Abstract

This paper presents a review of mobile positive pressure ventilation fans for use in rescue operations available on the European market in correlation with the approval regulations of the drive units. The authors determined the approval limits for harmful compound emissions by their power units, as applicable within the European Union. The purpose of this paper is to estimate the emissions of harmful compounds from the exhausts of rescue fan power units. It was demonstrated that electric fans are not in direct competition with internal combustion fans because they are provided in different power ranges, and 74% of the electric fan market falls between 1.1 kW and 2.2 kW, whereas fans powered by combustion engines are offered in a much higher power range from 0.7 kW to 92 kW, and the most popular power range offered by manufacturers is from 3.4 kW to 6.3 kW (57% of the market). On the basis of the limits derived from approval tests it can be demonstrated that 90% of engines on the European market which are used in fans (spark ignition (SI) engine up to 19 kW) are allowed carbon monoxide (CO) emissions of 610 g/kWh and hydrocarbon and nitrogen oxide emissions (HC + NOx) of 8 g/kWh.

1. Introduction

The issue of air pollution has been recognized by scientists [1] and legislators [2] for a long time and has also raised public concern [3] in recent years. Poor air quality particularly affects the residents of large cities globally [4,5,6]. This has led to specific legislation being introduced in order to curb the effects of exhaust products from combustion engines on the health and lives of humans [7]. The legal solutions forcing manufacturers to reduce emissions from combustion engines are very often the major incentive to introduce new technologies [8,9,10]. They also seem more effective than other methods introduced by legislators to reduce emissions into the air, e.g., by fuel tax reforms [11,12] or investing in new technologies without ensuring that they are implemented [13]. However, the European air pollutant emission limits introduced in the 1990s and their continual updates for road vehicles largely contributed to the use within the European Union of vehicles employing the latest combustion engine technologies [14]. Combustion engines in motor vehicles, in contrast to machinery engines, are characterized by high efficiency [15], emission reductions [16], effective onboard diagnostics and engine control systems [10,17], and a wide range of fuels used [18,19,20].

European Union (EU) legislators have laid out limits for emissions to air, grouping combustion engines by application, and then by power, displacement, engine type (spark ignited (SI) or compression-ignition (CI)), operating conditions and site, as well as the type of fuel used [21]. The basic groups are cars and light trucks [22,23,24], heavy-duty truck and bus engines [25,26,27,28,29], and non-road engines [13,30,31]. The regulations concerning road vehicles are more stringent than those for engines used in non-road machinery [32]. EU law is considerably more liberal for small engine non-road equipment, which is defined as featuring engines below 56 kW [13,31,32,33]. Some of the main reasons for this include the size and weight of those engines [34]. The use of innovative units in combustion engines requires space for additional engine equipment and efficient power generation systems [35,36]. Traditional non-road small engines are characterized by a mechanically or electronically regulated carburetor fuel supply system and an electromagnetic ignition system [31]. Introducing innovation in fuel delivery control requires the use of more sensors, e.g., an air temperature sensor in the intake manifold, an engine temperature sensor, a crankshaft and cam speed sensor, a flowmeter, an exhaust gas oxygen sensor, a throttle position sensor, etc. In addition, power supply is required for the controller and actuators e.g., for injectors [37,38], fuel pumps, electric throttle controls, etc. Providing power to such a large number of units necessitates having an efficient energy generator. Ensuring the highest standards in terms of fuel injection also requires using high pressure mechanical pumps, which also increase the size of the device [39,40]. The last system that is difficult to implement in non-road small engines is the exhaust after treatment system, because of its relatively large size. Non-road small engines are often smaller and lighter than the equipment described above, which is why legislators do not impose very strict emission requirements on this group of engines. In addition, the non-road small engine group is divided into handheld and non-handheld engines [13]. As weight is one of the most important utility properties in the handheld group, the exhaust emission requirements imposed on such engines are the most liberal. This group also includes, e.g., engines for petrol chainsaws, which allow various operating positions, contributing to issues with piston and crankshaft assembly lubrication [41]. Engines used in chainsaws are still two-stroke engines in which the air-fuel mixture contains oil. This type of engine has been excluded from many applications due to limits for emissions of harmful compounds in exhaust gas, but there are still applications in which they are allowed by European Union law. Another group of non-road small engines consists of non-handheld engines up to 56 kW which are used in portable and mobile equipment, such as fans for use in rescue operations, lawnmowers, and power generators. Due to this, their weight and size are also limited and the engine builds are relatively poor in terms of technological advancement [34,42]. The final group of non-road engines over 56 kW are engines built in a similar manner as those used in modern vehicles, as the size of the machinery in which they are used allows innovative engine equipment. Machines powered by these engines are usually stationary or rendered mobile by placement on trailers or vehicles, which reduces the impact of engine weight on the utility properties.

