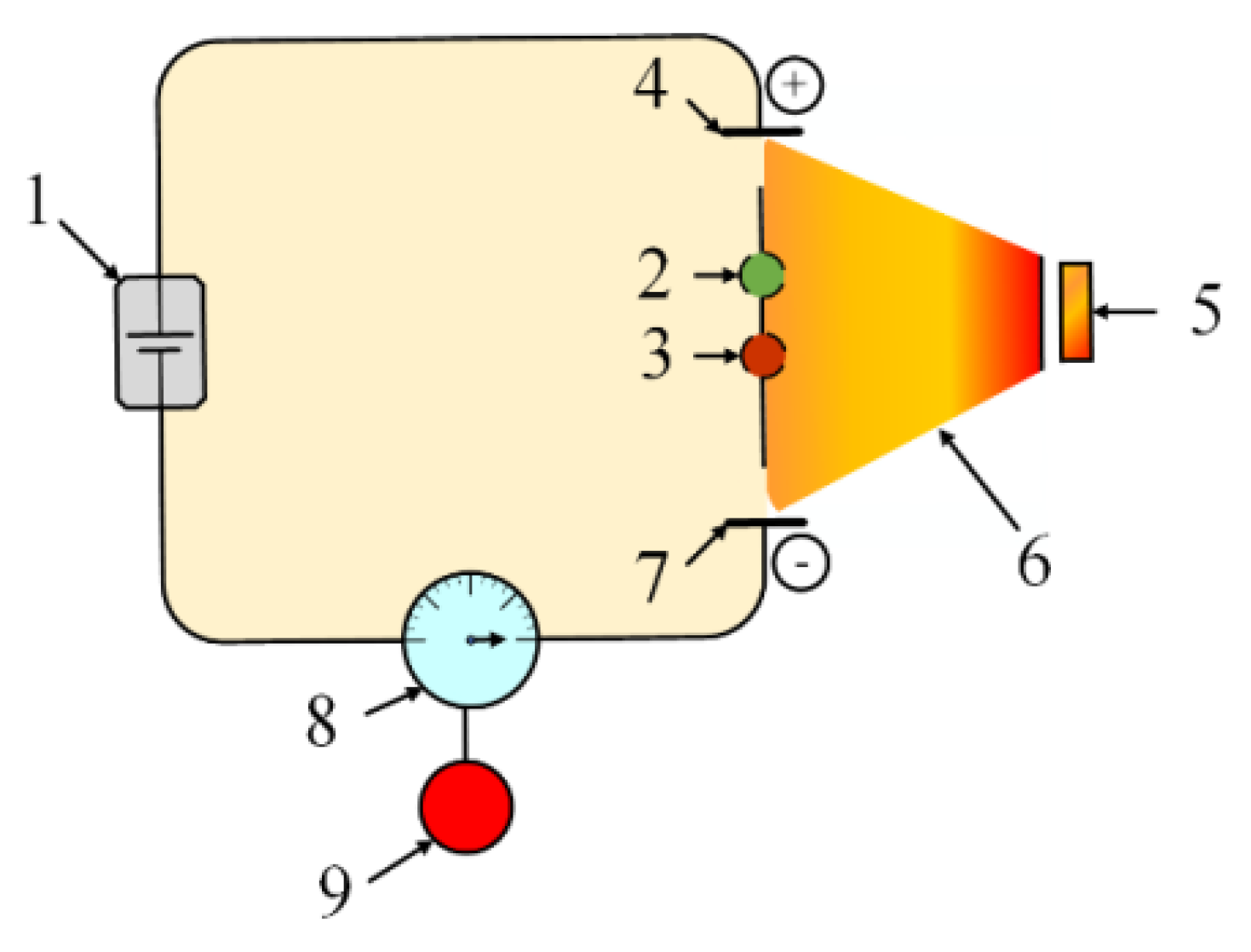

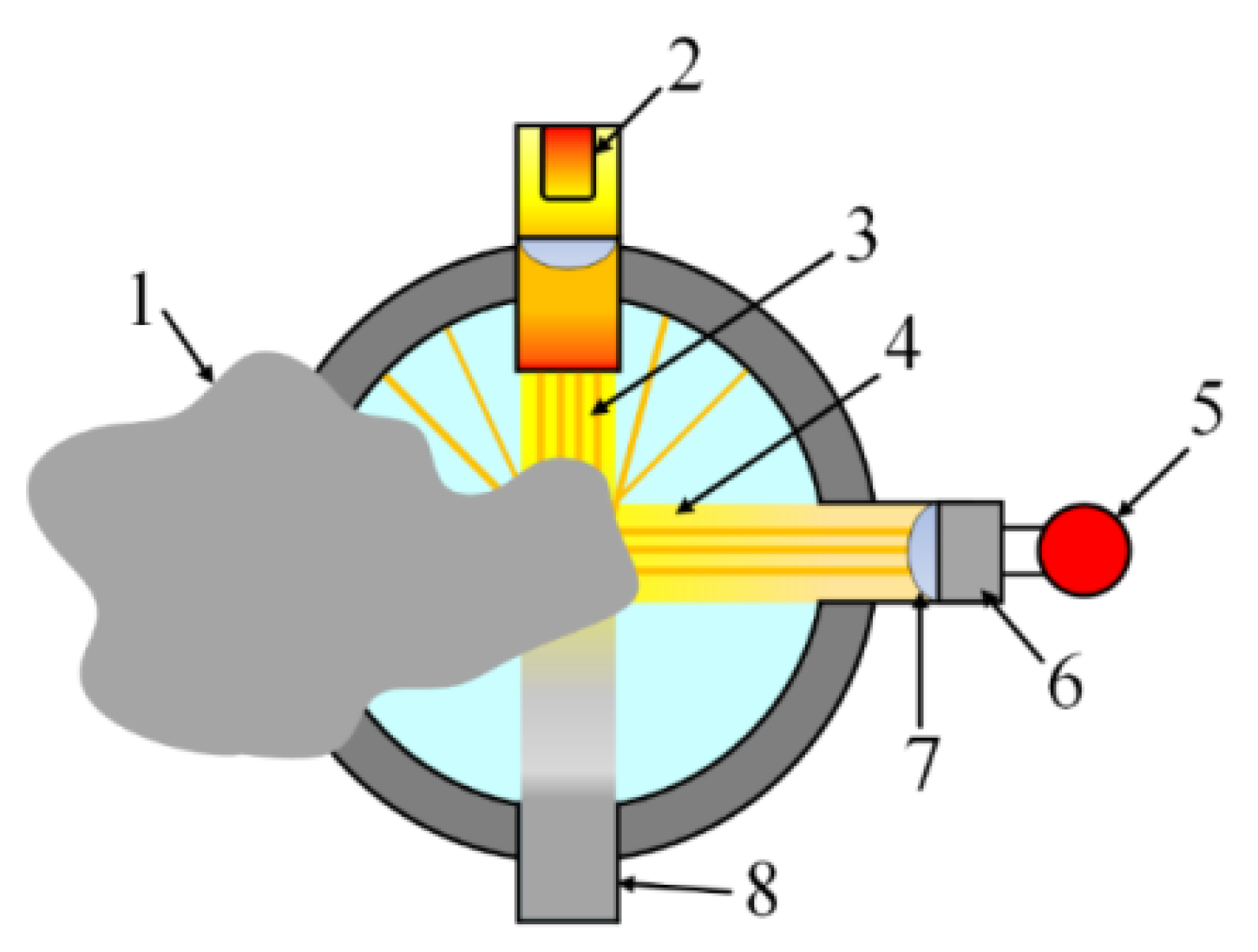

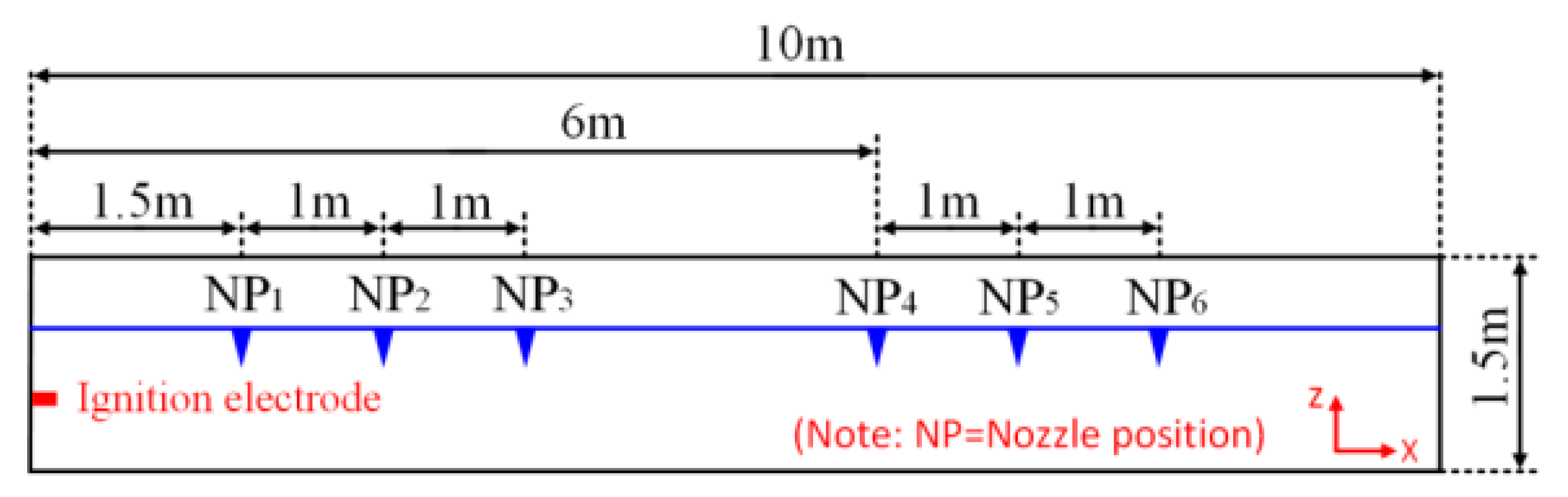

3. Fire Suppression Systems

4. Feedback Combustion Suppression Systems

5. Current Directions of Development

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AFFF | Aqueous film-forming foam |

| BLE IoT | A communication/localization network |

| CMOS-camera | Camera for image capturing in control area |

| Faster R-CNN | Flame detection model |

| IOT | Network technology of data transfer in the building |

| PLC | Personal computer |

| Rm | Droplet radius, mm |

| Ug | High-temperature gas flow rate, m/s |

| Um | Droplet movement rate, m/s |

| Red | Reynolds criterion for droplet |

| Reg | Reynolds criterion for gas |

| γf | Nondimensional coefficient for forecasting assessment of droplet entrainment of polydisperse flow by the high-temperature gases. |

References

- Rasbash, D.J.; Rogowski, Z.W. Extinction of fires in liquids by cooling with water sprays. Combust. Flame 1957, 1, 453–466. [Google Scholar] [CrossRef]

