1. Introduction

Coal is the main energy source in China. According to the preliminary calculation of the National Bureau of Statistics, coal consumption increased by 0.6% in 2020. Furthermore, coal provides 56.8% of the total energy supply in China. Coal consumption is expected to dominate China’s energy system, and the use of fossil energy will remain unchanged for many years. Coal will remain the country’s main energy source, closely related to national economic performance and energy security. However, after more than ten years of sustained and rapid development, the coal industry has many problems, such as backward mining technology, depth of deposits, large production systems, a harsh operating environment, severe ecological damage, severe aging of personnel, talent shortage, and low automation. Under China’s strategic “carbon neutrality” objectives, the coal industry should transform from extensive conventional development to high-quality development to coordinate the relationship between social development and carbon emission reduction. The transformation and upgrade of intelligent coal mining are critical to efficient coal production and the development of a high-quality coal industry [

1,

2]. Ventilation is a crucial aspect of intelligent mine construction [

3,

4].

An underground ventilation system provides fresh air and removes hazardous dust and gases to ensure safe and efficient production. However, with the increased complexity of ventilation networks, ensuring safe and economical ventilation systems becomes difficult [

5,

6,

7,

8,

9]. The total energy consumption of ventilation increases to 25–60% of the total energy consumption [

10,

11,

12,

13], and insufficient air volume in the location that requires air can result in casualties [

14]. Therefore, developing a novel intelligent decision-making algorithm has received considerable attention. An intelligent decision-making algorithm with high precision and rapid convergence can quickly provide the optimal control scheme when the air volume is insufficient at the location where the air is required and eliminate the safety risks of toxic and harmful gas diffusion and human suffocation in a timely manner. Intelligent decision-making algorithms use multiple air windows in the ventilation network to optimize the ventilation system [

15,

16,

17,

18].

The conventional decision-making methods for mine ventilation can be categorized into three categories:

Methods based on graph theory, such as the loop method and path method [

19,

20,

21,

22];

Methods based on nonlinear mathematical programming, such as the Lagrange multiplier method or unconstrained optimization by constructing a penalty function, and solving by Newton and quasi-Newton methods [

23,

24,

25,

26];

Methods based on evolutionary calculation [

27,

28,

29,

30,

31,

32].

The above methods have unique advantages and disadvantages. Each method exhibits unique advantages and disadvantages. Although graph theory solution methods require technicians, the adjustment effect cannot satisfy the optimal total air resistance value in the mine when the resistance changes. Continuous adjustment is required until certain criteria are satisfied. Ventilation power consumption is a critical consideration [

33,

34,

35]. However, only the target air volume is considered in such methods, and the ventilation power consumption is ignored. The mathematical programming solution should only set the optimization objectives and constraints that can be calculated. However, with the increasing complexity of the ventilation system and high-dimensional problems, this method cannot ensure convergence to global optimization or computational efficiency. Therefore, constructing a penalty function that accurately satisfies constraints, such as the node air volume balance and loop air pressure balance, should be considered. With the development of evolutionary computing, intelligent algorithms such as the genetic algorithm, simulated annealing algorithm and particle swarm optimization algorithm are used in mine ventilation; however, the decision-making efficiency and accuracy of large-scale networks are low. Thus, these methods cannot be applied in practice. With intelligent ventilation attracting considerable attention, optimality and speed of intelligent decision-making theory have become critical parameters, which makes studying an efficient intelligent decision-making algorithm crucial.

In this study, a novel decision-making algorithm was proposed to improve safety and reliability and reduce the energy consumption of the mine ventilation system. The objective function was constructed based on the economy and safety target for a ventilation system. The evolutionary bare-bones particle swarm optimization (BBPSO) algorithm was proposed to solve problems associated with a parallel computing architecture. Three strategies were proposed to improve intelligent decision-making for effectively realizing the key problem of fast global optimization decision-making in a large-scale ventilation system.

2. Mathematical Model

Particle swarm optimization (PSO) [

36] is an evolutionary computing technology proposed by Eberhart and Kennedy in 1995, Kennedy subsequently improved the algorithm and proposed BBPSO [

37]. To understand the BBPSO algorithm, PSO is first detailed.

2.1. Mathematical Model of PSO

PSO is an optimization algorithm based on group information sharing and is derived from simulating the foraging behavior of birds. Each particle in the algorithm is a solution in the solution space, which constantly updates its position and speed according to the group experience and the individual cognitive optimization process of searching for the optimal solution in a multi-dimensional space.

The algorithm flow is as follows: initialize the population of size

s living in the

D-dimensional space, and each particle has a random birth point position

Xi(0) and initialization speed

Vi(0) as follows:

The fitness value of each particle is calculated according to the population fitness function. After the t-th search, the optimal position searched by particle Xi is pi(t), and the optimal position searched by all particles in the population is pg(t).

The individual optimal adaptation value obtained by each search and the global optimal fitness value of the population update the speed and position of the next particle as follows:

where

w is the inertia weight,

c1 and

c2 are the learning weights of particles and populations, respectively, and

rand1 and

rand2 are random numbers uniformly distributed from 0 to 1.

