Thermal Response Measurement and Performance Evaluation of Borehole Heat Exchangers: A Case Study in Kazakhstan

Abstract

1. Introduction

- The features of heat transfer around BHEs during heat charging/discharging modes in seasonal conditions.

- Numerical modeling of the freezing factor mechanisms around a BHE during operation in severe winter conditions.

- Prediction of thermal interference between a system of BHEs for large scale GSHPs.

2. Experimental Investigation

2.1. TRT Device and Test Procedure

- an adaptive circulating pump with 50 W power consumption, for circulating the HTF,

- a rotameter for measuring the flow rate, a heater with a power of 4.8 kW to supply constant heat flux,

- an expansion tank with a volume of 8 L to keep the pressure constant,

- ball valves for connecting and for filling the loop with the required amount of water,

- temperature sensors for measuring the temperature change over time,

- manometer for monitoring the pressure in the loop,

- air remover to prevent air trap formation in the loop, and pipes for connecting the elements in one closed loop.

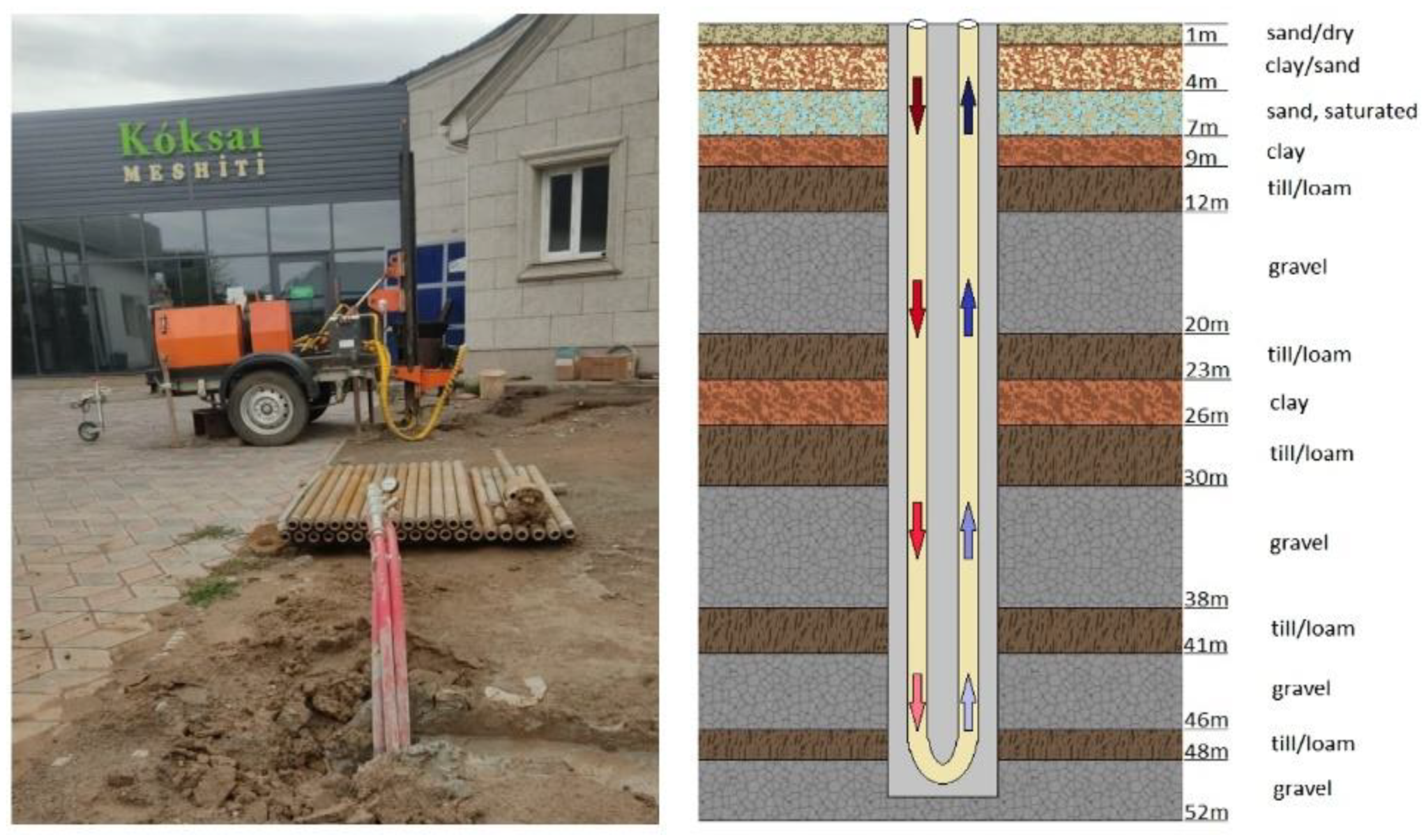

2.2. Location and Geological Structure of the Site for GSHP Construction

3. Solution Approaches

