Permeability and Mechanical Response of Granite after Thermal and CO2 Bearing Fluid Hydro-Chemical Stimulation

Abstract

1. Introduction

2. Materials and Methods

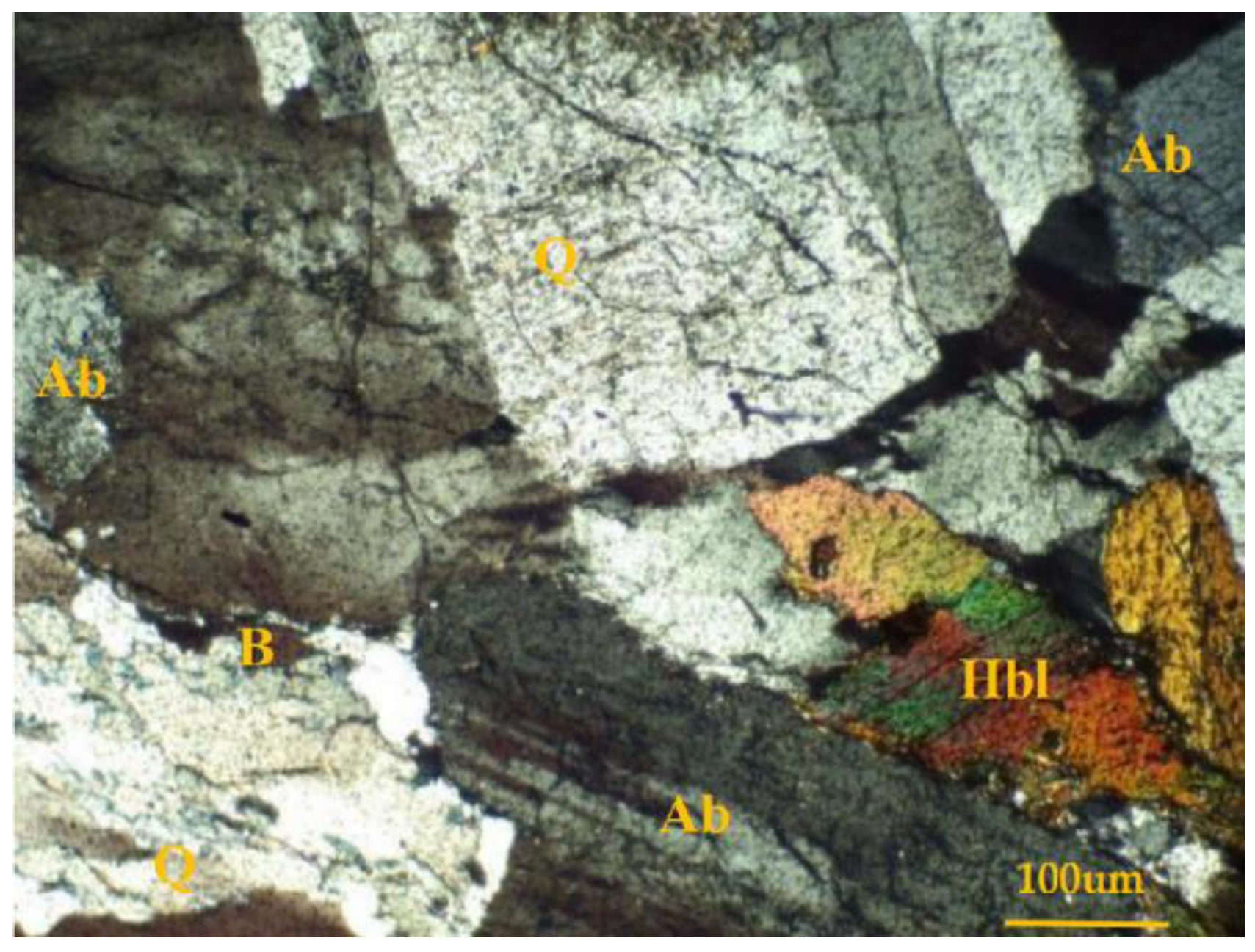

2.1. Sample Preparation

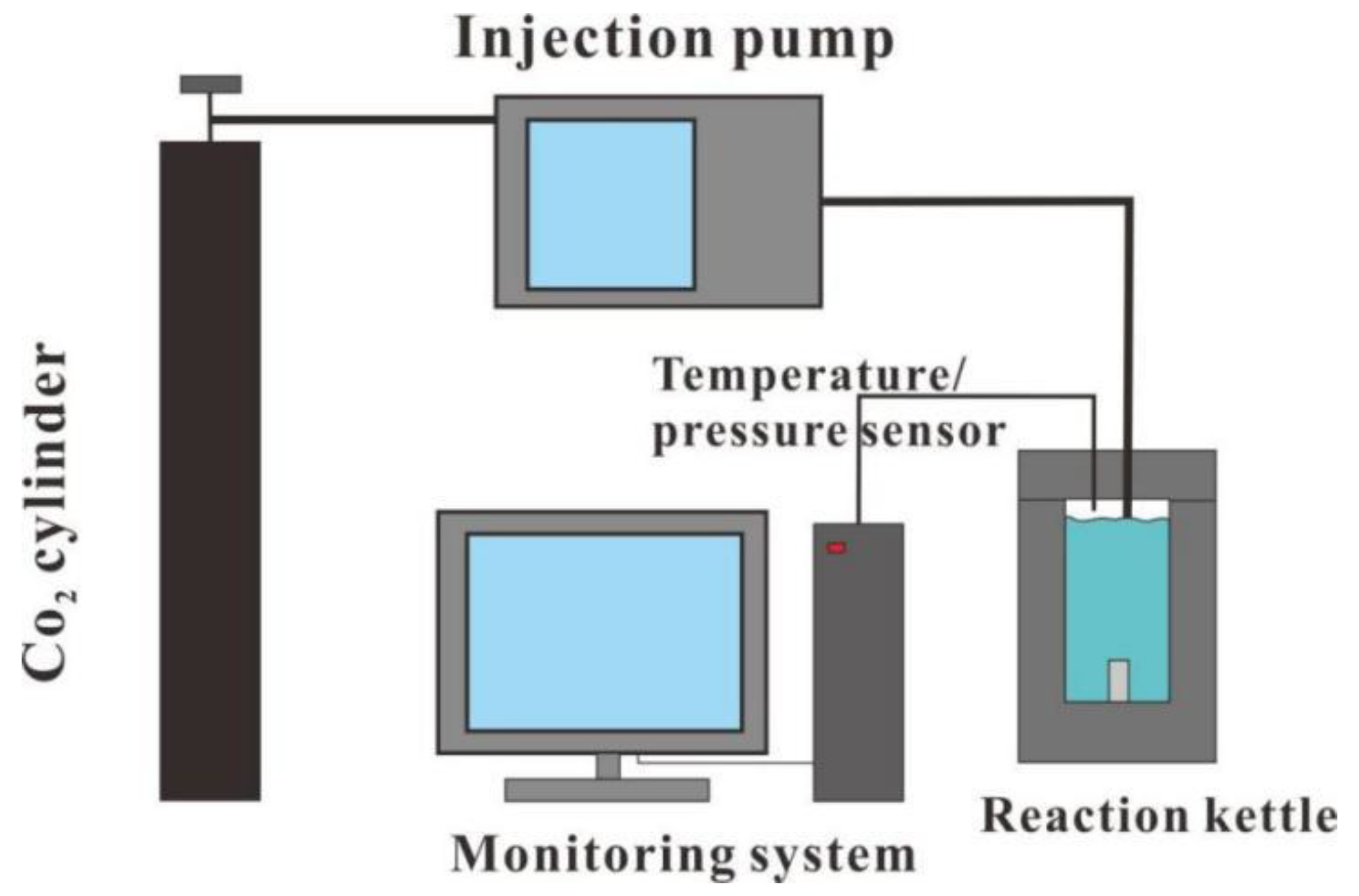

2.2. Experimental Conditions Set-Up

2.3. Test and Analysis Methods

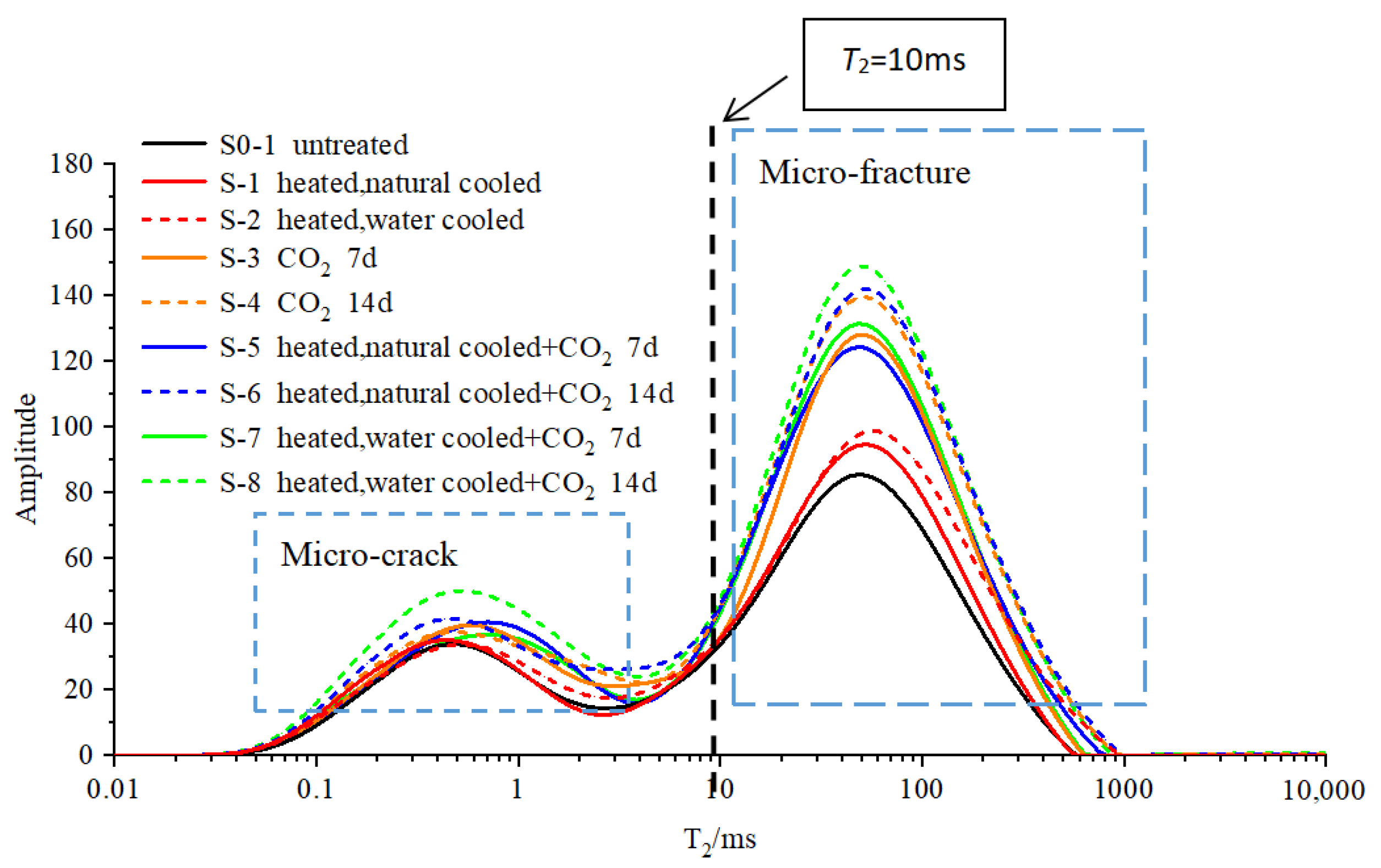

2.3.1. Nuclear Magnetic Analysis

2.3.2. Transient Pulse Method

2.3.3. Triaxial Compression Test

3. Results and Discussion

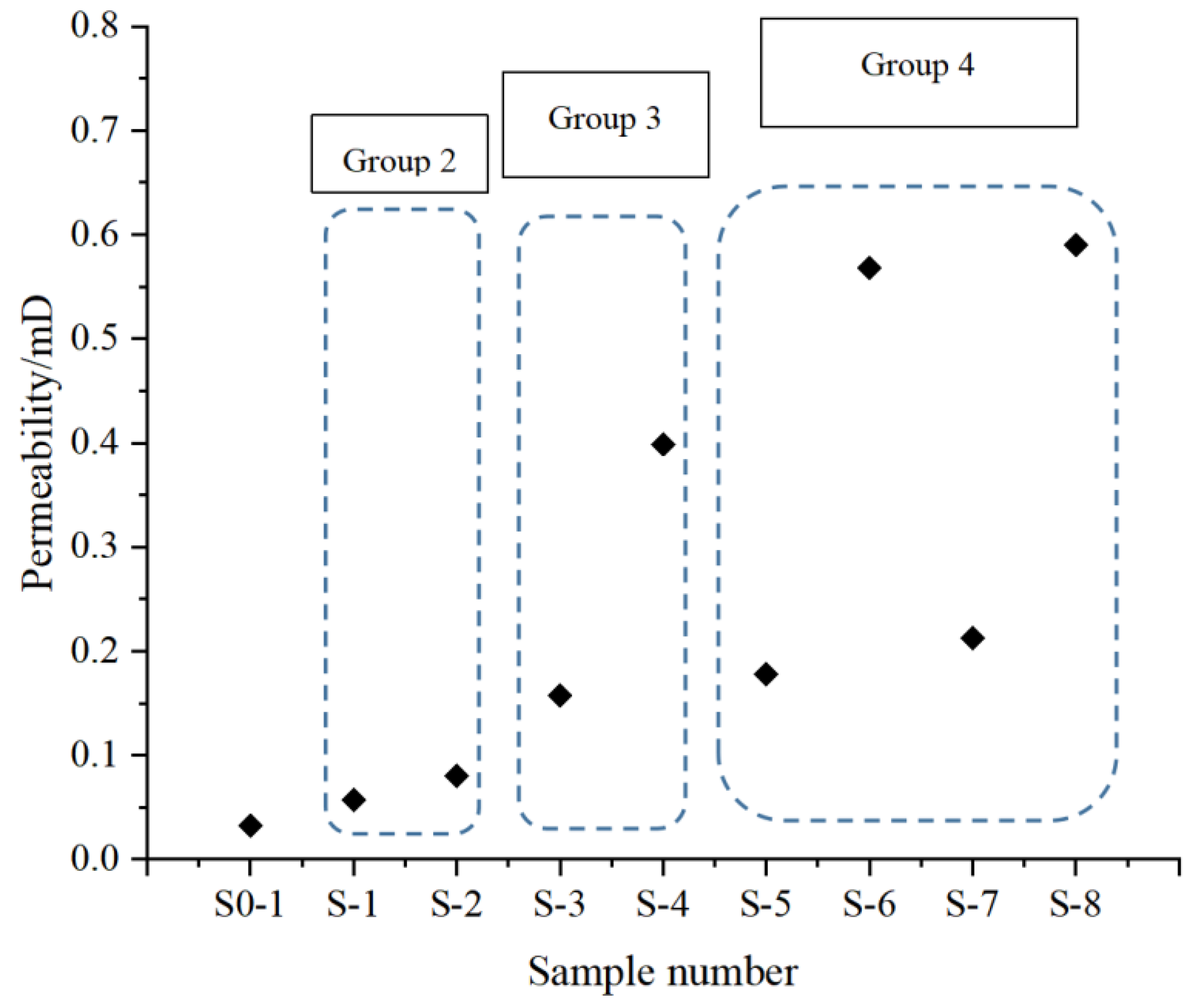

3.1. Changes of Micro-Structure and Permeability of Granite

3.1.1. T2 Spectra and Distribution of Pore-Fracture

3.1.2. Variation of Porosity

3.1.3. Variation of Permeability

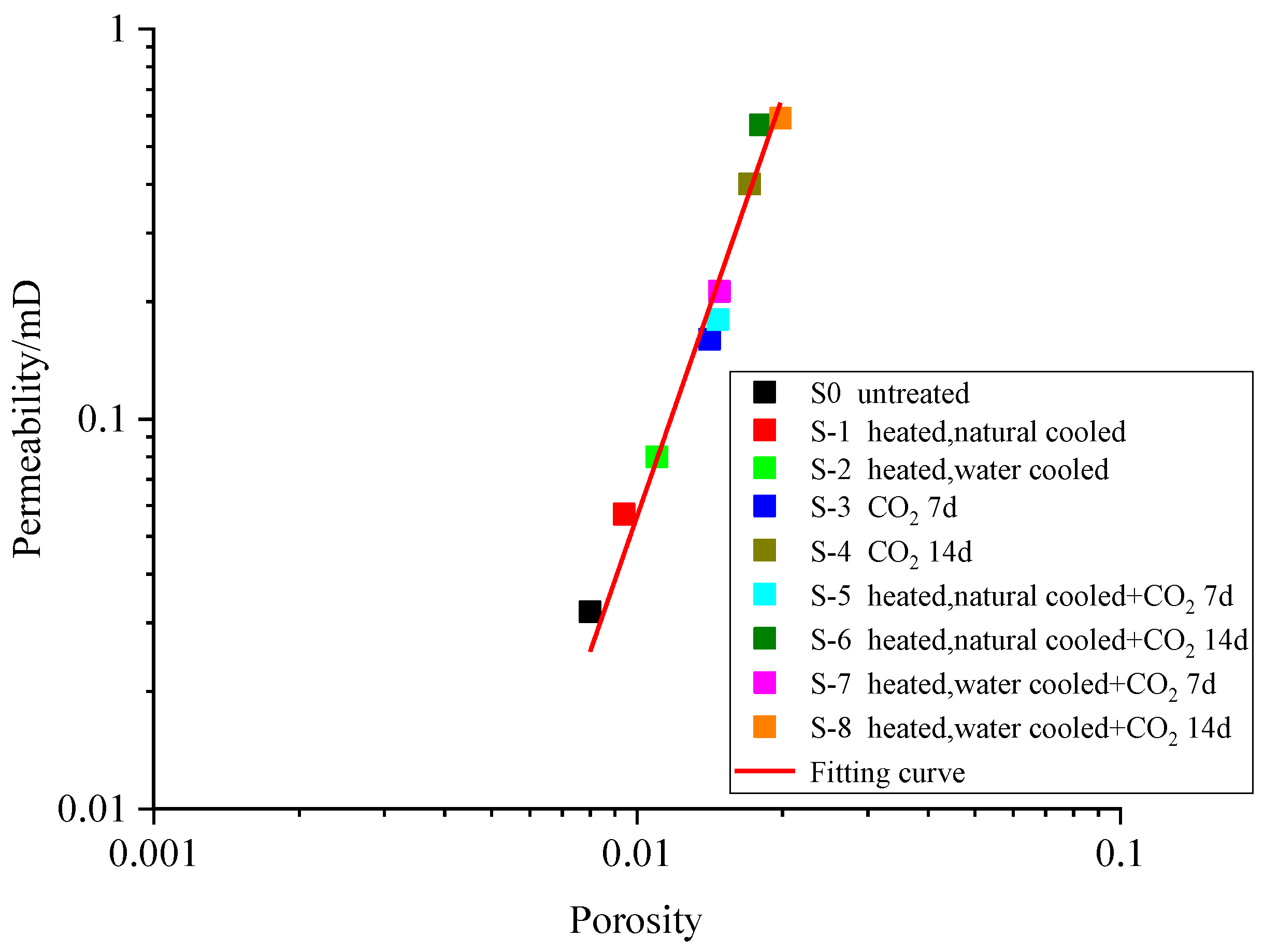

