Degradation of Concrete Structures in Nuclear Power Plants: A Review of the Major Causes and Possible Preventive Measures

Abstract

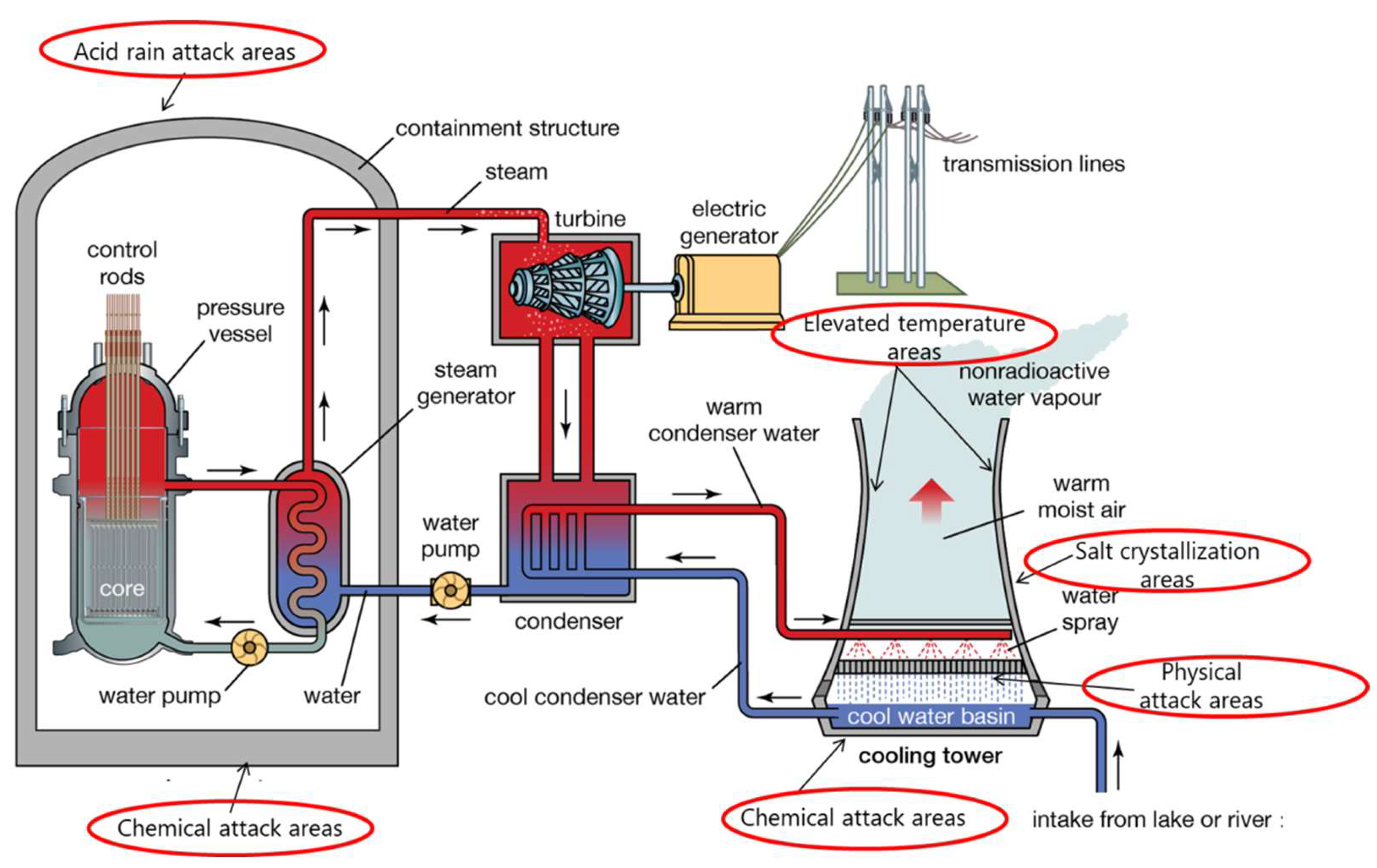

:1. Introduction

2. Concrete Degradation by Chemical Attack

2.1. Alkali–Aggregate Reactions

2.2. Leaching

2.3. Sulfate Attack

| Strategy | Results | Ref |

|---|---|---|

| Low water-to-binder (w/b) ratio + pozzolanic admixtures | The durability of concrete was enhanced significantly | [44] |

| Chloride in the presence of sodium sulfate | No deterioration was observed due to large fraction of ettringite | [37] |

| Low water-to-cement ratio and high concentration of chloride ions | Less expansion and less damage | [38] |

| Silica fumes (5–10% binder replacement levels) | Best resistance to sodium sulfate attack; however, a 15–20% strength loss can be expected | [39] |

| Natural volcanic pozzolan (5% binder replacement) | Improvement in sulfate resistance along with mechanical characteristics, and durability | [40] |

| Portland cement mortar with low C3S content and natural pozzolana | Improved the sulfate resistance of low C3A Portland cements | [41] |

| Marble, marble tiles and gravel tiles | Enhanced resistance to external sulfate attack for the sample containing marble | [42] |

| FA and granulated blast-furnace slag (GBFS) in 100% recycled coarse aggregate (RCA) | Better resistance against the sulfate attack and wetting-drying cycles | [43] |

2.4. Bases and Acids Attack

2.5. Carbonation

3. Concrete Degradation by Physical Attack

3.1. Elevated Temperature

3.2. Abrasion and Erosion

3.3. Radiation-Induced Degradation

3.4. Freeze–Thaw Distortions

3.5. Salt Crystallization

3.6. Fatigue and Vibration

4. Degradation of Mild Steel Reinforcement

5. Degradation of Prestressing Steel

6. Degradation of Liner Plate and Structural Steel

7. Conclusions and Future Perspectives: Observations and Recommendations for Concrete Use in NPPs

- Sulfate and acid attack are the most commonly occurring causes of concrete degradation in NPPs

- Of the various chemical degradation mechanisms of concrete, the least critical or rarely occurring event in NPPs is the carbonation of concrete.