All equipment used in rescue operations should be of top quality as it affects the safety of both firefighters and the people being rescued. The most important operating parameter for positive pressure ventilation fans is their capacity to remove the toxic products of thermal decomposition and combustion from buildings [43,44,45,46]. This depends on the flow pattern [47,48,49] and flow rate [50,51,52]. Other important parameters in the assessment of these devices are their weight and noise levels. However, it is also important to consider exhaust emissions from fan power units which affect their operators and the rescued individuals near the machine. Estimating the impact of these machines on their surroundings, and specifically determining the amount and quality of the selected harmful compounds in exhaust fumes is possible by analyzing the approval regulations for their power units. A review of the literature reveals that no such analysis was performed for rescue fans, while it was carried out for other equipment groups. Magagnotti et al. (2014) studied the exposure of mobile chipper operators to diesel exhaust [53], and Neri et al. (2016) studied emissions from petrol-powered chainsaws in the aspect of operator exposure [54].

The purpose of this paper is to carry out a review of the mobile positive pressure fan models available on the European market, indicating the type of their power unit and power range. On the basis of the conducted review of power unit type and power, it was determined which legal regulations on air pollution cover these devices in the territory of the European Union. This allowed us to define the maximum emissions of harmful exhaust gases depending on the type of power unit, assuming that the engines meet the approval standards in force in the European Union. Carbon monoxide (CO), hydrocarbon (HC), nitrogen oxide (NOx), and particulate matter ((PM) expressed in g/kWh or (PN) expressed in 1/kWh) emissions per hour were indicated by engine power.

2. Commercial Mobile Positive Pressure Ventilation Fans Available on the European Market

A review of the commercial power units for positive pressure ventilation fans available on the European market was conducted by brand, model, displacement, power, and power unit type. The reviewed devices predominantly feature electric power units or spark-ignited internal combustion engines. Positive pressure ventilation fans available on the European market in the first half of 2022 are presented in Table 1 (with electric engines) and Table 2 (with internal combustion engines)

Table 1.

Electric mobile positive pressure ventilation fans available on the European market.

Table 2.

Mobile positive pressure ventilation fans with internal combustion power units available on the European market.

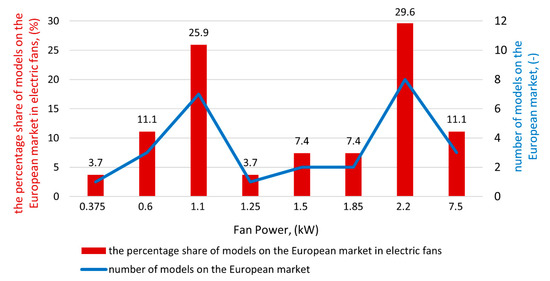

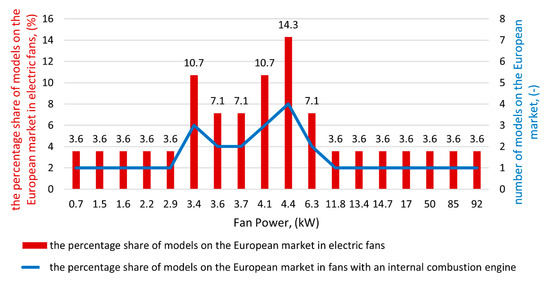

There are about 60 models of mobile fans designed for rescue operations available on the European market (Table 1 and Table 2). About a half of the available fans are powered by internal combustion engines (Table 2), and the other half are based on electric power units (Table 1). It can be noted that according to the type of power unit used (electric or internal combustion), these devices operate at different power ranges. Electric fans include devices with engine power ranging from 0.375 kW to 7.5 kW (Figure 1), while internal combustion engines powering fans have a considerably higher power range from 0.7 kW to 92 kW (Figure 2). The most popular power range provided by the manufacturers of electric fans is from 1.1 kW to 2.2 kW. Such devices account for 74% of the electric fan models available on the European market (Figure 1). For fans with internal combustion engines, the most popular power range is from 3.4 kW to 6.3 kW. Such devices account for 57% of the internal combustion fan models available on the European market (Figure 2). This leads to the conclusion that electric fans and fans with internal combustion engines do not compete with one another and in most cases they are used for different purposes during rescue operations.

Figure 1.

Electric fans on the European market.

Figure 2.

Fans with an internal combustion engine on the European market.

