Strategies for the Modelisation of Electric Vehicle Energy Consumption: A Review

Abstract

:1. Introduction

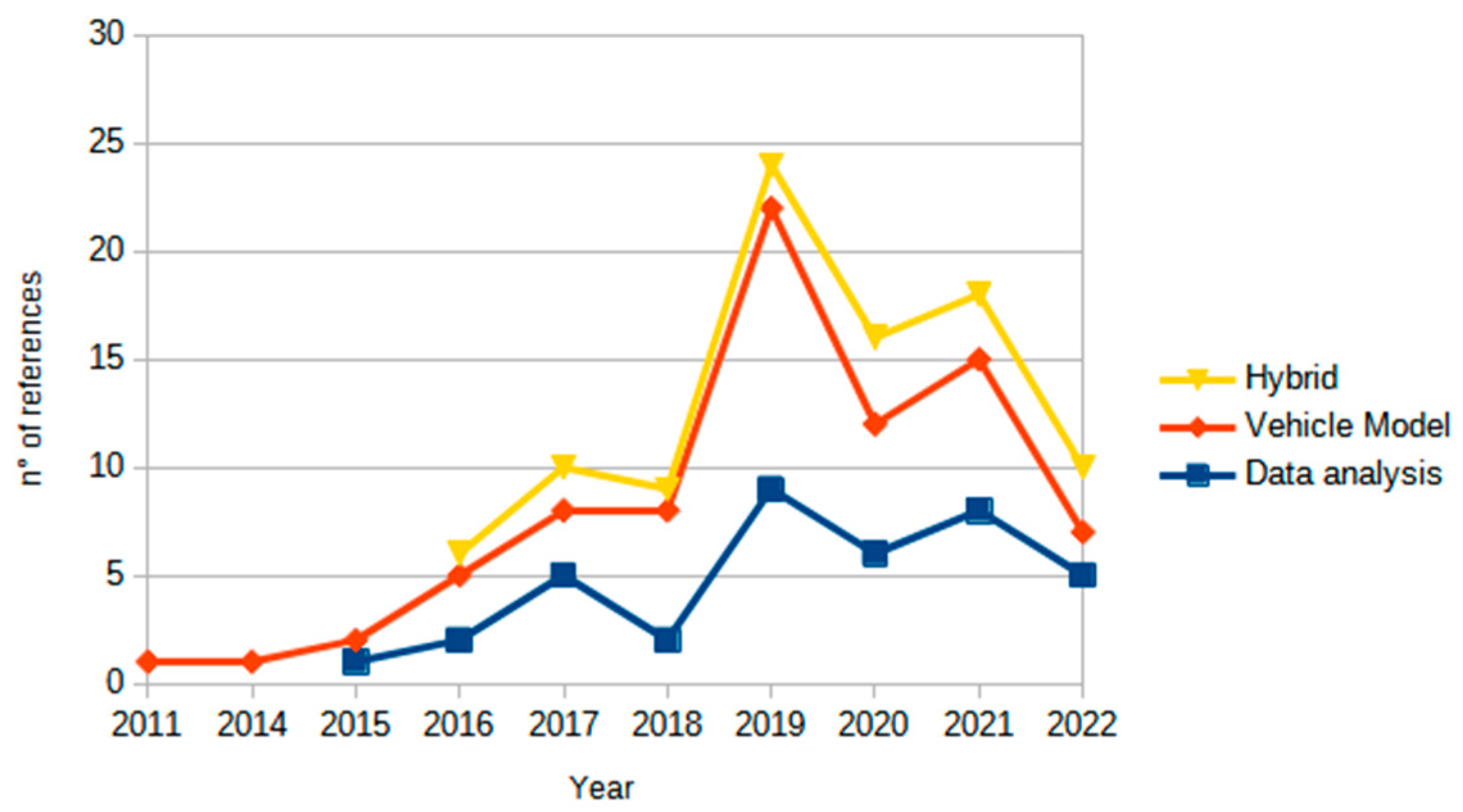

2. Literature Review

- Slope gradients;

- Driving styles;

- Auxiliary systems (e.g., air conditioner, etc.);

- Traffic [14].

- Slope gradients: the presence of a path with sensible variations of slope angles increases energy consumption.

- Driving styles: the influences on energy consumption depend on the driver’s attitude; the differences in the energy demands between driving styles are huge.

- Auxiliary systems (e.g., air conditioner, etc.): the impacts of these subsystems are less direct on ICEs and are hidden because of large tank capacities, but are still considerable.

- Traffic: driving within the city with subsequent stop-and-go dramatically increases energy consumption, with high values of fuel demand from the engine; this is reduced on highways since ICE works at its highest efficiency.

- Slope gradients: as previously mentioned for ICE, the effects include increased energy demand and consumption; this condition amplifies the gravity of the issue since (in general) mountainous environments suffer from a lack of charging infrastructure [5].

- Traffic: EVs suffer from the opposite conditions; if driving within the city is beneficial (thanks to regenerated energy during braking, which contributes to recovering and saving energy), problems emerge when driving along the highways (when there are few and less intensive braking opportunities), thus dramatically increasing the energy consumption [36,37,38,39].

| Type | Powertrain Characteristics | Advantages | Disadvantages | |

|---|---|---|---|---|

| ICE [40] |  | Fuel engine | Low refuelling time Many refuelling stations | GHG emissions Fossil fuel dependency Low efficiency Noise |

| HEV, mHEV, MHEV [26] |  | ICE, electric motor, and battery pack | Higher efficiency Lower emissions Many refuelling stations | GHG emissions Fossil fuel dependency Noise |

| PHEV [25] |  | ICE, electric motor, and battery pack | Higher efficiency Home/work recharge Many refuelling stations | Technological complexity |

| EREV [41] |  | Electric motor and battery pack, ICE (recharging battery) | Higher efficiency Home/work recharged Many refuelling stations | Technological complexity |

| BEV [42] |  | Electric motor and battery pack | Higher efficiency Home/work recharge Low noise No GHG emissions | Fewer recharging stations Long charging time Short driving range |

| FCEV [43] |  | Fuel tank, fuel cell, and electric motor | Higher efficiency Low noise No GHG emissions | Lack of refuelling stations Limited commercial availability Technological complexity |

3. Materials and Methods

- The available start data;

- The type (or the aim) of analysis to be set;

- The type of results to be provided.

- Vehicle model-driven approach;

- Data-driven analysis approach.

