Orderliness in Mining 4.0

Abstract

1. Introduction

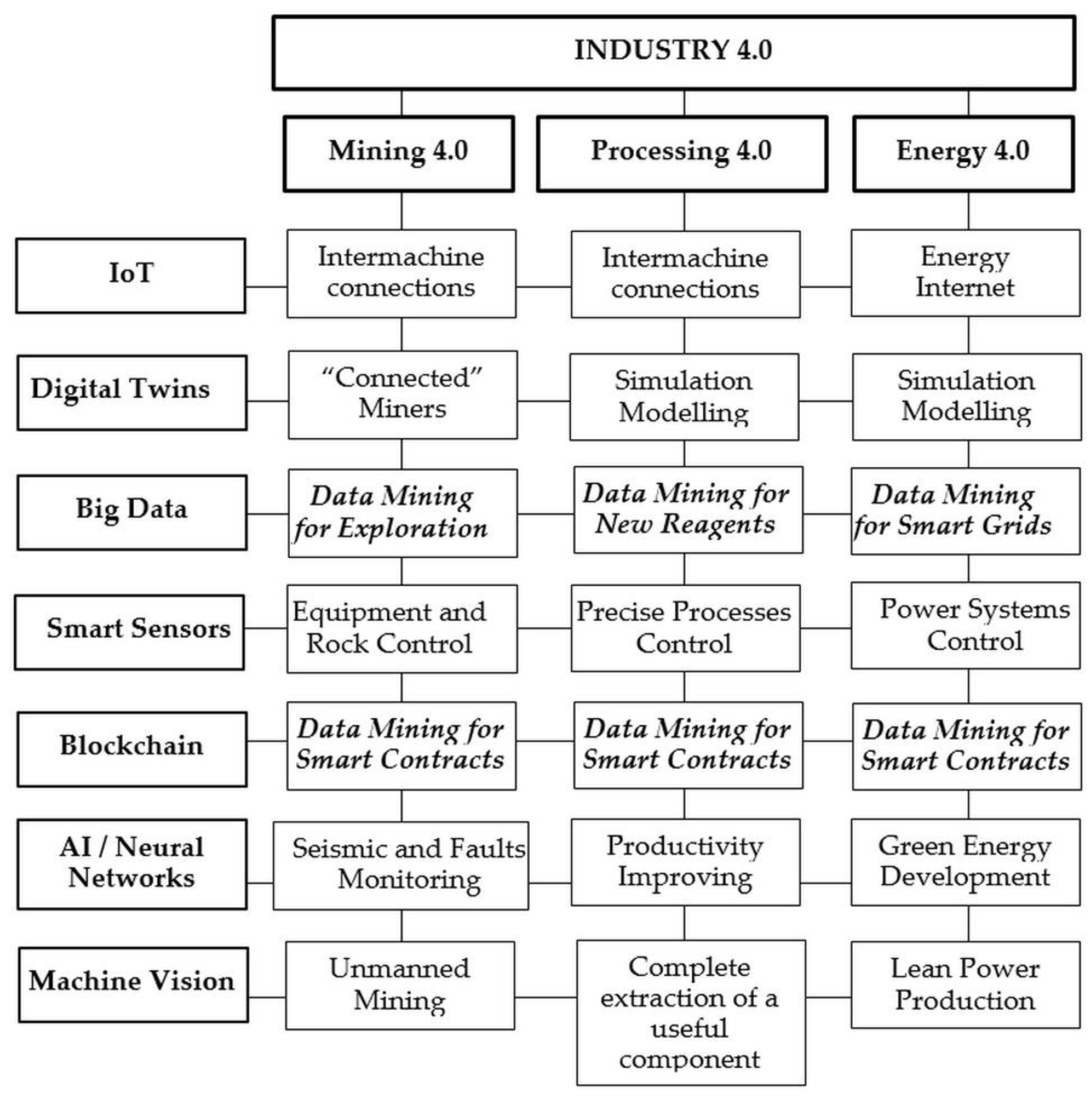

2. Digital Maturity of Mining 4.0

3. Data Mining in Transition to Mining 5.0

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Agricola, G. De Natura Forum, Quae Effluunt ex Terra; SNM: Bratislava, Slovakia, 1996. [Google Scholar]

- Agricola, G. De Re Metallica; Dover Publications: New York, NY, USA, 2013. [Google Scholar]

- Bin, A.; Rashid, A.S.; Zhang, J. Advances in Mineral Resources, Geotechnology and Geological Exploration; CRC Press: London, UK, 2022. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution; World Economic Forum: Geneva, Switzerland, 2016. [Google Scholar]