3.1. Analytical Solution: Line Source Model Based on Kelvin’s Theory

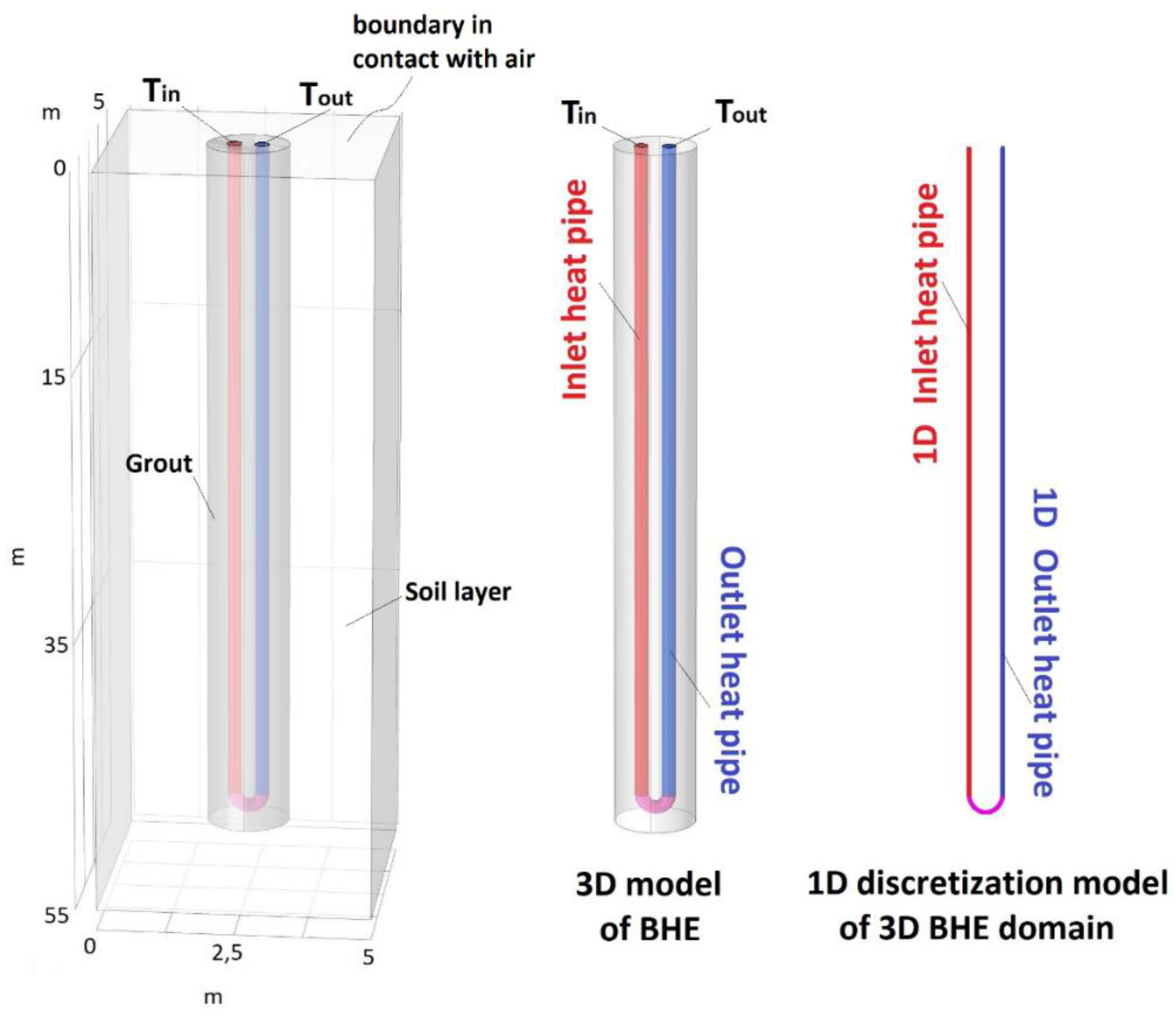

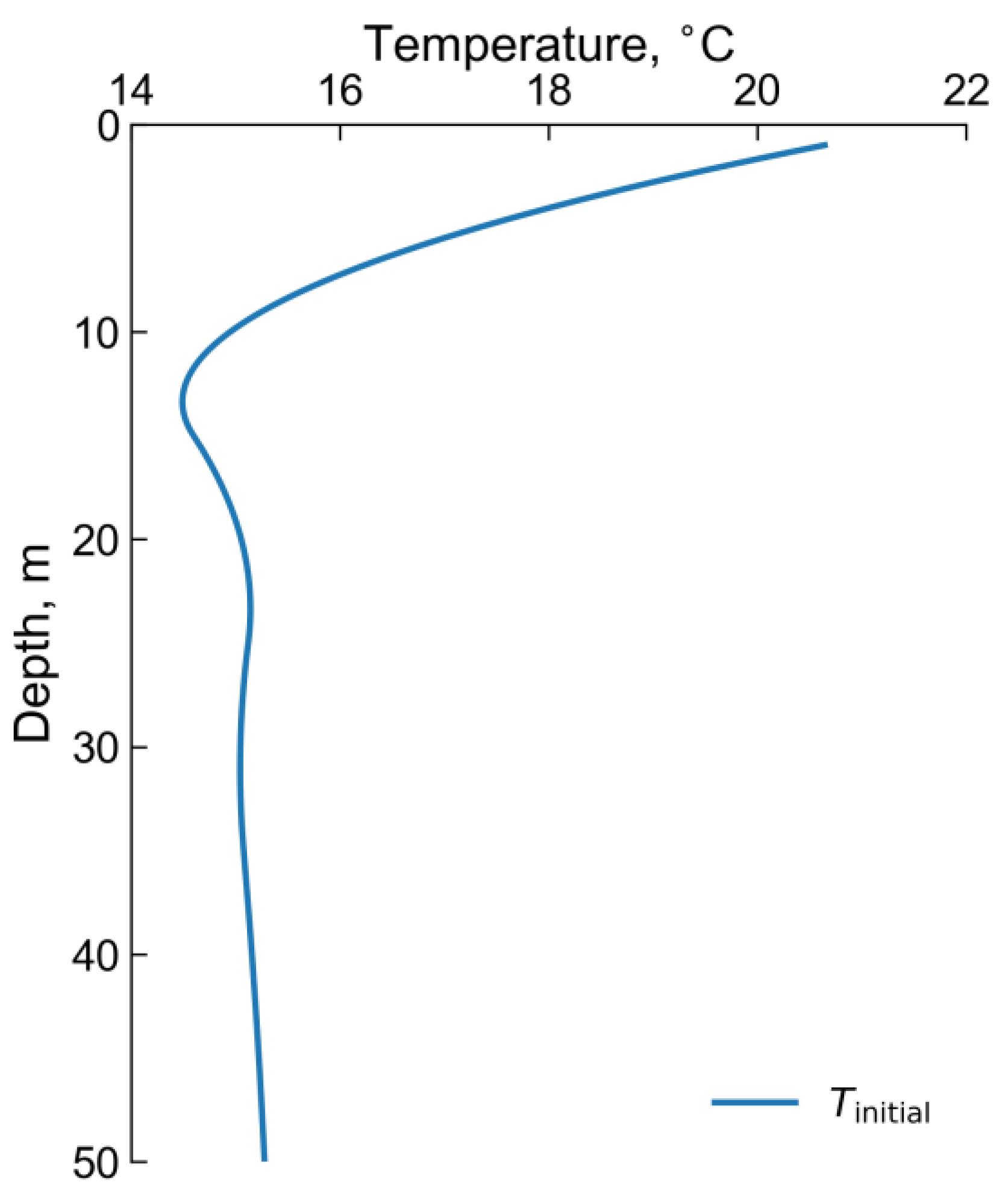

3.2. Numerical Simulation Procedure

3.3. Mathematical Formulation

4. Results and Discussions

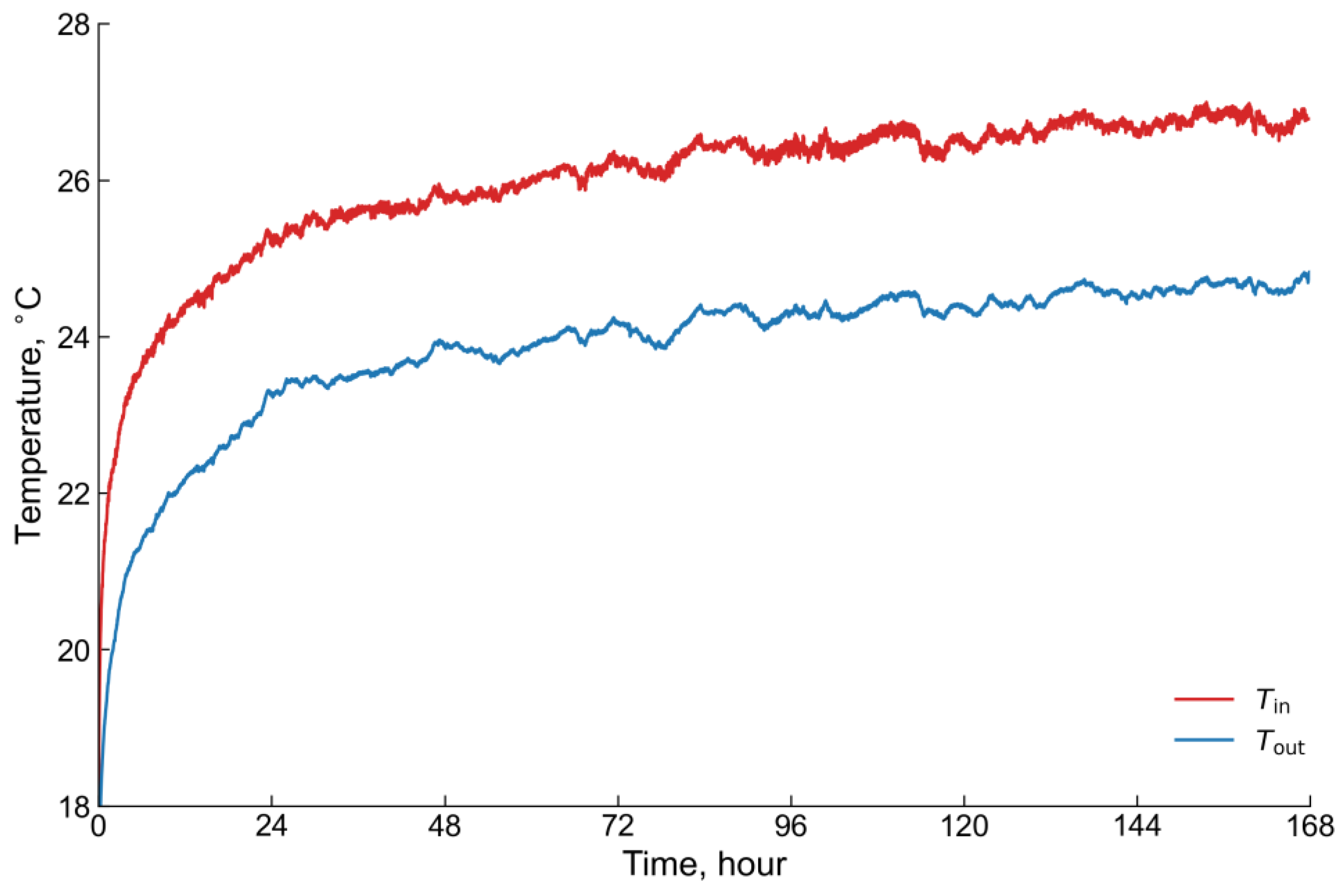

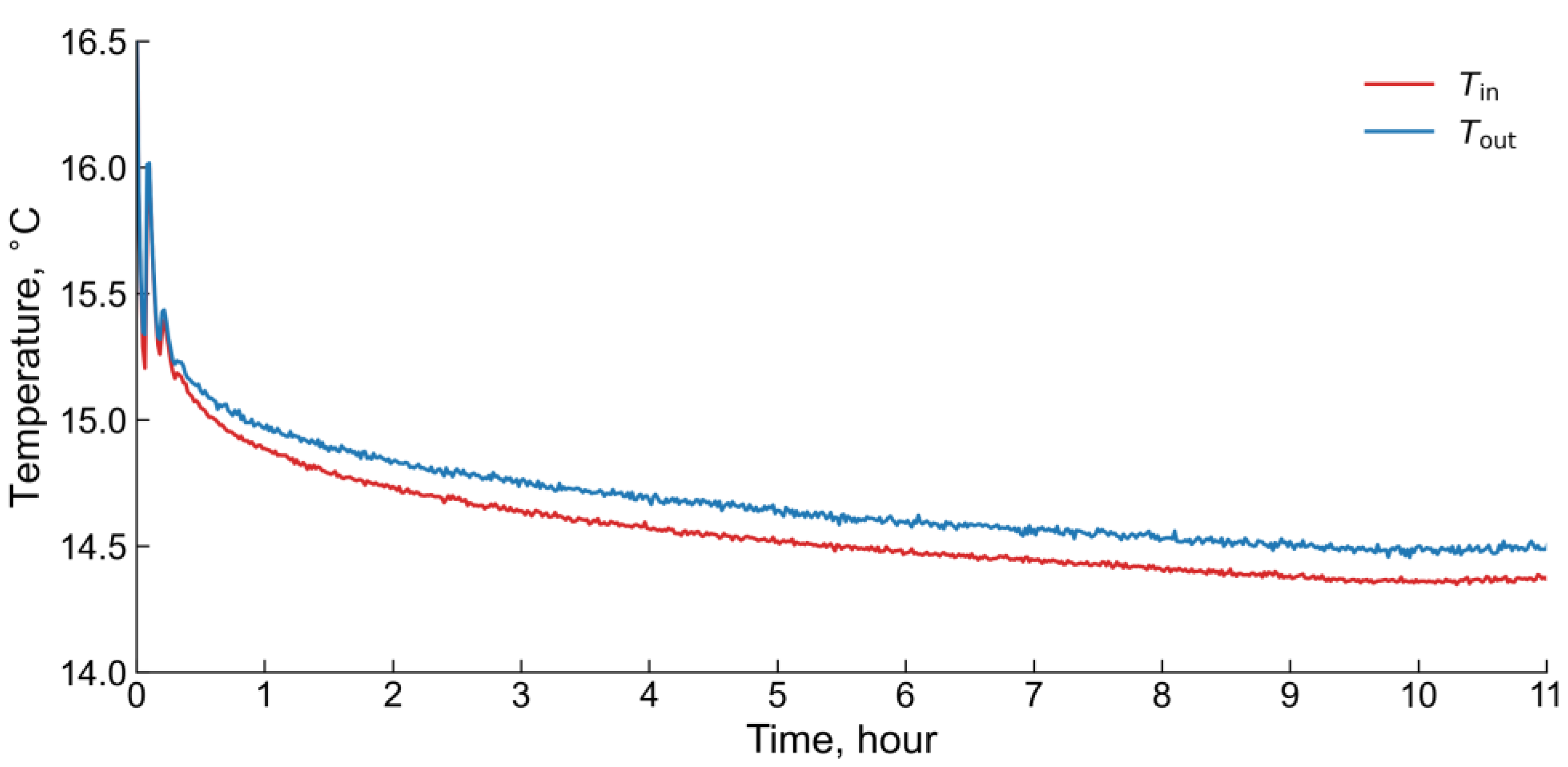

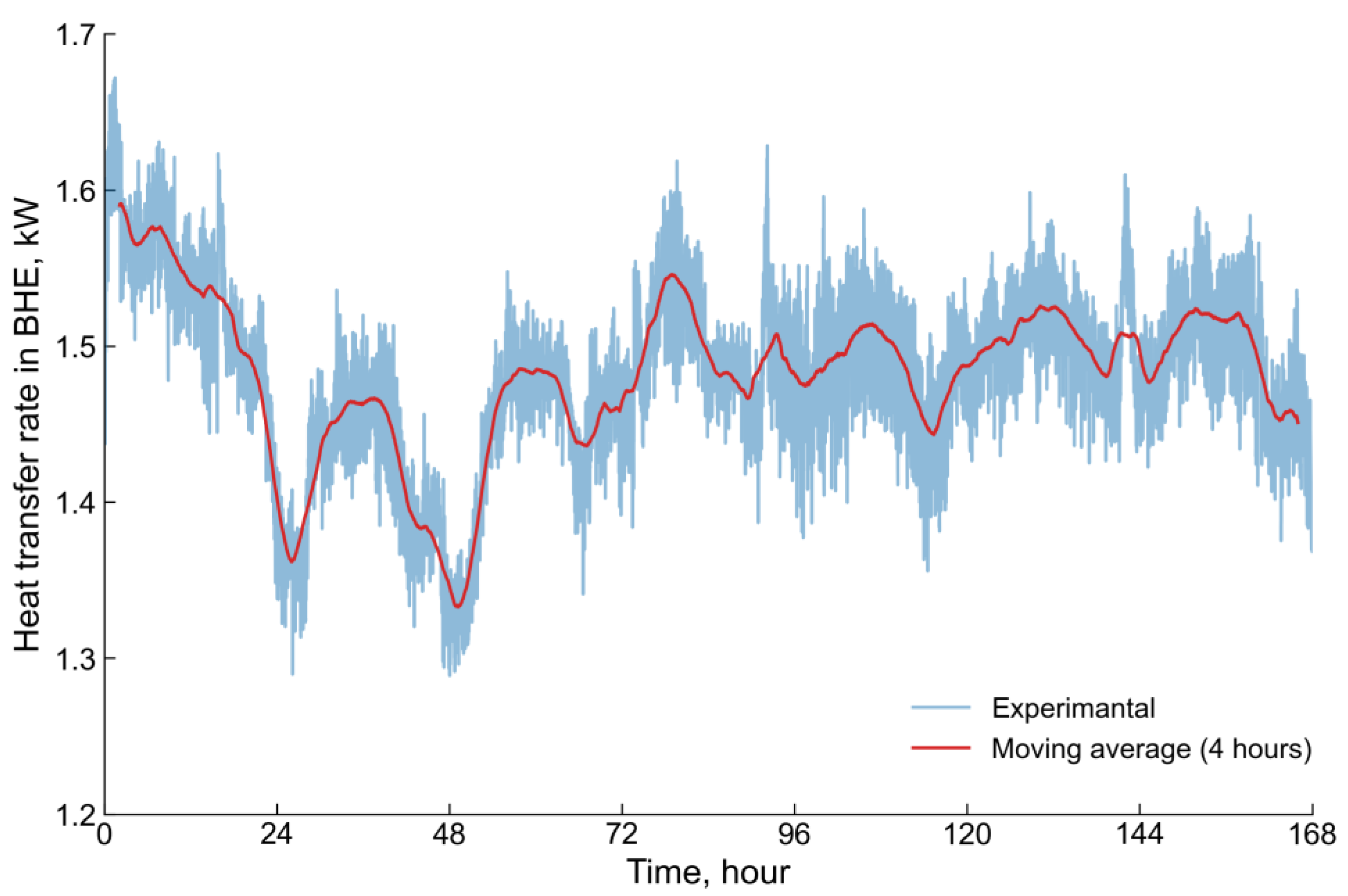

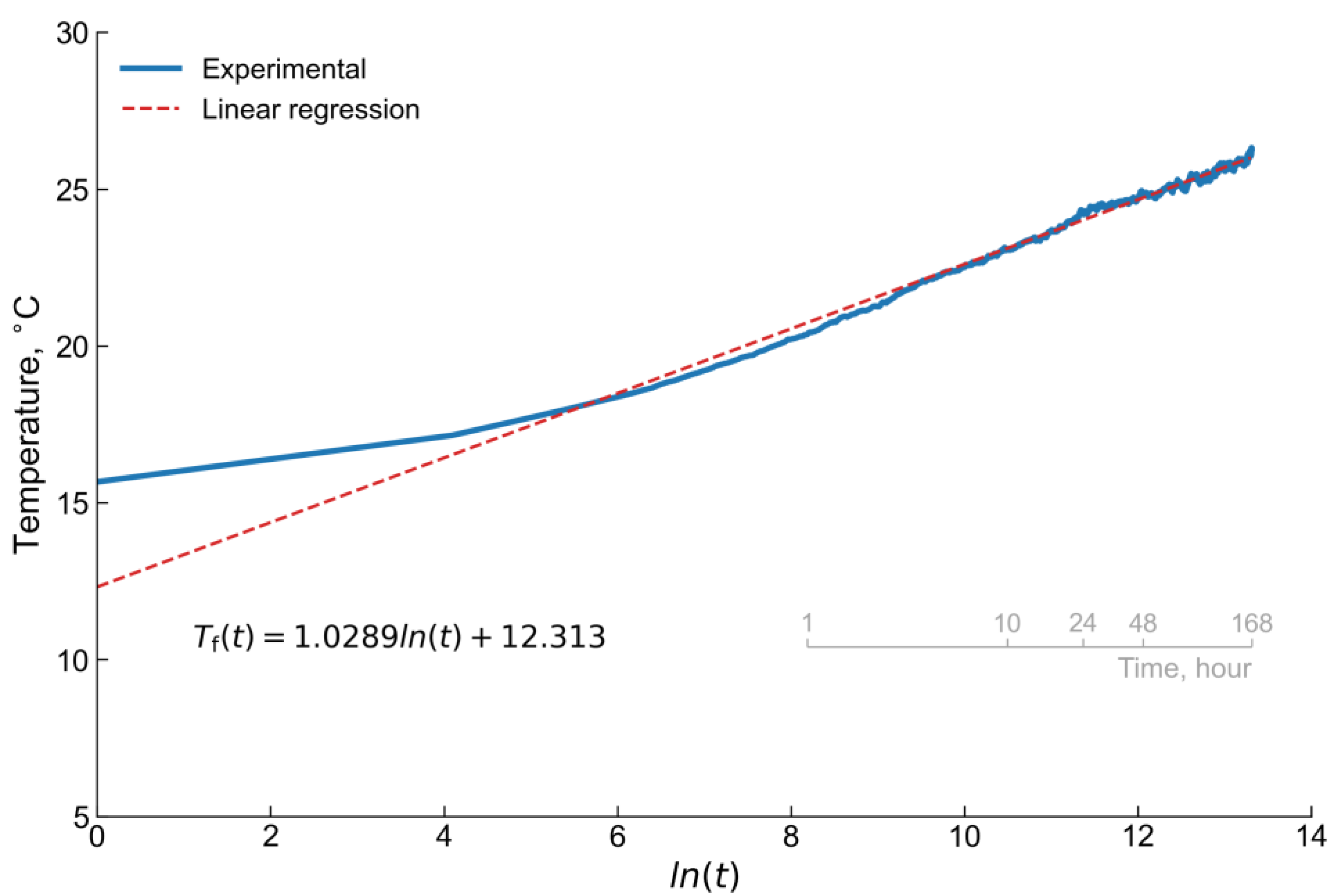

4.1. TRT Test Results

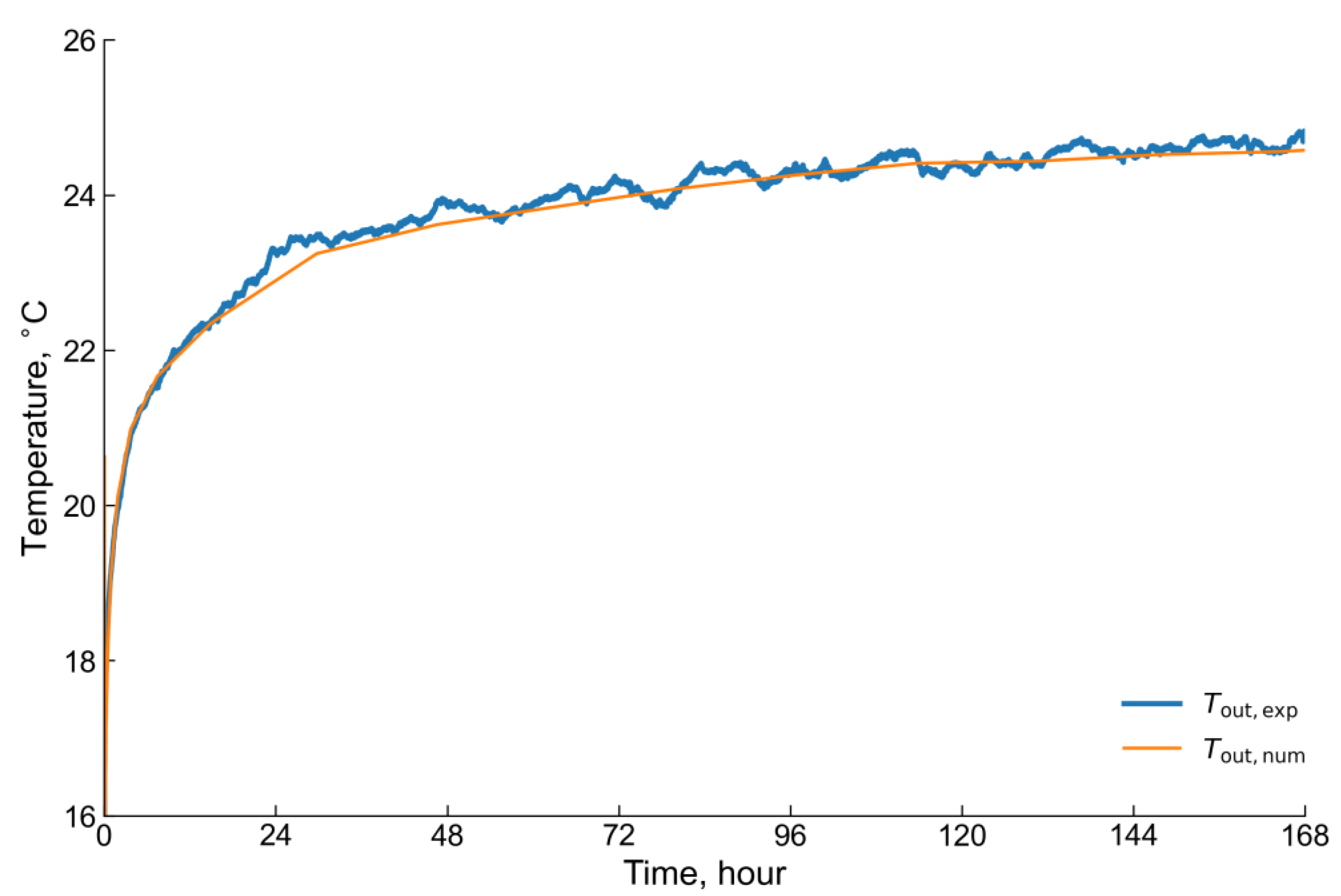

4.2. Numerical Model Verification

4.3. Results for BHE with Different Geometrics

5. Conclusions

- An energy efficient ground source heat pump system with appropriate ground heat exchangers was developed and tested.