- Of the various methods for reducing or preventing chemical attack the most effective is the use of mineral admixtures at suitable replacement levels in the binder. The use of these supplementary cementitious materials invariably prevents all kinds of chemical degradation mechanism by means of either alkali or lime sequestration, pore refinement, changes in ionic transport properties, etc.

- Another common recommendation for improving resistance of concrete against chemical attack is the use of low water/cement ratios.

- The use of specific types of cement such as low alkali cement for ASR prevention and low C3A cement for sulfate attack resistance is also suggested.

- Physical degradation issues specific to NPPs include elevated temperature and radiation exposure which needs to be addressed while designing concrete. General issues such as freeze–thaw effect and salt-crystallization are location specific and may be of a concern only if the NPP is located in regions of very cold climate or where sea water is used as coolant.

- Issues specific to components such as abrasion and erosion in parts related to movement of cooling water have to be addressed separately.

- In general, concrete with improved ductility (such as by using rubber crumps) is considered suitable to overcome many of these issues such as freeze–thaw degradation, abrasion and erosion resistance, etc.

- As in the case of chemical attack, the use of mineral admixtures is beneficial for almost all causes of physical degradation.

- Concrete made with specific aggregates, such as magnetite, barite, hematite, ilminite, etc., (in general high-density aggregates) exhibit a higher resistance to degradation damages caused by elevated temperatures and radiation exposure.

- Though there are different mechanisms of degradation of steel elements in NPPs, such as elevated temperature, fatigue and irradiation, the major issue is electrochemical corrosion.

- Corrosion mitigation strategies include modifying the concrete matrix characteristics as well as adding external corrosion protection techniques, such as cathodic protection.

- Since mineral additions can enhance chemical and physical characteristics of concrete, mixture proportions may be suitably designed to include required binder replacement with these mineral admixtures.

- A low water-to-cement ratio as well as low water-to-binder ratio, extended curing time, and reduced alkali content in the concrete can protect the concrete from chemical attack.

- Special aggregates based on availability and requirement should be chosen for each component of the NPPs while designing the concrete.

- The use of fibers in concrete is also recommended to increase crack resistance and mitigate further degradation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bruck, P.M.; Esselman, T.C.; Elaidi, B.M.; Wall, J.J.; Wong, E.L. Structural assessment of radiation damage in light water power reactor concrete biological shield walls. Nucl. Eng. Des. 2019, 350, 9–20. [Google Scholar] [CrossRef]

- Pomaro, B. A Review on Radiation Damage in Concrete for Nuclear Facilities: From Experiments to Modeling. Model. Simul. Eng. 2016, 2016, 4165746. [Google Scholar] [CrossRef] [Green Version]

- Naus, D. The management of aging in nuclear power plant concrete structures. JOM 2009, 61, 35–41. [Google Scholar] [CrossRef]

- Arel, H.Ş.; Aydin, E.; Kore, S.D. Ageing management and life extension of concrete in nuclear power plants. Powder Technol. 2017, 321, 390–408. [Google Scholar] [CrossRef]

- Do, M.J.; Chockie, A.D. Aging Degradation of Concrete Structures in Nuclear Power Plants; Statens kärnkraftinspektion: Washington, DC, USA, 1994. [Google Scholar]

- Wei, S.; Jiang, Z.; Liu, H.; Zhou, D.; Sanchez-Silva, M. Microbiologically induced deterioration of concrete: A review. Braz. J. Microbiol. 2013, 44, 1001–1007. [Google Scholar] [CrossRef]

- Yamanaka, T.; Aso, I.; Togashi, S.; Tanigawa, M.; Shoji, K.; Watanabe, T.; Watanabe, N.; Maki, K.; Suzuki, H. Corrosion by bacteria of concrete in sewerage systems and inhibitory effects of formates on their growth. Water Res. 2002, 36, 2636–2642. [Google Scholar] [CrossRef]

- Martin, W. Nuclear Power. Encyclopædia Britannica 1 June 2020, Encyclopædia Britannica, Inc. Available online: https://www.britannica.com/technology/nuclear-power (accessed on 3 September 2020).

- Neville, A. The confused world of sulfate attack on concrete. Cem. Concr. Res. 2004, 34, 1275–1296. [Google Scholar] [CrossRef]

- Remec, I.; Rosseel, T.M.; Field, K.G.; Pape, Y.L. Characterization of Radiation Fields for Assessing Concrete Degradation in Biological Shields of NPPs. EPJ Web Conf. 2017, 153, 05009. [Google Scholar] [CrossRef] [Green Version]

- Fameau, A.-L.; Salonen, A. Effect of particles and aggregated structures on the foam stability and aging. Comptes Rendus Phys. 2014, 15, 748–760. [Google Scholar] [CrossRef]

- Yang, K.-H.; Moon, G.-D.; Jeon, Y.-S. Implementing ternary supplementary cementing binder for reduction of the heat of hydration of concrete. J. Clean. Prod. 2016, 112, 845–852. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Steffens, A. Mathematical model for kinetics of alkali–silica reaction in concrete. Cem. Concr. Res. 2000, 30, 419–428. [Google Scholar] [CrossRef] [Green Version]

- Mark, A.; Arnon, B.; Sidney, M. Materials for concretes in relation to durability. In Durability of Concrete; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- Rajabipour, F.; Giannini, E.; Dunant, C.; Ideker, J.H.; Thomas, M.D. Alkali–silica reaction: Current understanding of the reaction mechanisms and the knowledge gaps. Cem. Concr. Res. 2015, 76, 130–146. [Google Scholar] [CrossRef]

- Lee, J.-C.; Jang, B.-K.; Shon, C.-S.; Kim, J.-H.; Chung, C.-W. Potential use of borosilicate glass to make neutron shielding mortar: Enhancement of thermal neutron shielding and strength development and mitigation of alkali-silica reaction. J. Clean. Prod. 2019, 210, 638–645. [Google Scholar] [CrossRef]