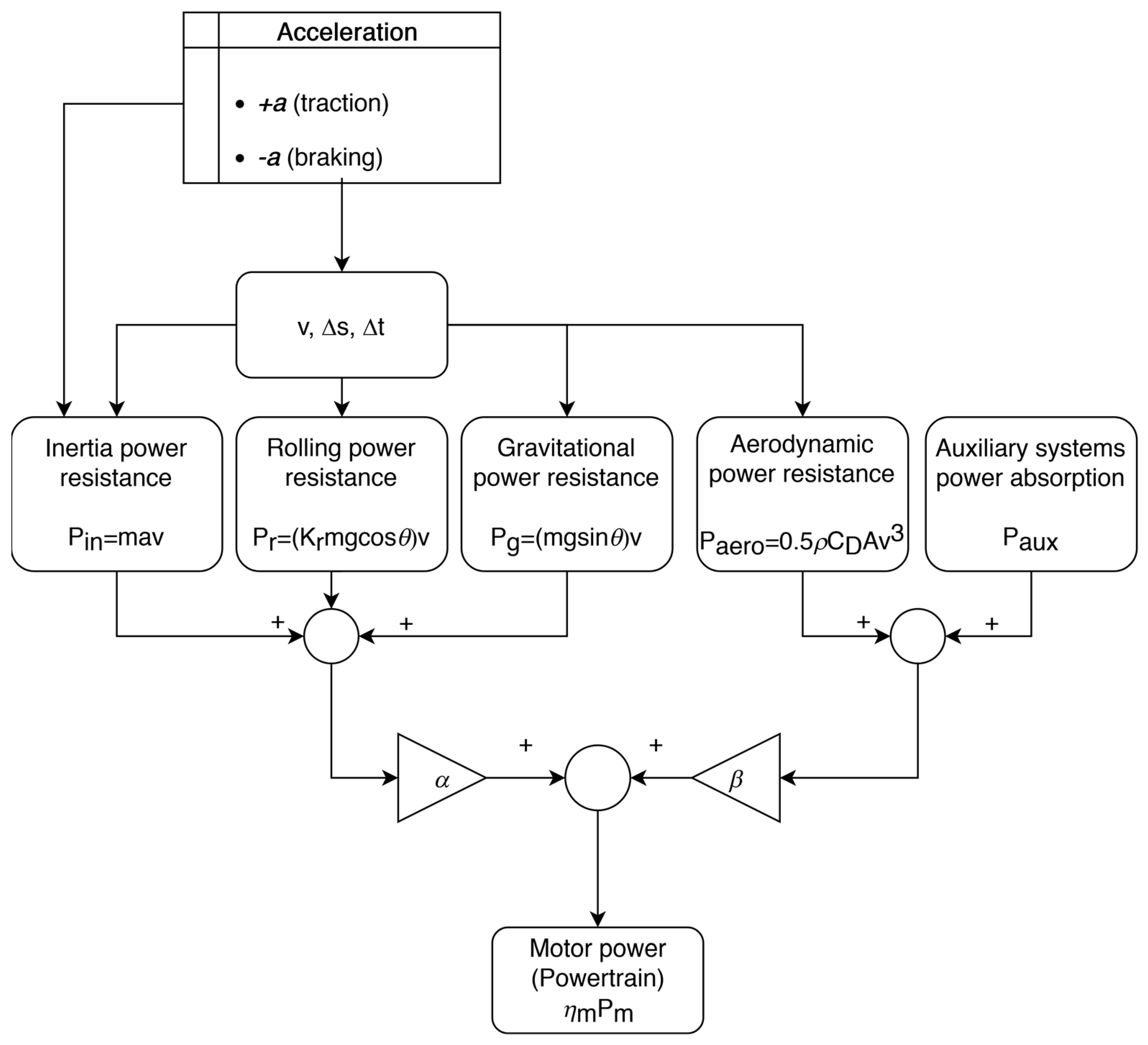

4. Vehicle Model-Driven Approach

- The forward vehicle model (FVM) starts from the already known powertrain characteristics and computes traction forces requested by the driver and generated by the powertrain unit to estimate vehicle kinematics through the vehicle modelisation;

- The backward vehicle model (BVM) starts from already known kinematic quantities and computes traction forces required from the powertrain unit to be generated, estimating the powertrain performance [34].

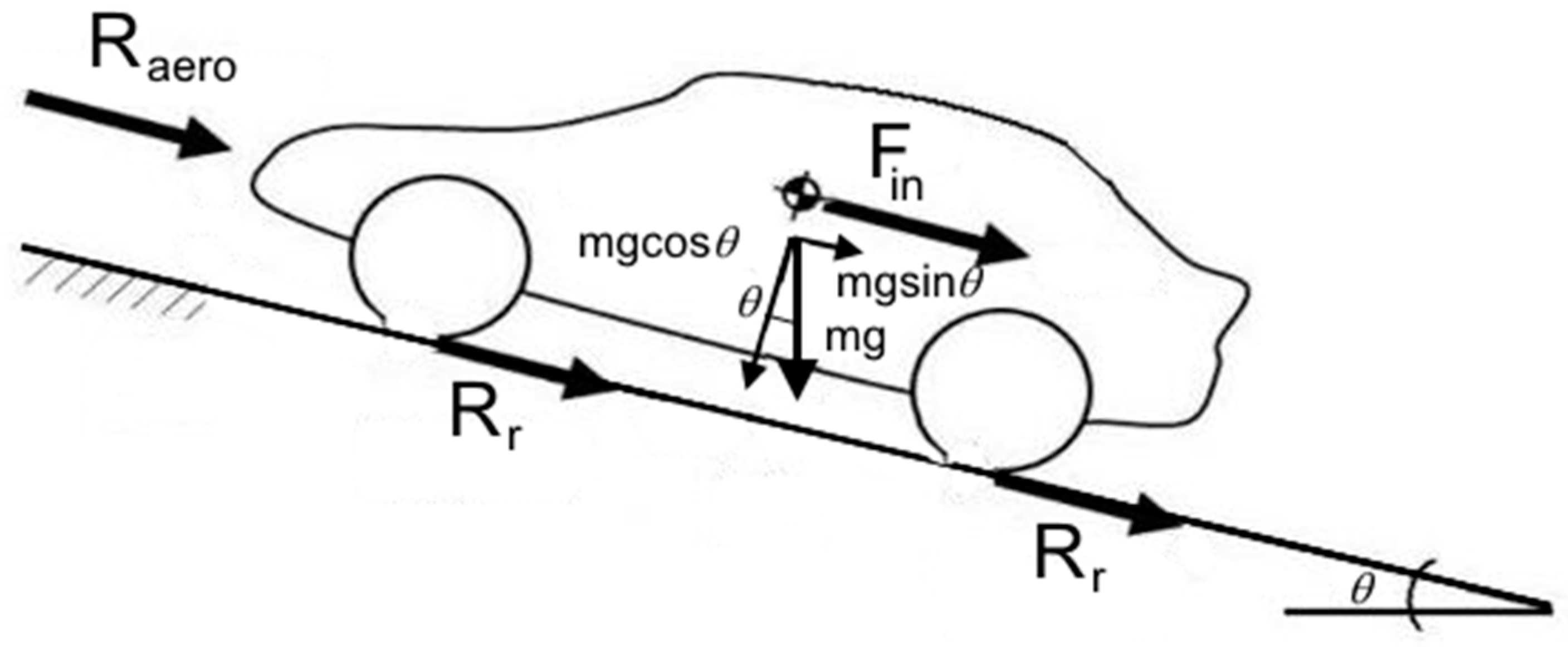

- Slope (or gravitational) resistance is defined according to the horizontal component of the weight as depicted in Figure 2 and reported in (1)

- Rolling resistance is generated by the non-uniform air pressure distribution into the tyre, combined with the elastic tyre deformation during rolling motion. It is modelled according to (2), considering the perpendicular component of the vehicle weight, as already reported in Figure 2. The rolling resistance coefficient shows static and dynamic terms, which depend on v2, as reported in (3)

- Inertia resistance (or inertia force) is commonly considered according to the famous Newtonian principle (4):

- Aerodynamic resistance is generated by fluid–dynamic interactions between the vehicle and air in motion. It is basically due to the air–surface friction, high-low pressure differences, and vortex generation in the rear low-pressure zone, where the separation of the boundary layer from the aerodynamic surface is frequent. Aerodynamic resistance is modelled according to the aerodynamic drag Formula (5):where all parameters involved are briefly reported and the meanings are explained in Table 2.