- Rasbash, D.J.; Rogowski, Z.W.; Stark, G.W.V. Mechanisms of extinction of liquid fires with water sprays. Combust. Flame 1960, 4, 223–234. [Google Scholar] [CrossRef]

- Liu, Z.; Kim, A.K. Review of water mist fire suppression systems—Fundamental studies. J. Fire Prot. Eng. 2000, 10, 32–50. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; KIM, A.K. A Review of Water Mist Fire Suppression Technology: Part II-Application Studies. J. Fire Prot. Eng. 2001, 11, 16–42. [Google Scholar] [CrossRef] [Green Version]

- Grant, G.; Brenton, J.; Drysdale, D. Fire suppression by water sprays. Prog. Energy Combust. Sci. 2000, 26, 79–130. [Google Scholar] [CrossRef]

- Santangelo, P.E.; Jacobs, B.C.; Ren, N.; Sheffel, J.A.; Corn, M.L.; Marshall, A.W. Suppression effectiveness of water-mist sprays on accelerated wood-crib fires. Fire Saf. J. 2014, 70, 98–111. [Google Scholar] [CrossRef]

- Ndubizu, C.C.; Ananth, R.; Tatem, P.A. Effects of droplet size and injection orientation on water mist suppression of low and high boiling point liquid pool fires. Combust. Sci. Technol. 2000, 157, 63–86. [Google Scholar] [CrossRef]