Due to the issue that exhaust fans powered by internal combustion engines require exhaust fume extraction, they are used mainly outdoors. In turn, due to the lack of concerns related to air pollution, electric fans can be used indoors. The lower power of fans also translates into smaller size, which makes it easier to use electric fans inside buildings. However, electric fans are often characterized by a much shorter operating time, similar to other battery-powered mobile devices [62].

3. European Laws Setting the Limits of Pollution Emissions from Internal Combustion Engines in Positive Pressure Ventilation Fans Used in Rescue Operations

The most popular group of positive pressure ventilation fans has been subject to regulations governing pollution from internal combustion engines across the European Union since 2002. The laws refer to spark-ignition combustion engines with a power of up to 19 kW for non-road usage. In 2016, currently applicable Stage V laws were enacted, and have been in full force and effect since 2019. The provisions are set out in Regulation (EU) 1628/2016. Under the regulation, engines applied in rescue positive pressure ventilation fans are placed in category NRS which includes SI engines having a reference power that is less than 56 kW, which are not intended for use in in handheld machinery (Table 3). SI engines with a power above 56 kW must meet emission standards for category NRE engines.

Table 3.

Stage V emission standards for non-handheld SI engines below 56 kW (NRS), where: A—the availability of selected categories of engines used in fans for rescue operations on the European market, B—category, C—power (P), D—displacement (V), E—date of entry into force, F—emission limits for hazardous exhaust gas compounds during European type approval tests [33].

Stage V emission limits for engines in non-road mobile machinery (category NRE) are shown in Table 4. These standards are applicable to CI engines from 0 to 56 kW and to all types of engines above 56 kW.

Table 4.

Stage V emission standards for non-road engines (NRE), where: A—the availability of selected categories of engines used in fans for rescue operations on the European market [33].

Based on the summary of internal combustion engines (Table 2) applied in fans, and the European type-approval tests (Table 3 and Table 4) it can be noted that not all engine categories refer to fans. Category NRS-vr/vi-1a engines do not refer to fans used in rescue operations because, according the results of studies performed by Kaczmarzyk et al., (2022) they work at maximum power levels in real-life operation conditions [63], and the category concerns a test for intermediate speed applications. The right category for the engines of fans used in rescue operations in this power and displacement range is NRS-vr/vi-1b, which is tested for rated speed applications. Moreover, categories NRS-v-2a and NRS-v-2b for engines having power in the range of 19 kW to 30 kW and displacement below or above 1000 cm3 are also unusual, as no positive pressure ventilation fans with combustion engines with such power range have been identified. Two out of all the structures available on the European market are not classified as category NRS engines, but as category NRE engines, with a power above 56 kW intended for non-road machinery. The categories listed in Table 4 are intended for low-power CI engines with a power of up to 56 kW. However, as regards this power range, only fans with SI engines belonging to the NRS category are available on the European market. Categories covering both CI and SI engines are demonstrated further in Table 4. Positive pressure ventilation fans with engines with a power above 92 kW have also not been found, and thus, as regards NRE engines, only category NRE-v/c-5 engines, characterized by a power range of 56 kW to 130 kW, can be discussed in the context of positive pressure ventilation fans.

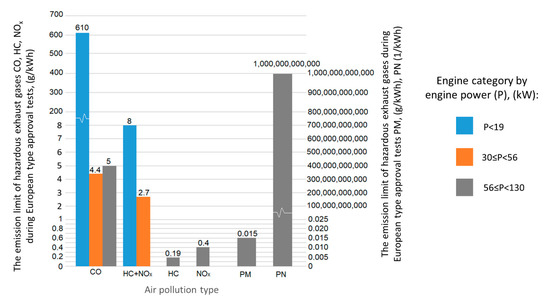

4. Allowable Limits of Emissions from Internal Combustion Engines Applied in Fans Used in Rescue Operations

Liberal European Union laws governing emissions from small non-road engines cover around 90% of fans available for sale on the European market. The provisions for fans with engines having a power of up to 19 kW allow CO emissions at the level of 610 g/kWh and HC + NOx emissions at the level of 8 g/kWh. More stringent emission limits are applicable to engines having higher power values (Figure 3). As regards fans with engines having a power with a range of 30 kW to 56 kW, accounting for a 3% market share in Europe, the allowable CO and HC + NOx emissions are lower by 99.3% and 66.2%, respectively (4.4 g/kWh and 2.7 g/kWh). The remaining 7% of the European market is taken by category NRE engines, which are not classified as category NRS, intended for higher-power drive units, notwithstanding the type of fuel or engine (SI and CI). Fans equipped with such engines are subject to the analysis of a greater number of air pollutants, and the set limits are relatively rigorous.

Figure 3.

Limits of air pollution generated by internal combustion engines of fans, depending on the power-related engine category.

