Microstructure, Deformation Characteristics and Energy Analysis of Mudstone under Water Absorption Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. X-ray Diffractometer (XRD)

2.2.2. Scanning Electron Microscopy (SEM)

2.2.3. Water Absorption

2.2.4. Pore Characteristic Analysis

- (1)

- Pore area: pore area is the estimated area occupied by pores in SEM image, affecting mechanical stability, and the total area of the SEM image is 300 μm2.

- (2)

- Face rate: this refers to the visible porosity of the rock under the microscope (excluding micropores), and is the percentage of the pore area in the total area of the observation field of view.

- (3)

- Pore diameter: the pore morphology of mudstone varies greatly and is irregular. For the convenience of quantifying the pore size, the equivalent diameter is used to represent the pore diameter.

- (4)

- Pore fractal dimension: fractal dimension can evaluate the complexity and heterogeneity of pore structure.

- (5)

- Roundness: the pore cross-section is close to the theoretical circle, the closer it is to the circle, the closer the value is to 1.

3. Results and Discussion

3.1. Development Characteristics of Microstructure

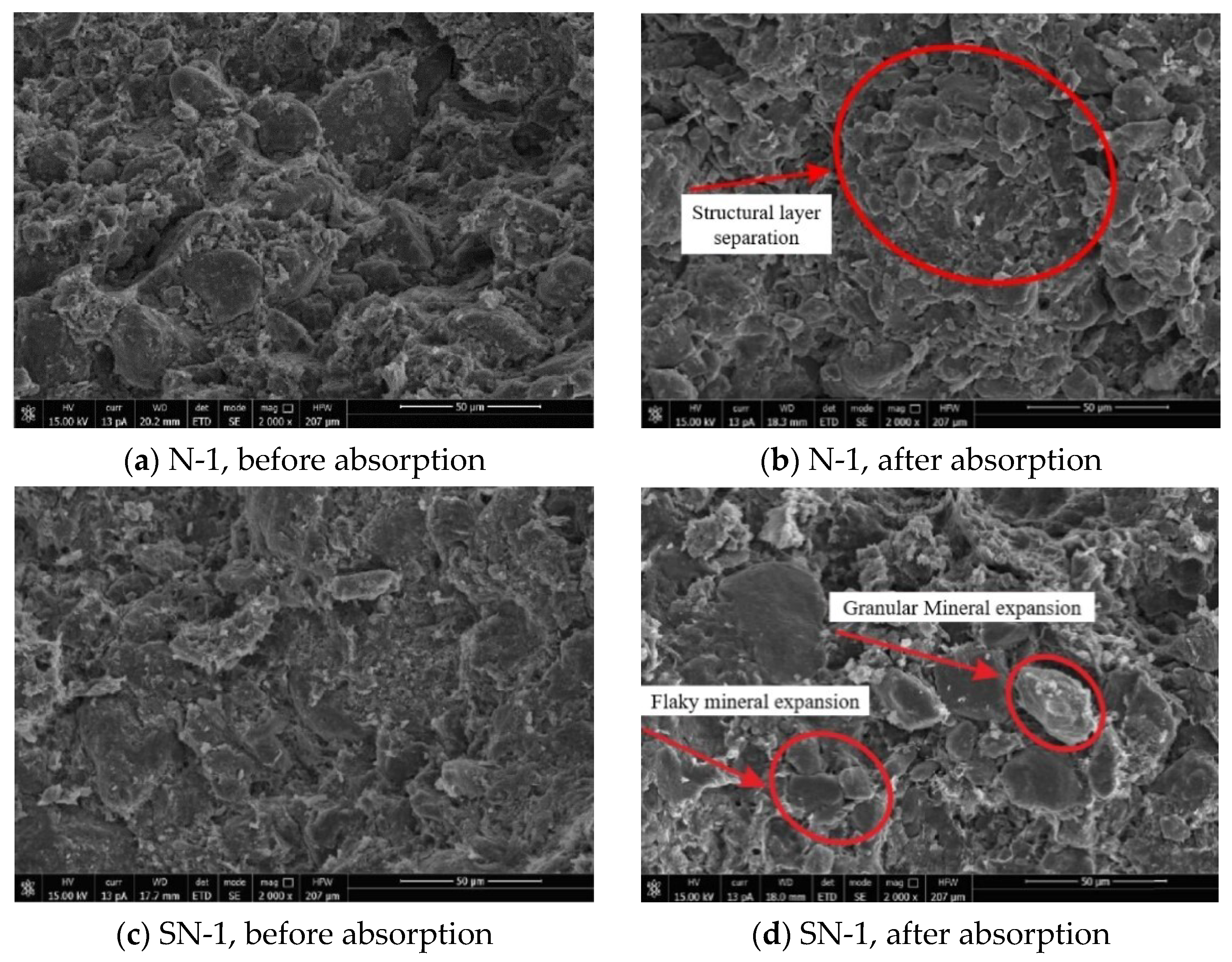

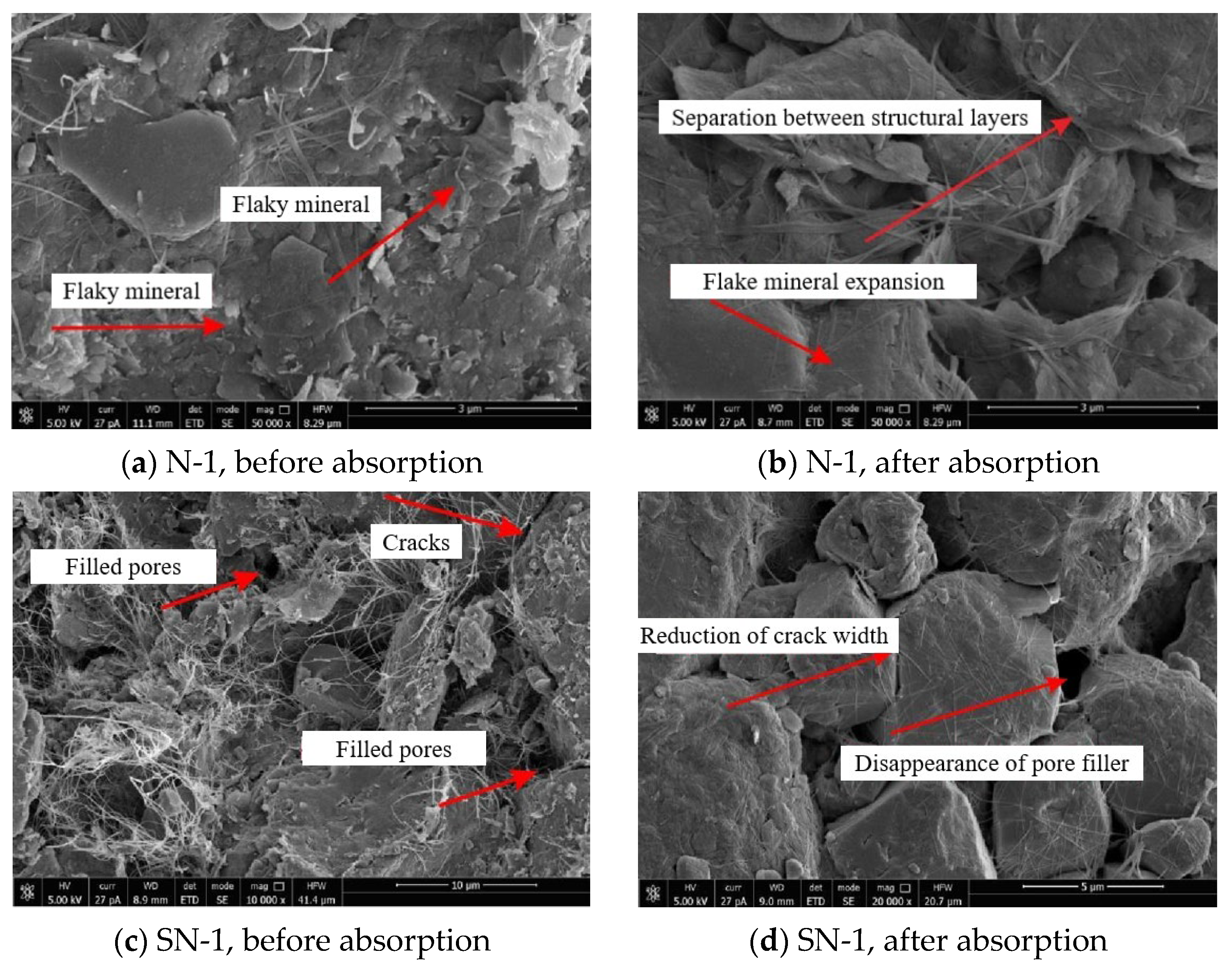

3.1.1. Development Characteristics of Clay Minerals

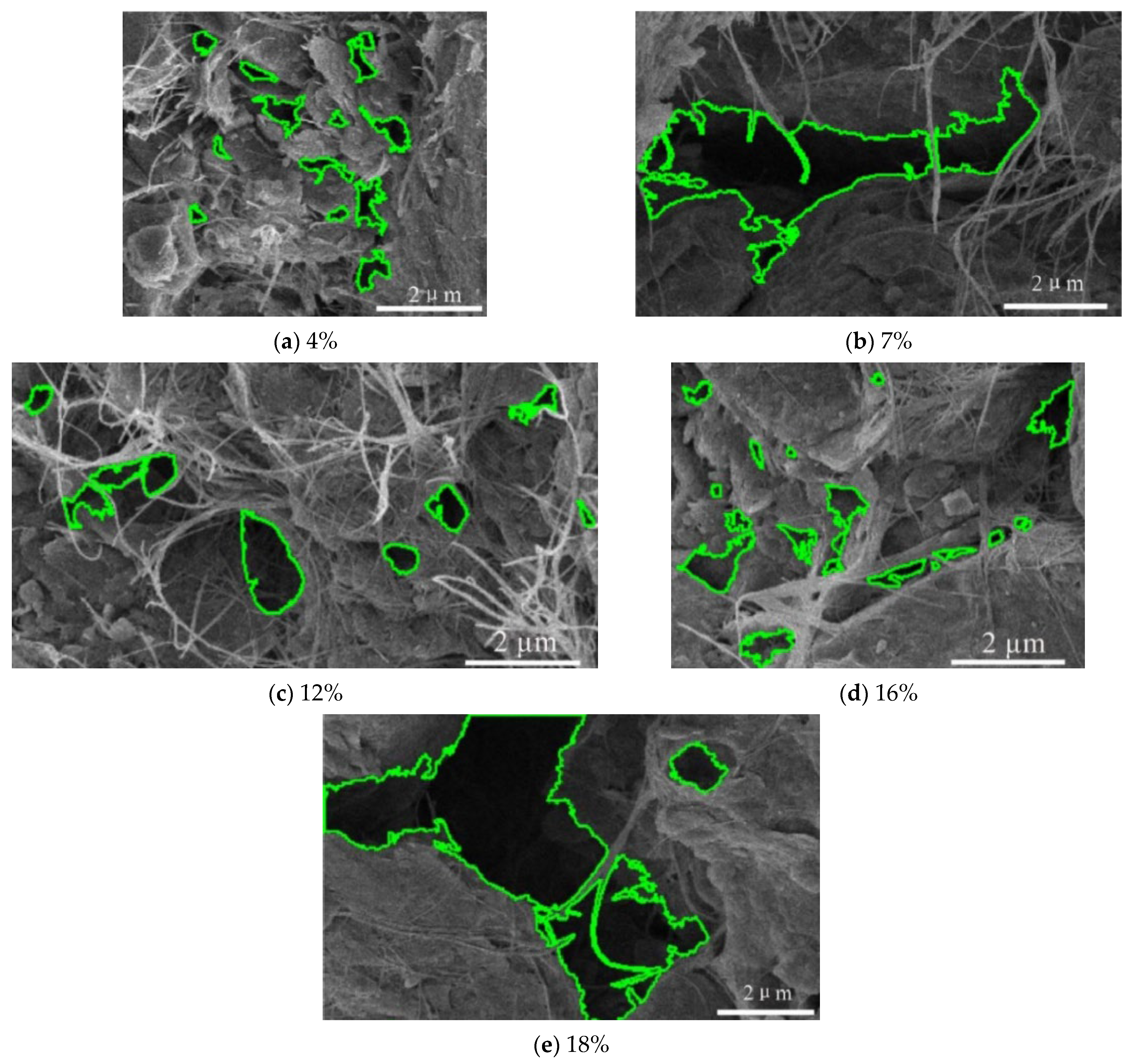

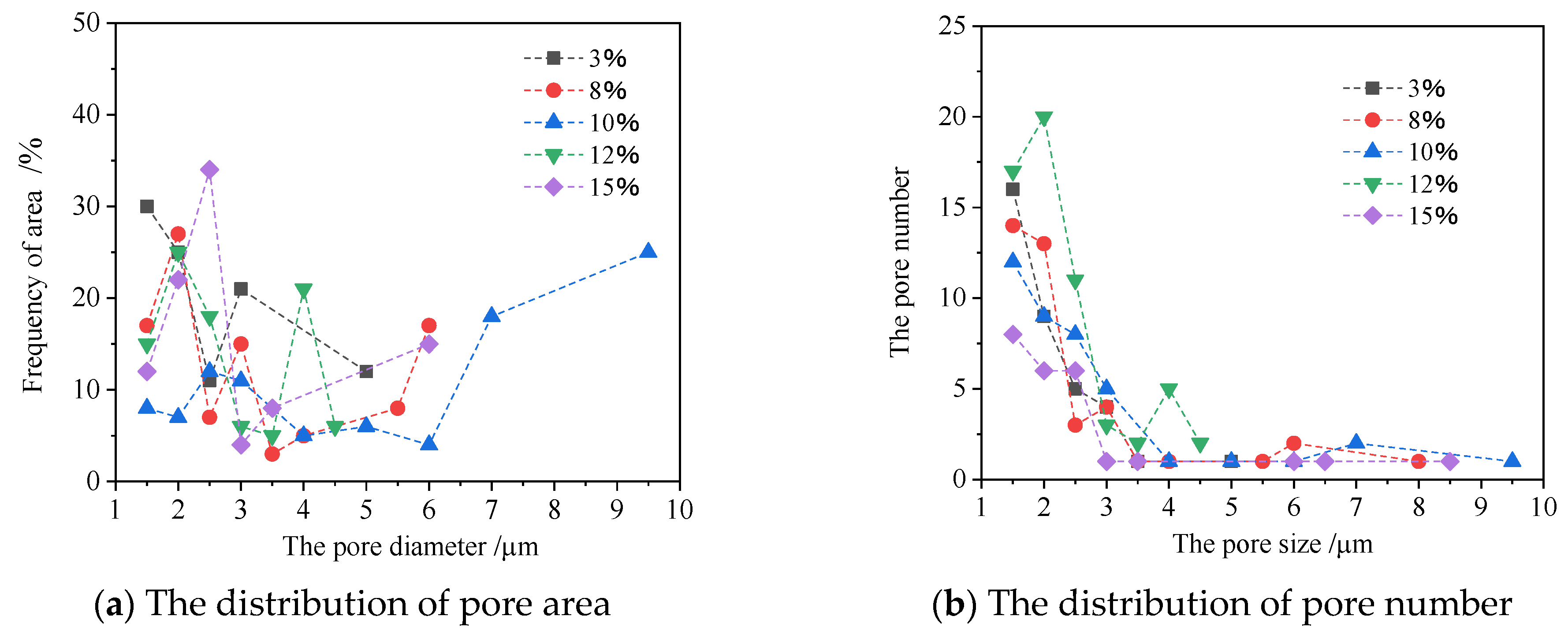

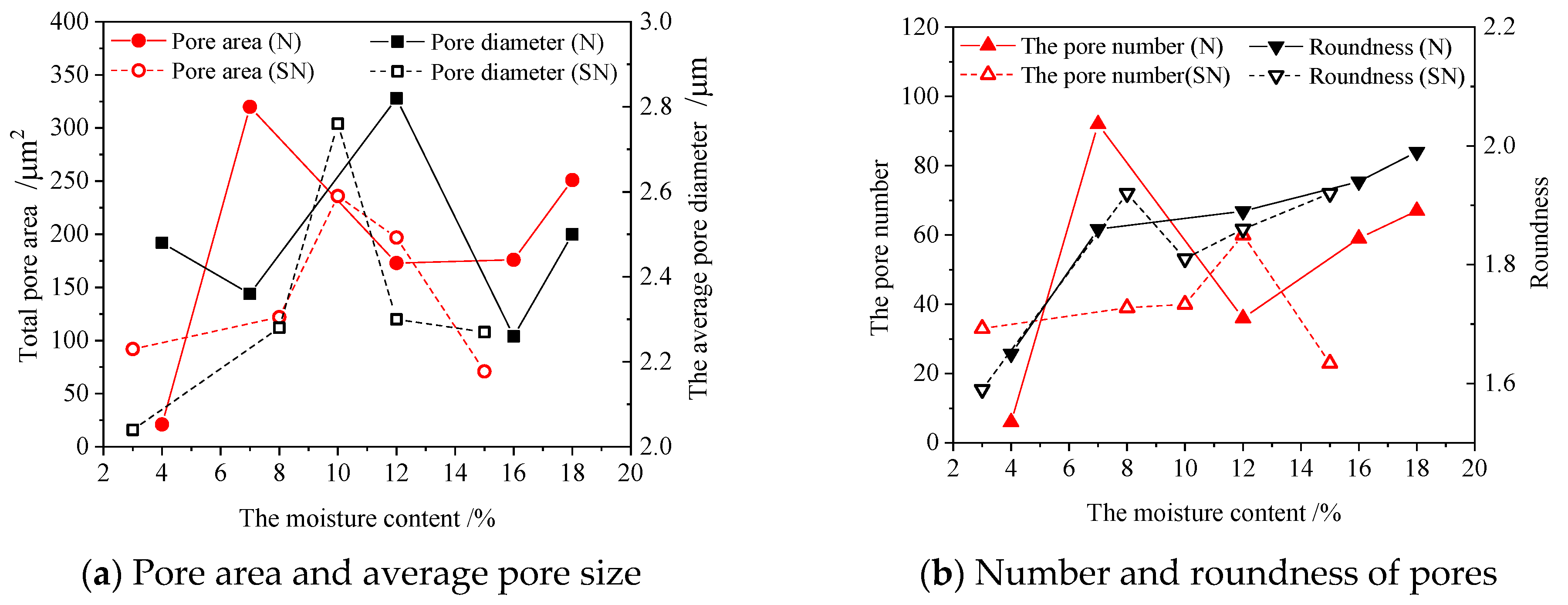

3.1.2. Development Characteristics of Pores

3.2. Water Absorption and Deformation Characteristics

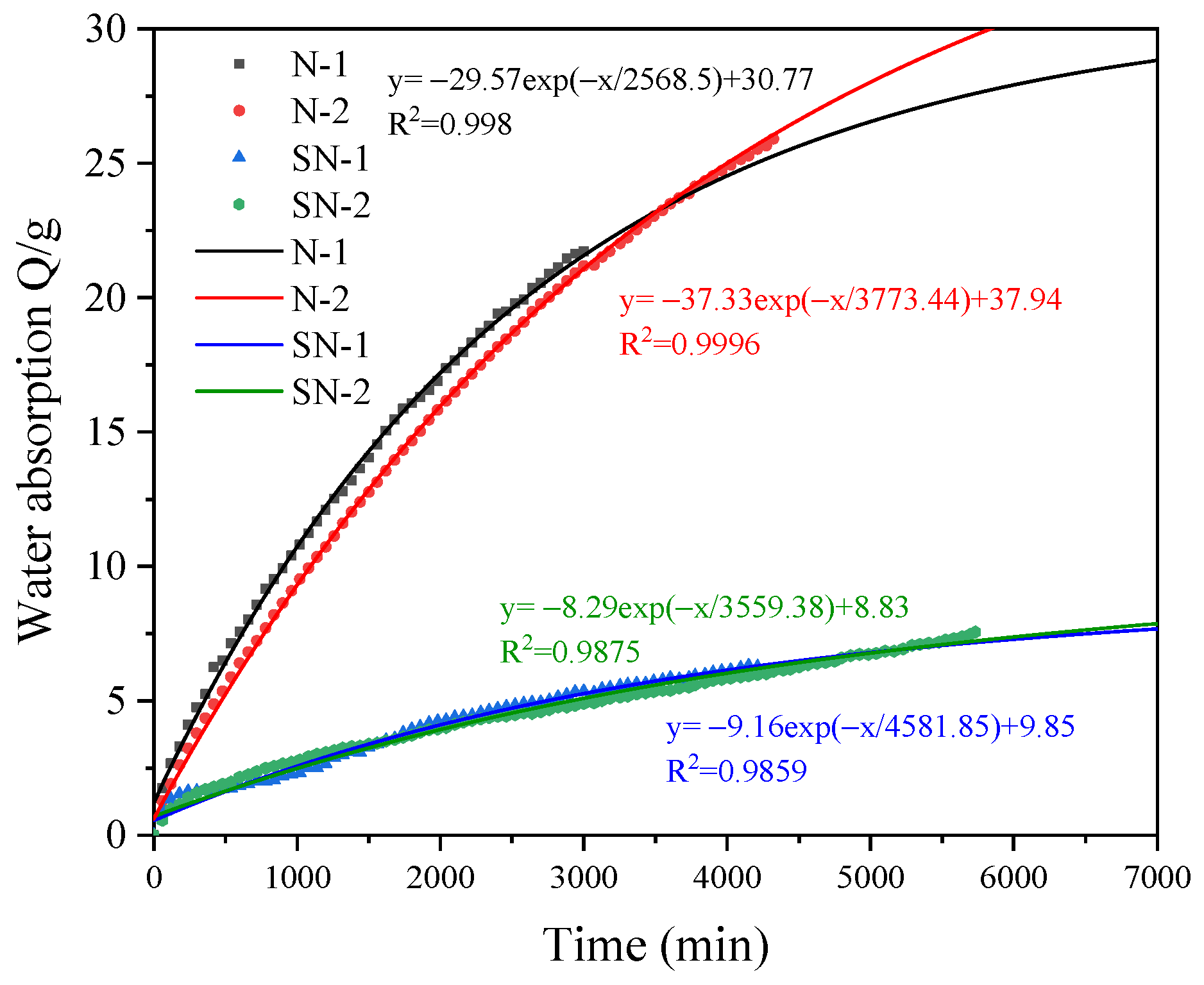

3.2.1. Water Absorption Characteristics

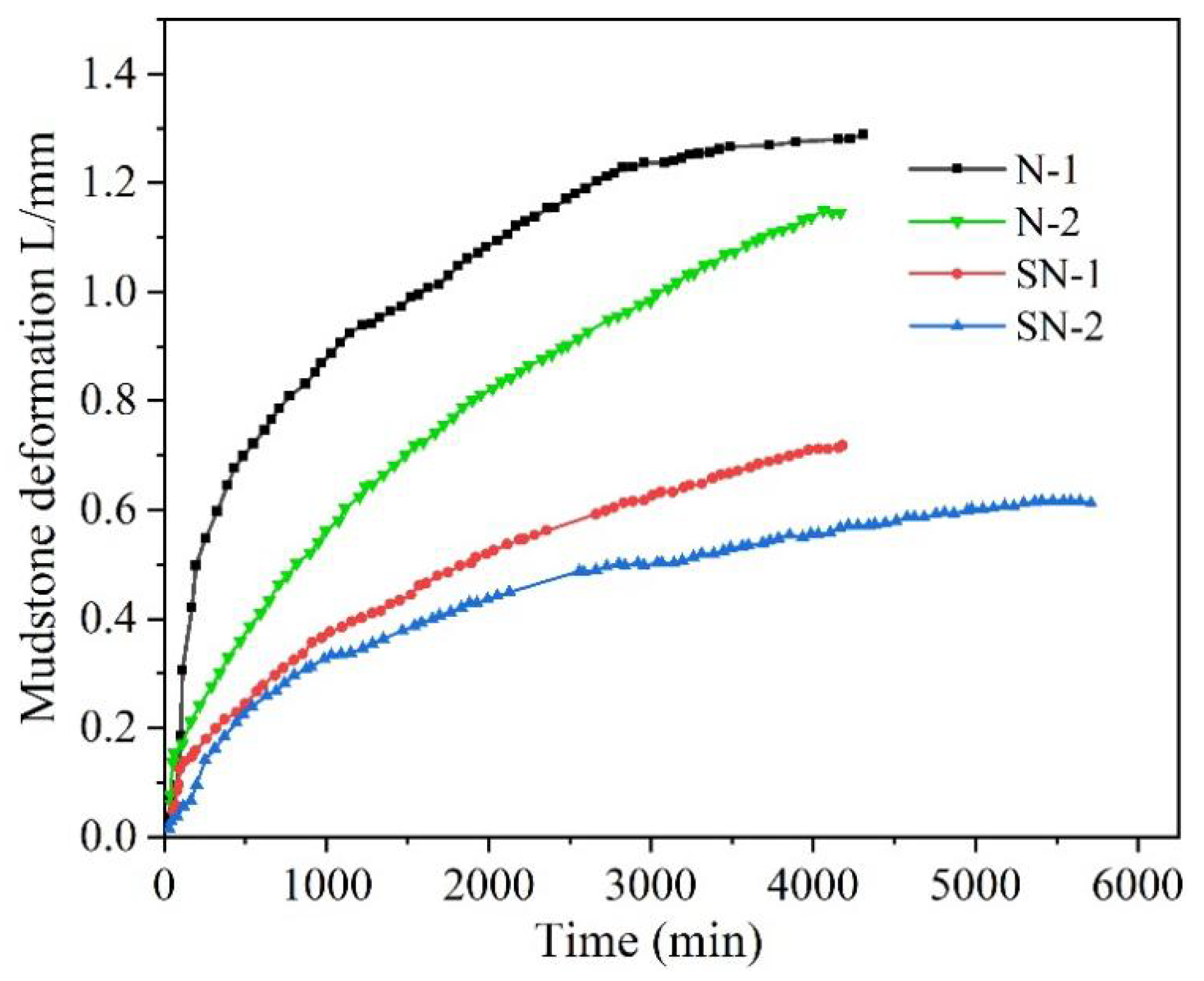

3.2.2. Deformation Characteristics

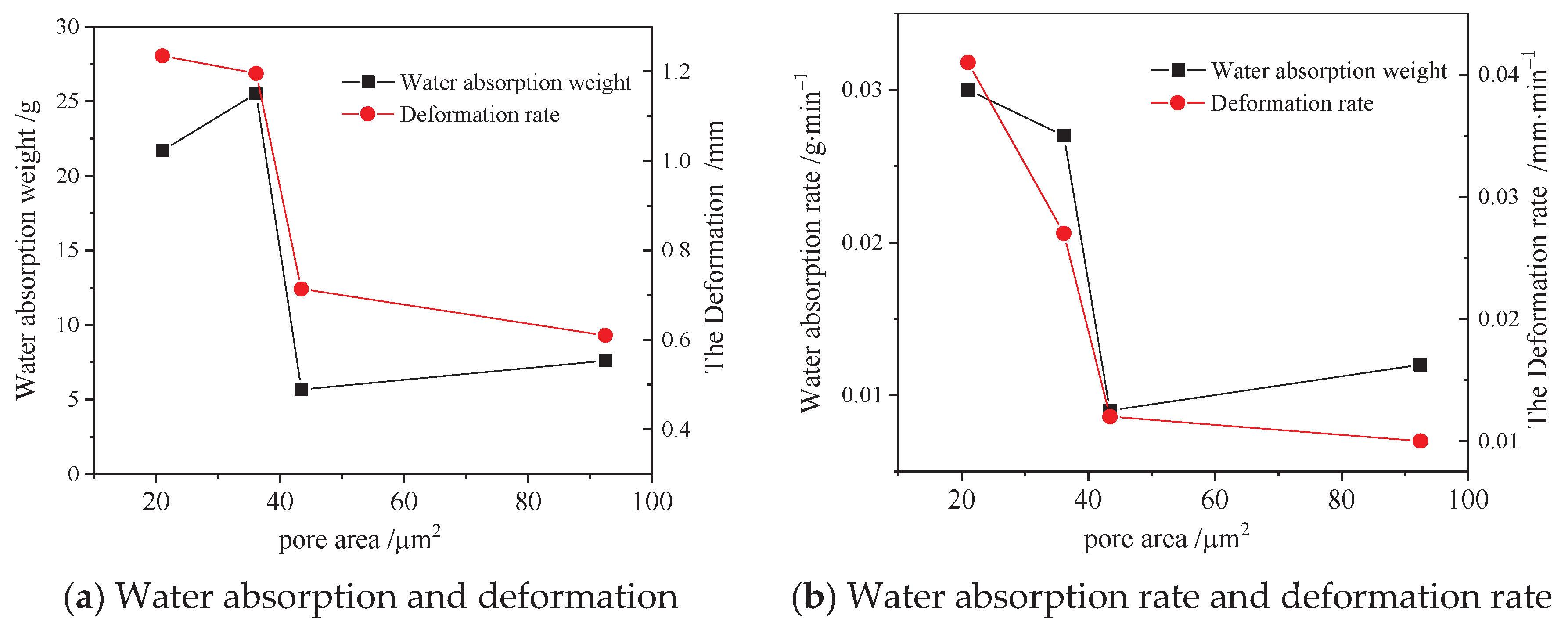

3.3. Relationship between Microstructure and Deformation

3.3.1. Relationship between Clay Mineral Content and Deformation