- Xishi, W.; Guangxuan, L.; Jun, Q.; Weicheng, F. Experimental study on the effectiveness of the extinction a pool fire with water mist. J. Fire Sci. 2002, 20, 279–295. [Google Scholar] [CrossRef]

- Qin, J.; Chow, W.K. Experimental data on water mist suppression. In Proceedings of the Procedia Engineering the 9th Asia-Oceania Symposium on Fire Science and Technology, Hefei, China, 17–20 October; Elsevier Ltd.: Amsterdam, The Netherlands, 2013; Volume 62, pp. 868–877. [Google Scholar]

- Liu, W.Y.; Chen, C.H.; Shu, Y.L.; Chen, W.T.; Shu, C.M. Fire suppression performance of water mist under diverse desmoking and ventilation conditions. Process Saf. Environ. Prot. 2020, 133, 230–242. [Google Scholar] [CrossRef]

- Zhou, Y.; Bu, R.; Zhang, X.; Fan, C.; Gong, J. Performance evaluation of water mist fire suppression: A clean and sustainable fire-fighting technique in mechanically-ventilated place. J. Clean. Prod. 2019, 209, 1319–1331. [Google Scholar] [CrossRef]

- Lun, P.Y.; Zhang, Q.; Li, X.K. Experimental study on the pulse water mist fire suppression system performance in a confined space. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 258. [Google Scholar] [CrossRef]

- Zhang, T.W.; Du, Z.M.; Han, Z.Y.; Liu, K. Performance evaluation of water mist with additives in suppressing cooking oil fires based on temperature analysis. Appl. Therm. Eng. 2016, 102, 1069–1074. [Google Scholar] [CrossRef]

- Liu, Z.; Carpenter, D.; Kim, A.K. Characteristics of large cooking oil pool fires and their extinguishment by water mist. J. Loss Prev. Process Ind. 2006, 19, 516–526. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Carpenter, D.; Kim, A. Application of Water Mist to Extinguish Large Oil Pool Fires for Industrial Oil Cooker Protection. Fire Saf. Sci. 2005, 8, 741–752. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Kim, A.K.; Carpenter, D.; Kanabus-Kaminska, J.M.; Yen, P.L. Extinguishment of cooking oil fires by water mist fire suppression systems. Fire Technol. 2004, 40, 309–333. [Google Scholar] [CrossRef] [Green Version]

- Santangelo, P.E.; Tartarini, P. Full-scale experiments of fire suppression in high-hazard storages: A temperature-based analysis of water-mist systems. Appl. Therm. Eng. 2012, 45–46, 99–107. [Google Scholar] [CrossRef]

- Koshiba, Y.; Yamamoto, Y.; Ohtani, H. Fire suppression efficiency of water mists containing organic solvents. J. Loss Prev. Process Ind. 2019, 62, 103973. [Google Scholar] [CrossRef]

- Kim, Y.H.; Lee, M.; Hwang, I.J.; Kim, Y.J. Noise reduction of an extinguishing nozzle using the response surface method. Energies 2019, 12, 4346. [Google Scholar] [CrossRef] [Green Version]

- Lu, J.; Liang, P.; Chen, B.; Wu, C.; Zhou, T. Investigation of the Fire-Extinguishing Performance of Water Mist with Various Additives on Typical Pool Fires. Combust. Sci. Technol. 2019, 192, 592–609. [Google Scholar] [CrossRef]

- Omidvar, A.; Mahdavi, A.; Mehryar, R. A simulated study on the effect of water temperature on cooling efficiency of water mist fire extinguishers. J. Therm. Eng. 2020, 6, 460–473. [Google Scholar] [CrossRef]

- Yu, H.-Z.; Liu, X. An Efficacy Evaluation of Water Mist Protection Against Solid Combustible Fires in Open Environment. Fire Technol. 2019, 55, 343–361. [Google Scholar] [CrossRef]

- Lin, Z.; Bu, R.; Zhao, J.; Zhou, Y. Numerical investigation on fire-extinguishing performance using pulsed water mist in open and confined spaces. Case Stud. Therm. Eng. 2019, 13, 100402. [Google Scholar] [CrossRef]

- Shrigondekar, H.; Chowdhury, A.; Prabhu, S.V. Characterization of a simplex water mist nozzle and its performance in extinguishing liquid pool fire. Exp. Therm. Fluid Sci. 2018, 93, 441–455. [Google Scholar] [CrossRef]

- Zhou, L.; Helun, L.; Li, D.; Yong, Z. Knapsack Water Mist Fire Extinguishing Device. Patent Number CN210543000, 19 May 2020. [Google Scholar]

- Wu, S. Aerosol Spray Nozzle. Patent Number CN210494998, 12 May 2020. [Google Scholar]

- Wu, Z. Movable water mist fire extinguishing device. Patent Number CN210409317, 28 April 2020. [Google Scholar]

- Shi, J.; Ren, W.; Liu, X. Novel technology for fire suppression using nitrogen-water mist in enclosed spaces. Geomat. Nat. Hazards Risk 2020, 11, 22–39. [Google Scholar] [CrossRef]

- Friedman, A.N.; Danis, P.I.; Fiola, G.J.; Barnes, C.A.; Stoliarov, S.I. Acoustically Enhanced Water Mist Suppression of Heptane Fueled Flames. Fire Technol. 2018, 54, 1829–1840. [Google Scholar] [CrossRef]

- Ayyubi, S.; Miao, Y.; Shi, H. Automating standalone smoke alarms for early remote notifications. In Proceedings of the 2014 13th International Conference on Control Automation Robotics and Vision, ICARCV 2014, Singapore, 10–12 December 2014; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2014; pp. 675–680. [Google Scholar]

- Lipu, M.S.H.; Karim, T.F.; Rahman, M.L.; Sultana, F. Wireless security control system & sensor network for smoke & fire detection. In Proceedings of the ICAMS 2010—Proceedings of 2010 IEEE International Conference on Advanced Management Science, Chengdu, China, 9–11 July 2010; Volume 3, pp. 153–157. [Google Scholar]

- Tanutama, L.; Atmadja, W. Home Security System with IOT Based Sensors Running on House Infra Structure Platform. In Proceedings of the IOP Conference Series, Earth and Environmental Science, Solo, Indonesia, 13–14 November 2019; Volume 426. [Google Scholar]