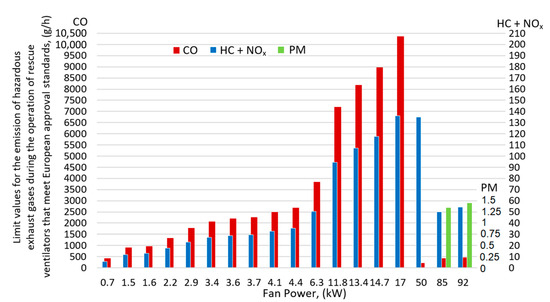

Assuming that internal combustion engines applied in ventilators are operated at maximum power [63], the values of exhaust gas emissions per hour can be estimated on the basis of engine power and allowable emission limits (Figure 4). It can be noted that low-power fan engines (between 0.7 kW and 17 kW), which are less technologically advanced, are characterized by a higher hourly pollutant emission than engines having substantially higher power (between 50 kW and 92 kW). An hour of operation of an engine with a power ranging from 0.7 kW to 17 kW may produce CO emissions at the level of 427 g/h to 10,370 g/h, while for engines having a higher power, between 50 kW and 92 kW, CO emissions should fall within the range of 220 g/h to 460 g/h. On the other hand, the HC + NOx emission increases with the engine power for units with a power from 0.7 kW to 17 kW in the range from 5.6 g/h to 136 g/h. Later, for the power from 50 kW to 85 kW, it decreases (from 135 g/h to 50 g/h), and then for the power of 92 kW, it starts to increase to 54 kW. The reduction of HC + NOx emissions for engines above 17 kW is not as large as the reduction of CO emissions for engines of the same power. For example, engines with a power of 85 kW to 92 kW may have HC + NOx emissions of 50 g/h to 54 g/h, as are engines of another 6.3 kW category, which may emit HC + NOx at the level of 50.4 g/h. For comparison, the permissible CO emission from these engines is from 425 g/h to 460 g/h (engines with power from 85 kW to 92 kW) and 2196 g/h for engines with a power of 6.3 kW. Based on the analysis, it can be concluded that the use of fans with higher-power engines, preferably above 19 kW, is more favorable in terms of air pollution as engines exceeding this power value belong to categories which are subject to relatively stringent emission limits. The assumptions are based on maximum emission values allowable during type-approval tests. According to the results of studies conducted by Warguła et al. in 2022, small engines SI, e.g., with a power of around 10 kW, are characterized by emission levels in type-approval tests which are close to the maximum allowable values. The study included engines with a classic carburetor fuel supply system (the most popular ones on the market) and the most innovative ones with electronically controlled carburetors, and they were characterized by CO emissions at the level of 408 g/kWh to 561 g/kWh and HC + NOx emission of 3.90 g/kWh to 4.53 g/kWh, respectively, compared with emission levels set in the European Union, namely CO 610 g/kWh and HC + NOx 8 g/kWh [33]. It should be borne in mind that along with the progressing wear and tear, engines are characterized by a greater loss of fuel dosage control precision and a higher probability that larger volumes of engine lubricating oil will be consumed, which might result in increased air pollution and in exceeding the emission limits applicable in type-approval tests.

Figure 4.

Estimated emissions from internal combustion engines of fans used in rescue operations per hour of work, determined on the basis of maximum air pollution emission limits in force during type-approval tests in the European Union area.

5. Conclusions

It has been shown that fans with electric and combustion engines do not constitute direct competition for each other because they are mainly offered in other power ranges on the European market. Increasing the competitiveness of electric fans on the market and, consequently, the possibility of replacing fans with a combustion engine will be possible when mobile electric fans are offered on the market in a larger power range. Improvement in the working conditions for fans with combustion engines can be achieved by lowering the permissible emission limits from engines at the stage of approval tests. Currently, internal-combustion drive units of positive pressure ventilation fans used in rescue operations in the European Union area are subject to type-approval tests specifying the limits of emissions of harmful chemical compounds in exhaust gases. The units are classified as non-road engines, where approximately 93% of fan models available on the European market fall within category NRS, which includes SI engines having a reference power that is less than 56 kW, which are not intended for use in handheld machinery. It is the group of internal combustion engines that are the least technologically advanced in terms of the emission of harmful exhaust gases. The remaining engines belong to category NRE, which refers to CI engines with a power of less than 56 kW and drive units with a power of above 56 kW, notwithstanding the engine type (SI and CI). These engines have more stringent emission requirements. The estimation of emissions from fans used in rescue operations based on allowable emission limits set during type-approval tests might be restricted by possible lower emissions in real-life conditions or increased emissions resulting from the wear and tear of machinery, which is an issue requiring further research. Based on the type-approval test limits, it can be stated that 90% of engines in fans used in rescue operations (SI engines with a power of up to 19 kW) on the European market are characterized by allowable CO emissions at the level of 610 g/kWh and HC + NOx emissions at the level of 8 g/kWh. Fans with engines falling within the power range of 30 kW to 56 kW, with a 3% market share in Europe, are characterized by allowable CO and HC + NOx emissions which are lower by 99.3% and 66.2%, respectively (4.4 g/kWh and 2.7 g/kWh). The remaining 7% of the European market is taken by CI engines subject to the most stringent requirements. Development work on internal combustion engines used in mobile positive pressure fans should be carried out mainly in the area of SI engines with a power below 19 kW. Further studies should be conducted with a view to verifying the real-life emissions of exhaust gases with the use of a portable emission measurement system (PEMS).

