Impact of Hydrogen on Natural Gas Compositions to Meet Engine Gas Quality Requirements

Abstract

:1. Introduction

2. Gas Compositions

3. Materials and Methods

3.1. Calculation of Thermodynamic Properties

3.2. Calculation of the Methane Number

3.3. Calculation of the Average Gas Composition

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hermesmann, M.; Muller, T.E. Green, Turquoise, Blue, or Grey? Environmentally friendly Hydrogen Production in Transforming Energy Systems. Prog. Energy Combust. Sci. 2022, 90, 100996. [Google Scholar] [CrossRef]

- Gahleitner, G. Hydrogen from renewable electricity: An international review of power-to gas pilot plants for stationary applications. Int. J. Hydrogen Energy 2013, 38, 2039–2061. [Google Scholar] [CrossRef]

- Howarth, R.W.; Jacobson, M.Z. How green is blue hydrogen? Energy Sci. Eng. 2021, 9, 1676–1687. [Google Scholar] [CrossRef]

- Wang, A.; Jens, J.; Mavins, D.; Moultak, M.; Schimmel, M.; van der Leun, K.; Peters, D.; Buseman, M. Analysing Future Demand, Supply, and Transport of Hydrogen. European Hydrogen Backbone in Cooperation with Gas for Climate. 2021. Available online: https://gasforclimate2050.eu/wp-content/uploads/2021/06/EHB_Analysing-the-future-demand-supply-and-transport-of-hydrogen_June-2021_v3.pdf (accessed on 17 August 2022).

- Aziz, M.; Wijayanta, A.T.; Nandiyanto, A.B. Ammonia as Effective Hydrogen Storage: A Review on Production, Storage and Utilization. Energies 2020, 13, 3062. [Google Scholar] [CrossRef]

- Pellegrini, M.; Guzzini, A.; Saccani, C. A Preliminary Assessment of the Potential of Low Percentage Green Hydrogen Blending in the Italian Natural Gas Network. Energies 2020, 13, 5570. [Google Scholar] [CrossRef]

- Ogden, J.; Myers Jaffe, A.; Scheitrum, D.; McDonald, Z.; Miller, M. Natural gas as a bridge to hydrogen transportation fuel: Insights from the literature. Energy Policy 2018, 115, 317–329. [Google Scholar] [CrossRef]

- Kuczy’nski, S.; Łaciak, M.; Olijnyk, A.; Szurlej, A.; Włodek, T. Thermodynamic and Technical Issues of Hydrogen and Methane-Hydrogen Mixtures Pipeline Transmission. Energies 2019, 12, 569. [Google Scholar] [CrossRef] [Green Version]

- Quintino, F.M.; Nascimento, N.; Fernandes, E.C. Aspects of Hydrogen and Biomethane Introduction in Natural Gas Infrastructure and Equipment. Hydrogen 2021, 2, 301–318. [Google Scholar] [CrossRef]

- Guandalini, G.; Colbertaldo, P.; Campanari, S. Dynamic modeling of natural gas quality within transport pipelines in presence of hydrogen injections. Appl. Energy 2017, 185, 1712–1723. [Google Scholar] [CrossRef]

- Schouten, J.A.; Michels, J.P.J.; Janssen-van Rosmalen, R. Effect of H2-injection on the thermodynamic and transportation properties of natural gas. Int. J. Hydrogen Energy 2004, 29, 1173–1180. [Google Scholar] [CrossRef]

- Mahajan, D.; Tan, K.; Venkatesh, T.; Kileti, P.; Clayton, C.R. Hydrogen Blending in Gas Pipeline Networks—A Review. Energies 2022, 15, 3582. [Google Scholar] [CrossRef]

- Mayrhofer, M.; Koller, M.; Seemann, P.; Prieler, R.; Hochenauer, C. Assessment of natural gas/hydrogen blends as an alternative fuel for industrial heat treatment furnaces. Int. J. Hydrogen Energy 2021, 46, 21672–21686. [Google Scholar] [CrossRef]

- Bard, J.; Gerhardt, N.; Selzam, P.; Beil, M.; Wiemer, M.; Buddensiek, M. The Limitations of Hydrogen Blending in the European Gas Grid. Available online: https://www.iee.fraunhofer.de/content/dam/iee/energiesystemtechnik/en/documents/Studies-Reports/FINAL_FraunhoferIEE_ShortStudy_H2_Blending_EU_ECF_Jan22.pdf (accessed on 20 August 2022).