- Rosseel, T.M.; Maruyama, I.; Le Pape, Y.; Kontani, O.; Giorla, A.B.; Remec, I.; Wall, J.J.; Sircar, M.; Andrade, C.; Ordonez, M. Review of the Current State of Knowledge on the Effects of Radiation on Concrete. J. Adv. Concr. Technol. 2016, 14, 368–383. [Google Scholar] [CrossRef] [Green Version]

- Sanchez, L.F.M.; Fournier, B.; Jolin, M.; Mitchell, D.; Bastien, J. Overall assessment of Alkali-Aggregate Reaction (AAR) in concretes presenting different strengths and incorporating a wide range of reactive aggregate types and natures. Cem. Concr. Res. 2017, 93, 17–31. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Effect of particle size on alkali–silica reaction in recycled glass mortars. Constr. Build. Mater. 2014, 66, 275–285. [Google Scholar] [CrossRef]

- Ramlochan, T.; Thomas, M.; Gruber, K.A. The effect of metakaolin on alkali–silica reaction in concrete. Cem. Concr. Res. 2000, 30, 339–344. [Google Scholar] [CrossRef]

- Shehata, M.H.; Thomas, M.D.A. The effect of fly ash composition on the expansion of concrete due to alkali–silica reaction. Cem. Concr. Res. 2000, 30, 1063–1072. [Google Scholar] [CrossRef]

- Boddy, A.M.; Hooton, R.D.; Thomas, M.D.A. The effect of the silica content of silica fume on its ability to control alkali–silica reaction. Cem. Concr. Res. 2003, 33, 1263–1268. [Google Scholar] [CrossRef]

- Yazıcı, H. The effect of steel micro-fibers on ASR expansion and mechanical properties of mortars. Constr. Build. Mater. 2012, 30, 607–615. [Google Scholar] [CrossRef]

- Giaccio, G.; Bossio, M.E.; Torrijos, M.C.; Zerbino, R. Contribution of fiber reinforcement in concrete affected by alkali–silica reaction. Cem. Concr. Res. 2015, 67, 310–317. [Google Scholar] [CrossRef]

- Kandasamy, S.; Shehata, M.H. Durability of ternary blends containing high calcium fly ash and slag against sodium sulphate attack. Constr. Build. Mater. 2014, 53, 267–272. [Google Scholar] [CrossRef]

- Tcherner, J.; Vaithilingam, L.; Han, M. Effective Aging Management of NPP Concrete Structures. J. Adv. Concr. Technol. 2017, 15, 1–9. [Google Scholar] [CrossRef] [Green Version]

- De Bel, R.; Bollens, Q.; Duvigneaud, P.-H.; Verbrugge, J.-C. Influence of curing time, percolation and temperature on the compressive strength of a loam treated with lime. In Proceedings of the Tremti, Paris, France, 24–26 October 2005; pp. 1–10. [Google Scholar]

- Rozière, E.; Loukili, A.; El Hachem, R.; Grondin, F. Durability of concrete exposed to leaching and external sulphate attacks. Cem. Concr. Res. 2009, 39, 1188–1198. [Google Scholar] [CrossRef] [Green Version]

- Dow, C.; Glasser, F.P. Calcium carbonate efflorescence on Portland cement and building materials. Cem. Concr. Res. 2003, 33, 147–154. [Google Scholar] [CrossRef]

- Jain, J.; Neithalath, N. Analysis of calcium leaching behavior of plain and modified cement pastes in pure water. Cem. Concr. Compos. 2009, 31, 176–185. [Google Scholar] [CrossRef]

- Han, F.; Liu, R.; Yan, P. Effect of fresh water leaching on the microstructure of hardened composite binder pastes. Constr. Build. Mater. 2014, 68, 630–636. [Google Scholar] [CrossRef]

- Gaitero, J.J.; Campillo, I.; Guerrero, A. Reduction of the calcium leaching rate of cement paste by addition of silica nanoparticles. Cem. Concr. Res. 2008, 38, 1112–1118. [Google Scholar] [CrossRef] [Green Version]

- Diab, A.M.; Elyamany, H.E.; Abd Elmoaty, A.E.M.; Shalan, A.H. Prediction of concrete compressive strength due to long term sulfate attack using neural network. Alex. Eng. J. 2014, 53, 627–642. [Google Scholar] [CrossRef]

- Arel, H.Ş.; Thomas, B.S. The effects of nano- and micro-particle additives on the durability and mechanical properties of mortars exposed to internal and external sulfate attacks. Results Phys. 2017, 7, 843–851. [Google Scholar] [CrossRef]

- Yu, D.; Guan, B.; He, R.; Xiong, R.; Liu, Z. Sulfate attack of Portland cement concrete under dynamic flexural loading: A coupling function. Constr. Build. Mater. 2016, 115, 478–485. [Google Scholar] [CrossRef]

- Bensted, J.; Rbrough, A.; Page, M.M. 4-Chemical degradation of concrete. In Durability of Concrete and Cement Composites; Page, C.L., Page, M.M., Eds.; Woodhead Publishing: Sawston, UK, 2007; pp. 86–135. [Google Scholar] [CrossRef]

- Maes, M.; De Belie, N. Resistance of concrete and mortar against combined attack of chloride and sodium sulphate. Cem. Concr. Compos. 2014, 53, 59–72. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, J.; Lv, Y.; Wang, D.; Ye, J. Study on the expansion of concrete under attack of sulfate and sulfate–chloride ions. Constr. Build. Mater. 2013, 39, 26–32. [Google Scholar] [CrossRef]

- Lee, S.T.; Moon, H.Y.; Swamy, R.N. Sulfate attack and role of silica fume in resisting strength loss. Cem. Concr. Compos. 2005, 27, 65–76. [Google Scholar] [CrossRef]

- Merida, A.; Kharchi, F. Pozzolan Concrete Durability on Sulphate Attack. Procedia Eng. 2015, 114, 832–837. [Google Scholar] [CrossRef] [Green Version]

- Irassar, E.F.; González, M.; Rahhal, V. Sulphate resistance of type V cements with limestone filler and natural pozzolana. Cem. Concr. Compos. 2000, 22, 361–368. [Google Scholar] [CrossRef]