- An apparatus and method for testing soil thermal response were developed.

- Drilling data were in accordance with the stratigraphic map of the geological exploration data.

- The results of the thermal response test and the line-source analytical model showed the soil thermal conductivity was = 2.35 W/m K, while the thermal resistance of the ground heat exchanger was = 0.20 m K/W.

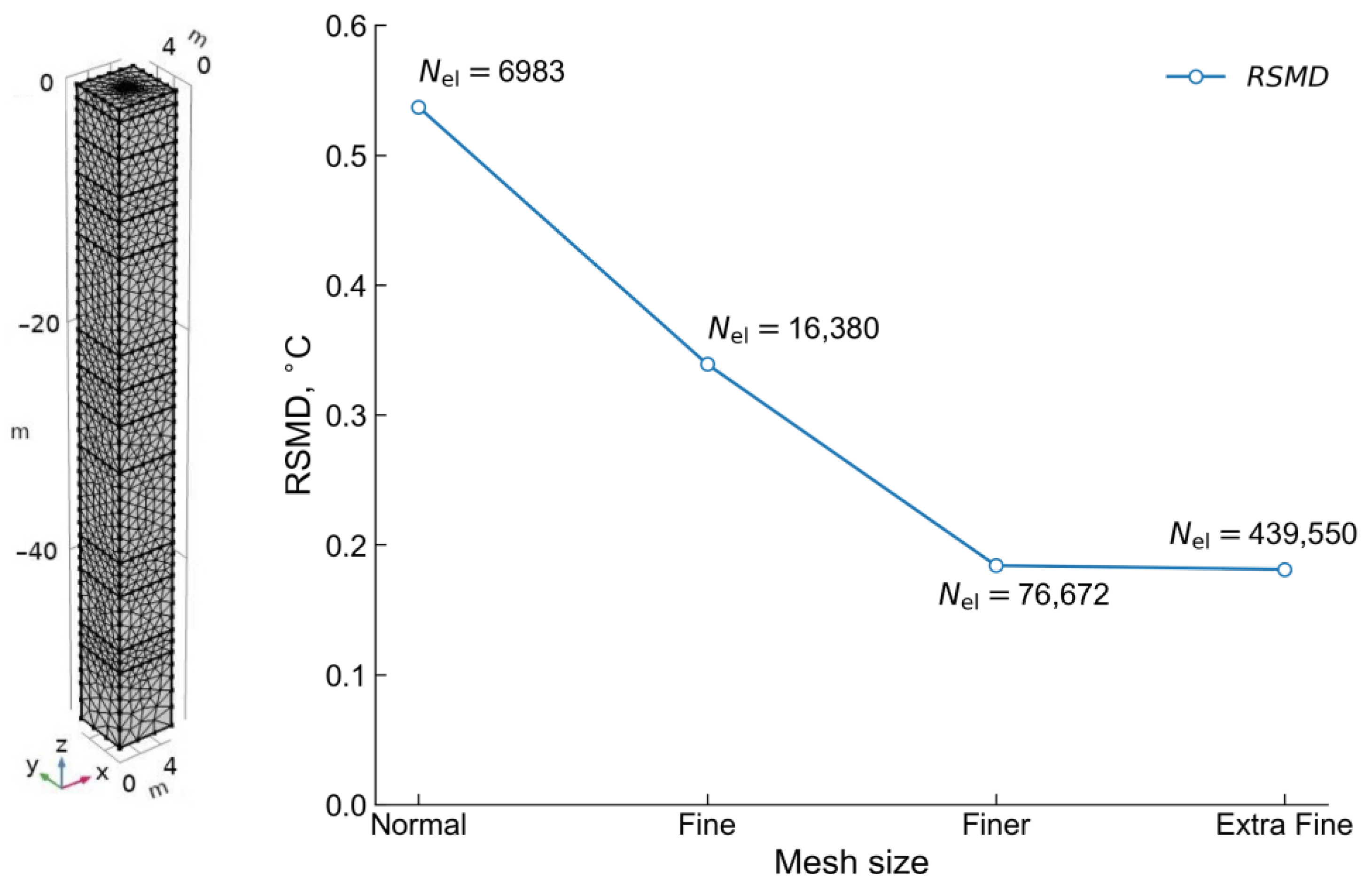

- A 3D numerical tool was developed and validated with the TRT test results.

- The validation results were found to be in good agreement, with an RMSD = 0.184 °C.