- Gondal, I.A. Hydrogen integration in power-to-gas networks. Int. J. Hydrogen Energy 2019, 44, 1803–1815. [Google Scholar] [CrossRef]

- Melaina, M.W.; Antonia, O.; Penev, M. Blending Hydrogen into Natural Gas Pipeline Networks: A Review of Key Issues; National Renewable Energy Laboratory: Golden, CO, USA, 2013. [Google Scholar] [CrossRef] [Green Version]

- Dell’Isola, M.; Ficco, G.; Moretti, L.; Perna, A.; Candelaresi, D.; Spazzafumo, G. Impact of hydrogen injection on thermophysical properties and measurement reliability in natural gas networks. E3S Web Conf. 2021, 312, 1004. [Google Scholar] [CrossRef]

- Abeysekera, M.; Wu, J.; Jenkins, N.; Rees, M. Steady state analysis of gas networks with distributed injection of alternative gas. Appl. Energy 2016, 164, 991–1002. [Google Scholar] [CrossRef] [Green Version]

- Deymi-Dashtebayaz, M.; Ebrahimi-Moghadam, A.; Pishbin, S.I.; Pourramezan, M. Investigating the effect of hydrogen injection on natural gas thermo-physical properties with various compositions. Energy 2019, 167, 235–245. [Google Scholar] [CrossRef]

- DS/EN 16726:2015+A1:2018; Gas Infrastructure—Quality of Gas—Group H. Dansk Standard: Nordhavn, Denmark, 2018.

- Latõšov, E.; Pakere, I.; Murauskaite, L.; Volkova, A. Impact of Grid Gas Requirements on Hydrogen Blending Levels. Environ. Clim. Technol. 2021, 25, 688–689. [Google Scholar] [CrossRef]

- Di Bella, G.; Flanagan, M.; Foda, K.; Maslova, S.; Pienkowski, A.; Stuermer, M.; Toscani, F. Natural Gas in Europe: The Potential Impact of Disruptions to Supply. International Monetary Fund 2022. Available online: https://www.imf.org/en/Publications/WP/Issues/2022/07/18/Natural-Gas-in-Europe-The-Potential-Impact-of-Disruptions-to-Supply-520934#:~:text=Our%20findings%20suggest%20that%20in,by%20up%20to%206%20percent (accessed on 22 August 2022).

- Zivkovic, M.; Ivic, M.; Ivezic, D.; Madzarevic, A. Effect of natural gas composition on methane number: A case of gas reservoirs in Serbia. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 2157–2165. [Google Scholar] [CrossRef]

- Kuczy’nski, S.; Łaciak, M.; Szurlej, A.; Włodek, T. Impact of Liquefied Natural Gas Composition Changes on Methane Number as a Fuel Quality Requirement. Energies 2020, 13, 5060. [Google Scholar] [CrossRef]

- Euromot, Position Paper: Revision of EU Rules on Gas Market Access—Euromot Position on Gas Quality Requirements. 2021. Available online: https://www.euromot.eu/wp-content/uploads/2021/06/EU-gas-legislation-revision_EUROMOT-position-on-gas-quality-requirements_FINAL_16-June-2021.pdf (accessed on 18 June 2022).