- Tennich, M.; Ben Ouezdou, M.; Kallel, A. Behavior of self-compacting concrete made with marble and tile wastes exposed to external sulfate attack. Constr. Build. Mater. 2017, 135, 335–342. [Google Scholar] [CrossRef]

- Qi, B.; Gao, J.; Chen, F.; Shen, D. Evaluation of the damage process of recycled aggregate concrete under sulfate attack and wetting-drying cycles. Constr. Build. Mater. 2017, 138, 254–262. [Google Scholar] [CrossRef]

- Nehdi, M.L.; Suleiman, A.R.; Soliman, A.M. Investigation of concrete exposed to dual sulfate attack. Cem. Concr. Res. 2014, 64, 42–53. [Google Scholar] [CrossRef]

- Xiao, J.; Qu, W.; Li, W.; Zhu, P. Investigation on effect of aggregate on three non-destructive testing properties of concrete subjected to sulfuric acid attack. Constr. Build. Mater. 2016, 115, 486–495. [Google Scholar] [CrossRef] [Green Version]

- Pacheco-Torgal, F.; Jalali, S. Sulphuric acid resistance of plain, polymer modified, and fly ash cement concretes. Constr. Build. Mater. 2009, 23, 3485–3491. [Google Scholar] [CrossRef] [Green Version]

- Araghi, H.J.; Nikbin, I.; Reskati, S.R.; Rahmani, E.; Allahyari, H. An experimental investigation on the erosion resistance of concrete containing various PET particles percentages against sulfuric acid attack. Constr. Build. Mater. 2015, 77, 461–471. [Google Scholar] [CrossRef] [Green Version]

- Roy, D.M.; Arjunan, P.; Silsbee, M.R. Effect of silica fume, metakaolin, and low-calcium fly ash on chemical resistance of concrete. Cem. Concr. Res. 2001, 31, 1809–1813. [Google Scholar] [CrossRef]

- Chang, Z.-T.; Song, X.-J.; Munn, R.; Marosszeky, M. Using limestone aggregates and different cements for enhancing resistance of concrete to sulphuric acid attack. Cem. Concr. Res. 2005, 35, 1486–1494. [Google Scholar] [CrossRef]

- Aydın, S.; Yazıcı, H.; Yiğiter, H.; Baradan, B. Sulfuric acid resistance of high-volume fly ash concrete. Build. Environ. 2007, 42, 717–721. [Google Scholar] [CrossRef]

- Gruyaert, E.; Van den Heede, P.; Maes, M.; De Belie, N. Investigation of the influence of blast-furnace slag on the resistance of concrete against organic acid or sulphate attack by means of accelerated degradation tests. Cem. Concr. Res. 2012, 42, 173–185. [Google Scholar] [CrossRef]

- Makhloufi, Z.; Bederina, M.; Bouhicha, M.; Kadri, E.-H. Effect of Mineral Admixtures on Resistance to Sulfuric Acid Solution of Mortars with Quaternary Binders. Phys. Procedia 2014, 55, 329–335. [Google Scholar] [CrossRef] [Green Version]

- Senhadji, Y.; Escadeillas, G.; Mouli, M.; Khelafi, H.; Benosman. Influence of natural pozzolan, silica fume and limestone fine on strength, acid resistance and microstructure of mortar. Powder Technol. 2014, 254, 314–323. [Google Scholar] [CrossRef]

- Siad, H.; Lachemi, M.; Sahmaran, M.; Hossain, K.M.A. Effect of glass powder on sulfuric acid resistance of cementitious materials. Constr. Build. Mater. 2016, 113, 163–173. [Google Scholar] [CrossRef]

- Phung, Q.T.; Maes, N.; Jacques, D.; Bruneel, E.; Van Driessche, I.; Ye, G.; De Schutter, G. Effect of limestone fillers on microstructure and permeability due to carbonation of cement pastes under controlled CO2 pressure conditions. Constr. Build. Mater. 2015, 82, 376–390. [Google Scholar] [CrossRef]

- Vodák, F.; Vydra, V.; Trtík, K.; Kapičková, O. Effect of gamma irradiation on properties of hardened cement paste. Mater. Struct. 2011, 44, 101–107. [Google Scholar] [CrossRef]

- William, K.; Xi, Y.; Naus, D. A Review of the Effects of Radiation on Microstructure and Properties of Concretes Used in Nuclear Power Plants; United States Nuclear Regulatory Commission, Office of Nuclear Regulatory: Rockville, MD, USA, 2013. [Google Scholar]

- Shi, Z.; Lothenbach, B.; Geiker, M.R.; Kaufmann, J.; Leemann, A.; Ferreiro, S.; Skibsted, J. Experimental studies and thermodynamic modeling of the carbonation of Portland cement, metakaolin and limestone mortars. Cem. Concr. Res. 2016, 88, 60–72. [Google Scholar] [CrossRef]

- Pan, X.; Shi, Z.; Shi, C.; Ling, T.-C.; Li, N. A review on surface treatment for concrete—Part 2: Performance. Constr. Build. Mater. 2017, 133, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Chang, C.-F.; Chen, J.-W. The experimental investigation of concrete carbonation depth. Cem. Concr. Res. 2006, 36, 1760–1767. [Google Scholar] [CrossRef]

- Zhu, Y.-G.; Kou, S.-C.; Poon, C.-S.; Dai, J.-G.; Li, Q.-Y. Influence of silane-based water repellent on the durability properties of recycled aggregate concrete. Cem. Concr. Compos. 2013, 35, 32–38. [Google Scholar] [CrossRef]

- Basheer, P.A.M.; Basheer, L.; Cleland, D.J.; Long, A.E. Surface treatments for concrete: Assessmentmethods and reported performance. Constr. Build. Mater. 1997, 11, 413–429. [Google Scholar] [CrossRef]

- Park, D.C. Carbonation of concrete in relation to CO2 permeability and degradation of coatings. Constr. Build. Mater. 2008, 22, 2260–2268. [Google Scholar] [CrossRef]