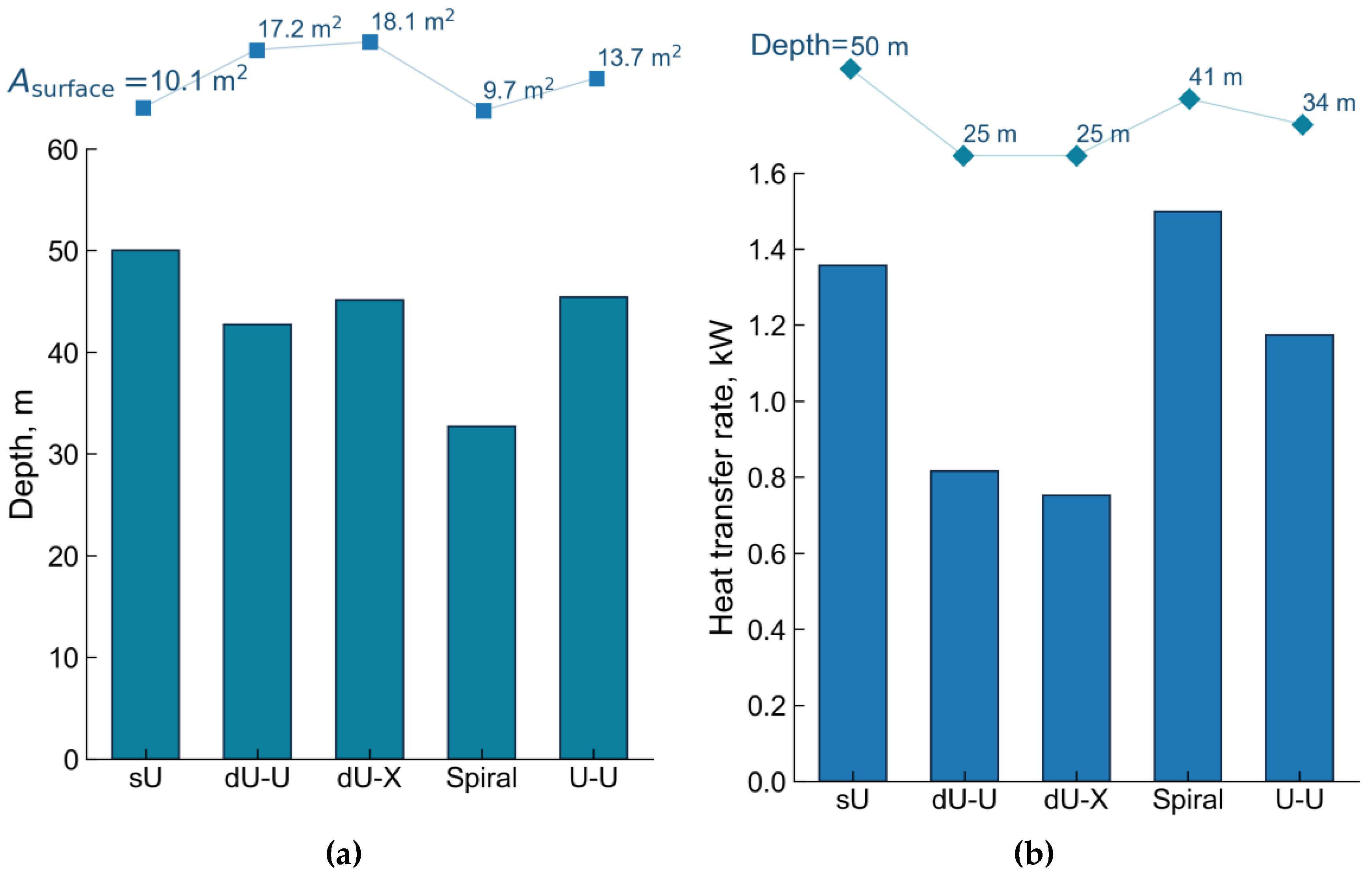

- Based on the numerical results of studying the effect of well depth and heat exchange surface area on heat transfer rates with various geometric configurations, it was found that the spiral configuration demonstrated 34.6% savings at this drilling depth compared to a conventional U-pipe with a value of 0.037 kW/m.

- It is found that the spiral heat exchanger extracts the highest amount of heat, followed by the multi-tube, double U-pipe parallel, double U-pipe cross and single U-pipe.

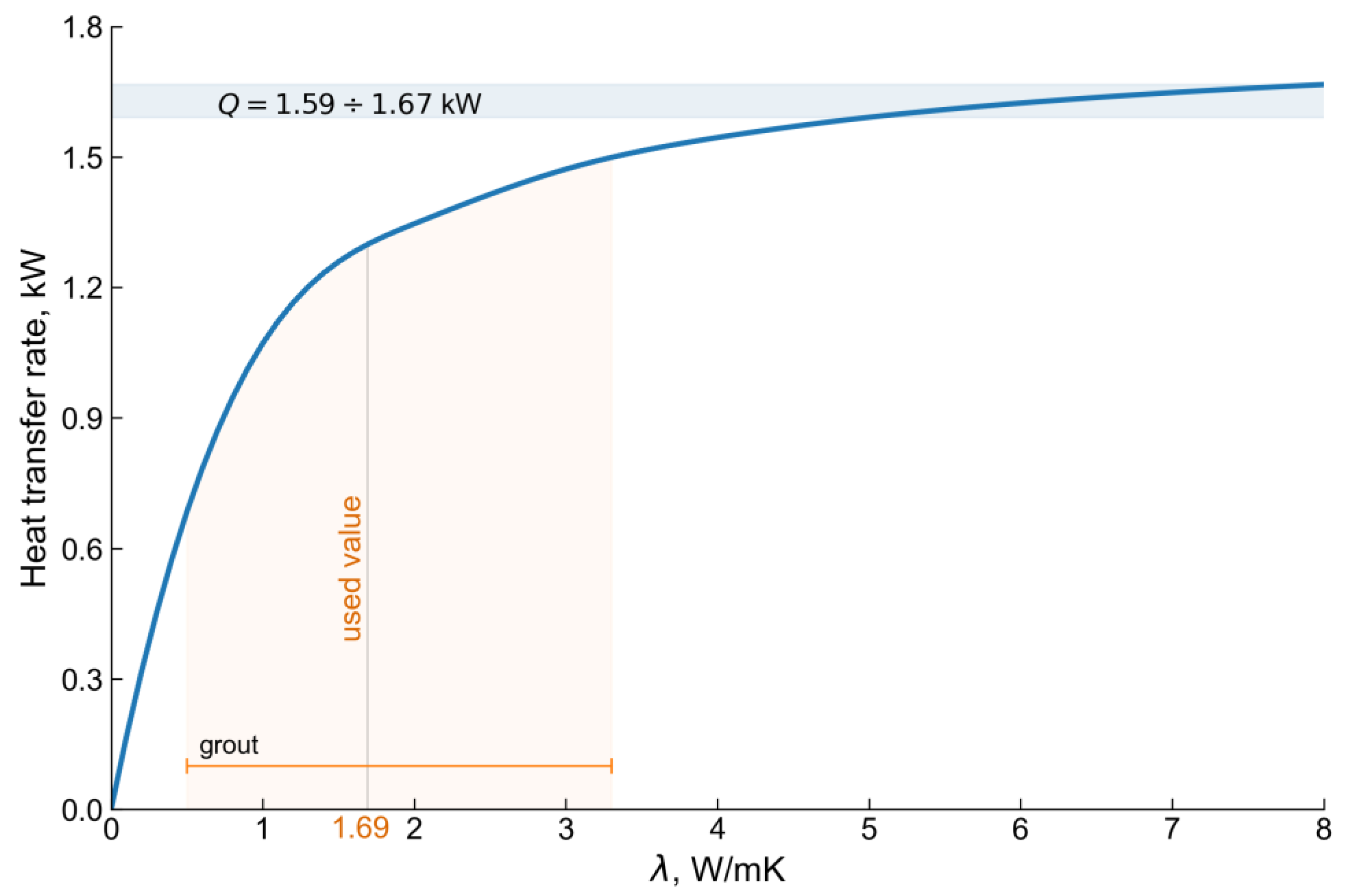

- According to the numerical results of the effect of the thermal conductivity of materials and the circulating fluid flow rate on the heat extraction, it was found that it makes no sense to increase the thermal conductivity of the grout above 3.0 W/m K, the thermal conductivity of the pipe above 2.0 W/m K, and the volumetric flow rate of the circulating fluid above 1.0 m3/h.

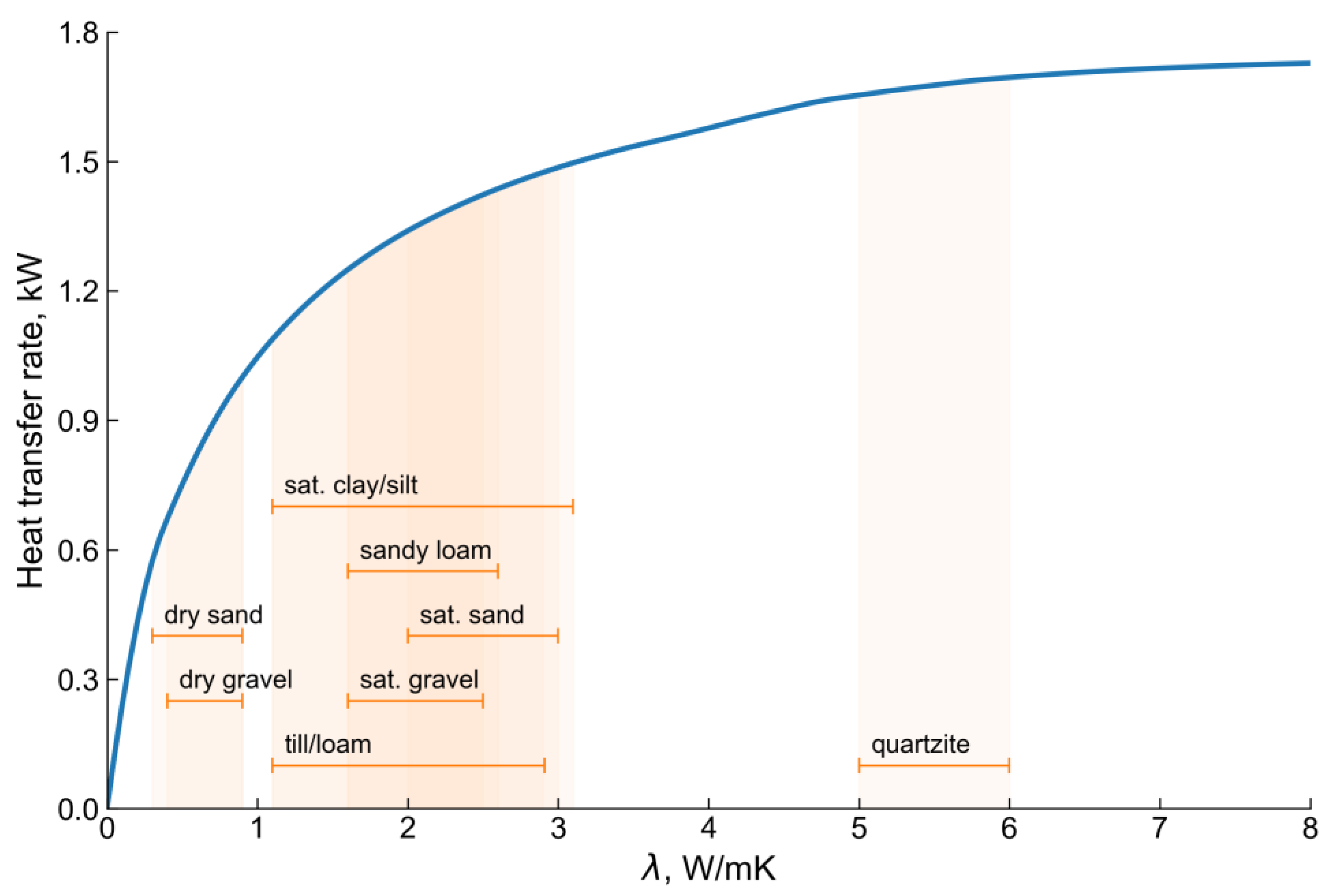

- With an increase in thermal conductivity of the soil, the heat extraction by the borehole heat exchanger increases.