3.1.4. Correlation Analysis between Porosity and Permeability

3.2. Changes of Mechanical Properties of Granite

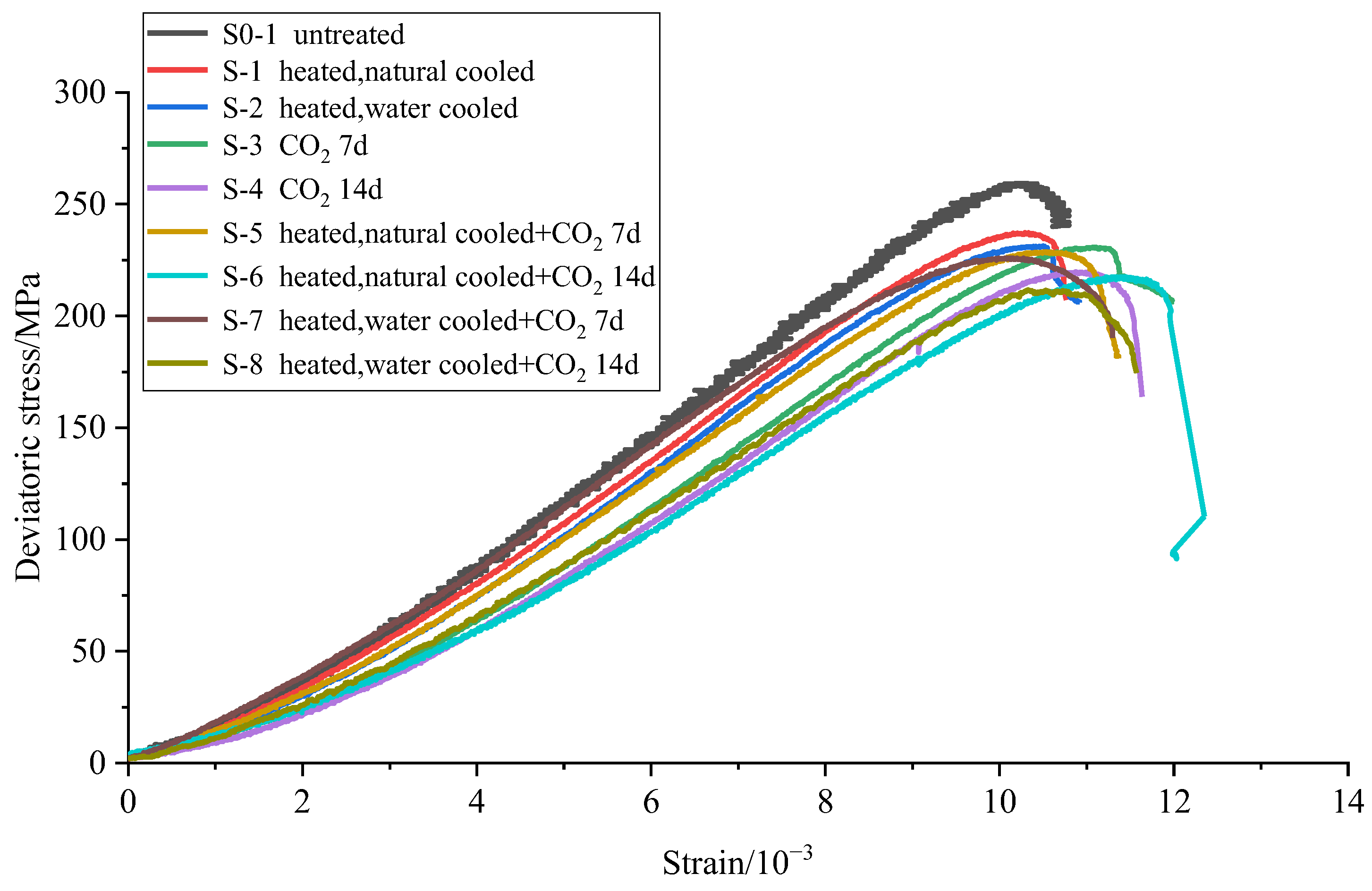

3.2.1. Stress-Strain Curves and Mechanical Parameters

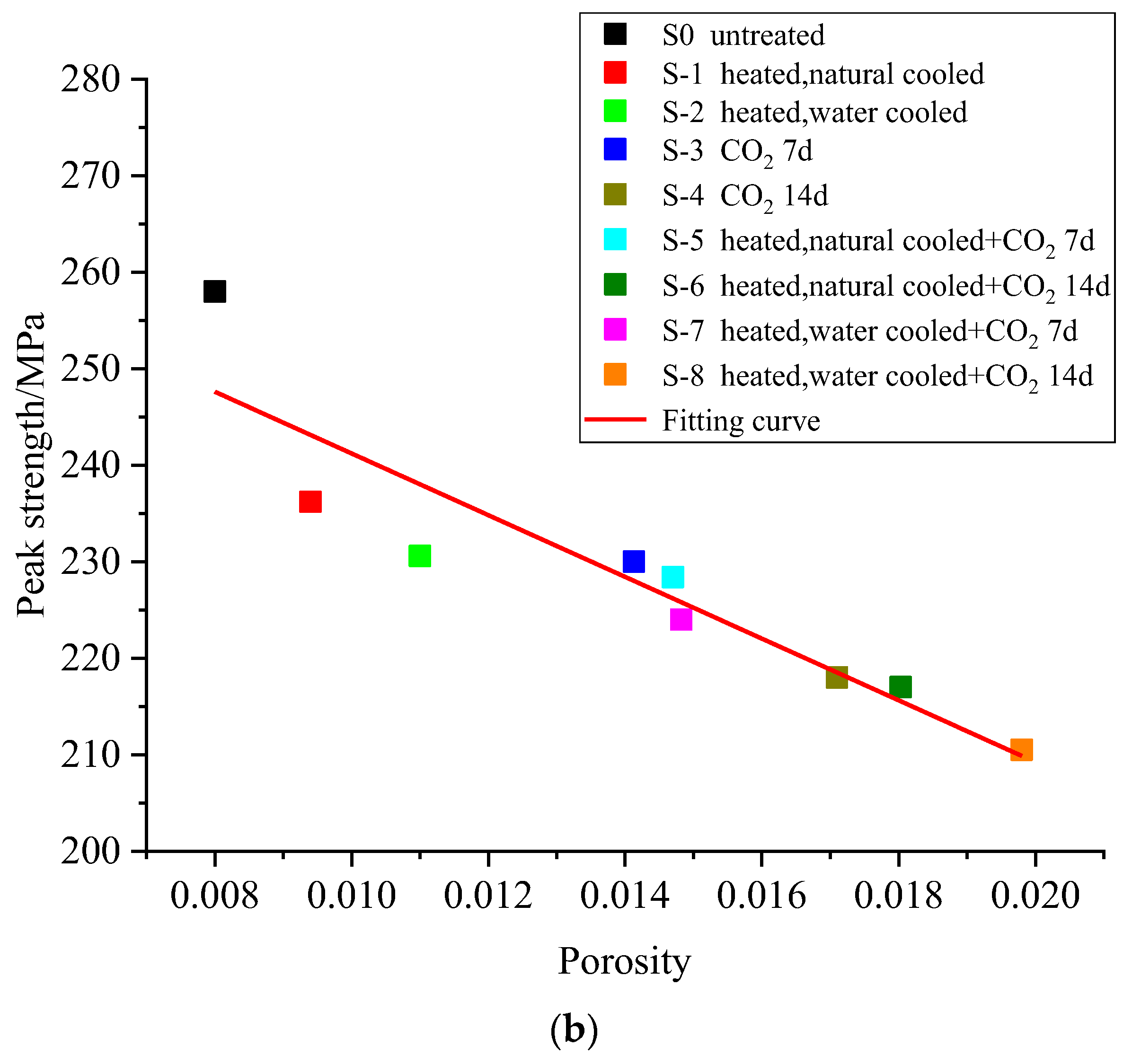

3.2.2. Correlation Analysis between Porosity and Mechanical Parameters of Granite

3.2.3. Mechanism of Thermal Stimulation and CO2 Bearing Solution Stimulation on Granite

4. Conclusions

- (1)

- Compared with the pure thermal or chemical stimulation, the superposition of thermal and CO2 hydro-chemical solution stimulation has a more positive promotion effect on the development of micro-fractures in granite, which causes an increase in permeability and a decrease in elastic modulus and compressive strength. When