Enhancement of the Biofuel Characteristics of Empty Fruit Bunches through Hydrothermal Carbonization by Decreasing the Inorganic Matters

Abstract

:1. Introduction

2. Materials and Methods

2.1. Empty Fruit Bunches (EFB)

2.2. Hydrothermal Carbonization (HTC)

2.3. Analysis of the Chemical Properties of EFB

2.4. Equilibrium Moisture Content (EMC) Test

2.5. Agglomeration Test

3. Results and Discussion

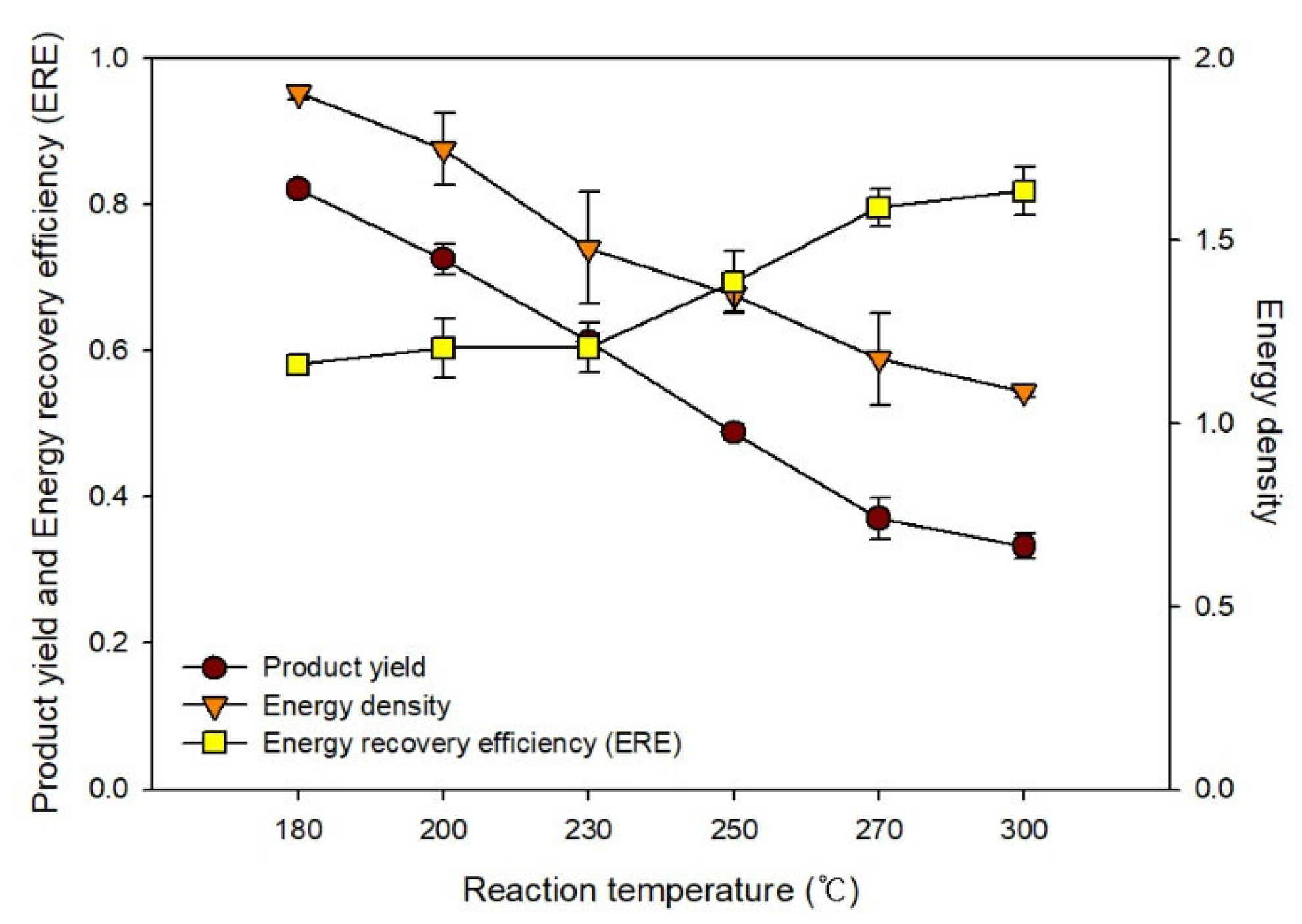

3.1. Changes in the Physical and Chemical Properties of EFB Due to HTC

3.2. Enhanced EMC

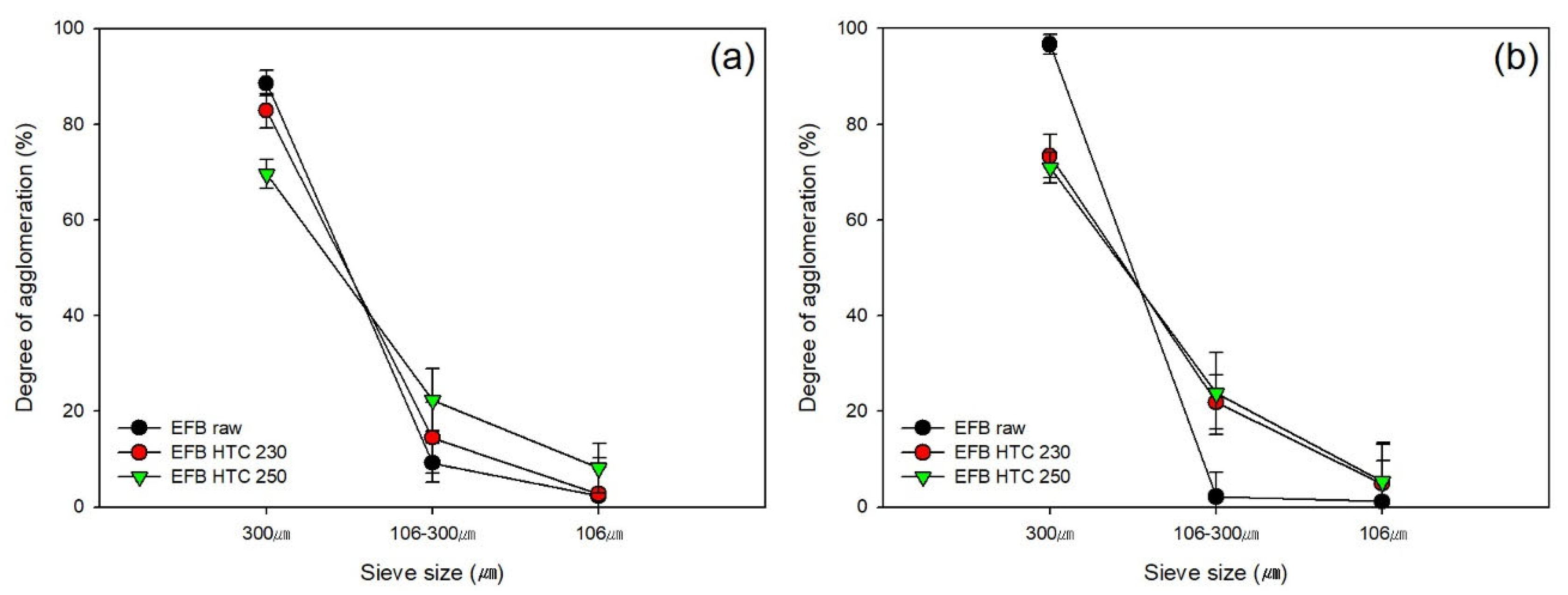

3.3. Degree of Agglomeration

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bilgen, S. Structure and environmental impact of global energy consumption. Renew. Sustain. Energy Rev. 2014, 38, 890–902. [Google Scholar] [CrossRef]

- Muhammad, B.; Khan, M.K.; Khan, M.I.; Khan, S. Impact of foreign direct investment, natural resources, renewable energy consumption, and economic growth on environmental degradation: Evidence from BRICS, developing, developed and global countries. Environ. Sci. Pollut. Res. 2021, 28, 21789–21798. [Google Scholar] [CrossRef] [PubMed]