2.2. Mathematical Model of BBPSO

In the follow-up study, Clerc and Kennedy analyzed the motion trajectories of particles and revealed that the direction of travel of particles oscillated around the direction of the weighted average of

pg and

pi. The proposed BBPSO algorithm is based on this method. Parameters, such as velocity term, inertia weight, and learning factors, are removed based on the PSO algorithm. Only Gaussian sampling was used to update the particle position, simplifying the complex parameter adjustment process and exhibits a stronger ability for random searching. The equation for updating BBPSO particles is as follows:

The center of the particle’s optimal position pi and the population’s optimal position pg determines the sampling center, and the distance between pi and pg determines the size of the sampling confidence interval. During the search process, the particles are likely to move toward the center position μi of pi and pg, and are in the α = 0.05 confidence interval of [μ − 1.96σ, μ + 1.96σ]. As the distance between pi and pg reduces, the sampling confidence interval also reduces. This characteristic attracts all particles to the vicinity of pg in the later search stage, which improves optimization accuracy.

3. Intelligent Decision Objectives and Constraints

3.1. Objective Function

The minimal ventilation power consumption (economy target) and the maximal air demand (safety target) are the two most critical economy and safety indicators of the ventilation system. Considering that the values of various dimensions cannot be added directly, the following standardized objective function is constructed:

where

is the objective function;

ω is the weight of the ventilation power consumption term, 0 <

ω < 1;

k is the number of fans;

qif is the fan air volume, in m

3/s,

is the fan pressure-characteristic equation;

is the fan power-characteristic equation;

ε is a minimum value that avoids the denominator being 0;

l is the number of wind locations;

qis is the supplied air volume at the location where air is required, m

3/s;

qil is the lower limit of the air volume at the location at where air is required,

qiu is the upper limit of the air volume at the location where air is required, m

3/s;

qir is the required air volume at the location where air is required, m

3/s.

3.2. Penalty Function

In the penalty function, a penalty is added to the infeasible solution, which forces the particle swarm to move toward the feasible solution. The penalty function must satisfy two conditions:

The search of particles should depend on the particle’s optimal value and the population’s optimal value. Therefore, the penalty function cannot be constructed by using a simple truncation method, and the penalty value should have a gradient;

The penalty value should be standardized.

Therefore, for each penalty item that is not in the reasonable interval, the distance is calculated between the penalty item and the center of the reasonable interval. Then the distance is introduced into the deformed tanh function, as in Equation (7), with the function image displayed in

Figure 1. The final penalty value of each item is in the (1, 2) range, a penalty gradient exists, and the number of penalty items can be approximated numerically for the algorithm to search the position conveniently with fewer penalty items as follows:

The fan operating conditions, air volume supplied at locations where air is required, wind speed, and direction are critical economy and safety indicators and are the penalty items for inspection and calculation:

- (1)

The penalty item of fan working condition is as follows:

where

qf is the fan’s operating air volume, in m

3/s;

qfu and

qfl are defined as the upper and lower air volume limits of fan, respectively, in m

3/s; the denominator is the standardized parameter for unifying the standardized magnitude scale;

dis1 is the distance between the fan working condition and the center of the reasonable operating range of the fan; and

pnl1 is the standardized fan item penalty value.

- (2)

The penalty item of supplied air volume at the location where air is required.

where

qis is the supplied air volume of the location

i where air is required, in m

3/s;

qiu and

qil are the upper and lower limits of the air volume at the location where air is required, respectively, in m

3/s;

qir is the demanded air volume at the location where air is required, in m

3/s.

dis2 is the distance between the supplied air volume of roadway

i and the center of the reasonable air demand range;

pnl2 is the standardized penalty value of air demand.

- (3)

The penalty items for checking the wind speed and wind direction of the roadway are as follows:

where

qi is the air volume of the roadway

i,

qiu and

qil are the upper and lower limits of the roadway air volume, respectively, in m

3/s;

dis3 is the distance between the air volume of the roadway

i and the center of the reasonable air volume range;

κ is the weight coefficient of the roadway, which is related to roadway type; and

pnl3 is the penalty item for wind speed checking.

3.3. Particle Construction Method

The objective function’s unknowns include the air window’s wind resistance to be adjusted and the air volume of all roadways. If the particles are constructed by the method of “wind resistance plus air volume”, in addition to the aforementioned penalty function, constraining and punishing the particles that do not satisfy the law of air volume balance and air pressure balance is critical. For large-scale ventilation systems, the dimension of the air volume parameter is high. Irrespective of the method used to construct the penalty function, the particles that satisfy the constraints are extremely rare in the whole high-dimensional search space. Therefore, satisfying the constraints accurately and achieving engineering precision is difficult. With the increase in the objective function’s dimension, the solution’s time complexity increases nonlinearly, and the decision-making efficiency of large-scale ventilation systems is extremely low. Therefore, the air volume parameters do not contribute to the construction of particles, and only “wind resistance” is used to construct particles, and the entire air volume is obtained through network calculation. Thus, the dimensions of the search space are considerably reduced, which improves accurate convergence and reduces the algorithm’s time complexity.