- De Vries, H.; Mokhov, A.V.; Levinsky, H.B. The impact of natural gas/hydrogen mixtures on the performance of end-use equipment: Interchangeability analysis for domestic appliances. Appl. Energy 2017, 208, 1007–1019. [Google Scholar] [CrossRef]

- BP, Statistical Review of World Energy 2022, 71st ed. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2022-full-report.pdf (accessed on 22 August 2022).

- Leicher, J.; Schaffert, J.; Cigarida, H.; Tali, E.; Burmeister, F.; Giese, A.; Albu, R.; Görner, K.; Carpentier, S.; Milin, P.; et al. The Impact of Hydrogen Admixture into Natural Gas on Residential and Commercial Gas Appliances. Energies 2022, 15, 777. [Google Scholar] [CrossRef]

- Baccanelli, M.; Langé, S.; Roccob, M.V.; Pellegrini, L.A.; Colombo, E. Low Temperature Techniques for Natural Gas Purification and LNG Production: An Energy and Exergy Analysis. Appl. Energy 2016, 180, 546–559. [Google Scholar] [CrossRef]

- Papadopoulo, M.; Kaddouh, S.; Pacitto, P.; Prieur Vernat, A. Life Cycle Assessment of the European Natural Gas Chain Focused on Three Environmental Impact Indicators. Marcogaz. 2011. Available online: https://www.cgoa.cz/informacezezahranici/pdfdoc/marcogazudrzitelnost/2011/WG-LCA-12-01_D023_WG_LCA_Final_Report_Life_Cycle_Assessment.pdf (accessed on 26 June 2022).

- GGTC—Natural Gas Composition. Available online: https://e-platform.ggtc.ge/gasanalisisen.aspx (accessed on 23 August 2022).

- International Group of LNG Exporters (GIIGNL), Annual Report 2018, International Group of LNG Exporters. 2018. Available online: https://giignl.org/wp-content/uploads/2021/08/rapportannuel-2018pdf.pdf (accessed on 25 June 2022).

- Euromot, Position Paper: Requirements on the Quality of Natural Gas. 2017. Available online: https://www.euromot.eu/wp-content/uploads/2018/02/EUROMOT-Position-Gas-Quality-2017-11-09-.pdf (accessed on 28 June 2022).

- DS/EN ISO 6976:2016; Natural Gas—Calculation of Calorific Values, Density, Relative Density and Wobbe Indices from Composition. Dansk Standard: Nordhavn, Denmark, 2016.

- Palmer, G. Methane Number. J. Nat. Gas Eng. 2017, 2, 134–142. [Google Scholar] [CrossRef]

- Zachariah-Wolff, J.L.; Egyedi, T.M.; Hemmes, K. From natural gas to hydrogen via the Wobbe index: The role of standardized gateways in sustainable infrastructure transitions. Int. J. Hydrogen Energy 2007, 32, 1235–1245. [Google Scholar] [CrossRef]

- Lamioni, R.; Bronzoni, C.; Folli, M.; Tognotti, L.; Galetti, C. Feeding H2-admixtures to domestic ceondensing boilers: Numerical simulations of combustion and pollutant formation in multi-hole burners. Appl. Energy 2022, 309, 118379. [Google Scholar] [CrossRef]

- Balanescu, D.T.; Homutescu, V.M. Effects of hydrogen-enriched methane combustion on latent heat recovery potential and environmental impact of condensing boilers. Appl. Therm. Eng. 2021, 197, 117477. [Google Scholar] [CrossRef]

- Roslyakov, P.V.; Rybakov, B.A.; Savitenko, M.A.; Ionkin, I.L.; Luning, B. Assessment of the Potential for Decreasing Greenhouse Gas Emissions in Burning Fuels in Boilers at Thermal-Power Plants (TPP) and Boiler House. Therm. Eng. 2022, 69, 718–726. [Google Scholar] [CrossRef]

| Origin | Methane [mol-%] | Ethane [mol-%] | Propane [mol-%] | Butane 1 [mol-%] | Higher Hydrocarbons [mol-%] | Carbon Dioxide [mol-%] | Nitrogen [mol-%] | Hydrogen Sulphide [mol-%] | Trade Movement [%] |