4.1. Microsimulation and PVM: Power-Based Vehicle Model

- PFM for a conventional fuel-engine vehicle model;

- PEM for an electric vehicle (EV) model;

- PPM for a plug-in hybrid electric vehicle (PHEV) model.

4.2. VRP: Vehicle Routing Problem

4.3. Multi-Objective Optimisation

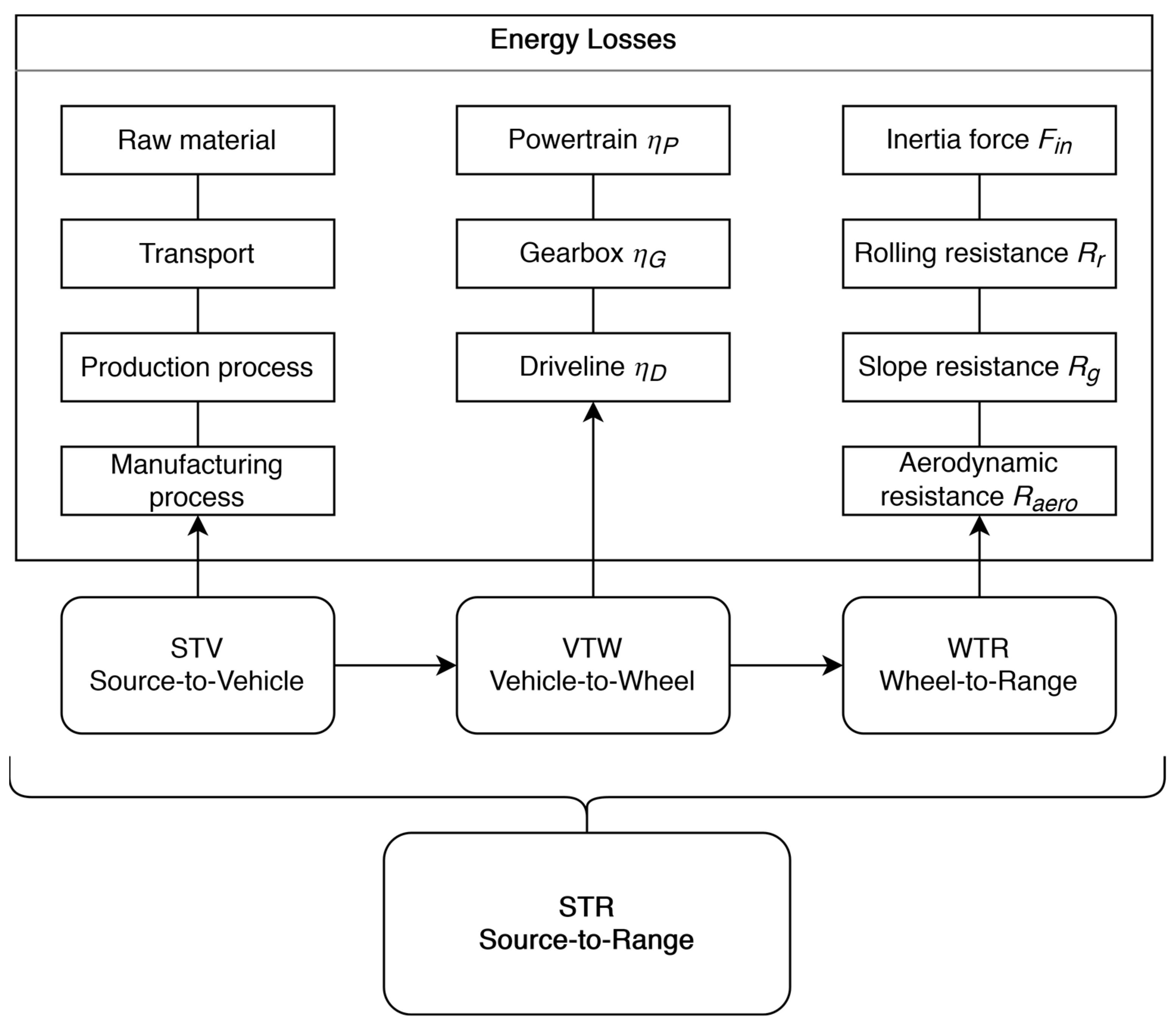

4.4. STR: Source-to-Range Model

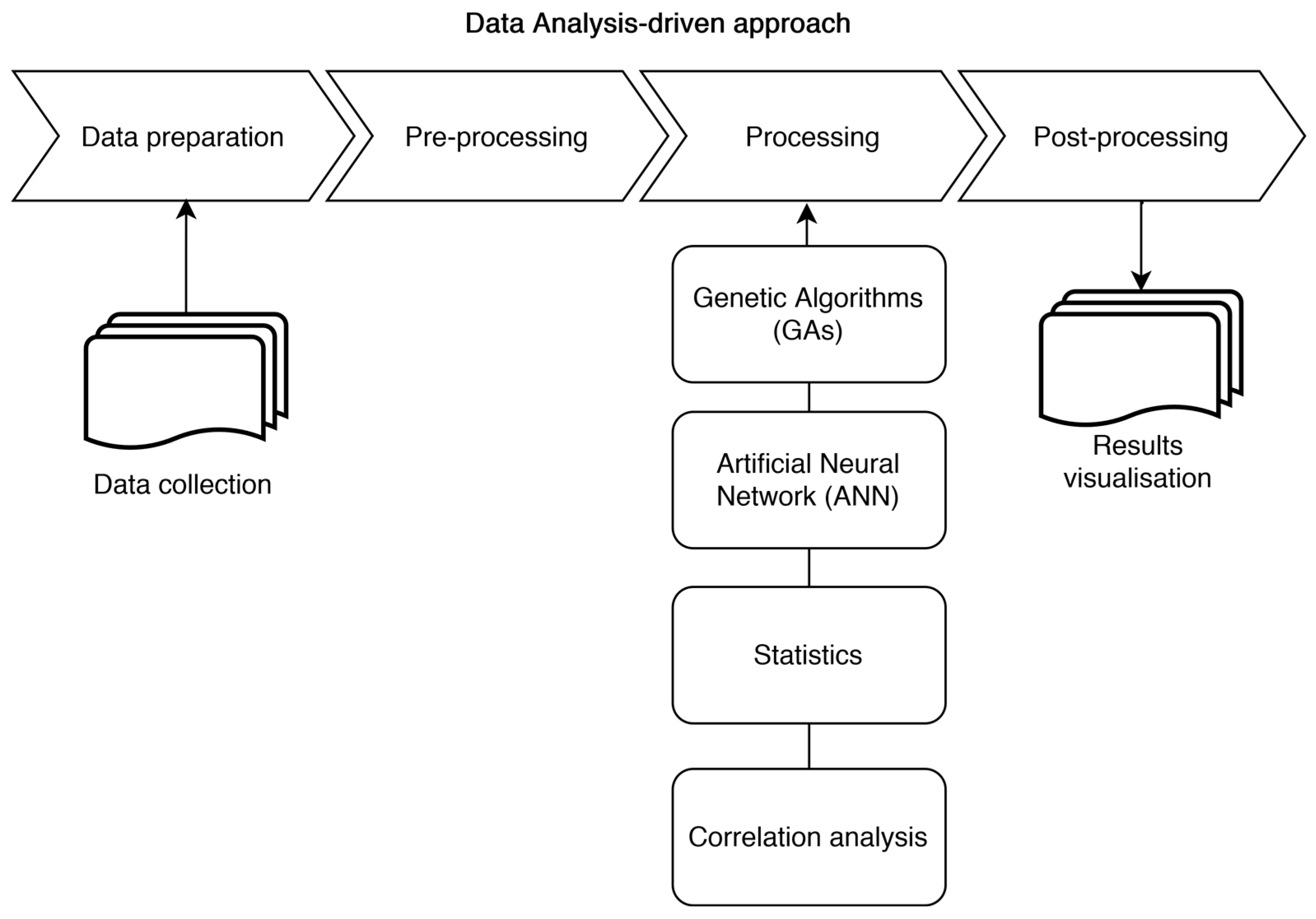

5. Data-Driven Analysis Approach

5.1. Machine Learning

5.2. Well-To-Wheel Problem (WTW)

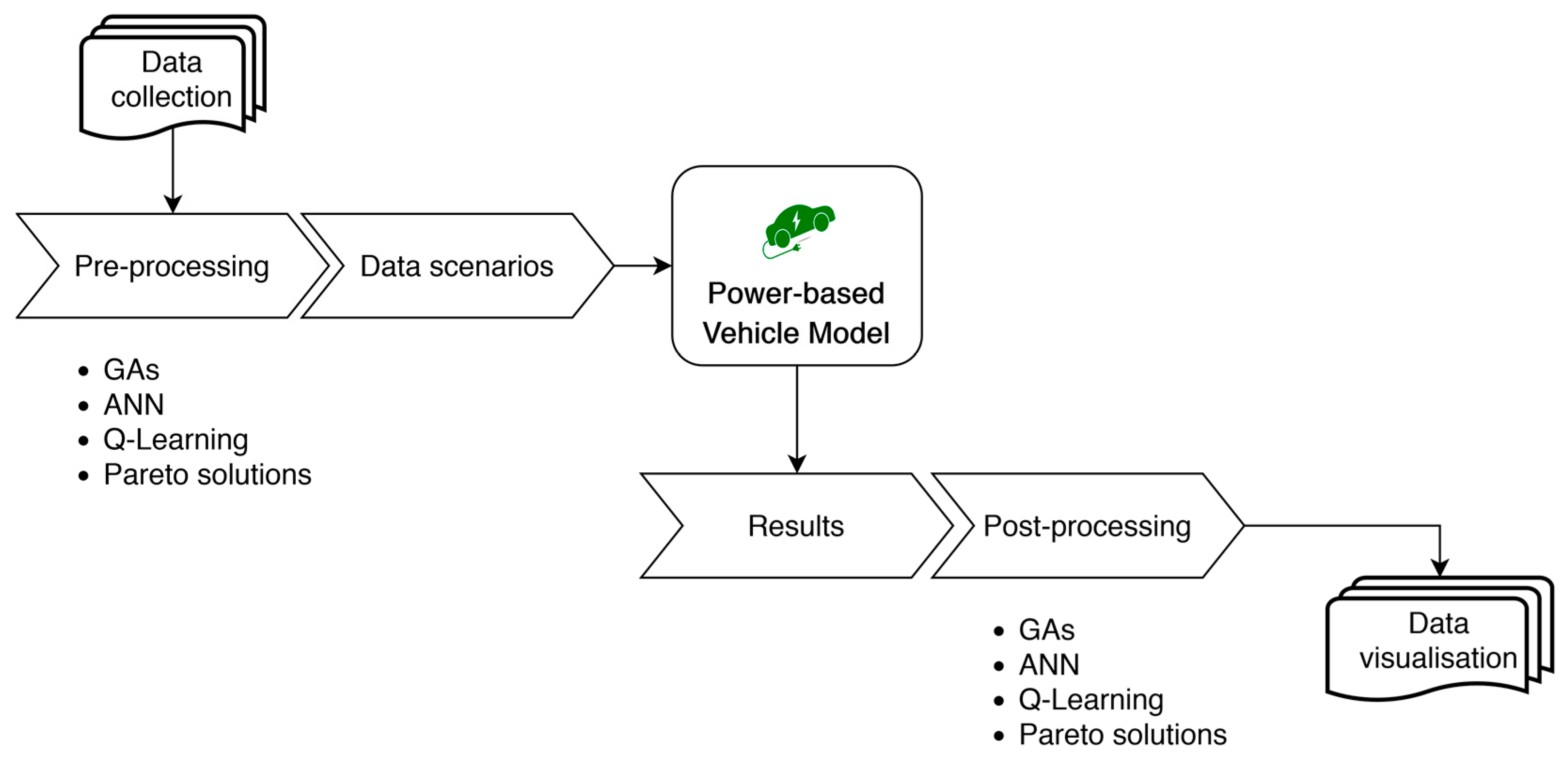

6. Hybrid Approach

7. Discussion

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

List of Abbreviations

| ANN | artificial neural network |

| BEV | battery electric vehicle |

| BVM | backward vehicle model |

| CPU | central processing unit |

| DA | data analysis |

| DDQN | double deep Q-learning network |

| DoE | design of experiments |

| EMS | energy management system |

| EREV | extended-range electric vehicle |

| EU | European Union |

| EV | electric vehicle |

| FCEV | fuel cell electric vehicle |

| FTP | federal test procedure |

| FVM | forward vehicle model |

| GA | genetic algorithm |

| GHG | greenhouse gases |

| GPU | graphics processing unit |

| HEV | hybrid electric vehicle |

| HVAC | heating, ventilating, air conditioning |

| HWFET | highway fuel economy test |

| ICE | internal combustion engine |

| LSLPP | large-scale learning and prediction process |