3.3.2. Relationship between Pore Structure Characteristics and Mudstone Water Absorption Deformation

3.4. Deformation Mechanism after Water Absorption

3.5. Mechanism of Energy Accumulation and Release

4. Conclusions

- (1)

- The development characteristics of clay minerals after encountering water are mainly shown in two aspects. The uneven strain produces expansion between adjacent particles and particle groups of clay mineral aggregate, making the pores smaller or causing them to disappear. Clay minerals easily adsorb bound water, resulting in the mutual separation of clay mineral layers.

- (2)

- The pore development characteristics of N-type mudstone are as follows: N-type mudstone has rapid pore development, lots of pores are produced in the early stage of water absorption, and the pore area and the number of pores suddenly increase, and then slightly decrease in the late stage of water absorption. With the progress of water absorption, the pore area and number of pores are reduced in the later stage, and the overall trend is decreasing.

- (3)

- There are some correlations between clay mineral content, pore area, and water absorption and deformation of mudstone, among which the correlation between clay mineral content and water absorption rate of mudstone is stronger, and the correlation with deformation volume and deformation rate is weaker. This paper analyzes the relationship between the microstructure and disintegration characteristics of mudstone in the Xining area and concludes that the mudstone with low clay mineral content and large pore area has stronger disintegration. Through the deduction of the formula, the elastic strain energy is the root cause of mudstone damage and fracture in the process of mudstone disintegration.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, X.M.; Wang, S.; Li, X.L.; Li, X.; Meng, J.; Li, Z.; Zhang, L.; Pu, D.; Wang, L. Research on theory and technology of floor