- (1)

Selection of the air window to be adjusted

The air window to be adjusted is selected according to the sensitivity of the air window roadway to the target location that requires air. When the target air volume is insufficient, the positive sensitivity (dij > 0, see Equation (16)) air window is adjusted. When the air volume of the target location required exceeds the limit, the negative sensitivity (dij < 0, see Equation (16)) air window is adjusted. In mines, multiple target locations that require air generally exist, and the sensor collects data to determine the required air volume and current air volume of the target location. According to the air volume adjustment, the sensitivity data calculated and stored in advance is used to calculate the appropriate air window combination to realize the multi-window linkage control of the ventilation system.

The sensitivity of the current state of the air window cannot accurately represent its adjustability. Therefore, the method of selecting five points in the sensitivity attenuation and considering the average value is used to represent the adjustability of the air window. The range of the attenuation area is related to the order of magnitude of the wind resistance of the adjacent roadway and is generally 10−4–101. The sensitivity is described later in the trans-border particle processing method.

- (2)

The mass flow network solution algorithm is used to solve the air volume iteratively.

For any circuit in the ventilation network, the following equilibrium law exists:

where

αi is the direction of roadway

i in the loop, clockwise is positive, and counterclockwise is negative;

ri0 is the standard wind resistance of roadway

i, N·s

2·m

−8;

ρ0 is the standard air density of roadway

i, in m

3/kg;

ρi is the air density of roadway

i, in m

3/kg;

hif is the fan pressure of roadway

i, Pa;

hia is the additional resistance of roadway

i.

The balance equation at the approximate point

qim(

k) of the

k-th iteration is expanded, and the expansion terms of the second-order and above are omitted to obtain the following formula:

The aforementioned formula is transformed, and to avoid nonconvergence, the denominator term is scaled to obtain the following formula:

The air volume is obtained by an iterative structure sequence.

4. Global Optimization Improvement Strategy

In the late searching period, the clustering characteristic of BBPSO improves the accuracy of the convergence solution. However, in the early searching period, this feature is not conducive to forming population diversity, and the algorithm may fall into premature convergence because of insufficient sampling. To enable the BBPSO to search for the optimal global solution, three aspects, namely the contraction factor, initial value, and the trans-border particles, are optimized.

4.1. Contraction Factor

A contraction factor is added to the variance of Gaussian sampling

σ, and the range of the contraction factor is mapped to the interval [

ξu,

ξl]. A large contraction factor in the early searching period can expand population diversity. With the epochs increasing, the contraction factor at the late searching period gradually decreases, which improves local optimization and resolves accuracy. The calculation formula of the contraction factor is as follows:

where

ξ is the contraction factor;

ξu and

ξl, are its upper and lower limits, respectively; in this paper, the values are 1.3 and 0.8; max

t is the maximum number of epochs; and

t is the number of epochs.

4.2. Optimized Initial Value

The quality of the initial particle value is a factor that considerably affects the algorithm’s convergence to the optimal global solution. The initial particle value is optimized from the perspective of ventilation system sensitivity [

38].

Sensitivity

dij is defined by the change rate of the air volume in roadway

j caused by a slight change of wind resistance in roadway

i as follows:

Furthermore,

tij is defined as the rate of change of sensitivity

dij:

Sensitivity can reflect the change of effective air volume caused by unit wind resistance adjustment, and the search efficiency in the high sensitivity area is higher than that in the low sensitivity area.

Figure 2 shows the sensitivity curve of roadway e

17 to roadway e

43 and the sensitivity attenuation rate in the calculation example in this paper. In low wind resistance areas, the sensitivity of the roadway is high, and the attenuation rate is also high. Any change in wind resistance considerably influences the air volume of the roadway. With the increase in the wind resistance, the sensitivity decreases to near 0 and remains flat, and the change of wind resistance has a limited influence on the air volume of the roadway. The region with high sensitivity and high attenuation rate occupies a small proportion of the entire search domain, but the search efficiency is high. Several valid points remain in the low-sensitivity region, which also requires allocating a small number of search resources.

In the conventional particle swarm initialization method, generally, uniform sampling is adopted in the search interval. However, this resource allocation method is not reasonable for the wind resistance parameters with variations in orders of magnitude. The high sensitivity interval is generally the wind resistance interval [0, 1], which only accounts for 0.2% of the entire search domain. In contrast, the low sensitivity interval is generally the wind resistance interval [1, 500], which accounts for 99.8% of the search domain. The probability of uniformly sampled initial particles falling into the high sensitivity interval [0, 1] is considerably smaller than that of falling into the low sensitivity interval [1, 500]. Thus, the most effective points would be missed, which could waste computing resources, resulting in low convergence efficiency or failure to converge to the optimal global value.

The problem of sampling deviation can be solved by changing the linear coordinate axis

r of the wind resistance to uniformly distributed sampling on the logarithm axis log

10(

r) and subsequently mapping back to the linear coordinate system when constructing particles.