- Lisakov, S.A.; Pavlov, A.N.; Sypin, E.V.; Leonov, G.V. Determination of control points quantity and their location in protected object for high-speed multipoint electro-optical system for fire detection and determine its spatial coordinates. In Proceedings of the International Conference of Young Specialists on Micro/Nanotechnologies and Electron Devices, Erlagol, Russia, 29 June–3 July 2017; pp. 371–377. [Google Scholar]

- Grinchenko, B.B.; Kuznetsov, A.V.; Bakanov, M.O.; Tarakanov, D.V. Multi-factor fire dynamics monitoring in textile industry buildings. Izvestiya Vysshikh Uchebnykh Zavedenii, Seriya Teknologiya Tekstil’noi Promyshlennosti 2019, 382, 178–183. [Google Scholar]

- Malykhina, G.F.; Guseva, A.I.; Militsyn, A.V. Early fire prevention in the plant. In Proceedings of the 2017 International Conference on Industrial Engineering, Applications and Manufacturing, ICIEAM 2017—Proceedings, St. Petersburg, Russia, 16–19 May 2017. [Google Scholar]

- Malykhina, G.F.; Guseva, A.I.; Militsin, A.V.; Nevelskii, A.S. Developing an intelligent fire detection system on the ships. In Proceedings of the CEUR Workshop Proceedings, CEUR-WS, Moscow, Russia, 24–26 November 2017; Volume 2064, pp. 289–296. [Google Scholar]

- Khoat, H.T.; Kim, J.T.; Quoc, T.D.; Kwark, J.H.; Ryou, H.S. A numerical analysis of the fire characteristics after sprinkler activation in the compartment fire. Energies 2020, 13, 3099. [Google Scholar] [CrossRef]

- Zhu, H.; Shen, Y.; Yan, Z.; Guo, Q.; Guo, Q. A numerical study on the feasibility and efficiency of point smoke extraction strategies in large cross-section shield tunnel fires using CFD modeling. J. Loss Prev. Process Ind. 2016, 44, 158–170. [Google Scholar] [CrossRef]

- Maheen, J.B.; Aneesh, R.P. Machine Learning Algorithm for Fire Detection using Color Correlogram. In Proceedings of the 2019 2nd International Conference on Intelligent Computing, Instrumentation and Control Technologies, ICICICT 2019, Kannur, India, 5–6 July 2019; pp. 1411–1418. [Google Scholar]

- Gagliardi, A.; Saponara, S. Advised: Advanced video smoke detection for real-time measurements in antifire indoor and outdoor systems. Energies 2020, 13, 2098. [Google Scholar] [CrossRef] [Green Version]

- Qiu, X.; Xi, T.; Sun, D.; Zhang, E.; Li, C.; Peng, Y.; Wei, J.; Wang, G. Fire Detection Algorithm Combined with Image Processing and Flame Emission Spectroscopy. Fire Technol. 2018, 54, 1249–1263. [Google Scholar] [CrossRef]

- Spurny, V.; Pritzl, V.; Walter, V.; Petrlik, M.; Baca, T.; Stepan, P.; Zaitlik, D.; Saska, M. Autonomous Firefighting Inside Buildings by an Unmanned Aerial Vehicle. IEEE Access 2021, 9, 15872–15890. [Google Scholar] [CrossRef]

- Naser, M.Z.; Lautenberger, C.; Kuligowski, E. Special Issue on “Smart Systems in Fire Engineering”. Fire Technol. 2021, 57, 2737–2740. [Google Scholar] [CrossRef]

- Panev, Y.; Kotsovinos, P.; Deeny, S.; Flint, G. The Use of Machine Learning for the Prediction of fire Resistance of Composite Shallow Floor Systems. Fire Technol. 2021, 57, 3079–3100. [Google Scholar] [CrossRef]

- Węgrzyński, W.; Krajewski, G.; Kimbar, G. Smart Smoke Control as an Efficient Solution for Smoke Ventilation in Converted Cellars of Historic Buildings. Fire Technol. 2020, 57, 3101–3123. [Google Scholar] [CrossRef]

- Richter, E.; Krause, U. Development of solid propellant for the production of fire suppression aerosols. Fire Safety Journal 2021, 120, 103113. [Google Scholar] [CrossRef]

- Agafonov, V.V.; Kopylov, S.N.; Sychev, A.V.; Uglov, V.A.; Zhyganov, D.B. The mechanism of fire suppression by condensed aerosols; All-Russian Scientific Research Institute for Fire Protection: Moscow, Russia, 2004; pp. 1–10. [Google Scholar]

- Li, G.; Pan, C.; Liu, Y.; Zhu, X.; Ni, X.; Zhao, X.; Chen, G.; Wang, X. Evaluation of the effect of water mist on propane/air mixture deflagration: Large-scale test. Process Saf. Environ. Prot. 2021, 147, 1101–1109. [Google Scholar] [CrossRef]

- Volkov, R.S.; Kuznetsov, G.V.; Strizhak, P.A. Analysis of the Characteristics of the Retardation and Entrainment of Droplets in a Polydisperse Water Flow by High-Temperature Gases Under Conditions of Intense Phase Transformations. J. Eng. Phys. Thermophys. 2015, 88, 937–947. [Google Scholar] [CrossRef]

- Volkov, R.S.; Kuznetsov, G.V.; Strizhak, P.A. Criterion expressions for conditions and deceleration and subsequent entrainment of water drops by high-temperature gases. Tech. Phys. 2015, 60, 1310–1315. [Google Scholar] [CrossRef]

- Volkov, R.S.; Kuznetsov, G.V.; Stizhak, P.A. The influence of initial sizes and velocities of water droplets on transfer characteristics at high-temperature gas flow. Int. J. Heat Mass Transf. 2014, 79, 838–845. [Google Scholar] [CrossRef]

- Lv, D.; Tan, W.; Zhu, G.; Liu, L. Gasoline fire extinguishing by 0.7 MPa water mist with multicomponent additives driven by CO2. Process Saf. Environ. Prot. 2019, 129, 168–175. [Google Scholar] [CrossRef]