the granite is heated to 300 °C and subjected to water cooling and CO2-water-rock reaction under high temperature and high pressure (240 °C, 20 MPa), the porosity increases by 27.6%, the permeability increases by 17 times, and the elastic modulus and peak strength degrade by 14.3% and 18.4%, respectively.

- (2)

- There is a strong correlation between porosity, permeability, elastic modulus and compressive strength of granite before and after combined thermal and chemical stimulation. The elastic modulus and compressive strength are negatively correlated with the porosity.

- (3)

- The combination of thermal and CO2 bearing fluid hydro-chemical stimulation technology can result in the variation of micro-structures of granite, which is helpful to reduce the mechanical strength of granite especially adjacent to the wellbore region, decreasing the intensity of subsequent hydraulic fracturing or supercritical CO2 fracturing.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Blackwell, D.; Frone, Z.; Richards, M. The future of geothermal energy: The shale gas analogy significant electrical EGS resource areas in the US. Trans. Geotherm. Resour. Council. 2013, 37, 117–122. [Google Scholar]

- Liu, H.; Wang, H.; Lei, H.; Zhang, L.; Zhou, L. Numerical modeling of thermal breakthrough induced by geothermal production in fractured granite. J. Rock Mech. Geotech. Eng. 2020, 12, 900–916. [Google Scholar] [CrossRef]

- Chen, S.; Ding, B.; Gong, L.; Huang, Z.; Yu, B.; Sun, S. Comparison of multi-field coupling numerical simulation in hot dry rock thermal exploitation of enhanced geothermal systems. Adv. Geo-Energy Res. 2019, 3, 396–409. [Google Scholar] [CrossRef]

- Lin, P.; Ping, Z.; Lin, S.; Zhang, Z. Advances in research on reservoirs of enhanced geothermal system. Sino-Glob. Energy 2015, 20, 21–30. [Google Scholar]

- Zhang, L.; Luo, F.; Xu, R.; Jiang, P.; Liu, H. Heat transfer and fluid transport of supercritical CO2 in enhanced geothermal system with local thermal non-equilibrium model. Energy Procedia 2014, 63, 7644–7650. [Google Scholar] [CrossRef]

- Evans, K.; Zappone, A.; Kraft, T.; Deichmann, N.; Moja, F. A survey of the induced seismic responses to fluid injection in geothermal and CO2 reservoirs in Europe. Geothermics 2012, 41, 30–54. [Google Scholar] [CrossRef]