| LSR | least square reduction |

| LSSP | large-scale simulation process |

| MHEV | mild hybrid electric vehicle |

| mHEV | micro-hybrid electric vehicle |

| NEDC | new European driving cycle |

| NN | neural network |

| OBD | on-board diagnostics |

| PHEV | plug-in hybrid electric vehicle |

| PI | proportional integral |

| PEM | power-based electric vehicle model |

| PFM | power-based fuel-engine vehicle model |

| PPM | power-based plug-in hybrid vehicle model |

| PVM | power-based vehicle model |

| SOC | state of charge |

| STR | source-to-range |

| SWOT | strength, weaknesses, opportunities, threats |

| VM | vehicle model |

| VRP | vehicle routing problem |

| WLTP | worldwide-harmonised light-duty vehicle test procedure |

| WTW | well-to-wheel |

References

- Fiori, C.; Ahn, K.; Rakha, H.A. Power-Based Electric Vehicle Energy Consumption Model: Model Development and Validation. Appl. Energy 2016, 168, 257–268. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Liu, P.; Zhang, Z. Energy Consumption Analysis and Prediction of Electric Vehicles Based on Real-World Driving Data. Appl. Energy 2020, 275, 115408. [Google Scholar] [CrossRef]

- Xiao, Y.; Zuo, X.; Kaku, I.; Zhou, S.; Pan, X. Development of Energy Consumption Optimization Model for the Electric Vehicle Routing Problem with Time Windows. J. Clean. Prod. 2019, 225, 647–663. [Google Scholar] [CrossRef]