Figure 3 shows the sensitivity curve and its attenuation rate on the logarithmic axis and the simulated sampling points on the logarithmic axis. The high sensitivity region is in the (−6–0) range on the logarithmic axis, and the low sensitivity region is in the (0–2.7) range on the logarithmic axis. The sensitivity to the logarithmic axis can force each order of the magnitude interval to allocate identical computing resources, whereas uniform sampling allocates more resources to the high-sensitivity region. The low sensitivity region is then considered to ensure a certain search power to effectively improve the algorithm’s computational efficiency and global optimization ability.

4.3. Processing of Trans-Border Particles

In the early searching period, the optimal particle value is far from the optimal population value, and particles exceed the boundary of the search domain during Gaussian sampling. In the conventional processing method, the trans-border particles are drawn back to the boundary of the search domain. However, this processing method exhibits two disadvantages. First, the particles at the boundary of the search domain are not the optimal solution to the target problem, especially for the complex ventilation system optimization problem; drawing back to the boundary results in waste computing resources. Second, simply drawing the trans-border particles back to the boundary of the search domain results in a loss of population diversity and omission of key information, leading the algorithm to converge on the optimal local solution. The correct processing of trans-border particles can affect the convergence trend of the particle swarm. The information of the trans-border particles should be maximally preserved to avoid wasting computing resources and expand the population diversity, which is conducive to global optimization.

Therefore, the strategy is formulated to improve population diversity for global optimization in the early stage and improve local search ability and accuracy in the subsequent stage. In the early search stage, the birth point of the particle is regenerated, and the parameters of the trans-border dimension of the particle are re-initialized and sampled in the search domain of this dimension. This method of addressing trans-border particles can improve population diversity without wasting resources. However, re-initializing the particle birth point in the subsequent search stage is not conducive to clustering the particle swarm. The elastic mirror boundary strategy [

39] was introduced to draw the trans-border particles from (±∞,

xib) to (

xib,

μ), and the corrected particle position is determined by the following formula:

where

i is the trans-border dimension;

is the modified position of the trans-border particle;

μi is the search center of dimension

i;

xib is the boundary dimension

i; and

is the position of the trans-border particle.

Figure 4 shows a schematic of the elastic mirror mechanism for handling trans-border particles. The 95% confidence range determined by the search center

μi is likely to fall outside the boundary, and the particle is out of bounds in the

D1 dimension. According to Equation (18), the greater the over-border distance of the particle is, the closer its corrected position is to the search center; when the particle trans-border distance is not large, the corrected position is near the boundary. This strategy maximally preserves its original characteristics while expanding the diversity of the population.

5. Intelligent Decision Architecture and Process for Large Ventilation Systems

5.1. Parallel Computing Architecture

As the serial calculation of the BBPSO algorithm proceeds, the fitness of all particles is calculated at each epoch. The convergence time of the algorithm increases nonlinearly as the network size and particle number increase. The complexity of BBPSO is determined by combinations of multiple factors, such as scale, dimension, and whether multiple objectives, multiple fans, or air windows with positive and negative sensitivity exist. The algorithm cannot converge rapidly because of the small feasible region and multiple peaks, which considerably reduces intelligent decision-making on the application efficiency of large-scale ventilation networks.

A parallel computing architecture for large ventilation networks is designed based on a parallel computing pool and shared memory technology, as shown in

Figure 5. The architecture consists of a particle layer, a computing layer, and a sharing layer. The particle layer typically undertakes various processes, each containing several particles as its basic unit. The particle swarm processes do not directly communicate with each other, and this layer stores the current position and optimal position of the particles of the entire particle swarm. The computing layer connects the particle layer and the sharing layer, collects information from the sharing layer and the particle layer, realizes the data exchange and high-speed parallel computing between the two layers, and feeds back better calculation results to the particle layer and the sharing layer. The sharing layer updates the optimal population value and the optimal fitness. The layer is the shared memory between multiple processes, and a process lock ensures the security of inter-process communication. Only one process can use the shared memory at a time. The parallel computing architecture can be deployed on elastic cloud servers for high-speed decision computing based on server load balancing.