- Mohammed Haneefa, K.; Santhanam, M.; Parida, F.C. Review of concrete performance at elevated temperature and hot sodium exposure applications in nuclear industry. Nucl. Eng. Des. 2013, 258, 76–88. [Google Scholar] [CrossRef]

- Arioz, O. Effects of elevated temperatures on properties of concrete. Fire Saf. J. 2007, 42, 516–522. [Google Scholar] [CrossRef]

- Reiterman, P.; Holčapek, O.; Jogl, M.; Konvalinka, P. Physical and Mechanical Properties of Composites Made with Aluminous Cement and Basalt Fibers Developed for High Temperature Application. Adv. Mater. Sci. Eng. 2015, 2015, 703029. [Google Scholar] [CrossRef] [Green Version]

- Koťátková, J.; Zatloukal, J.; Reiterman, P.; Patera, J.; Hlaváč, Z.; Brabec, P. The effect of elevated temperatures and nuclear radiation on the properties of biological shielding concrete. Key Eng. Mater. 2016, 677, 8–16. [Google Scholar] [CrossRef]

- Keppert, M.; Vejmelkova, E.; Černý, R.; Švarcová, S.; Bezdička, P. Microstructural changes and residual properties of fiber reinforced cement composites exposed to elevated temperatures. Cem. Wapno Beton 2012, 17, 77–89. [Google Scholar]

- Sancak, E.; Dursun Sari, Y.; Simsek, O. Effects of elevated temperature on compressive strength and weight loss of the light-weight concrete with silica fume and superplasticizer. Cem. Concr. Compos. 2008, 30, 715–721. [Google Scholar] [CrossRef]

- Chan, Y.; Luo, X.; Sun, W. Compressive strength and pore structure of high-performance concrete after exposure to high temperature up to 800 C. Cem. Concr. Res. 2000, 30, 247–251. [Google Scholar] [CrossRef]

- Demirel, B.; Keleştemur, O. Effect of elevated temperature on the mechanical properties of concrete produced with finely ground pumice and silica fume. Fire Saf. J. 2010, 45, 385–391. [Google Scholar] [CrossRef] [Green Version]

- Fillmore, D. Literature Review of the Effects of Radiation and Temperature on the Aging of Concrete; Idaho National Laboratory (INL): Idaho Falls, ID, USA, 2004. [Google Scholar]

- Horszczaruk, E.; Sikora, P.; Zaporowski, P. Mechanical Properties of Shielding Concrete with Magnetite Aggregate Subjected to High Temperature. Procedia Eng. 2015, 108, 39–46. [Google Scholar] [CrossRef] [Green Version]

- Sakr, K.; El-Hakim, E. Effect of high temperature or fire on heavy weight concrete properties. Cem. Concr. Res. 2005, 35, 590–596. [Google Scholar] [CrossRef]

- Al-Akhras, N.M.; Al-Akhras, K.M.; Attom, M.F. Performance of olive waste ash concrete exposed to elevated temperatures. Fire Saf. J. 2009, 44, 370–375. [Google Scholar] [CrossRef]

- Awal, A.S.M.A.; Shehu, I.A. Performance evaluation of concrete containing high volume palm oil fuel ash exposed to elevated temperature. Constr. Build. Mater. 2015, 76, 214–220. [Google Scholar] [CrossRef]

- Li, Q.; Li, Z.; Yuan, G. Effects of elevated temperatures on properties of concrete containing ground granulated blast furnace slag as cementitious material. Constr. Build. Mater. 2012, 35, 687–692. [Google Scholar] [CrossRef]

- Nadeem, A.; Memon, S.A.; Lo, T.Y. The performance of Fly ash and Metakaolin concrete at elevated temperatures. Constr. Build. Mater. 2014, 62, 67–76. [Google Scholar] [CrossRef]

- Rashad, A.M. An investigation of high-volume fly ash concrete blended with slag subjected to elevated temperatures. J. Clean. Prod. 2015, 93, 47–55. [Google Scholar] [CrossRef]

- Yen, T.; Hsu, T.-H.; Liu, Y.-W.; Chen, S.-H. Influence of class F fly ash on the abrasion–erosion resistance of high-strength concrete. Constr. Build. Mater. 2007, 21, 458–463. [Google Scholar] [CrossRef]

- Ghafoori, N.; Diawara, H. Abrasion resistance of fine aggregate-replaced silica fume concrete. Mater. J. 1999, 96, 559–569. [Google Scholar]

- Siddique, R. Effect of fine aggregate replacement with Class F fly ash on the abrasion resistance of concrete. Cem. Concr. Res. 2003, 33, 1877–1881. [Google Scholar] [CrossRef]

- Singh, G.; Siddique, R. Abrasion resistance and strength properties of concrete containing waste foundry sand (WFS). Constr. Build. Mater. 2012, 28, 421–426. [Google Scholar] [CrossRef]

- Kabay, N. Abrasion resistance and fracture energy of concretes with basalt fiber. Constr. Build. Mater. 2014, 50, 95–101. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Khoshnaw, G.; İpek, S. Abrasion and freezing–thawing resistance of pervious concretes containing waste rubbers. Constr. Build. Mater. 2014, 73, 19–24. [Google Scholar] [CrossRef]

- Mirhosseini, S.; Polak, M.A.; Pandey, M. Nuclear radiation effect on the behavior of reinforced concrete elements. Nucl. Eng. Des. 2014, 269, 57–65. [Google Scholar] [CrossRef]

- Le Pape, Y.; Field, K.G.; Remec, I. Radiation effects in concrete for nuclear power plants, Part II: Perspective from micromechanical modeling. Nucl. Eng. Des. 2015, 282, 144–157. [Google Scholar] [CrossRef]

- Le Pape, Y. Structural effects of radiation-induced volumetric expansion on unreinforced concrete biological shields. Nucl. Eng. Des. 2015, 295, 534–548. [Google Scholar] [CrossRef] [Green Version]