- Adebayo, T.S.; Awosusi, A.A.; Kirikkaleli, D.; Akinsola, G.D.; Mwamba, M.N. Can CO2 emissions and energy consumption determine the economic performance of South Korea? A time series analysis. Environ. Sci. Pollut. Res. 2021, 28, 38969–38984. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J.; Park, C.; Nepal, R.; Oh, S.C. Hydrothermal treatment of empty fruit bunches to enhance fuel characteristics. Energies 2021, 14, 1467. [Google Scholar] [CrossRef]

- Oh, H.; Hong, I.; Oh, I. South Korea’s 2050 carbon neutrality policy. East Asian Policy 2021, 13, 33–46. [Google Scholar] [CrossRef]

- Lee, H. Is carbon neutrality feasible for Korean manufacturing firms?: The CO2 emissions performance of the Metafrontier Malmquist-Luenberger index. J. Environ. Manag. 2021, 297, 113235. [Google Scholar] [CrossRef]

- Kumar, G.; Kim, S.H.; Lay, C.H.; Ponnusamy, V.K. Recent developments on alternative fuels, energy and environment for sustainability. Bioresour. Technol. 2020, 317, 124010. [Google Scholar] [CrossRef]

- Jang, E.S.; Ryu, D.Y.; Kim, D. Hydrothermal carbonization improves the quality of biochar derived from livestock manure by removing inorganic matter. Chemosphere 2022, 305, 135391. [Google Scholar] [CrossRef]

- Tan, C.; Saritpongteeraka, K.; Kungsanant, S.; Charnnok, B.; Chaiparapat, S. Low temperature hydrothermal treatment of palm fiber fuel for simultaneous potassium removal, enhanced oil recovery and biogas production. Fuel 2018, 234, 1055–1063. [Google Scholar] [CrossRef]

- Yan, M.; Hantoko, D.; Susanto, H.; Ardy, A.; Waluyo, J.; Weng, Z.; Lin, J. Hydrothermal treatment of empty fruit bunch and its pyrolysis chracteristics. Biomass Convers. Biorefinery 2019, 9, 709–717. [Google Scholar] [CrossRef]

- Ibrahim, M.H.W.; Mangi, S.A.; Zuki, S.S.M.; Jaya, R.P.; Supriyatno, D. Influence of palm oil biomass clinker and empty fruit bunch fibers on concrete properties. IIUM Eng. J. 2020, 21, 100–110. [Google Scholar] [CrossRef]

- Jamari, S.S.; Howse, J.R. The effect of the hydrothermal carbonization process on palm oil empty fruit bunch. Biomass Bioenergy 2012, 47, 82–90. [Google Scholar] [CrossRef]

- Chin, D.W.K.; Lim, S.; Pang, Y.L.; Lim, C.H.; Shuit, S.H.; Lee, K.M.; Chong, C.T. Effects of organic solvents on the organosolv pretreatment of degraded empty fruit bunch for fractionation and lignin removal. Sustainability 2021, 13, 6757. [Google Scholar] [CrossRef]

- Kim, B.; Ryu, C.; Lee, U.; Kim, Y.; Lee, J.; Song, J. A technical review on the protective measures of high temperature corrosion of boiler heat exchangers with additives. Clean Technol. 2017, 23, 223–236. [Google Scholar]

- Rowe, J.J.; Morey, G.W.; Silber, C.C. The ternary system K2SO4-MgSO4-CaSO4. J. Inorg. Nucl. Chem. 1967, 29, 925–942. [Google Scholar] [CrossRef]

- Yazhenskikh, E.; Jantzen, T.; Kobertz, D.; Hack, K.; Mueller, M. Critical thermodynamic evaluation of the binary sub-systems of the core sulphate system Na2SO4–K2SO4–MgSO4–CaSO4. Calphad 2021, 72, 102234. [Google Scholar] [CrossRef]

- Theis, M.; Skrifvars, B.J.; Zevenhoven, M.; Hupa, M.; Tran, H. Fouling tendency of ash resulting from burning mixtures of biofuels. Part 2: Deposit chemistry. Fuel 2006, 85, 1992–2001. [Google Scholar] [CrossRef]

- Kim, D.; Lee, K.; Park, K.Y. Hydrothermal carbonization of anaerobically digested sludge for solid fuel production and energy recovery. Fuel 2014, 130, 120–125. [Google Scholar] [CrossRef]