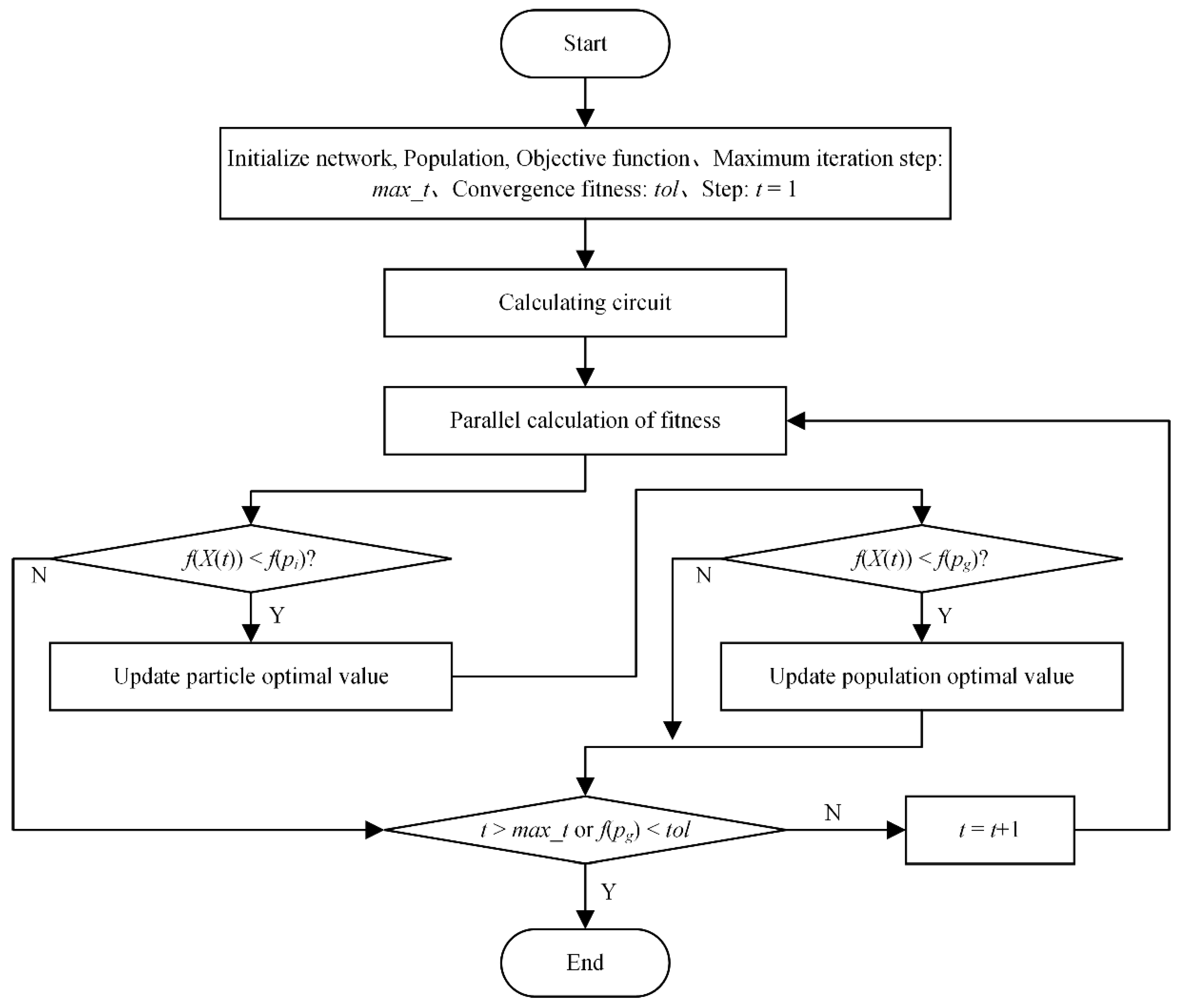

5.2. Intelligent Decision Application Process

The application process of the complete intelligent decision algorithm that is based on parallel architecture is further described in

Figure 6. The flow is described as follows:

Step 1: Initialize the ventilation system data, generate the population, generate the objective function, and use the field data collected by the sensor to generate the decision target, as well as other calculation parameters such as the maximum epochs and convergence fitness, go to Step 2;

Step 2: Because the loop does not require multiple repeated calculations, it is calculated according to the ventilation network data for particle fitness, go to Step 3;

Step 3: According to the particle position and objective function, calculate the fitness of each particle in parallel, go to Step 4;

Step 4: Determine whether the particle fitness is better than the current optimal particle fitness. If it is better, update the optimal particle fitness and go to Step 5; Otherwise, go to Step 6.

Step 5: Determine whether the particle fitness is better than the optimal population fitness. If it is better, then the optimal fitness of the population is updated, and go to Step 6.

Step 6: Determine whether the maximum number of evolutionary epochs is reached or the fitness is allowed. If so, end and output the optimal particle position; if not, go to Step 3 to enter the next round of calculation.

6. Calculation Example

Figure 7 shows a mine ventilation system with 189 roadways, 149 nodes, 1 main fan, 3 intake air shafts, and 2 mining faces. The red position is the target air-requiring location, and the blue position is the adjustable air window. Through the adjustment of the air window, the air volume at the target air-requiring location can confirm the standard while considering the fan’s safety and power consumption. The intelligent decision is calculated based on the real mine data. To facilitate visualization, in this example, only two locations (e

17, e

36) that require air as the targets are selected for optimization. Two positive sensitivity air windows (e

43, e

171) are selected for adjustment.

Five methods are used to solve the decision-making problem for the ventilation system in

Figure 7, including:

Parallel bare-bones particle swarm optimization algorithm with the strategy improved in this paper (BBPSO-Para-Improved);

Serial bare-bones particle swarm optimization algorithm with improved strategies (BBPSO-Seri-Improved);

Parallel bare-bones particle swarm optimization without improved strategies (BBPSO-Para);

Serial particle swarm optimization (PSO-Seri);

Serial genetic algorithm (GA-Seri).

A total of 18 clusters of calculations were conducted. Here, ω is 0.5, which can ensure the robustness of the decision scheme. When ω is close to 0 or 1, the algorithm is unstable. The ventilation disturbances may cause the decision to meet safety standards no longer. The particle number is set to 10, max t is set to 300 and tol is set to 0 to ensure that each algorithm completes 300 calculation epochs.