- Frenz, W. Industry 4.0 in Mining. In Yearbook of Sustainable Smart Mining and Energy; Frenz, W., Preusse, A., Eds.; Springer: New York, NY, USA, 2022; pp. 13–22. [Google Scholar] [CrossRef]

- Fataliyev, T.K.; Mehdiyev, S.A. The Impact of Industry 4.0 on the Formation of Science 4.0. Probl. Inf. Technol. 2022, 13, 40–47. [Google Scholar] [CrossRef]

- Wang, X.; Yao, F.; Wen, F. Applications of Blockchain Technology in Modern Power Systems: A Brief Survey. Energies 2022, 15, 4516. [Google Scholar] [CrossRef]

- Tyleckova, E.; Noskievicova, D. The role of big data in Industry 4.0 in mining industry in Serbia. CzOTO 2020, 2, 166–173. [Google Scholar] [CrossRef]

- Liu, C.; Chen, J.; Li, S.; Qin, T. Construction of Conceptual Prospecting Model Based on Geological Big Data: A Case Study in Songtao-Huayuan Area, Hunan Province. Minerals 2022, 12, 669. [Google Scholar] [CrossRef]

- Cehlar, M.; Zhironkin, S.A.; Zhironkina, O.V. Digital technologies of industry 4.0 in mining 4.0—Prospects for the development of geotechnology in the XXI century. Bull. KuzSTU 2020, 3, 80–90. [Google Scholar] [CrossRef]

- Lv, S.; Kim, H.; Zheng, B.; Jin, H. A Review of Data Mining with Big Data towards Its Applications in the Electronics Industry. Appl. Sci. 2018, 8, 582. [Google Scholar] [CrossRef]

- Huang, A.; Huo, Y.; Yang, J.; Gu, H.; Li, G. Computational Modeling and Prediction on Viscosity of Slags by Big Data Mining. Minerals 2020, 10, 257. [Google Scholar] [CrossRef]

- Statistical Review of World Energy. 70th Edition. BP p.l.c. London. 2021. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2021-full-report.pdf#page13 (accessed on 3 October 2022).

- Zaoui, F.; Souissi, N. Digital Maturity Assessment—A Case Study. J. Comput. Sci. 2022, 18, 724–731. [Google Scholar] [CrossRef]

- Espadinha-Cruz, P.; Godina, R.; Rodrigues, E.M.G. A Review of Data Mining Applications in Semiconductor Manufacturing. Processes 2021, 9, 305. [Google Scholar] [CrossRef]

- Kumar, R.; Prasad, A.; Kumar, A. Sustainable Smart Manufacturing Processes in Industry 4.0; CRC Press: New York, NY, USA, 2022; 328p. [Google Scholar]

- Singh, R.; Akram, S.V.; Gehlot, A.; Buddhi, D.; Priyadarshi, N.; Twala, B. Energy System 4.0: Digitalization of the Energy Sector with Inclination towards Sustainability. Sensors 2022, 22, 6619. [Google Scholar] [CrossRef] [PubMed]

- Clausen, E.; Sorensen, A.; Uth, F.; Mitra, R. Assessment of the Effects of Global Digitalization Trends on Sustainability in Mining; Federal Institute for Geosciences and Natural Resources: Hannover, Germany, 2020.

- Mateo, F.W.; Redchuk, A.; Tornillo, J.E. Industry 5.0 and new business models in mining. Adoption Case of Machine Learning to optimize the process at a copper Semi Autogenous Grinding (SAG) Mill. In Proceedings of the 5th European International Conference on Industrial Engineering and Operations Management, Rome, Italy, 26–28 July 2022; pp. 1–9. [Google Scholar]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Hossein, M.N.; Mohammadrezaei, M.; Hunt, J.; Zakeri, B. Internet of Things (IoT) and the Energy Sector. Energies 2020, 13, 494. [Google Scholar] [CrossRef]

- Da Silva, T.H.H. The circular economy and Industry 4.0: Synergies and challenges. Rev. Gest. 2022, 29, 300–313. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, D.; Bhamu, J. Machine Vision in Industry 4.0: Applications; Challenges and Future Directions. In Machine Vision for Industry 4.0. Applications and Case Studies; Raut, R., Krit, S., Chatterje, P., Eds.; CRC Press: Boca Raton, FL, USA, 2022; pp. 1–13. [Google Scholar] [CrossRef]