|---|---|---|---|---|---|---|---|---|---|

| Russia 2 | 98.79 | 0.44 | 0.10 | 0.04 | 0.03 | 0.05 | 0.55 | 0.00013 | 35.0 |

| Norway 2 | 92.64 | 5.08 | 0.89 | 0.21 | 0.06 | 0.61 | 0.52 | 0.00012 | 23.7 |

| Algeria 2 | 91.10 | 7.48 | 0.82 | 0.10 | 0.00 | 0.00 | 0.51 | 0.00013 | 7.1 |

| Azerbaijan 2 | 92.85 | 3.24 | 1.67 | 0.79 | 0.24 | 1.07 | 0.14 | 0.00 | 4.1 |

| Algeria–Skikda 3 | 91.40 | 7.35 | 0.57 | 0.05 | 0.00 | 0.00 | 0.63 | 0.00 | 1.1 |

| Algeria–Bethioua 3 | 89.55 | 8.20 | 1.30 | 0.31 | 0.00 | 0.00 | 0.64 | 0.00 | 1.1 |

| Algeria–Arzew 3 | 88.93 | 8.42 | 1.59 | 0.37 | 0.00 | 0.00 | 0.71 | 0.00 | 1.1 |

| Egypt–Idku 3 | 95.31 | 3.58 | 0.74 | 0.34 | 0.00 | 0.00 | 0.02 | 0.00 | 0.3 |

| Egypt–Damietta 3 | 97.25 | 2.49 | 0.12 | 0.12 | 0.00 | 0.00 | 0.02 | 0.00 | 0.3 |

| Nigeria 3 | 91.70 | 5.52 | 2.17 | 0.58 | 0.00 | 0.00 | 0.03 | 0.00 | 2.7 |

| Norway 3 | 92.03 | 5.75 | 1.31 | 0.45 | 0.00 | 0.00 | 0.46 | 0.00 | 0.1 |

| Peru 3 | 89.07 | 10.26 | 0.10 | 0.01 | 0.00 | 0.00 | 0.57 | 0.00 | 0.3 |

| Qatar 3 | 90.91 | 6.43 | 1.66 | 0.74 | 0.00 | 0.00 | 0.27 | 0.00 | 4.7 |

| Russia–Sakhalin 3 | 92.53 | 4.47 | 1.97 | 0.95 | 0.00 | 0.00 | 0.07 | 0.00 | 3.6 |

| Trinidad 3 | 96.78 | 2.78 | 0.37 | 0.06 | 0.00 | 0.00 | 0.01 | 0.00 | 0.5 |

| USA–Alaska 3 | 99.71 | 0.09 | 0.03 | 0.01 | 0.00 | 0.00 | 0.17 | 0.00 | 6.5 |

| Name | Value | Unit |

|---|---|---|

| Pressure at metering reference conditions, p2 | 101.325 | kPa |

| Absolute pressure, p0 | 101.325 | kPa |

| Temperature at metering reference conditions, T2 | 288.15 | K |

| Molar gas constant, R 1 | 8.3144621 | J/(mol∙K) |

| Molar mass of dry air of reference composition, Mair 1 | 28.96546 | g/mol |

| Compression factor of dry air at metering reference composition, Zair,2 1 | 0.999595 | - |

| Component | Molar Mass, Mi [g/mol] | Summation Factor at 15 °C, si | [kJ/mol] |