- Li, H.; Jiang, X.; Xu, Z.; Bowden, S. The effect of supercritical CO2 on failure mechanisms of hot dry rock. Adv. Geo-Energy Res. 2022, 6, 324–333. [Google Scholar] [CrossRef]

- Davies, R.; Foulger, G.; Bindley, A.; Styles, P. Induced seismicity and hydraulic fracturing for the recovery of hydrocarbons. Mar. Pet. Geol. 2013, 45, 171–185. [Google Scholar] [CrossRef]

- Rubinstein, J.L.; Mahani, A.B. Myths and facts on wastewater injection, hydraulic fracturing, enhanced oil recovery, and induced seismicity. Seismol. Res. Lett. 2015, 86, 1060–1067. [Google Scholar] [CrossRef]

- Pearson, C. The relationship between microseismicity and high pore pressures during hydraulic stimulation experiments in low permeability granitic rocks. J. Geophys. Res. 1981, 86, 7855–7864. [Google Scholar] [CrossRef]

- Jupe, A.J.; Green, A.; Wallroth, T. Induced microseismicity and reservoir growth at the Fjällbacka hot dry rocks project, Sweden. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1992, 29, 343–354. [Google Scholar] [CrossRef]

- Siratovich, P.A.; Sass, I.; Homuth, S.; Bjornsson, A. Thermal stimulation of geothermal reservoirs and laboratory investigation of thermally induced fractures. Trans.-Geotherm. Resour. Council. 2011, 35, 1529–1535. [Google Scholar]

- Portier, S.; Vuataz, F.D.; Nami, P.; Sanjun, B.; Gérard, A. Chemical stimulation techniques for geothermal wells: Experiments on the 3-well EGS system at Soultz-sous-forets, France. Geothermics 2009, 38, 349–359. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, S.; Liu, J. Study on the characteristics and development strategies of geothermal resources in China. J. Nat. Resour. 2015, 30, 1210–1221. [Google Scholar]

- Chaki, S.; Takarali, M.; Agbodjan, W.P. Influence of thermal damage on physical properties of a granite rock: Porosity, permeability and ultrasonic wave evolutions. Constr. Build. Mater. 2007, 22, 1456–1461. [Google Scholar] [CrossRef]

- Brace, W.F.; Walsh, J.B.; Frangos, W.T. Permeability of granite under high pressure. J. Geophys. Res. 1968, 73, 2225–2236. [Google Scholar] [CrossRef]

- Alm, O.; Jaktlund, L. The influence of microcrack density on the elastic and fracture mechanical properties of Stripa granite Ove Aim and Lise-Lotte Jaktlund. Phys. Earth Planet. Inter. 1985, 40, 161–179. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Chen, B.K.; Abdulagatov, I.W. Temperature-dependent mechanical behaviour of Australian Strathbogie granite with different cooling treatments-ScienceDirect. Eng. Geol. 2017, 229, 31–44. [Google Scholar] [CrossRef]

- Brotóns, V.; Tomás, R.; Ivorra, S.; Alarcón, J.C. Temperature influence on the physical and mechanical properties of a porous rock: San Julian’s calcarenite. Eng. Geol. 2013, 167, 117–127. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, J.; Hu, D.; Skoczylas, F.; Shao, J. Laboratory investigation on physical and mechanical properties of granite after heating and water cooling treatment. Rock Mech. Rock Eng. 2018, 51, 677–694. [Google Scholar] [CrossRef]

- Madirisha, M.; Hack, R.; Meer, F. The influence of chelating agents on clays in geothermal reservoir formations: Implications to reservoir acid stimulation. Geothermics 2022, 99, 102305. [Google Scholar] [CrossRef]

- Xu, T.; Rose, P.; Fayer, S.; Pruess, K. On modeling of chemical stimulation of an enhanced geothermal system using a high pH solution with chelating agent. Geofluids 2009, 9, 167–177. [Google Scholar] [CrossRef]

- Portier, S.; André, L.; Vuataz, F.D. Review on chemical stimulation techniques in oil industry and applications to geothermal systems. Engineering 2007, 32, 1–30. [Google Scholar]

- Xu, J.; Feng, B.; Cui, Z.; Liu, X.; Ke, Z.; Feng, G. Comparative study of acid and alkaline stimulants with granite in an enhanced geothermal system. Acta Geol. Sin. (Engl. Ed.) 2021, 95, 1926–1939. [Google Scholar] [CrossRef]

- Na, J.; Xu, T.; Wu, Y.; Feng, B.; Bao, X. Effectiveness of using mud acid as stimulation agent for enhanced geothermal systems (EGS) reservoir. J. Cent. South Univ. (Sci. Technol.) 2017, 48, 247–254. [Google Scholar]

- Wakahama, H.; Mitoa, S.; Ohsumi, T.; Ueda, A.; Yajima, T.; Satoh, H.; Sugiyama, K.; Ozawa, A.; Ajima, S.; Todaka, N. A concept of CO2 georeactor sequestration at the Ogachi HDR site, NE Japan. Energy Procedia 2009, 1, 3683–3689. [Google Scholar] [CrossRef]

- Matthes, L.; Lummer, R. Next generation acids-new retarded system for geothermal applications. Erdol Erdgas Kohle 2014, 130, 39–40. [Google Scholar]

- Qu, X.; Liu, L.; Ma, R.; Hu, D.; Chen, X.; Wang, Y. Experiment on debris-arkosic sandstone reformation by CO2 fluid. J. Jilin Univ. (Earth Sci. Ed.) 2008, 38, 959–964. [Google Scholar]

- Wang, G.; Zhao, J.; Zhang, F.; Tao, Y.; Yang, X.; Wang, H. Interactions of CO2-brine-rock in sandstone reservoir. J. Cent. South Univ. (Sci. Technol.) 2013, 44, 1168–1173. [Google Scholar]

- Ma, D.; Chen, Q.; Zhou, H.; Teng, Q.; Li, K.; Hu, D. Experimental study of liquid CO2 fracturing mechanism of glutenite. Rock Soil Mech. 2020, 41, 3996–4004. [Google Scholar]

- Zhao, R.; Sun, H.; Wu, Y.; Zhao, C. Influence of CO2 corrosion on rock structure and its mechanical characteristics. Sci. China Technol. Sci. 2010, 40, 822–828. [Google Scholar] [CrossRef]