Author Contributions

Conceptualization, Ł.W. and P.K.; methodology, Ł.W. and P.K.; software, Ł.W. and P.K.; validation, Ł.W. and P.K.; formal analysis, Ł.W. and P.K.; investigation, Ł.W. and P.K.; resources, Ł.W. and P.K.; data curation, Ł.W. and P.K.; writing—original draft preparation, Ł.W. and P.K.; writing—review and editing, Ł.W. and P.K.; visualization, Ł.W. and P.K.; supervision, Ł.W. and P.K.; project administration, Ł.W. and P.K.; funding acquisition, Ł.W. and P.K. All authors have read and agreed to the published version of the manuscript.

Funding

The research presented in the article was carried out as part of the Ministry of Education and Science program “Implementation Doctorate” executed in 2020–2024 (agreement no. DWD/4/22/2020).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Vichit-Vadakan, N.; Vajanapoom, N. Health Impact from Air Pollution in Thailand: Current and Future Challenges. Environ. Health Perspect. 2011, 119, A197–A198. [Google Scholar] [CrossRef] [PubMed]

- Feng, T.; Du, H.; Lin, Z.; Zuo, J. Spatial Spillover Effects of Environmental Regulations on Air Pollution: Evidence from Urban Agglomerations in China. J. Environ. Manag. 2020, 272, 110998. [Google Scholar] [CrossRef] [PubMed]

- Bickerstaff, K.; Walker, G. Public Understandings of Air Pollution: The ‘Localisation’ of Environmental Risk. Glob. Environ. Chang. 2001, 11, 133–145. [Google Scholar] [CrossRef]

- Calderón-Garcidueñas, L.; Kulesza, R.J.; Doty, R.L.; D’Angiulli, A.; Torres-Jardón, R. Megacities Air Pollution Problems: Mexico City Metropolitan Area Critical Issues on the Central Nervous System Pediatric Impact. Environ. Res. 2015, 137, 157–169. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, J.; Yu, D.; Ma, Q. The Relationship between Urban Form and Air Pollution Depends on Seasonality and City Size. Environ. Sci. Pollut. Res. 2018, 25, 15554–15567. [Google Scholar] [CrossRef]

- Velásquez, R.M.A.; Lara, J.V.M. Gaussian approach for probability and correlation between the number of COVID-19 cases and the air pollution in Lima. Urban Clim. 2020, 33, 100664. [Google Scholar] [CrossRef]

- Rubio, F.; Llopis-Albert, C.; Valero, F.; Besa, A.J. Sustainability and Optimization in the Automotive Sector for Adaptation to Government Vehicle Pollutant Emission Regulations. J. Bus. Res. 2020, 112, 561–566. [Google Scholar] [CrossRef]

- Selleri, T.; Melas, A.D.; Joshi, A.; Manara, D.; Perujo, A.; Suarez-Bertoa, R. An Overview of Lean Exhaust DeNOx Aftertreatment Technologies and NOx Emission Regulations in the European Union. Catalysts 2021, 11, 404. [Google Scholar] [CrossRef]

- Greim, H. Diesel Engine Emissions: Are They No Longer Tolerable? Arch. Toxicol. 2019, 93, 2483–2490. [Google Scholar] [CrossRef]

- Wierzbicki, S. Evaluation of the effectiveness of on-board diagnostic systems in controlling exhaust gas emissions from motor vehicles. Diagnostyka 2019, 20, 75–79. [Google Scholar] [CrossRef]

- Zimmer, A.; Koch, N. Fuel Consumption Dynamics in Europe: Tax Reform Implications for Air Pollution and Carbon Emissions. Transp. Res. Part A Policy Pract. 2017, 106, 22–50. [Google Scholar] [CrossRef]