Figure 8 shows the fitness contour and particle trajectory. The scope of the graph is a two-dimensional search domain. For better presentation, the linear axes are replaced by the logarithm axes, representing the logarithm of air window resistance. The blue region is the feasible region, and the red region is the infeasible region. The actual area of the feasible region is considerably smaller than the display area. After sampling statistics, the feasible domain in this example only accounts for approximately 2.19% of the search domain. Particles are randomly generated in the search domain, and particles aim to search the optimal value in the feasible domain. The particle swarm cooperatively completes the optimization through the iterative evolution of the population. The search process changes the position of the particles in the search domain, and each position corresponds to the control scheme of air window resistance. When the particle swarm finds the optimal value, the optimal position can be derived and transformed into the optimal control scheme. In the figure, the star represents the optimal population value, the arrow vector represents the particle, and the direction points to the sampling center of the optimal particle value and the optimal population value. Several particles are closely adjacent, overlapping, and marked by boxes in the figure.

When iteration begins, the particle distribution is dispersed. When iteration continues, the optimal value of the population is constantly updated. All particles gravitate to the center of the particle’s optimal value and the population’s optimal value and cluster around the optimal global value. The improvement to the optimization strategy proposed in this study allows the feasible region to be entered in fewer epochs, and the optimal global value can be searched in approximately 30 epochs.

Figure 9 shows the fitness curves of the five methods. The points in the figure represent the mean, and the strips represent the standard deviation. BBPSO-Para-Improved and BBPSO-Seri-Improved quickly searched toward the feasible region and determined the optimal global solution due to the rational optimization strategy and the rapid fitness decline. Because of the shared memory and process lock mechanisms, the search efficiency of parallel computing is approximately equivalent to serial computing. However, the search time for parallel computing is considerably less. BBPSO-Para is not optimized by strategy and requires more epochs than BBPSO-Para-Improved does. However, the method is generally superior to PSO and GA algorithms. For PSO-Seri, as the iteration progresses, the optimal particle and the optimal population values gradually approach, the search range reduces, and premature convergence can easily occur. The GA-Seri algorithm exhibits poor search efficiency and an extended iteration cycle because GA is more inclined to natural selection, and the population does not exhibit the directionality of independent selection, which results in achieving slow convergence and high precision difficult in fewer epochs.

Table 1 details the performance of five algorithms, including the average calculation time, the average convergence epochs (nonconvergence is calculated according to the maximum epoch number of 300), and average convergence rate. When the fitness is less than 0.65, the method converges to the optimal global solution. The improved BBPSO algorithm exhibited a stronger global optimization ability and converged on the optimal global solution quickly and efficiently. Thus, parallel computing considerably reduces the solving time and efficiency. The larger the scale of the ventilation system is, the higher the proportion of time consumed by inter-process communication than solving for small ventilation systems.

7. Conclusions

A mine ventilation intelligent decision-making algorithm based on BBPSO was developed to overcome the problems of low accuracies and slow speeds of conventional decision-making algorithms. Based on safety and economic factors, the objective function was constructed, and three constraints were imposed on the fan-working-condition value, the air-required value, and the wind-speed value. The improved strategies were developed based on three aspects: the contraction factor, optimized initial value, and processing of trans-bounder particles. The algorithm’s parallel computing architecture and engineering application flow were studied to improve efficiency and real-time responses when applied to the decision-making problem of large-scale mine ventilation systems. The simulation experiments were carried out on a real mine ventilation system. The results revealed that the proposed method exhibited better convergence accuracy and efficiency than other intelligent decision-making algorithms, resulting in more accurate and efficient decision-making for intelligent mine ventilation.

However, the effect of data error on decision accuracy should also be considered in real-world applications. Real ventilation systems in extensive ventilation regions are characterized by the possibility of many disturbances and synergistic effects of factors related to the ventilation of mine workings, which may cause disturbances in the operation of the algorithm and requires further research. For future work, we will focus on improving the algorithm’s robustness to run reliably in industrial scenarios.

Author Contributions

Conceptualization, J.L.; methodology, J.L.; software, J.L.; validation, J.L.; formal analysis, Y.L.; investigation, W.Z. and J.D.; resources, Y.L.; data curation, J.D. and Y.C.; writing—original draft preparation, J.L.; writing—review and editing, J.L.; visualization, J.L.; supervision, Y.L.; project administration, Y.L.; funding acquisition, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Acknowledgments

We thank all the cited authors in the reference list, whose excellent research has formed the basis of this study.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| X | Position of particle |

| V | Velocity of particle (PSO) |

| w, c | Weights (PSO) |

| rand | Random number |

| N | Normal distribution |

| pi | Optimal position of particle i |

| pg | Optimal position of population |

| Objective function |

| ω | Weight of the ventilation power |

| qif | Fan air volume |

| qis | Supplied air volume |

| qiu | Upper limit of the air volume |

| qil | Lower limit of the air volume |

| Fan pressure-characteristic equation |

| Fan power-characteristic equation |

| Deformed tanh function |

| dis | Distance |

| pnl | Penalty value |

| qfu | Upper air volume limits of fan |

| qfl | Lower air volume limits of fan |

| α | Direction of roadway |

| r | Resistance of roadway |

| ρ | Air density of roadway |

| ξ | Contraction factor |

| dij | Sensitivity |

| tij | Rate of change of sensitivity |

References

- Wang, G.; Wang, H.; Ren, H. Others 2025 Scenarios and Development Path of Intelligent Coal Mine. J. China Coal Soc. 2018, 43, 295–305. [Google Scholar]