- Al-Wreikat, Y.; Serrano, C.; Sodré, J.R. Driving Behaviour and Trip Condition Effects on the Energy Consumption of an Electric Vehicle under Real-World Driving. Appl. Energy 2021, 297, 117096. [Google Scholar] [CrossRef]

- Montero Romero, A.; Di Martino, A.; Longo, M.; Barelli, L.; Zaninelli, D. Full Implementation of Electric Mobility in a Countryside Region of Spain. Energies 2022, 15, 6336. [Google Scholar] [CrossRef]

- Krause, J.; Thiel, C.; Tsokolis, D.; Samaras, Z.; Rota, C.; Ward, A.; Prenninger, P.; Coosemans, T.; Neugebauer, S.; Verhoeve, W. EU Road Vehicle Energy Consumption and CO2 Emissions by 2050–Expert-Based Scenarios. Energy Policy 2020, 138, 111224. [Google Scholar] [CrossRef]

- Hao, H.; Qiao, Q.; Liu, Z.; Zhao, F. Impact of Recycling on Energy Consumption and Greenhouse Gas Emissions from Electric Vehicle Production: The China 2025 Case. Resour. Conserv. Recycl. 2017, 122, 114–125. [Google Scholar] [CrossRef]

- Qiao, Q.; Zhao, F.; Liu, Z.; Hao, H. Electric Vehicle Recycling in China: Economic and Environmental Benefits. Resour. Conserv. Recycl. 2019, 140, 45–53. [Google Scholar] [CrossRef]

- Huang, W.; Guo, Y.; Xu, X. Evaluation of Real-Time Vehicle Energy Consumption and Related Emissions in China: A Case Study of the Guangdong–Hong Kong–Macao Greater Bay Area. J. Clean. Prod. 2020, 263, 121583. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Ouyang, M. Energy Consumption of Electric Vehicles Based on Real-World Driving Patterns: A Case Study of Beijing. Appl. Energy 2015, 157, 710–719. [Google Scholar] [CrossRef]

- Colombo, C.G.; Miraftabzade, S.; Aimar, M.; Zaninelli, D.; Longo, M.; Yaici, W. A Comprehensive Study on Electrification of Old Bus Fleets: A Real Case Study in Ottawa. In Proceedings of the 2022 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Sorrento, Italy, 22–24 June 2022; pp. 844–849. [Google Scholar] [CrossRef]

- Liu, K.; Wang, J.; Yamamoto, T.; Morikawa, T. Exploring the Interactive Effects of Ambient Temperature and Vehicle Auxiliary Loads on Electric Vehicle Energy Consumption. Appl. Energy 2018, 227, 324–331. [Google Scholar] [CrossRef]

- Luin, B.; Petelin, S.; Al-Mansour, F. Microsimulation of Electric Vehicle Energy Consumption. Energy 2019, 174, 24–32. [Google Scholar] [CrossRef]

- Xie, Y.; Li, Y.; Zhao, Z.; Dong, H.; Wang, S.; Liu, J.; Guan, J.; Duan, X. Microsimulation of Electric Vehicle Energy Consumption and Driving Range. Appl. Energy 2020, 267, 115081. [Google Scholar] [CrossRef]

- Wang, Y.; Wen, Y.; Zhu, Q.; Luo, J.; Yang, Z.; Su, S.; Wang, X.; Hao, L.; Tan, J.; Yin, H.; et al. Real Driving Energy Consumption and CO2 & Pollutant Emission Characteristics of a Parallel Plug-in Hybrid Electric Vehicle under Different Propulsion Modes. Energy 2022, 244, 123076. [Google Scholar] [CrossRef]

- Hao, X.; Wang, H.; Lin, Z.; Ouyang, M. Seasonal Effects on Electric Vehicle Energy Consumption and Driving Range: A Case Study on Personal, Taxi, and Ridesharing Vehicles. J. Clean. Prod. 2020, 249, 119403. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, C.; Chen, X.; Zhang, C.; Chen, J. Annual Energy Consumption of Electric Vehicle Air Conditioning in China. Appl. Therm. Eng. 2017, 125, 567–574. [Google Scholar] [CrossRef]

- Wang, J.B.; Liu, K.; Yamamoto, T.; Morikawa, T. Improving Estimation Accuracy for Electric Vehicle Energy Consumption Considering the Effects of Ambient Temperature. Energy Procedia 2017, 105, 2904–2909. [Google Scholar] [CrossRef]

- Al-Wreikat, Y.; Serrano, C.; Sodré, J.R. Effects of Ambient Temperature and Trip Characteristics on the Energy Consumption of an Electric Vehicle. Energy 2022, 238, 122028. [Google Scholar] [CrossRef]

- Kaleybar, H.J.; Brenna, M.; Foiadelli, F. EV Charging Station Integrated with Electric Railway System Powering by Train Regenerative Braking Energy. In Proceedings of the 2020 IEEE Vehicle on Power Propulsion Conference VPPC, Virtual, 18 November–16 December 2020. [Google Scholar] [CrossRef]

- Zhang, S.; Gajpal, Y.; Appadoo, S.S.; Abdulkader, M.M.S. Electric Vehicle Routing Problem with Recharging Stations for Minimizing Energy Consumption. Int. J. Prod. Econ. 2018, 203, 404–413. [Google Scholar] [CrossRef]

- Saldarini, A.; Barelli, L.; Pelosi, D.; Miraftabzadeh, S.; Longo, M.; Yaici, W. Different Demand for Charging Infrastructure along a Stretch of Highway: Italian Case Study. In Proceedings of the 2022 IEEE International Conference on Environment and Electrical Engineering and 2022 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Prague, Czech Republic, 28 June–1 July 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Chung, Y.W.; Khaki, B.; Li, T.; Chu, C.; Gadh, R. Ensemble Machine Learning-Based Algorithm for Electric Vehicle User Behavior Prediction. Appl. Energy 2019, 254, 113732. [Google Scholar] [CrossRef]

- Ruan, J.; Walker, P.; Zhang, N. A Comparative Study Energy Consumption and Costs of Battery Electric Vehicle Transmissions. Appl. Energy 2016, 165, 119–134. [Google Scholar] [CrossRef] [Green Version]

- Da Silva, S.F.; Eckert, J.J.; Silva, F.L.; Silva, L.C.A.; Dedini, F.G. Multi-Objective Optimization Design and Control of Plug-in Hybrid Electric Vehicle Powertrain for Minimization of Energy Consumption, Exhaust Emissions and Battery Degradation. Energy Convers. Manag. 2021, 234, 113909. [Google Scholar] [CrossRef]

- Fanesi, M.; Scaradozzi, D. Optimize the Mild Hybrid Electric Vehicles Control System to Reduce the Emission. In Proceedings of the 2019 IEEE 23rd International Symposym on Consuming Technology ISCT, Ancona, Italy, 19–21 June 2019; pp. 317–321. [Google Scholar] [CrossRef]

- Fiori, C.; Ahn, K.; Rakha, H.A. Microscopic Series Plug-in Hybrid Electric Vehicle Energy Consumption Model: Model Development and Validation. Transp. Res. Part D Transp. Environ. 2018, 63, 175–185. [Google Scholar] [CrossRef]

- Sweeting, W.J.; Hutchinson, A.R.; Savage, S.D. Factors Affecting Electric Vehicle Energy Consumption. Int. J. Sustain. Eng. 2011, 4, 192–201. [Google Scholar] [CrossRef]