- Park, K.; Kim, H.-T.; Kwon, T.-H.; Choi, E. Effect of neutron irradiation on response of reinforced concrete members for nuclear power plants. Nucl. Eng. Des. 2016, 310, 15–26. [Google Scholar] [CrossRef]

- Kontani, O.; Ichikawa, Y.; Ishizawa, A.; Takizawa, M.; Sato, O. Irradiation Effects on Concrete Structures. In Infrastructure Systems for Nuclear Energy; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2014; pp. 459–473. [Google Scholar] [CrossRef]

- Silva, C.M.; Rosseel, T.M.; Kirkegaard, M.C. Radiation-Induced Changes in Quartz, a Mineral Analog of Nuclear Power Plant Concrete Aggregates. Inorg. Chem. 2018, 57, 3329–3338. [Google Scholar] [CrossRef]

- Pomaro, B.; Salomoni, V.A.; Gramegna, F.; Prete, G.; Majorana, C.E. Radiation damage evaluation on concrete within a facility for Selective Production of Exotic Species (SPES Project), Italy. J. Hazard. Mater. 2011, 194, 169–177. [Google Scholar] [CrossRef]

- Maruyama, I.; Takizawa, M.; Sato, O.; Etoh, J.; Kontani, O.; Sawada, S.; Ishikawa, S. Post-Japanese NRA Research Project on Soundness Evaluation Criteria for Radiation-Induced Concrete Degradation; IAEA International Atomic Energy Agency (IAEA): Lyon, France, 2021. [Google Scholar]

- Ichikawa, T.; Kimura, T. Effect of nuclear radiation on alkali-silica reaction of concrete. J. Nucl. Sci. Technol. 2007, 44, 1281–1284. [Google Scholar] [CrossRef]

- Vodák, F.; Trtík, K.; Sopko, V.; Kapičková, O.; Demo, P. Effect of γ-irradiation on strength of concrete for nuclear-safety structures. Cem. Concr. Res. 2005, 35, 1447–1451. [Google Scholar] [CrossRef]

- Akkurt, I.; Kilincarslan, S.; Basyigit, C. The photon attenuation coefficients of barite, marble and limra. Ann. Nucl. Energy 2004, 31, 577–582. [Google Scholar] [CrossRef]

- Akkurt, I.; Akyıldırım, H.; Mavi, B.; Kilincarslan, S.; Basyigit, C. Radiation shielding of concrete containing zeolite. Radiat. Meas. 2010, 45, 827–830. [Google Scholar] [CrossRef]

- Kharita, M.H.; Yousef, S.; AlNassar, M. The effect of carbon powder addition on the properties of hematite radiation shielding concrete. Prog. Nucl. Energy 2009, 51, 388–392. [Google Scholar] [CrossRef]

- Abo-El-Enein, S.A.; El-Sayed, H.A.; Ali, A.H.; Mohammed, Y.T.; Khater, H.M.; Ouda, A.S. Physico-mechanical properties of high performance concrete using different aggregates in presence of silica fume. HBRC J. 2014, 10, 43–48. [Google Scholar] [CrossRef] [Green Version]

- Thomas, C.; Rico, J.; Tamayo, P.; Setién, J.; Ballester, F.; Polanco, J.A. Neutron shielding concrete incorporating B4C and PVA fibers exposed to high temperatures. J. Build. Eng. 2019, 26, 100859. [Google Scholar] [CrossRef]

- Gencel, O.; Brostow, W.; Ozel, C.; Filiz, M. Concretes containing hematite for use as shielding barriers. Mater. Sci 2010, 16, 249–256. [Google Scholar]

- Masoud, M.A.; Kansouh, W.A.; Shahien, M.G.; Sakr, K.; Rashad, A.M.; Zayed, A.M. An experimental investigation on the effects of barite/hematite on the radiation shielding properties of serpentine concretes. Prog. Nucl. Energy 2020, 120, 103220. [Google Scholar] [CrossRef]

- Ouda, A.S. Development of high-performance heavy density concrete using different aggregates for gamma-ray shielding. HBRC J. 2015, 11, 328–338. [Google Scholar] [CrossRef] [Green Version]

- Fursa, T.V.; Dann, D.D.; Osipov, K.Y. Evaluation of freeze–thaw damage in concrete by the parameters of electric response under impact excitation. Constr. Build. Mater. 2016, 102, 182–189. [Google Scholar] [CrossRef]

- Chung, C.-W.; Shon, C.-S.; Kim, Y.-S. Chloride ion diffusivity of fly ash and silica fume concretes exposed to freeze–thaw cycles. Constr. Build. Mater. 2010, 24, 1739–1745. [Google Scholar] [CrossRef]

- Fan, Y.; Zhang, S.; Wang, Q.; Shah, S.P. Effects of nano-kaolinite clay on the freeze–thaw resistance of concrete. Cem. Concr. Compos. 2015, 62, 1–12. [Google Scholar] [CrossRef]

- Jang, J.G.; Kim, H.K.; Kim, T.S.; Min, B.J.; Lee, H.K. Improved flexural fatigue resistance of PVA fiber-reinforced concrete subjected to freezing and thawing cycles. Constr. Build. Mater. 2014, 59, 129–135. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.; Edmondson, V.; Dias, E. Crumb rubber used in concrete to provide freeze–thaw protection (optimal particle size). J. Clean. Prod. 2016, 112, 599–606. [Google Scholar] [CrossRef]

- Berkowski, P.; Kosior-Kazberuk, M. Effect of Fiber on the Concrete Resistance to Surface Scaling Due to Cyclic Freezing and Thawing. Procedia Eng. 2015, 111, 121–127. [Google Scholar] [CrossRef]

- Jones, M.R.; Dhir, R.K.; Gill, J.P. Concrete surface treatment: Effect of exposure temperature on chloride diffusion resistance. Cem. Concr. Res. 1995, 25, 197–208. [Google Scholar] [CrossRef]

- Almusallam, A.A.; Khan, F.M.; Dulaijan, S.U.; Al-Amoudi, O.S.B. Effectiveness of surface coatings in improving concrete durability. Cem. Concr. Compos. 2003, 25, 473–481. [Google Scholar] [CrossRef]