- Regardless of how large the thermal conductivity of the soil is, the heat extraction is limited by the borehole heat exchanger thermal performance.

- Heat transfer feature modeling around the borehole heat exchanger during charging/discharging modes.

- Heat transfer mechanisms around the borehole heat exchanger, considering the freezing factor during harsh winter conditions.

- Predicting the thermal interference for a system of borehole heat exchangers.

- Multidimensional parametric optimization of borehole heat exchanger thermal performance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Cross-section area of pipes, m2 | |

| Specific heat capacity of HTF, J/kg K | |

| Coefficient of Performance, - | |

| Diameter, m | |

| Roughness of the inner surface of the pipe, m | |

| Volume force, N | |

| Darcy friction factor, – | |

| Hydraulic heat, m | |

| Heat-transfer coefficient, W/m2 K | |

| Hydraulic conductivity, m/s | |

| Length, m | |

| Number, – | |

| Nusselt number, – | |

| Normal vector, – | |

| Pressure of HTF, Pa | |

| Prandtl number, – | |

| Heat transfer rate, W | |

| Heat transfer rate per unit length, W/m | |

| Thermal resistance, m K/W | |

| Radius, m | |

| Reynolds number, – | |

| Root Mean Square Deviation, ℃ | |

| Time, s | |

| Temperature, °C | |

| Mean velocity of HTF in BHE, m/s | |

| Filtration rate of groundwater flow, m/s | |

| Volume, m3 | |

| coordinates in Cartesian coordinate, m | |

| Inner perimeter of pipes, m | |

| Greek symbols | |

| Thermal diffusivity, m2/s | |

| Euler’s constant, – | |

| Thermal conductivity of the ground soil, W/m K | |

| Dynamic viscosity of HTF, | |

| Density, kg/ m3 | |

| Porosity, – | |

| Subscripts | |

| air | |

| borehole | |

| finite element | |

| effective | |

| experimental | |

| external | |

| fluid | |

| ground | |

| grout | |

| inlet | |

| initial | |

| internal | |

| numerical | |

| outlet | |

| pipe | |

| soil | |

| surface | |

| wall | |

| 0 | initial, undisturbed condition |

| t | tangent |

| Abbreviation | |

| BHE | Borehole Heat Exchanger |

| BTES | Borehole Thermal Energy Storage |

| CFD | Computational Fluid Dynamics |

| GHE | Ground Heat Exchanger |

| GSHP | Ground Source Heat Pump |

| HDPE | High-Density Polyethylene |

| HTF | Heat Transfer Fluid |

| TRT | Thermal Response Test |

| FEM | Finite Element Method |

Appendix A

| No. | Equipment Name | Specifications |

| 1 | Temperature sensors, Pt100 | Model:TS0010 Length: 1 m Class: Class C Tolerance: (0.6 + 0.008 * |t|) °C (|t| is the absolute value of the actual temperature) Electrical design: Three-wire system Probe: Temperature range: −40 °C~400 °C Material: Stainless steel Size: 4 mm × 50 mm/4 mm × 80 mm The wire: Temperature range E: −60 °C~250 °C Material: 3-Core Silver Fox Fur Jacket Teflon Insulated High Temperature Wire Net weight: 50 g |

| 2 | Rotameter, Emis Meta | Nominal diameter: 25 mm Reduced error: ± 4% Nominal medium pressure: дo 1 MPa Minimum medium pressure: 100 Pa … 1000 Pa Maximum viscosity of the medium: 5 mPa × s Medium temperature: −2 °C …+80 °C Ambient temperature: −40 °C …+70 °C Relative Humidity: no more than 95 ± 3% |

| 3 | Electrical heater, Caнгaй “УMT” | Supply voltage (three-phase): 3 × 380 ± 10 % V Supply voltage (single-phase): 3 × 380 ± 10 % V Frequency: 50 Hz Rated Power (no more): 1.6 + 3.2 kW Heated area: 48 m2 Heat transfer fluid pressure in the system: 0.25 MPa |

| 4 | Circulating Pump, Grundfos Alpha2 32–40 (180) Circulator Pump with Auto Adapt | Weight: 2.3 Kg Dimensions: 138 mm × 88 mm × 180 mm Connection Type: 2 Inch BSP Male Motor Size: 18 W Full Load Current (FLC): 0.18 A Voltage: 240 V 1 Ph 50 Hz Max Flow: 2.5 m3/h Max Head: 4 m Material: Cast Iron Impeller Material: Composite |

| 5 | Data logger, iDAQ PT-08 WiFi Data Acquisition Unit -8 Channel PT100 Thermometer Inputs | 8 × 3-wire or 4-wire: PT100 thermometer Inputs Measuring range: −200° to +800 °C Converter resolution: 22 bits Interface: USB 2.0 and Wi-Fi Built-in Web-server showing data in tabular and chart display formats Configurable alarms on each channel emails sent on alarm Internal Logger Memory: 256 Kb Configurable log rate: from 5 s to 24 h Data download: in CSV or Log formats Input connectors: 2 mm Screw terminals Supply: 5VDC @ 100 m (PSU included) Operating Temperature range: 0 °C to 70 °C operating Dimensions: 92 mm × 51 mm × 18.3 mm |

| 6 | Monometer | Maximum temperature: 150 °C Maximum pressure: 1 Mпa Manometer type: analog Principle of operation: pneumatic Connection: radial Case diameter: 10 mm Accuracy class: 1.5 |

| 7 | Voltage regulator | Model/series: ACH-3000/1-ЭM Input voltage range: 140–260 V Rated output voltage: 220 ± 3% Operating frequency: 50 Hz Efficiency: 97% High voltage protection (delay less than 1 s.): 220 ± 5 V Protection class: IP20 Maximum Power at Ubx ≥ 1900 V Maximum current: 15.8 A |

References

- Johannesson, T.; Axelsson, G.; Hauksdottir, S.; Chatenay, C.; Benediktsson, D.O.; Weisenberger, T.B. Preliminary Review of Geothermal Resources in Kazakhstan; Final Report Rev.2 prepared for the World Bank and the Government of Kazakhstan; World Bank: Washington, DC, USA, 2019; 84p. [Google Scholar]

- Moya, D.; Aldas, C.; Kaparaju, P. Geothermal energy: Power plant technology and direct heat applications. Renew. Sustain. Energy Rev. 2018, 94, 889–901. [Google Scholar] [CrossRef]

- Lee, K.C. Classification of geothermal resources–an engineering approach. In Proceedings of the Twenty-First Workshop on Geothermal Reservoir Engineering, Stanford University, Stanford, CA, USA, 22–24 January 1996. [Google Scholar]

- Muffler, P.; Cataldi, R. Methods for regional assessment of geothermal resources. Geothermics 1978, 7, 53–89. [Google Scholar] [CrossRef]

- Hochstein, M.P. Classification and assessment of geothermal resources. In Small Geothermal Resources; Dickson, M.H., Fanelli, M., Eds.; UNITAR/UNDP Centre for Small Energy Resources: Rome, Italy, 1990; pp. 31–59. [Google Scholar]

- Benderitter, Y.; Cormy, G. Possible approach to geothermal research and relative cost estimate. In Small Geothermal Resources; Dickson, M.H., Fanelli, M., Eds.; UNITAR/UNDP Centre for Small Energy Resources: Rome, Italy, 1990; pp. 61–71. [Google Scholar]

- Haenel, R.; Rybach, L.; Stegena, L. Handbook of Terrestrial Heat-Flow Density Determination; Kluwer Academic: Dordrecht, The Netherlands, 1988; pp. 9–57. [Google Scholar]

- Cunha, R.P.; Bourne-Webb, P.J. A critical review on the current knowledge of geothermal energy piles to sustainable climatize buildings. Renew. Sustain. Energy Rev. 2022, 158, 112072. [Google Scholar] [CrossRef]

- Deng, J.; Wei, Q.; He, S.; Liang, M.; Zhang, H. What is the main difference between medium-depth geothermal heat pump systems and conventional shallow-depth geothermal heat pump systems? Field tests and comparative study. Appl. Sci. 2019, 9, 5120. [Google Scholar] [CrossRef]

- Welsch, B.; Ruhaak, W.; Schulte, D.O.; Bar, K.; Saas, I. Characteristics of medium deep borehole thermal energy storage. Int. J. Energy Res. 2016, 40, 1855–1868. [Google Scholar] [CrossRef]

- Haehnlein, S.; Beyer, P.; Blum, P. International legal status of the use of shallow geothermal energy. Renew. Sustain. Energy Rev. 2010, 14, 2611–2625. [Google Scholar] [CrossRef]

- Pratiwi, A.S.; Trutnevyte, E. Life cycle assessment of shallow to medium-depth geothermal heating and cooling networks in the State of Geneva. Geothermics 2021, 90, 101988. [Google Scholar] [CrossRef]

- Romanov, D.; Leiss, B. Geothermal energy at different depth for district heating and cooling of existing and future building stock. Renew. Sustain. Energy Rev. 2022, 167, 112727. [Google Scholar] [CrossRef]

- Spitler, J.D.; Gehlin, S.E.A. Thermal response testing for ground source heat pump systems–An historical review. Renew. Sustain. Energy Rev. 2015, 50, 1125–1137. [Google Scholar] [CrossRef]

- Saktashova, G.; Aliuly, A.; Belyayev, Y.; Mohanraj, M.; Singh, R.M. Numerical heat transfer simulation of solar-geothermal hybrid source heat pump in Kazakhstan climates. Bulg. Chem. Commun. 2018, 50, 7–13. [Google Scholar]

- Santa, G.D.; Galgaro, A.; Sassi, R.; Cultrera, M.; Scotton, P.; Mueller, J.; Bertermann, D.; Mendrinos, D.; Pasquali, R.; Perego, R.; et al. An updated ground thermal properties database for GSHP applications. Geothermics 2020, 85, 101758. [Google Scholar] [CrossRef]