|---|---|---|---|

| Methane | 16.04246 | 0.04452 | 891.51 |

| Ethane | 30.06904 | 0.0919 | 1562.14 |

| Propane | 44.09562 | 0.1344 | 2221.1 |

| n-butane | 58.12220 | 0.184 | 2879.76 |

| i-butane | 58.12220 | 0.1722 | 2870.58 |

| n-pentane | 72.14878 | 0.2361 | 3538.6 |

| i-pentane | 72.14878 | 0.2251 | 3531.68 |

| Carbon dioxide | 44.0095 | 0.0752 | 0 |

| Hydrogen sulphide | 34.08088 | 0.0923 | 562.38 |

| Hydrogen | 2.01588 | −0.01 | 286.15 |

| Nitrogen | 28.0134 | 0.017 | 0 |

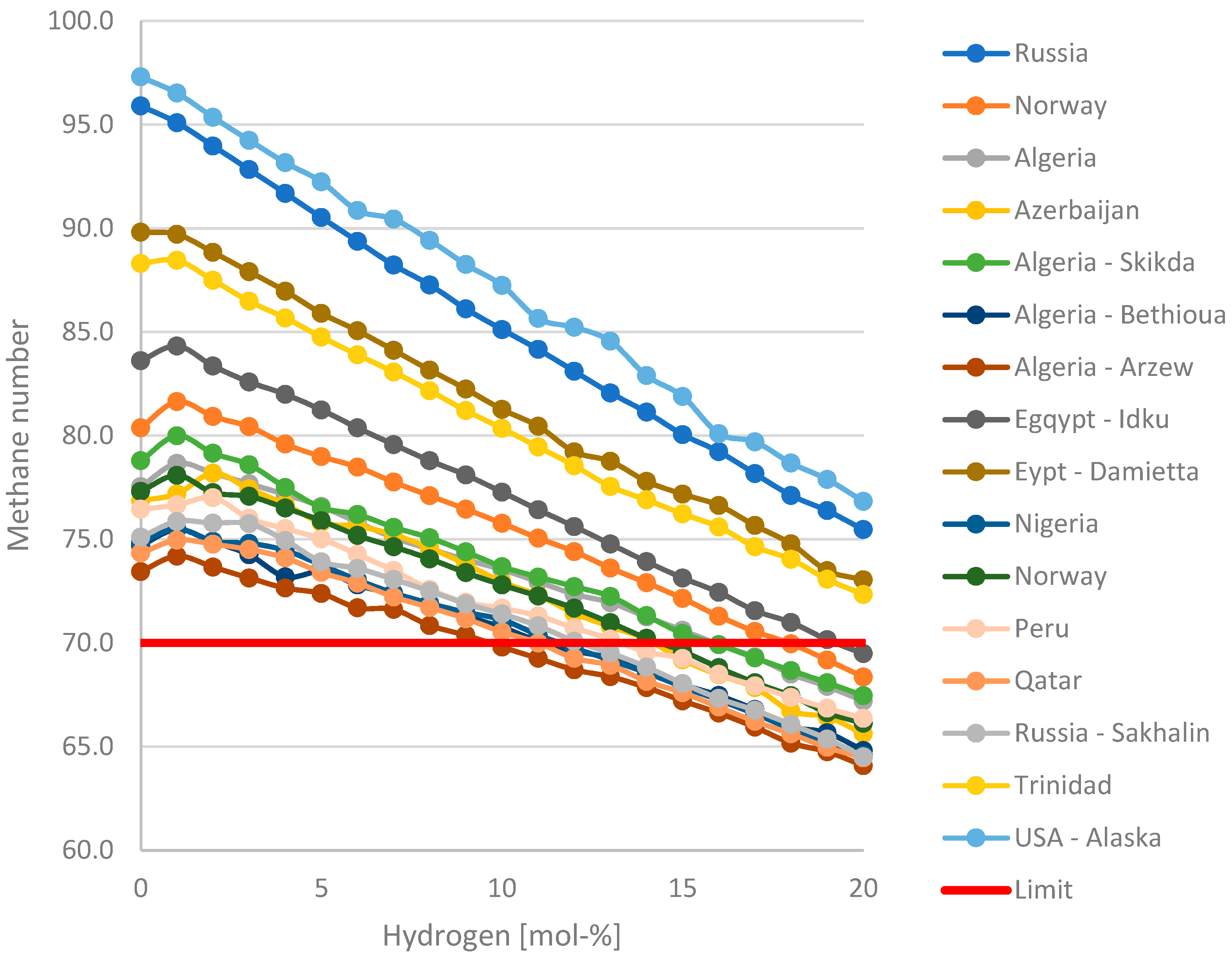

| Origin | Methane Number | Wobbe Index [MJ/m3] |

|---|---|---|

| Russia | 95.9 | 50.4 |

| Norway | 80.4 | 51.0 |

| Algeria | 77.5 | 51.9 |

| Azerbaijan | 76.9 | 51.2 |

| Algeria–Skikda | 78.8 | 51.7 |

| Algeria–Bethioua | 74.7 | 52.1 |

| Algeria–Arzew | 73.4 | 52.3 |

| Egypt–Idku | 83.6 | 51.7 |

| Egypt–Damietta | 89.8 | 51.2 |

| Nigeria | 74.9 | 52.5 |

| Norway | 77.3 | 51.9 |

| Peru | 76.5 | 52.0 |

| Qatar | 74.3 | 52.4 |

| Russia–Sakhalin | 75.1 | 52.4 |

| Trinidad | 88.3 | 51.3 |

| USA–Alaska | 97.3 | 50.6 |

| Origin | Max H2 Level [mol-%] | Methane Number at Max H2 Level | Wobbe Index at Max H2 Level [MJ/m3] |

|---|---|---|---|

| Russia | 12.0 | 83.1 | 49.0 |

| Norway | 16.0 | 71.3 | 49.0 |

| Algeria | 15.0 | 70.6 | 49.8 |

| Azerbaijan | 14.0 | 70.2 | 49.3 |

| Algeria–Skikda | 15.0 | 70.5 | 49.7 |

| Algeria–Bethioua | 11.0 | 70.1 | 50.6 |