heave control in semicoal rock roadway: Taking longhu coal mine in Qitaihe mining area as an Example. Lithosphere 2022, 2022, 3810988. [Google Scholar] [CrossRef]

- Tang, Q.; Katsumi, T.; Inui, T.; Li, Z.Z. Membrane behavior of bentonite-amended compacted clay towards Zn (II) and Pb (II). Membr. Water Treat 2015, 6, 393–409. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.L.; Qin, Q.Z. Study on surrounding rock control and support stability of Ultra-large height mining face. Energies 2022, 15, 6811. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, T.; Liu, Q.; Zhang, S.; Zhang, L. Quantitative evaluation of potential organic-matter porosity and hydrocarbon generation and expulsion from mudstone in continental lake basins: A case study of Dongying sag, eastern China. Mar. Pet. Geol. 2015, 66, 906–924. [Google Scholar] [CrossRef]

- Chen, G.; Chang, X.; Guo, X.; Pang, Y.; Zhang, P. Geochemical characteristics and organic matter enrichment mechanism of Permian black mudstone in the South Yellow Sea Basin, China. J. Pet. Sci. Eng. 2022, 208, 109248. [Google Scholar] [CrossRef]

- Jiang, Q.; Cui, J.; Feng, X. Application of computerized tomographic scanning to the study of water-induced weakening of mudstone. B Eng. Geol. Environ. 2014, 73, 1293–1301. [Google Scholar] [CrossRef]

- Tu, X.; Xie, C.; Antić, N. The influences of climatic and lithological factors on weathering of sediments in humid badland areas. Front. Earth. Sc-Switz. 2022, 10, 990. [Google Scholar] [CrossRef]

- Zeng, L.; Yu, H.C.; Gao, Q.F.; Bian, H.B. Mechanical behavior and microstructural mechanism of improved disintegrated carbonaceous mudstone. J. Cent. South Univ. (Engl. Ed.) 2022, 27, 1992–2002. [Google Scholar] [CrossRef]

- Hack, H. Weathering, erosion, and susceptibility to weathering. In Soft Rock Mechanics and Engineering; Springer: Cham, Switzerland, 2020; pp. 291–333. [Google Scholar] [CrossRef]