- Liu, H.; Shi, Y.; Fang, Z.; Liu, J.; Tong, R. Seepage characteristics of thermally and chemically treated Mesozoic granite from geothermal region of Liaodong Peninsula. Environ. Earth Sci. 2021, 80, 599. [Google Scholar] [CrossRef]

- Miao, S.; Cai, M.; Guo, Q.; Wang, P.; Liang, M. Damage effects and mechanisms in granite treated with acidic chemical solutions. Int. J. Rock Mech. Min. Sci. 2016, 88, 77–86. [Google Scholar] [CrossRef]

- Xu, T.; Wang, W.; Pruess, K. Numerical Simulation to Study the Feasibility of Using CO2 as a Stimulation Agent for Enhanced Geothermal Systems; Lawrence Berkeley National Lab.: Berkeley, CA, USA, 2010; pp. 1–8. [Google Scholar]

- Rosenbauer, R.J.; Koksalan, T.; Palandri, J.L. Experimental investigation of CO2-brine-rock interactions at elevated temperature and pressure: Implications for CO2 sequestration in deep-saline aquifers. Fuel Process. Technol. 2005, 8, 1581–1597. [Google Scholar] [CrossRef]

- Suto, Y.; Liu, L.; Yamasaki, N.; Hashidal, T. Initial behavior of granite in response to injection of CO2-saturated fluid. Appl. Geochem. 2007, 22, 202–218. [Google Scholar] [CrossRef]

- Shao, H.; Thompson, C.J.; Cantrell, K.J. Evaluation of experimentally measured and model-calculated pH for rock-brine-CO2 systems under geologic CO2 sequestration conditions. Chem. Geology. 2013, 359, 116–124. [Google Scholar] [CrossRef]

- Zheng, L.; Spycher, N.; Birkholzer, J.; Xu, T.; Apps, J.; Kharaka, Y. On modeling the potential impacts of CO2 sequestration on shallow groundwater: Transport of organics and co-injected H2S by supercritical CO2 to shallow aquifers. Int. J. Greenh. Gas Control 2013, 14, 113–127. [Google Scholar] [CrossRef]

- Ré, C.L.; Kaszuba, J.P.; Moore, J.N.; McPhersonc, B.J. Fluid-rock interactions in CO2-saturated, granite-hosted geothermal systems: Implications for natural and engineered systems from geochemical experiments and models. Geochim. Et Cosmochim. Acta. 2014, 141, 160–178. [Google Scholar]

- Shiraki, R.; Dunn, T.L. Experimental study on water-rock interactions during CO2 flooding in the Tensleep Formation, Wyoming, USA. Appl. Geochem. 2000, 15, 265–279. [Google Scholar] [CrossRef]

- Isaka, B.L.A.; Ranjith, P.G.; Rathnaweera, T.D.; Perera, M.S.A.; Kumari, W.G.P. Influence of long-term operation of supercritical carbon dioxide based enhanced geothermal system on mineralogical and microstructurally-induced mechanical alteration of surrounding rock mass. Renew. Energy 2019, 136, 428–441. [Google Scholar] [CrossRef]

- Zhou, K.; Li, J.; Xu, Y.; Zhang, Y.; Yang, P.; Chen, L. Experimental study of NMR characteristics in rock under freezing and thawing cycles. Chin. J. Rock Mech. Eng. 2012, 31, 731–737. [Google Scholar]

- Williams, J.L.A.; Taylor, D.G.; Maddinelli, G.; Enwere, P.; Archer, J.S. Visualization of fluid displacement in rock cores by NMR imaging. Magn. Reson. Imaging 1991, 9, 767–773. [Google Scholar] [CrossRef]

- Lucas-Oliveira, E.; Araujo-Ferreira, A.G.; Trevizan, W.A.; DosSantos, B.C.; Bonagamba, T.J. Sandstone surface relaxivity determined by NMR T2 distribution and digital rock simulation for permeability evaluation. J. Pet. Sci. Eng. 2020, 193, 107400. [Google Scholar] [CrossRef]

- Zhao, D.; Yuan, P. Research on the influence rule of ultrasonic vibration time on granite damage. J. Min. Sci. 2018, 54, 751–762. [Google Scholar] [CrossRef]

- Nakashima, Y.; Nakano, T.; Nakamura, K.; Uesugi, K.; Tsuchiyama, A.; Ikeda, S. Three-dimensional diffusion of non-sorbing species in porous sandstone: Computer simulation based on X-ray micro-tomography using synchrotron radiation. J. Contam. Hydrol. 2004, 74, 253–264. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Yao, C.; Tang, D.; Tang, S.; Huang, W. Petrophysical characterization of coals by low-field nuclear magnetic resonance (NMR). Fuel 2010, 89, 1371–1380. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, X.; Huang, X.; Wu, S. Morphological characterization of super fine pulverized coal particle. Part 2. AFM investigation of single coal particle. Fuel 2010, 89, 3884–3891. [Google Scholar] [CrossRef]

- Wang, H.; Yu, L.; Song, Y.; Zhao, Y.; Zhao, J.; Wang, D. Fractal analysis and its impact factors on pore structure of artificial cores based on the images obtained using magnetic resonance imaging. J. Appl. Geophys. 2012, 86, 70–81. [Google Scholar] [CrossRef]

- Guo, C.; Qin, Y.; Ma, D.; Xia, Y.; Bao, Y.; Chen, Y.; Lu, L. Pore structure and permeability characterization of high-rank coal reservoirs: A case of the Bide-Santang basin, Western Guizhou, South China. Acta Geol. Sin. (Engl. Ed.) 2020, 94, 29–38. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Pan, Z.; Yao, Y.; Li, J.; Qiu, Y. Pore structure and its impact on CH4 adsorption capacity and flow capability of bituminous and sub-bituminous coals from Northeast China. Fuel 2013, 103, 258–268. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Pan, Z.; Che, Y.; Liu, Z. Investigating the effects of seepage-pores and fractures on coal permeability by fractal analysis. Transp. Porous Media. 2016, 111, 479–497. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.; Yin, T. Factors affecting pore structure of granite under cyclic heating and cooling: A nuclear magnetic resonance investigation. Geothermics 2021, 96, 102198. [Google Scholar] [CrossRef]