- Desreveaux, A.; Bouscayrol, A.; Trigui, R.; Castex, E.; Klein, J. Impact of the Velocity Profile on Energy Consumption of Electric Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 11420–11426. [Google Scholar] [CrossRef]

- Jiménez, D.; Hernández, S.; Fraile-Ardanuy, J.; Serrano, J.; Fernández, R.; Alvarez, F. Modelling the Effect of Driving Events on Electrical Vehicle Energy Consumption Using Inertial Sensors in Smartphones. Energies 2018, 11, 412. [Google Scholar] [CrossRef]

- He, H.; Liu, D.; Lu, X.; Xu, J. ECO Driving Control for Intelligent Electric Vehicle with Real-Time Energy. Electronics 2021, 10, 2613. [Google Scholar] [CrossRef]

- Julio-Rodríguez, J.; Rojas-Ruiz, J.D.C.; Santana-Díaz, C.A.; Bustamante-Bello, A.; Ramirez-Mendoza, M.R.; Julio-Rodríguez, J.D.C.; Rojas-Ruiz, C.A.; Santana-Díaz, A.; Bustamante-Bello, R.; Ramirez-Mendoza, R.A. Environment Classification Using Machine Learning Methods for Eco-Driving Strategies in Intelligent Vehicles. Appl. Sci. 2022, 12, 5578. [Google Scholar] [CrossRef]

- Ramsey, D.; Bouscayrol, A.; Boulon, L.; Desreveaux, A.; Vaudrey, A. Flexible Simulation of an Electric Vehicle to Estimate the Impact of Thermal Comfort on the Energy Consumption. IEEE Trans. Transp. Electrif. 2022, 8, 2288–2298. [Google Scholar] [CrossRef]

- Miri, I.; Fotouhi, A.; Ewin, N. Electric Vehicle Energy Consumption Modelling and Estimation—A Case Study. Int. J. Energy Res. 2021, 45, 501–520. [Google Scholar] [CrossRef]

- Yi, Z.; Bauer, P.H. Effects of Environmental Factors on Electric Vehicle Energy Consumption: A Sensitivity Analysis. IET Electr. Syst. Transp. 2017, 7, 3–13. [Google Scholar] [CrossRef]

- El Amrani, S.; Chennani, M.; Belkhayat, D. Comparative Study of Electric Vehicle Energy Consumption between Trunk Roads and Highways. In Proceedings of the 7th International Renewable Sustainable Energy Conference IRSEC, Agadir, Morocco, 27–30 November 2019. [Google Scholar] [CrossRef]

- Madhusudhanan, A.K.; Na, X. Effect of a Traffic Speed Based Cruise Control on an Electric Vehicles Performance and an Energy Consumption Model of an Electric Vehicle. IEEE/CAA J. Autom. Sin. 2020, 7, 386–394. [Google Scholar] [CrossRef]

- Ahn, K.; Park, S.; Rakha, H.A. Impact of Intersection Control on Battery Electric Vehicle Energy Consumption. Energies 2020, 13, 3190. [Google Scholar] [CrossRef]

- Wager, G.; Whale, J.; Braunl, T. Driving Electric Vehicles at Highway Speeds: The Effect of Higher Driving Speeds on Energy Consumption and Driving Range for Electric Vehicles in Australia. Renew. Sustain. Energy Rev. 2016, 63, 158–165. [Google Scholar] [CrossRef]

- Xiong, H.; Liu, H.; Zhang, R.; Yu, L.; Zong, Z.; Zhang, M.; Li, Z. An Energy Matching Method for Battery Electric Vehicle and Hydrogen Fuel Cell Vehicle Based on Source Energy Consumption Rate. Int. J. Hydrogen Energy 2019, 44, 29733–29742. [Google Scholar] [CrossRef]

- Kusuma, C.F.; Budiman, B.A.; Nurprasetio, I.P. Simulation Method for Extended-Range Electric Vehicle Battery State of Charge and Energy Consumption Simulation Based on Driving Cycle. In Proceedings of the ICEVT 2019 6th International Conference on Electric Vehicle Technology, Bali, Indonesia, 18–21 November 2019; pp. 336–344. [Google Scholar] [CrossRef]

- Iora, P.; Tribioli, L. Effect of Ambient Temperature on Electric Vehicles’ Energy Consumption and Range: Model Definition and Sensitivity Analysis Based on Nissan Leaf Data. World Electr. Veh. J. 2019, 10, 2. [Google Scholar] [CrossRef] [Green Version]

- Ruan, J.; Zhang, B.; Liu, B.; Wang, S. The Multi-Objective Optimization of Cost, Energy Consumption and Battery Degradation for Fuel Cell-Battery Hybrid Electric Vehicle. In Proceedings of the 2021 11th International Conference on Power, Energy and Electric Engineering CPEEE, Shiga, Japan, 26–28 February 2021; pp. 50–55. [Google Scholar] [CrossRef]

- Ye, F.; Wu, G.; Boriboonsomsin, K.; Barth, M.J. A Hybrid Approach to Estimating Electric Vehicle Energy Consumption for Ecodriving Applications. In Proceedings of the IEEE Conference on Intelligence Transportation Systems ITSC, Rio de Janeiro, Brazil, 1–4 November 2016; pp. 719–724. [Google Scholar] [CrossRef]

- Li, W.; Stanula, P.; Egede, P.; Kara, S.; Herrmann, C. Determining the Main Factors Influencing the Energy Consumption of Electric Vehicles in the Usage Phase. Procedia CIRP 2016, 48, 352–357. [Google Scholar] [CrossRef] [Green Version]

- Wieczorek, M.; Lewandowski, M. A Mathematical Representation of an Energy Management Strategy for Hybrid Energy Storage System in Electric Vehicle and Real Time Optimization Using a Genetic Algorithm. Appl. Energy 2017, 192, 222–233. [Google Scholar] [CrossRef]

- Yi, Z.; Bauer, P.H. Adaptive Multiresolution Energy Consumption Prediction for Electric Vehicles. IEEE Trans. Veh. Technol. 2017, 66, 10515–10525. [Google Scholar] [CrossRef]

- Lei, F.; Bai, Y.; Zhu, W.; Liu, J. A Novel Approach for Electric Powertrain Optimization Considering Vehicle Power Performance, Energy Consumption and Ride Comfort. Energy 2019, 167, 1040–1050. [Google Scholar] [CrossRef]

- Teixeira, A.C.R.; Sodré, J.R. Impacts of Replacement of Engine Powered Vehicles by Electric Vehicles on Energy Consumption and CO2 Emissions. Transp. Res. Part D Transp. Environ. 2018, 59, 375–384. [Google Scholar] [CrossRef]

- Ruangjirakit, K.; Laoonual, Y.; Charadsuksawat, A.; Kiattikomol, V.; Sridan, S. A Study of Grid-to-Wheel Energy Consumption of Electric Vehicle on Real Road Tests in Bangkok. In Proceedings of the ITEC Asia-Pacific 2018 Transportation Electrification Conference and Expo, Asia-Pacific E-Mobility A Journey from Now Beyond, Bankok, Thailand, 6–9 June 2018. [Google Scholar] [CrossRef]

