Thermal Electrical Tests for Battery Safety Standardization

Abstract

:1. Introduction

2. Results

2.1. Overcharge Tests

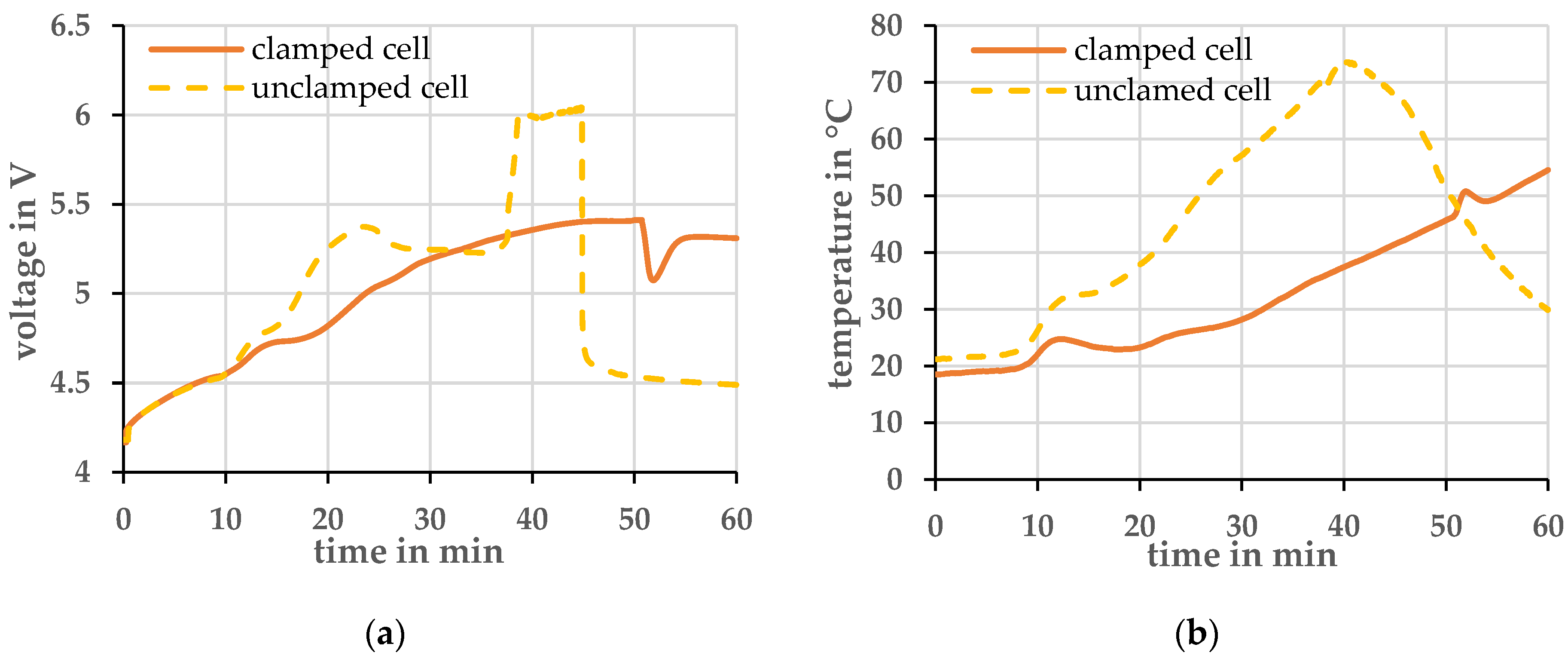

2.1.1. Overcharge Test of a Clamped and an Unclamped Cell

2.1.2. Effects of Different Charging Currents

2.1.3. Electrochemical Impedance Spectroscopy (EIS) of Overcharged Cells

2.2. Short-Circuit Test

2.2.1. Effects of Different Ambient Temperatures

2.2.2. Electrochemical Impedance Spectroscopy after Short-Circuit Test

3. Discussion

4. Materials and Methods

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, B.; Sharif, A.; Shahbaz, M.; Dong, K. Have electric vehicles effectively addressed CO2 emissions? Analysis of eight leading countries using quantile-on-quantile regression approach. Sustain. Prod. Consum. 2021, 27, 1205–1214. [Google Scholar] [CrossRef]