- Wang, G.; Liu, F.; Pang, Y.; Ren, H.; Ma, Y. Coal Mine Intellectualization: The Core Technology of High Quality Development. J. China Coal Soc. 2019, 44, 349–357. [Google Scholar] [CrossRef]

- Zhou, F.; Wei, L.; Xia, T. Others Principle, Key Technology and Preliminary Realization of Mine Intelligent Ventilation. J. China Coal Soc. 2020, 45, 2225–2235. [Google Scholar]

- Li, J.; Li, Y.; Zhang, J.; Li, B.; Zhang, Z.; Dong, J.; Cui, Y. Accurate and Real-Time Network Calculation for Mine Ventilation without Wind Resistance Measurement. J. Wind. Eng. Ind. Aerodyn. 2022, 230, 105183. [Google Scholar] [CrossRef]

- Semin, M.A.; Levin, L.Y. Stability of Air Flows in Mine Ventilation Networks. Process Saf. Environ. Prot. 2019, 124, 167–171. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, S.; Ma, X.; Wu, Z.; Zhang, W.; Shao, H. Study of the Destruction of Ventilation Systems in Coal Mines Due to Gas Explosions. Powder Technol. 2015, 286, 401–411. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, X.; Wang, L.; Li, L.; Zhang, M.; Zhou, A. Experimental Study on Propagation Law of Shock Wave and Airflow Induced by Coal and Gas Outburst in Mine Ventilation Network. Process Saf. Environ. Prot. 2021, 151, 299–310. [Google Scholar] [CrossRef]

- Zhou, A.; Wang, K.; Wu, L.; Xiao, Y. Influence of Gas Ventilation Pressure on the Stability of Airways Airflow. Int. J. Min. Sci. Technol. 2018, 28, 297–301. [Google Scholar] [CrossRef]

- Zhou, A.; Zhang, M.; Wang, K.; Elsworth, D.; Wang, J.; Fan, L. Airflow Disturbance Induced by Coal Mine Outburst Shock Waves: A Case Study of a Gas Outburst Disaster in China. Int. J. Rock Mech. Min. Sci. 2020, 128, 104262. [Google Scholar] [CrossRef]

- Du Plessis, G.E.; Liebenberg, L.; Mathews, E.H. The Use of Variable Speed Drives for Cost-Effective Energy Savings in South African Mine Cooling Systems. Appl. Energy 2013, 111, 16–27. [Google Scholar] [CrossRef]

- Ghoreishi-Madiseh, S.A.; Sasmito, A.P.; Hassani, F.P.; Amiri, L. Performance Evaluation of Large Scale Rock-Pit Seasonal Thermal Energy Storage for Application in Underground Mine Ventilation. Appl. Energy 2017, 185, 1940–1947. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. Simulation of a Novel Intermittent Ventilation System for Underground Mines. Tunn. Undergr. Space Technol. 2014, 42, 206–215. [Google Scholar] [CrossRef]

- Nel, A.J.H.; Arndt, D.C.; Vosloo, J.C.; Mathews, M.J. Achieving Energy Efficiency with Medium Voltage Variable Speed Drives for Ventilation-on-Demand in South African Mines. J. Clean. Prod. 2019, 232, 379–390. [Google Scholar] [CrossRef]

- Karacan, C.Ö. Development and Application of Reservoir Models and Artificial Neural Networks for Optimizing Ventilation Air Requirements in Development Mining of Coal Seams. Int. J. Coal Geol. 2007, 72, 221–239. [Google Scholar] [CrossRef]

- Chatterjee, A.; Zhang, L.; Xia, X. Optimization of Mine Ventilation Fan Speeds According to Ventilation on Demand and Time of Use Tariff. Appl. Energy 2015, 146, 65–73. [Google Scholar] [CrossRef] [Green Version]

- Tuck, M.; Finch, C.; Holden, J. Ventilation on Demand: A Preliminary Study for Ballarat Goldfields NL. In Proceedings of the 11th US/North American Mine Ventilation Symposium, University Park, PA, USA, 5–7 June 2006; pp. 11–14. [Google Scholar]

- Wallace, K.; Prosser, B.; Stinnette, J.D. The Practice of Mine Ventilation Engineering. Int. J. Min. Sci. Technol. 2015, 25, 165–169. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, S.; Ma, X.; Hu, L.; Wu, Z.; Shao, H.; Zhang, W.; Pei, X.; Wang, Y. An Automatic Approach for the Control of the Airflow Volume and Concentrations of Hazardous Gases in Coal Mine Galleries. J. Loss Prev. Process Ind. 2016, 43, 676–687. [Google Scholar] [CrossRef]