- Patrone, G.L.; Paffumi, E.; Otura, M.; Centurelli, M.; Ferrarese, C.; Jahn, S.; Brenner, A.; Thieringer, B.; Braun, D.; Hoffmann, T. Assessing the Energy Consumption and Driving Range of the QUIET Project Demonstrator Vehicle. Energies 2022, 15, 1290. [Google Scholar] [CrossRef]

- Zhang, Z.; Zou, Y.; Zhou, T.; Zhang, X.; Xu, Z. Energy Consumption Prediction of Electric Vehicles Based on Digital Twin Technology. World Electr. Veh. J. 2021, 12, 160. [Google Scholar] [CrossRef]

- Fritsch, M.; Liu-Henke, X. Optimization of Energy Consumption by Using an Intelligent Assistance System for an Electric Vehicle. In Proceedings of the 2017 12th International Conference on Ecological Vehicle Renewable Energies, EVER, Monte-Carlo, Monaco, 11–13 April 2017. [Google Scholar] [CrossRef]

- Li, Y.; Zhong, Z.; Zhang, K.; Zheng, T. A Car-Following Model for Electric Vehicle Traffic Flow Based on Optimal Energy Consumption. Phys. A Stat. Mech. its Appl. 2019, 533, 122022. [Google Scholar] [CrossRef]

- Wang, R.; Liu, H.; Li, M.J.; Sun, Q.; Li, X.; Wang, P. Fast Charging Control Method for Electric Vehicle-to-Vehicle Energy Interaction Devices. IEEE Trans. Transp. Electrif. 2022. [Google Scholar] [CrossRef]

- Kaleybar, H.J.; Brenna, M.; Li, H.; Zaninelli, D. Fuel Cell Hybrid Locomotive with Modified Fuzzy Logic Based Energy Management System. Sustainability 2022, 14, 8336. [Google Scholar] [CrossRef]

- Ruchita; Shankar, R. Hybrid Evs Using SWOT Analysis. In Proceedings of the 2nd International Conference on Emerging Frontiers in Electrical and Electronic Technologies (ICEFEET), Virtual, 24–25 June 2022. [Google Scholar] [CrossRef]

- Fafoutellis, P.; Mantouka, E.G.; Vlahogianni, E.I. Eco-Driving and Its Impacts on Fuel Efficiency: An Overview of Technologies and Data-Driven Methods. Sustainability 2020, 13, 226. [Google Scholar] [CrossRef]

- Wi, J.; Kim, H.; Yoo, J.; Son, H.; Kim, H.; Kim, B. Energy Consumption of Parallel Type Hybrid Electric Vehicle with Continuously Variable Transmission Using Electric Oil Pump. In Proceedings of the 13th International Conference on Ecological Vehicle Renewable Energies, EVER, Monte Carlo, Monaco, 10–12 April 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Spanoudakis, P.; Tsourveloudis, N.C.; Doitsidis, L.; Karapidakis, E.S. Experimental Research of Transmissions on Electric Vehicles’ Energy Consumption. Energies 2019, 12, 388. [Google Scholar] [CrossRef]

- Lin, X.; Li, Y.; Zhang, G. Bi-Objective Optimization Strategy of Energy Consumption and Shift Shock Based Driving Cycle-Aware Bias Coefficients for a Novel Dual-Motor Electric Vehicle. Energy 2022, 249, 123596. [Google Scholar] [CrossRef]

- Asef, P.; Bargallo, R.; Lapthorn, A.; Tavernini, D.; Shao, L.; Sorniotti, A. Assessment of the Energy Consumption and Drivability Performance of an IPMSM-Driven Electric Vehicle Using Different Buried Magnet Arrangements. Energies 2021, 14, 1418. [Google Scholar] [CrossRef]

- Li, L.; Liu, Q. Research on IPMSM Drive System Control Technology for Electric Vehicle Energy Consumption. IEEE Access 2019, 7, 186201–186210. [Google Scholar] [CrossRef]

- Desreveaux, A.; Bouscayrol, A.; Castex, E.; Trigui, R.; Hittinger, E.; Sirbu, G.M. Annual Variation in Energy Consumption of an Electric Vehicle Used for Commuting. Energies 2020, 13, 4639. [Google Scholar] [CrossRef]

- Wang, J.; Besselink, I.; Nijmeijer, H. Battery Electric Vehicle Energy Consumption Prediction for a Trip Based on Route Information. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 232, 1528–1542. [Google Scholar] [CrossRef] [Green Version]

- Pelletier, S.; Jabali, O.; Laporte, G. The Electric Vehicle Routing Problem with Energy Consumption Uncertainty. Transp. Res. Part B Methodol. 2019, 126, 225–255. [Google Scholar] [CrossRef]

- Basso, R.; Kulcsár, B.; Egardt, B.; Lindroth, P.; Sanchez-Diaz, I. Energy Consumption Estimation Integrated into the Electric Vehicle Routing Problem. Transp. Res. Part D Transp. Environ. 2019, 69, 141–167. [Google Scholar] [CrossRef]

- Li, J.; Wang, F.; He, Y. Electric Vehicle Routing Problem with Battery Swapping Considering Energy Consumption and Carbon Emissions. Sustainability 2020, 12, 10537. [Google Scholar] [CrossRef]

- Lin, J.; Zhou, W.; Wolfson, O. Electric Vehicle Routing Problem. Transp. Res. Procedia 2016, 12, 508–521. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.; Yu, L.; Li, J. Robust Electric Vehicle Routing Problem with Time Windows under Demand Uncertainty and Weight-Related Energy Consumption. Complex Syst. Model. Simul. 2022, 2, 18–34. [Google Scholar] [CrossRef]

- Peng, T.; Ou, X.; Yan, X. Development and Application of an Electric Vehicles Life-Cycle Energy Consumption and Greenhouse Gas Emissions Analysis Model. Chem. Eng. Res. Des. 2018, 131, 699–708. [Google Scholar] [CrossRef]

- Aljohani, T.M.; Ebrahim, A.; Mohammed, O. Real-Time Metadata-Driven Routing Optimization for Electric Vehicle Energy Consumption Minimization Using Deep Reinforcement Learning and Markov Chain Model. Electr. Power Syst. Res. 2021, 192, 106962. [Google Scholar] [CrossRef]

- Tu, W.; Santi, P.; Zhao, T.; He, X.; Li, Q.; Dong, L.; Wallington, T.J.; Ratti, C. Acceptability, Energy Consumption, and Costs of Electric Vehicle for Ride-Hailing Drivers in Beijing. Appl. Energy 2019, 250, 147–160. [Google Scholar] [CrossRef]

- Oh, G.; Leblanc, D.J.; Peng, H. Vehicle Energy Dataset (VED), A Large-Scale Dataset for Vehicle Energy Consumption Research. IEEE Trans. Intell. Transp. Syst. 2022, 23, 3302–3312. [Google Scholar] [CrossRef]

- Miraftabzadeh, S.M.; Longo, M.; Foiadelli, F.; Pasetti, M.; Igual, R. Advances in the Application of Machine Learning Techniques for Power System Analytics: A Survey. Energies 2021, 14, 4776. [Google Scholar] [CrossRef]

- Miraftabzadeh, S.M.; Foiadelli, F.; Longo, M.; Pasetti, M. A Survey of Machine Learning Applications for Power System Analytics. In Proceedings of the 2019 IEEE International Conference on Environment and Electric Engineering 2019 IEEE Industrial and Commercial Power Systems Europe EEEIC/I CPS, Genova, Italy, 10–14 June 2019. [Google Scholar] [CrossRef]