- Ghiji, M.; Novozhilov, V.; Moinuddin, K.; Joseph, P.; Burch, I.; Suendermann, B.; Gamble, G. A review of lithium-ion battery fire suppression. Energies 2020, 13, 5117. [Google Scholar] [CrossRef]

- Erd, A.; Stoklosa, J. Energy Dependencies in Li-Ion Cells and Their Influence on the Safety of Electric Motor Vehicles and Other Large Battery Packs. Energies 2020, 13, 6738. [Google Scholar] [CrossRef]

- Zhu, M.X.; Zhu, S.B.; Gong, J.H.; Zhou, Z. Experimental Study on Fire and Explosion Characteristics of Power Lithium Batteries with Surfactant Water Mist. In Proceedings of the Procedia Engineering 8th International Conference on Fire Dcience and Fire Protection Engineering (on the Development of Performance-based Fire Code), Nanjing, China, 27–29 October 2017; Volume 211, pp. 1083–1090. [Google Scholar]

- Kong, L.; Li, C.; Jiang, J.; Pecht, M.G. Li-ion battery fire hazards and safety strategies. Energies 2018, 11, 2191. [Google Scholar] [CrossRef] [Green Version]

- Guo, Q.; Ren, W.; Zhu, J.; Shi, J. Study on the composition and structure of foamed gel for fire prevention and extinguishing in coal mines. Process Saf. Environ. Prot. 2019, 128, 176–183. [Google Scholar] [CrossRef]

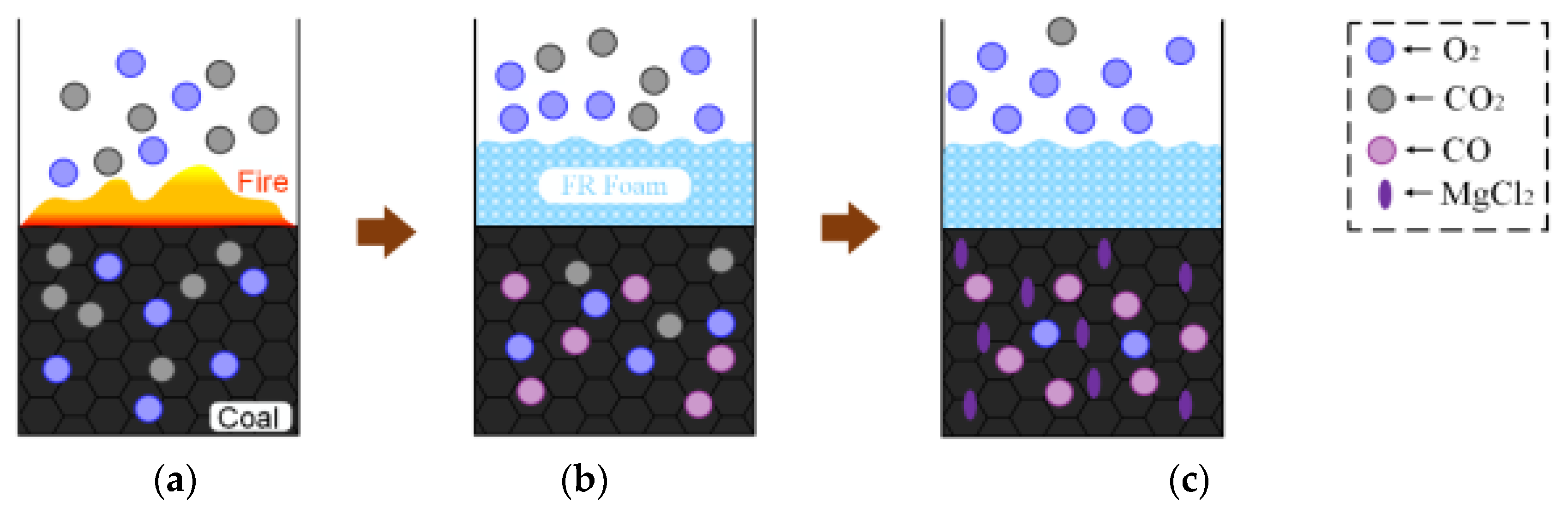

- Tang, Z.; Xu, G.; Yang, S.; Deng, J.; Xu, Q.; Chang, P. Fire-retardant foam designed to control the spontaneous combustion and the fire of coal: Flame retardant and extinguishing properties. Powder Technol. 2021, 384, 258–266. [Google Scholar] [CrossRef]

- Xi, Z.; Wang, X.; Wang, X.; Wang, L.; Li, D.; Guo, X.; Jin, L. Polymorphic foam clay for inhibiting the spontaneous combustion of coal. Process Saf. Environ. Prot. 2019, 122, 263–270. [Google Scholar] [CrossRef]

- Zhang, Y.; Lei, B.; Wu, B.; Meng, Y.; He, B. An experimental study on the heat and mass transfer of liquid nitrogen in a loose medium. Energies 2019, 12, 3464. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Liu, Y.; Shi, S.; Wang, G.G.X.; Li, H.; Wang, T. Micro-particles stabilized aqueous foam for coal spontaneous combustion control and its flow characteristics. Process Saf. Environ. Prot. 2020, 139, 262–272. [Google Scholar] [CrossRef]

- Xi, X.; Shi, Q.; Jiang, S.; Zhang, W.; Wang, K.; Zhengyan, W. Study on the effect of ionic liquids on coal spontaneous combustion characteristic by microstructure and thermodynamic. Process Saf. Environ. Prot. 2020, 140, 190–198. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, D.; Wang, L.; Zhong, X.; Chu, T. Experimental research on inhibition performances of the sand-suspended colloid for coal spontaneous combustion. Saf. Sci. 2012, 50, 822–827. [Google Scholar] [CrossRef]

- Sheng, Y.; Jiang, N.; Lu, S.; Wang, Q.; Zhao, Y.; Liu, X. Study of Environmental-Friendly Firefighting Foam Based on the Mixture of Hydrocarbon and Silicone Surfactants. Fire Technol. 2020, 56, 1059–1075. [Google Scholar] [CrossRef]

- Yu, X.; Jiang, N.; Miao, X.; Li, F.; Wang, J.; Zong, R.; Lu, S. Comparative studies on foam stability, oil-film interaction and fire extinguishing performance for fluorine-free and fluorinated foams. Process Saf. Environ. Prot. 2020, 133, 201–215. [Google Scholar] [CrossRef]