- Park, K.Y.; Lee, K.; Kim, D. Characterized hydrochar of algal biomass for producing solid fuel through hydrothermal carbonization. Bioresour. Technol. 2018, 258, 119–124. [Google Scholar] [CrossRef]

- Lee, J.; Cho, S.; Kim, D.; Ryu, J.; Lee, K.; Chung, H.; Park, K.Y. Conversion of slaughterhouse wastes to solid fuel using hydrothermal carbonization. Energies 2021, 14, 1768. [Google Scholar] [CrossRef]

- Liu, T.; Liu, Z.; Zheng, Q.; Lang, Q.; Xia, Y.; Peng, N.; Gai, C. Effect of hydrothermal carbonization on migration and environmental risk of heavy metals in sewage sludge during pyrolysis. Bioresour. Technol. 2018, 247, 282–290. [Google Scholar] [CrossRef]

- Olszewski, M.P.; Nicolae, S.A.; Arauzo, P.J.; Titirici, M.M.; Kruse, A. Wet and dry? Influence of hydrothermal carbonization on the pyrolysis of spent grains. J. Clean. Prod. 2020, 260, 121101. [Google Scholar] [CrossRef]

- Giguere, R.J.; Bray, T.L.; Duncan, S.M.; Majetich, G. Application of commercial microwave ovens to organic synthesis. Tetrahedron Lett. 1986, 27, 4945–4948. [Google Scholar] [CrossRef]

- Bach, Q.V.; Skreiberg, Ø. Upgrading biomass fuels via wet torrefaction: A review and comparison with dry torrefaction. Renew. Sustain. Energy Rev. 2016, 54, 665–677. [Google Scholar] [CrossRef]

- Kiranoudis, C.T.; Maroulis, Z.B.; Tsami, E.; Marinos-Kouris, D. Equilibrium moisture content and heat of desorption of some vegetables. J. Food Eng. 1993, 20, 55–74. [Google Scholar] [CrossRef]

- Bellur, S.R.; Coronella, C.J.; Vásquez, V.R. Analysis of biosolids equilibrium moisture and drying. Environ. Prog. Sustain. Energy 2009, 28, 291–298. [Google Scholar] [CrossRef]

- Namkung, H.; Kim, C.H.; Kim, D.; Yuan, X.; Kang, T.J.; Kim, H.T. Effect of bed agglomeration by mineral component with different coal types. J. Energy Inst. 2016, 89, 172–181. [Google Scholar] [CrossRef]

- Liu, Y.; He, Z.; Uchimiya, M. Comparison of biochar formation from various agricultural by-products using FTIR spectroscopy. Mod. Appl. Sci. 2015, 9, 246. [Google Scholar] [CrossRef] [Green Version]

- Reza, M.T.; Uddin, M.H.; Lynam, J.G.; Hoekman, S.K.; Coronella, C.J. Hydrothermal carbonization of loblolly pine: Reaction chemistry and water balance. Biomass Convers. Biorefinery 2014, 4, 311–321. [Google Scholar] [CrossRef]

- He, C.; Giannis, A.; Wang, J.Y. Conversion of sewage sludge to clean solid fuel using hydrothermal carbonization: Hydrochar fuel characteristics and combustion behavior. Appl. Energy 2013, 111, 257–266. [Google Scholar] [CrossRef]

- Chen, I.A.; Juenger, M.C. Incorporation of coal combustion residuals into calcium sulfoaluminate-belite cement clinkers. Cem. Concr. Compos. 2012, 34, 893–902. [Google Scholar] [CrossRef]

- Tripathi, P.; Lakshminarayana, R. Single particle and packed bed combustion characteristics of high ash and high plastic content refuse derived fuel. Fuel 2022, 308, 121983. [Google Scholar] [CrossRef]