- Lubelli, B.; Nijland, T.G.; van Hees, R.P.J.; Hacquebord, A. Effect of mixed in crystallization inhibitor on resistance of lime–cement mortar against NaCl crystallization. Constr. Build. Mater. 2010, 24, 2466–2472. [Google Scholar] [CrossRef]

- Gupta, S.; Pel, L.; Steiger, M.; Kopinga, K. The effect of ferrocyanide ions on sodium chloride crystallization in salt mixtures. J. Cryst. Growth 2015, 410, 7–13. [Google Scholar] [CrossRef]

- Chahal, N.; Siddique, R.; Rajor, A. Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of concrete incorporating silica fume. Constr. Build. Mater. 2012, 37, 645–651. [Google Scholar] [CrossRef]

- Shaheen, F.; Pradhan, B. Influence of sulfate ion and associated cation type on steel reinforcement corrosion in concrete powder aqueous solution in the presence of chloride ions. Cem. Concr. Res. 2017, 91, 73–86. [Google Scholar] [CrossRef]

- Zuquan, J.; Wei, S.; Yunsheng, Z.; Jinyang, J.; Jianzhong, L. Interaction between sulfate and chloride solution attack of concretes with and without fly ash. Cem. Concr. Res. 2007, 37, 1223–1232. [Google Scholar] [CrossRef]

- Shaheen, F.; Pradhan, B. Effect of chloride and conjoint chloride–sulfate ions on corrosion of reinforcing steel in electrolytic concrete powder solution (ECPS). Constr. Build. Mater. 2015, 101, 99–112. [Google Scholar] [CrossRef]

- Dehwah, H.A.F.; Maslehuddin, M.; Austin, S.A. Long-term effect of sulfate ions and associated cation type on chloride-induced reinforcement corrosion in Portland cement concretes. Cem. Concr. Compos. 2002, 24, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Aviam, O.; Bar-Nes, G.; Zeiri, Y.; Sivan, A. Accelerated biodegradation of cement by sulfur-oxidizing bacteria as a bioassay for evaluating immobilization of low-level radioactive waste. Appl. Environ. Microbiol. 2004, 70, 6031–6036. [Google Scholar] [CrossRef]

- Magniont, C.; Coutand, M.; Bertron, A.; Cameleyre, X.; Lafforgue, C.; Beaufort, S.; Escadeillas, G. A new test method to assess the bacterial deterioration of cementitious materials. Cem. Concr. Res. 2011, 41, 429–438. [Google Scholar] [CrossRef]

- Bertron, A. Understanding interactions between cementitious materials and microorganisms: A key to sustainable and safe concrete structures in various contexts. Mater. Struct. 2014, 47, 1787–1806. [Google Scholar] [CrossRef] [Green Version]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Decho, A.W. Overview of biopolymer-induced mineralization: What goes on in biofilms? Ecol. Eng. 2010, 36, 137–144. [Google Scholar] [CrossRef]

- Chajduk, E.; Bojanowska-Czajka, A. Corrosion mitigation in coolant systems in nuclear power plants. Prog. Nucl. Energy 2016, 88, 1–9. [Google Scholar] [CrossRef]

- Pei, X.; Noël, M.; Green, M.; Fam, A.; Shier, G. Cementitious coatings for improved corrosion resistance of steel reinforcement. Surf. Coat. Technol. 2017, 315, 188–195. [Google Scholar] [CrossRef]

- Sohail, M.G.; Kahraman, R.; Alnuaimi, N.A.; Gencturk, B.; Alnahhal, W.; Dawood, M.; Belarbi, A. Electrochemical behavior of mild and corrosion resistant concrete reinforcing steels. Constr. Build. Mater. 2020, 232, 117205. [Google Scholar] [CrossRef]

- SP, N. Electrochemical Realkalization and Chloride Extraction for Reinforced Concrete. Natl. Assoc. Corros. Eng. (NACE) 2007, 29, 125–131. [Google Scholar]

- Du Fengyin, J.Z.; Tiejun, Z.; Xueyan, D. Electrochemical chloride extraction from corrosion-resistant steel bar-reinforced concrete. Int. J. Electrochem. Sci. 2018, 13, 7076–7094. [Google Scholar] [CrossRef]

- Silva, M.R.; Nail, T. Biodeterioration of concrete structures in coastal zone. In Proceedings of the III International Conference on Sustainable Construction Materials and Technologies, Kyoto, Japan, 18–21 August 2013. [Google Scholar]

- Tao, Z. Mechanical properties of prestressing steel after fire exposure. Mater. Struct. 2015, 48, 3037–3047. [Google Scholar] [CrossRef]

| Mineral Admixture | Replacement Level | Results | Ref |

|---|---|---|---|

| High-reactivity metakaolin (HRM) | 20% | Reduction in alkali concentration, Reduction in long term concentrations of OH−, Na+, and K+ | [20] |

| Fly ash (FA) | 25–40% | Reduction in expansion and cracking | [21] |

| Silica fume | 8% to 12% | Able to control ASR | [22] |

| Steel fibers | 2% | Controls ASR expansion, mechanical properties can be restored | [23] |

| Mineral Admixture | Replacement Level | Results | Ref |

|---|---|---|---|

| Silica fume, FA, metakaolin | 0–30% | Chemical resistance was higher for silica fume followed by metakaolin and FA. The 0–10 wt.% replacement level showed high resistance for all the admixtures | [48] |

| Limestone aggregates and ternary cement containing FA and silica fume | 7% silica fume and 33% FA | The acid resistance was higher for concrete with limestone aggregates and ternary cement (with 33% FA and 7% silica fume) compared to other tested samples with different replacement levels | [49] |

| FA | 0–70% | Strength loss decreased to 21% from 58% for 70% replacement level from 0% replacement level. Similarly, weight loss decreased to 3.3% from 5% for standard curing concrete and 8.3% to 1.1% for steam-cured concrete. | [50] |