- Sivrikaya, E.; Iyigun, B.; Tekin, M.; Kivrak, M.F.; Cavdar, E.; Diker, C.; Ozfidan, O.; Kucuk, S. National legislation and international standards for fire detection and protection systems for industrial transformers and substations of industries facilities. In Proceedings of the 6th International Conference on Electrical and Electronics Engineering (ICEEE 2019), Istanbul, Turkey, 16–17 April 2019; pp. 251–257. [Google Scholar] [CrossRef]

- Yan, J.; Xuze, Z.; Yue, W. Research on Intelligent Firefighting Robot in Transformer Substation Based on Water Mist Technology. In Proceedings of the 2020 5th International Conference on Smart Grid and Electrical Automation, ICSGEA 2020, Zhangjiajie, China, 13–14 June 2020; pp. 134–139. [Google Scholar]

- Sazzad Sayyed, A.Q.M.; Hasan, M.T.; Mahmood, S.; Hossain, A.R. Autonomous Fire Fighter Robot Based on Image Processing. In Proceedings of the 2019 IEEE Region 10 Symposium, TENSYMP 2019, Kolkata, India, 7–9 June 2019; pp. 503–507. [Google Scholar]

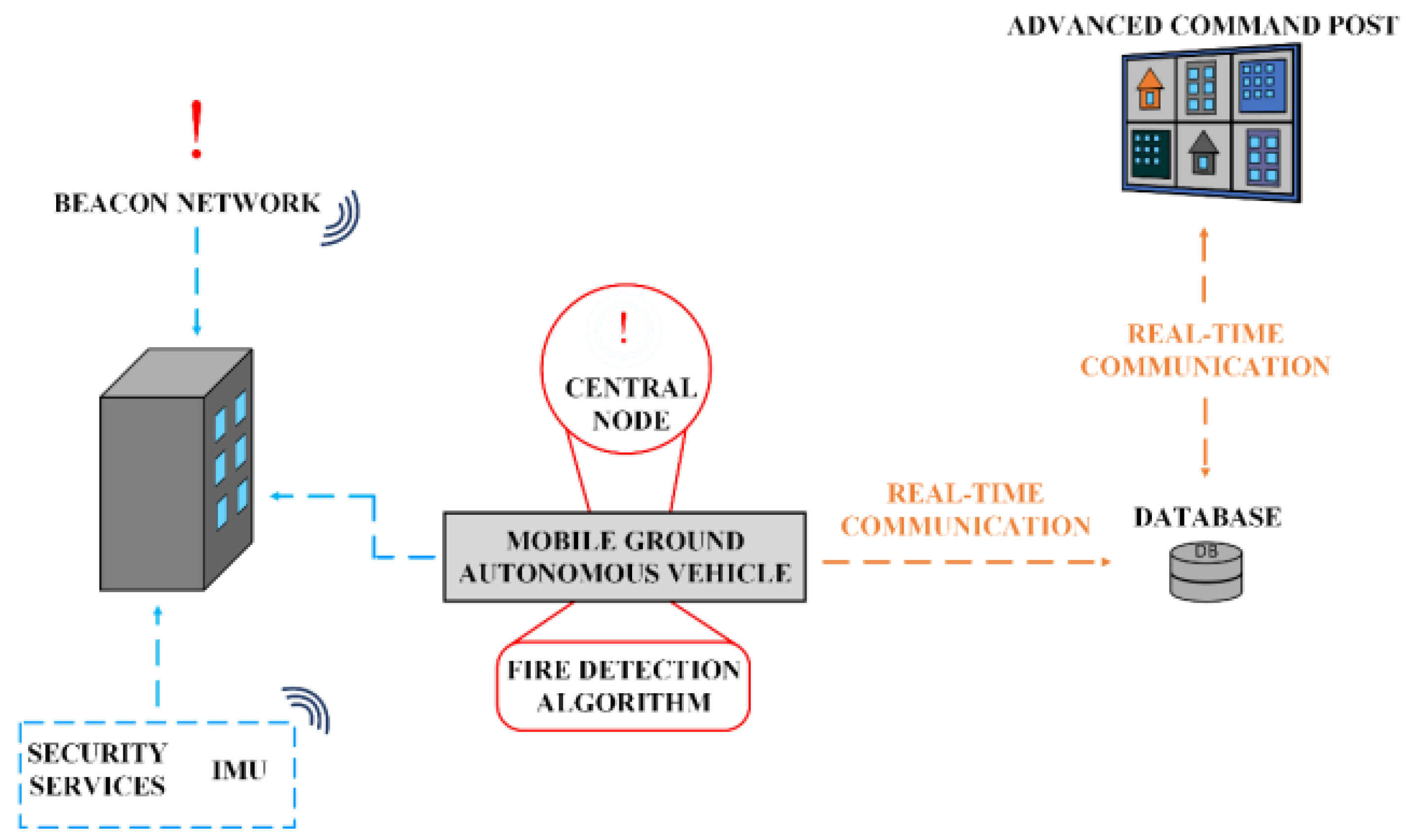

- Rodriguez-Sanchez, M.C.; Fernández-Jiménez, L.; Jiménez, A.R.; Vaquero, J.; Borromeo, S.; Lázaro-Galilea, J.L. Helpresponder—System for the security of first responder interventions. Sensors 2021, 21, 2614. [Google Scholar] [CrossRef] [PubMed]

- Sakita, Y. Study on the use of water gun and other fire protection systems for fires in cultural heritage buildings based on example analysis and consideration. Bull. Jpn. Assoc. Fire Sci. Eng. 2017, 67, 69–75. [Google Scholar] [CrossRef]

- Zorina, K.; Vasilieva, M.; Babikov, I.; Tanklevskiy, A. Comparison of technical-economic performance of traditional and innovational sprinkler extinguishing units. In Proceedings of the MATEC Web of Conferences International Scientific Conference on Energy, Environmental and Construction Engineering, Saint-Petersburg, Russia, 19–20 November 2018; Volume 245. [Google Scholar]