- Bertermann, D.; Muller, J.; Freitag, S.; Schwarz, H. Comparison between measured and calculated thermal conductivities within different grain size classes and their related depth ranges. Soil Syst. 2018, 2, 50. [Google Scholar] [CrossRef]

- Ramos-Escudero, A.; Garsia-Cascales, M.S.; Urchueguia, J.F. Evaluation of the shallow geothermal potential for heating and cooling and its integration in the socioeconomic environment: A case study in the region of Murcia, Spain. Energies 2021, 14, 5740. [Google Scholar] [CrossRef]

- Reuss, M. The use of borehole thermal energy storage (BTES) systems. In Advances in Thermal Energy Storage Systems, Methods and Applications; Cabeza, F.C., Ed.; Woodhead Publishing: Cambridge, UK, 2015; Volume in Woodhead Publishing Series in Energy; pp. 117–147. [Google Scholar]

- Gehlin, S. Thermal Response Test: Method, Development and Evaluation. Ph.D. Thesis, Lulea University of Technology, Lulea, Sweden, September 2002. [Google Scholar]

- Amanzholov, T.; Akhmetov, B.; Georgiev, A.; Kaltayev, A.; Popov, R.; Dzhonova-Atanasova, D.; Tungatarova, M. Numerical modelling as a supplementary tool for thermal response test. Bulg. Chem. Commun. 2016, 48, 109–114. [Google Scholar]

- Mogensen, P. Fluid to duct wall heat transfer in duct system heat storages. In Proceedings of the International Conference on Subsurface Heat Storage in Theory and Practice, Stockholm, Sweden, 6–8 June 1983; pp. 652–657. [Google Scholar]

- Luo, J.; Zhang, Y.; Tuo, J.; Xue, W.; Rohn, J.; Baumgartel, S. A novel approach to the analysis of thermal response test (TRT) with interrupted power input. Energies 2020, 13, 5033. [Google Scholar] [CrossRef]

- Li, P.; Guan, P.; Zheng, J.; Dou, B.; Tian, H.; Duan, X.; Liu, H. Field test and numerical simulation on heat transfer performance of coaxial borehole heat exchanger. Energies 2020, 13, 5471. [Google Scholar] [CrossRef]

- Piotrowska-Woroniak, J. Determination of the selected wells operational power with borehole heat exchangers operating in real conditions, based on experimental tests. Energies 2021, 14, 2512. [Google Scholar] [CrossRef]

- Hesselbrandt, M.; Erlstrom, M.; Sopher, D.; Acuna, J. Multidisciplinary approaches for assessing a high temperature borehole thermal energy storage facility at Linkoping, Sweden. Energies 2021, 14, 4379. [Google Scholar] [CrossRef]

- Giordano, N.; Lamarche, L.; Raymond, J. Evaluation of subsurface heat capacity through oscillatory thermal response tests. Energies 2021, 14, 5791. [Google Scholar] [CrossRef]

- Morchio, S.; Fossa, M.; Priarone, A.; Boccalatte, A. Reduced scale experimental modelling of distributed thermal response tests for the estimation of the ground thermal conductivity. Energies 2021, 14, 6955. [Google Scholar] [CrossRef]

- Pambou, C.H.K.; Raymond, J.; Miranda, M.M.; Giordano, N. Estimation of in situ heat capacity and thermal diffusivity from undisturbed ground temperature profile measured in ground heat exchangers. Geosciences 2022, 12, 180. [Google Scholar] [CrossRef]

- Zhou, A.; Huang, X.; Wang, W.; Jiang, P.; Li, X. Thermo-hydraulic performance of U-tube borehole heat exchanger with different cross-sections. Sustainability 2021, 13, 3255. [Google Scholar] [CrossRef]

- Wang, C.; Fu, Q.; Fang, H.; Lu, J. Estimation of ground thermal properties of shallow coaxial borehole heat exchanger using an improved parameter estimation method. Sustainability 2022, 14, 7356. [Google Scholar] [CrossRef]

- Bourhis, P.; Cousin, B.; Loria, A.F.R.; Laloui, L. Machine learning enhancement of thermal response tests for geothermal potential evaluations at site and regional scales. Geothermics 2021, 95, 102132. [Google Scholar] [CrossRef]

- Li, K.; Liu, Y.; Kang, Q. Estimating the thermal conductivity of soils using six machine learning algorithms. Int. Commun. Heat Mass Transf. 2022, 136, 106139. [Google Scholar] [CrossRef]

- Kerme, E.D.; Fung, A.S. Heat transfer analysis of single and double U-tube borehole heat exchanger with two independent circuits. J. Energy Storage 2021, 43, 103141. [Google Scholar] [CrossRef]

- Ingersoll, L.R.; Zobel, O.J.; Ingersoll, A.C. Heat Conduction: With Engineering, Geological, and Other Applications; The University of Wisconsin Press: Madison, WI, USA, 1954; pp. 1–325. [Google Scholar]

- Zeng, H.Y.; Diao, N.R.; Fang, Z.H. A finite line-source model for boreholes in geothermal heat exchangers. Heat Transf. Asian Res. 2002, 31, 558–567. [Google Scholar] [CrossRef]

- Hellstrom, G. Duct Ground Heat Storage Model, Manual for Computer Code; Department of Mathematical Physics, University of Lund: Lund, Sweden, 1989. [Google Scholar]

- Cao, S.J.; Kong, X.R.; Deng, Y.; Zhang, W.; Yang, L.; Ye, Z.P. Investigation on thermal performance of steel heat exchanger for ground source heat pump systems using full-scale experiments and numerical simulations. Appl. Therm. Eng. 2017, 115, 91–98. [Google Scholar] [CrossRef]

- Rees, S.J.; He, M. A three-dimensional numerical model of borehole heat exchanger heat transfer and fluid flow. Geothermics 2013, 46, 1–13. [Google Scholar] [CrossRef]

- Bouhacina, B.; Saim, R.; Oztop, H.F. Numerical investigation of a novel tube design for the geothermal borehole heat exchanger. Appl. Therm.Eng. 2015, 79, 153–162. [Google Scholar] [CrossRef]

- Vella, C.; Borg, S.P.; Micallef, D. The Effect of Shank-Space on the Thermal Performance of Shallow Vertical U-Tube Ground Heat Exchangers. Energies 2020, 13, 602. [Google Scholar] [CrossRef]

- Akhmetov, B.; Georgiev, A.G.; Kaltayev, A.; Dzhomartov, A.A.; Popov, R.; Tungatarova, M.S. Thermal energy storage systems–review. Bulg. Chem. Commun. 2016, 48, 31–40. [Google Scholar]

- Akhmetov, B.; Georgiev, A.; Popov, R.; Turtayeva, Z.; Kaltayev, A.; Ding, Y. A novel hybrid approach for in-situ determining the thermal properties of subsurface layers around borehole heat exchanger. Int. J. Heat Mass Transf. 2018, 126, 1138–1149. [Google Scholar] [CrossRef]

- Luo, J.; Pei, K.; Li, P. Analysis of the thermal performance reduction of a groundwater source heat pump (GWHP) system. Eng. Fail. Anal. 2022, 132, 105922. [Google Scholar] [CrossRef]

- Boon, D.P.; Farr, G.J.; Abesser, C.; Patton, A.M.; James, D.R.; Schofield, D.I.; Tucker, D.G. Groundwater heat pump feasibility in shallow urban aquifers: Experience from Cardiff, UK. Sci. Total Environ. 2019, 697, 133847. [Google Scholar] [CrossRef]

- Li, C.; Mao, J.; Peng, X.; Mao, W.; Xing, Z.; Wang, B. Influence of ground surface boundary conditions on horizontal ground source heat pump systems. Appl. Therm. Eng. 2019, 152, 160–168. [Google Scholar] [CrossRef]

- Liu, X.; He, M.; Wang, Y.; Zheng, B.; Li, C.; Zhu, X. Experimental study on heat transfer attenuation due to thermal deformation of horizontal GHEs. Geothermics 2021, 97, 102241. [Google Scholar] [CrossRef]

- Sang, J.; Liu, X.; Liang, C.; Feng, G.; Li, Z.; Wu, X.; Song, M. Differences between design expectations and actual operation of ground source heat pumps for green buildings in cold region of northern China. Energy 2022, 252, 124077. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, X.; Biswas, K.; Warner, J. A three-dimensional numerical investigation of a novel shallow bore ground heat exchanger integrated with phase change material. Appl. Therm. Eng. 2019, 162, 114297. [Google Scholar] [CrossRef]

- Warner, J.; Liu, X.; Shi, L.; Qu, M.; Zhang, M. A novel shallow bore ground heat exchanger for ground source heat pump applications—Model development and validation. Appl. Therm. Eng. 2020, 164, 114460. [Google Scholar] [CrossRef]

- Blazquez, C.S.; Martin, A.F.; Nieto, I.M.; Garcia, P.C.; Perez, L.S.S.; Gonzalez-Aguilera, D. Efficiency analysis of the main components of a vertical closed-loop system in a borehole heat exchanger. Energies 2017, 10, 201. [Google Scholar] [CrossRef]

- Bae, S.M.; Nam, Y.; Choi, J.M.; Lee, K.H.; Choi, J.S. Analysis on thermal performance of ground heat exchanger according to design type based on thermal response test. Energies 2019, 12, 651. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, Z.; Yuan, T. Study on the coupled heat transfer model based on groundwater advection and axial heat conduction for the double U-tube vertical borehole heat exchanger. Sustainability 2020, 12, 7345. [Google Scholar] [CrossRef]