| Algeria–Arzew | 9.0 | 70.4 | 51.0 |

| Egypt–Idku | 19.0 | 70.2 | 49.1 |

| Egypt–Damietta | 17.0 | 75.7 | 49.0 |

| Nigeria | 11.0 | 70.4 | 51.0 |

| Norway | 14.0 | 70.2 | 50.0 |

| Peru | 13.0 | 70.2 | 50.2 |

| Qatar | 11.0 | 70.0 | 50.9 |

| Russia–Sakhalin | 12.0 | 70.1 | 50.8 |

| Trinidad | 18.0 | 74.0 | 49.0 |

| USA–Alaska | 13.0 | 84.6 | 49.0 |

| Component | Average Gas Composition [mol-%] | Limits with Added Hydrogen [mol-%] |

|---|---|---|

| Methane | 95.1 | >82.4 |

| Ethane | 3.2 | <2.8 |

| Propane | 0.7 | <0.6 |

| Butane | 0.3 | <0.2 |

| Higher hydrocarbons | 0.04 | <0.03 |

| Carbon dioxide | 0.3 | <0.2 |

| Nitrogen | 0.5 | <0.4 |

| Hydrogen sulphide | 0.00009 | <0.00008 |

| Hydrogen | 0.0 | <13.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ingo, C.; Tuuf, J.; Björklund-Sänkiaho, M. Impact of Hydrogen on Natural Gas Compositions to Meet Engine Gas Quality Requirements. Energies 2022, 15, 7990. https://doi.org/10.3390/en15217990

Ingo C, Tuuf J, Björklund-Sänkiaho M. Impact of Hydrogen on Natural Gas Compositions to Meet Engine Gas Quality Requirements. Energies. 2022; 15(21):7990. https://doi.org/10.3390/en15217990

Chicago/Turabian StyleIngo, Christina, Jessica Tuuf, and Margareta Björklund-Sänkiaho. 2022. "Impact of Hydrogen on Natural Gas Compositions to Meet Engine Gas Quality Requirements" Energies 15, no. 21: 7990. https://doi.org/10.3390/en15217990