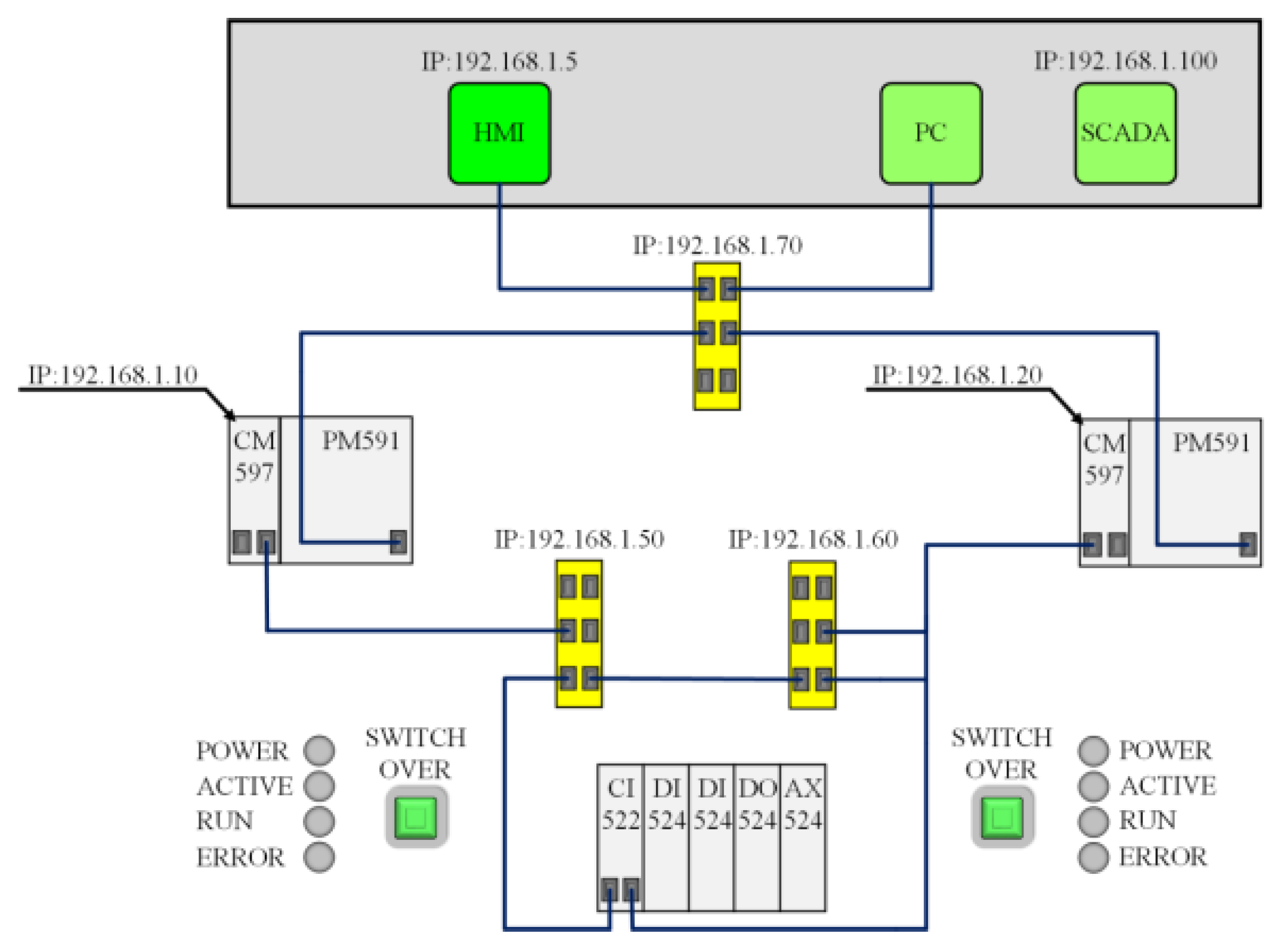

- Das, S.; Dhar, A.; Das, A.; Gayen, P.K.; Pal, B.; Biswas, P. Design and development of fire fighting system using hot redundant PLC in COVID situation. In Proceedings of the Journal of Physics: Conference Series. International Online Conference on Engineering Response to COVID-19, Kalyani, West Bengal, India, 8–9 October 2021; Volume 1797. [Google Scholar]

- Shrigondekar, H.; Chowdhury, A.; Prabhu, S.V. Performance by Various Water Mist Nozzles in Extinguishing Liquid Pool Fires. Fire Technol. 2021, 57, 2553–2581. [Google Scholar] [CrossRef]

- Shrigondekar, H.; Chowdhury, A.; Prabhu, S.V. Performance of water mist system with base injection in extinguishing small container fires. J. Loss Prev. Process Ind. 2021, 71, 104448. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, W.; Wang, Q. Optimization of water mist droplet size by using CFD modeling for fire suppressions. J. Loss Prev. Process Ind. 2016, 44, 626–632. [Google Scholar] [CrossRef]

- Zhu, J.; Li, W.; Lin, D.; Cheng, H.; Zhao, G. Intelligent Fire Monitor for Fire Robot Based on Infrared Image Feedback Control. Fire Technol. 2020, 56, 2089–2109. [Google Scholar] [CrossRef]

- Guo, J.; Hou, Z.; Xie, X.; Yao, S.; Wang, Q.; Jin, X. Faster R-CNN Based Indoor Flame Detection for Firefighting Robot. In Proceedings of the 2019 IEEE Symposium Series on Computational Intelligence, SSCI 2019, Xiamen, China, 6–9 December 2019; pp. 1390–1395. [Google Scholar]

- Li, M.; Jiang, Y.; Wu, Z.; Fan, R. Real-Time Prediction of Smoke Spread Affected by Multiple Factors in Subway Tunnel Using CAERES-DNN Model. Fire Technol. 2021, 57, 2025–2059. [Google Scholar] [CrossRef]