- Chen, S.; Tang, D.; Tao, S.; Ji, X.; Xu, H. Fractal analysis of the dynamic variation in pore-fracture systems under the action of stress using a low-field NMR relaxation method: An experimental study of coals from western Guizhou in China. J. Pet. Sci. Eng. 2019, 173, 617–629. [Google Scholar] [CrossRef]

- Kozeny, J. Ueber die kapillare Leitung des Wassers im Boden. Stizungsber Akad Wiss Wien. 1927, 136, 271–306. [Google Scholar]

- Carman, P.C. Fluid flow through granular beds. Trans. Inst. Chem. Eng. 1973, 15, 150–167. [Google Scholar] [CrossRef]

- Na, J.; Feng, B.; Lan, C.; Xu, T.; Bao, X. Effectiveness of using supercritical CO2 as stimulation agent for enhanced geothermal systems. J. Cent. South Univ. (Sci. Technol.) 2014, 45, 2447–2458. [Google Scholar]

- Deng, S.; Jiang, Q.; Shang, K.; Jing, X.; Xiong, F. Effect of high temperature on micro-structure and permeability of granite. Rock Soil Mech. 2021, 42, 1601–1611. [Google Scholar]

- Song, R.; Wang, Y.; Tang, Y.; Peng, J.; Liu, J.; Yang, C. 3D Printing of natural sandstone at pore scale and comparative analysis on micro-structure and single/two-phase flow properties. Energy 2022, 261, 125226. [Google Scholar] [CrossRef]

- Song, R.; Liu, J.; Yang, C.; Sun, S. Study on the multi-phase heat and mass transfer mechanism in the dissociation of methane hydrate in reconstructed real-shape porous sediments. Energy 2022, 254, 124421. [Google Scholar] [CrossRef]

- Neumann, M.; Stenzel, O.; Willot, F.; Holzer, L.; Schmidt, V. Quantifying the influence of microstructure on effective conductivity and permeability: Virtual materials testing. Int. J. Solids Struct. 2020, 184, 211–220. [Google Scholar] [CrossRef]

- Ge, X.; Xiao, Y.; Fan, Y.; Liu, J.; Zhang, Y. Laboratory investigation of the relationship between static rock elastic parameters and low field nuclear magnetic resonance data. Int. J. Rock Mech. Min. Sci. 2020, 127, 104207. [Google Scholar] [CrossRef]

- Siratovich, P.A.; Villeneuve, M.C.; Cole, J.W.; Kennedy, B.M.; Bégué, F. Saturated heating and quenching of three crustal rocks and implications for thermal stimulation of permeability in geothermal reservoirs-ScienceDirect. Int. J. Rock Mech. Min. Sci. 2015, 80, 265–280. [Google Scholar] [CrossRef]

- Xi, B.; Cheng, Z.; He, S.; Yang, Y.; Liu, J. Experimental study on permeability characteristics and its evolution of granite after high temperature. Chin. J. Rock Mech. Eng. 2021, 40, 2716–2723. [Google Scholar]

- Kovacik, J. Correlation between Young’s modulus and porosity in porous materials. J. Mater. Sci. Lett. 1999, 18, 1007–1010. [Google Scholar] [CrossRef]

- Cheng, Z.; Xi, B.; Yang, X.; He, S.; Li, X. Experimental study on the evolution of granite permeability under thermal shock. J. Taiyuan Univ. Technol. 2021, 52, 198–203. [Google Scholar]

| Potassium Feldspar | Albite | Quartz | Biotite | Hornblende | Clinochlore |

|---|---|---|---|---|---|

| 30.7% | 27.3% | 21.8% | 14.2% | 4.4% | 1.6% |

| Group | Number | Heat Treatment Conditions | Cooling Mode | Water-Rock Reaction Conditions | Reaction Time (d) |

|---|---|---|---|---|---|

| Original sample | S0-1 | -- | -- | -- | -- |

| S0-2 | |||||

| S0-3 | |||||

| Thermal-cold stimulation | S-1 | 300 °C, 4 h | Natural cooling | -- | -- |

| S-2 | 300 °C, 4 h | Water cooling | -- | -- | |

| CO2 stimulation | S-3 | -- | -- | 240 °C, 20 MPa | 7 |

| S-4 | -- | -- | 240 °C, 20 MPa | 14 | |

| Thermal + chemical stimulation | S-5 | 300 °C, 4 h | Natural cooling | 240 °C, 20 MPa | 7 |

| S-6 | 300 °C, 4 h | Natural cooling | 240 °C, 20 MPa | 14 | |

| S-7 | 300 °C, 4 h | Water cooling | 240 °C, 20 MPa | 7 | |

| S-8 | 300 °C, 4 h | Water cooling | 240 °C, 20 MPa | 14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, R.-C.; Liu, H.-J.; Song, Y.-J.; Xie, L.-H.; Ban, S.-N. Permeability and Mechanical Response of Granite after Thermal and CO2 Bearing Fluid Hydro-Chemical Stimulation. Energies 2022, 15, 8280. https://doi.org/10.3390/en15218280

Tong R-C, Liu H-J, Song Y-J, Xie L-H, Ban S-N. Permeability and Mechanical Response of Granite after Thermal and CO2 Bearing Fluid Hydro-Chemical Stimulation. Energies. 2022; 15(21):8280. https://doi.org/10.3390/en15218280

Chicago/Turabian StyleTong, Rong-Chen, He-Juan Liu, Yu-Jia Song, Li-Huan Xie, and Sheng-Nan Ban. 2022. "Permeability and Mechanical Response of Granite after Thermal and CO2 Bearing Fluid Hydro-Chemical Stimulation" Energies 15, no. 21: 8280. https://doi.org/10.3390/en15218280

APA StyleTong, R.-C., Liu, H.-J., Song, Y.-J., Xie, L.-H., & Ban, S.-N. (2022). Permeability and Mechanical Response of Granite after Thermal and CO2 Bearing Fluid Hydro-Chemical Stimulation. Energies, 15(21), 8280. https://doi.org/10.3390/en15218280