- Creutzig, F.; McGlynn, E.; Minx, J.; Edenhofer, O. Climate Policies for Road Transport Revisited (I): Evaluation of the Current Framework. Energy Policy 2011, 39, 2396–2406. [Google Scholar] [CrossRef]

- Waluś, K.J.; Warguła, Ł.; Krawiec, P.; Adamiec, J.M. Legal Regulations of Restrictions of Air Pollution Made by Non-Road Mobile Machinery—The Case Study for Europe: A Review. Environ. Sci. Pollut. Res. 2018, 25, 3243–3259. [Google Scholar] [CrossRef]

- Frey, H.C. Trends in Onroad Transportation Energy and Emissions. J. Air Waste Manag. Assoc. 2018, 68, 514–563. [Google Scholar] [CrossRef]

- Leach, F.; Kalghatgi, G.; Stone, R.; Miles, P. The Scope for Improving the Efficiency and Environmental Impact of Internal Combustion Engines. Transp. Eng. 2020, 1, 100005. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A.; Martini, G.; Dilara, P. Overview of Vehicle Exhaust Particle Number Regulations. Processes 2021, 9, 2216. [Google Scholar] [CrossRef]

- Beik, Y.; Dziewiątkowski, M.; Szpica, D. Exhaust Emissions of an Engine Fuelled by Petrol and Liquefied Petroleum Gas with Control Algorithm Adjustment. SAE Int. J. Engines 2020, 13, 739–760. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Villalta, D.; Guzmán-Mendoza, M. Methanol and OMEx as Fuel Candidates to Fulfill the Potential EURO VII Emissions Regulation under Dual-Mode Dual-Fuel Combustion. Fuel 2021, 287, 119548. [Google Scholar] [CrossRef]

- Hunicz, J.; Matijošius, J.; Rimkus, A.; Kilikevičius, A.; Kordos, P.; Mikulski, M. Efficient Hydrotreated Vegetable Oil Combustion under Partially Premixed Conditions with Heavy Exhaust Gas Recirculation. Fuel 2020, 268, 117350. [Google Scholar] [CrossRef]

- Rimkus, A.; Stravinskas, S.; Matijošius, J. Comparative Study on the Energetic and Ecologic Parameters of Dual Fuels (Diesel–NG and HVO–Biogas) and Conventional Diesel Fuel in a CI Engine. Appl. Sci. 2020, 10, 359. [Google Scholar] [CrossRef]

- Hooftman, N.; Messagie, M.; Van Mierlo, J.; Coosemans, T. A Review of the European Passenger Car Regulations—Real Driving Emissions vs. Local Air Quality. Renew. Sustain. Energy Rev. 2018, 86, 1–21. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Joshi, A.; Ntziachristos, L.; Dilara, P. European Regulatory Framework and Particulate Matter Emissions of Gasoline Light-Duty Vehicles: A Review. Catalysts 2019, 9, 586. [Google Scholar] [CrossRef]

- Grigoratos, T.; Fontaras, G.; Giechaskiel, B.; Zacharof, N. Real World Emissions Performance of Heavy-Duty Euro VI Diesel Vehicles. Atmos. Environ. 2019, 201, 348–359. [Google Scholar] [CrossRef]

- Puricelli, S.; Cardellini, G.; Casadei, S.; Faedo, D.; van den Oever, A.E.M.; Grosso, M. A Review on Biofuels for Light-Duty Vehicles in Europe. Renew. Sustain. Energy Rev. 2021, 137, 110398. [Google Scholar] [CrossRef]

- Weller, K.; Lipp, S.; Röck, M.; Matzer, C.; Bittermann, A.; Hausberger, S. Real World Fuel Consumption and Emissions From LDVs and HDVs. Front. Mech. Eng. 2019, 5, 45. [Google Scholar] [CrossRef]

- Merkisz, J.; Kozak, M.; Molik, P.; Nijak, D.; Andrzejewski, M.; Nowak, M.; Rymaniak, Ł.; Ziółkowski, A. The Analysis of the Emission Level from a Heavy-Duty Truck in City Traffic. Siln. Spalinowe 2012, 51, 80–88. [Google Scholar] [CrossRef]

- Merkisz, J.; Fuć, P.; Lijewski, P.; Pielecha, J. Actual Emissions from Urban Buses Powered with Diesel and Gas Engines. Transp. Res. Procedia 2016, 14, 3070–3078. [Google Scholar] [CrossRef]

- Lijewski, P.; Merkisz, J.; Fuć, P.; Ziółkowski, A.; Rymaniak, Ł.; Kusiak, W. Fuel Consumption and Exhaust Emissions in the Process of Mechanized Timber Extraction and Transport. Eur. J. For. Res. 2017, 136, 153–160. [Google Scholar] [CrossRef]