- Beard, K.W. Linden’s Handbook of Batteries, 5th ed.; McGraw Hill: New York, NY, USA, 2019. [Google Scholar]

- Osieczko, K.; Zimon, D.; Płaczek, E.; Prokopiuk, I. Factors that influence the expansion of electric delivery vehicles and trucks in EU countries. J. Environ. Manag. 2021, 296, 113177. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Guo, W.; Wu, H.; Lin, L.; Liu, Q.; Han, X.; Xie, Q.; Liu, P.; Zheng, H.; Wang, L.; et al. Challenges and Recent Advances in High Capacity Li-Rich Cathode Materials for High Energy Density Lithium-Ion Batteries. Adv. Mater. 2021, 33, e2005937. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Guo, Z.; Yan, K.; Wan, S.; He, F.; Sun, B.; Wang, G. Towards high-energy-density lithium-ion batteries: Strategies for developing high-capacity lithium-rich cathode materials. Energy Storage Mater. 2021, 34, 716–734. [Google Scholar] [CrossRef]

- Edström, K.; Dominko, R.; Fichtner, M.; Perraud, S. Battery 2030+ Roadmap; Uppsala University: Uppsala, Sweden, 2020. [Google Scholar]

- Tarascon, J.M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar] [CrossRef]

- IEC 62660-2; Secondary Lithium-Ion Cells for the Propulsion of Electric Road Vehicles: Part 2: Reliability and Abuse Testing, 2nd ed. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2018.

- IEC 62660-3; Secondary Lithium-Ion Cells for the Propulsion of Electric Road Vehicles: Part 3: Safety Requirements, 2nd ed. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2022; p. 201.

- IEC 62133-2; Secondary Cells and Batteries Containing Alkaline or Other non-Acid Electrolytes-Safety Requirements for Portable Sealed Secondary Cells, and for Batteries made from Them, for Use in Portable Applications: Part 2: Lithium Systems, 1st ed. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2021.

- ISO 12405-4; Electrically Propelled Road Vehicles–Test Specification for Lithium-Ion Traction Battery Packs and Systems: Part 4: Performance Testing, 1st ed. International Organization for Standardization (ISO): Geneva, Switzerland, 2018.

- Zeng, Y.; Wu, K.; Wang, D.; Wang, Z.; Chen, L. Overcharge investigation of lithium-ion polymer batteries. J. Power Sources 2006, 160, 1302–1307. [Google Scholar] [CrossRef]

- Juarez-Robles, D.; Vyas, A.A.; Fear, C.; Jeevarajan, J.A.; Mukherjee, P.P. Overcharge and Aging Analytics of Li-Ion Cells. J. Electrochem. Soc. 2020, 167, 90547. [Google Scholar] [CrossRef]

- Chen, Z.; Qin, Y.; Amine, K. Redox shuttles for safer lithium-ion batteries. Electrochim. Acta 2009, 54, 5605–5613. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, J.; Sun, Z.; Wang, L.; Xu, R.; Li, M.; Chen, Z. A comprehensive review of battery modeling and state estimation approaches for advanced battery management systems. Renew. Sustain. Energy Rev. 2020, 131, 110015. [Google Scholar] [CrossRef]

- Xiong, R.; Li, L.; Tian, J. Towards a smarter battery management system: A critical review on battery state of health monitoring methods. J. Power Sources 2018, 405, 18–29. [Google Scholar] [CrossRef]

- Larsson, F.; Mellander, B.-E. Abuse by External Heating, Overcharge and Short Circuiting of Commercial Lithium-Ion Battery Cells. J. Electrochem. Soc. 2014, 161, A1611–A1617. [Google Scholar] [CrossRef]