- Hu, W.; Longson, I. A Computer Method for the Generalized Controlled Flow Problem in Ventilation Networks. Min. Sci. Technol. 1989, 8, 153–167. [Google Scholar] [CrossRef]

- Pach, G. Optimization of Forced Air Flow by the Comparison of Positive and Negative Regulations in Mine Ventilation Network. Arch. Min. Sci. 2018, 63, 853–870. [Google Scholar]

- Wang, K.; Jiang, S.; Wu, Z.; Shao, H.; Zhang, W.; Pei, X.; Cui, C. Intelligent Safety Adjustment of Branch Airflow Volume during Ventilation-on-Demand Changes in Coal Mines. Process Saf. Environ. Prot. 2017, 111, 491–506. [Google Scholar] [CrossRef]

- Xu, R.; Shi, S. The Path Method of the Regulation of Air Quantity of in the Mine Ventilation Network. J. Fuxin Min. Inst. 1984, 3, 21–30. [Google Scholar]

- Hu, W.; Longson, I. The Optimization of Airflow Distribution in Ventilation Networks Using a Nonlinear Programming Method. Min. Sci. Technol. 1990, 10, 209–219. [Google Scholar] [CrossRef]

- Huang, Y.; Li, H.-S. Solution of Problems Relevant to Optimal Control of Mine Ventilation Network by Non-Linear Programming Technique. J. China Coal Soc. 1995, 20, 14–19. [Google Scholar]

- Li, B.-R.; Inoue, M.; Shen, S.-B. Mine Ventilation Network Optimization Based on Airflow Asymptotic Calculation Method. J. Min. Sci. 2018, 54, 99–110. [Google Scholar] [CrossRef]

- Nyaaba, W.; Frimpong, S.; El-Nagdy, K.A. Optimisation of Mine Ventilation Networks Using the Lagrangian Algorithm for Equality Constraints. Int. J. Min. Reclam. Environ. 2015, 29, 201–212. [Google Scholar] [CrossRef]

- Chen, K.; Si, J.; Zhou, F.; Zhang, R.; Shao, H.; Zhao, H. Optimization of Air Quantity Regulation in Mine Ventilation Networks Using the Improved Differential Evolution Algorithm and Critical Path Method. Int. J. Min. Sci. Technol. 2015, 25, 79–84. [Google Scholar] [CrossRef]

- Jia, P.; Jia, J.; Song, L.; Li, Z.; Li, B. Theory of RPOD Adjustment of Air Volume for Mine Intelligent Ventilation. Int. J. Vent. 2021, 1–14. [Google Scholar] [CrossRef]

- Li, J.; Chen, K.; Lin, B. Genetic Algorithm for the Optimization of Mine Ventilation Network. J. China Univ. Min. Technol. 2007, 36, 789–793. [Google Scholar]

- Lowndes, I.S.; Fogarty, T.; Yang, Z.Y. The Application of Genetic Algorithms to Optimise the Performance of a Mine Ventilation Network: The Influence of Coding Method and Population Size. Soft Comput. 2005, 9, 493–506. [Google Scholar] [CrossRef]

- Sui, J.; Yang, L.; Zhu, Z.; Fang, H.; Hua, Z. Mine Ventilation Optimization Analysis and Airflow Control Based on Harmony Annealing Search. J. Comput. 2011, 6, 1270–1277. [Google Scholar] [CrossRef]

- Wu, X.; Han, Z.; Wei, L.; Zuo, Y.; Xu, J.; Li, A. Intelligent on-demand adjustment algorithm and key technology of mine air flow. J. China Univ. Min. Technol. 2021, 50, 725–734. [Google Scholar]

- Cheng, J.; Yang, S. Data Mining Applications in Evaluating Mine Ventilation System. Saf. Sci. 2012, 50, 918–922. [Google Scholar] [CrossRef]

- El-Nagdy, K.A. Stability of Multiple Fans in Mine Ventilation Networks. Int. J. Min. Sci. Technol. 2013, 23, 569–571. [Google Scholar] [CrossRef]

- Sjöström, S.; Klintenäs, E.; Johansson, P.; Nyqvist, J. Optimized Model-Based Control of Main Mine Ventilation Air Flows with Minimized Energy Consumption. Int. J. Min. Sci. Technol. 2020, 30, 533–539. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of the ICNN’95—International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; Volume 4, pp. 1942–1948. [Google Scholar]

- Kennedy, J. Bare Bones Particle Swarms. In Proceedings of the 2003 IEEE Swarm Intelligence Symposium, SIS’03 (Cat. No.03EX706), Indianapolis, IN, USA, 26 April 2003; pp. 80–87. [Google Scholar]

- Jia, J.; Jia, P.; Li, Z. Theoretical Study on Stability of Mine Ventilation Network Based on Sensitivity Analysis. Energy Sci. Eng. 2020, 8, 2823–2830. [Google Scholar] [CrossRef]

- Wang, D.-F.; Meng, L.; Zhao, W.-J. Improved bare bones particle swarm optimization with adaptive search center. Chin. J. Comput. 2016, 39, 2652–2667. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).