- Zhang, D.; Guo, Z. Mobile Sentry Robot for Laboratory Safety Inspection Based on Machine Vision and Infrared Thermal Imaging Detection. Secur. Commun. Netw. 2021, 2021, 6612438. [Google Scholar] [CrossRef]

| Main Parameters | Advantages | Drawbacks | References |

|---|---|---|---|

| Remote application. Main equipment is microphone and dynamic speaker. Making calls and sending messages to a mobile device. | Signal transmission to special services. Reduction in response time for fire suppression measures. Simple setting. No changes in plant smoke sensor settings required. | Need to enable buildings to transmit warnings to other fire safety systems. Individual software development is needed | [30] |

| IOT technology, in particular LoRaWAN technology. | Wireless data transmission. Low power consumption. | Suitable only for accommodation facilities. Limited size of data warehouse. Accumulator battery operation. | [32] |

| Adaptive method for processing measurement results in a multi-sensor system based on Thread wireless interface. | Easy to reconfigure the enterprise topology. Possible on-site installation during construction and repair. Uses sensors instead of detectors. | Fire simulation is carried out with the help of a fire dynamics simulator at the “Polytechnic” supercomputer center. | [35] |

| Set of sensors for measuring temperature, carbon dioxide concentration, carbon monoxide concentration, and smoke concentration. Thread wireless interface (data exchange at three levels of ISO). | Continuous analysis of sensor information. | Optimization of sensor location in a building. | [36] |

| Video control systems based on computer vision. | Fire recognition from a video frame using a color correlogram. | Soft picture. Low light conditions. Interference. Additional computing capacity is required. | [39] |

| Smoke detection in limited environments, both isolated and open areas. Colour analysis, image segmentation, stain marking, and geometric characteristic analysis. | Fire detection time is a few seconds. | [40] | |

| Spectroscopy of free radicals. | Possibility of temperature determination by emission spectroscopy. | [41] | |

| Unmanned aerial vehical (UAV). | Assessment of the status for transfer to fire service specialists. Territory monitoring. | Assessment of the situation for open areas only. | [42] |

| Room Type | Combustible Material | Water Additive | Formula | Percentage Ratio of Additive | Thermal and Chemical Reactions during Extinction | References |

|---|---|---|---|---|---|---|

| Public catering facilities | Animal and vegetable oil | Organic potassium salt | CH3COOK | 5% | Evaporation of alkali droplets (endothermic process)—cooling effect. High temperatures increase fat washing rate (due to glycoside’s interaction with alkaline solution)—mass fraction of fuel decreases. | [13] |

| K2C2O4 | Saponification foam is formed on the oil surface. Foam has a certain thickness and strength—blocking the oxidizing agent input into the combustion zone. | |||||

| Non-metallic salt | NH4H2PO4 | 5% | At high temperatures, the final product of the interaction between the solution and high-temperature combustion products is metaphoric acid, which insulates contact between the combustible substance and oxygen, thus blocking the input of the oxidizer into the combustion zone. Metaphoric acid undergoes a series of reactions at high temperatures and generates a free radical—interruption of the combustion process. | [13] | ||

| Inorganic potassium salt | KNO3 | 5% | Evaporation of solution droplets (endothermic process)—cooling effect. Evaporation of the solution generates a KOH (at high temperatures) that is attached to the saponification. | [13] | ||

| KH2PO4 | A film is formed on the surface of the combustible substance—blocking the input of the oxidizing agent into the combustion zone. | |||||

| KCl | Evaporation of solution droplets (endothermic process)—cooling effect. At high temperatures, the separated KCl particle dissociates K+, which joins the chain reaction—interruption of the combustion process. | |||||

| Storage (high-risk storage) | Wooden pallets, cardboard boxes, and plastic | Specialty Additive F-500 EA (Hazard Control Technologies Inc.) | 2% | Interaction of micelles (formed in a mixture of water with additives) with a flame and combustible materials—reduction in the temperature of a flame burning area and a combustible material. | [17] | |

| Industrial | n-Heptane | Organic solvents: ethanol and propanol-1 | 7 vol.% 3 vol.% | Intensive evaporation of extinguishing solution—cooling of flame area and blocking of oxidizer input into combustion area. | [18] | |

| Industrial | Flammable liquids (petrol, diesel, and transformer oil) | Organic flame retardant (carbamide) | 1 wt.% | During the carbamide decomposition reaction a large amount of heat is absorbed—reduction in the flame temperature. Flame-retardant gases (NH3 and CO2) are formed—preventing the oxidizing agent from entering the combustion zone. | [20] | |

| Industrial | Propane | Potassium carbonate | K2CO3 | 5% | K+ ions in potassium carbonate, which are alkaline metal ions, participate with water molecules in water mist in the interrupting the chain reaction of an explosion and consume more free radicals in the explosion—the effect of fire suppression is increased. | [48] |

| Industrial | Petrol | Potassium bromide | KBr | Reduction in radical concentration by interruption of chain fire reactions | [52] | |

| Polysorbate-80 (Tween-80) | Used as an emulsifier to reduce the rate of gasification. | |||||

| Dissolved CO2 | When sprayed water mist with dissolved CO2 from the nozzle, dissolved CO2 is volatilized due to loss of pressure, which is an endothermic process—cooling effect. | |||||

| Industrial | Lithium-type battery | Surface-active substance (SAS) | Not more than 5% | Combustion temperature is reduced due to good wetting ability. | [55] | |

| Industrial | n-Heptane | Silicone SAS OFX-5211 (key component for fluorine free foam) | 3.3% | High stability provided by hydrocarbon surface-active substances and foam stabilizer mixtures, as well as the rapid spread of foam provided by silicone surface-active substance. | [64] | |

| AFFF | The fire-extinguishing mechanism is the insulation of liquid fuel from oxygen by a layer of foam and aqueous film. Good fluidity properties—blocking oxidizer input to combustion zone. | [64] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuznetsov, G.; Kopylov, N.; Sushkina, E.; Zhdanova, A. Adaptation of Fire-Fighting Systems to Localization of Fires in the Premises: Review. Energies 2022, 15, 522. https://doi.org/10.3390/en15020522

Kuznetsov G, Kopylov N, Sushkina E, Zhdanova A. Adaptation of Fire-Fighting Systems to Localization of Fires in the Premises: Review. Energies. 2022; 15(2):522. https://doi.org/10.3390/en15020522

Chicago/Turabian StyleKuznetsov, Geniy, Nikolay Kopylov, Elena Sushkina, and Alena Zhdanova. 2022. "Adaptation of Fire-Fighting Systems to Localization of Fires in the Premises: Review" Energies 15, no. 2: 522. https://doi.org/10.3390/en15020522