- Javadi, H.; Ajarostaghi, S.S.M.; Pourfallah, M.; Zaboli, M. Performance analysis of helical ground heat exchangers with dif-ferent configurations. Appl. Therm. Eng. 2019, 154, 24–36. [Google Scholar] [CrossRef]

- Zarella, A.; De Carli., M.; Galgaro, A. Thermal performance of two types of energy foundation pile: Helical pipe and triple U-tube. Appl. Therm. Eng. 2013, 61, 301–310. [Google Scholar] [CrossRef]

- Quaggiotto, D.; Zarella, A.; Emmi, G.; De Carli, M.; Pockele, L.; Vercruysse, J.; Psyk, M.; Righini, D.; Galgaro, A.; Mendrinos, D.; et al. Simulation-Based Comparison Between the Thermal Behavior of Coaxial and Double U-Tube Borehole Heat Ex-changers. Energies 2019, 12, 2321. [Google Scholar] [CrossRef]

- Feidt, M. Finite Physical Dimensions Optimal Thermodynamics 1; Elsevier ISTE Press Ltd.: Amsterdam, The Netherlands, 2017; p. 245. [Google Scholar] [CrossRef]

- Feidt, M. Finite Physical Dimensions Optimal Thermodynamics 2; Elsevier ISTE Press Ltd.: Amsterdam, The Netherlands, 2018; p. 194. [Google Scholar] [CrossRef]

- Colombo, L.P.M.; Lucchini, A.; Molinaroli, L. Experimental analysis of the use of R1234yf and R1234ze(E) as drop-in alternatives of R134a in a water-to-water heat pump. Int. J. Refrig. 2020, 115, 18–27. [Google Scholar] [CrossRef]

- Molinaroli, L.; Lucchini, A.; Colombo, L.P.M. Drop-in analysis of R450A and R513A as low-GWP alternatives to R134a in a water-to-water heat pump. Int. J. Refrig. 2022, 135, 139–147. [Google Scholar] [CrossRef]

- Yerdesh, Y.; Amanzholov, T.; Aliuly, A.; Seitov, A.; Toleukhanov, A.; Murugesan, M.; Botella, O.; Feidt, M.; Wang, H.S.; Tsoy, A.; et al. Experimental and Theoretical Investigations of a Ground Source Heat Pump System for Water and Space Heating Applications in Kazakhstan. Energies 2022, 15, 8336. [Google Scholar] [CrossRef]

- Russian Geological Research Institute (VSEGEI). Available online: https://rasterdb.vsegei.ru/img.php?id=41510 (accessed on 29 September 2022).

- Erol, S.; Grathwohl, P.; Blum, P.; Bayer, P. Estimation of Heat Extraction Rates of GSHP Systems under Different Hydrogeological Conditions. Ph.D. Thesis, University of Tuebingen, Tübingen, Germany, 2011. [Google Scholar]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids; Oxford University Press: Oxford, UK, 1959; pp. 1–310. [Google Scholar]

- Gnielinski, V. New Equations for Heat and Mass Transfer in Turbulent Pipe and Channel Flow. Int. Chem. Eng. 1976, 16, 359–368. [Google Scholar]

- Churchill, S.W. Friction factor equation spans all fluid-flow regimes. Chem. Eng. 1997, 84, 91–92. [Google Scholar]

- Allan, M.L.; Kavanaugh, S.P. Thermal conductivity of cementitious grouts and impact on heat exchanger length design for ground source heat pumps. HVACR Res. 1999, 5, 85–96. [Google Scholar] [CrossRef]

| Formation Thickness, m | Characteristics of Rocks |

|---|---|

| 180 | Boulders, pebble, gravel, sand, sandy loam and till/loam |

| 200 | Boulder-pebbles, sand, loess loam, gravel |

| 30–230 | Boulder-pebbles, sand, loess loam |

| 440–900 | Middle-Upper Pliocene. Ili retinue. Pale clays, silts, sands, gravel-stones, sand-pebbles |

| 400–1080 | Red-brown mudstones with interlayers of green-gray, rubble |

| 720 | Silts, red-brown mudstones with green-gray interlayers, rubble |

| 900–1200 | Liparitic and dacitic porphyries, tuff lavas, tuffs, porphyrites, interbeds of tuff sandstones |

| 820–1200 | Katmen suite. Andesitic, andesite-basaltic porphyrites, their tuffs, dacitic porphyries and their tuffs, conglomerates, sandstones with Caenodendron primaevum Z a l., Lepidodendron cf. obovatum Sternb., Asterocalamites serobiculatus (Schloth.) Zeil. |

| Soil Layers | Depth, m | Thermal Conductivity , W/m K [16] | Density , 103 kg/m3 [19] | Volumetric Heat Capacity , MJ/m3 K [19] | Porosity [63] |

|---|---|---|---|---|---|

| sand, dry | 0–1 | 0.40 | 2.00 | 1.45 | 0.31 |

| sandy clay | 1–4 | 1.60 [17] | 2.10 | 2.45 | 0.35 [17] |

| sand, moist | 4–7 | 1.40 | 2.10 | 2.50 | 0.31 |

| clay | 7–9 | 1.80 | 2.10 | 2.40 | 0.45 |

| till/loam | 9–12 | 2.40 | 2.05 | 2.00 | 0.45 [17] |

| gravel | 12–20 | 1.80 | 2.10 | 2.40 | 0.26 |

| till/loam | 20–23 | 2.40 | 2.05 | 2.00 | 0.45 [17] |

| clay | 23–26 | 1.80 | 2.10 | 2.40 | 0.45 |

| till/loam | 26–30 | 2.40 [17] | 2.05 | 2.00 | 0.45 [17] |

| gravel | 30–38 | 1.80 | 2.10 | 2.40 | 0.26 |

| till/loam | 38–41 | 2.40 | 2.05 | 2.00 | 0.45 [17] |

| gravel | 41–46 | 1.80 | 2.10 | 2.40 | 0.26 |

| till/loam | 46–48 | 2.40 | 2.05 | 2.00 | 0.45 [17] |

| gravel | 48–52 | 1.80 | 2.10 | 2.40 | 0.26 |

| Time | Slope k | BHE (W) | (W/m K) | (m K/W) | |

|---|---|---|---|---|---|

| Overall | 1.03 | 12.313 | 1470 | 2.2720 | 0.1929 |

| 10 h | 0.98 | 12.979 | 1470 | 2.3879 | 0.2016 |

| 1st day | 0.94 | 13.503 | 1470 | 2.4895 | 0.2082 |

| 2nd day | 1.04 | 12.122 | 1470 | 2.2501 | 0.1891 |

| Mean | - | - | - | 2.35 | 0.20 |

| Parameters | Values |

|---|---|

| Borehole size | |

| Borehole depth (sU) | 50 m |

| Borehole radius | 0.08 m |

| Inner radius of pipe | 0.028 m |

| Outer radius of pipe | 0.032 m |

| Half of the U-tube shank spacing (for sU, dU-U, dU-X) | 0.1 m |

| Helix coil radius (Spiral) | 0.06 m |

| Helix pitch (Spiral) | 0.1 m |

| Thermal conductivity of pipe | 0.4 W/(m K) |

| Working fluid properties | |

| Fluid type | Water |

| Specific heat capacity of fluid | 4183 J/(kg K) |

| Density of circulating fluid | 997 kg/m3 |

| Thermal conductivity fluid | 0.5947 W/(m K) |

| Dynamic viscosity of fluid | 0.0008905 kg/(m s) |

| Fluid flow rate | 0.6 (m3/h) |

| Inlet fluid temperature (charging) | 50 °C |

| Inlet fluid temperature (discharging) | 5 °C |

| Grout thermal properties | |

| Specific heat capacity of grout | 1000 J/(kg K) |

| Density of the grout | 2800 kg/m3 |

| Thermal conductivity of the grout | 1.7 W/(m K) |

| Soil thermal properties | |

| Specific heat capacity of soil | 1200 J/(kg K) |

| Density of soil | 2500 kg/m3 |

| Thermal conductivity of the soil | 1.75 W/(m K) |

| Porosity of the soil | 0.36 |

| Undisturbed ground temperature | 15 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amanzholov, T.; Seitov, A.; Aliuly, A.; Yerdesh, Y.; Murugesan, M.; Botella, O.; Feidt, M.; Wang, H.S.; Belyayev, Y.; Toleukhanov, A. Thermal Response Measurement and Performance Evaluation of Borehole Heat Exchangers: A Case Study in Kazakhstan. Energies 2022, 15, 8490. https://doi.org/10.3390/en15228490

Amanzholov T, Seitov A, Aliuly A, Yerdesh Y, Murugesan M, Botella O, Feidt M, Wang HS, Belyayev Y, Toleukhanov A. Thermal Response Measurement and Performance Evaluation of Borehole Heat Exchangers: A Case Study in Kazakhstan. Energies. 2022; 15(22):8490. https://doi.org/10.3390/en15228490

Chicago/Turabian StyleAmanzholov, Tangnur, Abzal Seitov, Abdurashid Aliuly, Yelnar Yerdesh, Mohanraj Murugesan, Olivier Botella, Michel Feidt, Hua Sheng Wang, Yerzhan Belyayev, and Amankeldy Toleukhanov. 2022. "Thermal Response Measurement and Performance Evaluation of Borehole Heat Exchangers: A Case Study in Kazakhstan" Energies 15, no. 22: 8490. https://doi.org/10.3390/en15228490

APA StyleAmanzholov, T., Seitov, A., Aliuly, A., Yerdesh, Y., Murugesan, M., Botella, O., Feidt, M., Wang, H. S., Belyayev, Y., & Toleukhanov, A. (2022). Thermal Response Measurement and Performance Evaluation of Borehole Heat Exchangers: A Case Study in Kazakhstan. Energies, 15(22), 8490. https://doi.org/10.3390/en15228490