- Dai, Z.; Guo, J.; Yu, F.; Zhou, Z. Long-term uplift of high-speed railway subgrade caused by swelling effect of red-bed mudstone: Case study in Southwest China. Bull. Eng. Geol. Environ. 2021, 80, 4855–4869. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, Q. Effects of rainwater softening on red mudstone of deep-seated landslide, Southwest China. Eng. Geol. 2016, 204, 1–13. [Google Scholar] [CrossRef]

- Sutton, D.; McCabe, B.; Cripps, J. A laboratory study of the expansion of an Irish pyritic mudstone/siltstone fill material. Eng. Geol. 2013, 152, 194–201. [Google Scholar] [CrossRef] [Green Version]

- Gu, F.; Presti, D.; Heitzman, M.; Powell, B.; Allison, V. Feasibility of using more polishable aggregates in dense-graded asphalt surface mixture: Case study of dolomite. Constr. Build. Mater. 2022, 342, 127915. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.; Wang, S. Effect of Gas on Burst Proneness and Energy Dissipation of Loaded Coal: An Experimental Study Using a Novel Gas-Solid Coupling Loading Apparatus. Shock. Vib. 2021, 2021, 8854538. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Jiao, J.; Liu, J.; Chen, F.; Song, Z. Comparative Study of Pore Structure Characteristics between Mudstone and Coal under Different Particle Size Conditions. Energies 2021, 14, 8435. [Google Scholar] [CrossRef]

- Zhao, J.; He, X.; Shao, T. Material composition and microstructure of purple soil and purple mudstone in Chongqing area. Acta Pedol. Sin. 2012, 49, 212–219. [Google Scholar] [CrossRef]

- Ye, D.; Liu, G.; Luo, N.; Gao, F.; Zhu, X.; Yue, F. Quantitative Analysis of the Topological Structure of Rock Pore Network. Geofluids 2021, 2021, 5517489. [Google Scholar] [CrossRef]

- Yang, L.; Ge, H.; Shi, X.; Cheng, Y.; Zhang, K. The effect of microstructure and rock mineralogy on water imbibition characteristics in tight reservoirs. J. Nat. Gas Sci. Eng. 2018, 34, 1461–1471. [Google Scholar] [CrossRef]

- Su, X.; Tang, H.; Huang, L.; Shen, P.; Xia, D. The role of pH in red-stratum mudstone disintegration in the Three Gorges reservoir area, China, and the associated micromechanisms. Eng. Geol. 2022, 279, 105873. [Google Scholar] [CrossRef]

- Dong, X.; Wu, Y.; Cao, K.; Muhammad Khan, N.; Hussain, S.; Lee, S.; Ma, C. Analysis of Mudstone Fracture and Precursory Characteristics after Corrosion of Acidic Solution Based on Dissipative Strain Energy. Sustainability 2021, 13, 4478. [Google Scholar] [CrossRef]

- Zha, H.; Fu, H.; Zeng, L.; Zhu, X.; Jia, C. Use of sodium alginate as a novel cementitious material to improve the engineering properties of disintegrated carbonaceous mudstone. B Eng. Geol. Environ. 2022, 81, 431. [Google Scholar] [CrossRef]

- Tang, Q.; Liu, W.; Wang, H.; Cheng, R.; Qian, Y. Membrane behavior of bentonite-amended Fukakusa clay in K, Na and Ca solutions. J. Cent. South Univ. (Engl. Ed.) 2016, 23, 3122–3131. [Google Scholar] [CrossRef]

- Fu, J.; Yu, Y. Experimental study on pore characteristics and fractal dimension calculation of pore structure of aerated concrete block. Adv. Civ. Eng. 2019, 2019, 8043248. [Google Scholar] [CrossRef] [Green Version]

- Das, D.; Mishra, B.; Gupta, N. Understanding the influence of petrographic parameters on strength of differently sized shale specimens using XRD and SEM. Int. J. Min. Sci. Technol. 2021, 31, 953–961. [Google Scholar] [CrossRef]

- Huang, S.; He, Y.; Liu, G. Effect of water content on the mechanical properties and deformation characteristics of the clay-bearing red sandstone. Bull. Eng. Geol. Environ. 2021, 80, 1767–1790. [Google Scholar] [CrossRef]

- He, M. Latest progress of soft rock mechanics and engineering in China. J. Rock Mech. Min. Sci. 2014, 6, 165–179. [Google Scholar] [CrossRef] [Green Version]

- Doostmohammadi, R.; Moosavi, M.; Mutschler, T.; Osan, C. Influence of cyclic wetting and drying on swelling behavior of mudstone in south west of Iran. Environ. Geol. 2009, 58, 999–1009. [Google Scholar] [CrossRef]

- Higuchi, K.; Chigira, M.; Lee, D. Pore-water chemistry and its influence on rock mechanical properties and hydrogeophysical processes in a mudstone slope in the southwestern Taiwan badlands. Catena 2020, 190, 104533. [Google Scholar] [CrossRef]

- Li, X.; Li, X. Micro–Macro Quantification of the Internal Structure of Granular Materials. J. Eng. Mech. 2009, 135, 641–656. [Google Scholar] [CrossRef]

- Sun, Q.; Cheng, X.; Ji, S. Advances in the micro–macro mechanics of granular soil materials. Adv. Mech. 2011, 41, 351–371. [Google Scholar] [CrossRef]

- Xu, J.; Li, G.; Rong, H.; Gomah, M.E. Effect of Moisture on the Macro Failure Characteristics of Weakly Consolidated Mudstone: Mesomechanism. Geofluids 2022, 2022, 8254114. [Google Scholar] [CrossRef]