- Rymaniak, Ł.; Fuć, P.; Lijewski, P.; Kamińska, M.; Daszkiewicz, P.; Ziółkowski, A. Evaluating the Environmental Costs in Poland of City Buses Meeting the Euro VI Norm Based on Tests in Real Operating Conditions. Arch. Transp. 2019, 52, 109–115. [Google Scholar] [CrossRef]

- Lončarević, Š.; Ilinčić, P.; Šagi, G.; Lulić, Z. Problems and Directions in Creating a National Non-Road Mobile Machinery Emission Inventory: A Critical Review. Sustainability 2022, 14, 3471. [Google Scholar] [CrossRef]

- Warguła, Ł.; Lijewski, P.; Kukla, M. Influence of Non-Commercial Fuel Supply Systems on Small Engine SI Exhaust Emissions in Relation to European Approval Regulations. Environ. Sci. Pollut. Res. 2022, 29, 55928–55943. [Google Scholar] [CrossRef]

- Lijewski, P.; Fuć, P.; Dobrzyński, M.; Markiewicz, F. Exhaust emissions from small engines in handheld devices. MATEC Web Conf. 2017, 118, 00016. [Google Scholar] [CrossRef]

- Regulation (EU). On Requirements for Emission Limit Values of Gaseous and Particulate Pollutants and Type-approval with Respect to Internal Combustion Engines for Mobile Machines Non-road, Amending Regulations (EU) No 1024/2012 and (EU) No 167/2013 and Amending and Repealing Directive 97/68/WE. No 2016/1628 of the European Parliament and of the Council of 14 September 2016. Off. J. Eur. Union. 2016, 252, 53–117. [Google Scholar]

- Warguła, Ł.; Waluś, K.J.; Krawiec, P. Small Engines Spark Ignited (SI) for Non-Road Mobile Machinery-Review. In Transport Means 2018, Proceedings of the 22nd International Scientific Conference, Trakai, Lithuania, 3–5 October 2018; Kaunas University of Technology: Kaunas, Lithuania, 2018; pp. 585–591. [Google Scholar]

- Warguła, Ł.; Kukla, M.; Lijewski, P.; Dobrzyński, M.; Markiewicz, F. Influence of Innovative Woodchipper Speed Control Systems on Exhaust Gas Emissions and Fuel Consumption in Urban Areas. Energies 2020, 13, 3330. [Google Scholar] [CrossRef]

- Warguła, Ł.; Krawiec, P.; Waluś, K.J.; Kukla, M. Fuel Consumption Test Results for a Self-Adaptive, Maintenance-Free Wood Chipper Drive Control System. Appl. Sci. 2020, 10, 2727. [Google Scholar] [CrossRef]

- Szpica, D. Investigating Fuel Dosage Non-Repeatability of Low-Pressure Gas-Phase Injectors. Flow Meas. Instrum. 2018, 59, 147–156. [Google Scholar] [CrossRef]

- Szpica, D.; Czaban, J. Operational Assessment of Selected Gasoline and LPG Vapour Injector Dosage Regularity. Mechanics 2014, 20, 480–488. [Google Scholar] [CrossRef]

- Wieland, A.; Achleitner, E.; Lyubar, A.; Schlücker, E. Rail Pressure-Based Diagnostic Functions for Gasoline Direct Injection Systems. MTZ Worldw. 2020, 81, 56–61. [Google Scholar] [CrossRef]

- Lee, Z.; Kim, D.; Park, S. Effects of Spray Behavior and Wall Impingement on Particulate Matter Emissions in a Direct Injection Spark Ignition Engine Equipped with a High Pressure Injection System. Energy Convers. Manag. 2020, 213, 112865. [Google Scholar] [CrossRef]

- Warguła, Ł.; Krawiec, P.; Kukla, M.; Wieczorek, B.; Kaczmarzyk, P. Innovations in chainsaws utilised as mechanical rescue devices. Saf. Fire Technol. 2020, 55, 142–153. [Google Scholar] [CrossRef]

- Warguła, Ł.; Krawiec, P.; Waluś, K.; Polasik, J. Electronic Control Injection-Ignition Systems in Propulsion of Non-Road Mobile Machinery. J. Mech. Transp. Eng. 2018, 70, 61–78. [Google Scholar] [CrossRef]

- Krawiec, P.; Warguła, Ł.; Dziechciarz, A.; Małozięć, D.; Ondrušová, D. Ocena emisji związków chemicznych podczas rozkładu termicznego i spalania pasów klinowych. Przemysł Chem. 2020, 99, 92–98. [Google Scholar] [CrossRef]