- Uthathip, N.; Bhasaputra, P.; Pattaraprakorn, W. Application of ANFIS Model for Thailand’s Electric Vehicle Consumption. Comput. Syst. Sci. Eng. 2021, 42, 69–86. [Google Scholar] [CrossRef]

- Yao, J.; Moawad, A. Vehicle Energy Consumption Estimation Using Large Scale Simulations and Machine Learning Methods. Transp. Res. Part C Emerg. Technol. 2019, 101, 276–296. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, D.; Meng, Q.; Ong, G.P.; Lee, D.H. Network-Level Energy Consumption Estimation for Electric Vehicles Considering Vehicle and User Heterogeneity. Transp. Res. Part A Policy Pract. 2020, 132, 30–46. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, D.; Cai, Y.; Meng, Q.; Ong, G.P. A Trajectory-Based Energy Consumption Estimation Method Considering Battery Degradation for an Urban Electric Vehicle Network. Transp. Res. Part D Transp. Environ. 2019, 74, 142–153. [Google Scholar] [CrossRef]

- Morlock, F.; Rolle, B.; Bauer, M.; Sawodny, O. Forecasts of Electric Vehicle Energy Consumption Based on Characteristic Speed Profiles and Real-Time Traffic Data. IEEE Trans. Veh. Technol. 2020, 69, 1404–1418. [Google Scholar] [CrossRef]

- Tseng, C.M.; Chau, C.K. Personalized Prediction of Vehicle Energy Consumption Based on Participatory Sensing. IEEE Trans. Intell. Transp. Syst. 2017, 18, 3103–3113. [Google Scholar] [CrossRef] [Green Version]

- Bucher, D.; Martin, H.; Hamper, J.; Jaleh, A.; Becker, H.; Zhao, P.; Martin, R. Exploring Factors That Influence Individuals’ Choice Between Internal Combustion Engine Cars and Electric Vehicles. Agil. GIScience Ser. 2020, 1, 1–23. [Google Scholar] [CrossRef]

- Liu, K.; Yamamoto, T.; Morikawa, T. Impact of Road Gradient on Energy Consumption of Electric Vehicles. Transp. Res. Part D Transp. Environ. 2017, 54, 74–81. [Google Scholar] [CrossRef]

- Xu, B.; Shi, J.; Li, S.; Li, H.; Wang, Z. Energy Consumption and Battery Aging Minimization Using a Q-Learning Strategy for a Battery/Ultracapacitor Electric Vehicle. Energy 2021, 229, 120705. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, G.; Wei, S. Velocity Prediction Using Markov Chain Combined with Driving Pattern Recognition and Applied to Dual-Motor Electric Vehicle Energy Consumption Evaluation. Appl. Soft Comput. 2021, 101, 106998. [Google Scholar] [CrossRef]

- Foiadelli, F.; Longo, M.; Miraftabzadeh, S. Energy Consumption Prediction of Electric Vehicles Based on Big Data Approach. In Proceedings of the IEEE International Conference on Environment and Electric Engineering 2018 IEEE Industrial and Commercial Power Systems Europe EEEIC/I CPS, Palermo, Italy, 12–15 June 2018. [Google Scholar] [CrossRef]

- Miraftabzadeh, S.M.; Longo, M.; Foiadelli, F. Estimation Model of Total Energy Consumptions of Electrical Vehicles under Different Driving Conditions. Energies 2021, 14, 854. [Google Scholar] [CrossRef]

- Chen, J.; Liang, M.; Ma, X. Probabilistic Analysis of Electric Vehicle Energy Consumption Using MPC Speed Control and Nonlinear Battery Model. IEEE Green Technol. Conf. 2021, 2021, 181–186. [Google Scholar] [CrossRef]

- Hu, X.; Liu, T.; Qi, X.; Barth, M. Reinforcement Learning for Hybrid and Plug-In Hybrid Electric Vehicle Energy Management: Recent Advances and Prospects. IEEE Ind. Electron. Mag. 2019, 13, 16–25. [Google Scholar] [CrossRef]

- Yang, S.C.; Li, M.; Lin, Y.; Tang, T.Q. Electric Vehicle’s Electricity Consumption on a Road with Different Slope. Phys. A Stat. Mech. Appl. 2014, 402, 41–48. [Google Scholar] [CrossRef]

- Fiori, C.; Marzano, V.; Punzo, V.; Montanino, M. Energy Consumption Modeling in Presence of Uncertainty. IEEE Trans. Intell. Transp. Syst. 2021, 22, 6330–6341. [Google Scholar] [CrossRef]

| Parameter | SI Unit | Physical Meaning |

|---|---|---|

| (kg/m3) | Air density | |

| (-) | Aerodynamic drag coefficient 1 | |

| (m2) | Vehicle cross-sectional front surface | |

| (m/s) | Longitudinal vehicle speed |

| Strength | Weaknesses | |

|---|---|---|

| Internal elements | Technical specifications considered | Focus on local subsystems |

| Vehicle-to-vehicle comparison | ||

| Opportunities | Threats | |

| External elements | Integration with Virtual/Augmented Reality | No interactions with the surrounding environment |

| Strength | Weaknesses | |

|---|---|---|

| Internal elements | Big data | No technical analysis |

| Machine learning | ||

| Opportunities | Threats | |

| External elements | Extract patterns | No vehicle model |

| Evaluate behaviours |

| Strategies to Evaluate EV Energy Consumption | |||

|---|---|---|---|

| Data-Driven Analysis | Vehicle Model-Driven | Hybrid | |

| PROs | Evaluate trends [10,16,72] | Sensitivity analysis [27,48] | Merges advantages of DA-VM approaches |

| Big data analysis for prediction [23] | Simulations on real data for prediction | More complete insight into the problem | |

| Real/real-time starting dataset [4,73] | Vehicle technical specs considered [24,44] | Statistics prediction on big data through vehicle model [86] | |

| Correlation/co-factor analysis [45] | Best working point identification | ||

| Interactions considered | Evaluation of vehicle performances [1,91,92] | ||

| Clustering/class comparison [78] | Vehicle-to-vehicle comparison [1,5,34] | ||

| CONs | Global optimisation | Local optimisation [21] | Computational heaviness |

| No knowledge of vehicle | No interactions with the surrounding systems/environment | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Martino, A.; Miraftabzadeh, S.M.; Longo, M. Strategies for the Modelisation of Electric Vehicle Energy Consumption: A Review. Energies 2022, 15, 8115. https://doi.org/10.3390/en15218115

Di Martino A, Miraftabzadeh SM, Longo M. Strategies for the Modelisation of Electric Vehicle Energy Consumption: A Review. Energies. 2022; 15(21):8115. https://doi.org/10.3390/en15218115

Chicago/Turabian StyleDi Martino, Andrea, Seyed Mahdi Miraftabzadeh, and Michela Longo. 2022. "Strategies for the Modelisation of Electric Vehicle Energy Consumption: A Review" Energies 15, no. 21: 8115. https://doi.org/10.3390/en15218115

APA StyleDi Martino, A., Miraftabzadeh, S. M., & Longo, M. (2022). Strategies for the Modelisation of Electric Vehicle Energy Consumption: A Review. Energies, 15(21), 8115. https://doi.org/10.3390/en15218115