- Sun, X.; Shi, F.; Ye, C.; Zhang, Y.; Cui, L.; Zhao, W. Research on strength softening characteristics and microscopic mechanism of sandstone after absorbing water. Earth Environ. Sci. 2021, 861, 022033. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, J.; Zhang, A. Permanent deformation and prediction model of construction and demolition waste under repeated loading. J. Cent. South Univ. 2022, 29, 1363–1375. [Google Scholar] [CrossRef]

- Zhang, J.; Li, C.; Ding, L. Performance evaluation of cement stabilized recycled mixture with recycled concrete aggregate and crushed brick. Constr. Build. Mater. 2021, 296, 123596. [Google Scholar] [CrossRef]

- Wang, C.; He, B.; Hou, X.; Li, J.; Liu, L. Stress–Energy Mechanism for Rock Failure Evolution Based on Damage Mechanics in Hard Rock. Rock Mech. 2020, 53, 1021–1037. [Google Scholar] [CrossRef]

- Tsoutrelis, C.E.; Exadaktylos, G.E. Effect of rock discontinuities on certain rock strength and fracture energy parameters under uniaxial compression. Geotech. Geol. Eng. 1993, 11, 81–105. [Google Scholar] [CrossRef]

- Liu, X.S.; Ning, J.G.; Tan, Y.L.; Gu, Q.H. Damage constitutive model based on energy dissipation for intact rock subjected to cyclic loading. Int. J. Rock Mech. Min. 2016, 85, 27–32. [Google Scholar] [CrossRef]

- Xiao, J.; Ding, D. Inverted S-shaped model for nonlinear fatigue damage of rock. Int. J. Rock Mech. Min. 2009, 46, 643–648. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, X.T.; Zhang, X. Strain energy evolution characteristics and mechanisms of hard rocks under true triaxial compression. Eng. Geol. 2019, 260, 105222. [Google Scholar] [CrossRef]

- Ma, Q.; Tan, Y.L.; Liu, X.S. Experimental and numerical simulation of loading rate effects on failure and strain energy characteristics of coal-rock composite samples. J. Cent. South. Univ. 2021, 28, 3207–3222. [Google Scholar] [CrossRef]

| Serial Number | Quartz | Clay Mineral | Feldspar | Calcite | Dolomite | Analcite | Siderite | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Illite | Chlorite | Kaolinite | ||||||||

| Mudstone | N-1 | 40.71 | 20.47 | 8.76 | 15.57 | 1.99 | 0.44 | |||

| N-2 | 43.98 | 21.02 | 5.82 | 17.12 | 7.06 | 2.87 | 2.13 | |||

| Sandy mudstone | SN-1 | 41.34 | 20.12 | 5.76 | 20.18 | 10.62 | 1.98 | |||

| SN-2 | 47.93 | 16.13 | 7.82 | 10.13 | 10.53 | 3.52 | 3.94 | |||

| Rate of Water Content (%) | 4 | 7 | 12 | 16 | 18 |

|---|---|---|---|---|---|

| Total void area (μm2) | 21.01 | 319.60 | 172.93 | 175.80 | 251.37 |

| Average pore diameter (μm) | 2.48 | 2.36 | 2.81 | 2.26 | 2.49 |

| Number of pores | 6 | 92 | 36 | 59 | 67 |

| Max pore diameter (μm) | 8.12 | 9.59 | 9.59 | 7.66 | 11.94 |

| Roundness | 1.65 | 1.85 | 1.89 | 1.93 | 1.98 |

| Minimum pore diameter (μm) | 0.71 | 0.64 | 0.66 | 0.72 | 0.55 |

| Fractional dimension | 1.13 | 1.09 | 1.09 | 1.10 | 1.09 |

| Rate of Water Content (%) | 3 | 8 | 10 | 12 | 15 |

|---|---|---|---|---|---|

| Total void area (μm2) | 92.44 | 121.90 | 236.03 | 196.75 | 71.17 |

| Average pore diameter (μm) | 2.03 | 2.28 | 2.76 | 2.30 | 2.27 |

| Number of pores | 33 | 39 | 40 | 60 | 23 |

| Max pore diameter (μm) | 6.64 | 8.55 | 10.35 | 5.39 | 8.89 |

| Roundness | 1.59 | 1.92 | 1.80 | 1.85 | 1.91 |

| Minimum pore diameter (μm) | 0.73 | 0.65 | 0.91 | 0.77 | 0.55 |

| Fractional dimension | 1.08 | 1.09 | 1.08 | 1.11 | 1.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Z.; Xu, Q.; Luo, X.; Huang, R.; Liao, X.; Tang, Q. Microstructure, Deformation Characteristics and Energy Analysis of Mudstone under Water Absorption Process. Energies 2022, 15, 7511. https://doi.org/10.3390/en15207511

Feng Z, Xu Q, Luo X, Huang R, Liao X, Tang Q. Microstructure, Deformation Characteristics and Energy Analysis of Mudstone under Water Absorption Process. Energies. 2022; 15(20):7511. https://doi.org/10.3390/en15207511

Chicago/Turabian StyleFeng, Zheyuan, Qi Xu, Xinyu Luo, Ruyu Huang, Xin Liao, and Qiang Tang. 2022. "Microstructure, Deformation Characteristics and Energy Analysis of Mudstone under Water Absorption Process" Energies 15, no. 20: 7511. https://doi.org/10.3390/en15207511

APA StyleFeng, Z., Xu, Q., Luo, X., Huang, R., Liao, X., & Tang, Q. (2022). Microstructure, Deformation Characteristics and Energy Analysis of Mudstone under Water Absorption Process. Energies, 15(20), 7511. https://doi.org/10.3390/en15207511