- Laloui, L.; Rotta Loria, A.F. Energy and geotechnologies. In Analysis and Design of Energy Geostructures. Theoretical Essentials and Practical Application; Academic Press: London, UK, 2020; pp. 3–23. [Google Scholar] [CrossRef]

- Lazarenko, Y.; Garafonova, O.; Marhasova, V.; Tkalenko, N. Digital Transformation in the Mining Sector: Exploring Global Technology Trends and Managerial Issues. E3S Web Conf. 2021, 315, 04006. [Google Scholar] [CrossRef]

- Abrahamsson, L.; Johansson, B.; Johansson, J. Future of metal mining: Sixteen predictions. Int. J. Min. Miner. Eng. 2009, 1, 304–312. [Google Scholar] [CrossRef]

- Qassimi, S.; Abdelwahed, E.H. Disruptive Innovation in Mining Industry 4.0. In Studies in Distributed Intelligence; Elhoseny, M., Yuan, X., Eds.; Springer: New York, NY, USA, 2022; pp. 7–28. [Google Scholar] [CrossRef]

- Ivanov, S.V.; Chekina, V.D. Development of Mining in the Conditions of Industry 4.0: New Challenges and Opportunities. Econ. Ind. 2020, 1, 102–111. [Google Scholar] [CrossRef]

- Carrasco, Y. Mining 4.0: A Digital Transformation Approach to Mining Sector. In Proceedings of the Conference Technology Management and Leadership in Digital Transformation—Looking Ahead to Post-COVID Era, Portland, OR, USA, 7–11 August 2022; pp. 1–6. [Google Scholar]

- Nagovitsyn, O.; Churkin, O.; Gilyarova, A. Effects of application of industry-4.0 technologies and digitalization in mining. In Proceedings of the 21st International Multidisciplinary Scientific GeoConference SGEM 2021, Albena, Bulgary, 26 June–5 July 2021; STEF92 Technology Ltd.: Sofia, Bulgary, 2021; pp. 347–354. [Google Scholar] [CrossRef]

- Nad, A.; Jooshaki, M.; Tuominen, E.; Michaux, S.; Kirpala, A.; Newcomb, J. Digitalization Solutions in the Mineral Processing Industry: The Case of GTK Mintec; Finland. Minerals 2022, 12, 210. [Google Scholar] [CrossRef]

- Hoffmann, R.; Minkin, V.I.; Carpenter, B.K. Ockham’s Razor and Chemistry. HYLE-Int. J. Philos. Chem. 1997, 3, 3–28. [Google Scholar]

| Century | Stages of Industrial Development | Key Innovations | Stages of Development of Geotechnology | Mining Innovations |

|---|---|---|---|---|

| First half of the 19th century | Industry 1.0 | Coal and coke, steam engines | Mining 1.0 | Mechanization of auxiliary processes |

| Second half of the 19th–early 20th centuries | Industry 2.0 | Electricity, in-line production, oil and gas production, internal combustion engines | Mining 2.0 | Mechanization of the main processes |

| Second half of the 20th century | Industry 3.0 | Automation, analog computing and control systems | Mining 3.0 | High capacity equipment, analog telemetry |

| Beginning of the 21st century | Industry 4.0 | Digitization, Internet of Things, artificial intelligence, machine vision, blockchain | Mining 4.0 | Unmanned technologies, remote process control, smart robots |

| Stages of Industrial Development | Description | Key Innovations | Stages of Development of Geotechnology | Mining Innovations |

|---|---|---|---|---|

| Industry 5.0 | Synergy of humans and autonomous machines | Ubiquitous machine learning, self-educating collaborative robots, integration of the physical and virtual world into big data, Data Mining by machines | Mining 5.0 | Complete replacement of people by collaborative robots in mines, smart contracts in the raw materials market, machine vision, artificial intelligence, digital twins based on Data Mining |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhironkin, S.; Gasanov, M.; Suslova, Y. Orderliness in Mining 4.0. Energies 2022, 15, 8153. https://doi.org/10.3390/en15218153

Zhironkin S, Gasanov M, Suslova Y. Orderliness in Mining 4.0. Energies. 2022; 15(21):8153. https://doi.org/10.3390/en15218153

Chicago/Turabian StyleZhironkin, Sergey, Magerram Gasanov, and Yulia Suslova. 2022. "Orderliness in Mining 4.0" Energies 15, no. 21: 8153. https://doi.org/10.3390/en15218153

APA StyleZhironkin, S., Gasanov, M., & Suslova, Y. (2022). Orderliness in Mining 4.0. Energies, 15(21), 8153. https://doi.org/10.3390/en15218153