| EFB | Hydrothermal Carbonization at | ||||||

|---|---|---|---|---|---|---|---|

| 180 °C | 200 °C | 230 °C | 250 °C | 270 °C | 300 °C | ||

| Ultimate analysis (wt.%, on dry basis) | |||||||

| Carbon | 46.05 | 47.85 | 47.53 | 51.43 | 56.77 | 68.57 | 68.86 |

| Hydrogen | 5.80 | 5.97 | 5.96 | 5.82 | 5.04 | 4.96 | 4.84 |

| Oxygen | 44.50 | 44.86 | 45.16 | 40.52 | 34.97 | 23.07 | 22.19 |

| Nitrogen | 0.34 | 0.28 | 0.27 | 0.40 | 0.75 | 0.87 | 0.94 |

| Atomic O/C ratio | 0.72 | 0.70 | 0.71 | 0.59 | 0.46 | 0.25 | 0.24 |

| Atomic H/C ratio | 1.51 | 1.50 | 1.51 | 1.36 | 1.07 | 0.87 | 0.84 |

| Proximate analysis (wt.%, on dry basis) | |||||||

| Fixed carbon | 15.61 | 18.52 | 18.74 | 24.24 | 33.67 | 49.04 | 52.11 |

| Volatile matter | 80.67 | 80.45 | 80.02 | 73.93 | 63.86 | 48.43 | 44.71 |

| Ash | 3.72 | 1.02 | 1.24 | 1.84 | 2.46 | 2.53 | 3.17 |

| Fuel ratio | 0.19 | 0.23 | 0.23 | 0.33 | 0.53 | 1.01 | 1.17 |

| Calorific value (MJ/kg) | 16.5 | 19.15 | 19.91 | 19.93 | 22.89 | 26.24 | 26.99 |

| Component (wt.%) | Raw | Hydrothermal Carbonization at | |||||

|---|---|---|---|---|---|---|---|

| 180 °C | 200 °C | 230 °C | 250 °C | 270 °C | 300 °C | ||

| MgO | 1.79 | 0.00 | 0.71 | 0.44 | 0.76 | 0.71 | 1.03 |

| Al2O3 | 0.38 | 1.55 | 1.90 | 2.04 | 2.17 | 2.54 | 2.37 |

| SiO2 | 11.50 | 32.92 | 41.97 | 48.57 | 40.58 | 39.62 | 39.82 |

| P2O5 | 2.02 | 1.39 | 1.24 | 2.28 | 5.12 | 4.41 | 7.67 |

| SO3 | 2.66 | 16.15 | 11.14 | 9.90 | 10.13 | 15.66 | 12.93 |

| Cl | 4.88 | 2.34 | 2.41 | 2.16 | 1.64 | 1.88 | 1.51 |

| K2O | 62.43 | 23.22 | 22.28 | 20.69 | 16.09 | 16.57 | 11.44 |

| CaO | 9.04 | 3.77 | 6.02 | 6.11 | 13.63 | 11.50 | 15.42 |

| Cr2O3 | 0.00 | 0.00 | 0.00 | 0.00 | 0.56 | 0.00 | 0.00 |

| Fe2O3 | 2.57 | 6.70 | 4.63 | 3.97 | 6.07 | 4.04 | 4.99 |

| SnO2 | 2.74 | 11.96 | 7.71 | 3.84 | 3.25 | 3.06 | 2.83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryu, D.; Lee, J.; Kim, D.; Jang, K.; Lee, J.; Kim, D. Enhancement of the Biofuel Characteristics of Empty Fruit Bunches through Hydrothermal Carbonization by Decreasing the Inorganic Matters. Energies 2022, 15, 8154. https://doi.org/10.3390/en15218154

Ryu D, Lee J, Kim D, Jang K, Lee J, Kim D. Enhancement of the Biofuel Characteristics of Empty Fruit Bunches through Hydrothermal Carbonization by Decreasing the Inorganic Matters. Energies. 2022; 15(21):8154. https://doi.org/10.3390/en15218154

Chicago/Turabian StyleRyu, Doyoon, Jongkeun Lee, Doyong Kim, Kyehwan Jang, Jongwook Lee, and Daegi Kim. 2022. "Enhancement of the Biofuel Characteristics of Empty Fruit Bunches through Hydrothermal Carbonization by Decreasing the Inorganic Matters" Energies 15, no. 21: 8154. https://doi.org/10.3390/en15218154

APA StyleRyu, D., Lee, J., Kim, D., Jang, K., Lee, J., & Kim, D. (2022). Enhancement of the Biofuel Characteristics of Empty Fruit Bunches through Hydrothermal Carbonization by Decreasing the Inorganic Matters. Energies, 15(21), 8154. https://doi.org/10.3390/en15218154