| Blast furnace slag | 50% | High resistance to the acidic environments | [51] |

| Slag and pozzolan | 30% each | Good resistance to acid attack | [52] |

| Natural pozzolan and limestone fine | - | The acid resistance was improved; however, the rate of resistance varied depending on the proportion of supplementary cementitious materials | [53] |

| Glass powder | 45% replacement level of cement | Enhanced mortar resistance against sulfuric acid attack. | [54] |

| Mineral Admixture | Replacement Level | Results | Ref |

|---|---|---|---|

| Ilmenite concrete | - | The concrete attenuation coefficient of ilmenite concrete was higher than gravel and baryte concrete by 39.8% and 8% of 60Co at laboratory temperatures, respectively. | [74] |

| OWA | 22% | The resistance of OWA concrete to elevated temperature was high at 22% compared to 7% and 15% at a w/c ratio of 0.5. The resistance was less for OWA concrete at a w/c ratio of 0.7. | [75] |

| GGBFS | 10–50% | The relative compressive strength of concrete with 0%, 10%, 30% and 50% GGBFS was decreased with an increase in GGBFS content while the relative modulus of elasticity increased with GGBFS content. | [77] |

| High-performance concrete (HPC) made with metakaolin and FA | 20% FA 10–20% metakaolin | The result showed that concrete with 20% FA displayed better performance while concrete containing metakaolin (10 and 20%) showed higher degradation in terms of durability and mass loss at temperatures above 400 °C | [78] |

| FA | 70% | Concrete with a high volume of FA (70% replacement level) exhibited a higher fire resistance. | [79] |

| Palm oil fuel ash (POFA) | 70% | The concrete containing palm oil fuel ash (POFA) showed no change in compressive strength up to 400 °C and a significant strength loss beyond 600 °C. At elevated temperatures, a better performance was obtained for a higher replacement level of POFA of up to 70%. | [76] |

| Magnetite | 2300 kg/m3 | Enhanced the mechanical properties significantly up to a temperature of 450 °C. | [73] |

| Mineral Admixture | Replacement Level | Results | Ref |

|---|---|---|---|

| Magnetite | 1457 kg/m3 | Concrete made with magnetite aggregate enhanced the shielding efficiency against γ-rays | [103] |

| Barite aggregates | - | The photon linear attenuation coefficients were higher for barite aggregate than marble and limra | [96] |

| Carbon powder | 15% | The strength of concrete increased while the shielding property against gamma rays and neutrons remained unchanged | [98] |

| Limestone aggregate, B4C and PVA | 350, 120 and 7 kg/m3 | At high temperatures, compressive strength increased by 15% at temperatures between 20 °C and 200 °C and reached 18% while severe losses in the compressive strength (90% loss) were observed at 1000 °C. | [100] |

| Hematite | 10% | The composite with 10% hematite lost only 7.8% of the compressive strength while the plain concrete lost 21.3% of its compressive strength after 30 freeze–thaw cycles | [101] |

| Barite/hematite | 50% | The incorporation of hematite or barite enhanced the attenuation properties. The best ratio found was 50% barite | [102] |

| Material | Damage Cause | Potential Areas | Preventive Measures |

|---|---|---|---|

| Concrete | Chemical attack | Surface exposed to cooling water sources, containment shield, floor and slabs, areas exposed to water | Use of mineral admixtures at suitable replacement levels in binder, use of cements with low water/cement ratios, low alkali, and low C3A |

| Freeze–thaw cycles | Structures for water collection, water intake and discharge structures, cooling water sources | Use of concrete with improved ductility, use of mineral admixtures | |

| Thermal attack | Containment shield structures, areas close to hot piping system or reactor pressure vessel. | Use of concrete made with high density aggregates (such as magnetite, barite, hematite, ilminite, etc.) | |

| Radiation | Containment areas near reactor pressure vessel, some localized areas | Use of concrete made with high density aggregates (such as magnetite, barite, hematite, ilminite, etc.) | |

| Abrasion | cooling water intake and discharge structures, floor and slab elements | Use of concrete with improved ductility | |

| Fatigue and vibration | Areas under equipment support, containment areas near line anchors | Use of concrete with improved ductility | |

| Steel reinforcement | Corrosion | Outer layer steel in all structures | Use of corrosion inhibitors, coatings and cathodic protection |

| Radiation | Containment structures near reactor pressure vessel boundaries | The concrete covering of steel gives protection from radiation | |

| Fatigue | Local areas subjected to repeated loads | Unlikely to have failures of steel reinforcement due to fatigue | |

| Prestressed steel | Corrosion | Containment building | Use of organic corrosion inhibitors |

| Stress relaxation | Fuel pool structures in containment building | - | |

| Liner plate and structural steel | Corrosion | Localized areas or uniformly throughout the steel | Use of coatings and cathodic protection |

| Fatigue | Weld defects and arc strike areas, structural attachments and concrete-to-floor boundaries | Improving weld details and other geometric considerations |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rasheed, P.A.; Nayar, S.K.; Barsoum, I.; Alfantazi, A. Degradation of Concrete Structures in Nuclear Power Plants: A Review of the Major Causes and Possible Preventive Measures. Energies 2022, 15, 8011. https://doi.org/10.3390/en15218011

Rasheed PA, Nayar SK, Barsoum I, Alfantazi A. Degradation of Concrete Structures in Nuclear Power Plants: A Review of the Major Causes and Possible Preventive Measures. Energies. 2022; 15(21):8011. https://doi.org/10.3390/en15218011

Chicago/Turabian StyleRasheed, Pathath Abdul, Sunitha K. Nayar, Imad Barsoum, and Akram Alfantazi. 2022. "Degradation of Concrete Structures in Nuclear Power Plants: A Review of the Major Causes and Possible Preventive Measures" Energies 15, no. 21: 8011. https://doi.org/10.3390/en15218011

APA StyleRasheed, P. A., Nayar, S. K., Barsoum, I., & Alfantazi, A. (2022). Degradation of Concrete Structures in Nuclear Power Plants: A Review of the Major Causes and Possible Preventive Measures. Energies, 15(21), 8011. https://doi.org/10.3390/en15218011