- Krawiec, P.; Warguła, Ł.; Małozięć, D.; Kaczmarzyk, P.; Dziechciarz, A.; Czarnecka-Komorowska, D. The Toxicological Testing and Thermal Decomposition of Drive and Transport Belts Made of Thermoplastic Multilayer Polymer Materials. Polymers 2020, 12, 2232. [Google Scholar] [CrossRef]

- Krawiec, P.; Warguła, Ł.; Czarnecka-Komorowska, D.; Janik, P.; Dziechciarz, A.; Kaczmarzyk, P. Chemical Compounds Released by Combustion of Polymer Composites Flat Belts. Sci. Rep. 2021, 11, 8269. [Google Scholar] [CrossRef]

- Rabajczyk, A.; Zielecka, M.; Małozięć, D. Hazards Resulting from the Burning Wood Impregnated with Selected Chemical Compounds. Appl. Sci. 2020, 10, 6093. [Google Scholar] [CrossRef]

- Kaczmarzyk, P.; Klapsa, W.; Janik, P.; Krawiec, P. Identification and Evaluation of Technical and Operational Parameters of Mobile Positive Pressure Ventilation Fans Used during Rescue Operations. Saf. Fire Technol. 2021, 58, 74–91. [Google Scholar] [CrossRef]

- Cimolino, U.; Emrich, C.; Svensson, S. Taktische Ventilation: Be-und Entlüftungssysteme im Einsatz; Ecomed-Storck GmbH: Landsberg am Lech, Germany, 2012; ISBN 978-3-609-68426-0. [Google Scholar]

- Garcia, K.; Kauffmann, R.; Schelble, R. Positive Pressure Attack for Ventilation & Firefighting; PennWell Books: Tulsa, OK, USA, 2006; ISBN 978-1-59370-048-5. [Google Scholar]

- Kaczmarzyk, P.; Janik, P.; Klapsa, W.; Bugaj, G. Possibilities of Using Mobile Fans and the Parameters Conditioning the Effectiveness of Tactical Mechanical Ventilation. Saf. Fire Technol. 2022, 59, 58–82. [Google Scholar] [CrossRef]

- Lambert, K.; Merci, B. Experimental Study on the Use of Positive Pressure Ventilation for Fire Service Interventions in Buildings with Staircases. Fire Technol. 2014, 50, 1517–1534. [Google Scholar] [CrossRef]

- Panindre, P.; Mousavi, N.S.S.; Kumar, S. Improvement of Positive Pressure Ventilation by Optimizing Stairwell Door Opening Area. Fire Saf. J. 2017, 92, 195–198. [Google Scholar] [CrossRef]

- Magagnotti, N.; Picchi, G.; Sciarra, G.; Spinelli, R. Exposure of Mobile Chipper Operators to Diesel Exhaust. Ann. Occup. Hyg. 2014, 58, 217–226. [Google Scholar] [CrossRef][Green Version]

- Neri, F.; Foderi, C.; Laschi, A.; Fabiano, F.; Cambi, M.; Sciarra, G.; Aprea, M.C.; Cenni, A.; Marchi, E. Determining Exhaust Fumes Exposure in Chainsaw Operations. Environ. Pollut. 2016, 218, 1162–1169. [Google Scholar] [CrossRef]

- Ramfan. Available online: https://ramfan.pl/ (accessed on 30 December 2021).

- Rosenbauer. Available online: https://www.Rosenbauer.com (accessed on 30 December 2021).

- Leader. Available online: https://www.leader-group.company/en/firefighting-equipment/fire-ventilators (accessed on 30 December 2021).

- Batfan. Available online: https://strefa998.pl/turbowentylator/2512-wentylator-oddymiajacy-akumulatorowy-batfan-3-li.html (accessed on 30 December 2021).

- Alusteel. Available online: http://alusteel.pl/wentylatory (accessed on 30 December 2021).

- Fogo. Available online: https://www.fogo.pl/ (accessed on 30 December 2021).

- Pavliš. Available online: https://www.firefighting-phhp.com (accessed on 30 December 2021).

- Poje, A.; Mihelič, M. Influence of Chain Sharpness, Tension Adjustment and Type of Electric Chainsaw on Energy Consumption and Cross-Cutting Time. Forests 2020, 11, 1017. [Google Scholar] [CrossRef]

- Kaczmarzyk, P.; Warguła, Ł.; Janik, P.; Krawiec, P. Influence of Measurement Methodologies for the Volumetric Air Flow Rate of Mobile Positive Pressure Fans on Drive Unit Performance. Energies 2022, 15, 3953. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).