- Sauer, D.U. Grundlagen der Impedanspektroskopie für die Charakterisierung von Batterien. Tech. Mitt. 2006, 99, 74–80. [Google Scholar]

- Kriston, A.; Pfrang, A.; Döring, H.; Fritsch, B.; Ruiz, V.; Adanouj, I.; Kosmidou, T.; Ungeheuer, J.; Boon-Brett, L. External short circuit performance of Graphite-LiNi1/3Co1/3Mn1/3O2 and Graphite-LiNi0.8Co0.15Al0.05O2 cells at different external resistances. J. Power Sources 2017, 361, 170–181. [Google Scholar] [CrossRef]

- Diekmann, J.; Kwade, A. Recycling of Lithium-Ion Batteries: The LithoRec Way; Springer: Braunschweig, Germany, 2017. [Google Scholar]

- Lv, S.; Wang, X.; Lu, W.; Zhang, J.; Ni, H. The Influence of Temperature on the Capacity of Lithium Ion Batteries with Different Anodes. Energies 2022, 15, 60. [Google Scholar] [CrossRef]

| Standard | Application |

|---|---|

| IEC 62660-2 | Electric vehicles- Abuse test |

| IEC 62660-3 | Electric vehicles- Safety tests |

| ISO 12405-2 | Electric Vehicles- High Energy Applications |

| IEC 62133-2 | Use in portable devices |

| Standard | SoC | Charging Current | Ambient Temperature | Termination Criteria | Failure Criteria |

|---|---|---|---|---|---|

| IEC 62660-2 | 100% | Agreement with manufacturer | 20 °C | Agreement with manufacturer | Fire and/or explosion |

| IEC 62660-3 | 100% | 1 C | 20 °C | 120% voltage 130% capacity | |

| ISO 12405-2 | 100% | 1 C | 20 °C | 130% voltage 55 °C | |

| IEC 62133-2 | 0% | 2 C | 20 °C | 140% voltage |

| Standard | SoC | Short-Circuit Resistor | Ambient Temperature | Termination Criteria | Failure Criteria |

|---|---|---|---|---|---|

| IEC 62660-2 | 100% | <5 mΩ | 20 °C | 10 min | Fire and/or explosion |

| IEC 62660-3 | 100% | <5 mΩ | 20 °C | 10 min | |

| ISO 12405-2 | 100% | 20 mΩ (−10 mΩ) | 20 °C | 10 min | |

| IEC 62133-2 | 100% | 80 mΩ ± 20 mΩ | 55 °C ± 5 °C | 24 h |

| Item | Value |

|---|---|

| Cell chemistry | NMC |

| Cell capacity | 5 Ah |

| Voltage range | 2.7–4.2 V |

| Maximum discharge current | 25 A |

| Maximum charging current | 10 A |

| Cell weight | 120 g |

| Cell dimensions | Length: 102 mm |

| Width: 107 mm | |

| Thickness: 5.9 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stein, A.; Kehl, D.; Jackmann, C.; Essmann, S.; Lienesch, F.; Kurrat, M. Thermal Electrical Tests for Battery Safety Standardization. Energies 2022, 15, 7930. https://doi.org/10.3390/en15217930

Stein A, Kehl D, Jackmann C, Essmann S, Lienesch F, Kurrat M. Thermal Electrical Tests for Battery Safety Standardization. Energies. 2022; 15(21):7930. https://doi.org/10.3390/en15217930

Chicago/Turabian StyleStein, Annika, Daniel Kehl, Cedric Jackmann, Stefan Essmann, Frank Lienesch, and Michael Kurrat. 2022. "Thermal Electrical Tests for Battery Safety Standardization" Energies 15, no. 21: 7930. https://doi.org/10.3390/en15217930

APA StyleStein, A., Kehl, D., Jackmann, C., Essmann, S., Lienesch, F., & Kurrat, M. (2022). Thermal Electrical Tests for Battery Safety Standardization. Energies, 15(21), 7930. https://doi.org/10.3390/en15217930